Page 1

4

3-Axis Magnetoresistive Sen

sors

and

4

Small Size for

Highly Integrated Products. Just Add a Micro

-

4

Low Cost

4Designed for High Volume, Cost Sensitive OEM Designs

4

4.0 x

4.0 x 1.3mm

Low He

ight Profile

4

Easy to Assemble & Compatible with High Speed SMT Assembly

4

Low Voltage Operations (

2.5

to 3.3V)

4Compatible for Battery Powered Applications

4

Built-In S

trap Drive Circuit

s

4S

et/Reset

and Offset Stra

p Drivers

for Degaussing,

Self Test, and

4

I2C Digital Interface

4Popular Two

-

Wire Serial Data Interface for Consumer Electronics

4Lead Free Package Construction

4Complies with Current Environmental Standards

4

Wide

Magnetic Field Range (+/

-

6 Oe)

4Sensor

s Can Be Used in Strong Magnetic Field Environments

4

Available in Tape & Reel Packaging

4High Volume OEM Assembly

3-Axis Digital Compass IC

HMC5843

The Honeywell HMC5843 is a surface mount multi-chip module designed

for low field magnetic sensing with a digital interface for applications such

as low cost compassing and magnetometry. The HMC5843 includes our

state of the art 1043 series magneto-resistive sensors plus Honeywell

developed ASIC containing amplifi cation, strap drivers, offset cancellation,

12-bit ADC and an I2C serial bus interface. The HMC5843 is in a 4.0 by 4.0

by 1.3mm surface mount leadless chip carrier (LCC). Applications for the

HMC5843 include Consumer Electronics, Auto Navigation Systems,

Personal Navigation Devices, and Magnetometers.

The HMC5843 utilizes Honeywell’s Anisotropic Magnetoresistive (AMR) technology that provides advantages over other

magnetic sensor technologies. The sensors feature precision in-axis sensitivity and linearity, solid-state construction with

very low cross-axis sensitivity designed to measure both direction and magnitude of Earth’s magnetic fields, from tens of

micro-gauss to 6 gauss. Honeywell’s Magnetic Sensors are among the most sensitive and reliable low-field sensors in the

industry.

Honeywell continues to maintain product excellence and performance by introducing innovative solid-state magnetic

sensor solutions. These are highly reliable, top performance products that are delivered when promised. Honeywell’s

magnetic sensor solutions provide real solutions you can count on.

FEATURES BENEFITS

ASIC in a Single Package

LCC Surface Mount Package

Controller Interface, Plus Two External SMT Capacitors

Offset Compensation

Page 2

HMC5843

www.honeywell.com

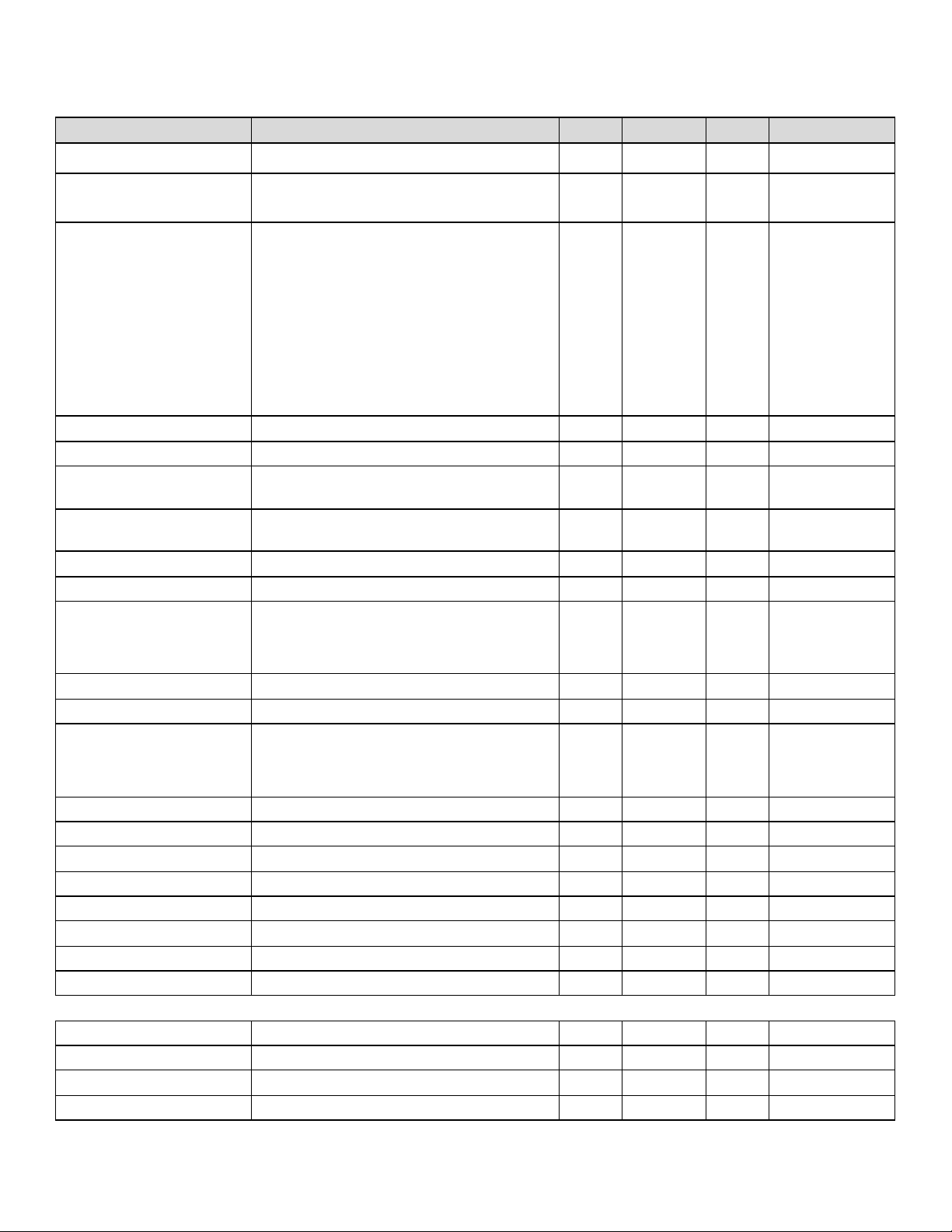

SPECIFICATIONS (* Tested at 25°C except stated otherwise. )

Characteristics Conditions* Min Typ Max Units

Power Supply

Supply Voltage AVDD Referenced to AGND

DVDD Referenced to DGND

Current Draw Sleep Mode (dual supplies)

Idle Mode (dual supplies)

Measurement Mode

AVDD = 2.5 volts, DVDD = 1.8 volts

Sleep Mode (single supply)

Idle Mode (single supply)

Measurement Mode

AVDD = 2.5 volts

Performance

Field Range Full scale (FS) – total applied field -4 +4 gauss

Cross-Axis Sensitivity Cross field = 0.5 gauss,

Happlied = ±3 gauss

Disturbing Field Sensitivity starts to degrade.

Use S/R pulse to restore sensitivity.

