Page 1

查询hmc1022供应商

SENSOR PRODUCTS

APPLICATIONS

Compassing

Navigation Systems

Attitude Reference

Traffic Detection

Medical Devices

Non-Contact Switch

1- and 2-Axis Magnetic

Sensors

HMC1001 / 1002

HMC1021 / 1022

onfigured as a 4-element

wheatstone bridge, these

C

magnetoresistive sensors

convert magnetic fields to

a differential output volt-

age, capable of sensing

magnetic fields as low as

30 µgauss. These MRs

offer a small, low cost,

high sensitivity and high

reliability solution for low

field magnetic sensing.

Not actual size

FEATURES AND BENEFITS

Wide Field Range Field range up to ±6 gauss, (earth’s field = 0.5 gauss)

Small Package

Solid State These small devices reduce board assembly costs, improve reliability and ruggedness com-

On-Chip Coils Patented on-chip set/reset straps to reduce effects of temperature drift, non-linearity errors and

Cost Effective The sensors were specifically designed to be affordable for high volume OEM applications.

• Designed for 1- and 2-axis to work together to provide 3-axis (x, y, z) sensing

• 1-axis part in an 8-pin SIP or an 8-pin SOIC or a ceramic 8-pin DIP package

• 2-axis part in a 16-pin or 20-pin SOIC package

pared to mechanical fluxgates.

loss of signal output due to the presence of high magnetic fields

Patented on-chip offset straps for elimination of the effects of hard iron distortion

Page 2

LINEAR MAGNETIC FIELD SENSORS

HMC1001/1002 SPECIFICATIONS

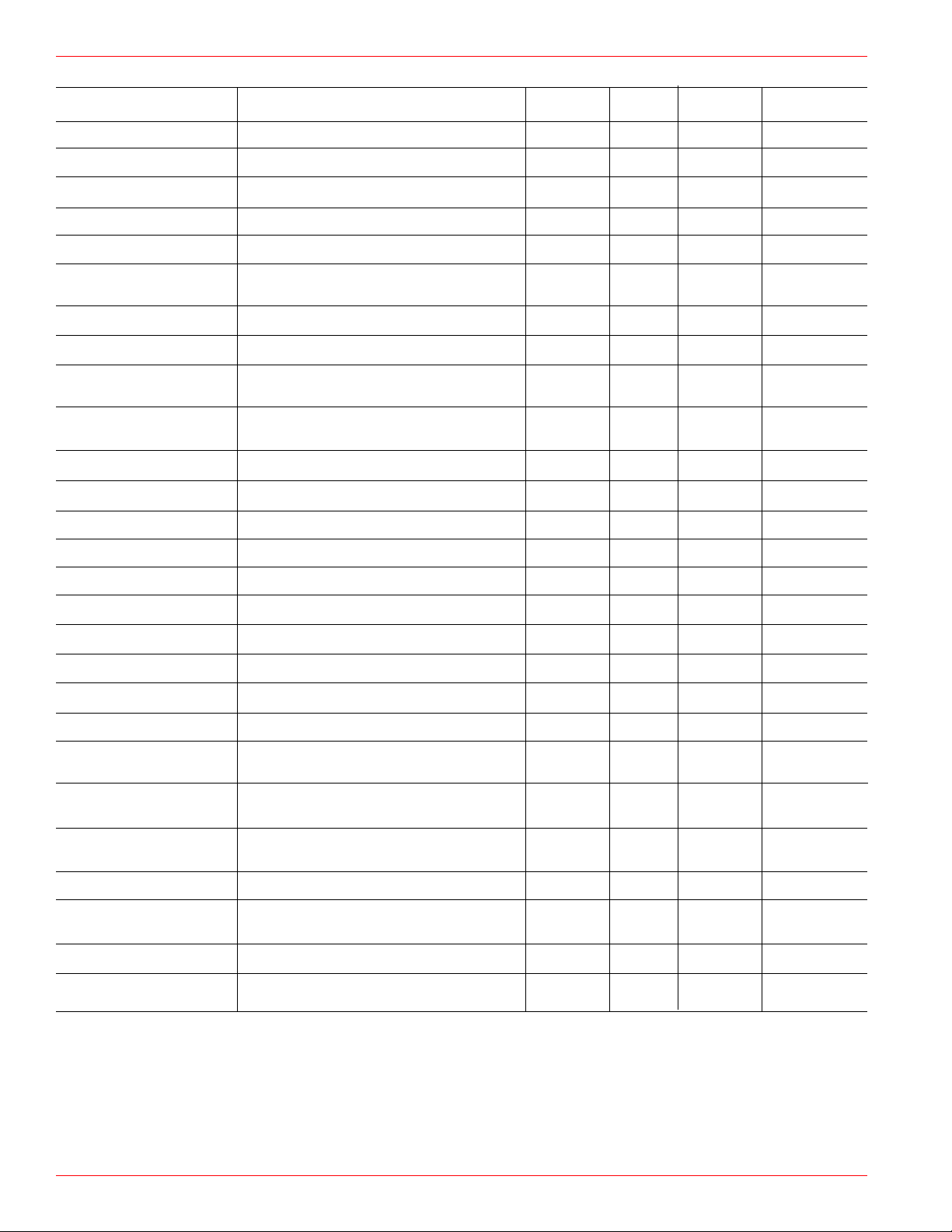

Characteristics Conditions* Min Typ Max Unit

Bridge Supply Vbridge referenced to GND 5 12 Volts

Bridge Resistance Bridge current = 10mA 600 850 1200 ohm

Operating Temperature (4) -55 150 °C

Storage T emper ature (4) Unbiased -55 175 °C

Field Range (4) Full scale (FS), total applied field -2 +2 gauss

Linearity Error (4) Best fit straight line ±1 gauss 0.1 0.5 %FS

±2 gauss 1 2

Hysteresis Error (4) 3 sweeps across ±2 gauss 0.05 0.10 %FS

Repeatability Error (4) 3 sweeps across ±2 gauss 0.05 0.10 %FS

S/R Repeatability (1) 10

S/R Repeatability (2) Output variation after alternate S/R pulses 2 100 µV

Bridge Offset Offset = (OUT+) – (OUT-), Field=0 gauss -60 -15 30 mV

after Set pulse, Vbridge=8V

Sensitivity S/R Current = 3A 2.5 3.2 4.0 mV/V/gauss

Noise Density (4) Noise at 1 Hz, Vbridge=5V 29 nV/ Hz

Resolution (4) Bandwidth=10Hz, Vbridge=5V 27 µgauss

Bandwidth (4) Magnetic signal (lower limit = DC) 5 MHz

OFFSET Strap Measured from OFFSET+ to OFFSET- 2.5 3.5 ohm

OFFSET Strap Ω Tempco (4) T

A = -40 to 125° C 0.39 %/° C

OFFSET Field (4) Field applied in sensitive direction 46 51 56 mA/gauss

Set/Reset Strap Measured from S/R+ to S/R- 1.5 1.8 ohm

Set/Reset Current (2) (3) (4) 2 µs current pulse, 1% duty cycle 3.0 3.2 5 Amp

Set/Reset Ω Tempco (4) T

A = -40 to 125° C 0.37 %/° C

Disturbing Field (4) Sensitivity starts to degrade. 3 gauss

Use S/R pulse to restore sensitivity.

