Page 1

查询HMC1055供应商

HMC1055

Advance Information SENSOR PRODUCTS

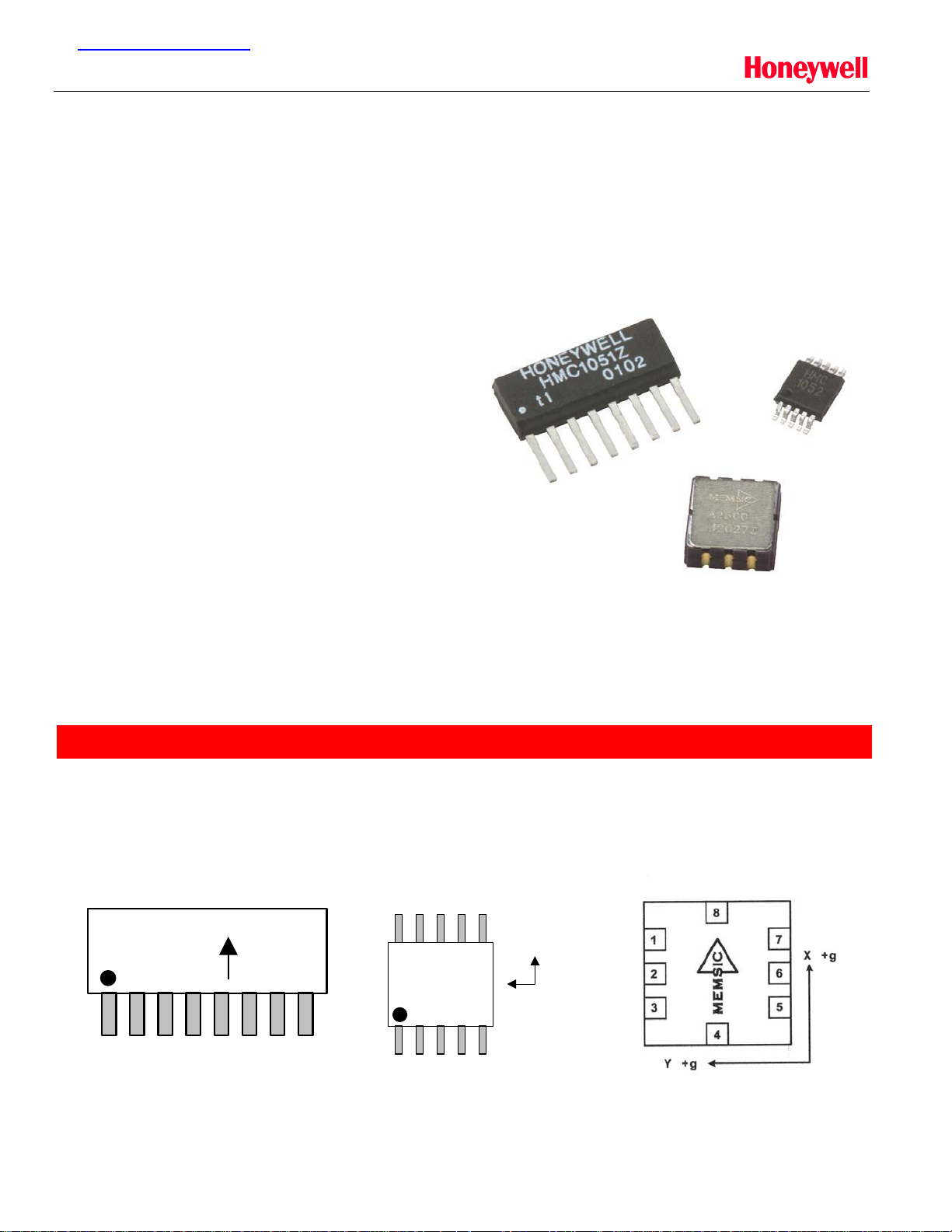

3-AXIS COMPASS SENSOR SET

Features

x 3 Precision Sensor Components

x 2-Axis Magnetoresistive Sensor for X-Y Axis

Earth’s Field Detection

x 1-Axis Magnetoresistive Sensor for Z-Axis Earth’s

Field Detection

x 2-Axis Accelerometer for 60° Tilt Compensation

x 2.7 to 5.5 volt Supply Range

x 3-Axis Compass Reference Design Included

Product Description

The Honeywell HMC1055 3-Axis Compass Sensor Set

combines the popular HMC1051Z one-axis and the

HMC1052 two-axis magneto-resistive sensors plus a 2axis MEMSIC MXS3334UL accelerometer in a single

kit. By combining these three sensor packages, OEM

compass system designers will have the building

blocks needed to create their own tilt compensated

compass designs using these proven components.

The HMC1055 chip set includes the three sensor

integrated circuits and an application note describing

sensor function, a reference design, and design tips for

integrating the compass feature into other product

platforms.

