Page 1

33-00331EF-05

HPSR10*

CAUTION

HONEYWELL HYDRONIC PRO

SWITCHING RELAY PANEL

INSTALLATION INSTRUCTIONS

WHAT'S IN THE BOX?

• Hydronic Zone Panel

• Mounting Hardware (3 Screws and 3 Wall Anchors)

• 1, 2-Amp Fuse; 1, 6-Amp Fuse

• Install Manuals (English & French)

1. Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

2. Use copper conductors only.

3. Use only NEC Class 1 wire for all line voltage

wiring connections. Class 1 wires must be

rated for at least 167 °F (75 °C).

4. For installation by professionals only.

PANEL SPECIFICATIONS

Table 1.

Model Zones Transformers Input Power

HPSR103 3 (1) 24V 40VA 120VAC, 60Hz, 1 15 amps 6 Amp Yes 11-3/4" 8-3/4" 2-1/8"

HPSR104 4 (1) 24V 40VA 120VAC, 60Hz, 1 20 amps 6 Amp Yes 11-3/4" 8-3/4" 2-1/8"

HPSR106 6 (1) 24V 40VA 120VAC, 60Hz, 1 20 amps 6 Amp Yes 11-3/4" 8-3/4" 2-1/8"

NOTES:

• All circulator relay connections, including ZC/ZR, are rated for 5A full load and 30A locked rotor (1/6 to 1/2HP

depending on technology) at 120VAC. Check circulator plate ratings to ensure full load current is not exceeded.

• End switch connections are rated 24V, 1 Amp.

• All thermostat connections supply a 24V Class 2 output.

