Page 1

Power Products

HPFF12(E)/HPFF12CM(E)

Notification Appliance Circuit Expander

Instruction Manual

Document 53576 Rev: B3

10/1/2018 ECN: 18-476

Page 2

Fire Alarm & Emergency Communication System Limitations

While a life safety system may lower insurance rates, it is not a substitute for life and property insurance!

An automatic fire alarm system—typically made up of smoke

detectors, heat detectors, manual pull stations, audible warning

devices, and a fire alarm control panel (FACP) with remote notification capability—can provide early warning of a developing fire. Such

a system, however, does not assure protection against property

damage or loss of life resulting from a fire.

An emergency communication system—typically made up of an

automatic fire alarm system (as described above) and a life safety

communication system that may include an autonomous control

unit (ACU), local operating console (LOC), voice communication,

and other various interoperable communication methods—can

broadcast a mass notification message. Such a system, however,

does not assure protection against property damage or loss of life

resulting from a fire or life safety event.

The Manufacturer recommends that smoke and/or heat detectors

be located throughout a protected premises following the

recommendations of the current edition of the National Fire

Protection Association Standard 72 (NFPA 72), manufacturer's

recommendations, State and local codes, and the

recommendations contained in the Guide for Proper Use of System

Smoke Detectors, which is made available at no charge to all

installing dealers. This document can be found at http://

www.systemsensor.com/appguides/. A study by the Federal

Emergency Management Agency (an agency of the United States

government) indicated that smoke detectors may not go off in as

many as 35% of all fires. While fire alarm systems are designed to

provide early warning against fire, they do not guarantee warning or

protection against fire. A fire alarm system may not provide timely or

adequate warning, or simply may not function, for a variety of

reasons:

Smoke detectors may not sense fire where smoke cannot reach

the detectors such as in chimneys, in or behind walls, on roofs, or

on the other side of closed doors. Smoke detectors also may not

sense a fire on another level or floor of a building. A second-floor

detector, for example, may not sense a first-floor or basement fire.

Particles of combustion or “smoke” from a developing fire may

not reach the sensing chambers of smoke detectors because:

• Barriers such as closed or partially closed doors, walls, chimneys, even wet or humid areas may inhibit particle or sm

oke

flow.

•

Smoke particles may become “cold,” stratify, and not reach t

he

c

eiling or upper walls where detectors are located.

• Smoke particles may be blown away from detectors by air outlets, such as air conditioning vents.

• Smoke particles may be drawn into air returns before reachi

ng

t

he detector.

The amount of “smoke” present may be insufficient to alarm smoke

detectors. Smoke detectors are designed to alarm at various levels

of smoke density. If such density levels are not created by a developing fire at the location of detectors, the detectors will not go into

alarm.

Smoke detectors, even when working properly, have sensing limitations. Detectors that have photoelectronic sensing chambers tend

to detect smoldering fires better than flaming fires, which have little

visible smoke. Detectors that have ionizing-type sensing chambers

tend to detect fast-flaming fires better than smoldering fires.

Because fires develop in different ways and are often unpredictable

in their growth, neither type of detector is necessarily best and a

given type of detector may not provide adequate warning of a fire.

Smoke detectors cannot be expected to provide adequate warning

of fires caused by arson, children playing with matches (especially

in bedrooms), smoking in bed, and violent explosions (caused by

escaping gas, improper storage of flammable materials, etc.).

Heat detectors do not sense particles of combustion and alarm

only when heat on their sensors increases at a predetermined rate

or reaches a predetermined level. Rate-of-rise heat detectors may

be subject to reduced sensitivity over time. For this reason, the rateof-rise feature of each detector should be tested at least once per

year by a qualified fire protection specialist. Heat detectors are

designed to protect property, not life.

IMPORTANT! Smoke detectors must be installed in the same

room as the control panel and in rooms used by the system for the

connection of alarm transmission wiring, communications, signaling, and/or power. If detectors are not so located, a developing fire

may damage the alarm system, compromising its ability to report a

fire.

Audible warning devices such as bells, horns, strobes, speakers and displays may not alert people if these devices are located

on the other side of closed or partly open doors or are located on

another floor of a building. Any warning device may fail to alert people with a disability or those who have recently consumed drugs,

alcohol, or medication. Please note that:

• An emergency communication system may take priority over a

fire alarm system in the event of a life safety emergency.

• Voice messaging systems must be designed to meet intelligibility

requirements as defined by NFPA, local codes, and Authoritie

s

Havi

ng Jurisdiction (AHJ).

• Language and instructional requirements must be clearly disseminated on any local displays.

• Strobes can, under certain circumstances, cause seizures in

people with conditions such as epilepsy.

• Studies have shown that certain people, even when they hear a

fire alarm signal, do not respond to or comprehend the meani

ng

of

the signal. Audible devices, such as horns and bells, can hav

e

di

fferent tonal patterns and frequencies. It is the property

owner's responsibility to conduct fire drills and other traini

ng

ex

ercises to make people aware of fire alarm signals an

d

i

nstruct them on the proper reaction to alarm signals.

• In rare instances, the sounding of a warning device can ca

use

t

emporary or permanent hearing loss

.

A

life safety system will not operate without any electrical power. If

AC power fails, the system will operate from standby batteries only

for a specified time and only if the batteries have been properly

maintained and replaced regularly.

Equipment used in the system may not be technically compatible

with the control panel. It is essential to use only equipment listed for

service with your control panel.

Telephone lines needed to transmit alarm signals from a premises

to a central monitoring station may be out of service or temporarily

disabled. For added protection against telephone line failure,

backu

p radio transmission systems are recommended.

The most common cause of life safety system malfunction is inadequate maintenance. To keep the entire life safety system in excellent working order, ongoing maintenance is required per the

manufacturer's recommendations, and UL and NFPA standards. At

a minimum, the requirements of NFPA 72 shall be followed. Environments with large amounts of dust, dirt, or high air velocity require

more frequent maintenance. A maintenance agreement should be

arranged through the local manufacturer's representative. Maintenance should be scheduled as required by National and/or local fire

codes and should be performed by authorized professional life

safety system installers only. Adequate written records of all inspections should be kept.

Limit-D2-2016

2 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 3

Installation Precautions

Adherence to the following will aid in problem-free installation with long-term reliability:

WARNING - Several different sources of power can be connected to the fire alarm control panel. Disconnect all sources of

power before servicing. Control unit and associated equipment

may be damaged by removing and/or inserting cards, modules, or

interconnecting cables while the unit is energized. Do not attempt

to install, service, or operate this unit until manuals are read and

understood.

CAUTION - System Re-acceptance Test after Software

Changes: To ensure proper system operation, this product must be

tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Re-acceptance testing is

required after any change, addition or deletion of system components, or after any modification, repair or adjustment to system

hardware or wiring. All components, circuits, system operations, or

software functions known to be affected by a change must be 100%

tested. In addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that are not directly

affected by the change, up to a maximum of 50 devices, must also

be tested and proper system operation verified.

This system meets NFPA requirements for operation at 0-49º C/

32-120º F and at a relative humidity . However, the useful life of

the system's standby batteries and the electronic components may

be adversely affected by extreme temperature ranges and humidity.

Therefore, it is recommended that this system and its peripherals

be installed in an environment with a normal room temperature of

15-27º C/60-80º F.

Verify that wire sizes are adequate for all initiating and indicating

device loops. Most devices cannot tolerate more than a 10% I.R.

drop from the specified device voltage.

Like all solid state electronic devices, this system may operate

erratically or can be damaged when subjected to lightning induced

transients. Although no system is completely immune from lightning transients and interference, proper grounding will reduce susceptibility. Overhead or outside aerial wiring is not recommended,

due to an increased susceptibility to nearby lightning strikes. Consult with the Technical Services Department if any problems are

anticipated or encountered.

Disconnect AC power and batteries prior to removing or inserting

circuit boards. Failure to do so can damage circuits.

Remove all electronic assemblies prior to any drilling, filing,

reaming, or punching of the enclosure. When possible, make all

cable entries from the sides or rear. Before making modifications,

verify that they will not interfere with battery, transformer, or printed

circuit board location.

Do not tighten screw terminals more than 9 in-lbs. Over-tightening may damage threads, resulting in reduced terminal contact

pressure and difficulty with screw terminal removal.

This system contains static-sensitive components. Always

ground yourself with a proper wrist strap before handling any circuits so that static charges are removed from the body. Use static

suppressive packaging to protect electronic assemblies removed

from the unit.

Follow the instructions in the installation, operating, and programming manuals. These instructions must be followed to avoid

damage to the control panel and associated equipment. FACP

operation and reliability depend upon proper installation.

Precau-D1-9-2005

FCC Warning

WARNING: This equipment generates, uses, and can radi-

ate radio frequency energy and if not installed and used in

accordance with the instruction manual may cause interference to radio communications. It has been tested and found

to comply with the limits for class A computing devices pursuant to Subpart B of Part 15 of FCC Rules, which is

designed to provide reasonable protection against such

interference when devices are operated in a commercial

environment. Operation of this equipment in a residential

area is likely to cause interference, in which case the user

will be required to correct the interference at his or her own

expense.