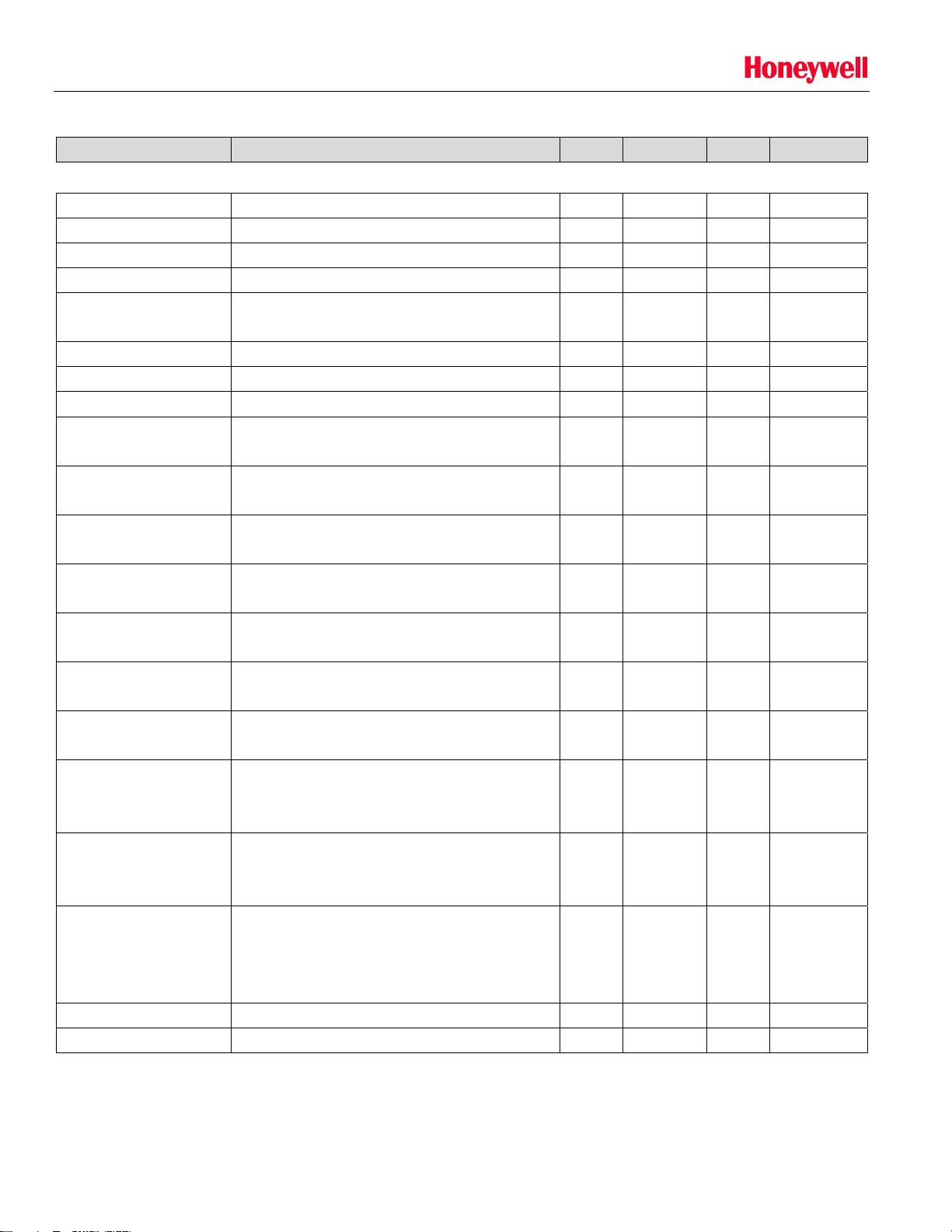

DIAGRAMS

Pinouts (top view)

HONEYWELL

HMC1051Z

HMC

1052

678910

B

A

12345678

12345

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 1

Page 2

HMC1055

Advance Information SENSOR PRODUCTS

SPECIFICATIONS – MAGNETIC SENSORS HMC1051Z, HMC1052

Characteristics Conditions* Min Typ Max Units

Bridge Elements

Supply Vbridge referenced to GND 1.8 2.5 20 Volts

Resistance Bridge current = 1mA 800 1000 1500 ohms

Field Range Full scale (FS) – total applied field -6 +6 gauss

Sensitivity Set/Reset Current = 0.5A 0.8 1.0 1.2 mV/V/gauss

Bridge Offset Offset = (OUT+) – (OUT-)

Field = 0 gauss after Set pulse

Bandwidth Magnetic signal (lower limit = DC) 5 MHz

Noise Density @ 1kHz, Vbridge=5V 50 nV/sqrt Hz

Resolution 50Hz Bandwidth, Vbridge=5V 120

Disturbing Field Sensitivity starts to degrade.

Use S/R pulse to restore sensitivity.

Max. Exposed

No perming effect on zero reading 10000 gauss

Field

Operating

Ambient -40 125 °C

Temperature

Storage

Ambient, unbiased -55 150 °C

Temperature

Sensitivity

Tempco

Bridge Offset

Tempco

Bridge Ohmic

TA=-40 to 125°C, Vbridge=5V

T

=-40 to 125°C, Ibridge=5mA

A

TA=-40 to 125°C, No Set/Reset

T

=-40 to 125°C, With Set/Reset

A

Vbridge=5V, TA=-40 to 125°C 2100 2500 2900 ppm/°C

Tempco

Sensitivity Ratio of

TA=-40 to 125°C 95 101 105 %

X,Y Sensors

(HMC1052 Only)

X,Y sensor

Sensitive direction in X and Y sensors 0.01 degree

Orthogonality

(HMC1052)

Linearity Error Best fit straight line

± 1 gauss

± 3 gauss

± 6 gauss

Hysteresis Error 3 sweeps across ±3 gauss 0.06 %FS

Repeatability Error 3 sweeps across ±3 gauss 0.1 %FS

* Tested at 25°C except stated otherwise.

-1.25 ±0.5 +1.25 mV/V

Pgauss

20 gauss

-3000 -2700

-2400 ppm/°C

-600

±500

ppm/°C

±10

0.1

0.5

%FS

1.8

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 2

Page 3

HMC1055

Advance Information SENSOR PRODUCTS

SPECIFICATIONS – MAGNETIC SENSORS HMC1051Z, HMC1052

Characteristics Conditions* Min Typ Max Units

Set/Reset Strap

Resistance Measured from S/R+ to S/R- 3 4 5 ohms

Current 0.1% duty cycle, or less,

2Psec current pulse

Resistance

Tempco

Offset Straps

Resistance Measured from OFFSET+ to OFFSET- 12 15 18 ohms

Offset

Constant

Resistance

Tempco

* Tested at 25°C except stated otherwise.