Sensitivity Tempco (4) T

A = -40 to 125° C Vbridge=8V -0.32 -0.3 -0.28 %/° C

Ibridge=5mA -0.06

Bridge Offset Tempco (4) T

A = -40 to 125° C no Set/Reset ±0.03 %/° C

Vbridge=5V with Set/Reset ±0.001

Resistance T empco (4) T

A = -40 to 125° C 0.25 %/° C

Cross-Axis Effect (4) Cross field=1gauss no Set/Reset ±3 %FS

(see AN-205) with Set/Reset +0.5

Max. Exposed Field (4) No perming effect on zero reading 10000 gauss

Weight HMC1001 0.14 gram

HMC1002 0.53

(1) VBridge = 4.3V, IS/R = 3.2A, VOUT = VSET – VRESET

(2) If VBridge = 8.0V, IS/R = 2.0A, lower S/R current leads to greater output variation.

(3) Effective current from power supply is less than 1mA.

(4) Not tested in production, guaranteed by characterization.

(*) Tested at 25° C except otherwise stated.

Units: 1 gauss (g) = 1 Oersted (in air), = 79.58 A/m, 1G = 10E-4 Tesla, 1G = 10E5 gamma.

2

Page 3

LINEAR MAGNETIC FIELD SENSORS

HMC1021/1022 SPECIFICATIONS

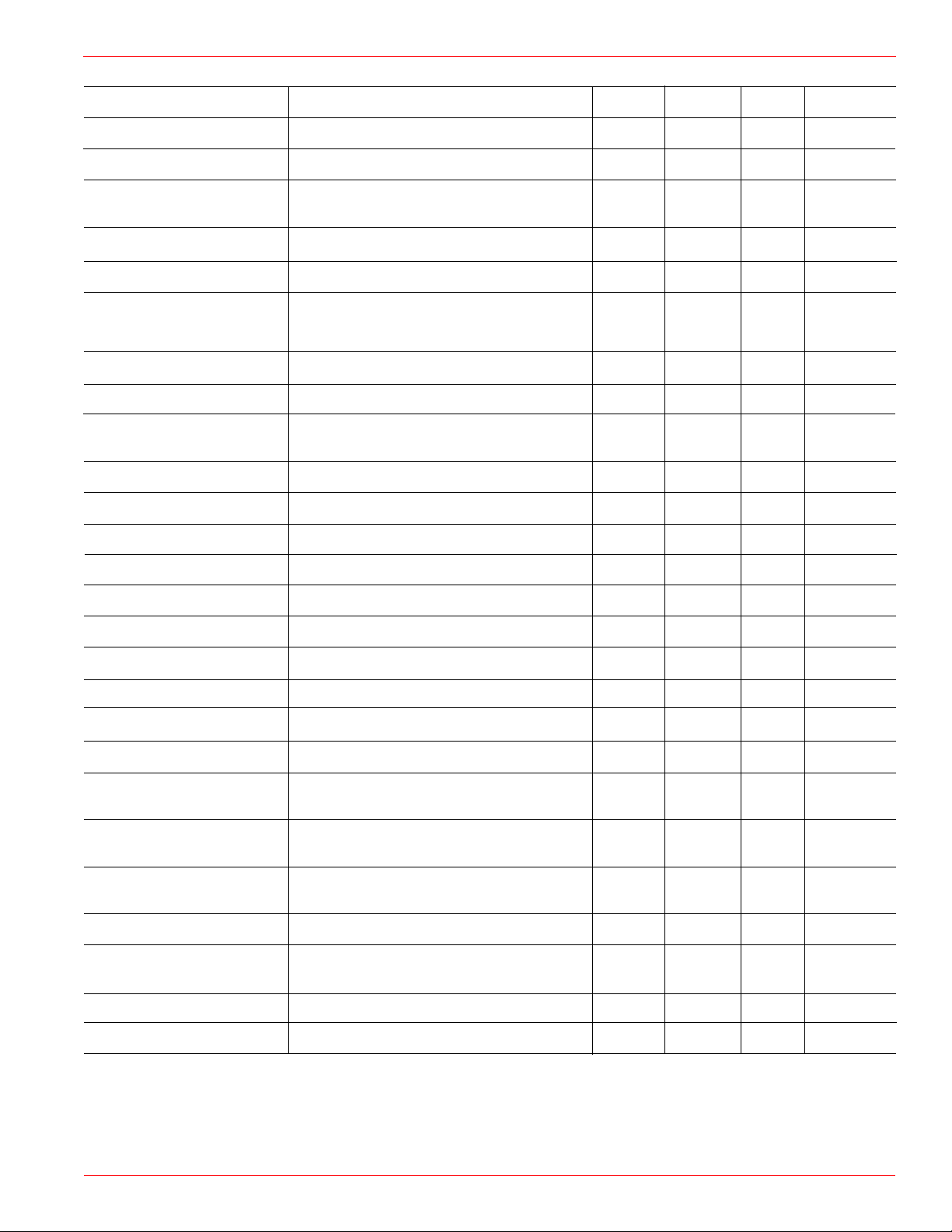

Characteristic Conditions** Min Typ Max Unit

Bridge Supply Vbridge referenced to GND 5 25 Volts

Bridge Resistance Bridge current = 5mA 800 1100 1300 Ω

Operating Temperature (1) HMC1021S, 1021Z, 1022 -55 150 °C

HMC1021D* - 55 300*

Storage T emper ature (1) Unbiased -55 175 °C

Field Range (1) Full scale (FS), — total applied field -6 +6 gauss

Best fit straight line ±1 gauss 0.05

Linearity Error (1) ±3 gauss 0.4 %FS

±6 gauss 1.6

Hysteresis Error (1) 3 sweeps across ±3 gauss 0.08 %FS

Repeatability Error (1) 3 sweeps across ±3 gauss 0.08 %FS

Bridge Offset Offset = (OUT+) – (OUT-), Field = 0 gauss -10 ±2.5 11.25 mV

After Set pulse, Vbridge=5V

Sensitivity S/R Current = 0.5A 0.8 1.0 1.25 mV/V/gauss

Noise Density (1) Noise at 1Hz, Vbridge=5V 48 nV/√Hz

Resolution (1) Bandwidth=10Hz, Vbridge=5V 85 µgauss

Bandwidth (1) Magnetic signal (lower limit = DC) 5 MHz

OFFSET Strap Measured from OFFSET+ to OFFSET- 38 50 60 Ω

OFFSET Strap Ω Tempco (1) T

A = -40 to 125° C 0.39 %/° C

OFFSET Field (1) Field applied in sensitive direction 4.0 4.6 6.0 mA/gauss

Set/Reset Strap Measured from S/R+ to S/R- 5.5 7.7 9 Ω

Set/Reset Current 2µs current pulse, 1% duty cycle 0.5 0.5 4.0 Amp

Set/Reset Ω Tempco (1) T

A = -40 to 125° C 0.37 %/° C

Disturbing Field (1) Sensitivity starts to degrade. Use S/R 20 gauss

pulse to restore sensitivity.