Maximum

Combined

Load

Pump

Fuse

Priority

Zone

Control

Type 1 Enclosure

Width Height Depth

Page 2

HPSR10*

M37084

M37085

M37086

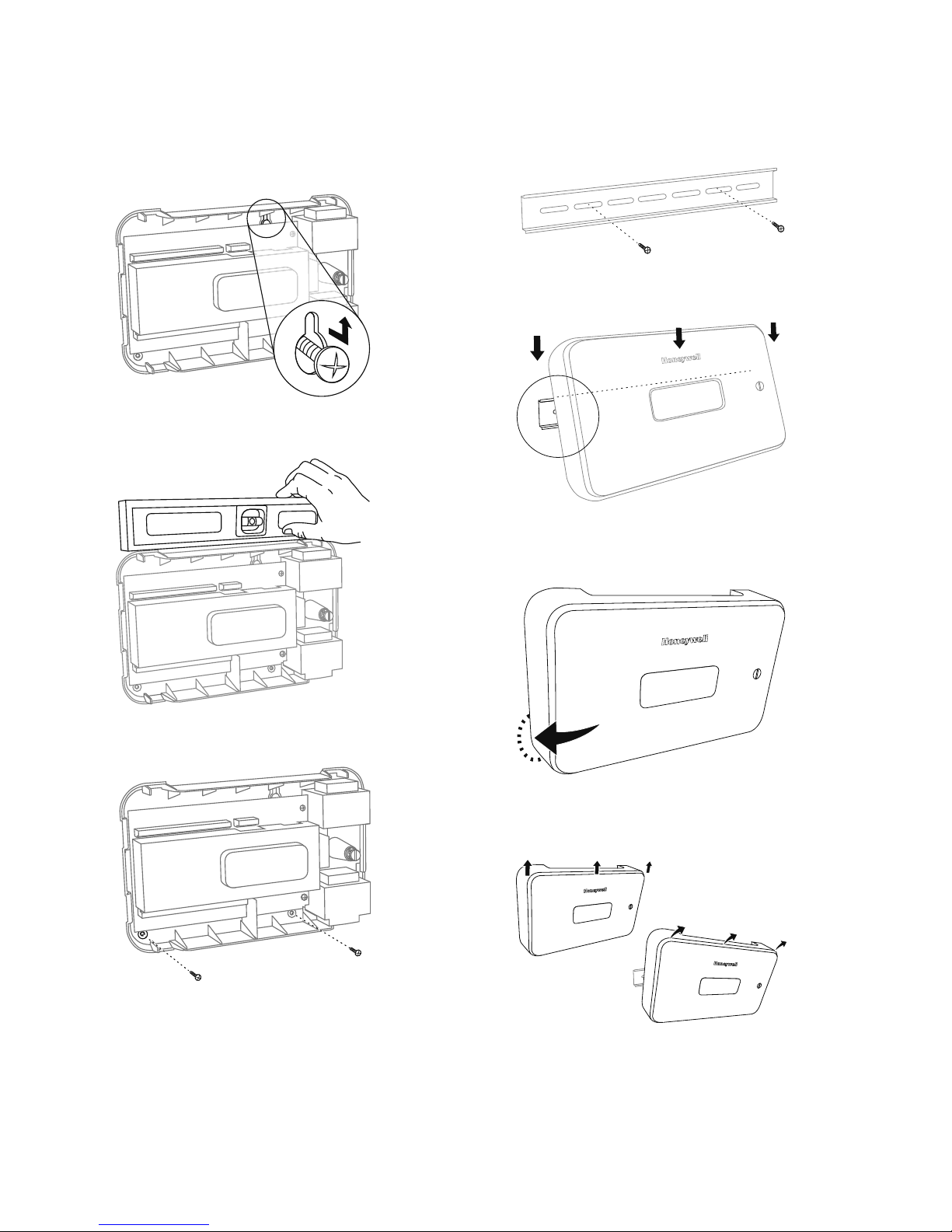

MOUNTING

Hang Hole Flow

1. Hang the panel on a wall-mounted screw.

Fig. 1.

2. Level the panel.

Din Rail Flow

1. Mount the DIN rail as per manufacturers instruc-

tions.

Fig. 4.

2. Hang panel by the tabs on the rail’s top edge.

M37083

M37087

Fig. 5.

3. Snap into rail by pressing the bottom of panel

against the wall.

Fig. 2.

3. Put the 2 bottom screws in.

Fig. 3.

M37088

Fig. 6.

4. To remove, lift up on panel and pull the top away

from the wall.

M37089

Fig. 7.

33-00331EF—05 2

Page 3

HPSR10*

R: 24V Hot (Commonly Red)

W: Heat (Commonly White)

C: Common 24V (Commonly Blue)

R W C

M37090

WIRING AND SETUP

Power Input

Honeywell Hydronic Panels include a convenient wiring

terminal for wiring 120V/60Hz/1Ph power. These

terminals, found at the bottom left side of the panel,

provide power to the transformer and all pumps installed

on the system.

Status Indicators

Honeywell Hydronic Panels feature Advanced Status

Lighting. This includes a transformer status light on the

status panel, and an Input Power Status Light near the

bottom left corner of the Zone Panel. These indicators

show the Power Status of the Panel at all times.

NOTE: Line volt LED is not visible with mylar cover

installed.

Zone Pump

Honeywell Hydronic Panels are compatible with common

zone Pumps and can be wired in as show in the wiring

diagrams on pages 4 and 5.

Thermostat Compatibility

THE HPSR10* zone panels are compatible with electronic,

power stealing, and electro mechanical thermostats.

Dedicated R and W terminals provide heat call messages

from the thermostat to the zone panel and with C terminal

may also provide auxiliary 24V power to electronic

thermostats.

Priority Override

Honeywell Hydronic Panels support priority operation and

can be enabled with the use of a switch located in the top

right section of the panel labeled "Priority Zone".

When priority operation is enabled, the panel employs a

priority override function which operates as shown below:

1. If a priority zone calls for 60 continuous minutes,

priority operation is disabled and control is returned

to each zone.

2. Once the priority zone satisfies, priority override is

disabled and standard operation resumes.

Grounding

A grounding bar has been provided below pump

connection terminal blocks.

NOTE: It is up to the installer to ensure that the 40VA per

transformer limit is not exceeded.

Additionally Honeywell Hydronic Panels are compatible

with Honeywell Equipment Interface Modules in

installations were sufficient wiring is not available.

Fig. 8.

NOTE: For power stealing thermostats, wire to R and W

on the zone panel. There are no additional components required to make these thermostats

function. For all thermostats that require a C wire

for power there is a C terminal available on the

panel for each thermostat.

