Page 1

APPLICATION

HR150, 200, 205; ER150, 200

Perfect Window™

Fresh Air Ventilation Systems

PRODUCT DATA

FEATURES

• Low voltage, high-speed override.

• Integral balancing dampers for quick installation.

• Provides ventilation that helps contractors meet

ASHRAE 62-89.

• 4-speed fan control.

• Automatic, economical built-in frost control available

for operation to design temperatures of -40°F (-40°C).

• HR150, HR200 and HR205 models have an easy-toclean aluminum cross-flow core.

• ER150 and ER200 models have an advanced enthalpy

heat and moisture recovery fixed core.

• Includes vibration isolation hardware and duct collars.

• Insulated cabinet made of rugged steel.

• Permanent (washable) prefilters.

• Quiet operation.

• Digital fan timer option on all models.

The HR150, HR200, and HR205 Perfect Window™ Fresh Air

Ventilation Systems provide proper levels of ventilation with

energy savings by transferring heat between the exhaust and

fresh air streams.

The ER150 and ER200 Perfect Window™ Fresh Air

Ventilation Systems provide proper levels of ventilation with

energy savings by transferring heat and moisture between the

exhaust and fresh air streams.

The ER150C and ER200C are specifically designed for

installations in unconditioned spaces such as attics and

garages.

Contents

Application/Features..........................................................1

Specifications/Ordering Information ..................................2

Planning the Installation ....................................................5

Installation .........................................................................8

Wiring ................................................................................9

Startup and Checkout/Service...........................................11

Troubleshooting.................................................................13

Parts List ...........................................................................15

® U.S. Registered Trademark

Copyright © 2004 Honeywell International Inc.

All Rights Reserved

68-0171-9

Page 2

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit might not exactly match the listed specifications. Also, this product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

TRADELINE® Models

TRADELINE models are selected and packaged to provide

ease of stocking, ease of handling and maximum replacement

value.

TRADELINE Models Available:

HR150, HR200, and HR205 Fresh Air Ventilation Systems:

Includes heat transfer core, prefilters, fan and blower

assembly and frost control.

HR150B: 150 cfm, aluminum core, manual control and

frost control.

HR200B: 200 cfm, aluminum cross flow core, manual

control and frost control.

HR205B: 200 cfm, aluminum cross flow core and frost

control (available in Canada only).

ER150B: 150 cfm, moisture transferring core, manual

control and frost control.

ER150C: 150 cfm, moisture transferring core, manual

control and without frost control.

ER200B: 200 cfm, moisture transferring core, manual

control and frost control.

ER200C: 200 cfm, moisture transferring core, manual

control and without frost control.

Color: White

Electrical Ratings:

Power Rating: 120 Vac, 60 Hz

Consumption:

Nominal Current (Amps)

HR150/

Mode

Minimum speed 0.7 0.8 0.07

Maximum speed 1.7 1.7 1.4

ER150

HR200/

ER200 HR205

Mounting:

Most models mount in conditioned space such as a

basement, utility room, hallway or closet. Can also be

mounted in conditioned attic space.

NOTE: ER150C and ER200C models can be installed in

unconditioned spaces such as attics and garages.

Approvals:

Home Ventilation Institute (HVI): Certified.

Canadian Standards Association: Approved.

ETL: Certified to UL1812.

Installed Weight:

HR150/HR200: 70 lb (32 kg).

HR205: 87 lb (40 kg).

ER150/ER200: 70 lb (32 kg).

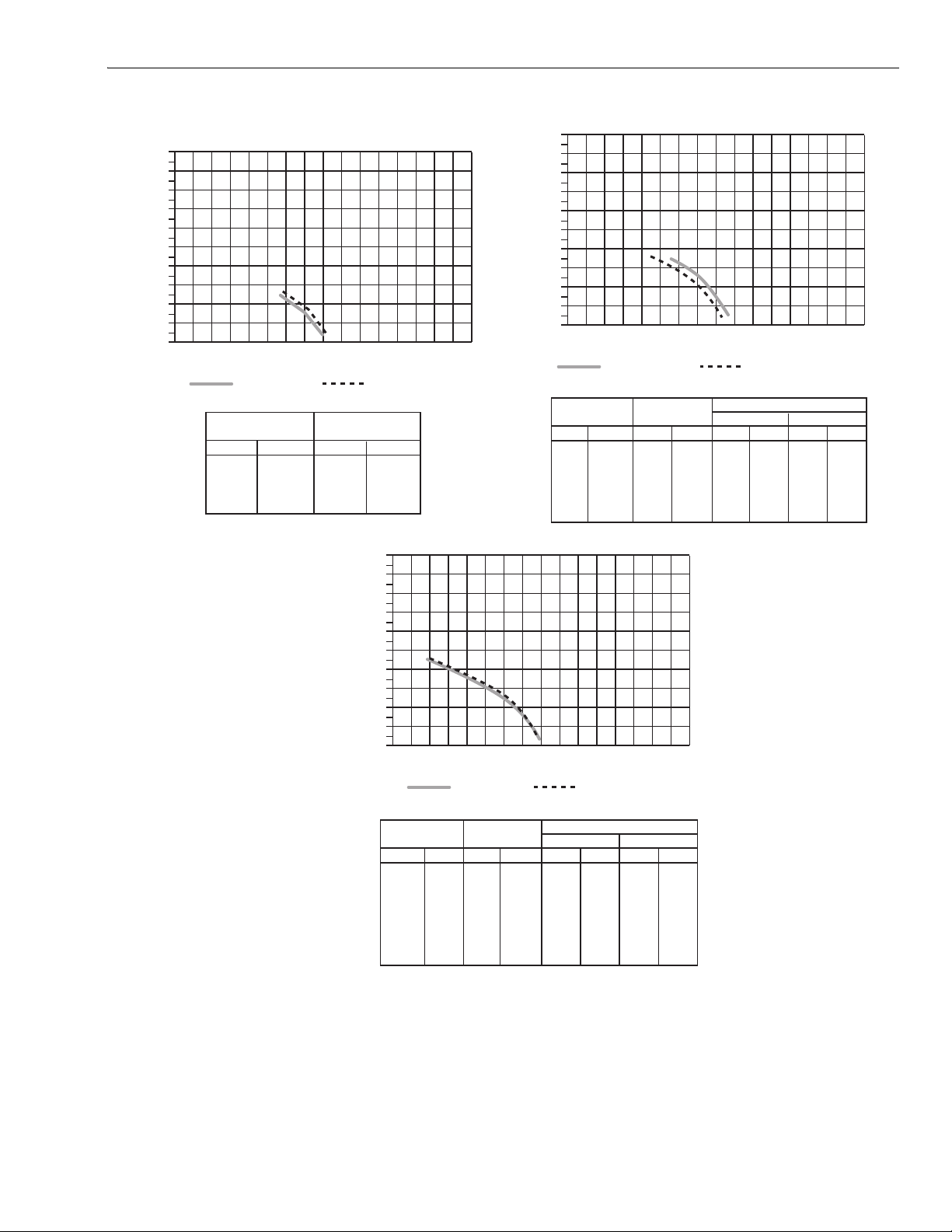

HVI Certifier Ventilation Performance: See Fig. 1.

