Page 1

GENERAL

These variable frequency drives provide step-less speed

control for all basic HVAC applications:

• Pumps

• Fans

• Compressors

FEATURES

• Most compact size in the market (especially IP54)

• Integrated RFI-filters and AC-chokes

• Credit card size “Quick Guide” for installation and

commissioning attached to every unit

• 30s Start-Up Wizard

• HVAC-optimized software

• Easy “keypad – remote” change with 1 button

• Trip free operation with safety switch

• Silent motor operation with 6 kHz switching

frequency

• Overtemperature ride-through

• Power ride-through

• Integrated PID controller

• Normal and Inverse regulation

• Sleep Mode

• Anti-Windup function

• Integrated Pump/Fan Cascade Controller

HVAC03C2 – HVAC61C2

HVAC03C5 – HVAC61C5

NXL HVAC INVERTERS

PRODUCT DATA

SPECIFICATIONS

Mains Connection

Input voltage U

Input Frequency 45…66 Hz

Connection to mains Once per minute or less

Motor Connection

Output voltage 0 - U

Continuous output current:

Low overload

(for Fan/Pump)

Starting Torque:

Low overload

(for Fan/Pump)

Starting Current 2 x IH 2s/20s

Output Frequency 0…320 Hz

Frequency resolution 0.01 Hz

Control Characteristics

Control Method Frequency Control U/f, Open

Switching Frequency 1...16 kHz; default 6 kHz (no

Frequency reference:

Analogue input Resolution 0.1% (10 bit),

Keypad reference Resolution 0.01 Hz

Field Weakening point 30…320 Hz

Acceleration time 0.1…3000 sec

Deceleration time 0.1…3000 sec

Braking torque DC-brake: 30%*TN (without

380…500 Vac (±10%), 3~

in

in

I

max. +45°C (with 24h average

150%

: Ambient peak temperature

L

ambient +40°C), overload 1.1 x IL

(1min/10min)

Loop Sensorless Vector Control

derating)

accuracy ±1%

brake option)

® U.S. Registered Trademark EN0B-0619GE51 R1107

Copyright © 2007 Honeywell Inc. • All rights reserved

Page 2

NXL HVAC VARIABLE FREQUENCY DRIVES

Ambient Conditions

Ambient operating Temperature:

Low overload

(for Fan/Pump)

Storage temperature -40…+70°C

Relative humidity 0…95% RH, non-condensing,

Air quality:

Chemical vapors IEC 721-3-3, unit in operation,

Mechanical particles IEC 721-3-3, unit in operation,

Altitude 100% load capacity (no derating)

-1% derating for each 100 m

Relative humidity 0…95% RH, non-condensing,

Vibration: 5...150 Hz

EN50178/EN60068-2-6 Displacement amplitude 1(peak)

Max acceleration amplitude 1 g

Shock: UPS Drop Test (for applicable

EN50178, IEC 68-2-27 UPS weights)

Storage and shipping: max 15 g,

Enclosure class IP21 : HVAC__C2

IP54 : HVAC__C5

-10°C (no frost)…+45°C

(with 24 h average ambient

+40°C)

non-corrosive, no dripping water

class 3C2

class 3S2

up to 1000 m

above 1000 m; max. 3000 m

non-corrosive, no dripping water

mm at 5...15.8 Hz

at 15.8...150 Hz

11 ms (in package)

Electro Magnetic Compatibility (EMC)

Immunity Complies with EN50082-1, -2,

EN61800-3

Emissions:

IP21: HVAC__C2 EMC-level H: EN 61800-3 (2004)

Cat C2, EN 55011 Class A

IP54: HVAC__C5 EMC level C: EN 61800-3 (2004)

Cat C1, EN 55011 Class B

Safety

EN50178, EN60204-1, CE, GOST R, IEC 61800-5 (see unit

nameplate for more detailed approvals)

Control connections

Analogue input voltage 0...+10V, Ri = 200kΩ,

Resolution 10 bit, accuracy ±1%

Galvanically isolated

Analogue input current 0(4)…20 mA, Ri = 250Ω,

differential resolution 0.1%,

accuracy ±1%, electrically

isolated

Digital inputs 6 positive logic; 18…24 Vdc (+1

analogue input can be configured

as digital input)