Sensitivity T empco (1) T

A = -40 to 125° C Vbridge=5V -0.32 -0.3 -0.28 %/° C

Ibridge=5mA -0.06

Bridge Offset Tempco (1) T

A = -40 to 125° C no Set/Reset ±0.05 %/° C

Vbridge=5V with Set/Reset ±0.001

Resistance T empco (1) Vbridge=5V , T

A = –40 to 125° C 0.25 %/° C

Cross-Axis Effect (1) Cross field=1 gauss

(see AN-205) Happlied=±1 gauss +0.3 %FS

Max. Exposed Field (1) No perming effect on zero reading 10000 gauss

Set/Reset (1) S/R current ≥ 0.5 Amps 30 µV

*Please reference data sheet, HTMC1021D for specifications.

(1) Not tested in production, guaranteed by characterization.

Units: 1 gauss (G) = 1 Oersted (in air), 1G = 79.58 A/m,

1G = 10E-4 Tesla, 1G = 10E5 gamma

**Tested at 25° C except otherwise stated.

3

Page 4

LINEAR MAGNETIC FIELD SENSORS

KEY PERFORMANCE DATA

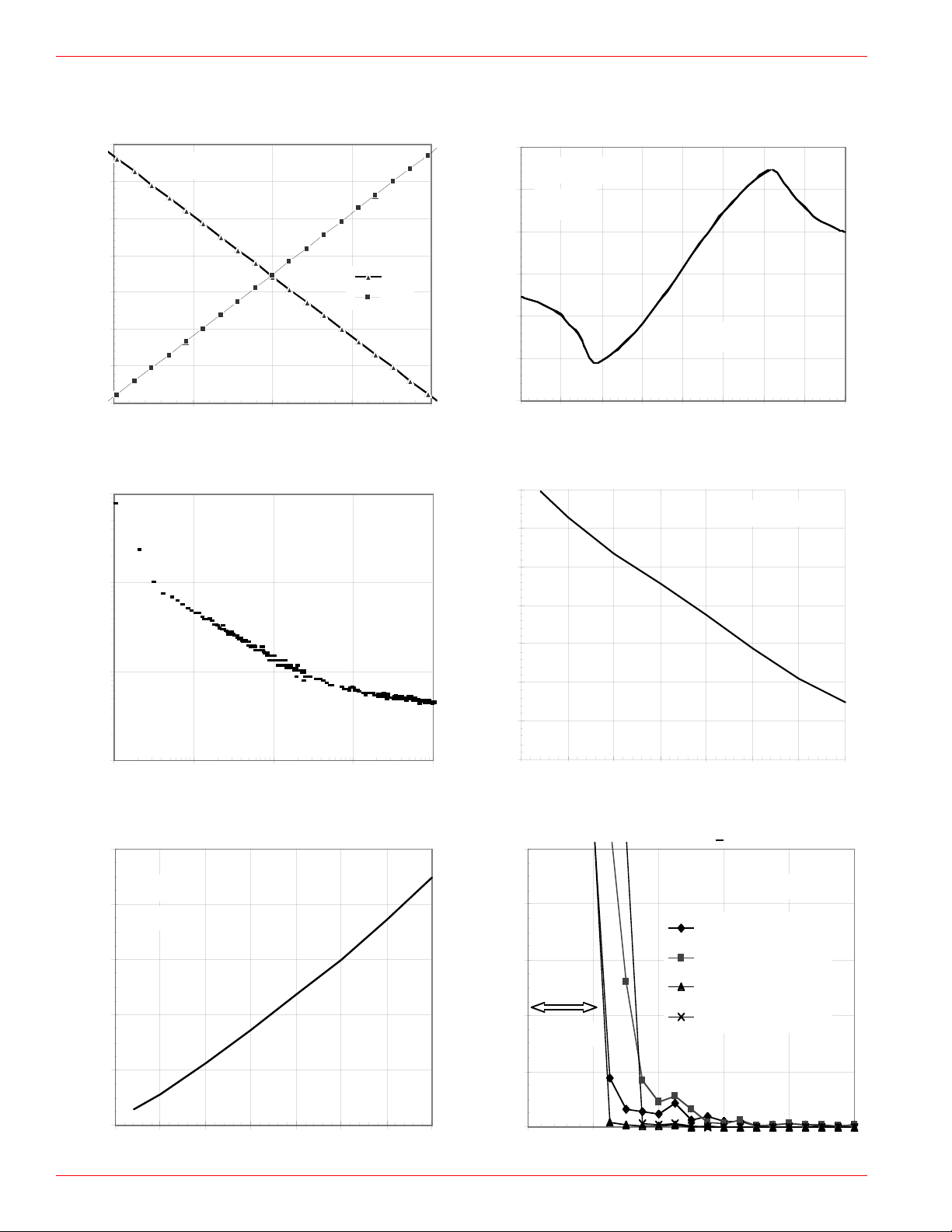

Sensor output vs magnetic field

after being set or reset

1021/1022

Vb=5V

Reset

Set

Voltage Output (mV)

2 sweeps

Output Voltage (mV)

15

10

5

0

-5

-10

-15

Sensor output vs magnetic field

Output is repeatable in field range ±20 Oe

60

1021/1022

40

Vb=5V

20

0

-20

2 sweeps

-40

-20

-2 -1 0 1 2

Field (Oe)

Sensor noise vs frequency

1000

1021/1022

Vb=5V

100

10

Noise Density (nV/rt Hz)

1

0.1 1 10 100 1000

Frequency (Hz)

Bridge resistance vs temperature

1400

All types

1300

Vb=5V

-60

-20 -15 -10 -5 0 5 10 1 5 20

Field (Oe)

Sensitivity vs temperature

1.3

Constant voltage power supply

1021/1022

1.2

1.1

1

0.9

0.8

Sensitivity (mV/V/Oe)

0.7

0.6

-50 -25 0 25 50 75 100 125

Vb=5V

Temperature (C)

Effects of set/reset pulse variation

2µ sec pulse duration, S/R voltage >4V is recommended

1

Vb=5V

1021/1022

0.8

Null Voltage (mV) (Set)