SPECIFICATIONS – ACCELEROMETER MXS3334UL

Characteristics Conditions* Min Typ Max Units

Sensor Input

Range ±1 g

Non-Linearity Best fit straight line 0.5 1.0 % of FS

Alignement Error ±1.0 degree

Transverse

Sensitivity

Sensitivity

Digital Outputs Vdd = 5.0 volts 19.00 20.00 21.00

Change Over

Temperature

Resistance TA= -40 to 125°C 3900 ppm/°C

Zero g Bias Level

0 g Offset -0.1 0.00 +0.1 g

0 g Duty Cycle 48 50 52 % Duty Cycle

0 g Offset Over

Temperature

Performance

Noise Density rms 0.2 0.4 mg/sqrt-Hz

Frequency

Response

Tested at 25°C except stated otherwise.

(available on die)

Field applied in sensitive direction

(Each Axis)

Compensated (-40°C to +105°C)

(Each Axis)

TA= -40 to 125°C 3700 ppm/°C

DC Current

TA= -40 to 125°C 3900 ppm/°C

-40°C, Uncompensated

+105°C, Uncompensated

' from 25°C

' from 25°C

' from 25°C, based on 20%/g

3dB Bandwidth 25 Hz

0.4 0.5 4 Amp

10 mA/gauss

±2.0 %

%Duty

Cycle/g

+100 %

-50

< 3.0

±0.75

±0.015

mg/°C

%/°C

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 3

Page 4

HMC1055

Advance Information SENSOR PRODUCTS

MXS3334UL SPECIFICATIONS

Characteristics Conditions* Min Typ Max Units

Voltage Reference

Vref Vdd = 2.7 to 5.0 2.4 2.5 2.65 volts

Change Over

Temperature

Current Drive

Source 100

Capability

Self Test

Continuous

Voltage Under

Vdd = 5.0 volts, D

Vdd = 2.7 volts, D

OUTX

OUTX

and D

and D

OUTY

OUTY

Failure

(D

Digital Outputs

OUTX

and D

Normal Range Vdd = 5.00 volts

)

OUTY

Vdd = 2.7 volts

0.1

0.1

Current Source or Sink (Vdd =2.7 to 5.0v) 100

Rise/Fall Time Vdd = 2.7 to 5.0 volts 90 100 110

Turn-On Time Vdd = 5.0 volts

Vdd = 2.7 volts

Power Supply

Operating Voltage

2.7 5.25 volts

Range

Supply Current Vdd = 5.0 volts

Vdd = 2.7 volts

3.0

4.0

Temperature

Operating Range -40 +105 °C

Storage Range -65 +150 °C

Tested at 25°C except stated otherwise.

0.1 mV/°C

PA

5.0

volts

2.7

4.9

volts

2.6

PA

Ksec

100

40

3.6

4.9

4.2

5.8

msec

mA

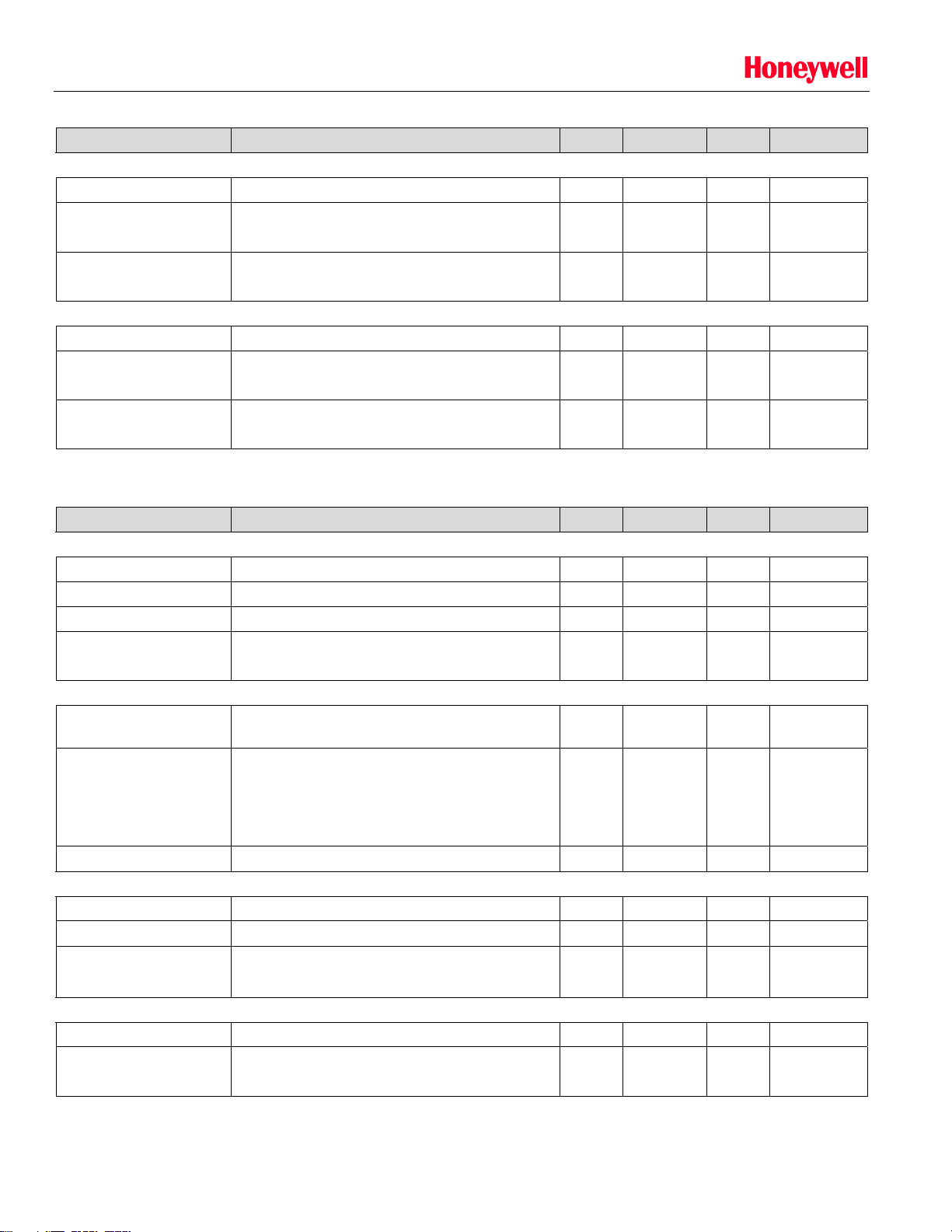

Pin Configurations (Arrow indicates direction of applied field that generates a positive output voltage after a SET pulse.)