Auxiliary voltage +24 V, ±15%, max. 100 mA

Output reference voltage +10 V, +3%, max. load 10 mA

Analogue output 0(4)…20 mA; RL max. 500 Ω;

resolution 16 bit; accuracy ±1%

Relay outputs 2 programmable change over

relay output (1 NO/NC and 1

NO). Switching capacity: 24 Vdc

/ 8 A, 250 Vac / 8 A, 125 Vdc /

0.4 A. Min. switching load: 5 V /

10 mA

Motor thermistor Input R

= 4.7 kΩ (PTC), electrically

TRIP

isolated

Protections

Overvoltage protection 911 Vdc

Undervoltage protection 333 Vdc

Earth-fault protection In case of earth fault in motor or

motor cable, only the frequency

converter is protected

Unit overtemp. protection YES

Motor overload protection YES

Motor stall protection

YES

(fan/pump blocked)

Motor underload prot. YES

(pump dry / belt broken detection)

Short-circuit protection YES

of +24V and +10V

reference voltages

Overcurrent protection Trip limit 4,0*I

instantaneously

H

EN0B-0619GE51 R1107 2

Page 3

NXL HVAC VARIABLE FREQUENCY DRIVES

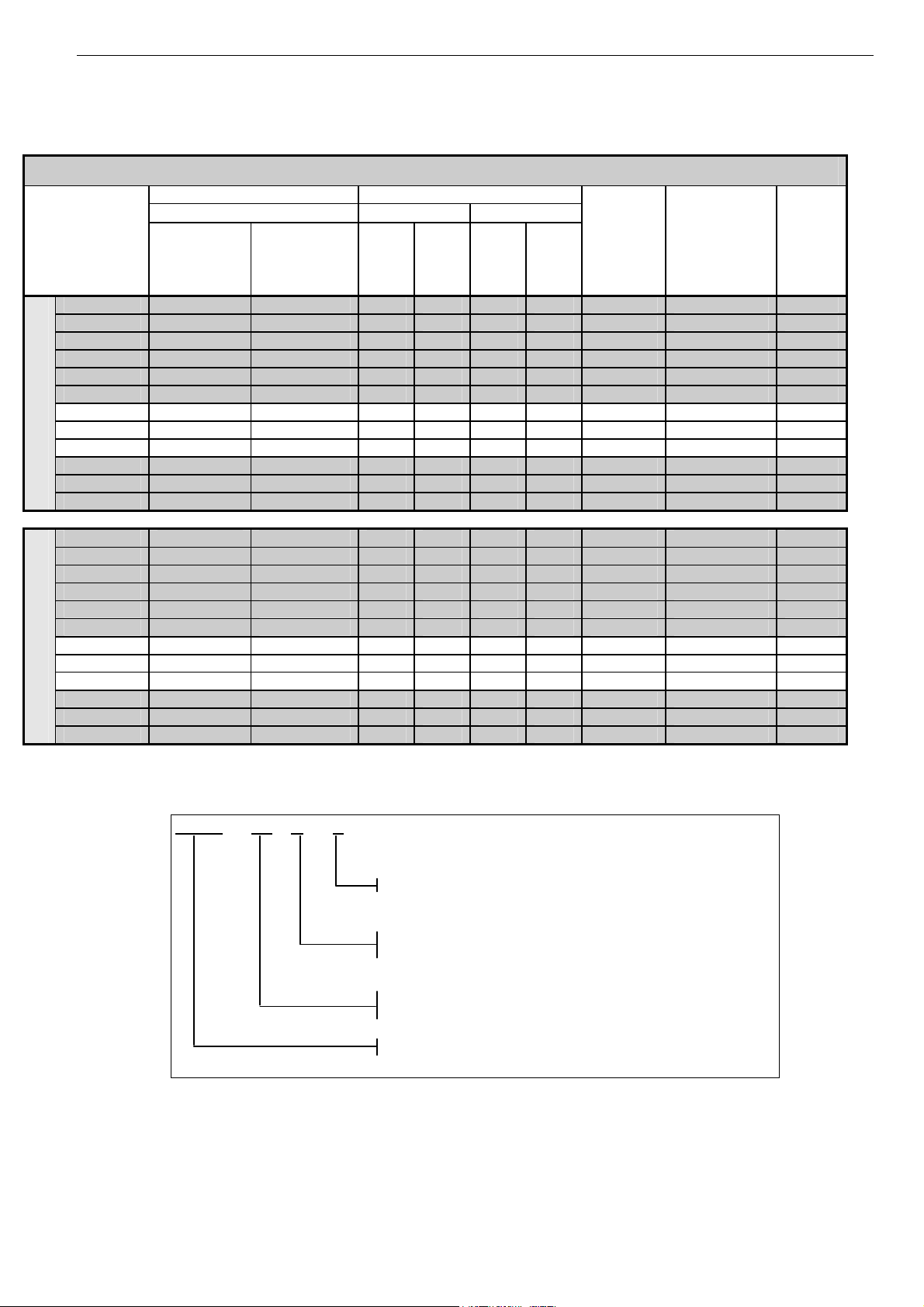

MODELS

Mains voltage 380-500 V, 50/60 Hz, 3~ Series NXL HVAC

Frequency

converter type

HVAC03C2

HVAC04C2

HVAC05C2

HVAC07C2

HVAC09C2

HVAC12C2

HVAC16C2

HVAC23C2

EMC-level H

HVAC31C2

HVAC38C2

HVAC46C2

HVAC61C2

HVAC03C5

HVAC04C5

HVAC05C5

HVAC07C5

HVAC09C5

HVAC12C5

HVAC16C5

HVAC23C5

EMC-level C

HVAC31C5

HVAC38C5

HVAC46C5

HVAC61C5

Motor shaft power Loadability

400V supply Low High

Low overload

(for pump/fan)

40°C P(kW)

1.1

1.5

2.2

3

4

5.5

7.5

11

15

18.5

22

30

1.1

1.5

2.2

3

4

5.5

7.5

11

15

18.5

22

30

High overload (for

machines) 50°C