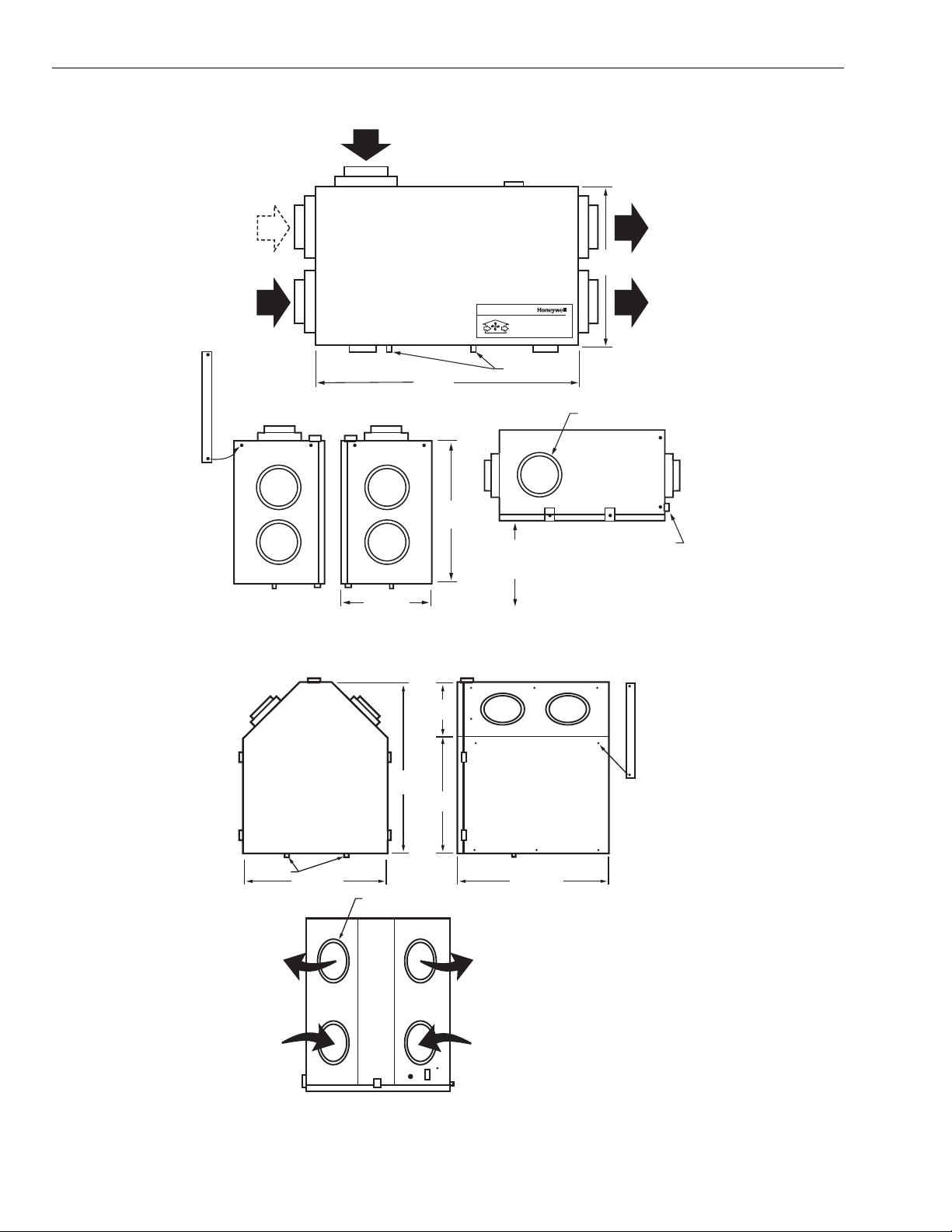

Dimensions: See Fig. 2 and 3.

Accessories:

See the HR Accessory Items Parts List that follows the

Troubleshooting Guide.

HR150, HR200, HR205

Maximum Temperature Recovery: 80%.

Sensible Efficiency (Performance per CAN/CSA-C439-88):

Low Speed at 32°F (0°C): 68%.

High Speed at 32°F (0°C): 62%.

Low Speed at -13°F (-25°C): 60%.

ER150, ER200

Sensible Efficiency (Performance per CAN/CSA-C439-88):

110 cfm at 61°F (16°C): 79%.

Moisture Transfer Ratio: 26%.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0171-9 2

Page 3

2

A

A

1.8

1.6

1.4

1.2

1

0.8

0.6

in. wg (Pa = n x 248.8)

0.4

0.2

0

0

50 150100 200 250 300 350

HR150/ER150 VENTILATION PERFORMANCE

EXT STATIC

(Pa) (in. wg) (L/s) (cfm)

100

125

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

cfm (L/s = n x 0.4719)

NET SUPPLY NET EXHAUST

NET SUPPLY

PRESSURE

25

50

75

.1

.2

.3

.4

.5

AIR FLOW

91

177

89

164

84

156

78

143

69

123

2

1.8

1.6

1.4

1.2

1

0.8

0.6

in. wg (Pa = n x 248.8)

0.4

0.2

0

0

EXT. STATIC

(Pa) (in. wg) (L/s) (cfm) (L/s) (cfm) (L/s) (cfm)

100

125

150

175

200

225

PRESSURE

25

50

75

2

1.8

1.6

1.4

1.2

1

0.8

0.6

in. wg (Pa = n x 248.8)

0.4

0.2

0

0

50 150100 200 250 300 350

400

GROSS SUPPLY GROSS EXHAUST

HR200/ER200 VENTILATION PERFORMANCE (HVI)

EXT STATIC

PRESSURE

(Pa) (in. wg) (L/s) (cfm) (L/s) (cfm) (L/s) (cfm)

25

50

75

100

125

M6561

50 150100 200 250 300 350

cfm (L/s = n x 0.4719)

NET SUPPLY NET EXHAUST

150

175

.1

.2

.3

.4

.5

.6

.7

NET SUPPLY

AIR FLOW

104

97

91

87

80

73

64

HR205 VENTILATION PERFORMANCE (HVI)

.1

.2

.3

.4

.5

.6

.7

.8

.9

NET SUPPLY

AIR FLOW

93

196

89

188

84

178

78

165

71

149

62

131

51

109

37

79

23

48

GROSS AIR FLOW

SUPPLY

94

199

90

190

85

181

79

167

71

151

63

133

52

110

38

80

23

49

EXHAUST

93

88

83

77

73

64

51

41

22

cfm (L/s = n x 0.4719)

GROSS AIR FLOW

SUPPLY

214

102

206

98

193

93

184

88

170

81

155

74

137

65

400

197

186

176

153

154

134

108

86

47

M6563

216

208

197

186

172

157

138

EXHAUST

97

93

88

82

75

67

54

206

197

186

174

159

142

114

M6562A

400

Fig. 1. Ventilation Performance.

3 68-0171-9

Page 4

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

FRESH AIR

FROM OUTSIDE

DEFROST

PORT

STALE AIR

FROM HOUSE

Fresh Air Ventilation System

Système de ventilation à air frais

DRAIN SPOUTS

SERVICE

CLEARANCE

25

(635)

WEIGHT: 70 lb (32 kg)

SHIPPING WEIGHT: 72 lb (33 kg)

MOUNTING

STRAP (4)

14-3/4 (375)

33-5/8 (854)

(483)

19

Fig. 2. HR150/ER150 and HR200/ER200 dimensions in in. (mm).