3 33-00331EF—05

Page 4

HPSR10*

M37092

R W C

ZONE 1

(PRIOR ITY)

R W C

R W C

R W C

R W C

R W C

ZONE 2 ZONE 3 ZONE 4 ZONE 5 ZONE 6

T T

T T

BOILER

ON OFF ON OFF

24V THERMOSTAT CONNECTIONS

120 VAC PUMP CONNECTIONS

LIN E VOLTA GE

IN

LIN E VOLT

STATUS

POWER IN

24 VAC

120 VAC POWER TO

TRA NSFORMER

HPSR106

SIX ZONE

SWITCHING RELAY

LOW LIMIT

SWITCH

ZONE 6 FUSE

END SW ITC H

FUSE

40 VA

120 VAC INPUT

N

H

FACTORY

INSTALLED

JUMPER

TO BOI LER

TO DHW

Zone

T-stat Cal l

Pump On

DHW Prior ity

123456

Power

Boil er

End Switch

HWSR506 6 ZONE PUMP CONTROLLER

ZR

ZC

2 AMP

TRANSFORMER

FUSE

ZONE 1

FUSE

ZONE 2

FUSE

ZONE 3

FUSE

ZONE 4

FUSE

ZONE 5

FUSE

PRIORITY

END

SWITCH

PRIORITY

END

SWITCH

PRIORITY

ZONE

ZONE 1

(PRIOR ITY)

ZONE 2

ZONE 3

ZONE 4 ZONE 5

ZONE 6

GROUNDING BAR

INCLUDED

FOR GROUNDING

THERMOSTAT WIRING

CONNECTED

THERMOSTAT WIRING

NON-CONNECTED

OR POWER STEALING

Standard Wiring Layout

Below wiring diagrams represent a 6 zone pump panel and a 4 zone pump panel. Wiring diagram for the 3 zone pump

panel is identical to the 4 zone pump panel but with zone 4 depopulated.

NOTE: In addition to the low limit switch, each zone pump connection is protected by a 6 Amp fuse.

NOTE: In addition to the low limit switch, each zone pump connection is protected by a 6 Amp fuse.

THERMOSTAT WIRING

NON-CONNECTED

OR POWER STEALING

R W C R W C R W C R W C

ZONE 1

ZONE 2 ZONE 3 ZONE 4

(PRIOR ITY)

24V THERMOSTAT CONNECTIONS

HPSR104

FOUR ZONE

PUMP CONTROLLER

LIN E VOLT

STATUS

LIN E VOLTA GE

IN

GROUNDING BAR

FOR GROUNDING

(PRIOR ITY)

N

120 VAC INPUT

H

INCLUDED

ZONE 1

FUSE

ZONE 1

THERMOSTAT

WIRING

CONNECTED

Zone

T-stat Call

Pump On

DHW Priority

120 VAC PUMP CONNECTIONS

FUSE

ZONE 3

ZONE 3

FUSE

ZONE 4

ZONE 4

FUSE

ZONE 2

ZONE 2

T T

BOIL ER

PRIORITY

SWITCH

1234

Fig. 9.

TO BOI LER

TO DHW

T T

ON OFF ON OFF

PRIORITY

END

END

SWITCH

END SW ITC H

FUSE

BOIL ER END

SWITCH

ZR

FACTORY

INSTALLED

JUMPER

Fig. 10.

PRIORITY

ZC

ZONE

POWER IN

24 VAC

Power

Boiler

End Switch

2 AMP

TRANSFORMER

FUSE

120 VAC POWER TO

TRA NSFORMER

40 VA

M37203

33-00331EF—05 4

Page 5

HPSR10*

T-STAT

CALL

STATUS OF

ZR/ZC

CLOSED

BOILER RELAY=ON

END SWITCH=ON

ZONE PUMP=OFF

OPEN

NO PRIORITY ZONE OR PRIORITY END SWITCH

BOILER RELAY=ON

END SWITCH=ON

ZONE PUMP=ON

M37144

Boiler Controls

Honeywell Hydronic Panels are capable of managing boilers with DHW priority. The panel features two isolated end

switches labeled Boiler and End Switch for TT outputs to the boiler. Two slide switches are available to provide simple

programing of the end switches to meet the desired application. See the operational matrix below detailing functionality

of the switches.

Additionally, this panel features a LOW LIMIT input which must be closed for pumps to be activated. This input comes

with a factory installed jumper for cold start boiler operation when the controlling Aquastat has a HIGH LIMIT only. If the

installed boiler requires warm up time then this jumper should be removed and wired to the boiler.