P(kW)

0.75

1.1

1.5

2.2

3

4

5.5

7.5

11

15

18.5

22

0.75

1.1

1.5

2.2

3

4

5.5

7.5

11

15

18.5

22

Rated

continuous

current

(A)

I

L

3.3

4.3

5.6

7.6

9

12

16

23

31

38

46

61

3.3

4.3

5.6

7.6

9

12

16

23

31

38

46

61

current

13.2 9 13.5 MF4/IP21 128x292x190 5

17.6 12 18 MF5/IP21 144x391x214 8.1

25.3 16 24 MF5/IP21 144x391x214 8.1

13.2 9 13.5 MF4/IP54 128x292x190 5

17.6 12 18 MF5/IP54 144x391x214 8.1

25.3 16 24 MF5/IP54 144x391x214 8.1

Mechanical

size

10%

over-

load

(A)

Rated

continuous

current

(A)

I

H

50%

over-

load

current

(A)

Enclosure

and

protection

class

3.6 2.2 3.3 MF4/IP21 128x292x190 5

4.7 3.3 5.0 MF4/IP21 128x292x190 5

5.9 4.3 6.5 MF4/IP21 128x292x190 5

8.4 5.6 8.4 MF4/IP21 128x292x190 5

9.9 7.6 11.4 MF4/IP21 128x292x190 5

34 23 35 MF5/IP21 144x391x214 8.1

42 31 47 MF6/IP21 195x519x237 18.5

51 38 57 MF6/IP21 195x519x237 18.5

67 46 69 MF6/IP21 195x519x237 18.5

3.6 2.2 3.3 MF4/IP54 128x292x190 5

4.7 3.3 5.0 MF4/IP54 128x292x190 5

5.9 4.3 6.5 MF4/IP54 128x292x190 5

8.4 5.6 8.4 MF4/IP54 128x292x190 5

9.9 7.6 11.4 MF4/IP54 128x292x190 5

34 23 35 MF5/IP54 144x391x214 8.1

42 31 47 MF6/IP54 195x519x237 18.5

51 38 57 MF6/IP54 195x519x237 18.5

67 46 69 MF6/IP54 195x519x237 18.5

PRODUCT IDENTIFICATION CODE

Dimensions

WxHxD

[mm]

Weight

(kg)

HVAC 03 C 2

Enclosure & EMC classification

2 = IP21, EMC class H (fulfils EN 61800-3 cat C2, EN 55011 class A)

5 = IP54, EMC class C (full fils EN 61800-3 cat C1, EN 55011 class B)

Control keypad

C = Standard 7-segment keypad

Nominal current (low overload)

03 = 3 A etc.