Canadian Requirements

This digital apparatus does not exceed the Class A limits for

radiation noise emissions from digital apparatus set out in

the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux appareils

numeriques de la classe A prescrites dans le Reglement sur

le brouillage radioelectrique edicte par le ministere des

Communications du Canada.

HARSH™, NIS™, and NOTI•FIRE•NET™ are all trademarks; and Acclimate®, FlashScan®, Honeywell®. NOTIFIER®, ONYX®, ONYXWorks®, VeriFire®, and

VIEW® are all registered trademarks of Honeywell International Inc. Microsoft® and Windows® are registered trademarks of the Microsoft Corporation. Chrome™ and

Google™ are trademarks of Google Inc. Firefox® is a registered trademark of The Mozilla Foundation.

©2018 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited.

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 3

Page 4

Software Downloads

In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make frequent

upgrades to the embedded software in our products. To ensure that you are installing and programming the latest features, we

strongly recommend that you download the most current version of software for each product prior to commissioning any system.

Contact Technical Support with any questions about software and the appropriate version for a specific application.

Documentation Feedback

Your feedback helps us keep our documentation up-to-date and accurate. If you have any comments or suggestions about our online

Help or printed manuals, you can email us.

Please include the following information:

• Product name and version number (if applicable)

• Printed manual or online Help

• Topic Title (for online Help)

• Page number (for printed manual)

• Brief description of content you think should be improved or corrected

• Your suggestion for how to correct/improve documentation

Send email messages to:

FireSystems.TechPubs@honeywell.com

Please note this email address is for documentation feedback only. If you have any technical issues, please contact Technical

Services.

4 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 5

Table of Contents

Section 1: System Overview............................................................................................................................................. 7

1.1: General...............................................................................................................................................................................................................7

1.2: Features..............................................................................................................................................................................................................7

1.3: Start-up Procedure .............................................................................................................................................................................................8

1.4: Jumpers ..............................................................................................................................................................................................................8

1.4.1: Charger Disable Jumper (J1) ..................................................................................................................................................................9

1.4.2: Ground Fault Disable Jumper (J2)..........................................................................................................................................................9

1.5: LED Indicators .................................................................................................................................................................................................. 9

1.6: Specifications ....................................................................................................................................................................................................9

Section 2: Installation ..................................................................................................................................................... 13

2.1: Backbox Mounting ..........................................................................................................................................................................................13

2.2: Chassis-Mounting in FACP Cabinets ..............................................................................................................................................................16

2.3: NAC Circuit Wiring ........................................................................................................................................................................................20

2.3.1: Four NACs Configured for Class B (Style Y)......................................................................................................................................20

2.3.2: Two NACs Configured for Class A (Style Z) ......................................................................................................................................21

2.3.3: Mixing Class B and Class A NACs ......................................................................................................................................................22

2.3.4: HPP31076 Optional Class A (Style Z) Adapter ...................................................................................................................................23

2.4: Mounting Addressable Modules......................................................................................................................................................................23

2.4.1: Mounting Modules from Honeywell Fire Systems ..............................................................................................................................24

2.4.2: Mounting Six-Circuit Modules from Honeywell Fire Systems............................................................................................................25

2.5: Power-Limited Wiring Requirements..............................................................................................................................................................25

2.5.1: Power-Limited Wiring, Standard Chassis ............................................................................................................................................26

2.5.2: Power-Limited Wiring, FACP Cabinet ................................................................................................................................................27

Section 3: Programming Options .................................................................................................................................. 29

3.1: DIP Switch Settings .........................................................................................................................................................................................29

3.2: Programmable Features ...................................................................................................................................................................................30

3.2.1: Input/Output Functions.........................................................................................................................................................................30

3.2.2: Synchronization Type ...........................................................................................................................................................................30

3.2.3: Trouble Reporting Delay with an AC Failure ......................................................................................................................................30

3.2.4: Split Alarm and Silencing ....................................................................................................................................................................31

Section 4: Trouble Supervision...................................................................................................................................... 32

4.1: Supervised Functions and Field Wiring...........................................................................................................................................................32

4.2: Trouble Reporting............................................................................................................................................................................................32

4.2.1: Normal/Standby ...................................................................................................................................................................................32

4.2.2: Alarm ...................................................................................................................................................................................................33

4.2.3: TB2: AC FAIL Contacts.......................................................................................................................................................................33

4.2.4: TB2: TROUBLE Contacts....................................................................................................................................................................33

4.2.5: TB3: Initiating Device Inputs SIGNAL 1 and SIGNAL 2 ...................................................................................................................33

4.2.6: Trouble Memory...................................................................................................................................................................................33

4.2.7: Ground Fault Detection ........................................................................................................................................................................34

4.2.8: NAC Overload Protection and Indication.............................................................................................................................................34

Section 5: Applications................................................................................................................................................... 35

5.1: Controlling Four NAC Circuits from a Single Source ....................................................................................................................................35

5.2: Controlling and Silencing Four NACs ............................................................................................................................................................36

5.3: Split Alarm and Selective Silence....................................................................................................................................................................37

5.3.1: Selective Silence ...................................................................................................................................................................................37

5.3.2: Split Alarm Mode .................................................................................................................................................................................38

5.4: Connecting Multiple Units ..............................................................................................................................................................................39

Section 6: Power Supply Requirements........................................................................................................................ 42

6.1: Overview..........................................................................................................................................................................................................42

6.2: Calculating the AC Branch Circuit Current.....................................................................................................................................................42

6.3: Calculating the System Current Draw .............................................................................................................................................................42

6.3.1: Overview...............................................................................................................................................................................................42

6.3.2: How to Calculate System Current Draw ..............................................................................................................................................43

6.4: Calculating the Battery Size ............................................................................................................................................................................44

6.4.1: NFPA Battery Requirements ................................................................................................................................................................44

6.4.2: Selecting and Locating Batteries ..........................................................................................................................................................44

6.5: NAC Circuit Loop Wiring Requirements........................................................................................................................................................44

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 5

Page 6

It is imperative that the installer understand the requirements of the Authority Having Jurisdiction (AHJ) and be familiar with the stan-

This product has been certified to comply with the requirements in the Standard for Control Units and Accessories for Fire Alarm Systems, UL 864, 9th Edition. Operation of this product with products not tested for UL 864, 9th Edition has not been evaluated. Such operation requires the approval of the local Authority Having Jurisdiction (AHJ).

dards set forth by the following regulatory agencies:

• Underwriters Laboratories Standards

• NFPA 72 National Fire Alarm Code

Before proceeding, the installer should be familiar with the following documents.

NFPA Standards

NFPA 72 National Fire Alarm Code

NFPA 70 National Electrical Code

Underwriters La

UL 464 Audible Signaling Appliances

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1638 Visual Signaling Appliances

UL 1971 Signaling Devices for Hearing Impaired

Other:

NEC Article 250 Grounding

NEC Article 300 Wiring Methods

NEC Article 760 Fire Protective Signaling Systems

Applicable Local and State Building Codes

Requirements of the Local Authority Having Jurisdiction (LAHJ)

HPP Documents:

HPP Device Compatibility

HPFF8(E)/HPFF8CM(E) NAC Expander

HPP31076 Optional Class A (Style Z) Adapter

boratories Documents:

cument #54399

Do

Document #53499

Document #53728

6 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 7

The Honeywell Power Products FireForce (HPFF) is one of the most innovative fire alarm remote power supplies available that complies with UL 864 9th Edition. Designed with advanced switch-mode power supply technology and built with the latest surface-mount

electronic manufacturing techniques, they incorporate several new features that demanding installers requested to speed them through

installation and servicing.

The HPFF12 is a 12.0 A power supply that provides power for Notification Appliance Circuit (NAC) expansion to support ADA requirements and strobe synchronization (sync). It provides filtered 24 VDC power to drive four NAC outputs. The four-output circuits may be

configured as: four Class B (Style Y); two Class A (Style Z); two Class B and one Class A; or four Class A with the optional HPP31076

Class A adapter installed. The input circuits, which control the power supply operation, are triggered by the reverse polarity of a NAC or

by the reverse polarity of a 12 VDC or 24 VDC power source. The power supply is compatible with 12 VDC or 24 VDC control panels.

It contains an internal battery charger capable of charging up to 26.0 AH (amp hour) batteries.

The HPFF12 is a wall cabinet unit that can accommodate up to two 18 AH batteries. It can be configured to internally house one addressable control or relay module, a six-circuit relay module, or a six-circuit control module. (Modules available through authorized Honey-

well Fire Systems distributors.)

HPFF12CM is a chassis-mount model that can fit two 12.0 AH batteries. It is used for a multi-pack option that allows up to three

HPFF12CM units to be mounted in a compatible Fire Alarm Control Panel (FACP) cabinet; these separately sold cabinets are also

referred to as the large equipment enclosure. The addressable control or relay module option is not available on these models. (Equip-

ment enclosures available through authorized Honeywell Fire Systems distributors.)

HPFF12 and HPFF12CM power supply models operate at 120 VAC/60 Hz.

HPFF12E and HPFF12CME power supply models are export units that operate at 240 VAC/50 Hz.

NOTE: When an HPFF12CM unit is mounted in a FACP cabinet, the top row must be left open for proper heat dissipation.