Max. Exposed Field No perming effect on zero reading 10000 gauss

Measurement Period Output Rate = 50Hz (10Hz typ.) - 10 msec

I2C Address 7-bit address

8-bit read address

8-bit write address

I2C Rate Controlled by I2C Master -10 +10 %

I2C bus pull-up Internal passive resistors 50 kilo-ohms

I2C Hysteresis Hysteresis of Schmitt trigger inputs on SCL

and SDA - Fall (DVDD=1.8V)

Rise (DVDD=1.8V)

Self Test Positive and Negative Bias Mode ±0.55 gauss

Mag Dynamic Range 3-bit gain control ±0.7 ±1.0 ±4.0 gauss

Linearity Full scale input range 0.1 ±% FS

Gain Tolerance All gain/dynamic range settings ±5 %

Bandwidth -3dB point 10 kHz

Resolution AVDD=3.0V, GN 7 milli-gauss

Signal-to Noise Ratio 70 dB

Turn-on Time 200 us

General

ESD Voltage 700 V

Operating Temperature Ambient -30 85 °C

Storage Temperature Ambient, unbiased -40 125 °C

Weight Nominal 50 milli-grams

2.5

1.6

-

-

-

-

-

-

±0.2% %FS/gauss

20 gauss

0x1E

1.8

2.5

240

0.8

110

340

0.9

0x3D

0x3C

0.603

1.108

3.3

2.0

-

-

-

-

-

-

hex

Volts

Volts

Volts

Volts

uA

uA

mA

uA

uA

mA

hex

hex

2

Page 3

HMC5843

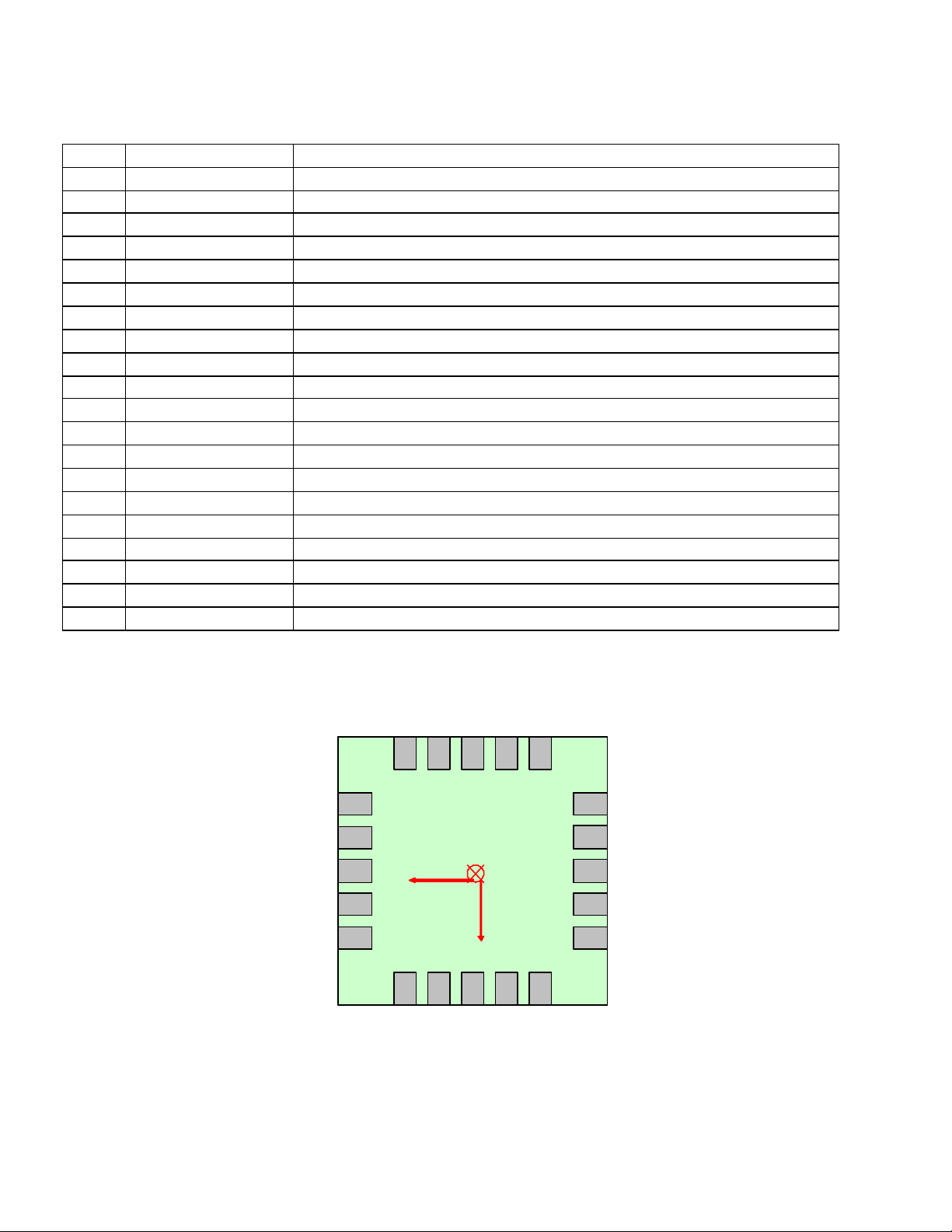

PIN CONFIGURATIONS

(Arrow indicates direction of applied field that generates a positive output voltage after a SET pulse.)