Product range: HVAC = NXL HVAC

Fig. 1. Product Identification Code

3 EN0B-0619GE51 R1107

Page 4

NXL HVAC VARIABLE FREQUENCY DRIVES

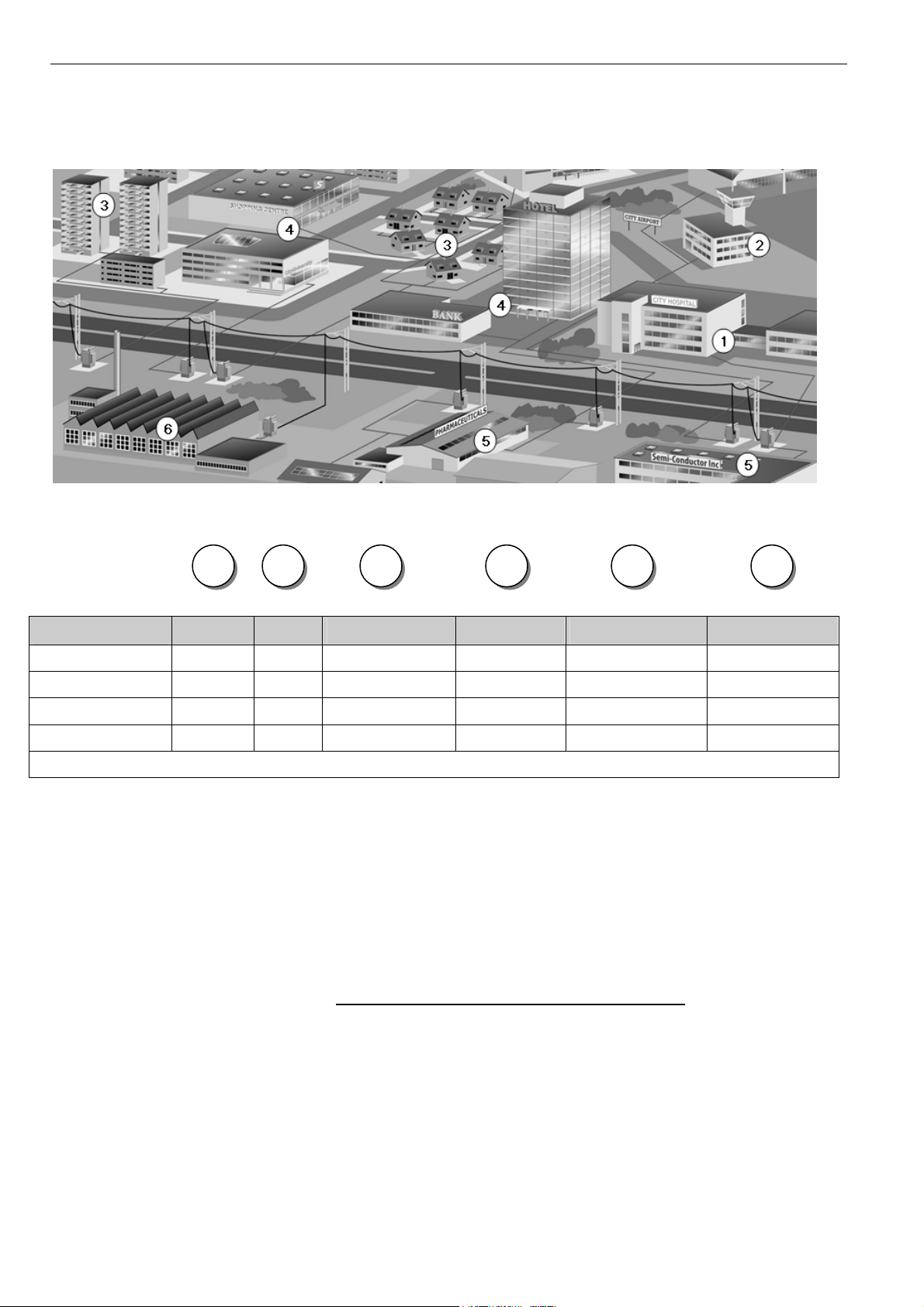

HONEYWELL EMC CLASSES AND MARKET REQUIREMENTS

Fig. 2. EMC classes in practice

1 2 3 4 5 6

EMC levels

C O O

H R R R R O O

L R R

T R (IT Network)