STALE AIR

TO OUTSIDE

19

(483)

FRESH AIR

TO HOUSE

ALL DUCT CONNECTIONS

ARE 6 (150).

HR

CONTROLS

M6546B

DRAIN

SPOUTS

STALE AIR

EXHAUST

SUPPLY OF

FRESH AIR

7-1/2

(191)

25-1/2

(648)

18

(457)

26-1/2 (673)22-1/2 (572)

ALL DUCT CONNECTIONS

ARE 6 (150).

FRESH AIR

SUPPLY TO

BUILDING

STALE AIR

RETURN FROM

BUILDING

WEIGHT: 87 lb. (40 kg)

SHIPPING WEIGHT: 89 lb. (41 kg)

Fig. 3. HR205 dimensions in in. (mm).

MOUNTING

STRAP (4)

M6547A

68-0171-9 4

Page 5

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

A

PLANNING THE INSTALLATION

Application

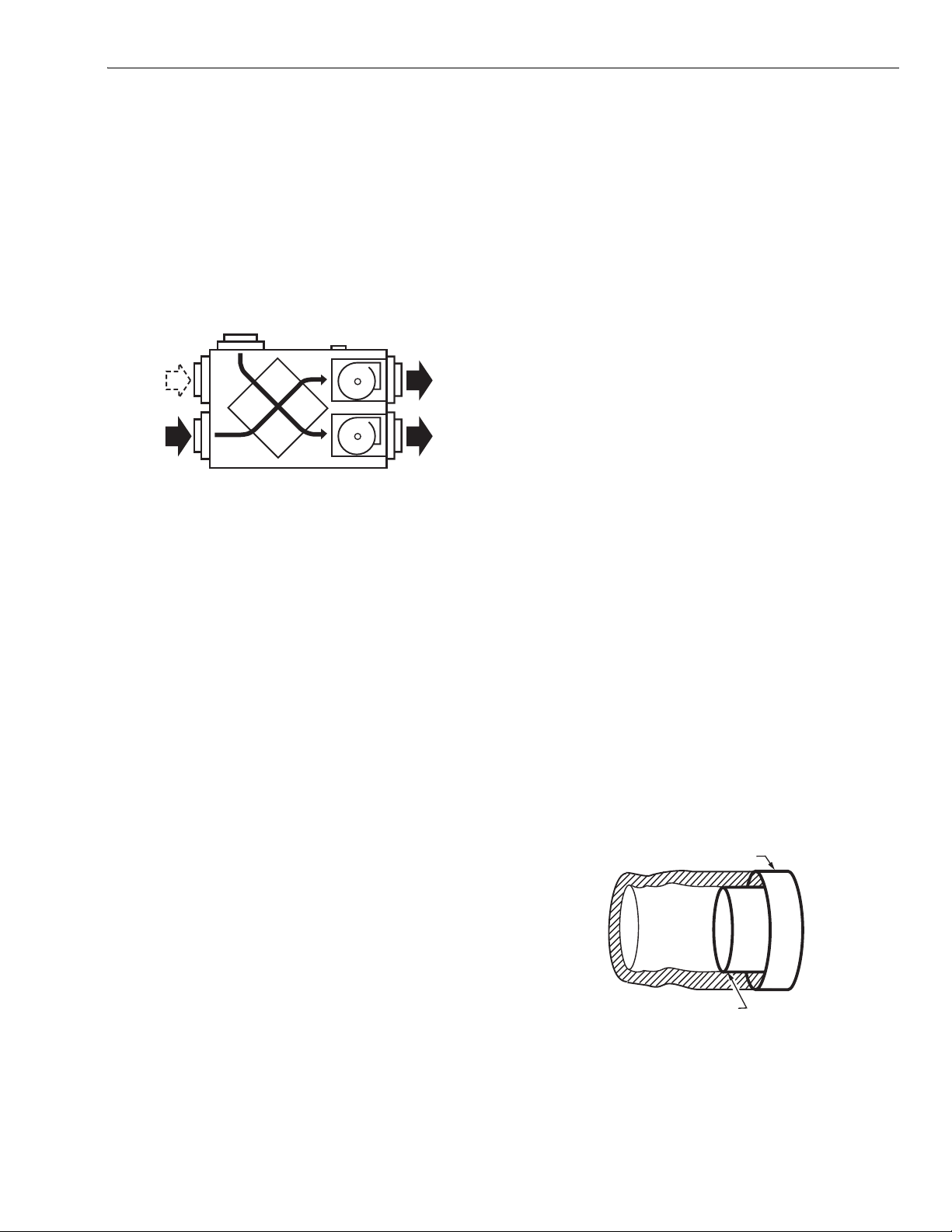

The Fresh Air Ventilation System is designed to supply fresh

air and exhaust stale air. The system draws fresh outdoor air

through the ventilator for distribution throughout the house.

Stale air is exhausted through the ventilator and to the

outdoors. Heat is transferred from one airstream to the other

as the air passes through the opposite sides of the heat

transfer core. See Fig. 4.

FRESH

AIR IN

DEFROST

PORT

STALE

IR FROM

HOUSE

Fig. 4. Duct connections and airflow.

Sizing

There are several methods that can provide satisfactory

results for sizing a ventilator to provide adequate ventilation

for a home. The ASHRAE Standard 62-1989 Ventilation for

Acceptable Indoor Air Quality suggests the following:

— .35 air changes per hour (ach) but not less than 15 cfm per

person for living areas = house size (sq ft) • ceiling height

(ft) / 60 (min) •.35 (ach)

Example:

= 2000 sq ft • 8 ft / 60 min •.35 ach = 93 cfm

— 50 cfm intermittent or 20 cfm continuous capacity for

bathrooms

Example:

50 cfm intermittent • 3 bathrooms = 150 cfm

20 cfm continuous • 3 bathrooms = 60 cfm

— 100 cfm intermittent or 25 cfm continuous capacity for

kitchens

STALE

AIR TO

OUTSIDE

FRESH

AIR TO

HOUSE

M6553B

Option 2: Fresh Air Ventilation System provides continuous

93 cfm fresh air supply, 150 cfm intermittent exhaust capacity

for bathrooms and continuous 50 cfm kitchen ventilation.

Supply air flow required = 93 cfm

Exhaust air flow required = 200 cfm

Honeywell HR200/ER200 have the exhaust capacity required

to meet the ventilation needs of this application. See Fig. 1.

Mounting Position and Location

The HR150/ER150, HR200/ER200 and HR205 can be

suspended from exposed ceiling joists, ceiling surface or floor

mounted. (Level ventilator so drains function correctly.)

NOTE: ER150C and ER200C are specifically designed for

installations in unconditioned spaces such as attics

and garages. (These units are not equipped with

drain kits.)

• Locate fresh air intake 6 ft (2m) or more from stale air

exhaust to prevent exhaust air from re-entering.

• Locate ventilator where length of ducting required is

minimal.

Install HR150/ER150, HR200/ER200 and HR205 in a

conditioned space using these guidelines:

• Pipe drain line (ER150C and ER300C do not have drain

kits) from the ventilator to a drain.