Pin Name Description

1 SCL Serial Clock – I2C Master/Slave Clock

2 SDAP Serial Data Pull-up Resistor – 50k-ohm to VDD

3 SCLP Serial Clock Pull-up Resistor – 50k-ohm to VDD

4 NC No Connection

5 NC No Connection

6 OFFP Offset Strap Positive

7 OFFN Offset Strap Negative

8 NC No Connection

9 SETP Set/Reset Strap Positive – S/R Capacitor (C2) Connection

10 SETN Set/Reset Strap Negative – Test Point

11 SVDD Sensor Supply – Test Point

12 DGND Digital Supply Ground/Return

13 C1 Reservoir Capacitor (C1) Connection

14 SETC S/R Capacitor (C2) Connection – Driver Side

15 DVDD Digital Positive Supply

16 VREN Voltage Regulator Enable, (GND = Dual Supply, AVDD = Single Supply)

17 AGND Analog Supply Ground/Return

18 AVDD Analog Positive Supply

19 DRDY Data Ready – Test Point

20 SDA Serial Data – I2C Master/Slave Data

Table 1: Pin Configurations

20

SDA

20

SDA

DRDY

DRDY

19

19

18

AVDD

18

AVDD

AGND

AGND

17

17

16

VREN

16

VREN

SDAP

SCLP

SDAP

SETC

SETC

SCLP

X

X

C1

C1

TP1

TP1

Z

Z

DGND

DGND

TP0

TP0

1112131415

1112131415

SVDD

SVDD

SCL

SCL

1 2 3 4 5

1 2 3 4 5

Y

Y

DVDD

DVDD

HMC5843 – bottom view

HMC5843 – bottom view

10

10

6

OFFP

6

OFFP

7

OFFN

7

OFFN

8

NC

8

NC

9

SETP

9

SETP

SETN

SETN

www.honeywell.com 3

Page 4

HMC5843

www.honeywell.com

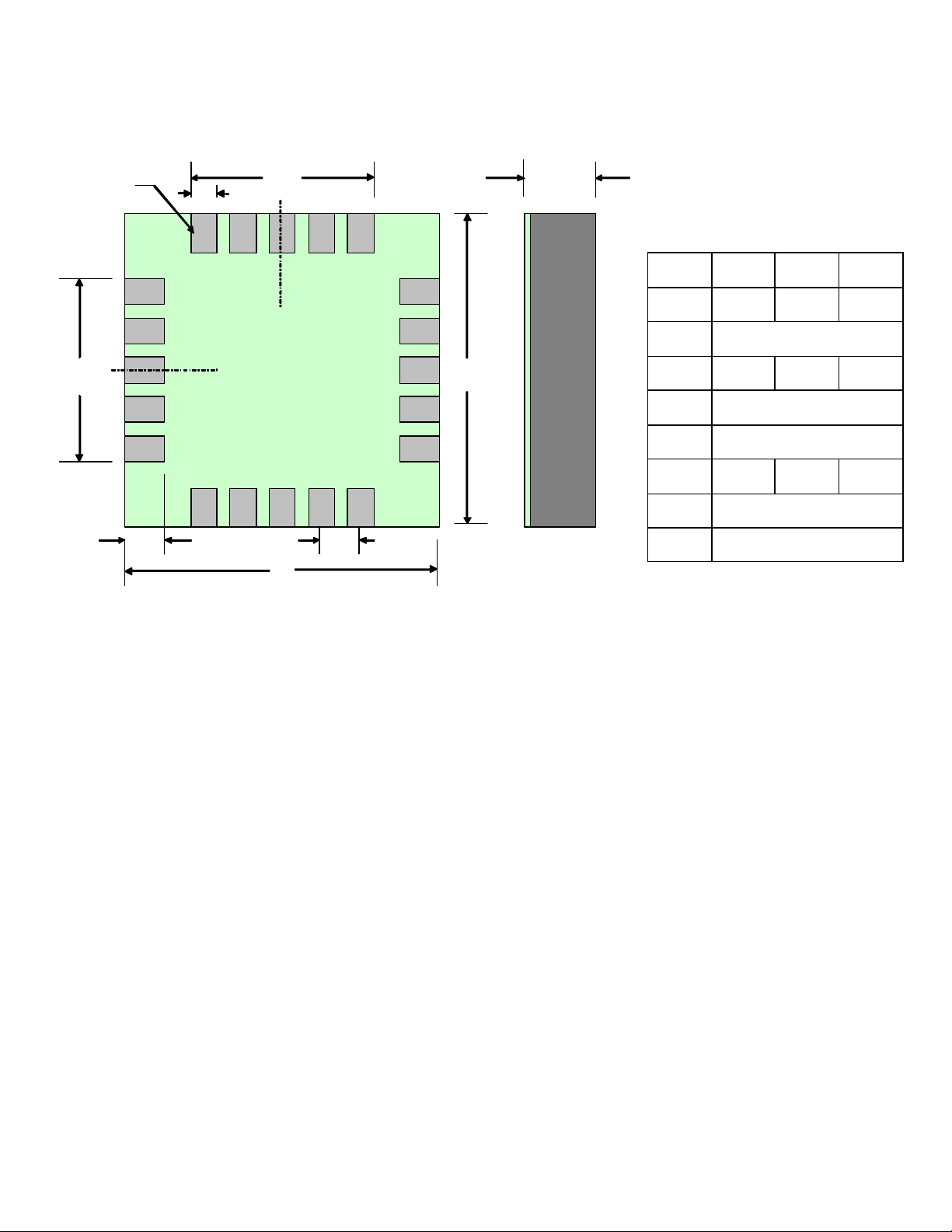

PACKAGE OUTLINES

PACKAGE DRAWING HMC5843 (20-PIN LPCC, dimensions in millimeters)

Pin 1

D2 A

D3

Sym Min Nom Max

A 1.20 - 1.46

D 4.0 BSC

E2

E

L e

D

HMC5843 – bottom view

D2 2.25

D3 0.25 x 20 pins

E 4.0 BSC

E2 2.25

e 0.50 Basic

L 0.40 x 20 pins

MOUNTING CONSIDERATIONS

The following is the recommend printed circuit board (PCB) footprint for the HMC5843.

PCB Pad Definition and Traces

The HMC5843 is a fine pitch LCC package with a 0.50mm pin pitch (spacing), with the pin pads defined as 0. 40mm by

0.25mm in size. PCB pads are recommended to be oversized by 0.025mm from each pad for a short dimension oversize

of 0.05mm. The interior PCB pad is recommended to be 0.05mm oversized per pin with an exterior oversize of 0.20mm

for proper package centering and to permit test probing. Size the traces between the HMC5843 and the external

capacitors (C1 and C2) to handle the 1 ampere peak current pulses with low voltage drop on the traces.

Stencil Design and Solder Paste

A 4 mil stencil and 100% paste coverage is recommended for the electrical contact pads.

Pick and Place

Placement is machine depe ndant and no restrictions are recommended, and have been tested with mechanical centering.

Placement force should be equivalent 1206 SMT resistors and enough force should be used to squeeze the paste out

from the package/contact pad overlap and to keep the package pin contacts vertical.

Reflow and Rework

No special profile is required for the HMC5843 and compatible with lead eutectic and lead-free solder paste reflow

profiles. Honeywell recommends the adherence to solder paste manufacturer’s guidelines. The HMC5843 may be

reworked with soldering irons, but extreme care must be taken not to overheat the copper pads from the part’s fiberglass

substrate. Irons with a tip temperature no greater than 315°C should be used. Excessive rework risks the copper pads

pulling away into the molten solder.