Fig. 11.

PRIORITY ZONE, NO PRIORITY END SWITCH

T-STAT

CALL

WAIT FOR

PRIORITY ZONE

TO SATISFY

DEACTIVATE ALL

OTHER ZONES

PRIORITY ZONE?

IS PRIORITY

YES

YES

IS THIS THE

NO

ACTIVE?

NO

STATUS OF

ZR/ZC

CLOSED

OPEN

BOILER RELAY = ON

END SWITCH = ON

ZONE PUMP = ON

BOILER RELAY = ON

END SWITCH = ON

ZONE PUMP = OFF

M37145

T-STAT

CALL

WAIT FOR

PRIORITY ZONE

TO SATISFY

DEACTIVATE ALL

OTHER ZONES

YES

PRIORITY ZONE?

NO

YES

Fig. 12.

PRIORITY ZONE, PRIORITY END SWITCH

STATUS OF

ZR/ZC

IS THIS THE

IS PRIORITY

ACTIVE?

NO

OPEN

STATUS OF

ZR/ZC

OPEN

CLOSED

Fig. 13.

CLOSED

BOILER RELAY = ON

END SWITCH = ON

ZONE PUMP = ON

BOILER RELAY = ON

END SWITCH = ON

ZONE PUMP = OFF

BOILER RELAY = ON

END SWITCH = OFF

ZONE PUMP = ON

BOILER RELAY = ON

END SWITCH = OFF

ZONE PUMP = OFF

M37146

5 33-00331EF—05

Page 6

HPSR10*

M37098

Zone

T-s tat Call

Pump On

DHW Priority

123456

Power

Boiler

End Switch

HWSR506 6 ZONE PUMP CONTROLLER

M37301

TROUBLESHOOTING

Status Label

Fig. 14.

This panel provides a status indicator label which is

available both when the panel cover is in place and

removed. Descriptions of the indictor LED's are shown

below:

T-stat Call LED's indicate the thermostat associated with

that specific zone is calling for heat.

Pump On LED's indicate which circulators in the system

are being energized (or powered).

Mylar cover

DHW Priority LED indicate the priority zone is active and

calling.

Power LED indicates the transformer is powered.

Boiler and End Switch LED's indicate when each relay is

energized and calling for heat.

Table 2. Color Chart.

T-Stat

Call

Blue Green White White Red

Pump On

DHW

Priority

Power

Boiler &

End

Switch

REGULATORY INFORMATION

This device complies with part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

5-YEAR LIMITED WARRANTY

Honeywell warrants this product to be free from defects in the workmanship or materials, under normal use and service,

for a period of five (5) years from the date of purchase by the consumer. If at any time during the warranty period the

product is determined to be defective or malfunctions, Honeywell shall repair or replace it (at Honeywell's option).

This warranty does not cover removal or reinstallation costs. This warranty shall not apply if it is shown by Honeywell that

the defect was caused by damage which occurred while the product was in the possession of a consumer.

All details on this limited warranty are explained in our Tradeline Catalog. If you have any questions, please write

Honeywell Customer Care, 1985 Douglas Dr, Golden Valley, MN 55422 or call 1-800-468-1502.

In the U.S.:

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

Fig. 15. Mylar cover.

® U.S. Registered Trademark

© 2018 Honeywell International Inc.

33-00331EF—05 M.S. Rev. 03-18

Printed in United States

Page 7

HPSR10*

MISE EN GARDE

PANNEAU DE RÉGULATEURS DE POMPES

HYDRONIQUE PRO HONEYWELL

INSTRUCTIONS D’INSTALLATION

CONTENU DE L’EMBALLAGE

• Panneau de régulateurs de pompes de zone

hydronique

• Quincaillerie de montage (3 vis et 3 ancrages muraux)

• 1 fusible de 2 A; 1 fusible de 6 A

• Manuels d’installation (anglais et français)

1. Débranchez l’alimentation électrique avant de

commencer l’installation afin de prévenir les

chocs électriques ou les dommages matériels.

2.

Utilisez uniquement des conducteurs en cuivre.

3. Utilisez uniquement un câble NEC de classe 1

pour tous les raccordements de câblage de

tension secteur. Les câbles de classe 1 doivent

être adaptés à une température d’au moins

75 °C (167 °F).