HMC1051

Vcc

(3)

HMC1051

BRIDGE A BRIDGE B

Vo+(A)

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 4

GND Plane

(2)

Vo-(A)

S/R+

(6)

(8)

Set/Reset Strap

(4)

GND1(B)

(1)

S/R-

(7)

GND2(B)

(5)

HMC1051Z Pinout

HONEYWELL

HMC1051Z

12345678

Page 5

HMC1055

Advance Information SENSOR PRODUCTS

HMC1052

MXD3334UL

(7)

(7)

Sck

Sck

(optional)

(optional)

Vcc

Vcc

(5)

(5)

HMC1052

HMC1052

BRIDGE A BRIDGE B

BRIDGE A BRIDGE B

GND2

OUT-

OUT-

(10)

(10)

GND2

(9)

(9)

CLK

CLK

Heater

Heater

Control

Control

GND1

GND1

(3)

(3)

S/R+

S/R+

(6)

(6)

Oscillator

Oscillator

OUT+

OUT+

Internal

Internal

(4)

(4)

Set/Reset Strap

Set/Reset Strap

OUT-

OUT-

(7)

(7)

Continous

Continous

Self Test

Self Test

GND

GND

(1)

(1)

S/R-

S/R-

(8)

(8)

Temperature

Temperature

Reference

Reference

Sensor

Sensor

Voltage

Voltage

OUT+

OUT+

(2)

(2)

HMC1052 Pinout

678910

B

HMC

A

1052

12345

(1)

(1)

T

T

OUT

OUT

V

V

(6)

(6)

REF

REF

1

2

8

7

X +g

6

Low Pass

Gnd

Gnd

Low Pass

Filter

Filter

Low Pass

Low Pass

Filter

Filter

V

V

DA

DA

(4)(3)(8)

(4)(3)(8)

D

D

(5)

(5)

OUTX

OUTX

(2)

(2)

D

D

OUTY

OUTY

2-AXIS

2-AXIS

SENSOR

SENSOR

V

V

DD

DD

X axis

X axis

Factory Adjust

Factory Adjust

Offset & Gain

Offset & Gain

Y axis

Y axis

Pin Descriptions

HMC1051Z

Pin Name Description

1 GND1(B) Bridge B Ground 1 (normally left open)

2 Vo+(A) Bridge Output Positive

3 Vcc Bridge Positive Supply

4 GND Plane Bridge Ground (substrate)

5 GND2(B) Bridge B Ground 2 (normally left open)

6 S/R+ Set/Reset Strap Positive

7 S/R- Set/Reset Strap Negative

8 Vo-(A) Bridge Output Negative

3

Y +g

MEMSIC

4

Top View

5

Solid State Electronics Center • www.magneticsensors.com• (800) 323-8295•Page 5

Page 6

HMC1055

Advance Information SENSOR PRODUCTS

HMC1052

Pin Name Description

1 GND Bridge B Ground

2 OUT+ Bridge B Output Positive

3 GND1 Bridge A Ground 1

4 OUT+ Bridge B Output Positive

5 Vcc Bridge Positive Supply

6 S/R+ Set/Reset Strap Positive

7 OUT- Bridge B Output Negative

8 S/R- Set/Reset Strap Negative

9 GND2 Bridge A Ground 2

10 OUT- Bridge A Output Negative

MXD3334UL

Pin Name Description

1T

2D

OUT

OUTY

3 Gnd Ground

4V

5D

6V

DA

OUTX

ref

7 Sck Optional External Clock

8V

DD

Temperature (Analog Voltage)

Y-Axis Acceleration Digital Signal

Analog Supply Voltage

X-Axis Acceleration Digital Signal

2.5V Reference

Digital Supply Voltage

Package Dimensions

HMC1051Z

HMC1052

Symbol Millimeters

Min Max

A

A1

B

D

E

e

H

h

1.371 1.728

0.101 0.249

0.355 0.483

9.829 11.253

3.810 3.988

1.270 ref

6.850 7.300

0.381 0.762

Symbol Millimeters

Min Max

A

A1

B

D

E1

e

E

L1

- 1.10

0.05 0.15

0.15 0.30

2.90 3.10

2.90 3.10

0.50 BSC

4.75 5.05

0.95 BSC

Inches x 10E-3

Min Max

54 68

4 10

14 19

387 443

150 157

50 ref

270 287

15 30

Inches x 10E-3

Min Max

- 43

2.0 5.9

5.9 11.8

114 122

114 122

2.0 BSC

187 199

37.4

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 6

Page 7

HMC1055

Advance Information SENSOR PRODUCTS

MXS3334UL

Application Notes

The HMC1055 Chipset is composed of three sensors packaged as integrated circuits for tilt compensated electronic

compass development. These three sensors are composed of a Honeywell HMC1052 two-axis magnetic field sensor,

a Honeywell HMC1051Z one-axis magnetic sensor, and the Memsic MXS3334UL two-axis accelerometer.

Traditionally, compassing is done with a two-axis magnetic sensor held level (perpendicular to the gravitational axis)

to sense the horizontal vector components of the earth’s magnetic field from the south pole to the north pole. By

incorporating a third axis magnetic sensor and the two-axis accelerometer to measure pitch and roll (tilt), the compass

is able to be electronically “gimbaled” and can point to the north pole regardless of level.