4

Page 5

HMC5843

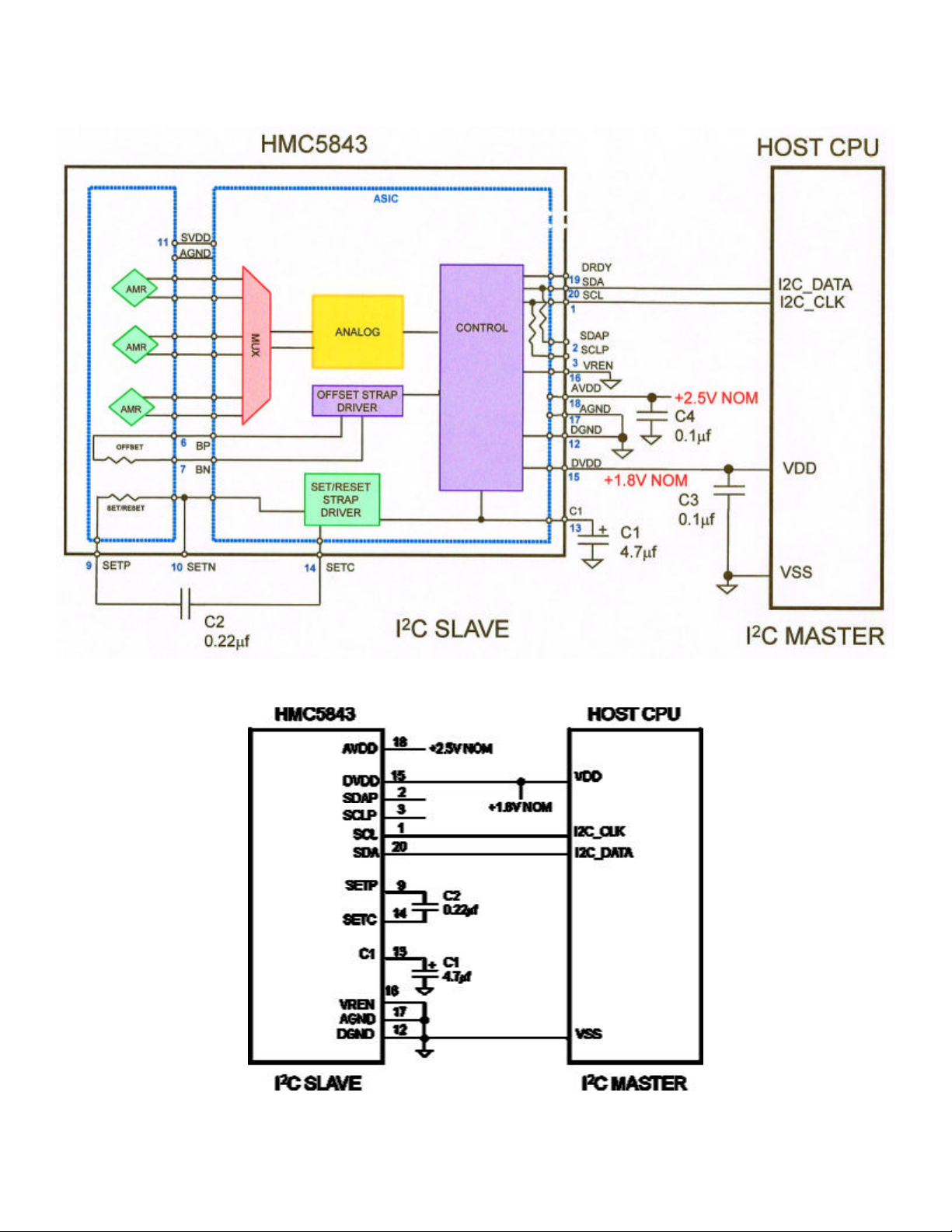

INTERNAL SCHEMATIC DIAGRAM

HMC5843

DUAL SUPPLY REFERENCE DESIGN

www.honeywell.com 5

Page 6

HMC5843

www.honeywell.com

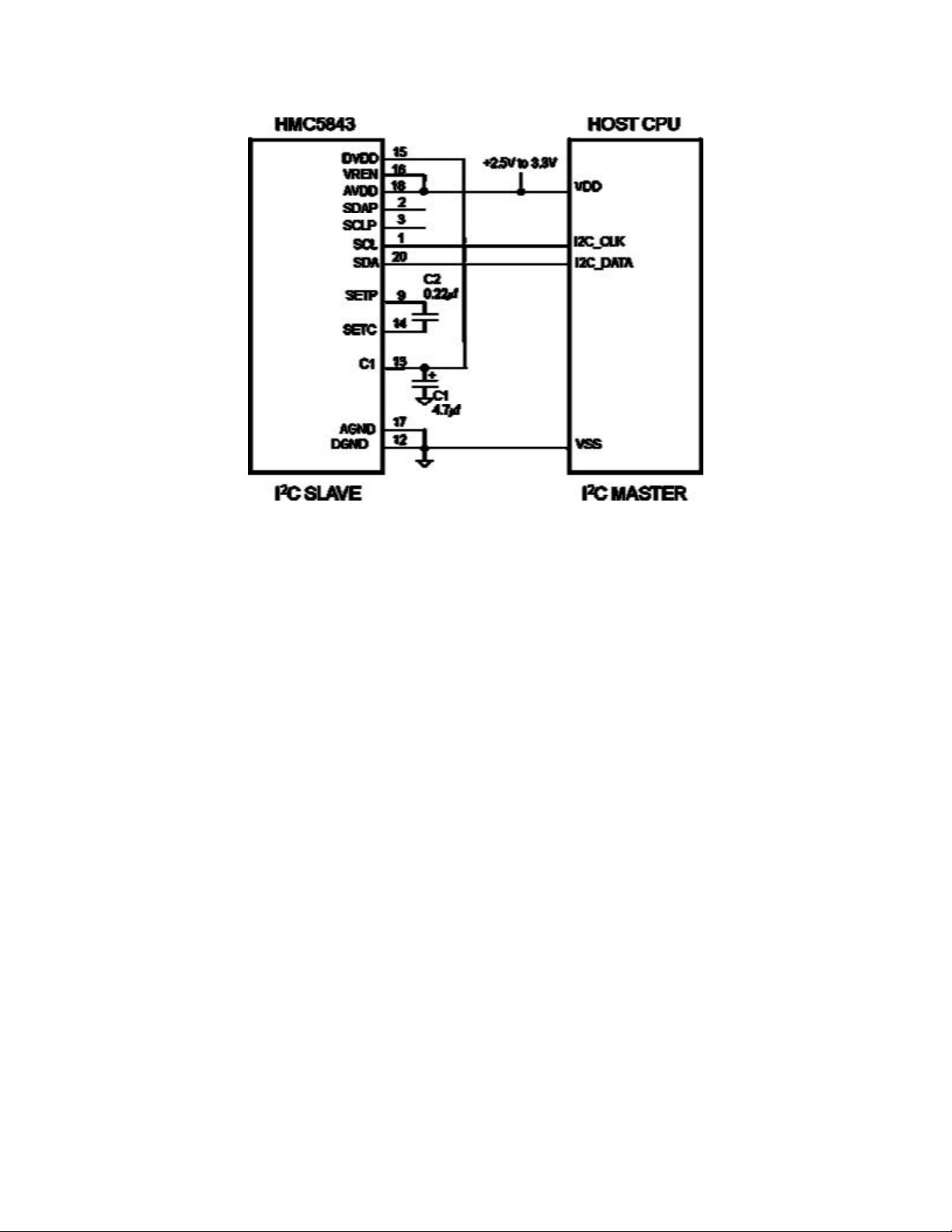

SINGLE SUPPLY REFERENCE DESIGN

BASIC DEVICE OPERATION

Anisotropic Magneto-Resistive Sensors

The Honeywell HMC5843 magnetoresistive sensor circuit is a trio of sensors and application specific support circuits to

measure magnetic fields. With power supply applied, the sensor converts any incident magnetic field in the sensitive axis

directions to a differential voltage output. The magnetoresistive sensors are made of a nickel-iron (Permalloy) thin -film and

patterned as a resistive strip element. In the presence of a magnetic field, a change in the bridge resistive elements

causes a corresponding change in voltage across the bridge outputs.

These resistive elements are aligned together to have a common sensitive axis (indicated by arrows on the pinouts) that

will provide positive voltage change with magnetic fields increasing in the sensitive direction. Because the output only is in

proportion to the one -dimensional axis (the principle of anisotropy) and its magnitude, additional sensor bridges placed at

orthogonal directions permit accurate measurement of arbitrary field direction.

Self Test

An offset strap is designed for self test function. The offset strap measures nominally 13 ohms, and requires 10mA for

each gauss of induced field. The straps will easily handle currents to buck or boost fields through the ±4 gauss linear

measurement range, but designers should note the extreme thermal heating on the sensor die when doing so.

6

Page 7

HMC5843

DVDD

AVDD

Pin

Modes

Description

High High AGND

All, except

Internal voltage regulator: Disabled.

High Low AGND

Idle Internal voltage regulator: Disabled.

Internally

High AVDD

All, except

Internal voltage regulator: Enabled

Low Low -- Off Device in off mode.

Power Management

This device is capable of operating with a single supply (AVDD) or dual supplies (AVDD and DVDD). Pin VREN makes

this selection by enabling the internal digital supply voltage regulator. When VREN is tied to AVDD, the device is in single

supply operation; this device is powered from AVDD; and the internal voltage regulator is enabled. When VREN is tied

to AGND this devices operates with both AVDD and DVDD as supplies. The table below shows the modes available at

the various power supply conditions.