4. Pour installation par des professionnels

seulement.

SPÉCIFICATIONS DU PANNEAU

Tableau 1.

Charge

Modèle Zones Transformateurs Alimentation

HPSR103 3 (1) 24 V 40 VA 120 V c. a.,

60 Hz, 1

HPSR104 4 (1) 24 V 40 VA 120 V c. a.,

60 Hz, 1

HPSR106 6 (1) 24 V 40 VA 120 V c. a.,

60 Hz, 1

REMARQUE :

• Tous les raccordements du relais du circulateur, y compris les ZC/ZR, sont adaptés à un rotor bloqué de 30 A et à une

charge nominale de 5 A (1/6 à 1/2 HP en fonction de la technologie) à 120 V c. a. Vérifiez les valeurs sur la plaque du

circulateur afin de vous assurer que le courant nominal n’est pas dépassé.

• Les raccordements de l’interrupteur d’extrémité sont adaptés à du 24 V, 1 A.

• Tous les raccordements du thermostat alimentent une sortie de classe 2 de 24 V.

combinée

maximale

15 A 6 A Oui 11-3/4" 8-3/4" 2-1/8"

20 A 6 A Oui 11-3/4" 8-3/4" 2-1/8"

20 A 6 A Oui 11-3/4" 8-3/4" 2-1/8"

Fusible

de la

pompe

Commande

des zones

prioritaires

Boîtier de type 1

Largeur Hauteur Profondeur

Page 8

HPSR10*

M37084

M37085

M37086

MONTAGE

Trou de suspension

1. Accrochez le panneau à une vis fixée au mur.

M37083

Fig. 1.

2. Mettez le panneau de niveau.

Rail DIN

1. Montez le rail DIN conformément aux instructions

du fabricant.

Fig. 4.

2. Suspendez le panneau par les languettes sur le bord

supérieur du rail.

M37087

Fig. 5.

Fig. 2.

3. Installez les 2 vis du bas.

Fig. 3.

3. Emboîtez le panneau dans le rail en appuyant le bas

du panneau contre le mur.

M37088

Fig. 6.

4. Pour retirer le panneau, soulevez-le et écartez la

partie supérieure du mur.

33-00331EF—05 2

M37089

Fig. 7.

Page 9

HPSR10*

CÂBLAGE ET

CONFIGURATION

Alimentation du panneau

Les panneaux hydroniques Honeywell comprennent une

borne de câblage pratique pour une alimentation de

120V/60Hz/1Ph. Ces bornes, situées dans le côté

inférieur gauche du panneau, fournissent l’alimentation

au transformateur et à toutes les pompes installées sur le

système.

Témoins d’état

Les panneaux hydroniques Honeywell intègrent des

témoins d’état de pointe. Il y a un témoin pour le

transformateur sur le circuit de contrôle et un témoin

d'alimentation situé près du coin inférieur gauche du

circuit de contrôle de zone. Ces témoins affichent l’état

d’alimentation du panneau en tout temps.

REMARQUE : le témoin de tension secteur n’est pas

visible lorsque le couvercle en mylar est

installé.

Pompe de zone

Les panneaux hydroniques Honeywell sont compatibles

avec les pompes de zone classiques et peuvent être

raccordés comme indiqué dans les schémas de câblage

aux pages 4 et 5.

Dérivation prioritaire

Les panneaux hydroniques Honeywell offrent une

fonction prioritaire qui peut être activée à l’aide d’un

interrupteur situé dans la partie supérieure droite du

panneau marquée « Zone prioritaire ».

Lorsque le fonctionnement prioritaire est activé, le

panneau recourt à une fonction de dérivation prioritaire

qui agit comme suit :

1. Si une zone prioritaire nécessite de la chaleur

pendant 60 minutes, le fonctionnement prioritaire

est désactivé et le contrôle est rétabli pour chaque

zone.

2. Une fois les besoins de la zone prioritaire satisfaits,

la dérivation prioritaire est désactivée et le

fonctionnement classique est rétabli.

Mise à la terre

Une barre de mise à la terre a été fournie en dessous des

borniers de raccordement de la pompe.