• Use an existing electrical outlet with appropriate current

rating (or install one) close to ventilator power cord.

• Allow space for drain line by placing the ventilator at least

10 in. (254 mm) off the floor.

• For access and removal of ventilator core, allow at least

25 in. (635 mm) of open space in front of unit.

Ducting

Ducting between the ventilator and the outdoors must be

insulated and have a continuous air vapor barrier. See Fig. 5.

IMPORTANT

All ducting to the outdoors must be terminated above

anticipated snow lines and be fitted with a weather

cap that incorporates bird screening.

SEAL OUTER LINING OF FLEX

DUCT TO OUTER COLLAR

Example:

100 cfm intermittent • 1 kitchen = 100 cfm

25 cfm continuous • 1 kitchen = 25 cfm

INSULATED

FLEX DUCT

COLLAR ON

VENTILATOR

Option 1: Fresh Air Ventilation System provides continuous

fresh air supply of 93 cfm, and intermittent capacity for

bathrooms of 150 cfm. A separate 100 cfm exhaust fan is

used for the range hood.

Supply air flow required = 93 cfm

Exhaust air flow required = 150 cfm

Any Honeywell ventilation unit provides suitable ventilation

capacity. See Fig. 1.

Design and installation of ductwork must be according to

standard HVAC practice to deliver required quantities of fresh

air to temperature-controlled space and exhaust equivalent

quantities of room air to the outside.

5 68-0171-9

SEAL INTERIOR LINING OF

FLEX DUCT TO INSIDE COLLAR

Fig. 5. Sealing insulated duct terminations.

M6557

Page 6

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

A

Keep intake and exhaust duct runs as short as possible with

few bends or elbows.

• Keep duct sizes as large as possible throughout the

installation.

• Use a 6 in. diameter round duct for all connections to and

from the ventilator.

• Separate outside intake and exhaust vents by at least

6 ft (2m).

NOTES:

— Do not locate the fresh air vent where it blows

directly onto occupants or the thermostat.

— Do not locate the fresh air intake close to known

sources of pollutants such as automobile exhaust,

a dryer vent or chimney smoke.

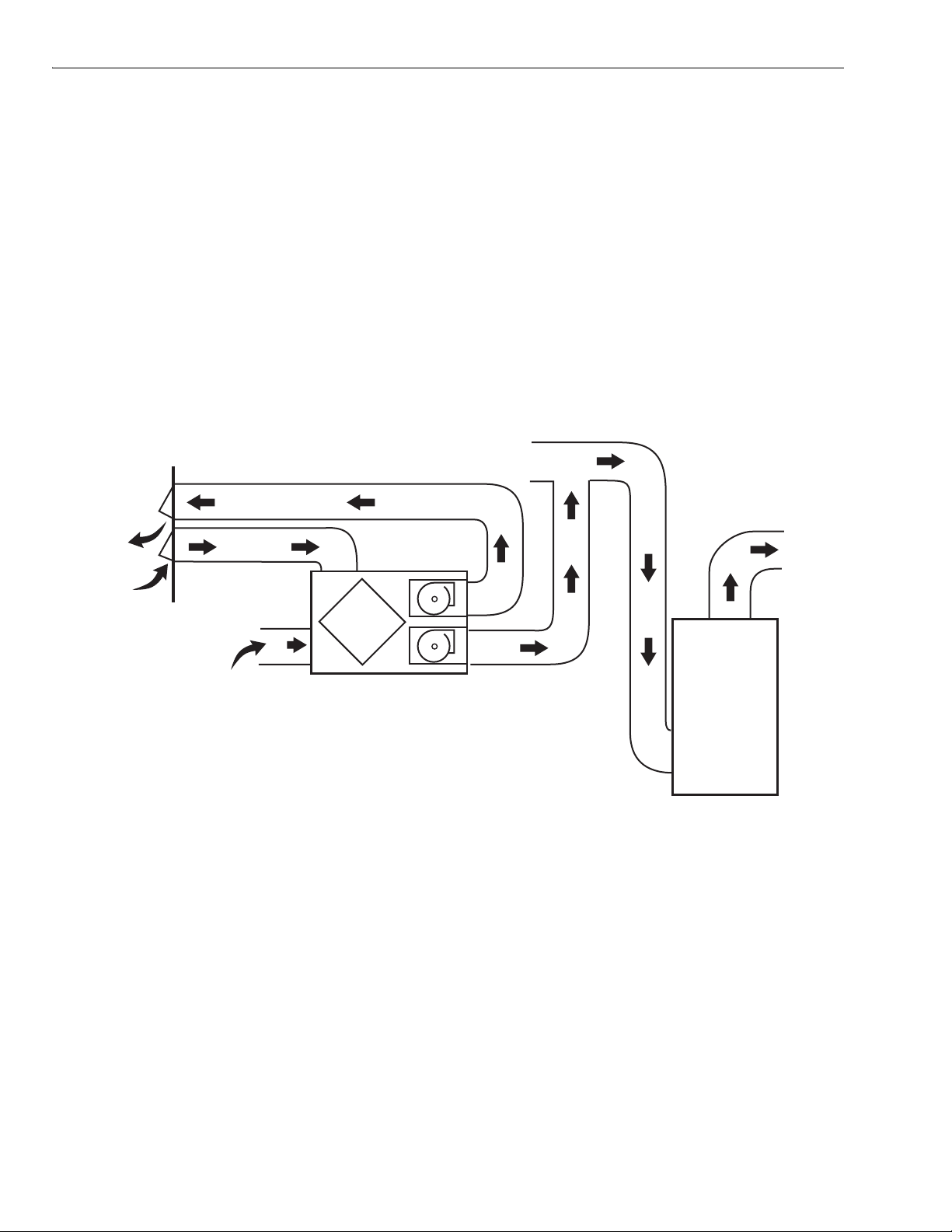

• Ducting the supply outlet and/or the exhaust inlet of the

ventilator to the return air plenum of the air handler is an

excellent way to distribute fresh air and exhaust stale air

from all parts of the house, while reducing installation

OUTDOORS

costs. When choosing this method, balance the ventilator

when the air handler is running and interlock the ventilator

so that it can run only when the air handler runs. See

Fig. 6. An alternate method is to balance the ventilator

when the air handler is not running and let the ventilator

run whether the air handler is running or not, see Fig. 7. An

independent installation is shown in Fig. 8.

NOTE: When the home is occupied, continuous operation of

the ventilator is recommended. When the furnace air

handler operates, fresh air is distributed through the

heating/air conditioning supply registers. When the

air handler is off, fresh air is delivered through both

supplies and returns.

• An electrical interlock or an automatically powered damper

must be used to prevent unwanted entry of outside air if the

ventilator is turned off while the furnace air handler

continues to operate.

RETURN

AIR

COLD AIR

RETURN

EXHAUST AIR FROM

VARIOUS PARTS OF

HOME (BATHROOMS

IF REQUIRED; KITCHENS

IF REQUIRED; ROOMS

WITHOUT OPERABLE WINDOWS,

ND POTENTIALLY BASEMENTS).