1.1 General

The HPFF power supplies are used as remotely mounted power supplies and battery chargers. The Fire Alarm Control Panel (FACP) or

initiating device is connected to the input circuit(s). When the control input circuit activates due to the reverse polarity of the signal from

the initiating device, the power supply will activate its NAC outputs.

During the inactive or non-alarm state, the power supply supervises its NAC field wiring independently for short and open conditions. If

a NAC fault is detected, the power supply will open the initiating device input signal to notify the FACP and the Normally-Closed Trouble contact. If an AC loss is detected, the power supply will open the initiating device input signal, Normally-Closed Trouble, and a dedicated AC Fail contact.

If an alarm condition occurs and the NAC outputs are activated, the supervision and charger are disabled and the NAC circuit is no longer supervised (except for excessive loading or shorts). Supervision of other power supply faults such as battery voltage, AC loss, and

ground fault will continue and may be monitored via Trouble contacts.

Section 1: System Overview

1.2 Features

• The enclosures offered are self-contained lockable cabinets

– If the local Authority Having Jurisdiction (AHJ) requires the fire protection system to have matching locks, the units’ locks may

be swapped in the field to accommodate Honeywell Fire Systems branded panels: Honeywell, Notifier, Gamewell-FCI, Silent

Knight, Farenhyt, and Fire-Lite Alarms

• 24 VDC remote power supply

• Outputs are completely power-limited

• Four output circuits:

– Fully filtered power

– Four 24 VDC Class B (Style Y), or two Class A (Style Z), or two Class B (Style Y) and one Class A (Style Z) NACs (special

application)

– Four 24 VDC Class A (Style Z) NACs (special application) with optional HPP31076 Class A adapter

• Status LED indicators on control PCB

– Power On LED

– Auxiliary Trouble LED

– Battery Trouble LED

– Ground Fault LED

– Individual NAC Trouble LEDs

• Maximum current for any one output circuit: 3.0 A

• Maximum total continuous current available: 12.0 A for HPFF12, HPFF12E, HPFF12CM, and HPFF12CME

• NAC overload protection and indication:

– Shorted or excessively loaded NAC outputs automatically protect themselves

– Status LEDs will illuminate steady to indicate the circuit affected

• Integral supervised battery charger:

– Capable of charging 7.0 AH to 26.0 AH batteries

– For lead-acid batteries only

– Battery Trouble LED blinks to indicate charger fault

• Fully supervised power supply, battery, and NACs

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 8

System Overview Start-up Procedure

!

• Two independent optically-isolated input/control circuits, compatible with 12 VDC and 24 VDC control panel NACs

• Selectable strobe synchronization for NACs compatible with System Sensor, Cooper Wheelock, Faraday, Amseco, and Gentex

notification appliances

• Selectable pass-through or filtered input

– Pass-through input of steady, coded audible, and synchronized strobe signals to NAC outputs

– Filtered for full-wave-rectified polarity-reversing inputs or reducing spurious noise to generate steady-on NAC outputs

• Silenceable with two independent alarm inputs or by passed-through synchronization protocol

• Split Alarm mode allows a combination of coded signals outputs and Selectable Silence on NAC pairs

• Selectable silence with two independent alarm inputs and the HPFF programmed in Split Alarm mode

• End-of-line resistor compare:

– Attach a single reference resistor to match value of the NAC end-of-line resistor (ELR)

– Provides use of a wide range of ELR resistors’ values: 1.9K ohms to 25K ohms

– Eases retrofit installations by matching existing ELR value without having to locate in the field. (ELRs must be UL Listed.)

• NAC Trouble memory:

– Individual NAC Trouble LEDs blink if past troubles occurred

– Aids installer or repair personnel to find the location of past troubles

• Fixed, clamp-style terminal blocks to accommodate 12 AWG (3.31 mm²) to 22 AWG (0.326 mm²) wire

• Separate Trouble and AC Fail Form-C relay contacts

• Initiating device input signal is interrupted for Trouble indication at device or FACP

• Optional two-hour delay:

– In opening of Trouble contacts upon AC loss (AC Fail contact always transfers immediately upon AC loss)

– In interruption of initiating device input signal for Trouble indication at device or FACP

– UL 864 9th Edition requires 1-3 hour delay, therefore always programming for the two-hour delay is recommended

• Auxiliary output:

– Continuous 24 VDC output (even in alarm): 2.0 A

– Resettable fuse (PTC) limited

• Mounting locations on the Control circuit board for optional addressable relay and control modules

1.3 Start-up Procedure

1. Configure the power supply jumpers as described in Section 1.4, “Jumpers”, on page 8.

2. Install the power supply as described in Section 2, “Installation”, on page 13.

3. Program the power supply as described in Section 3, “Programming Options”, on page 29.

4. Wire the power supply circuits, referring to the options described in Section 4, “Trouble Supervision”, on page 32 and the

application examples in Section 5, “Applications”, on page 35.

5. Connect the primary source wiring while observing the following:

• HPFF12 and HPFF12CM: make certain the primary source is 120 VAC, 60 Hz, 5.0 A.

• HPFF12E and HPFF12CME: make certain the primary source is 240 VAC, 50 Hz, 2.80 A.

• Run a pair of wires (with earth ground conductor) from the protected premises’ main breaker box to TB1 on the internal 24 VDC

power supply circuit board.

• For power supplies: use 14 AWG (2.089 mm²) wire with 600 V insulation.

• Connect ground of the protected premise to ground stud of the enclosure using a dedicated nut/lockwasher supplied in the

hardware kit.

WARNING: DISCONNECT POWER

MAKE CERTAIN THAT THE AC CIRCUIT BREAKER IS OFF BEFORE MAKING ANY WIRING CONNECTIONS

BETWEEN THE CIRCUIT BREAKER AND THE POWER SUPPLY.

6. Apply power to the power supply using the following procedure:

– Apply AC power by turning on the AC mains circuit breaker connected to the power supply.

– Connect a properly charged battery to the TB1 on the unit’s internal Control circuit board.

1.4 Jumpers

The HPFF power supplies are comprised internally of two basic components: a 24 VDC power supply and a Control circuit board. The

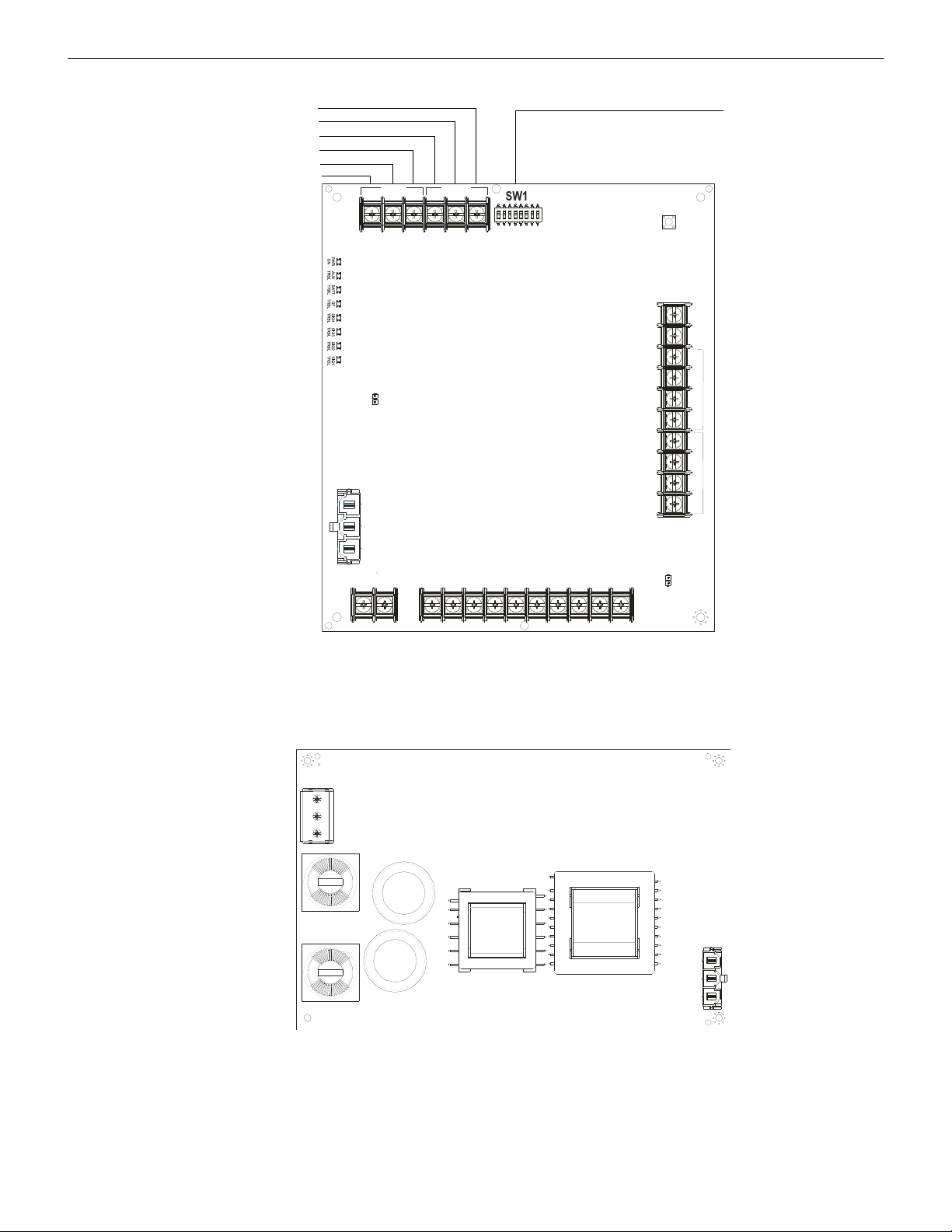

HPFF12 models have an installed 12.0 A power supply. Jumpers are located on the control circuit board; see Figure 1.1, “Control Circuit

Board”.