1200

1100

Resistance (ohm)

1000

900

-50 -25 0 25 5 0 75 100 125

Temperature (C)

0.6

0.4

Nonrepeatability

0.2

0

012345

4

no set/reset in

no set/reset in t

region

this region

Null Voltage (mV) (Reset)

Sensitivity (mV/V/Oe) (Set)

Sensitivity (mV/V/Oe) (Reset)

Set/Reset Voltage (V)

Page 5

5

6

7

8

)

)

3

4

5

PACKAGE / PINOUT SPECIFICATIONS

LINEAR MAGNETIC FIELD SENSORS

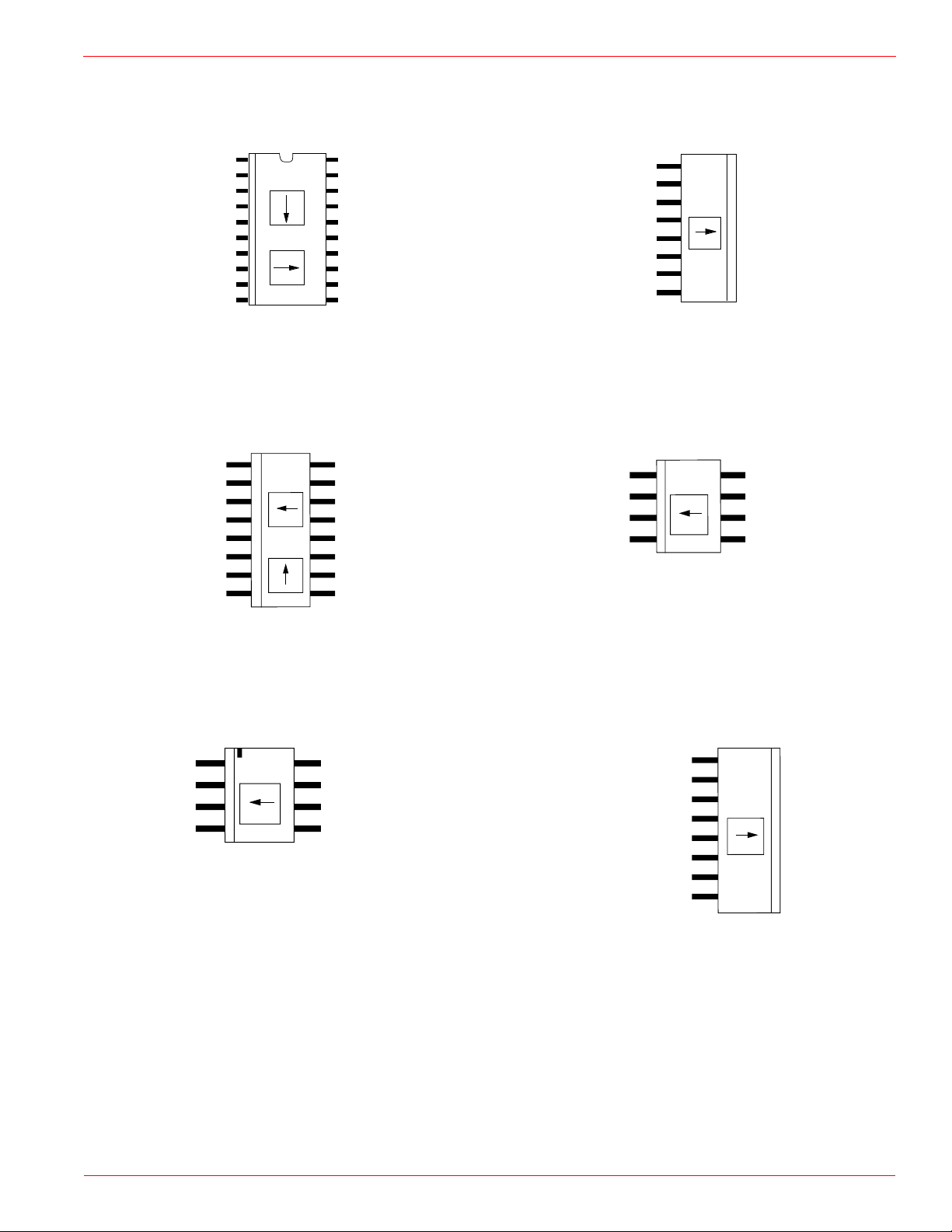

HMC1002—Two-Axis MR Microcircuit

GND1 (A) 1

OUT+ (A) 2

OFFSET- (A) 3

Vbridge (A) 4

OUT- (A)

GND2 (A)

S/R- (B)

GND1 (B)

Out+ (B) 9

OFFSET- (B) 10

Die A

Die B

20 S/R- (A)

19 NC

18 GND PLN

17 OFFSET (+A

16 S/R+ (A)

15 OFFSET+ (B

14 S/R+ (B)

13 GND2 (B)

12 OUT- (B)

11 Vbridge (B)

HMC1022—Two-Axis MR Circuit

OFFSET- (A) 1

OUT+ (A) 2

VBRIDGE (A) 3

OUT- (A) 4

OUT- (B) 5

VBRIDGE (B) 6

GND (A) 7

S/R+ (B) 8

•

Die A

Die B

16 OFFSET+ (A)

15 S/R- (A)

14 S/R+ (A)

13 GND (B)

12 OUT+ (B)

11 OFFSET- (B)

10 OFFSET+ (B)

9 S/R- (B)

HMC1001—One Axis MR Microcircuit

S/R+ 1

OFFSET+ 2

S/RGND

Out+

OFFSET- 6

Vbridge 7

Out- 8

•

Die

HMC1021S—One-Axis MR Circuit

OUT+ 1

VBRIDGE 2

GND 3

OUT- 4

•

Die

HMC1021S

8 OFFSET7 OFFSET+

6 S/R5 S/R+

OUT+ 1

VBRIDGE 2

GND 3

OUT- 4

HMC1021Z—One-Axis MR CircuitHMC1021D—One-Axis MR Circuit

Die

Arrow indicates direction of applied field that generates a

8 OFFSET7 OFFSET+

VBRIDGE 2

6 S/R5 S/R+

OFFSET+ 6

OFFSET- 7

positive output voltage after a SET pulse.

OUT+ 8

OUT- 1

S/R+ 3

GND 4

S/R- 5

•

Die

5

Page 6

LINEAR MAGNETIC FIELD SENSORS

R

BASIC DEVICE OPERATION

Honeywell magnetoresistive sensors are simple resistive

bridge devices (Figure 1) that only require a supply voltage

to measure magnetic fields. When a voltage from 0 to 10

volts is connected to Vbridge, the sensor begins measuring

any ambient, or applied, magnetic field in the sensitive axis.