VREN

Supported

Off

regulated

Table 2: Operational Modes and Supply States

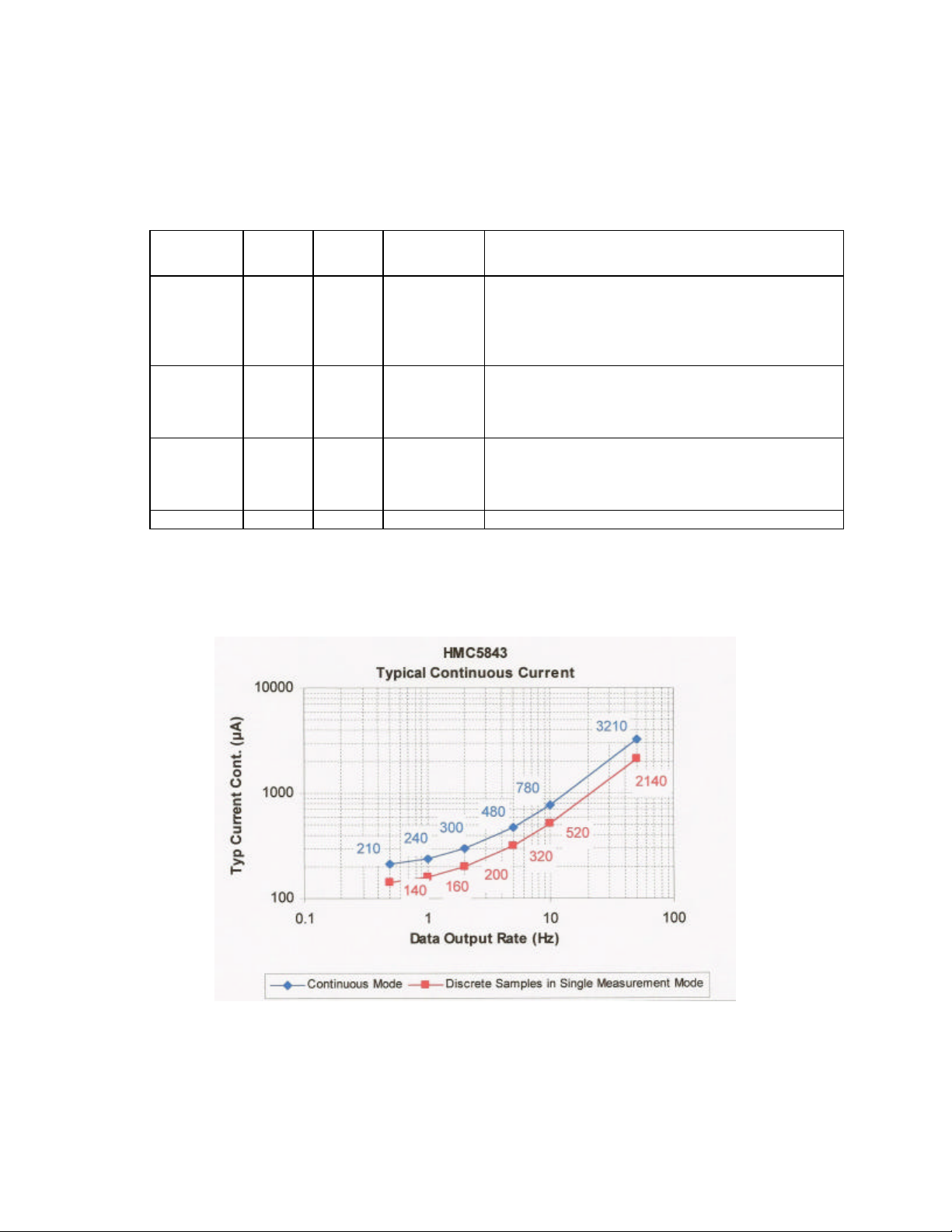

Note the continuous current draw versus data update rate in micro-amperes shown in the graph below. Under 10Hz, the

current stays below 1mA.

Off

Digital I/O pins: Range from DGND to DVDD.

Device fully functional. Digital logic blocks are

powered from DVDD supply, including all onboard clocks.

Digital I/O pins: Range from DGND to DVDD.

Device Measurement functionality not supported.

Device I2C bus and register access supported.

Digital I/O pins: Range from AGND to AVDD

Device fully functional. Digital logic blocks are

powered through on-board regulator.

www.honeywell.com 7

Page 8

HMC5843

www.honeywell.com

Voltage Regulator

This ASIC has an internal voltage regulator which, depending on the application needs, may be used instead of supplying

voltage to pin DVDD. If DVDD pin is used, the internal voltage regulator is not engaged. When both supplies are used,

DVDD is typically high before AVDD, but no latch-up conditions will exist if DVDD is brought high after AVDD.

Power on Reset

Power on reset (POR) circuit shall return the device to the power -on default state. All registers shall be returned to their

default values. Circuitry shall return to it default state, such as, but not limited to: MUX channel, ADC state machine, an d

bias current.

I2C Interface

Control of this device is carried out via the I2C bus. This device will be connected to this bus as a slave device under the

control of a master device, such as the processor.

This device shall be compliant with I2C-Bus Specification, document number: 9398 393 40011. As an I2C compatible

device, this device has a 7-bit serial address and supports I2C protocols. This device shall support standard and fast

modes, 100kHz and 400kHz respectively, but cannot support the high speed mode (Hs). External pull-up resistors are

required to support these standard and fast speed modes. Depending on the application, the internal pull-ups may be

used to support slower data speeds than specified by I2C standards. This device does not contain 50nsec spike

suppression as required by fast mode operation in the I2C-Bus Specification, “Table 4 Characteristics of the SDA and

SCL I/O stages for F/S-mode I2C-bus devices”.

Activities required by the master (register read and write) have priority over internal activities, such as the measurement.

The purpose of this priority is to not keep the master waiting and the I2C bus engaged for longer than necessary .

I2C Pull-up Resistors

Pull-up resistors are placed on the two I2C bus lines. Typically these resistors are off-chip, but, to conserve board space

in specific low clock speed applications, they are internal to this device.

Internal Clock

The device has an internal clock for internal digital logic functions and timing management.

H-Bridge for Set/Reset Strap Drive

The ASIC contains large switching FETs capable of delivering a large but brief pulse to the Set / Reset strap of the

sensor. This strap is largely a resistive load.

8

Page 9

HMC5843

Charge Current Limit

The current that reservoir capacitor (C1) can draw when charging is limited. When using dual supplies this device shall

limit the current drawn from DVDD source to charge this capacitor. When only a single supply is used, Pin DVDD is

externally tied to pin C1. In this configuration, current is still limited. For example, the internal voltage regulator will limit

this current draw.

Bias Current Generator

The bias current generator is used to apply a bias current to the offset strap of the magneto-resistive sensor, which

creates an artificial magnetic field bias on the sensor. This function is enabled and the polarity is set by bits MS[n] in the

configuration register. The bias current generator generates dc current supplied from the AVDD supply.

MODES OF OPERATION

This device has several modes whose primary purpose is power management. This section describes these modes.

Continuous-Measurement Mode

During continuous -measurement mode, the device continuously makes measurements and places measured data in data

output registers. Settings in the configuration register affect the data output rate (bits DO[n]), the measurement

configuration (bits MS[n]), and the gain (bits GN[n]) when in continuous-measurement mode. To conserve current

between measurements, the device is placed in a state similar to idle mode, but the mode is not changed to idle mode.

That is, MD[n] bits are unchanged. Data can be re-read from the data output registers if necessary; however, if the

master does not ensure that the data register is accessed before the completion of the next measurement, the new

measurement may be lost. All registers maintain values while in continuous -measurement mode. The I2C bus is enabled

for use by other devices on the network in while continuous -measurement mode.

Single-Measurement Mode

This is the default single supply power-up mode. In dual supply configuration this is the default mode when AVDD goes

high. During single-measurement mode, the device makes a single measurement and places the measured data in data

output registers. Settings in the configuration register affect the measurement configuration (bits MS[n]), and the gain

(bits GN[n]) when in single-measurement mode. After the measurement is complete and output data registers are

updated, the device is placed sleep mode, and the mode register is changed to sleep mode by setting MD[n] bits. All

registers maintain values while in single -measurement mode. The I2C bus is enabled for use by other devices on the

network while in single -measurement mode.

Idle Mode

During this mode the device is accessible through the I2C bus, but major sources of power consumption are disabled,

such as, but not limited to, the ADC, the amplifier, the SVDD pin, and the sensor bias current. All registers maintain

values while in idle mode. The I2C bus is enabled for use by other devices on the network while in idle mode.

Sleep Mode

This is the default dual supply power-up mode when only DVDD goes high and AVDD remains low. During sleep mode

the device functionality is limited to listening to the I2C bus. The internal clock is not running and register values are not

maintained whil e in sleep mode. The only functionality that exists during this mode is the device is able to recognize and

execute any instructions specific to this device but does not change from sleep mode due to other traffic on the I2C bus.

The I2C bus is enabled for use by other devices on the network while in sleep mode. This mode has two practical

differences from idle mode. First this state will create less noise on system since the clock is disabled, and secondly this

state is a lower current consuming state since the clock is disabled.

Off Mode

During off mode device is off. No device functionality exists. Both AVDD and DVDD are low. The I2C bus is enabled for

use by other devices on the network in off mode. In this mode the I2C pins shall be in a high impedance state.

www.honeywell.com 9

Page 10

HMC5843

www.honeywell.com

01 Configuration Register B

Read/Write

03 D

ata Output X MSB Register

Read

06 Data Output Y LSB Register

Read

08 Data Output Z LSB Register

Read

11 Identification Register B

Read

REGISTERS

This device is controlled and configured via a number of on-chip registers, which are described in this section. In the

following descriptions, set implies a logic 1, and reset or clear implies a logic 0, unless stated otherwise.

Register List

The table below lists the registers and their access. All address locations are 8 bits.

Address Location Name Access

00 Configuration Register A Read/Write

02 Mode Register Read/Write

04 Data Output X LSB Register Read

05 Data Output Y MSB Register Read

07 Data Output Z MSB Register Read

09 Status Register Read

10 Identification Register A Read

12 Identification Register C Read

Table 5: Register List

Register Access

This section describes the process of reading from and writing to this device. The devices uses an address pointer to

indicate which register location is to be read from or written to. These pointer locations are sent from the master to this

slave device and succeed the 7-bit address plus 1 bit read/write identifier.