NOTES:

FURNACE BLOWER NEED NOT OPERATE TO PROVIDE GOOD AIR DISTRIBUTION/QUALITY WITH THIS SYSTEM.

1.

IF FURNACE BLOWER OPERATION IS REQUIRED TO HELP DISTRIBUTE SUPPLY AIR: RUN CONTINUOUSLY

2.

OR INTERLINK ELECTRICALLY (LOW VOLTAGE) USING OPTIONAL 32003248-001 BLOWER INTERFACE KIT.

NO SEPARATION REQUIREMENTS ARE NECESSARY BETWEEN DIRECT CONNECTION POINT AND FURNACE.

3.

4.

WEATHER-HOOD ARRANGEMENT IS FOR DRAWING ONLY. 6 FT (2m) MINIMUM SEPARATION REQUIRED,

18 IN. (0.46m) ABOVE GRADE MINIMUM.

Fig. 6. Direct connection of supply air stream to furnace cold air return for HRV/ERV.

FORCED AIR

FURNACE

COMBUSTION

OR ELECTRIC

M6549C

68-0171-9 6

Page 7

RETURN

AIR

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

OUTDOORS

NOTES:

1.

FURNACE BLOWER IS REQUIRED TO OPERATE WHEN VENTILATION IS REQUIRED.

SET THE FURNACE BLOWER TO RUN CONTINUOUSLY, OR INTERLINK ELECTRICALLY

(LOW VOLTAGE) USING OPTIONAL 32003248-001 BLOWER INTERFACE KIT.

2.

MINIMUM SEPARATION OF 40 IN. IS REQUIRED BETWEEN THE TWO

DIRECT CONNECTIONS.

3.

EXHAUST AIR CONNECTION SHOULD BE UPSTREAM OF THE SUPPLY

AIR CONNECTION TO PREVENT EXHAUSTING ANY FRESH AIR.

4.

WEATHER-HOOD ARRANGEMENT IS FOR DRAWING ONLY. 6 FT. (2 m)

MINIMUM SEPARATION REQUIRED, 18 IN. (0.46m) ABOVE GRADE MINIMUM.

40 IN. (1m) MINIMUM

COLD AIR

RETURN

FORCED AIR

FURNACE

COMBUSTION

OR ELECTRIC

M6548D

Fig. 7. Direct connection of ventilator supply air stream and exhaust air stream to furnace cold air return.

ADJUSTABLE

STALE AIR

RETURN

ADJUSTABLE FRESH

AIR SUPPLY

ADJUSTABLE DAMPERS FOR

BALANCING AIR FLOW INTO

AND OUT OF THE HOUSE

NOTES:

VENTILATOR EXHAUSTS FROM KITCHEN AND/OR

1.

BATHROOMS OR OTHER CENTRAL LOCATIONS

TO OUTDOORS.

VENTILATOR SUPPLIES OUTDOOR AIR DIRECTLY TO

2.

EACH BEDROOM, TO EACH FLOOR WITHOUT A

BEDROOM, AND TO THE PRINCIPAL LIVING AREAS.

FLEXIBLE INSULATED DUCTING

WITH A VAPOR BARRIER

Fig. 8. Independent ventilator installation.

FRESH AIR

SUPPLY HOOD

STALE AIR

EXHAUST HOOD

M4911A

7 68-0171-9

Page 8

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

Balancing Airflow

Balancing the airflow verifies that the Fresh Air Ventilation

System is delivering the intended airflow and energy

performance. Use the Airflow Balancing instructions in the

Installation section to check and balance the airflow.

Controls

Remote Override Switch Functions On/Off Control

If continuous ventilation is not required, an on/off control can

be used to activate the ventilator when it is switched to

Standby. Controls that can be used for this function include

dehumidistats, timers, wall switches and the ventilate function

of the Perfect Climate Comfort Center™. If moisture control in

bathrooms is a primary function of the system, a dehumidistat

can be used to switch the ventilator from a Low or Standby

setting to the High setting. Moisture removal throughout the

entire home can only be achieved when the outside air

contains less moisture than the inside air (typically during cold

weather conditions).

The Perfect Climate Comfort Center™ can automatically

control the ventilator by using the programmed times or

manually control it by pressing the Ventilate button on the

keypad. See the Perfect Climate Comfort Center™ Users

Guide, form 69-0893, for complete instructions.

Digital Fan Timer

The ventilator controls are compatible with the Digital Fan

Timer. If more than one timer is activated, each runs

independently with the ventilator running at high speed until all

timers have timed out. Up to four timers can be installed in a

system. For complete instructions on the operation of the

Digital Fan Timer, refer to the instructions packed with the

timer.

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow these

instructions could damage the product or cause a hazardous condition.

2. Check the ratings on the product to make sure the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

CAUTION

Electrical shock hazard.

Can cause personal injury or equipment damage.

Disconnect power supply to prevent electrical shock or

equipment damage.

Unpacking Fresh Air Ventilation System

Check that all the components are included. The Fresh Air

Ventilation System is shipped assembled. The carton contains

the following:

• Fresh Air Ventilation System.

• Vibration isolation straps (4).

• Drain fittings (2) and T fitting (1).

• Literature package.

Except for the mounting hardware and drain fittings, the

ventilator is ready for installation. Wiring, drain connections

and ducting are required to complete the installation.

Mounting

Moisture Control

When a building is new, there is excess moisture in the wood,

plaster, cement and other construction materials. When the

new building is occupied, the activities of the occupants also

increase the moisture level. There can also be high levels of

formaldehyde and other chemicals that were used in the

building materials. Running the ventilation system on high

speed provides optimum indoor air pollutant reduction. High

speed also provides maximum moisture removal when the

outside air contains less moisture than the inside air.

(Typically during cold weather conditions.)

Operating Damper Frost Control

Some models have an electronically-controlled damper frost

control mechanism. When the outside temperature drops

below 27°F (-3°C), the defrost timer is activated. At the end of

the 17 minute run cycle, when the core can experience some

nominal frost buildup, the timer activates a motor-driven

damper door that simultaneously opens the defrost port and

closes off the supply air port. On the HR205, exhaust air is

used for defrost. At the end of the 4.5 minute defrost cycle, the

damper operates in the opposite direction and ventilation is

resumed. The cycles continue until the outdoor temperature

rises above the defrost temperature.

Suspended from Floor Joists

1. Mount the four vibration isolation straps (provided) to

the side of the ventilator using the mounting screws

located on the cabinet. See Fig. 2 and 3.

2. Securely fasten the other ends of the straps to the floor

joists with wide-head nails (not supplied), making sure

the unit is level. The straps are designed to reduce

noise, resonance or harmonics; therefore, using the full

length of the strap between the ventilator and the floor

joists is recommended.

NOTE: Removing door and core reduces the weight of

the ventilator, making it easier to lift into place.

Floor Mounting

The mounting hardware included is not needed for floor

mounting.

1. Use 2 x 4 in. wood pieces to build a frame to support the

ventilator along the bottom edge. The frame must hold

the ventilator at least 10 in. up from the floor to allow

clearance for the drain line.

2. Set the frame back approximately 2 in. from the frontedge to avoid interference with the hinged door.

3. Place the ventilator on the frame. Secure the ventilator

to the frame using screws and a strip of wood or metal;

screw into the side walls of the ventilator within 1 in. of

the bottom.