In addition to the bridge circuit, the sensor has two on-chip

magnetically coupled straps—the OFFSET strap and the

Set/Reset strap. These straps are patented by Honeywell

and eliminate the need for external coils around the devices.

Vbridge

OUT+

(5)

R

=600-1200 Ω

R

(7)

GND

(4)

OFFSET +

R

OUT-

(8)

R

(2)

S/R +

(1)

3.5 Ω max.

Ioffset

2.0 Ω max.

Iset, -Ireset

OFFSET -

(6)

S/R -

(3)

Figure 1—On-Chip components (HMC1001)

Magnetoresistive sensors are made of a nickel-iron

(Permalloy) thin film deposited on a silicon wafer and

patterned as a resistive strip. In the presence of an applied

magnetic field, a change in the bridge resistance causes a

corresponding change in voltage output.

An external magnetic field applied normal to the side of the

film causes the magnetization vector to rotate and change

angle. This in turn will cause the resistance value to vary (∆R/

R) and produce a voltage output change in the Wheatstone

bridge. This change in the Permalloy resistance is termed the

magnetoresistive effect

and is directly related to the angle of

the current flow and the magnetization vector.

During manufacture, the easy axis (preferred direction of

magnetic field) is set to one direction along the length of the

film. This allows the maximum change in resistance for an

applied field within the permalloy film. However, the influence

of a strong magnetic field (more than 10 gauss) along the

easy axis could upset, or flip, the polarity of film

magnetization, thus changing the sensor characteristics.

Following such an upset field, a strong restoring magnetic

field must be applied momentarily to restore, or set, the

sensor characteristics. This effect will be referred to as

applying a set pulse or reset pulse. Polarity of the bridge

output signal depends upon the direction of this internal film

magnetization and is symmetric about the zero field output.

The OFFSET strap allows for several modes of operation

when a dc current is driven through it.

• An unwanted magnetic field can be subtracted out

• The bridge offset can be set to zero

• The bridge output can drive the OFFSET strap to cancel

out the field being measured in a closed loop configuration

• The bridge gain can be auto-calibrated in the system on

command.

The Set/Reset (S/R) strap can be pulsed with a high current to:

• Force the sensor to operate in the high sensitivity mode

• Flip the polarity of the output response curve

• Be cycled during normal operation to improve linearity

and reduce cross-axis effects and temperature effects.

The output response curves shown in Figure 2 illustrate the

effects of the S/R pulse. When a SET current pulse (Iset) is

driven into the SR+ pin, the output response follow the curve

with the positive slope. When a RESET current pulse

(Ireset) is driven into the SR- pin, the output response follow

the curve with the negative slope. These curves are mirror

images about the origin except for two offset effects.

In the vertical direction, the bridge offset shown in Figure 2,

is around -25mV. This is due to the resistor mismatch during

the manufacture process. This offset can be trimmed to zero

by one of several techniques. The most straight forward

technique is to add a shunt (parallel) resistor across one leg

of the bridge to force both outputs to the same voltage. This

must be done in a zero magnetic field environment, usually

in a zero gauss chamber.

The offset of Figure 2 in the horizontal direction is referred to

here as the external offset. This may be due to a nearby ferrous

object or an unwanted magnetic field that is interfering with the

applied field being measured. A dc current in the OFFSET

strap can adjust this offset to zero. Other methods such as

shielding the unwanted field can also be used to zero the

external offset. The output response curves due to the SET

and RESET pulses are reflected about these two offsets.

40

20

0

-20

Vcc=8V

response

after Ireset

(1001/1002)

bridge

offset

response

after Iset

-40

Output Voltage (mV)

-60

-80

-1.50

-1.25

-1.00

external

offset

-0.75

-0.50

Applied Field (Gauss)

-0.25

0.00

0.25

0.50

0.75

1.00

1.25

1.50

Figure 2—Output Voltage vs. Applied Magnetic Field

6

Page 7

NOISE CHARACTERISTICS

LINEAR MAGNETIC FIELD SENSORS

The noise density curve for a typical MR sensor is shown

in Figure 3. The 1/f slope has a corner frequency near 10

Hz and flattens out to 3.8 nV/√Hz. This is approximately

equivalent to the Johnson noise (or white noise) for an

850Ω resistor—the typical bridge resistance. To relate the

noise density voltage in Figure 3 to the magnetic fields, use

the following expressions:

For Vsupply=5V and Sensitivity=3.2mV/V/gauss,

Bridge output response = 16 mV/gauss

or

16 nV/µgauss

The noise density at 1Hz ≈ 30nV/√Hz

and corresponds to 1.8 µgauss/√Hz

For the noise components, use the following expressions:

1/f noise(0.1-10Hz) = 30 * √(ln(10/.1)) nV

64 nV (rms)

4 µgauss (rms)

27 µgauss (p-p)

white noise (BW=1KHz) = 3.8 * √BW nV

120 nV (rms)

50 µgauss (p-p)

1000

Hz)

√

100

(1001/1002)

then it can be compensated for by applying an equal and

opposite field using the OFFSET strap. Another use for the

OFFSET strap would be to drive a current through the strap

that will exactly cancel out the field being measured. This is

called a closed loop configuration where the current feedback

signal is a direct measure of the applied field.

The field offset strap (OFFSET+ and OFFSET-) will generate

a magnetic field in the same direction as the applied field

being measured. This strap provides a 1 Oersted (Oe) field

per 50 mA of current through it in HMC1001/2 and 1 Oe/5mA

in HMC1021/2. (Note: 1 gauss=1 Oersted in air). For

example, if 25 mA were driven from the OFFSET+ pin to the

OFFSET- pin in HMC1001/2, a field of 0.5 gauss would be

added to any ambient field being measured. Also, a current

of -25 mA would subtract 0.5 gauss from the ambient field.

The OFFSET strap looks like as a nominal resistance

between the OFFSET+ and OFFSET- pins.

The OFFSET strap can be used as a feedback element in

a closed loop circuit. Using the OFFSET strap in a current

feedback loop can produce desirable results for measuring

magnetic fields. To do this, connect the output of the bridge

amplifier to a current source that drives the OFFSET strap.

Using high gain and negative feedback in the loop, this will

drive the MR bridge output to zero, (OUT+) = (OUT-). This

method gives extremely good linearity and temperature

characteristics. The idea here is to always operate the MR

bridge in the balanced resistance mode. That is, no matter

what magnetic field is being measured, the current through

the OFFSET strap will cancel it out. The bridge always

“sees” a zero field condition. The resultant current used to

cancel the applied field is a direct measure of that field

strength and can be translated into the field value.

10

Noise Density (nV/

1

0.1 1 10 100 1000

Frequency (Hz)

Figure 3—Typical Noise Density Curve

WHAT IS

OFFSET

STRAP?