To minimize the communication between the master and this device, the address pointer updated automatically without

master intervention. This automatic address pointer update has two additional features. First when address 12 or higher

is accessed the pointer updates to address 00 and secondly when address 09 is reached, the pointer rolls back to

address 03. Logically, the address pointer operation functions as shown below.

If (address pointer = 09) then address pointer = 03

Else if (address pointer >= 12) then address pointer = 0

Else (address pointer) = (address pointer) + 1

The address pointer value itself cannot be read via the I2C bus.

Any attempt to read an invalid address location returns 0’s, and any write to an invalid address location or an undefined bit

within a valid address location is ignored by this device.

10

Page 11

HMC5843

0 1 1 5 1 0 0 10 (default)

Configuration Register A

The configuration register is used to configure the device for setting the data output rate and measurement configuration.

CRA0 through CRA7 indicate bit locations, with CRA denoting the bits that are in the configuration register. CRA7 denotes

the first bit of the data stream. The number in parenthesis indicates the default value of that bit.

CRA7 CRA6 CRA5 CRA4 CRA3 CRA2 CRA1 CRA0

(0) (0) (0) DO2 (1) DO1 (0) DO0 (0) MS1 (0) MS0 (0)

Table 6: Configuration Register A

Location Name Description

CRA7 to CRA5 0 These bits must be cleared for correct operation.

CRA4 to CRA2 DO2 to DO0

CRA1 to CRA0 MS1 to MS0

Table 7: Configuration Register A Bit Designations

The Table below shows minimum output data rates given PVT conditions. All three channels shall be measured within a

given data rate.

Data Output Rate Bits. These bits set the rate at which

data is written to all three data output registers.

Measurement Configuration Bits. These bits define the

measurement flow of the device, specifically whether or

not to incorporate an applied bias to the sensor into the

measurement.

DO2 DO1 DO0 Minimum Data Output Rate (Hz)

0 0 0 0.5

0 0 1 1

0 1 0 2

1 0 1 20

1 1 0 50

1 1 1 Not used

Table 8: Data Output Rates

MS1 MS0 Mode

Normal measurement configuration (default). In normal measurement

0 0

0 1

1 0

configuration the device follows normal measurement flow. Pins BP and BN

are left floating and high impedance.

Positive bias configuration. In positive bias configuration, a positive current

is forced across the resistive load on pins BP and BN.

Negative bias configuration. In negative bias configuration, a negative

current is forced across the resistive load on pins BP and BN.

1 1 This configuration is not used.

www.honeywell.com 11

Table 9: Measurement Modes

Page 12

HMC5843

www.honeywell.com

Configuration Register B

The configuration register B for setting the device gain. CRB0 through CRB7 indicate bit locations, with CRB denoting the

bits that are in the configuration register. CRB7 denotes the first bit of the data stream. The number in parenthesis

indicates the default value of that bit.

CRB7 CRB6 CRB5 CRB4 CRB3 CRB2 CRB1 CRB0

GN2 (0) GN1 (0) GN0 (1) (0) (0) (0) (0) (0)

Table 10: Configuration B Register

Location Name Description

Gain Configuration Bits. These bits configure the gain for

CRB7 to CRB5 GN2 to GN0

CRB4 to CRB0 0 This bit must be cleared for correct operation.

Table 11: Configuration Register B Bit Designations

the device. The gain configuration is common for all

channels.

The table below shows nominal gain settings.

GN2 GN1 GN0

0 0 0 ±0.7Ga 1620

0 0 1 ±1.0Ga (default) 1300

0 1 0 ±1.5Ga 970

0 1 1 ±2.0Ga 780

1 0 0 ±3.2Ga 530

1 0 1 ±3.8Ga 460

1 1 0 ±4.5Ga 390

1 1 1

Sensor Input Field

Range:

±6.5Ga

(Not Recommended)

Gain

(counts/

milli-gauss)

280

Output Range

0xF800–0x07FF

(-2048–2047 )

0xF800–0x07FF

(-2048–2047 )

0xF800–0x07FF

(-2048–2047 )

0xF800–0x07FF

(-2048–2047 )

0xF800–0x07FF

(-2048–2047 )

0xF800–0x07FF

(-2048–2047 )

0xF800–0x07FF

(-2048–2047 )

0xF800–0x07FF

(-2048–2047 )

Table 12: Gain Settings

12

Page 13

HMC5843

The resolution of the HMC5843 is based on the gain selection (zero to 7) and the influence of the analog power supply rail

(AVDD). The following graph shows the interaction.

Mode Register

The mode register is an 8-bit register from which data can be read or to which data can be written. This register is used to

select the operating mode of the device. MR0 through MR7 indicate bit locations, with MR denoting the bits that are in the

mode register. MR7 denotes the first bit of the data stream. The number in parenthesis indicates the default value of that

bit.

12

10

8

6

4

Resolution (mGa )

2

HMC5843 Resolution

Gain

0

1

2

3

4

5

6

7

3.23.02.82.62.4

AVDD (V)

MR7 MR6 MR5 MR4 MR3 MR2 MR1 MR0

(0) (0) (0) (0) (0) (0) MD1 (1) MD0 (0)

Table 14: Mode Register

Location Name Description

MR7 to

MR2

MR1 to

MR0

0 These bits must be cleared for correct operation.

MD1 to

MD0

Mode Select Bits. These bits select the operation mode of

this device.

Table 15: Mode Register Bit Designations

www.honeywell.com 13

Page 14

HMC5843

www.honeywell.com

Continuous

-

Conversion Mode. In continuous

-

conversion mode, the

Single

-

Conversion Mode. When

single

-

conversion mode is selected,

MD1 MD0 Mode

device continuously performs conversions an places the result in the

data register. RDY goes high when new data is placed in all three

0 0

0 1

1 0 Idle Mode. Device is placed in idle mode.

1 1 Sleep Mode. Device is placed in sleep mode.

Data Output X Registers A and B

The data output X registers are two 8-bit registers, data output register A and data output register B. These registers

store the measurement result from channel X. Data output X register A contains the MSB from the measurement result,

and data output X register B contains the LSB from the measurement result. The value stored in these two registers is a

16-bit value in 2’s complement form, whose range is 0xF800 to 0x07FF. DXRA0 through DXRA7 and DXRB0 through

DXRB7 indicate bit locations, with DXRA and DXRB denoting the bits that are in the data output X registers. DXRA7 and

DXRB7 denote the first bit of the data stream. The number in parenthesis indicates the default value of that bit.

In the event the ADC reading overflows or underflows for the given channel, or if there is a math overflow during the bias

measurement, this data register will contain the value -4096 in 2’s complement form. This register value will clear when

after the next valid measurement is made.

registers. After a power-on or a write to the mode or configuration

register, the first measurement set is available from all three data

output registers after a period of 2/fDO and subsequent

measurements are available at a frequency of fDO, where fDO is the

frequency of data output.

device performs a single measurement, sets RDY high and returned

to sleep mode. Mode register returns to sleep mode bit values. The

measurement remains in the data output register and RDY remains

high until the data output register is read or another conversion is

performed.

Table 16: Operating Modes

DXRA7 DXRA6 DXRA5 DXRA4 DXRA3 DXRA2 DXRA1 DXRA0

(0) (0) (0) (0) (0) (0) (0) (0)

DXRB7 DXRB6 DXRB5 DXRB4 DXRB3 DXRB2 DXRB1 DXRB0

(0) (0) (0) (0) (0) (0) (0) (0)

Table 17: Data Output X Registers A and B

Data Output Y Registers A and B

The data output Y registers are two 8-bit registers, data output register A and data output register B. These registers

store the measurement result from channel Y. Data output Y register A contains the MSB from the measurement result,

and data output Y register B contains the LSB from the measurement result. The value stored in these two registers is a

16-bit value in 2’s complement form, whose range is 0xF800 to 0x07FF. DYRA0 through DYRA7 and DYRB0 through

DYRB7 indicate bit locations, with DYRA and DYRB denoting the bits that are in the data output Y registers. DYRA7 and

DYRB7 denote the first bit of the data stream. The number in parenthesis indicates the default value of that bit.