8 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 9

LED Indicators System Overview

TB2

LEDs

N/O

N/C

COMM

N/O

N/C

COMM

AC FAIL

TROUBLE

J1

!

J2

1L2 2L1 2L2

3L1 3L2

4L1 4L2

1.4.1 Charger Disable Jumper (J1)

The HPFF power supplies’ battery charger capacity is 26 AH maximum using the integral

charger with a maximum charging rate of 0.75 A. The integral charger on the Control circuit

board must be disabled in certain situations by removing the charger-disable jumper. One

situation is when system requires a common battery set, as is possible in the large equipment

enclosure. Another situation is if the system requires a larger battery capacity than the integral charger can charge in the proper time. Larger capacity batteries can be used if they are

housed in an external UL-Listed enclosure, along with a UL-Listed battery charger that can

restore the full charge to the batteries in the proper time.

CAUTION: BATTERY CHARGER DISABLE

THE BATTERY CHARGER IS AUTOMATICALLY DISABLED DURING ALARM, SO BATTERIES WILL NOT BE

CHARGED WHEN THE POWER SUPPLY IS IN THE ALARM STAGE.

Larger capacity batteries can be used if they are housed in an external UL-Listed enclosure, along with a UL-Listed battery charger suitable for fire alarm service and with sufficient capacity to restore the full charge in the required time. The alternate enclosure and battery

charger shall be listed for Fire Protective Signaling use.

1.4.2 Ground Fault Disable Jumper (J2)

The Ground Fault detection circuit on the Control circuit board monitors the impedance

from earth ground to any user wiring point, including +24 VDC. An exception is the

initiating device signal inputs because they are optically-isolated from the rest of the

circuitry and should be detected by the initiating device or FACP. Remove ground-fault

disable jumper to disable the ground fault detection.

If the common circuitry of two or more HPFFs are connected together, or if the common of an HPFF is connected to the common of a system, such as a single battery connected to multiple units, then the ground fault jumpers must be removed from all but

one of the units. The unit with the jumper installed provides the ground monitoring for

the whole system. If two or more units are connected together with ground fault monitoring enabled, then the monitoring circuits interfere with each other, and false ground faults will be generated.

1.5 LED Indicators

Indicator Name State Trouble Condition

LED 1, 2, 3, 4 SIG(1, 2, 3, 4) TRBL

LED 5 GF TRBL Steady illumination An earth ground fault is present

LED 6 BAT TRBL

LED 7 AUX TRBL Steady illumination Excessive loading or shorted auxiliary output

LED 8 POWER ON

NOTE: If all four SIG TRBL LEDs are illuminated steady, check if the reference ELR resistor is missing or doesn’t match the ELR resistors

used to terminate the Class B circuits. Otherwise, each NAC must have a trouble.

1.6 Specifications

Refer to Section 1.1, “Control Circuit Board”, on page 11 for terminal locations.

Primary AC Power — TB1 (on 24 VDC power-supply circuit board)

• HPFF12 and HPFF12CM: 120 VAC, 60 Hz, 5.0 A

• HPFF12E and HPFF12CME: 240 VAC, 50 Hz, 2.80 A

• Wire size: 14AWG (2.08 mm²) with 600 V insulation

Initiating Device Signal Inputs — TB3 (on Control circuit board); terminals SIGNAL1: +IN, –IN, +OUT, –OUT, and SIGNAL2:

+IN, –IN, +OUT, –OUT

• Supervised by FACP or initiating device, power-limited

• A supervisory relay must be used if initiating device is a power source.

Blinking NAC Trouble Memory

Steady illumination Open or shorted NAC

Blinking Charger Fault

Steady illumination Low or missing battery

Blinking Low (brown-out) or missing AC input

Steady illumination Normal/Standby

Table 1.1 LED Indicators

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 9

Page 10

System Overview Specifications

• Available for one of the following:

– 4-wire inputs; or

– 2-wire inputs and an ELR; or

– facilitate multiple unit systems

• Trigger input voltage: 12 and 24 VDC

• Input trigger draw in alarm polarity:

– 12 VDC, 5.68 mA maximum per input

– 24 VDC, 12.26 mA maximum per input

• 12 AWG (3.31 mm²) to 18 AWG (0.821 mm²)

End-of-line Resistor Reference – TB3 (on Control circuit board); terminals REF+ and REF–

• Used for the ELR compare feature

• Range: 1.9K ohms to 25K ohms

• 12 AWG (3.31 mm²) to 22 AWG (0.326 mm²)

NAC Output Circuits — TB4 (on Control circuit board); terminals 1L1(+), 1L2(–), 2L1(+), 2L2(–), 3L1(+), 3L2(–), 4L1(+), and

4L2(–) — alarm polarity in parentheses (See below for other TB4 terminals.)

• Supervised, special application, and power-limited

• Voltage rating: 24 VDC filtered.

• Current:

– Maximum for any one circuit: 3.0 A

– Maximum total continuous for all outputs: HPFF12, HPFF12CM, HPFF12E, HPFF12CME: 12.0 A

• Output circuit types:

– four Class B (Style Y); or

– two Class A (Style Z);

– two Class B (Style Y) and one Class A (Style Z) NACs; or

– four Class A (Style Z) NACs with optional HPP31076 Class A adapter

• 12 AWG (3.31 mm²) to 18 AWG (0.75 mm²)

• Refer to the HPP Device Compatibility Document #54399. for listed compatible devices.

Trouble Contact Rating — TB2 (on Control circuit board); terminals TROUBLE: N/C, COM, and N/O

• Not supervised

• Fail-safe Form-C relay

• Normally energized, transfers with NAC, battery, charger (in standby), AC loss, ground fault, and auxiliary output trouble

• 2.0 A @ 30 VDC

• AC loss trouble can be delayed for 2 hours (see “Programming Options”)

• 12 AWG (3.31 mm²) to 18 AWG (0.75 mm²)

AC Fail Contact Rating — TB2 (on Control circuit board); terminals AC FAIL: N/C, COM, N/O (See above for other TB4 terminals.)

• Not supervised

• Fail-safe Form-C relay

• Normally energized, always transfers with AC loss

• 2.0 A @ 30 VDC

• 12 AWG (3.31 mm²) to 18 AWG (0.75 mm²)

Battery Charging Circuit — TB1 (on Control circuit board); terminals +BATT and –BATT

• Supervised, non-power-limited

• Supports lead-acid type batteries only

• Float charge voltage: 26.6 VDC

• Charger disabled if battery voltage falls below 15 VDC

• Maximum charge current: 0.75 A

• Battery fuse (F1): 15 A, 32 V

• Maximum battery capacity: 26.0 AH

• Minimum battery capacity: 7.0 AH

• Power supply draws a maximum standby current of 75 mA from batteries

Auxiliary Output — TB4 (on Control circuit board); terminals +A and –A (See above for other TB4 terminals.)

• Voltage checked for excessive loading, power limited (PTC), special application

• Voltage rating: 24 VDC continuous (even in alarm)

• Current: 2.0 A maximum. (Subtract auxiliary load from total to determine available NAC load.)

• 12 AWG (3.31 mm²) to 18 AWG (0.75 mm²)

• For a list compatible optional modules that can be connected to the Auxiliary output, see the HPP Device Compatibility Document

#54399.