Any ambient magnetic field can be canceled by driving a

defined current through the OFFSET strap. This is useful

for eliminating the effects of stray hard iron distortion of the

earth’s magnetic field. For example, reducing the effects of

a car body on the earth’s magnetic field in an automotive

compass application. If the MR sensor has a fixed position

within the automobile, the effect of the car on the earth’s

magnetic field can be approximated as a shift, or offset, in

this field. If this shift in the earth's field can be determined,

The OFFSET strap can also be used to auto-calibrate the

MR bridge while in the application during normal operation.

This is useful for occasionally checking the bridge gain for

that axis or to make adjustments over a large temperature

swing. This can be done during power-up or anytime during

normal operation. The concept is simple; take two point

along a line and determine the slope of that line—the gain.

When the bridge is measuring a steady applied magnetic

field the output will remain constant. Record the reading for

the steady field and call it H1. Now apply a known current

through the OFFSET strap and record that reading as H2.

The current through the OFFSET strap will cause a change

in the field the MR sensor measures—call that delta applied

field (∆Ha). The MR sensor gain is then computed as:

MRgain = (H2-H1) / ∆Ha

There are many other uses for the OFFSET strap than those

described here. The key point is that ambient field and the

OFFSET field simply add to one another and are measured

by the MR sensor as a single field.

7

Page 8

LINEAR MAGNETIC FIELD SENSORS

WHAT IS

SET/RESET

STRAP?

Most low field magnetic sensors will be affected by large

magnetic disturbing fields (>4 - 20 gauss) that may lead to

output signal degradation. In order to reduce this effect, and

maximize the signal output, a magnetic switching technique

can be applied to the MR bridge that eliminates the effect

of past magnetic history. The purpose of the Set/Reset

(S/R) strap is to restore the MR sensor to its high sensitivity

state for measuring magnetic fields. This is done by pulsing

a large current through the S/R strap. The Set/Reset (S/R)

strap looks like a resistance between the SR+ and SR- pins.

This strap differs from the OFFSET strap in that it is

magnetically coupled to the MR sensor in the cross-axis, or

insensitive, direction. Once the sensor is set (or reset), low

noise and high sensitivity field measurement can occur. In

the discussion that follows, the term “set” refers to either a

set or reset current.

When MR sensors exposed to a magnetic disturbing field,

the sensor elements are broken up into ramdonly oriented

magnetic domains (Figure 4A) that leads to sensitivity

degrading. A current pulse (set) with a peak current above

minimum current in spec through the Set/Reset strap will

generate a strong magnetic field that realigns the magnetic

domains in one direction (Figure 4B). This will ensure a high

sensitivity and repeatable reading. A negative pulse (Reset)

will rotate the magnetic domain orientation in the opposite

direction (Figure 4C), and change the polarity of the sensor

outputs. The state of these magnetic domains can retain for

years as long as there is no magnetic disturbing field

present.

Easy Axis

Permalloy (NiFe) Resistor

Magnetization

Random

Domain

Orientations

Fig.4A

After a

Set Pulse

longer, to conserve power. The only requirement is that

each pulse only drive in one direction. That is, if a +3.5 amp

pulse is used to “set” the sensor, the pulse decay should not

drop below zero current. Any undershoot of the current

pulse will tend to “un-set” the sensor and the sensitivity will

not be optimum.

Using the S/R strap, many effects can be eliminated or

reduced that include: temperature drift, non-linearity errors,

cross-axis effects, and loss of signal output due to the

presence of a high magnetic fields. This can be accomplished by the following process:

• A current pulse, Iset, can be driven from the S/R+ to the

S/R- pins to perform a “SET” condition. The bridge output

can then be measured and stored as Vout(set).

• Another pulse of equal and opposite current should be

driven through the S/R pins to perform a "RESET" condition. The bridge output can then be measured and stored

as Vout(reset).

• The bridge output, Vout, can be expressed as: Vout =

[Vout(set) - Vout(reset)]/2. This technique cancels out

offset and temperature effects introduced by the electronics as well as the bridge temperature drift.

There are many ways to design the set/reset pulsing circuit,

though, budgets and ultimate field resolution will determine

which approach will be best for a given application. A simple

set/reset circuit is shown in Figure 5.

6-9V

S/R+

S/R-

0.2µF

3

IRF7105

5,6

7,8

1

25K

4

0.1µF

2

SET RESETRESET

Signal should be in

RESET state when idle

Signal input

5V

Manual Switch

Fig.4B

Magnetization

After a

Reset Pulse

Fig.4C

Figure 4—

The on-chip S/R should be pulsed with a current to realign,

or“flip”, the magnetic domains in the sensor. This pulse can

be as short as two microsecond and on average consumes

less than 1 mA dc when pulsing continuously. The duty

cycle can be selected for a 2 µsec pulse every 50 msec, or

Figure 5—Single-Axis Set/Reset Pulse Circuit (1001)

The magnitude of the set/reset current pulse depends on

the magnetic noise sensitivity of the system. If the minimum

detectable field for a given application is roughly 500

µgauss in HMC1001/2, then a 3 amp pulse (min) is adequate.

If the minimum detectable field is less than 100 µgauss,

then a 4 amp pulse (min) is required. The circuit that

generates the S/R pulse should be located close to the MR

sensor and have good power and ground connections.

The set/reset straps on the Honeywell magnetic sensors

are labeled S/R+ and S/R-. There is no polarity implied

since this is simply a metal strap resistance.

8

Page 9

LINEAR MAGNETIC FIELD SENSORS

V

V

V

S/R

K

F

)25K

HMC

N

(1)T

R

K

F

V

V

V

F*

SHDN

V

GND

C

C

F

Vout

C

C

F*1µF

V

V

MAX

A

*U

V2µF

F

K

K

K

F

S/R

k

F(2)

)

HMC

(1) HEXFET

K

K

F1nF

V74HC

Single Clock Circuitry—

Some form of clock is needed to

trigger the set and reset pulses (Figure 6) to create the

switching signal. The circuit shown in Figure 8 can be used

to create a strong (>4Amp) pulse. The diodes, resistors,

capacitors and inverters basically create the TRS and the

TSR delays. Now a single signal (Clock) can trigger a set or

reset pulse. The minimum timing between the rising and

falling edges of Clock are determined by the 25KΩ and 1nF

time constant. That is, the minimum high and low time for

Clock is ≈25 µs.

Micro Processor—

The circuit in Figure 9 generates a strong

set/reset pulse (>4 Amp) under microprocessor control. The

5

Clock

16

set

TPW ≈ 2 µsec

S/R

reset

-16

Figure 6—Single Clock Set/Reset Timing

SET and RESET signals are generated from a

microprocessor and control the P and N channel HEXFET

drivers (IRF7105). The purpose of creating the TRS and the

TSR delays are to make sure that one HEXFET is off before

the other one turns on. Basically, a break-before-make

switching pattern. The current pulse is drawn from the 4.7

µF capacitor. If the 5V to 20V converter is used as shown in

Figure 7, then the resultant noise and droop on the 16-20V

supply is not an issue. But if the 16-20V supply is used

elsewhere in the system, then a series dropping resistor

(≈500Ω) should be placed between the 4.7µF capacitor and

the supply.