68-0171-9 8

Page 9

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

4. Connect the drain lines to a drain; see Installing Drain

Line and P-Trap section.

5. Connect the ventilator to the ducts.

Installing Drain Line and P-Trap

There are two holes at the bottom of the ventilator for the

drain pan connectors.

1. Insert the connectors through the hole in the drain pan

and the bottom of the unit.

2. Place the washer and nut on the connector.

3. Hand tighten the nut. See Fig. 9.

DRAIN

PAN

HR

BOTTOM

NUT

Fig. 9. Installing drain line.

Construct a P-trap using the plastic T-fitting provided.

1. Cut two lengths of 1/2 in. ID hose and connect each

drain fitting to the end of the T-fitting.

2. Position the center leg of the T-fitting so it points

upward.

3. Connect the drain line to the center leg and tape it in

place to prevent any kinks. See Fig. 10.

O RING

WASHER

M6552

WIRING

CAUTION

Electrical Shock Hazard.

Can cause personal injury.

Be sure ventilator is correctly grounded.

Confirm polarity of power line switched with safety

(disconnect) switch when cleaning or servicing unit.

IMPORTANT

The hot line (black) is the correct line to switch. See

Fig. 11. To confirm correct polarity, use voltmeter or

test lamp to verify there is no power after the switch

when the door is open. Check between that point

and ground (on cabinet). This process must be used

because occasionally some dwellings are incorrectly

wired.

Heat Recovery Ventilator (HRV) and Energy

Recovery Ventilator (ERV) Connections

The connector is a three-prong, 120 Vac plug with ground. If

further wiring is required, Honeywell recommends that a

licensed electrician make all electrical connections. It is very

important that the unit be correctly grounded.

Digital Fan Timer Connections

CAUTION

Electrical Hazard.

Can cause equipment damage.

Disconnect HRV/ERV from power source before

connecting or disconnecting digital fan timer or other

device to HRV/ERV high-speed override terminals.

TAPE

TO DRAIN

T FITTING

M6551

Fig. 10. Installing P-trap.

This creates a trap that will hold some condensation and

prevent odors from being drawn up through the drain hose

into the unit. If the unit is installed during a season when it is

unlikely that condensation will form, fill the trap with tap water.

IMPORTANT

Do not connect external power sources to the highspeed override terminals.

Mount digital fan timer in a full or one-half depth electrical box

in the living space. See Fig. 11 for the 32003487 digital 20minute fan timer and the W8150A Fresh Air Ventilation

Control wiring diagrams. (See Accessory Parts List, items 9

and 10, for the W8150A Fresh Air Ventilation Control and the

32003487 Digital Fan Timer.)

9 68-0171-9

Page 10

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

8150

OL

C

0

W8150A

SPEED CONTROL SWITCH

LEGEND

HIGH VOLTAGE

LOW VOLTAGE

4

BROWN

TRANSFORMER

21

3

YELLOW

AUTO

BLUE

FAN MOTOR DETAILS

T4

T8

BLACK

WHITE

GREEN

BRN

BRN

CAP

FAN

MOTOR

DIRECT MOUNTED CAPACITOR

DEFROST DETAILS

BI-DIRECTIONAL

DAMPER MOTOR

BLACK

ORANGE

BLACK

ORANGE

RED

RED

PLUG IN

CONNECTOR

32003487-001 FAN TIMER

RED

1

BLACK

2

GREEN

120V

SUPPLY

CARD

P1

GROUND

DEFROST

PCB PLUG-IN

12

34

PIN 1–RED

PIN 2–ORANGE

PIN 3–BLACK

PIN 4–SPARE

WHITE

SEE

DETAILS

P1

BLACK

T2

T1

GROUND

3/4 AMP FUSE

THERMISTOR

W

TO

MOTOR

T3 T4 T5 T6 T7 T8 T9

C4

P1

K1 K2 K3 K4

FACTORY

INSTALLED

JUMPER

12 VAC

P4

HS

BLUE

P3

REMOTE

DFR2

DFR3

SW1

FRESH AIR VENTILATION CONTR

AT12

Ventilation Control

Auto

Continuous

Off

(Remote Only)

Ventilation Control

Service

1

HR150/ER150

RED

BLACK

BLACK

T10C5T11

ON

T12

DEHUMIDISTAT

RECIRCULATE

P5

RED

+12V

ORANGE

OBCS

BLACK

GREEN

LED DRIVE

LOW FAN

GROUND

GREEN

COMMS

FAN TIMER

W8150A1001

VENTILATION

CONTROL OR

REMOTE

SWITCH

1

DO NOT REMOVE JUMPER.

2

MAXIMUM WIRE IS 100 FEET (30 METERS).

USE 20 GAUGE WIRE.

Fig. 11. Internal schematic for fresh air ventilation systems.

68-0171-9 10

NOTES:

– BALANCE THE HRV/ERV TO 160 CFM OR LOWER.

– SET VENTILATOR SPEED KNOB TO 0.

1

2

REMOTE AUX DAMPER

EARD DAMPER NOT USED WITH HRV/ERV.

SEE THE W8150 FRESH AIR VENTILATION CONTROL LITERATURE,

68-0282, FOR COMPLETE WIRING INSTRUCTIONS.

M22137

Page 11

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

Airflow Balancing

Volume-balanced airflow in the ventilator is required. Volume

of outside air brought in must equal the volume of air the unit

exhausts. If airflow is not correctly balanced:

• unit does not operate at its maximum efficiency.

• negative or positive air pressure can occur in the house.

• unit will not defrost properly.

• warranty can be voided.

Excessive positive pressure can drive moist indoor air into

building external walls where it can condense (in cold

weather) and degrade structural components. Moist indoor air

can also cause keyholes to freeze.

PUSH AND TURN WITH

SLOTTED SCREWDRIVER.

DAMPER AUTOMATICALLY

LOCKS WHEN PRESSURE

IS RELEASED.

M13462

Excessive negative pressure can have several undesirable

side effects; in some geographic locations, soil gases such as

methane and radon can be drawn into the home through

basement/ground contact areas. Excessive negative pressure

can also cause back drafting of vented combustion equipment

when adequate combustion air supply is not provided.

Balancing Procedure

Six-inch (150 mm) diameter flow collars connected to inclined

or digital manometer, or magnehelic, with range of 0 to.25 in.

(0 to 62.5 Pa) of water are recommended for accurate airflow

measurements. To avoid airflow turbulence and incorrect

readings, flow stations should be located at a distant point of

at least five duct diameters; for example, 6 in. (150 mm) duct

requires five diameters x 6 in. (150 mm) = 30 in. (76 cm) from

nearest valve or flow restriction. This requirement applies to

both stale air to exchanger duct and fresh air to house duct.

Before balancing, make sure:

• all sealing of the ductwork system is completed.

• all of the ventilator system components are in place and

functioning properly.

• balancing dampers are fully open.

• unit is on High speed.

• airflows in branch lines to specific areas of house are

adjusted before balancing the unit. (A smoke pencil used at

the grilles is a good indicator of relative airflow for each

branch line.)

After taking readings in stale air and fresh air ducts, duct with

lower cfm (L/s) velocity reading should remain as is, while

duct with higher reading should be dampered back to match

lower reading. See Fig. 12.