10 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 11

Specifications System Overview

TB3

TB4

TB1

TB2

SW2

LEDs

REF+ REF– + IN – IN + OUT – IN + OUT+ OUT + IN – OUT

SIGNAL 1

SIGNAL 2

BATT+ BATT–

A+

N/O

N/C

COMM

N/O

N/C

COMM

AC FAIL

TROUBLE

J1

J2

1L1 1L2 2L1 2L2

3L1 3L2

4L1 4L2A–

REF+

REF–

Signal 1 +IN

Signal 1 –IN

Signal 1 +OUT

Signal 1 –OUT

Signal 2 +IN

Signal 2 –IN

Signal 2 +OUT

Signal 2 –OUT

LEDs:

LED1 (Power On)

LED2 (Auxiliary Trouble)

LED3 (Battery Trouble)

LED4 (Ground Fault Trouble)

LED5 (Signal 4 Trouble)

LED6 (Signal 3 Trouble)

LED7 (Signal 2 Trouble)

LED8 (Signal 1 Trouble)

TB2: AC Fail & Trouble Relays

Trouble N/C

Trouble COMM

Trouble N/O

AC Fail N/C

AC Fail COMM

AC Fail N/O

T

B

1

:

B

a

t

t

e

r

y

+

-

J1: Charger Disable

J2: Ground Fault

Disable

HPFF812PCA2.wmf

S

W

1

(

l

e

f

t

t

o

r

i

g

h

t

)

:

S

I

G

S

E

L

A

C

2

H

R

S

Y

N

S

E

L

‘

B

’

S

Y

N

S

E

L

‘

A

’

S

I

G

3

/

4

‘

B

’

S

I

G

3

/

4

‘

A

’

S

I

G

1

/

2

‘

B

’

S

I

G

1

/

2

‘

A

’

TB3: ELR Reference/

IDC Inputs

Alarm Polarity

Shown

A+ A- 1L1 1L2 2L1 2L2 3L1 3L2 4L1 4L2

TB4: Auxiliary/NAC Outputs

Figure 1.1 Control Circuit Board

SW2: Reset

FF12pca.wmf

Figure 1.2 HPFF12 24 VDC Power Supply Circuit Board

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 11

Page 12

Notes

12 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 13

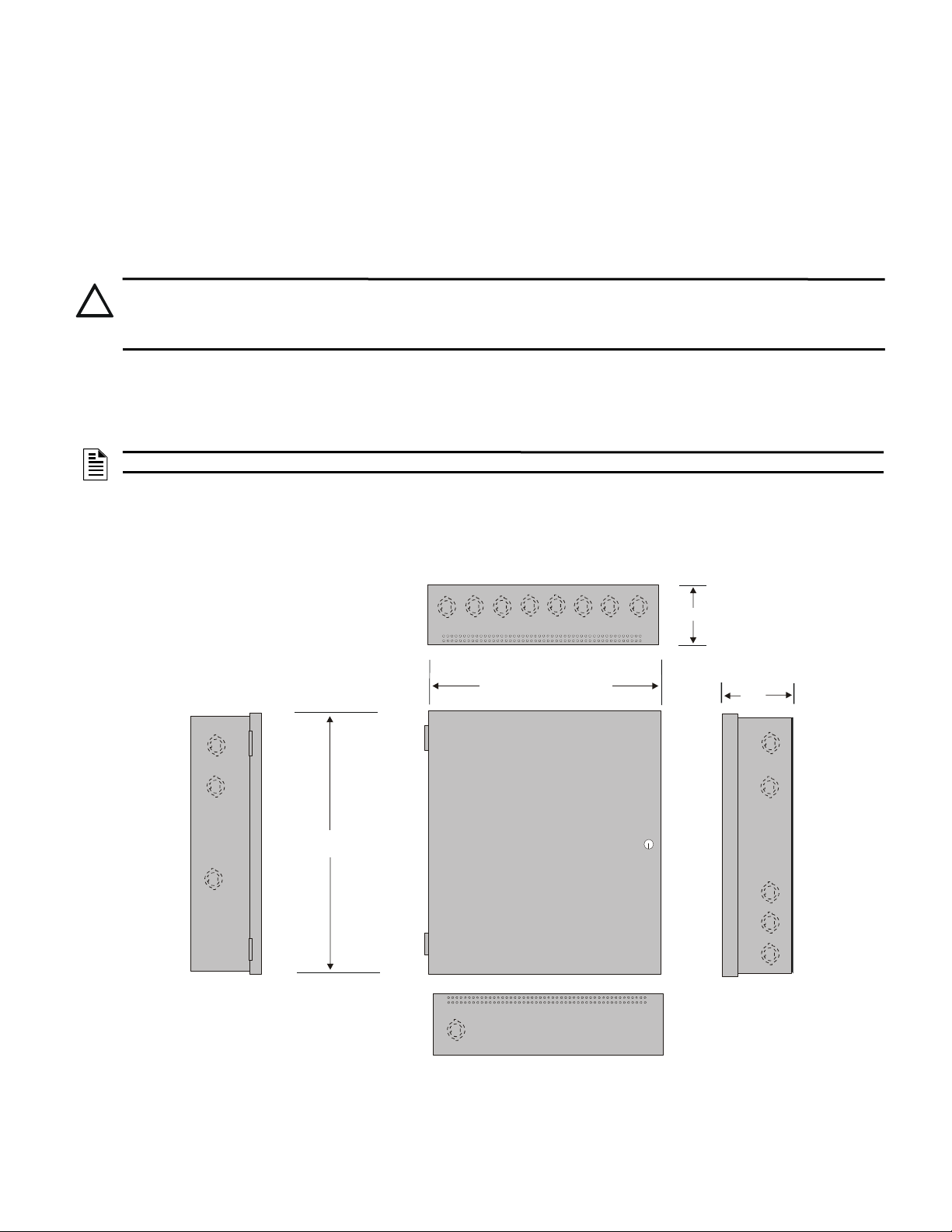

The standard cabinet may be either semi-flush or surface mounted. Fire Alarm Control Panel (FACP) cabinets can only be wall mounted.

!

ff8cab.wmf

Figure 2.1 Standard Cabinet: Dimensions

Door = 19.26” (48.92cm)

Backbox = 19.0” (48.26cm)

Door = 16.821” (42.73cm)

Backbox = 16.65” (42.29cm)

Depth = 5.207” (13.23cm)

Depth =

5.257”

(13.353cm)

Top

Bottom

Left Side Right Side

Each cabinet mounts using two or three key slots and two 0.250" (6.35 mm) diameter holes in the backbox. The key slots are located at

the top of the backbox and the two securing holes at the bottom.

Carefully unpack the system and check for shipping damage. Mount the cabinet in a clean, dry, vibration-free area where extreme temperatures are not encountered. The area should be readily accessible with sufficient room to easily install and maintain the panel. Locate

the top of the cabinet approximately 5 feet (1.5 m) above the floor with hinge mounting on the left. Determine the number of conductors

required for the devices to be installed. Sufficient knockouts are provided for wiring convenience. Select the appropriate knockout(s) and

pull the conductors into the box. All wiring should be in accordance with the National and/or Local codes for fire alarm systems and

power supplies.

2.1 Backbox Mounting

CAUTION: STATIC SENSITIVE COMPONENTS

THE CIRCUIT BOARD CONTAINS STATIC-SENSITIVE COMPONENTS. ALWAYS GROUND YOURSELF WITH A STATIC

STRAP BEFORE HANDLING ANY BOARDS SO THAT THE STATIC CHARGES ARE REMOVED FROM THE BODY. USE

STATIC SUPPRESSIVE PACKAGING TO PROTECT ELECTRONIC ASSEMBLIES.

To prevent damage to the circuit board and to facilitate backbox mounting, the chassis with the 24 VDC power supply and the Control

circuit board can be easily removed. Loosen the two #8-32 nuts securing the top flanges of the chassis, then slide the chassis up to free it

from the lower tabs. Place the chassis assembly in a safe location until it can be reinstalled in the backbox.

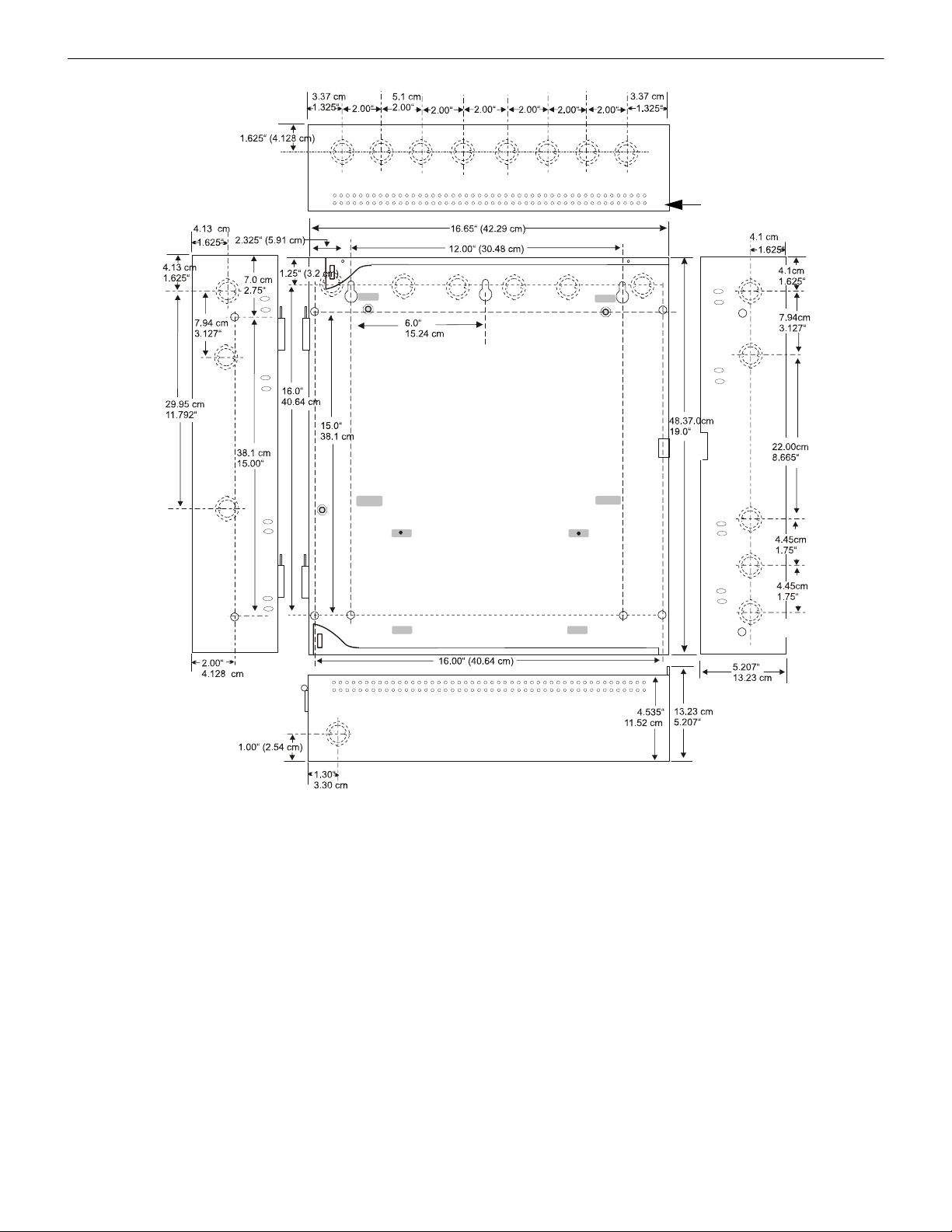

1. Mark and pre-drill a hole in the wall for the center top keyhole mounting bolt using the dimensions illustrated in Figure 2.2 or

Figure 2.3.