2

0.22µ

5

1

8

7

5

se tantalum capacitors

662

1+

1-

cc

3

2-

2+

1µ

0.22µ

4

6

1N5818

20

1µ

12

Figure 7—5V to 20V Converter

Cloc

SET

RESET

S/R

5

T

RS

T

RS ≥ 5 µsec

T

SR ≥ 5 µsec

T

PW ≈ 2 µsec

+16 to 20V

25

25

0.1µ

3

4

IRF7106 (1)

5,6

7,8

2

1

14

8943

7

1N4001

25

04

1n

25

10

21

2N3904

65

Figure 8—Single Clock Set/Reset Pulse Circuit (1001/1002)

5

T

SR

16

set

10

SET

3904

2

-16

reset

T

PW

RESET

+16 to 20V

25

4

0.1µ

2

4.7µF(3

strap @ 4.5Ω typ.

3A peak (min.)

0.22µ

17

S/R

(2) 0.22µF Tantalum or a

0.68 µF Ceramic CK06

(3) Tantalum, low R

3

5,6

7,8

s with≈0.2ΩRon

4.7µF(1

0.22µ

IRF7106 (2)

S/R

1

antalum,low

(2) HEXFETs with ≈0.2Ω Ron

2003

*

1

strap @ 4.5Ω typ.

3A peak (min.)

2003

1

17

*

•HMC2003 contains one HMC1001 and one HMC1002; together they make the 3-axis sensor.

Three S/R straps are in serial, the total resistance is ~4.5Ω.

Figure 9—Set/Reset Circuit With Microprocessor Control (1001/1002)

9

Page 10

LINEAR MAGNETIC FIELD SENSORS

S/R

K

F

)

HMC

*

(1)T

R

F

F10K

ZTX

ZTX

S/R

K

F

HMC

F

K

ZTX

V

V

Low Field Measurements—

When measuring 100 µgauss

resolution or less, the permalloy film must be completely

set, or reset, to insure low noise and repeatable

measurements. A current pulse of 4 amps, or more, for just

a couple microseconds will ensure this. The circuits in

Figures 8 and 9 are recommended for applications of

HMC1001/2 that require low noise and high sensitivity

magnetic readings.

Low Cost—

For minimum field measurements above 500

µgauss, a less elaborate pulsing circuit can be used. In both

Figures 10 and 11, the pulse signal is switched using lower

cost Darlington transistors and fewer components. This circuit

may have a more limited temperature range depending on the

quality of transistors selected. If accuracy is not an issue and

cost is, then the reset only circuit in Figure 11 will work.

+16 to 20V

0.022µ

0.022µ

Clock

10

4.7µF(1

705

605

0.22µ

strap @ 4.5Ω typ.

3A peak (min.)

17

S/R

antalum,low

2003

1

Figure 10—Single Clock Set/Reset Circuit (1001/1002)

For any magnetic sensor application, if temperature drift is

not an issue, then the reset pulse need only be occasionally

applied. This will save power and enable the use of digital

filtering techniques as shown in Figure 12. Circumstances

for a reset pulse would be 1) power on or, 2) field over/

under range condition. Any other time the sensor should

perform normally.

Clock

+5V

200

0.1µF

0.1µF

0.1µF

0.1µF

10K

10K

1µF (1)

1µF (1)

FMMT717

FMMT617

HMC1022

8

0.1µF

0.1µF

(1) Tantalum, low R

9,1514

Figure 12—5V Circuit for SET/RESET (1021/1022)

The circuit in Figure 13 generates a strong set/reset pulse

under a microprocessor clock driven control. A free running

555 timer can also be used to clock the circuit. The SET

current pulse is drawn from the 1 µF capacitor and a 200

ohm dropping resistor should be placed in series with the

supply to reduce noise.

strap @ 4.5Ω typ.

3A peak (min.)

17

S/R

2003

1

*

Clock

+16 to 20V

100

0.22µ

0.022µ

605

10

5

Clock

S/R

TPW ≈ 2 µsec

reset

-16

*The HMC2003 has 3-axis S/R straps in series.

These are the HMC1001 and HMC1002 sensors.

Figure 11—Single Clock Reset Only Circuit (1001/1002)

10

Page 11

LINEAR MAGNETIC FIELD SENSORS

5V

Clock

+5 to 6V

4 to14V

set

T

PW ~ 2 µsec

S/R

-4 to -14V

reset

Clock

set rst set

Figure 13—Set/Reset Pulse With Clock Control (1021/1022)

Low Power—

For low power application, down to 3.3 volt

supply, the circuit shown in Figure 15 can be used. These

low threshold FETs provide low on-resistance (0.3Ω) at

V

GS=2.7V. The set/reset pulsing does not need to be

continuous. To save power, the SET pulse can be initially

applied followed by a single RESET pulse. The offset (OS)

can be calculated as:

200

4

2

3

5,6

7,8

1

1µF (1)

IRF7105 (2)

DI9952 (2)

(1) Tantalum, low R

(2) Rds ~0.2 ohm

HMC1022

14

0.1µF

SET Pulse

Read Vset

RESET Pulse

Read Vrst

8

9,15

S/R

OS = (Vset + Vrst)/2

This offset term will contain the DC offset of both the sensor

bridge and interface electronics, as well as the temperature

drift of the bridge and interface electronics. Store this value

and subtract it from all future bridge output readings. Once

the bridge is RESET, it will remain in that state for years—

or until a disturbing field (>20 gauss) is applied. A timer can

be set, say every 10 minutes, to periodically update the

offset term. A flow chart is shown in Figure 14 along with a

timing diagram in Figure 15 to illustrate this process.