O = optional, R = required

Hospital Airport Residential Area Commercial Light Industry Area Heavy Industry

C = EN61800-3 [2004] Category C1 (standard in IP54 units)

H = EN61800-3 [2004] Category C2 (standard in IP21 units)

L = EN61800-3 [2004] industrial requirements fulfilled (standard in Honeywell inverters >160kW)

T =

EN61800-3 [2004] IT network (e.g. ships) requirements fulfilled, units can be easily converted to T-

class from standard EMC class. Instructions for this can be found from NXL HVAC User’s Manual

which can be downloaded from

http://inettrack.europe.honeywell.com/support/

EN0B-0619GE51 R1107 4

Page 5

NXL HVAC VARIABLE FREQUENCY DRIVES

A

A

MECHANICAL DIMENSIONS AND MOUNTING

The frequency converter shall be fixed with four screws (or bolts, depending on the unit size).

Ø

Ø

W2

W2

D1

D1

H1 H2

H1 H2

W1

W1

H3

H3

E1Ø

E1Ø

E2Ø*

E2Ø*

Ø

Ø

fr5ip21.fh8

fr5ip21.fh8

Fig. 3. NXL HVAC dimensions

Dimensions Type

MF4 (HVAC03-12)

W1 W2 H1 H2 H3 D1

128 100 327 313 292 190 7 3 x 28.3

∅ E1∅ E2∅*

MF5 (HVAC16-31) 144 100 419 406 391 214 7 2 x 37 1 x 28.3

MF6 (HVAC38-61) 195 148 558 541 519 237 9 3 x 37

Enough free space shall be left above and below the frequency converter to ensure sufficient air circulation and cooling. You will

find the required dimensions for free space in the table below.

C

A B C D

MF4 (HVAC03-12) 20 20 100 50

MF5 (HVAC16-31) 20 20 120 60

MF6 (HVAC38-61) 30 20 160 80

B

D

NK5_2

B

A = clearance around the freq. converter (see also B)

B = distance from one frequency converter to another or

C = free space above the frequency converter

D = free space underneath the frequency converter

Type Dimensions [mm]

distance to cabinet wall

Fig. 4. NXL HVAC installation space

5 EN0B-0619GE51 R1107

Page 6

NXL HVAC VARIABLE FREQUENCY DRIVES

REQUIRED COOLING AIR

Type Cooling air required [m3/h)

MF4 (HVAC03-12) 70

MF5 (HVAC16-31) 190

MF6 (HVAC38-61) 425

CABLING

Fig. 4. NXL HVAC power connections

Use cables with heat resistance of at least +70°C. The cables and the fuses must be dimensioned according to the tables below.

The fuses function also as cable overload protection. These instructions apply only to cases with one motor and one cable

connection from the frequency converter to the motor. In any other case, ask the technical support for more information.

L1 L2 L3

B- B+ R-

Connection Cable type

U/T1 V/T2 W/T3

nxlk58.fh8

Mains cable

Power cable intended for fixed installation and the specific mains voltage. Shielded cable not

required. (NKCABLES/MCMK or similar recommended)

Power cable equipped with compact low-impedance shield and intended for the specific mains

Motor cable

voltage. (NKCABLES /MCCMK, SAB/ÖZCUY-J or similar recommended).