NOTE: See the EQ Series Install Sheet PN 53412 for door-mounting details and measurements for B-size and C-size backboxes.

2. Install the center top fastener in the wall with screw head protruding.

3. Place backbox over the top screw, level and secure.

4. Mark and drill the left and right upper and lower mounting holes.

Note: outer holes (closest to sidewall) are used for 16" O.C. stud mounting.

5. Install remaining fasteners.

Section 2: Installation

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 14

Installation Backbox Mounting

Semi-Flush Mounting

Do not recess box more

than 3.875” into wall to

avoid covering venting

holes on top of box.

92udlsencl.wmf

Figure 2.2 Standard Cabinet: Dimensions for Wall-mounting

14 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 15

Backbox Mounting Installation

(13.097cm)

5.156”

5.93”

(15.062cm)

5.93”

(15.062cm)

7.12”

(18.084cm)

(6.197cm)

2.44”

0.875” (2.223cm)

1.125” (2.858cm)

45-3/4"

(116.21)

24.125” (61.28cm)

24.0” (60.96cm)

1.625”

(4.13cm)

2.06”

(5.24cm)

11. 5”

(29.21cm)

5.16”

(13.1cm)

(10.16cm)

4”

4”

(5.08cm)

1”

(2.54cm)

11”

(27.94cm)

11”

(27.94cm)

2.625”

(6.604cm)

0.875 (2.22cm)

1.125 (2.86cm)

0.875 (2.22cm)

1.125 (2.86cm)

1.875”

(4.7cm)

37.03”

(94.06cm)

0.31”

(0.79cm)

0.31”

(0.79cm)

45.875”

(116.52cm)

2.25”

(5.72cm)

2.25”

(5.72cm)

19.5”

(49.53cm)

16.0” (40.64cm)

1.125”

(2.858 cm)

0.50”

(1.27 cm)

0.50”

(1.27 cm)

0.250”

(0.635 cm)

HPFF8LargeEqpt.wmf

Chassis-

mounting

studs

(2 per row of

backbox)

Keyholes

2 places

Mounting holes

2 places

e

q

c

a

b

-

d

2

.

w

m

f

Four rows of

Equipment

c

a

b

t

o

p

.

w

m

f

Top View of Backbox

c

a

b

4

k

e

y

h

o

l

e

.

w

m

f

Keyhole dimensions

Height of

mounting bolt

after installation

NOTE: See CAB-4 Series Install Sheet PN 15330 and EQ Series Install Sheet PN 53412 for door-mounting details and

measurements for A, B, and C size backboxes. This drawing shows EQBB-D4 knockout locations.

Top knockout:

Inner:

Outer:

Four Lower knockouts:

Inner:

Outer:

Knockouts:

Inner:

Outer:

Figure 2.3 FACP Cabinet-Mounting Details: Backbox-Mounting Holes and Chassis-Mounting Studs (EQBB-D4

shown)

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 15

Page 16

Installation Chassis-Mounting in FACP Cabinets

EQ Series Backboxes

(EQBB-D4 shown)

Note: Two-row and three-row mounting is equivalent. Drawings are not to scale.

E

Q

D

c

a

b

i

n

e

t

m

o

u

n

t

i

n

g

h

o

l

e

s

.

w

m

f

Figure 2.4 Chassis-Mounting in FACP Cabinet: Overview

2.2 Chassis-Mounting in FACP Cabinets

Up to three HPFF12CM units can fit into the FACP cabinet. Compatible Fire Alarm Control Panel cabinets include:

Number of Units

Supported

EQ Series Backboxes & Doors

One EQBB-B4 with EQDR-B4 or FCI-VDR-B4B

Two EQBB-C4 with EQDR-C4 or FCI-VDR-C4B

Three EQBB-D4 with EQDR-D4 or FCI-VDR-D4B

Table 2.1 FACP Cabinets

NOTES:

1. When an HPFF12CM unit is mounted in a FACP cabinet, the top row must be left open for proper heat dissipation.

2. Alternate the mounting direction for HPFF12CM as shown in Figure 2.7. Battery must be on left side of bottom row.

See power-limited wiring Section 2.5.2, “Power-Limited Wiring, FACP Cabinet”, on page 27.

Attaching the HPFF12CM onto Mounting Plates

1. Attach power cable to the FFSMTR9-PCA (ships unplugged) as shown in Figure 2.5.

2. Attach mounting plates as shown in Figure 2.6.

3. For the bottom-most chassis-mounting plate only, install four #8-32 keps nuts on the plate’s studs as shown in Figure 2.6. This will

properly space the battery well away from the backbox’s mounting hardware.

4. Align HPFF12CM module with the backbox’s mounting studs; fasten securely using four #8-32 keps nuts as shown in Figure 2.7.

5. Install battery well by resting the bottom on top of the studs and securing the top with two #8-32 keps nuts as shown in Figure 2.7.

16 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 17

Chassis-Mounting in FACP Cabinets Installation

h

p

f

f

1

2

c

m

-

c

a

b

l

e

.

w

m

f

Attach plug to

transformer.

(Ships unplugged.)

Figure 2.5 Attaching Transformer Plug

Note: Components have been

removed from this graphic for

illustration purposes only.

hpff12cm-plate-mtg.wmf, hpff12cm-bottom-

Attach each chassis-

mounting plate to

backbox with two

#8-32 kep nuts.

For the bottom chassis-mounting plate only:

Install four #8-32 kep nuts onto studs

where battery well is to be located.

NOTE: This can be done before or after

attaching chassis-mounting plate to backbox.

Note: Two-row and three-row mounting is equivalent.

Figure 2.6 Installing Chassis-Mounting Plates onto Backbox (EQBB-D4 Shown)

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 17

Page 18

Installation Chassis-Mounting in FACP Cabinets

h

p

f

f

1

2

c

m

m

n

t

-

e

q

d

s

i

z

e

.

w

m

f

Do not mount

HPFF12CM

in top row.

The HPFF12CM

chassis-mounting

direction must be

alternated for proper

heat dissipation.

Battery must be on left

side of bottom row.

Attach

HPFF12CM

module with four

#8-32 keps nuts.

Secure top of

battery well with

two #8-32 keps nuts.

Figure 2.7 HPFF12CM: Chassis-Mounting in Backbox

(EQBB-D4 Shown)

18 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

See power-limited wiring “HPFF12CM(E) Power-Limited Wiring, EQBB-D4 Backbox” on page 27.

Page 19

Chassis-Mounting in FACP Cabinets Installation

Figure 2.8 Two HPFF12CM Modules in an

EQBB-C4 Backbox

h

p

f

f

1

2

c

m

m

n

t

-

e

q

c

s

i

z

e

.

w

m

f

Figure 2.9 One HPFF12CM Module in an

EQBB-B4 Backbox

h

p

f

f

1

2

c

m

m

n

t

-

e

q

c

s

i

z

e

.

w

m

f

See power-limited wiring “HPFF12CM(E) Power-Limited Wiring, EQBB-D4 Backbox” on page 27.

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 19

Page 20

Installation NAC Circuit Wiring

TB4TB1

TB2

LEDs

REF+ REF– + IN – IN

+ OUT

– IN

+ OUT+ OUT

+ IN

– OUT

SIGNAL 1

SIGNAL 2

BATT+ BATT–

A+

N/O

N/C

COMM

N/O

N/C

COMM

AC FAIL

TROUBLE

1L1 1L2 2L1 2L2

3L1 3L2

4L1 4L2A–

+

-

+

-

+

-

+

-

-

+

-

+

-

+

-

+

Reference Resistor

H

P

F

F

1

2

N

A

C

C

l

a

s

s

B

.

w

m

f

Horn Strobe

Horn Strobe

Horn Strobe

EOL same as

Reference Resistor

Alarm Polarity Shown

• Trouble on NAC1

will illuminate

LED1 SIG1 TRBL.