The HMC1052 two-axis magnetic sensor contains two Anisotropic Magneto-Resistive (AMR) sensor elements in a

single MSOP-10 package. Each element is a full wheatstone bridge sensor that varies the resistance of the bridge

magneto-resistors in proportion to the vector magnetic field component on its sensitive axis. The two bridges on the

HMC1052 are orientated orthogonal to each other so that a two-dimensional representation of an magnetic field can

be measured. The bridges have a common positive bridge power supply connection (Vb); and with all the bridge

ground connections tied together, form the complete two-axis magnetic sensor. Each bridge has about an 1100-ohm

load resistance, so each bridge will draw several milli-amperes of current from typical digital power supplies. The

bridge output pins will present a differential output voltage in proportion to the exposed magnetic field strength and the

amount of voltage supply across the bridge. Because the total earth’s magnetic field strength is very small (~0.6

gauss), each bridge’s vector component of the earth’s field will even be smaller and yield only a couple milli-volts with

nominal bridge supply values. An instrumentation amplifier circuit; to interface with the differential bridge outputs, and

to amplify the sensor signal by hundreds of times, will then follow each bridge voltage output.

The HMC1051Z is an additional magnetic sensor in an 8-pin SIP package to place the sensor silicon die in a vertical

orientation relative to a Printed Circuit Board (PCB) position. By having the HMC1052 placed flat (horizontal) on the

PCB and the HMC1051Z vertical, all three vector components of the earth’s magnetic field (X, Y, and Z) are sensed.

By having the Z-axis component of the field, the electronic compass can be oriented arbitrarily; and with a tilt sensor,

perform tilt-compensated compass heading measurements as if the PCB where perfectly level.

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 7

Page 8

HMC1055

Advance Information SENSOR PRODUCTS

C1

C1

150P

VCC

VCC

VEE

VEE

VCC

VCC

VEE

VEE

Vdd

Vdd

150P

Vdd

Vdd

X1

X1

LMV324M

LMV324M

C2

C2

150P

150P

Vdd

Vdd

X2

X2

LMV324M

LMV324M

5

5

Vref

Vref

14

14

C6

C6

0.1U

0.1U

C7

C7

0.1U

0.1U

Vdd

Vdd

Vdd

Vdd

18

18

R12

R12

10K

10K

R13

R13

10K

10K

R10

R10

10

10

DO0

DO0

MICRO-

MICRO-

CONTROLLER

CONTROLLER

VDD

VDD

AN0

AN0

AN1

AN1

AN2

AN2

AN3

AN3

GND

GND

NC

NC

DI0

DI0

DI1

DI1

SCK

SCK

CS

CS

RXD

RXD

TXD

TXD

R1A6R2A

R1A6R2A

7

7

R3A R4A

R3A R4A

HMC1052

HMC1052

R1B11R2B

R1B11R2B

10

10

R3B R4B

R3B R4B

Rsr1

Rsr1

4

4

Vdd

Vdd

R1

R1

1.00MEG

1.00MEG

R2

R2

4.99K

4.99K

1

1

2

Vref

Vref

Vref

Vref

R9

R9

220

220

2

R3

R3

1.00MEG

1.00MEG

R5

R5

1.00MEG

1.00MEG

13

13

12

12

R7

R7

1.00MEG

1.00MEG

R4

R4

4.99K

4.99K

R6

R6

4.99K

4.99K

R8

R8

4.99K

4.99K

C4

C4

1U

1U

8

8

9

9

15

16

16

Vref

Vref

15

X4

X4

IRF7509P

IRF7509P

X5

X5

IRF7509N

IRF7509N

R18

R18

1.00MEG

1.00MEG

24

24

23

23

R20

R20

1.00MEG

1.00MEG

VCC

VCC

VEE

VEE

C5

C5

150P

150P

Vdd

Vdd

X3

X3

LMV324M

LMV324M

25

25

Rsr2

Rsr2

4

4

HMC1051Z

HMC1051Z

R14Z21R15Z

R14Z21R15Z

22

22

R16Z R17Z

R16Z R17Z

C3

C3

0.22U

0.22U

Vdd

Vdd

R19

R19

4.99K

4.99K

R21

R21

4.99K

4.99K

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 8

VDAVDD

VDAVDD

VREF

VREF

DOUTY

DOUTY

MXS3334UL

MXS3334UL

TOUT

TOUT

NC

NC

DOUTX

DOUTX

GND

GND

Figure 1

Figure 1

SCK

SCK

3-Axis Compass Reference Design

Page 9

HMC1055

Advance Information SENSOR PRODUCTS

The MXS3334UL is a two-axis accelerometer in an 8-pin LCC package that provides a digital representation of the

earth’s gravitational field. When the MXS3334UL is held level and placed horizontally on a PCB, both digital outputs

provide a 100 Hz Pulse Width Modulated (PWM) square wave with a 50 percent duty cycle. As the accelerometer is

pitched or rolled from horizontal to vertical, the Doutx and Douty duty cycles will shift plus or minus 20% of its duty

from the 50% center point.