Return unit to appropriate fan speed for normal operation.

STARTUP AND CHECKOUT

After installation is complete, check to be sure system is

working correctly. On units with microprocessor control, select

ventilation speed by touching fan control pad on base module

until desired speed is indicated. On units with manual control,

turn speed selection knob to desired speed. Activate two-wire

control devices in system to make sure devices switch

ventilator to High speed. For operating instructions, see

instructions packed with digital fan timer. Leave instructions

with homeowner.

Fig. 12. Balancing airflow.

SERVICE

CAUTION

Electrical shock hazard.

Can cause personal injury or equipment damage.

Disconnect power to unit before starting maintenance.

For maximum efficiency, the Fresh Air Ventilation System

must be maintained on a regular basis. Honeywell recommends checking and cleaning at least twice a year, preferably

at the beginning of each heating and cooling season.

Cleaning Filters and Core

HR150, HR200 AND HR205 MODELS

Remove the room air filter, fresh air filter and heat transfer

core from the ventilator as a unit.

1. Open ventilator door by loosening draw latches on top

of unit and swinging door open. For easier access,

remove door by moving it right to disengage hinges.

2. Carefully grip ends of core, (be careful not to damage

aluminum fins); then pull evenly outward. Core fits

tightly, but slides out of channels.

3. Once core is removed, filters can be removed by removing clips holding them in place. Note clip installation for

reassembly.

4. Wash the filters and the core in warm soapy water. Do

not wash them in a dishwasher.

5. Place the clean filter (wet or dry) over the core and

secure it in place with the clips.

6. Reinstall core by sliding it into the four corner channels.

(Water cannot damage gasket and label on core ends,

so it is not necessary to remove them from the core.)

ER150 AND ER200 MODELS

1. Open access door, carefully grip core ends and pull it

out evenly. Core fits tightly but slides out of cabinet.

2. Remove filter clip, remove filters from core and rinse

filters with water or a combination of soap and water. Do

not clean in a dishwasher.

3. With filters removed, clean core with a vacuum cleaner.

Vacuum only filter sides of core to pull dirt back out of

core and not through it.

4. Reinstall clean filter and reattach retaining clip.

5. Reinstall clean core.

11 68-0171-9

Page 12

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

Inspecting Exterior Hoods

Inspect exterior hoods at least monthly. Be sure exhaust and

fresh air supply hoods are not blocked or restricted by leaves,

grass or snow. In winter, be sure snow does not block hoods

and frost does not accumulate on wire mesh bird screen.

IMPORTANT

Blocked hoods can cause house/building pressure

change that can lead to possible combustion product

spillage from heating appliances.

68-0171-9 12

Page 13

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

TROUBLESHOOTING

See Table 1.

Table 1. Troubleshooting Guide.

Symptom Cause Solution

Poor

airflow

Supply air feels

cold

Dehumidistat is

not operating

Humidity

levels are too

high; condensation appears

on windows

Humidity levels

too low

Ventilator and/

or ducts have

frost buildup

• Plugged outside hood 1/4 in. (6 mm) mesh. • Clean exterior hoods or vents

• Filters plugged. • Remove and clean filter.

• Core obstructed. • Remove and clean core.

• House grilles closed or blocked. • Check and open grilles.

• Dampers (if installed) are closed. • Open and adjust dampers

• Poor power supply at site. • Have electrician check supply voltage at house.

• Ductwork is restricting airflow. • Check duct installation.

• Improper speed control setting. • Increase speed of ventilator.

• Ventilator airflow improperly balanced. • Have contractor balance ventilator airflow.

• Poor location of supply grilles, airflow can

irritate the occupant.

• Outdoor temperature extremely cold. • Turn down ventilator supply speed. Use a small duct heater

• Incorrect connection to external 24-volt control.

• Staple/nail is shorting out external low voltage.

• Check dehumidistat setting; it could be at Off. • Set dehumidistat at the desired setting.

• Dehumidistat is set too high. • Set dehumidistat lower.

• Undersized ventilator (hot tub, indoor pool, etc) • Cover pools and hot tubs when not in use.

• Lifestyle of occupants. • Avoid hanging clothes to dry, storing wood and venting

• Moisture coming into home from crawl space

not vented or heated.

• Moisture is remaining in bathroom and kitchen

areas.

• Condensation is forming in spring and fall. • On humid days, as seasons change, condensation

• Ventilator speed is set too low. • Increase speed of ventilator.

• Dehumidistat control set too low. • Set dehumidistat higher.

• Blower speed of ventilator is too high. • Decrease ventilator blower speed.

• Lifestyle of occupants. • Increase humidity with humidifiers.

• Ventilator airflow can be incorrectly balanced. • Have a contractor balance ventilator airflow.

• Ventilator airflow is incorrectly balanced. NOTE: Minimal frost build-up is expected on cores before

• Malfunction of ventilator defrost system. • Have HVAC contractor check defrost system.

• Locate grilles high on walls or under baseboards; install

ceiling-mounted diffuser or grilles to avoid blowing directly

on occupants (example: over a sofa).

(1kW to temper the supply air.

• Placement of furniture or closed doors is restricting movement of air in the home.

• If supply air is ducted in furnace return, run furnace fan continuously to distribute ventilation air comfortably.

• Check that correct wires were used.

• Check external wiring for a short.

clothes dryer inside. Consider moving wood outside.

• Vent crawl space and place vapor barrier on floor of crawl

space.

• Size bathroom ducts to remove moist air as effectively as

possible; use bathroom fan to remove additional moisture.

appears but air quality remains high with some ventilator

use.

unit initiates defrost cycle functions.

• Check operation of dampers in exhaust vent; damper

vanes may be held open or damaged.

• Have HVAC contractor balance ventilator.

13 68-0171-9

Page 14

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

Table 1. Troubleshooting Guide.

Symptom Cause Solution

Condensation

or ice buildup

in insulated

duct to outside

Water in

ventilator

bottom

• Incomplete vapor barrier around insulated duct. • Tape and seal all joints.

• Tape any hole or tears made in outer duct covering.

• Hole or tear in outer duct covering. • Ensure vapor barrier is completely sealed.

• Drain pans are plugged.

• Improper connection of ventilator drain lines.

• Ensure O-ring on drain nozzle adjusted correctly.

• Look for kinks in line.

• Ventilator is not level. • Level ventilator.

• Drain lines are obstructed. • Check water drain connections.

• Ventilator heat exchange not correctly installed. • Make sure water drains correctly from pan.

68-0171-9 14

Page 15

PARTS LIST

HR Parts List

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

Item Number

(Fig. 13 and 14)

1 209746 209746 209746 Heat Transfer Core, Aluminum with Plastic Frame

2 208359 208359 208359 Blower Motor

3 50002341-001 50002341-001 — Blower Housing Kit

4 209711 209711 209711 Motor Capacitor

5 208509 208509 208509 Condensate Pan, Left or Right

6 209723 209723 209723 Foam Prefilter, Set of 2

7 209722 209722 209722 Clip for Foam Prefilter

8 208514 208514 208514 Drain Spout

9 208516 208516 208516 Duct Collar, Red

10 208517 208517 208517 Duct Collar, Blue

11 208518 208518 — H-Channel, 13-1/4 in.