• Trouble on NAC2

will illuminate

LED2 SIG2 TRBL.

• Trouble on NAC3

will illuminate

LED3 SIG3 TRBL.

• Trouble on NAC4

will illuminate

LED4 SIG4 TRBL.

NAC 4

NAC 3

NACs 1 - 3 are wired the same as NAC4 and use

an ELR which is the same as Reference Resistor.

NAC 1 NAC 2

Figure 2.10 Four NACs in Class B (Style Y)

2.3 NAC Circuit Wiring

For wiring sizes, see Section 6.5, “NAC Circuit Loop Wiring Requirements”.

2.3.1 Four NACs Configured for Class B (Style Y)

Figure 2.10 shows four NACs configured for Class B (Style Y).

NOTES:

1. Typical ELRs for new installations can be 3.9k or 4.7k ohm.

2. The same gauge wire must be used if two conductors are connected to the same terminal of any terminal block.

3. Do not complete a continuous circuit around the screw terminal. There must be two separate wires on either side of the screw at the

terminal block. “T-tapping” is absolutely NOT ALLOWED.

20 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 21

NAC Circuit Wiring Installation

+

-

+

-

+

-

+

-

TB3

TB4TB1

TB2

LEDs

REF+ REF– + IN – IN

+ OUT

– IN

+ OUT+ OUT

+ IN

– OUT

SIGNAL 1

SIGNAL 2

BATT+ BATT–

A+

N/O

N/C

COMM

N/O

N/C

COMM

AC FAIL

TROUBLE

1L1 1L2 2L1 2L2

3L1 3L2

4L1 4L2A–

-

+

-

+

-

+

-

+

NAC 2

H

P

F

F

1

2

N

A

C

C

l

a

s

s

A

.

w

m

f

Horn Strobe

Horn Strobe

Horn Strobe

Alarm Polarity

Shown

• Trouble on NAC1

will illuminate

LED1 SIG1 TRBL and

LED2 SIG2 TRBL

• Trouble on NAC2

will illuminate

LED3 SIG3 TRBL

and LED4 SIG4 TRBL

Note: NAC 2 in Class A;

no ELR required.

Note: NAC 1 Class A

wired same as NAC2.

NAC 1

Figure 2.11 Two NACs in Class A (Style Z)

2.3.2 Two NACs Configured for Class A (Style Z)

Figure 2.11 shows two NACs configured for Class A (Style Z).

NOTES:

1. Typical ELRs for new installations can be 3.9k or 4.7k ohm.

2. The same gauge wire must be used if two conductors are connected to the same terminal of any terminal block.

3. Do not complete a continuous circuit around the screw terminal. There must be two separate wires on either side of the screw at the

terminal block. “T-tapping” is absolutely NOT ALLOWED.

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 21

Page 22

Installation NAC Circuit Wiring

+

-

+-+-+

-

NOTE: NAC 1 and NAC 2 in

Class B (Style Y) - See

Section 2.3.1 for wiring.

NAC 3

H

P

F

F

1

2

N

A

C

C

l

a

s

s

A

w

i

t

h

B

.

w

m

f

Horn Strobe

Horn Strobe

Horn Strobe

Alarm Polarity

Shown

Note: NAC 3 in Class A;

no ELR required.

NAC 1

• Trouble on NAC1

will illuminate

LED1 SIG1 TRBL

• Trouble on NAC2

will illuminate

LED2 SIG2 TRBL

• Trouble on NAC3

will illuminate

LED3 SIG3 TRBL and

LED4 SIG4 TRBL

Reference Resistor

(Same as ELRs for

NAC 1 & NAC2)

NAC 2

Figure 2.12 Configuring Two Class B NACs and One Class A NAC on One HPFF

2.3.3 Mixing Class B and Class A NACs

Figure 2.12 shows two NACs configured for Class B (Style Y) and one NAC configured for

Class A (Style Z).

NOTES:

1. Typical ELRs for new installations can be 3.9k or 4.7k ohm.

2. The same gauge wire must be used if two conductors are connected to the same terminal of any terminal block.

3. Do not complete a continuous circuit around the screw terminal. There must be two separate wires on either side of the screw at the

terminal block. “T-tapping” is absolutely NOT ALLOWED.

22 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 23

Mounting Addressable Modules Installation

TB4TB1

TB2

LEDs

REF+ REF– + IN – IN

+ OUT

– IN

+ OUT+ OUT

+ IN

– OUT

SIGNAL 1

SIGNAL 2

BATT+ BATT–

A+

N/O

N/C

COMM

N/O

N/C

COMM

AC FAIL

TROUBLE

1L1 1L2 2L1 2L2

3L1 3L2

4L1 4L2A–

-

+

-

+

-

+

-

+

}

NAC4

NAC Return

}

}

}

}

NAC3NAC2NAC1

– +– +– + – +

NAC Out

}

H

P

F

F

1

2

-

H

P

P

3

1

0

7

6

-

N

A

C

s

.

w

m

f

Reference Resistor

3.9K ohm is required

for the Class A adapter

Alarm Polarity

Shown

• Trouble on NAC1

will illuminate

LED1 SIG1 TRBL

• Trouble on NAC2

will illuminate

LED2 SIG2 TRBL

• Trouble on NAC3

will illuminate

LED3 SIG3 TRBL

• Trouble on NAC4

will illuminate

LED4 SIG4 TRBL

Note: ELR is not required, but

the 3.9kohm reference resistor

is required.

NACs 1 - 3 are wired the same

as NAC4.

Note: Use wire gauge from

12AWG-18AWG.

Figure 2.13 Four Class A (Style Z) NACs with HPP31076 Adapter

2.3.4 HPP31076 Optional Class A (Style Z) Adapter

The HPP31076 is an optional adapter to connect four Class A (Style Z) NAC circuits. It mounts directly onto the terminal block TB4 of

the Control circuit board. The adapter kit includes two plastic standoffs to provide support. The same gauge wire must be used if two

conductors are connected to the same terminal of any terminal block.

NOTE: Only use batteries with a maximum height of 4 inches in applications that require this adapter in the standard enclosure.

Otherwise, there is insufficient space to connect NAC field wiring, and a separate NFPA and UL 864 rated enclosure is required.

2.4 Mounting Addressable Modules

NOTES:

1. Typical ELRs for new installations can be 3.9k or 4.7k ohm.

2. The same gauge wire must be used if two conductors are connected to the same terminal of any terminal block.

3. Do not complete a continuous circuit around the screw terminal. There must be two separate wires on either side of the screw at the

terminal block. “T-tapping” is absolutely NOT ALLOWED.

The HPFF12 and the HPFF12E are designed to mount Honeywell Fire Systems addressable control or relay modules on the Control circuit board inside the power supply cabinet. This allows power to be fed from the Auxiliary output directly to the module, if needed, without running the power wires outside the cabinet. For a list of compatible optional modules that can be connected to the Auxiliary output,

see the HPP Device Compatibility Document. Two single output modules may be mounted directly above each other if required by applications such as Split Alarm or Selective Silence. Alternately, two outputs of a 6-output addressable module can also be used and

mounted on the Control board.

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 23

Page 24

Installation Mounting Addressable Modules

H

P

F

F

1

2

m

n

t

c

m

f

.

w

m

f

Standoff Standoff

Standoff

Standoff

Figure 2.14 Mounting Details for Control & Relay Modules from Honeywell Fire Systems

2.4.1 Mounting Modules from Honeywell Fire Systems

Addressable modules can be mounted directly to the Control circuit board as shown in Figure 2.14 for the wall cabinet. This allows wiring to remain in the cabinet. Two modules can be mounted on top of each other if the application requires two independent inputs, such

as silencing. Alternately, two outputs of a six-output addressable module can also be used. The six-output module can also be mounted

directly on the Control board.

Mounting addressable modules on the Control circuit board is also possible in the HPFF12CM(E) units. However, the six-output module

must be mounted in an optional multi-module chassis if used in the large cabinet enclosure.

See Section 2.5, “Power-Limited Wiring Requirements”.

24 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 25

Power-Limited Wiring Requirements Installation

H

P

F

F

1

2

m

n

t

6

u

p

.

w

m

f

Figure 2.15 Mounting Details for Six-Output Modules from Honeywell Fire Systems

Standoff

Standoff

Standoff

Standoff

2.4.2 Mounting Six-Circuit Modules from Honeywell Fire Systems

Six-output addressable modules can be mounted directly to the control circuit board as shown in Figure 2.15 for the wall cabinet. This

allows wiring to remain in the cabinet. However, the six-output module cannot be mounted as shown in the HPFF12CM(E) units when

used in the large equipment enclosure. An optional multi-module chassis is available from Honeywell Fire Systems.

See Section 2.5, “Power-Limited Wiring Requirements”.

2.5 Power-Limited Wiring Requirements

Power-limited and non-power-limited circuit wiring must remain separated in the cabinet. All power-limited wiring must remain at least

0.25" away from any non-power-limited circuit wiring. Furthermore, all power-limited circuit wiring and non-power-limited circuit wiring must enter and exit the cabinet through different conduits. An example of this is shown below. Your specific application may require

different conduit knockouts to be used in the standard cabinet. Any conduit knockouts may be used. For power-limited applications, use

of conduit is optional.