Compatibilité avec les thermostats

Les panneaux HPSR10* sont compatibles avec les

thermostats électroniques, les thermostats

électromécaniques et les thermostats qui n'ont pas besoin

du fil commun (fil C) pour l'alimentation. Chaque

thermostat a ses propres bornes R et W pour permettre au

thermostat de transmettre des demandes de chauffage au

panneau. La borne C offre du 24 V c. a aux thermostats

électroniques qui ont besoin de l'alimentation.

REMARQUE : il incombe à l’installateur de veiller à ce que

la limite de 40 VA par transformateur ne soit

pas dépassée.

En outre, les panneaux hydroniques Honeywell sont

compatibles avec les modules d’interface de l’équipement

Honeywell dans les installations ne disposant pas de

suffisamment de câblage.

R : 24 V (généralement rouge)

W : Chauffage (généralement blanc)

C : Commun (généralement bleu)

R W C

Fig. 8.

REMARQUE : Pour les thermostats qui n'ont pas besoin

du fil commun (fil C) pour l'alimentation,

branchez chaque thermostat au R et au W

du panneau. Ces thermostats n'ont besoin

d'aucun autre accessoire pour fonctionner.

Pour les thermostats qui ont besoin du fil

commun (fil C) pour l’alimentation, une

borne C est disponible sur le panneau pour

chaque thermostat.

MF37090

3 33-00331EF—05

Page 10

HPSR10*

MF37092

R W C

ZONE 1

(PRIORITÉ)

R W C

R W C

R W C

R W C

R W C

ZONE 2 ZONE 3 ZONE 4 ZONE 5 ZONE 6

T T

T T

CHAUDIÈRE

RACCORDEMENTS DES THERMOSTATS DE 24 V

RACCORDEMENTS DES POMPES 120 V c. a.

ALIMENTATION

ÉTAT DE LA

TENSION

SECTEUR

120 V c.a. (AU TRANSFO.)

RÉGULATEUR DE

POMPES À

6 ZONES HPSR106

INTERRUPTEUR DE

LIMITE INFÉRIEURE

FUSIBLE ZONE 6

FUSIBLE

INTERRUPTEUR

D’EXTRÉMITÉ

40 VA

ENTRÉE 120 V c. a.

N

H

CAVALIER POSÉ

EN USINE

VERS LA CHAUDIÈRE

VERS L’ECS

Zone

Demande du

thermostat

Pompe activée

Priorité de l’ECS

123456

Priorité

de l’ECS

Chaudière

Interrupteur

d’extrémité

RÉGULATEUR DE POMPE 6 ZONES HWSR506

ZR

ZC

FUSIBLE DE

TRANSFORMATEUR

2 A

FUSIBLE

ZONE 1

FUSIBLE

ZONE 2

FUSIBLE

ZONE 3

FUSIBLE

ZONE 4

FUSIBLE

ZONE 5

INTERRUPTEUR

D’EXTRÉMITÉ

PRIORITAIRE

INTERRUPTEUR

D’EXTRÉMITÉ

PRIORITAIRE

ZONE

PRIORITAIRE

ZONE 1

(PRIORITÉ)

ZONE 2

ZONE 3

ZONE 4 ZON E 5

ZONE 6

CÂBLE DE MISE À LA TERRE ET

CONNECTEUR POUR LA MISE À

LA TERRE INCLUS.

CÂBLAGE DU THERMOSTAT

AVEC LE FIL C

CÂBLAGE DU THERMOSTAT

SANS LE FIL C

MARCHE/ARRÊT MARCHE/ARRÊT

24 V c.a.

(DU TRANSFO.)

Disposition standard du câblage

Les schémas de câblage ci-dessous représentent un panneau de régulateurs de pompes à 6 zones et un à 4 zones. Les

schémas de câblage pour le panneau à 3 zones est similaire à celui à 4 zones.

Fig. 9.

REMARQUE : en plus de l'interrupteur de limite inférieure, chaque raccordement de pompe est protégé par un fusible de

6 A.

(PRIORITÉ)

RACCORDEMENTS DES THERMOSTATS DE 24 V

ÉTAT DE LA

TENSION

SECTEUR

ALIMENTATION

CÂBLE DE MISE À LA TERRE ET

CONNECTEUR POUR LA MISE À

LA TERRE INCLUS.