In the event the ADC reading overflows or underflows for the given channel, or if there is a math overflow during the bias

measurement, this data register will contain the value -4096 in 2’s complement form. This register value will clear when

after the next valid measurement is made.

14

Page 15

HMC5843

DYRA7 DYRA6 DYRA5 DYRA4 DYRA3 DYRA2 DYRA1 DYRA0

(0) (0) (0) (0) (0) (0) (0) (0)

DYRB7 DYRB6 DYRB5 DYRB4 DYRB3 DYRB2 DYRB1 DYRB0

(0) (0) (0) (0) (0) (0) (0) (0)

Table 18: Data Output Y Registers A and B

Data Output Z Registers A and B

The data output Z registers are two 8-bit registers, data output register A and data output register B. These registers

store the measurement result from channel Z. Data output Z register A contains the MSB from the measurement result,

and data output Z register B contains the LSB from the measurement result. The value stored in these two registers is a

16-bit value in 2’s complement form, whose range is 0xF800 to 0x07FF. DZRA0 through DZRA7 and DZRB0 through

DZRB7 indicate bit locations, with DZRA and DZRB denoting the bits that are in the data output Z registers. DZRA7 and

DZRB7 denote the first bit of the data stream. The number in parenthesis indicates the default value of that bit.

In the event the ADC reading overflows or underflows for the given channel, or if there is a math overflow during the bias

measurement, this data register will contain the value -4096 in 2’s complement form. This register value will clear when

after the next valid measurement is made.

DZRA7 DZRA6 DZRA5 DZRA4 DZRA3 DZRA2 DZRA1 DZRA0

(0) (0) (0) (0) (0) (0) (0) (0)

DZRB7 DZRB6 DZRB5 DZRB4 DZRB3 DZRB2 DZRB1 DZRB0

(0) (0) (0) (0) (0) (0) (0) (0)

Table 19: Data Output Z Registers A and B

Data Output Register Operation

When one or more of the output registers are read, new data cannot be placed in any of the output data registers until all

six data output registers are read. This requirement also impacts DRDY and RDY, which cannot be cleared until new

data is placed in all the output registers.

Status Register

The status register is an 8-bit read-only register. This register is used to indicate device status. SR0 through SR7

indicate bit locations, with SR denoting the bits that are in the status register. SR7 denotes the first bit of the data stream.

SR7 SR6 SR5 SR4 SR3 SR2 SR1 SR0

(0) (0) (0) (0) (0) REN (0) LOCK (0) RDY(0)

Table 20: Status Register

www.honeywell.com 15

Page 16

HMC5843

www.honeywell.com

Ready Bit. Set when data is written to all six data registers.

Location Name Description

SR7 to

SR3

SR2 REN

SR1 LOCK

SR0 RDY

Identification Register A

The identification register A is used to identify the device. IRA0 through IRA7 indicate bit locations, with IRA denoting the

bits that are in the identification register A. IRA7 denotes the first bit of the data stream. The number in parenthesis

indicates the default value of that bit.

The identification value for this device is stored in this register. This is a read-only register.

Register values. ASCII value H

0 These bits must be cleared for correct operation.

Regulator Enabled Bit. This bit is set when the internal

voltage regulator is enabled. This bit is cleared when the

internal regulator is disabled.

Data output register lock. This bit is set when this some but

not all for of the six data output registers have been read.

When this bit is set, the six data output registers are locked

and any new data will not be placed in these register until

on of four conditions are met : one, all six have been read

or the mode changed, two, a POR is issued, three, the

mode is changed, or four, the measurement is changed.

Cleared when device initiates a write to the data output

registers, when in off mode, and after one or more of the

data output registers are written to. When RDY bit is clear

it shall remain cleared for a minimum of 5 µs. DRDY pin

can be used as an alternative to the status register for

monitoring the device for conversion data.

Table 21: Status Register Bit Designations

IRA7 IRA6 IRA5 IRA4 IRA3 IRA2 IRA1 IRA0

0 1 0 0 1 0 0 0

Table 22: Identification Register A Default Values

16

Page 17

HMC5843

Identification Register B

The identification register B is used to identify the device. IRB0 through IRB7 indicate bit locations, with IRB denoting the

bits that are in the identification register A. IRB7 denotes the first bit of the data stream.

Register values. ASCII value 4

Identification Register C

The identification register C is used to identify the device. IRC0 through IRC7 indicate bit locations, with IRC denoting the

bits that are in the identification register A. IRC7 denotes the first bit of the data stream.

Register values. ASCII value 3

IRB7 IRB6 IRB5 IRB4 IRB3 IRB2 IRB1 IRB0

0 0 1 1 0 1 0 0

Table 23: Identification Register B Default Values

IRC7 IRC6 IRC5 IRC4 IRC3 IRC2 IRC1 IRC0

0 0 1 1 0 0 1 1

Table 24: Identification Register C Default Values

www.honeywell.com 17

Page 18

HMC5843

www.honeywell.com

I2C COMMUNICATION PROTOCOL

The HMC5843 communicates via a two -wire I2C bus system as a slave device. The HMC5843 uses a simple protocol

with the interface protocol defined by the I2C bus specification, and by this document . The data rate is at the standard mode 100kbps or 400kbps rates as defined in the I2C Bus Specifications. The bus bit format is an 8-bit Data/Address

send and a 1-bit acknowledge bit. The format of the data bytes (payload) shall be case sensitive ASCII characters or

binary data to the HMC5843 slave, and binary data returned. Negative binary values will be in two’s complement form.

The default (factory) HMC5843 7-bit slave address is 0x3C for write operations, or 0x3D for read operations.

The HMC5843 Serial Clock (SCL) and Serial Data (SDA) lines have optional internal pull-up resistors, but require resistive

pull-ups (Rp) between the master device (usually a host microprocessor) and the HMC5843. Pull-up resistance values of

about 10k ohms are recommended with a nominal 1.8-volt digital supply voltage (DVDD). Other values may be used as

defined in the I2C Bus Specifications or with the internal 50k ohm pull-up resistors (SDAP, SCLP) that can be tied to

DVDD.

The SCL and SDA lines in this bus specification can be connected to a host of devices. The bus can be a single master to

multiple slaves, or it can be a multiple master configuration. All data transfers are initiated by the master device which is

responsible for generating the clock signal, and the data transfers are 8 bit long. All devices are addressed by I2C’s

unique 7 bit address. After each 8-bit transfer, the master device generates a 9 th clock pulse, and releases the SDA line.

The receiving device (addressed slave) will pull the SDA line low to acknowledge (ACK) the successful transfer or leave

the SDA high to negative acknowledge (NACK).

Per the I2C spec, all transitions in the SDA line must occur when SCL is low. This requirement leads to two unique

conditions on the bus associated with the SDA transitions when SCL is high. Master device pulling the SDA line low while

the SCL line is high indicates the Start (S) condition, and the Stop (P) condition is when the SDA line is pulled high while

the SCL line is high. The I2C protocol also allows for the Restart condition in which the master device issues a second

start condition without issuing a stop.

All bus transactions begin with the master device issuing the start sequence followed by the slave address byte. The

address byte contains the slave address; the upper 7 bits (bits7-1), and the Least Significant bit (LSb). The LSb of the

address byte designates if the operation is a read (LSb=1) or a write (LSb=0). At the 9 th clock pulse, the receiving slave

device will issue the ACK (or NACK). Following these bus events, the master will send data bytes for a write operation, or

the slave will clock out data with a read operation. All bus transactions are terminated with the master issuing a stop

sequence.

I2C bus control can be implemented with either hardware logic or in software. Typical hardware designs will release the

SDA and SCL lines as appropriate to allow the slave device to manipulate these lines. In a software implementation, care

must be taken to perform these tasks in code.