(360º earthing of both motor and FC connection required to meet the EMC requirements)

Control cable

Screened cable equipped with compact low-impedance shield (NKCABLES /jamak, SAB/ÖZCuYO or similar)

[mm2]

Terminal cable size (min/max) Frame Type I

Earth

terminal

[mm2]

Control

terminal

[mm2]

Relay

terminal

[mm2]

L

[A]

Fuse

[A]

Mains

cable

Cu [mm2]

Main terminal

MF4 HVAC03—09 7—9 10 3*1.5+1.5 1—4 1—2.5 0.5—1.5 0.5—2.5

MF4 HVAC12 12 16 3*2.5+2.5 1—4 1—2.5 0.5—1.5 0.5—2.5

MF5 HVAC16 16 20 3*4+4 1—10 1—10 0.5—1.5 0.5—2.5

MF5 HVAC23 22 25 3*6+6 1—10 1—10 0.5—1.5 0.5—2.5

MF5 HVAC31 31 35 3*10+10 1—10 1—10 0.5—1.5 0.5—2.5

MF6 HVAC38—46 38—46 50 3*10+10 2.5—50 Cu

6—35 0.5—1.5 0.5—2.5

6—50 Al

MF6 HVAC61 61 63 3*16+16 2.5—50 Cu

6—35 0.5—1.5 0.5—2.5

6—50 Al

EN0B-0619GE51 R1107 6

Page 7

21 RO1

22 RO1

23 RO1

Fig. 5. NXL HVAC control connections

1 + 10 V

Reference output

ref

(voltage for potentiometer etc.)

2 AI1 + Analogue Input 1 (V signal)

3 AI1 – I/O Ground

4 AI2 + Analogue Input 2 (mA signal)

5 AI2 – Analogue Input 2 (mA signal)

6 +24 V +24 V output (max. 0.1 A)

7 GND I/O ground

8 DIN1 Digital Input 1 (Start forward)

Relay 1

NO/NC

(fault)

NXL HVAC VARIABLE FREQUENCY DRIVES

9 DIN2 Digital Input 2

(Start reverse)

10 DIN3 Digital Input 3

(Preset speed 1,

default: 10 Hz)

11 GND I/O Ground

18 AO1 +

19 AO1 –

Analogue output 1

Range 0–20 mA/R

max. 500 Ω

,

L

A RS485 Modbus RTU, serial bus

B RS485 Modbus RTU, serial bus

30 +24V Input for +24 V backup voltage

12 + 24 V +24 V output (max. 150 mA)

13 GND I/O ground

14 DIE1

15 DIE2

16 DIE3

25 ROE1

26 ROE1

28 TI+

29 TI –

Exp. Digital Input 1

(Preset speed 2, default: 50 Hz)

Exp. Digital Input 2

(Fault Reset)

Exp. Digital Input 3

(Disable PID)

Exp. Relay 1

NO (run)

Thermistor Input;

Rtrip = 4.7 k1Ω (PTC)

7 EN0B-0619GE51 R1107

Page 8

NXL HVAC VARIABLE FREQUENCY DRIVES

FEATURES / FUNCTIONS

• Easy to set-up features

30 second start-up wizard

VFD programming in just 4 easy steps:

1. Activate the Start-up Wizard

2. Select the mode (fan or pump)

3. Tune the motor nominal speed

4. Tune the motor nominal current

- RESULT: Fully configured drive ready to accept 0-10 V analogue

speed signal from controller in 30 seconds!

Quick installation guide

- Includes 1-page instructions for installation & set-up

- All the essential information on installation and basic

commissioning on 1 paper

- Attached to every product

“Keypad – Remote” Operation

- Single button operation to change the control to manual

(keypad) and back

- Useful function when commissioning and testing HVAC

applications.

- Consistency: all Honeywell VFDs behave in similar way

Press

LEFT ARROW for 3 s to

change control place

EN0B-0619GE51 R1107 8

Page 9

NXL HVAC VARIABLE FREQUENCY DRIVES

• Compact and Robust design

Features Functions Benefits

• NXL HVAC available with both IP21 and

Enclosure Class

Modular design

Built in input AC choke

and RFI filter

IP54

• Smallest and lightest inverter available in

the market (especially IP54)

• Separated cooling channel (no electronics

in air flow)

• Power electronics fully enclosed in metal

• Easily replaceable cooling fans

• Protection against input voltage surges

• Lower total harmonic distortion THD

• Fulfills all EMC requirements in buildings

• Consumes less space

• Easy to install

• Increased reliability

• Easy maintenance

• Compact

• No additional costs

• Uninterruptible operation and energy saving functions

Features Functions Benefits

Overtemperature ridethrough

Automatically adjusts switching frequency to

adapt to unusual increase in ambient

temperature

• Uninterruptible operation

Power ride-through

Trip free output

switching

Auto restart function

Energy Saving

Function “Flux

Optimization”

Automatically lowers motor speed to adapt to

sudden voltage drop such as power loss

Ensures trip free operation when an output

switch (e.g. safety switch) is operated

between the motor and the VFD. Truly

intelligent and highly reliable function to

ensure better functionality than with any other

VFD

Auto restart function can be configured to

make VFD restart automatically once fault is

addressed

Flux Optimization automatically minimizes

energy consumption.