CÂBLAGE DU THERMOSTAT

SANS LE FIL C

R W C R W C R W C R W C

ZONE 1

ZONE 2 ZONE 3 Z ONE 4

RÉGULATEUR DE

POMPES À 4 ZONES

HPSR104

N

H

RACCORDEMENTS DES POMPES 120 V c. a.

ZONE 1

FUSIBLE

ZONE 1

(PRIORITÉ)

ENTRÉE 120 V c. a.

FUSIBLE

ZONE 2

CÂBLAGE DU

THERMOSTAT

AVEC LE FIL C

Demande du

thermostat

Pompe activée

Priorité de l’ECS

ZONE 3

ZONE 2

FUSIBLE

ZONE 3

Zone

ZONE 4

FUSIBLE

ZONE 4

T T

CHAUDIÈRE

1234

T T

MARCHE/ARRÊT MARCHE/ARRÊT

INTERRUPTEUR

D’EXTRÉMITÉ

PRIORITAIRE

D’EXTRÉMITÉ

PRIORITAIRE

FUSIBLE INTERRUPTEUR

D’EXTRÉMITÉ

INTERRUPTEUR

D’EXTRÉMITÉ DE LA

CHAUDIÈRE

ZR

CAVALIER POSÉ

EN USINE

VERS LA CHAUDIÈRE

VERS L’ECS

INTERRUPTEUR

ZONE

PRIORITAIRE

Alimentation

Chaudière

Interrupteur

d’extrémité

120 V c.a.

(AU TRANSFO.)

ZC

FUSIBLE DE

TRANSFORMATEUR

2 A

24 V c.a.

(DU TRANSFO.)

40 VA

MF37203

REMARQUE : en plus de l'interrupteur de limite inférieure, chaque raccordement de pompe est protégé par un fusible de

33-00331EF—05 4

6A.

Fig. 10.

Page 11

HPSR10*

ZONE PRIORITAIRE, INTERRUPTEUR D’EXTRÉMITÉ PRIORITAIRE

MF37146

DEMANDE DU

THERMOSTAT

STATUT

DE ZR/ZC

FERMÉ

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = MARCHE

POMPE DE LA ZONE = MARCHE

EST-CE UNE ZONE

PRIORITAIRE ?

DÉSACTIVER TOUTES

LES AUTRES ZONES

OUI

LA PRIORITÉ

EST-ELLE

ACTIVE ?

NON

NON

ATTENDRE QUE LES

BESOINS DE LA

ZONE PRIORITAIRE

SOIENT SATISFAITS

OUI

STATUT

DE ZR/ZC

FERMÉ

OUVERT

OUVERT

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = MARCHE

POMPE DE LA ZONE = ARRÊT

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = ARRÊT

POMPE DE LA ZONE = MARCHE

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = ARRÊT

POMPE DE LA ZONE = ARRÊT

Contrôles de la chaudière

Les panneaux hydroniques Honeywell permettent de gérer les chaudières avec une priorité pour l’ECS. Le panneau est

doté de deux interrupteurs d’extrémité isolés marqués « Chaudière » et « Interrupteur d’extrémité » pour les sorties TT

vers la chaudière. Deux interrupteurs sont disponibles afin de faciliter la programmation des interrupteurs d’extrémité et

ainsi obtenir l’application souhaitée. Consultez la matrice de fonctionnement ci-dessous afin d’en savoir plus sur le

fonctionnement des interrupteurs.

En outre, ce panneau dispose d'une entrée de LIMITE INFÉRIEURE qui doit être fermée pour permettre l’activation des

pompes. Cette entrée est livrée avec un cavalier posé en usine pour un démarrage à froid de la chaudière lorsque le

contrôleur Aquastat dispose d’une LIMITE SUPÉRIEURE uniquement. Si la chaudière installée requiert un temps de

préchauffage, alors ce cavalier doit être retiré et raccordé à la chaudière.

AUCUNE ZONE PRIORITAIRE OU INTERRUPTEUR D’EXTRÉMITÉ PRIORITAIRE

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = MARCHE

POMPE DE LA ZONE = MARCHE

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = MARCHE

POMPE DE LA ZONE = ARRÊT

MF37144

DEMANDE DU

THERMOSTAT

STATUT DE

ZR/ZC

FERMÉ

OUVERT

Fig. 11.