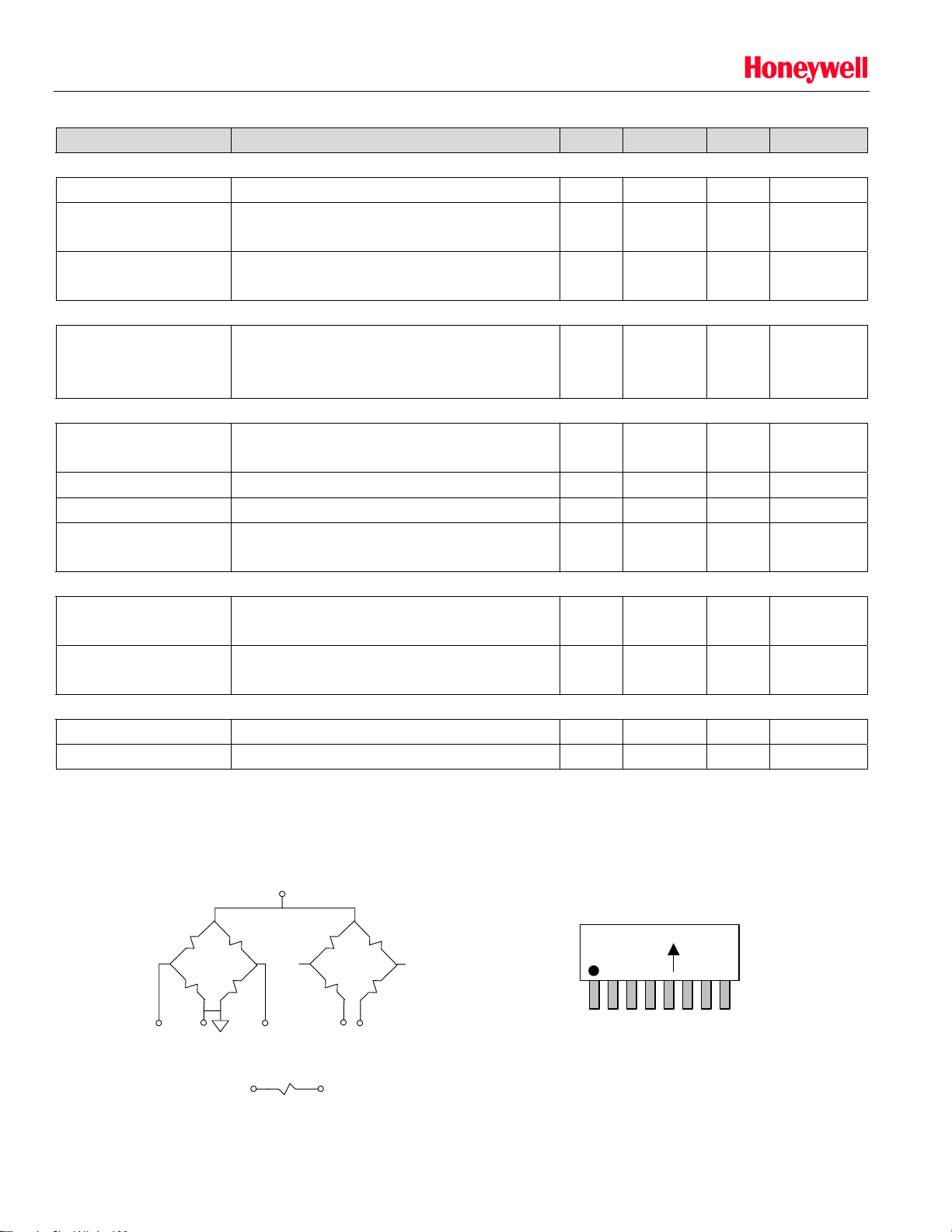

The reference design in Figure 1 shows a reference design incorporating all three sensor elements of the HMC1055

chipset for a tilt compensated electronic compass operating from a 5.0 volt regulated power supply described as Vdd.

The HMC1052 sensor bridge elements A and B are called out as R1A, R2A, R3A, R4A, and R1B, R2B, R3B, R4B

respectively; and create a voltage dividing networks that place nominally 2.5 volts into the succeeding amplifier

stages. The HMC1051Z sensor bridge elements R14Z, R15Z, R16Z, and R17Z also do a similar voltage dividing

method to its amplifier stage.

In this design each amplifier stage uses a single operational amplifier (op-amp) from a common LMV324M quad opamp Integrated Circuit (IC). For example, resistors R1, R2, R3, and R4 plus capacitor C1 configure op-amp X1 into an

instrumentation amplifier with a voltage gain of about 200. These instrumentation amplifier circuits take the voltage

differences in the sensor bridges, and amplify the signals for presentation at the micro-controller Analog to Digital

Converter (ADC) inputs, denoted as AN1, AN2, and AN3. Because the zero magnetic field reference level is at 2.5

volts, each instrumentation amplifier circuit receives a 2.5 volt reference voltage (Vref) from a resistor divider circuit

composed of R12 and R13.

For example, a +500 milli-gauss earth’s field on bridge A of the HMC1052 will create a 2.5 milli-volt difference voltage

at the sensor bridge output pins (0.5 gauss multiplied by the 1.0mV/V/gauss sensitivity rating). This 2.5mV then is

multiplied by 200 for 0.5 volt offset that is referenced to the 2.5 volt Vref for a total of +3.0 volts at AN1. Likewise any

positive and or negative magnetic field vectors from bridge B and the HMC1051Z bridge are converted to voltage

representations at AN2 and AN3.

The micro-controller also receives the sensor inputs from the MXS3334UL accelerometer directly from Doutx and

Douty into two digital inputs denoted as DI0 and DI1. Optionally, the MXS3334UL temperature output pin (Tout) can

routed to another microcontroller ADC input for further temperature compensation of sensor inputs. Power is supplied

to the MXS3334UL from the 5.0 volt Vdd source directly to the accelerometer VDA pin and on to the VDD pin via a ten

ohm resistor (R10) for modest digital noise decoupling. Capacitors C6 and C7 provide noise filtering locally at the

accelerometer and throughout the compass circuit.

The set/reset circuit for this electronic compass is composed of MOSFETs X4 and X5, capacitors C3 and C4, and

resistor R9. The purpose of the set/reset circuit is to re-align the magnetic moments in the magnetic sensor bridges

when they exposed to intense magnetic fields such as speaker magnets, magnetized hand tools, or high current

conductors such as welding cables or power service feeders. The set/reset circuit is toggled by the microcontroller

and each logic state transition creates a high current pulse in the set/reset straps for both HMC1052 and the

HMC1051Z.

Operational Details

With the compass circuitry fully powered up, sensor bridge A creates a voltage difference across OUTA- and OUTA+

that is then amplified 200 times and presented to microcontroller analog input AN1. Similarly, bridges B and C create

a voltage difference that is amplified 200 times and presented to microcontroller analog inputs AN2 and AN3. These

analog voltages at AN1 and AN2 can be thought of as “X” and “Y” vector representations of the magnetic field. The

third analog voltage (AN3) plus the tilt information from accelerometer, is added to the X and Y values to create tilt

compensated X and Y values, sometimes designated X’ and Y’.