OPERATIONAL EXAMPLES

The HMC5843 has a fairly quick stabilization time from no voltage to stable and ready for data retrieval. The nominal 5

milli-seconds with the factory default single measurement mode means that the six Bytes of magnetic data registers

(DXRA, DXRB, DYRA, DYRB, DZRA, and DZRB) are filled with a valid first measurement.

To change the measurement mode to continuous measurement mode, after the 5 milli -second power-up time send the

three bytes:

0x3C 0x02 0x00

This writes the 00 into the second register or mode register to switch from single to continuous measurement mode

setting. With the data rate at the factory default of 10Hz updates (100 milli -seconds interval), a 100 milli-second delay

should be made by the I2C master before querying the HMC5843 data registers for new measurements. To clock out the

new data, send:

0x3D, and clock out DXRA, DXRB, DYRA, DYRB, DZRA, DZRB located in registers 3 through 8. The HMC5843 will

automatically re -point back to register 3 for the next 0x3D query, expected 100 milli-seconds or later.

18

Page 19

HMC5843

Ordering Number

Product

Honeywell

Form #900367

©2009

Honeywell International Inc.

SELF TEST OPERATION

To check the HMC5843 for proper operation, a self test feature in incorporated in which the sensor offset straps are

excited to create a nominal field strength (bias field) to be measured. To implement this self test, the least significant bits

(MS1 and MS0) of configuration register A are changed from 00 to 01 (0x12 or 0b000xxx01). By placing the mode register

into single-conversion mode (0x01), two data acquisition cycles will be made on each magnetic vector. The first

acquisition will be a set pulse followed shortly by measurement data of the external field. The second acquisition will have

the offset strap excited in the positive bias mode (~5.5mA in offset straps) to create about a 0.55 gauss self test field plus

the external field. The first acquisition values will be subtracted from the second acquisition, and the net measurement will

be placed into the data output registers.

If the configuration register B is left at the factory default value of 0x20, values around +715 ADC counts (0.55Ga * 1300

counts/Ga) will be placed in the data output registers. To leave the self test mode, change MS1 and MS0 bit of the

configuration register A back to 0x 00. Also change the mode register if single-conversion mode is not the intended next

mode of operation.

SCALE FACTOR CALIBRATION

Using the method described above in section SELF TEST OPERATION, user can scale sensors’ sensitivity to match each

other. Since placing device in positive bias mode (or alternatively negative bias mode) applies the same artificial field on

all three axis, the resulting ADC measurement in data output registers can be used to scale the sensors.

EXTERNAL CAPACITORS

The two external capacitors should be ceramic type construction with low ESR characteristics. Reservoir capacitor C1 is

nominally 4.7 micro-farads in capacitance, with the set/reset capacitor C2 nominally 0.22 micro-farads in capacitance.

Low ESR characteristics may not be in many smallest size SMT ceramic capacitors (0402), so be prepared to up-size the

capacitors to gain Low ESR characteristics.

ORDERING INFORMATION

HMC5843

HMC5843-TR

HMC5843-demo

HMC5843-eval

3-Axis Digital Compass IC

Tape and Reel 2.5k pieces/reel

Demonstration Kit

Evaluation Board

FIND OUT MORE

For more information on Honeywell’s Magnetic Sensors visit us online at www.honeywell.com/magneticsensors or contact

us at 800-323-8295 (763 -954-2474 internationally).

The application circuits herein constitute typical usage and interface of Honeywell product. Honeywell does not warranty or assume liability of customerdesigned circuits derived from this description or depiction.

Honeywell reserves the right to make changes to improve reliability, function or design. Honeywell does not assume any liability arising out of the

application or use of any product or circuit described herein; neither does it convey any license under its patent rights nor the rights of others.

U.S. Patents 4,441,072, 4,533,872, 4,569,742, 4,681,812, 4,847,584 and 6,529,114 apply to the technology described

12001 Highway 55

Plymouth, MN 55441

Tel: 800-323-8295

www.honeywell.com 19

www.honeywell.com/magneticsensors

February 2009

Page 20

New Products Announcement

New Evaluation & Demonstration Products

Now Available From Honeywell

Effective Tools to Assist Integrating

Honeywell’s Magnetic Sensor Technology

Honeywell has recently added a new line of evaluation and demonstration boards to the magnetic sensor family. These

new products allow engineers to evaluate the products in a pin-out configuration as well as provide necessary

application information such as product schematics. The new products include:

• HMC1042L 2-axis + HMC1041Z 1-axis Demonstration Board

This demonstration board for the 2-axis HMC1042L and 1-axis HMC1041Z provides the sensors

to create 3-axis magnetic sensing prototype with support analog circuitry for earth's magnetic

field detection. Along with the magnetoresistive sensors, three difference amplifier circuits, and

a MOSFET-based set/reset strap driver circuit are included on a 1" by 1" printed circuit board

with two rows of 0.1" spaced pins for solder-less prototyping usage. The difference amplifiers

are set up for high gains with a +/-1 gauss dynamic range. The magnetic XYZ vector outputs are

analog voltages with respect to rail-splitter voltage reference. The set/reset input is 3 volt CMOS

logic levels. Included with this demo are 3 HMC1041Z & 3 HMC1042L samples.

• HMC1043 3-axis Demonstration Board

This demonstration board for the 3-axis HMC1043 provides the sensors to create 3-axis

magnetic sensing prototypes with support analog circuitry for earth's magnetic field detection.

Along with the magnetoresistive sensors, three difference amplifier circuits, and a MOSFETbased set/reset strap driver circuit are included on a 1" by 1" printed circuit board with two

rows of 0.1" spaced pins for solder-less prototyping usage. The difference amplifiers are set up

for high gains with a +/ -1 gauss dynamic range. The magnetic XYZ vector outputs are analog

voltages with respect to rail -splitter voltage reference. The set/reset input is 3 volt CMOS logic

levels. Included with this demo are 3 HMC1043 samples.

• HMC5843 3-axis Compass IC Evaluation Board

The HMC5843 evaluation board for the Compass IC contains the HMC5843 atop a 0.8" by 0.8"

plug-board with wide-DIP spaced (0.6") pins for solder less breadboard compatibility. The

evaluation board also contains the two capacitors and I2C pullup resistors needed for typical

function for the retrieval of the XYZ magnetic field information. Both single and dual supply

configurations of the HMC5843 are supported.

• HMC5843 3-axis Compass IC Demonstration Board

The demonstration board for the 3-axis Compass IC provides the HMC5843 plus serial bus

conversion circuits to convert the I2C data to USB interfacing for personal computers. Includes a

6-foot USB cable, software, user manual & 5 samples of the HMC5843.

Page 21

• HMC6343 3-axis Compass with Algorithms Evaluation Board

The HMC6343 evaluation board for the tilt-compensated digital compass IC contains the

HMC6343 mounted on the 0.8" by 0.8" plug-board with wide-DIP spaced (0.6") pins for

solderless breadboard compatibility. The board also contains the external capacitor and I2C

pullup resistors for typical function of the compass. The board contains the four connections

(VDD, GND, SCL, SDA) plus other breakouts.

• HMC6343 3-axis Compass with Algorithms Demonstration Board

The demonstration board for the 3-axis Compass IC provides the HMC6343 part plus serial bus

conversion circuits to convert the I2C data to USB interfacing to personal computers. This small

printed circuit board comes with a 6-foot USB cable and Windows demonstration software to

provide a user friendly way of viewing compass heading, pitch and roll data n umerically and on

aviation-type displays. Communication can still be enabled with the HMC6343, even without the

provided demonstration software, as long as the developer creates a program to emulate the

I2C data packets. This demonstration board uses the USB power supply from the host computer

(~+5 volts) and a green LED indicates power presence.

HMC1042L and HMC1043 evaluation boards coming soon!

For more information regarding these products and engineering development tools call 1-763-954-2474 or toll free at

1-800-323-8295 or visit the Honeywell web site at www.honeywell.com/magnticsensors. From this Internet location,

visitors can immediately download product specifications and other related product information.

To make purchasing quick and easy, products can be ordered from our on line store at http://shop.ssec.honeywell.com/.

Loading...

Loading...