12 208519 208519 208519 Door Hinge, Complete

13 208520 208520 208520 Door Latch, Complete

14 209715 209715 — Defrost Damper Motor, Bi-directional

15 208522 208522 208522 Defrost Damper Door

16 208526 208526 208526 Speed Control Knob

17 208383 208383 208383 Manual Speed Control, 5-Position

18 50002342-001 50002342-001 50002342-001 Electronic Control Kit (Control Board, Transformer)

19 208365 208365 208365 Thermistor Assembly

20 208368 208368 208368 Door Interlock Switch

21 50002340-001 50002340-001 — Door

Part Number for

DescriptionHR150B HR200B HR205B

15 68-0171-9

Page 16

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

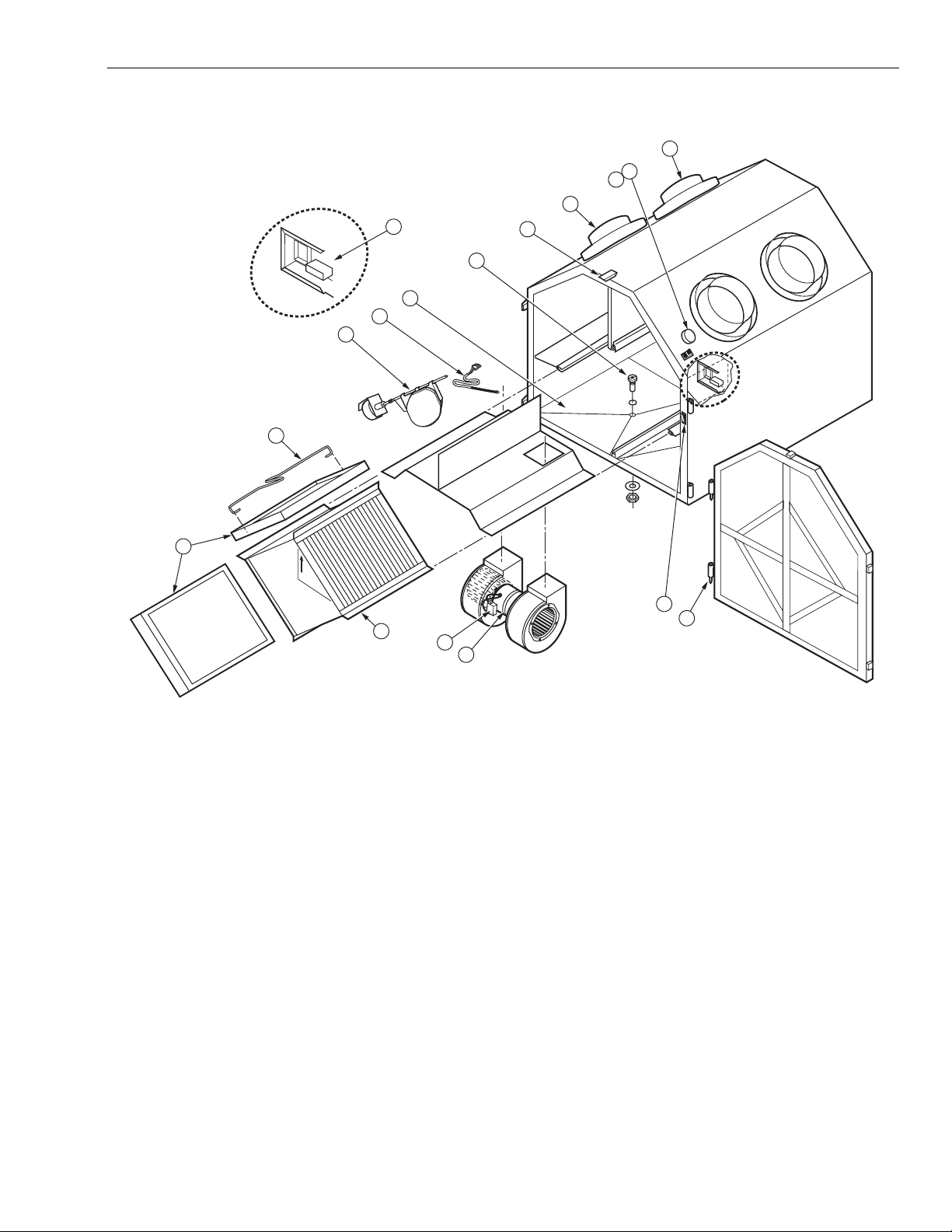

ER Parts List

Item Number

See Fig. 15

1 32002074-001 32002074-001 Cross-Flow Enthalpy Core, with Guide Channels

2 208359 208359 Blower Motor

3 50002341-001 50002341-001 Blower Housing Kit

4 209711 209711 Motor Capacitor

5 208509 208509 Condensate Pan, Left or Right

6 32002114-001 32002114-001 Foam Prefilter, Set of two

7 209722 209722 Clip for Foam Prefilter

8 208514 208514 Drain Spout

9 208516 208516 Duct Collar, Red

10 208517 208517 Duct Collar, Blue

11 208518 208518 H-Channel

12 208519 208519 Door Hinge, Complete

13 208520 208520 Door Latch, Complete

14 209715 209715 Defrost Damper Motor, Bi-directional

15 208522 208522 Defrost Damper Door

16 208526 208526 Speed Control Knob

17 208383 208383 Manual Speed Control, 5-Position

18 50002342-001 50002342-001 Electronic Control Kit (Control Board, Transformer)

19 208365 208365 Thermistor Assembly

20 208368 208368 Door Interlock Switch

21 50002340-001 50002340-001 Door

Part Number for

DescriptionER150 ER200

68-0171-9 16

Page 17

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

Accessory Items Parts List Not Shown—All Models

Item Number Part Number Description

1 208378 Ducting Elbow, 4 in., plastic

2 208373 Diffuser—4 in. diameter

3 208374 Diffuser—5 in. diameter

4 208375 Diffuser—6 in. diameter

5 208379 Installation Parts Kit

6 272813 Flow Measuring Station—6 in.

7 208372 Airflow Balancing Kit*

8 W8150A1001 Fresh Air Ventilation Control

9 32003487-001 Digital Fan Timer, 20-minute

*Includes magnehelic pressure gauge and two 6 in. flow measuring stations.

17 68-0171-9

Page 18

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

5

8

11

13

18

19

20

15

14

7

10

9

6

1

17

16

7

12

21

3

2

4

Fig. 13. HR150 and HR200 exploded view of parts keyed to HR Parts List.

M15511C

68-0171-9 18

Page 19

HR150, 200, 205; ER150, 200 PERFECT WINDOW™ FRESH AIR VENTILATION SYSTEMS

10

17

16

9

18

8

5

19

15

7

13

6

20

1

4

2

12

M15476A

Fig. 14. HR205 exploded view of parts keyed to HR Parts List.

19 68-0171-9

Page 20

5

10

11

13

18

19

20

15

14

7

10

9

6

1

16

17

12

21

7

3

Fig. 15. ER150 and ER200 exploded view of ER Parts List.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

M1V 4Z9

2

4

M11889B

68-0171-9 G.H. Rev. 7-04 www.honeywell.com/yourhome

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...