To get these X, Y, and Z values extracted, the voltages at AN1 through AN3 are to be digitized by the

microcontroller’s onboard Analog-to-Digital Converter (ADC). Depending on the resolution of the ADC, the resolution

of the Compass is set. Typically compasses with one degree increment displays will have 10-bit or greater ADCs, with

8-bit ADCs more appropriate for basic 8-cardinal point (North, South, East, West, and the diagonal points)

compassing. Individual microcontroller choices have a great amount of differing ADC implementations, and there may

be instances where the ADC reference voltage and the compass reference voltage can be shared. The point to

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 9

Page 10

HMC1055

Advance Information SENSOR PRODUCTS

remember is that the analog voltage outputs are referenced to half the supplied bridge voltage and amplified with a

similar reference.

The most often asked question on AMR compass circuits is how frequent the set/reset strap must be pulsed. The

answer for most low cost compasses is fairly infrequently; from a range of once per second, to once per compass

menu selection by the user. While the set circuit draws little energy on a per pulse basis, a constant one pulse per

second rate could draw down a fresh watch battery in less than a year. In the other extreme of one “set” pulse upon

the user manually requesting a compass heading, negligible battery life impact could be expected. From a common

sense standpoint, the set pulse interval should be chosen as the shortest time a user could withstand an inaccurate

compass heading after exposing the compass circuit to nearby large magnetic sources. Typical automatic set

intervals for low cost compasses could be once per 10 seconds to one per hour depending on battery energy

capacity. Provision for a user commanded “set” function may be a handy alternative to periodic or automatic set

routines.

In portable consumer electronic applications like compass-watches, PDAs, and wireless phones; choosing the

appropriate compass heading data flow has a large impact on circuit energy consumption. For example, a one

heading per second update rate on a sport watch could permit the compass circuit to remain off to nearly 99 percent

of the life of the watch, with just 10 millisecond measurement snapshots per second and a one per minute set pulses

for perming correction. The HMC1052 and HMC1051Z sensors have a 5 MHz bandwidth in magnetic field sensing, so

the minimum snapshot measurement time is derived principally by the settling time of the op-amps plus the sampleand-hold time of the microcontroller’s ADCs.

In some “gaming” applications in wireless phones and PDAs, more frequent heading updates permits virtual reality

sensor inputs for software reaction. Typically these update rates follow the precedent set more than a century ago by

the motion picture industry (“Movies”) at 20 updates or more per second. While there is still some value in creating off

periods in between these frequent updates, some users may choose to only switch power on the sensor bridges

exclusively and optimize the remainder of the circuitry for low power consumption.

Compass Firmware Development

To implement an electronic compass with tilt compensation, the microcontroller firmware must be developed to gather

the sensor inputs and to interpret them into meaningful data to the end user system. Typically the firmware can be

broken into logical routines such as initialization, sensor output collection and raw data manipulation, heading

computation, calibration routines, and output formatting.

For the sensor output data collection, the analog voltages at microcontroller inputs AN0 through AN3 are digitized and

a “count” number representing the measured voltage is the result. For compassing, the absolute meaning of the ADC

counts scaled back to the sensor’s milli-gauss measurement is not necessary, however it is important to reference the

zero-gauss ADC count level. For example, an 8-bit ADC has 512 counts (0 to 511 binary), then count 255 would be

the zero offset and zero-gauss value.

In reality errors will creep in due to the tolerances of the sensor bridge (bridge offset voltage), multiplied by the

amplifier gain stages plus any offset errors the amplifiers contribute; and magnetic errors from hard iron effects

(nearby magnetized materials). Usually a factory or user calibration routine in a clean magnetic environment will

obtain a correction value of counts from mid ADC scale. Further tweaking of the correction value for each magnetic

sensor axis once the compass assembly is in its final user location, is highly desired to remove the magnetic

environment offsets.

For example, the result of measuring AN0 (Vref) is about count 255, and the measuring of AN1, AN2, and AN3 results

in 331, 262, and 205 counts respectively. Next calibration values of 31, -5, and 20 counts would be subtracted to

result in corrected values of 301, 267, and 205 respectively. If the pitch and roll were known to be zero; then the AN3

(Z-axis output) value could be ignored and the tilt corrected X and Y-axis values would be the corrected values of AN1

and AN2 minus the voltage reference value of AN0. Doing the math yields arctan [y/x] or arctan [(267-255)/(301-255)]

or 14.6 degrees east of magnetic north.

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 10

Page 11

HMC1055

Advance Information SENSOR PRODUCTS

Heading Computation

Once the magnetic sensor axis outputs are gathered and the calibration corrections subtracted, the next step toward

heading computation is to gather the pitch and roll (tilt) data from the MEMSIC MXS3334UL accelerometer outputs.

The MXS3334UL in perfectly horizontal (zero tilt) condition produces a 100Hz, 50 percent duty cycle Pulse Width

Modulated (PWM) digital waveform from its Doutx and Douty pins corresponding to the X and Y sensitive axis. These

output pins will change their duty cycle from 30% to 70% when tilted fully in each axis (±1g). The scaling of the PWM

outputs is strictly gravitational, so that a 45 degree tilt results in 707 milli-g’s or a slew of ±14.1% from the 50% center

point duty cycle.

With the MXS3334UL’s positive X-axis direction oriented towards the front of the user’s platform, a pitch downward

will result in a reduced PWM duty cycle, with a pitch upward increasing in duty cycle. Likewise, the Y-axis arrow is 90

degrees counter-clockwise which results in a roll left corresponding to a decreasing duty cycle, and roll right to an

increasing duty cycle.

Measuring the pitch and roll data for a microcontroller is reasonably simple in that the Doutx and Douty logic signals

can be sent to microcontroller digital input pins for duty cycle measurement. At firmware development or factory

calibration, the total microcontroller clock cycles between Doutx or Douty rising edges should be accrued using an

interrupt or watchdog timer feature to scale the 100Hz (10 millisecond) edges. Then measuring the Doutx and Douty

falling edges from the rising edge (duty cycle computation) should be a process of clock cycle counting. For example,

a 1MHz clocked microcontroller should count about 10,000 cycles per rising edge, and 5,000 cycle counts from rising

to falling edge would represent a 50% duty cycle or zero degree pitch or roll.