ZONE PRIORITAIRE, AUCUN INTERRUPTEUR D’EXTRÉMITÉ PRIORITAIRE

DEMANDE DU

THERMOSTAT

ATTENDRE QUE

LES BESOINS DE

LA ZONE PRIORITAIRE

SOIENT SATISFAITS

OUI

DÉSACTIVER TOUTES

LES AUTRES ZONES

OUI

EST-CE UNE ZONE

PRIORITAIRE ?

NON

LA PRIORITÉ

EST-ELLE

ACTIVE ?

STATUT

DE ZR/ZC

NON

Fig. 12.

Fig. 13.

5 33-00331EF—05

FERMÉ

OUVERT

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = MARCHE

POMPE DE LA ZONE = MARCHE

RELAIS DE LA CHAUDIÈRE = MARCHE

INTERRUPTEUR D’EXTRÉMITÉ = MARCHE

POMPE DE LA ZONE = ARRÊT

MF37145

Page 12

HPSR10*

MF37098

Zone

Demande du

thermostat

Pompe activée

Priorité de l’ECS

123456

Alimentation

Chaudière

Interrupteur

d’extrémité

RÉGULATEUR DE POMPES À 6 ZONES HWSR506

Priorité

zone 1

Marche/

Arrêt

Marche/

Arrêt

Chaudière

Interrupteur

d’extrémité

Interrupteur

d’extrémité

prioritaire

Zone

prioritaire

CIRCULATEURS 120 V C.A.

Priorité

zone 1

Entrée

120 V c.a.

120 V c.a.

THERMOSTATS 24 V CA

MF37301

DÉPANNAGE

Témoin d’état

Fig. 14.

Ce panneau affiche un témoin d’état, que le couvercle soit

placé ou non. Une description des témoins est fournie

ci-dessous :

Le témoin « Demande du thermostat » indique que le

thermostat associé à cette zone spécifique, demande du

chauffage.

Le témoin « Pompe activée » indique lesquels des

circulateurs du système sont alimentés.

Le témoin « Priorité de l’ECS » indique que la zone

prioritaire est active et demande du chauffage.

Le témoin « Alimentation » indique que le transformateur

est alimenté.

Les témoins « Chaudière » et « Interrupteur d’extrémité »

indiquent que chaque relais est alimenté et demande du

chauffage.

Tableau 2. Panneau des couleurs.

Demande du

thermostat

Pompe

activée

Priorité de

l’ECS

Alimentation

Chaudière et

Interrupteur

d’extrémité

Bleu Vert Blanc Blanc Rouge

INFORMATIONS

RÉGLEMENTAIRES

Cet appareil est conforme à la partie 15 des

réglementations de la FCC. Son fonctionnement est

soumis aux deux conditions suivantes :

(1) Ce dispositif ne peut pas causer d’interférences

dangereuses, et

(2) ce dispositif ne doit accepter aucune interférence

reçue, notamment les interférences à l’origine d’un

fonctionnement indésirable.

Couvercle en mylar

Fig. 15. Couvercle en mylar.

GARANTIE LIMITÉE DE 5 ANS

Honeywell garantit ce produit contre tout vice de fabrication ou de matériau dans la mesure où il en est fait une utilisation

et un entretien convenables, et ce, pour cinq (5) ans à partir de la date d’achat par le consommateur. En cas de défaillance

ou de mauvais fonctionnement pendant la période de garantie, Honeywell remplacera ou réparera le produit (à sa

discrétion).

La présente garantie ne couvre pas les frais de retrait ou de réinstallation. La présente garantie ne s’appliquera pas s’il est

démontré par Honeywell que la défaillance est due à un endommagement du produit qui s'est produit lorsque le

consommateur l’avait en sa possession.

Tous les détails concernant la garantie limitée sont inclus dans notre catalogue Tradeline. Si vous avez des questions,

veuillez écrire à Honeywell Customer Care, 1985 Douglas Dr, Golden Valley, MN 55422 ou composez le 1-800-468-1502.

Aux États-Unis :

Honeywell

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® Marque de commerce déposée aux États-Unis

© 2018 Honeywell International Inc.

33-00331EF—05 M.S. Rev. 03-18

Imprimé aux États-Unis

Loading...

Loading...