• Uninterruptible operation

• Uninterruptible operation

• Uninterruptible operation

• Even 5% increase in energy

savings.

9 EN0B-0619GE51 R1107

Page 10

NXL HVAC VARIABLE FREQUENCY DRIVES

• VFD and motor control features

Features Functions Benefits

Best in performance

Flying start

Automatic torque boost

function

Motor auto identification

High Switching

Frequency

Prohibit frequency

Temperature-controlled

fans

Ability to get an already spinning fan under

speed control

Boosts initial voltage to start high inertia fans

Performs measurements to find out motor

internal variables such as stator resistance.

Honeywell HVAC drive has higher switching

frequency than the most of the competition as

standard (= no derating required)

Overriding the critical frequencies to avoid

resonance

Fan stops operating when not needed

• HVAC control features

• Improved performance

• Important in clean room

production to ensure the

standard conditions

• Avoids tripping and enables

smooth starts also to high

inertia loads

• Increased reliability

• Less audible noise from the

motor

•

Elimination of resonance

• Less audible noise from VFD

itself

• Increase of energy savings

Features Functions Benefits

• Normal and Inverse Regulation

• Delta P regulation with 2 standard pressure

Inbuilt PID controllers

Sleep Mode Shutting down the motor, when no demand

Fire override mode Keeps fan/pump running in case of fire

Pump and Fan Cascade

Controller

-

transmitters

• Less wiring since sensor normally close to

inverter

Controls total pumping system with several

parallel pumps by equally sharing the load

• Cost saving

• Faster response in process

closed loop

• Energy saving

• Legal requirement

• Longer lifetime of the system

• Lower investment cost for

pumping system

EN0B-0619GE51 R1107 10

Page 11

NXL HVAC VARIABLE FREQUENCY DRIVES

OPTIONAL ACCESSORIES

Field bus option boards

Fieldbus Order type code

Metasys N2 NXOPTC2

Profibus DP NXOPTC3

LonWorks NXOPTC4

Profibus DP (D9 type connector) NXOPTC5

CANopen (slave) NXOPTC6

Devicenet NXOPTC7

Metasys N2 (with D9 connector) NXOPTC8

Modbus/TCP (Ethernet) NXOPTCI

BACnet NXOPTCJ

Option Order type code Note

Panel door installation sets

PC-adapter NXLPANRS

RS232 Cables

Relay expander boards (*

Analogue I/O expander board (* NXOPTB4 1 Analogue input (mA) and 2 Analogue Outputs (mA)

(* when using this part of the standard I/O is replaced (3 Digital inputs, 1 relay and Thermistor input)

DRA-02L NXL Door installation set for display panel, 2m cable

DRA-04L NXL Door installation set for display panel, 4m cable

This adapter and RS232 cable are needed for PC

connection

RS232C2M 2m RS232 serial link cable for PC connection

RS232C-4M 4m RS232 serial link cable for PC connection

RS232C15.0M 15m RS232 serial link cable for PC connection

NXOPTB2 1 Relay NO/NC, 1 relay NO and thermistor input

NXOPTB5 3 Relays NO

SPARE PARTS

Type Order type code Note

I/O spare parts NXLOPTAI

Keypad spare parts NXPANC NXL standard keypad

NX-FAN-4 MF4 (HVAC03-12) main cooling fan assembly

Standard I/O replacement for:

3 DI, 1 RO (NC), Thermistor

Main cooling fans

11 EN0B-0619GE51 R1107

NX-FAN-5 MF5 (HVAC16-31) main cooling fan assembly

NX-FAN-6 MF6 (HVAC38-61) main cooling fan assembly

Page 12

NXL HVAC VARIABLE FREQUENCY DRIVES

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Straße 17

D-71101 Schönaich

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0619GE51 R1107

Loading...

Loading...