Once the duty cycle is measured for each axis output and mathematically converted to a gravitational value, these

values can be compared to a memory mapped table, if the user desires the true pitch and roll angles. For example, if

the pitch and roll data is to be known in one degree increments, a 91-point map can be created to match up

gravitational values (sign independent) with corresponding degree indications. Because tilt-compensated compassing

requires sine and cosine of the pitch and roll angles, the gravitational data is already formatted between zero and one

and does not require further memory maps of trigonometric functions. The gravity angles for pitch and roll already fit

the sine of the angles, and the cosines are just one minus the sine values (cosine = 1 – sine).

The equations:

X’ = X * cos(I) + Y * sin(T) * sin(I) – Z * cos(T) * sin(I)

Y’ = Y * cos(T) + Z * sin(T)

Create tilt compensated X and Y magnetic vectors (X’, Y’) from the raw X, Y, and Y magnetic sensor inputs plus the

pitch (I) and roll (T) angles. Once X’ and Y’ are computed, the compass heading can be computed by equation:

Azimuth (Heading) = arctan (Y’ / X’)

To perform the arc-tangent trigonometric function, a memory map needs to be implemented. Thankfully the pattern

repeats in each 90° quadrant, so with a one-degree compass resolution requirement, 90 mapped quotients of the arctangent function can be used. If 0.1° resolution is needed then 900 locations are needed and only 180 locations with

0.5° resolution. Also, special case quotient detections are needed for the zero and inifinity situations at 0°, 90, 180°,

and 270° prior to the quotient computation.

After the heading is computed, two heading correction factors may be added to handle declination angle and platform

angle error. Declination angle is the difference between the magnetic north pole and the geometric north pole, and

varies depending on the latitude and longitude (global location) of the user compass platform. If you have access to

Global Positioning Satellite (GPS) information resulting in a latitude and longitude computation, then the declination

angle can be computed or memory mapped for heading correction. Platform angle error may occur if the sensors are

not aligned perfectly with the mechanical characteristics of the user platform. These angular errors can be inserted in

firmware development and or in factory calibration.

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 11

Page 12

HMC1055

Advance Information SENSOR PRODUCTS

COMPASS CALIBRATION

In the paragraphs describing raw magnetic sensor data, the count values of X, Y, and Z are found from inputs AN0 to

AN3. A firmware calibration routine will create Xoff, Yoff and Xsf, and Ysf for calibration factors for “hard-iron”

distortions of the earth’s magnetic field at the sensors. Typically these distortions come from nearby magnetized

components. Soft-iron distortions are more complex to factor out of heading values and are generally left out for low

cost compassing applications. Soft-iron distortion arises from magnetic fields bent by un-magnetized ferrous materials

either very close to the sensors or large in size. Locating the compass away from ferrous materials provides the best

error reduction. The amount of benefit is dependant on the amount of ferrous material and its proximity to the

compass platform.

To derive the calibration factors, the sensor assembly (platform) and its affixed end-platform (e.g. watch/human, boat,

auto, etc.) are turned at least one complete rotation as the compass electronics collects many continuous readings.

The speed and rate of turn are based on how quickly the microcontroller can collect and process X, Y, and Z data

during the calibration routine. A good rule of thumb is to collect readings every few degrees by either asking the user

to make a couple rotations or by keeping in the rotation(s) slow enough to collect readings of the correct rate of turn.

The Xh and Yh readings during calibration are done with Xoff and Yoff at zero values, and axis scale factors (Xsf and

Ysf) at unity values. The collected calibration X and Y values are then tabulated to find the min and max of both X and

Y. At the end of the calibration session, the Xmax, Ymax, Xmin, and Ymin values are converted to the following:

Xsf = 1 or (Ymax –Ymin) / (Xmax – Xmin) , whichever is greater

Ysf = 1 or (Xmax –Xmin) / (Ymax – Ymin) , whichever is greater

Xoff = [(Xmax – Xmin)/2 – Xmax] * Xsf

Yoff = [(Ymax –Ymin)/2 –Ymax] * Ysf

Z-axis data is generally not corrected if the end-platform can not turned upside-down. In portable or hand-held

applications, then the compass assembly can be tipped upside down and Zoff can be computed like Xoff and Yoff, but

with only two reference points (upright and upside down). Factory values for Zoff maybe the only values possible.

Creating corrected X, Y, and Z count values are done as previously mentioned by subtracting the offsets. The scale

factor values are used only after the Vref counts are subtracted form the offset corrected axis counts. For more details

on calibration for iron effects, see the white paper “Applications of Magnetoresistive Sensors in Navigation Systems”

located on the magneticsensors.com website.

Offsets due to sensor bridge offset voltage of each sensor axis are part of the Xoff, Yoff, and Zoff computation. These

offsets are present even with no magnetic field disturbances. To find their true values, the set and reset drive circuits

can be toggled while taking measurements shortly after each transition. After a reset pulse, the magnetic field portion

of the sensor bridge will have flipped polarity while the offset remains the same. Thus two measurements, after a

reset and a set pulse can be summed together. The magnetic portions of the sum will cancel, leaving just a double

value of the offset. The result can then be divide by two to derive the bridge offset.

The reason for knowing the bridge offset, is that the offset will drift with temperature. Should the user desire the best

accuracy in heading, a new calibration should be performed with each encounter with a new temperature

environment. See application notes AN-212, AN-213, and AN-214 for further compass design considerations.

Ordering Information

Ordering Number Product

HMC1055 3-Axis Compass Sensor Set

Honeywell reserves the right to make changes to improve reliability, function or design. Honeywell does not assume

any liability arising out of the application or use of any product or circuit described herein; neither does it convey any

license under its patent rights nor the rights of others.

900302 12-02 Rev –

Solid State Electronics Center • www.magneticsensors.com • (800) 323-8295 • Page 12

Loading...

Loading...