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 25

Page 26

Installation Power-Limited Wiring Requirements

TB3

TB4TB1

TB2

LEDs

REF+ R EF– + IN – IN

+ OUT

– IN

+ OUT+ OUT

+ IN

– OUT

SIGNAL 1

SIGNAL 2

BATT+ BATT–

A+

N/O

N/C

COMM

N/O

N/C

COMM

AC FAIL

TROUBLE

1L1 1L2 2L1 2L2 3L1 3L2 4L1 4L2A–

Input Circuits

Power-limited

Specific Application:

Power & SLC are

power-limited

Output Circuits

Power-limited

AC Circuits

Nonpower-limited

Relay Contacts

Nonpower-limited

H

P

F

F

8

1

2

m

n

t

p

w

r

l

i

m

.

w

m

f

Battery connections

Nonpower-limited

Figure 2.16 Power-Limited Wiring Example:

HPFF12(CM)(E) Shown with Single-input Control Module

Input Circuits

Power-limited

Specific Application:

Power & SLC are

power-limited

Output Circuits

Power-limited

AC Circuits

Non-power-limited

Relay Contacts

Nonpower-limited

H

P

F

F

1

2

m

n

t

p

w

r

l

i

m

6

u

p

.

w

m

f

Battery connections

Nonpower-limited

Maintain vertical

separation where

power-limited and

non-power-limited

circuits appear

close together.

Figure 2.17 Power-Limited Wiring Example:

HPFF12(E) Shown with Multi-module

2.5.1 Power-Limited Wiring, Standard Chassis

26 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 27

Power-Limited Wiring Requirements Installation

– +

– +

– + – +

Knockout for

Power-limited wiring

Output circuits and

Auxiliary Output:

Power-limited

Battery connections:

Non-power-limited

Relay Contacts:

Non-power-limited

Knockout for

Non-power-limited

wiring

Knockout for

Power-limited wiring

AC Power:

Non-power-limited

(See Figure 2.19 for

wiring detail.)

Maintain 0.25" in. vertical

separation where

power-limited and

non-power-limited circuits

appear to “cross”

Figure 2.18 Power-Limited Wiring Example: EQBB-D4 with HPFF12CM(E)

Input Circuits:

Power-limited

Output circuits and

Auxiliary Output:

Power-limited

Knockout for

Non-power-limited

wiring

2.5.2 Power-Limited Wiring, FACP Cabinet

HPFF12CM(E) Power-Limited Wiring, EQBB-D4 Backbox

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018 27

Page 28

Installation Power-Limited Wiring Requirements

Ground Stud

TB1 on 24 VDC circuit board

L1

Ground

L2

Ground Stud

Wire Nut

Line Neutral Ground

Ring Terminal

Figure 2.19 Power-Limited Wiring Example: EQBB-D4 AC Wiring (Expanded)

28 HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 29

This section describes the programming options available via DIP switch settings. The HPFF can be field-programmed using DIP switch

Switches 2-7

shown in OFF position

Switch 1

shown in ON position

H

P

F

F

8

1

2

-

s

w

1

.

w

m

f

Figure 3.1 Field-Programming DIP Switches

SW1 on the Control circuit board. Refer to the following illustration for switch location and DIP switch settings for ON and OFF positions.

3.1 DIP Switch Settings

The following table lists the programmable features and the switch settings required to select a particular feature. A detailed description

of each is presented in the following pages.

1 SIG 1/2 “A”

2 SIG 1/2 “A”

3 SIG 3/4 “B”

4 SIG 3/4 “B”

5 SYN SEL “B”

6 SYN SEL “A”

7 AC 2HR OFF - No delay in Trouble reporting with an AC failure.

8 SIG SEL This switch works in conjunction with the initiating device signal input(s) and switches 1 through 6 to

1 OFF, 2 OFF = Pass-through (of Steady On, sync, or coded; DO NOT use with full-wave rectified input).

1 ON, 2 OFF = Temporal.

1 OFF, 2 ON = Sync generator (see switches 5 & 6).

1 ON, 2 ON = Pass-through Filtered (use for full-wave rectified inputs).

3 OFF, 4 OFF = Pass-through (of Steady On, sync, or coded; DO NOT use with full-wave rectified input).

3 ON, 4 OFF = Temporal.

3 OFF, 4 ON = Sync generator (see switches 5 & 6).

3 ON, 4 ON = Pass-through Filtered (use for full-wave rectified inputs).

5 OFF, 6 OFF = Cooper Wheelock

5 ON, 6 OFF = System Sensor

5 OFF, 6 ON = Amseco and Faraday

5 ON, 6 ON = Gentex

ON - 2 hour delay in Trouble reporting with an AC failure.

See Sections 3.2.3 and 3.2.4 for further details of TB2 immediate AC Fail and programmed no delay/delayed

Trouble contacts.

determine General Alarm*, Split Alarm**, or Silencing***.

8 ON = Split Alarm**

8 OFF, Signal Input 1 ON, Signal Input 2 ON = General Alarm* on all four NAC outputs.

8 OFF, Signal Input 1 ON, Signal Input 2 OFF = Silencing*** of all four NAC outputs.

*General Alarm is visual strobe and audible horn activation.

**Split Alarm is Signal Input I controlling NAC outputs 1 and 2, and Signal Input 2 controlling NAC outputs 3

and 4.

***Silencing is visual strobe activation but audible horn is silenced for the initiating device.

Section 3: Programming Options

SW1 DIP Switch

• NAC outputs 1 and 2 are controlled by Signal Input 1.

• NAC outputs 3 and 4 are controlled by Signal Input 2.

Table 3.1 DIP Switch Settings

HPFF12 NAC Expander — P/N 53576:B3 10/1/2018

Page 30

Programming Options Programmable Features

3.2 Programmable Features

3.2.1 Input/Output Functions

DIP switches 1 through 4 are used to determine the input to output functions of the HPFF power supplies. The NAC outputs are programmed in pairs. DIP switches 1 and 2 are used to determine the input to output functions for NAC outputs 1 and 2. DIP switches 3 and

4 are used determine the input to output functions for NAC outputs 3 and 4.

NAC Outputs 1 & 2

DIP Switch 1 DIP Switch 2 Function

OFF OFF Pass-through (of Steady On, sync, or audible coded; DO NOT use with full-wave rectified input).

ON OFF Temporal generator.

OFF ON Sync generator (see Synchronization Type below).

ON ON Pass-through Filtered (use for full-wave rectified inputs).

Table 3.2 Input/Output Configurations for NACs 1 & 2

NAC Outputs 3 & 4

DIP Switch 3 DIP Switch 4 Function

OFF OFF

ON OFF

OFF ON

ON ON

The pass-through feature passes any signal on the initiating device inputs to the NAC outputs. These signal inputs are independent in

pass-through, so visual sync protocol and audible coded signals may be passed simultaneously. The signal types may include steady-on,

march time, temporal or audible coded signals.

The temporal generator feature is used to have the power supply generate a temporal audible code.

The filtered feature is used to provide a steady-on output with full-wave rectified unfiltered input, and can be used to reduce or eliminate

spurious outputs that are caused by noise on the inputs.

Pass-through (of Steady On, sync, or audible coded; DO NOT use with full-wave rectified input).

Temporal generator.

Sync generator (see Synchronization Type below).

Pass-through Filtered (use for full-wave rectified inputs).

Table 3.3 Input/Output Configurations for NACs 3 & 4

3.2.2 Synchronization Type

Synchronization is a feature that controls the activation of notification appliances in such a way that all devices turn on and off at exactly

the same time. Unsynchronized strobe activation can be a potential hazard and can cause confusion. The HPFF power supplies can be

programmed to operate with a variety of manufacturers’ devices.

DIP switches 5 and 6 are used to select the synchronization type when switches 1 & 2 and 3 & 4 are programmed for the power supply to

be a sync generator.

DIP Switch 5 DIP Switch 6 Synchronization Type

OFF OFF

ON OFF

OFF ON

ON ON

Cooper Wheelock devices

System Sensor devices

Amseco and Faraday devices

Gentex devices

Table 3.4 Synchronization Type for DIP Switches 5 and 6

3.2.3 Trouble Reporting Delay with an AC Failure

There are three ways to report trouble of AC loss or brownout. The transfer of TB2's AC FAIL contacts, TB2's TROUBLE contacts, and

the opening of the FACP or initiating device SIGNAL 1’s and SIGNAL 2’s connections on TB3.

Both SIGNAL 1’s and SIGNAL 2’s +IN to +OUT connections are opened to disconnect Class B ELR’s or the positive wire run of Class

A configuration. They remain closed in the alarm state, even if a trouble condition exists, to pass the alarm signal if multiple units are

connected. Therefore, supervised monitoring TB2's AC FAIL and TROUBLE contacts is necessary for UL 864 9th Edition compliance.

• DIP switch 7 set to the ON position will delay the transfer of the TB2's TROUBLE contacts and the opening of connections on TB3

for 2 hours (unless in alarm state), upon an AC loss or brownout.

• DIP switch 7 set to the OFF position will have no delay in the transfer of the TB2's TROUBLE contacts and the opening of ELR

connections on TB3 (unless in alarm state), upon an AC loss or brownout.