Reset

Set

Vout

a

T

Vp

TbT

set

a

c

T

d

T

read

Vset

d

T

read

Vrst

OS = (Vset+Vrst)/2

Vout = Vrst - OS

Timer

expired?

n

Read Vrst

y

Figure 14—Low Power Set/Rst Flowchart

+3.3 to

6.5V

Set

200

1,3

2,4

5,6,7,8

5,6,7,8

1µF (1)

+

NDS9933

HMC1022

8

0.1µF

9,1514

S/R

a > 5 µsec

T

b > 1 µsec

T

c > 20 µsec, 50 msec(max)

T

d > 20 µsec Vp > 3 V

T

PW ~ 2 µsec

T

Figure 15—Single Clock Set/Reset Pulse Circuit (1021/1022)

PW

T

reset

-Vp

Reset

2,4

1,3

NDS8926

(1) Tantalum, low R

(2) Rds ~0.2 ohm

S/R

11

Page 12

LINEAR MAGNETIC FIELD SENSORS

*R

Vref

R1*

R2*

K

LM

V

V

Ain+Ai

Ref

Ref

CONV

SCLK

SDATA

NDRDY

XIN

CAL

NCS

V

Gnd

V

V

V

S/R

Vref

K

R3**

K

Gai

F#

R1*

V

V

Calib

LED

*R

Vref

R1*

R2*

K

LM

V

V

Ai

Ai

Ref

Ref

CONV

SCLK

SDATA

NDRDY

XIN

CAL

NCS

V

Gnd

V

V

V

S/R

A

Simple Circuit Application

The circuit in Figure 16 shows a simple application of a

magnetic sensor. This circuit acts as a proximity sensor

and will turn on the LED when a magnet is brought within

0.25 to 0.5 inch of the sensor. The amplifier acts as a

simple comparator and switches low when the HMC1001

bridge output exceeds 30mV. The magnet must be

magnet

movement

Magnetic

Sensor

7

8

5

HMC1001

4

rate:

1. Trim R1 for (+V) - (-V) < 30mV

2. Apply signal < 30mV, LED should be off.

3. Apply signal > 30mV, LED should be on.

+5

100

7

1

+

AMP04

-

8

5

4

* R1 is used to trim switchpoint

# provides 10Hz rolloff

3

V+

2

V-

0.15µ

6

Vout

n=1000,BW=10Hz

+5

400

Figure 16—Magnetic Proximity Switch

+6-15

5 mA

BS250

7

4

Magnetic

Sensor

HMC1001

1.6Ω

13

+

8

5

22.1

100

0.01

10

1

LMC7101

-+

34

strong (200 gauss) and have one of its magnetic poles

point along the sensitive direction of the sensor. This

circuit can be used to detect a door open/closed status or

the presence or absence of an item. Figures 17, 18, 19,

20 and 21 show other circuit examples.

Magnetic

Sensor

7

+5

HMC1001

4

1.6Ω

+

8

5

13

Pulse

650

1.5nF#

1

8

2

-

3

6

+

AMP04

5

+

25

440

2.5V

1 or R2 used to trim offest

# provides 1KHz rolloff

out

CS5509

16 bit A/D

7

n+

8

n-

9

+

10

-

12

6,11,13

+

2

14

15

16

4

3

1

Figure 17—One-Axis Sensor With Digital Interface

650

1.5nF#

1

8

2

-

3

6

+

AMP04

5

+

out

25

440

2.5V

CS5509

16 bit A/D

7

8

n-

9

+

10

-

12

6,11,13

+

2

14

15

16

4

3

1

+5

Serial Bus

Interface

+5

Serial Bus

Interface

1 or R2 used to trim offest

**R3 = 451Ω for 1 axis, 921Ω for 2 axis, or 1411Ω for 3 axis

Pulse

# provides 1KHz rolloff

Figure 18—One-Axis Sensor With Constant Bridge Current and Digital Interface

+5V

10K

4.7uF

tantalum

SW1

1M

OUT-1

V

BRIDGE

S/R+3

GND4

S/R-5

O

FFSET+

FFSET-

O

OUT+8

HMC1021S

+5V

200

2

Sensitive

Direction

6

7

Z

-

MP623

+

+5V

2.5V

LM404-2.5

25K

V+

Vout

Gnd

(1) Momentarily close switch SW1. This creates a SET pulse. (2) Measure bridge output (OUT+) - (OUT-) NOTE: Bridge

output signal will be 5mV/gauss (3) Measure Vout after AD623 amplifier (G~500) NOTE: Vout signal will be 2.5V/gauss

Figure 19—One-Axis Low Cost Sensor

12

Page 13

+5V

+5V

X

1,6

11

Y

8,13

20

14

Magnetic

Magnetic

SensorS

Sensors

4

HMC1002

1.6

1.6

7,18

V+

650

1

R1*

5

2

-

3

2

9

12

16

* R1-R4 used to trim offest

# provides 1KHz rolloff

0.2µF

R2*

V+

R3*

R4*

4.7µF

tantalum

5,6

7,8

2

3

+

5

Vref

650

1

-

+

5

Vref

1K

3

IRF7105

1

8

AMP04

8

AMP04

1.5nF#

6

1.5nF#

6

4

2

LINEAR MAGNETIC FIELD SENSORS

TLC2543

25K

+5V

0.1µF

25K

LM440

2.5V

0.22µF

4.7µF

SR

+

12V

+

12 bit A/D

1

AIN0

2

AIN1

14

Ref+

13

Ref-

10

Gnd

MAX662A

C2-

4

C2+

6

SHDN

Vout

Signal input

5V

Manual Switch

DOUT

NCS

C1+

C1-

Vcc

GND

0.1µF

20

V+

18

CLK

17

DIN

16

15

19

EOC

23

+

0.22µF

1

5

8

7

Signal should be in Rst

state when idle

Set RstRst

+5V

Serial Bus

Interface

+5V

4.7µF

Figure 20—Two-Axis Sensor With Set/Reset Circuit and Digital Interface

+5V

Vb

Vb

Vb

Magnetic

Magnetic

Sensors

Sensor

S/R straps

HMC1001

S/R strap

-

1µF

1 F

LM324a

Vref

NDC7001 or

equiv.

+

Vref

-

+

-

+

0.1µF

0.1 F

0.1µF

0.1 F

-

+

0.1µF

0.1 F

+

LM324b

Vref

+

LM324c

Vref

Vref

+

LM324d

Vref

S/R

100K

100K

0.1uF

Sel1

Sel2

A B

0X

1X

X

2X

3X

4052

200

+5V

Vr ef

+

Output

utp

u

t

O

S/R Control

Figure 21—Three-Axis Low Cost Magnetic Sensor

13

Page 14

LINEAR MAGNETIC FIELD SENSORS

PACKAGE OUTLINES

HMC1002—Package Outline

h

h × 45°

A1

H

A

A

A1

D

20 11

1 10

B

HMC1001—8-Pin SIP and

HMC1021Z—8-Pin SIP

D

HE

1

e B

E

e

8

Symbol

A

A1

B

D

E

e

H

h

Symbol

A

A1

B

D

E

e

H

h

Millimeters Inches

Min

2.489

0.127

0.457

12.675

7.264

1.270 ref

1.270

0.381

Min

1.371

0.101

0.355

9.829

3.810

1.270 ref

5.014

6.850 7.300 0.270 0.287

0.381

Max

2.642

0.279

0.483

12.929

7.417

10.566

ref

Millimeters Inches

Max

1.728

0.249

0.483

11.253

3.988

5.314

0.762

Min

.098

.005

.014

.499

.286

.050 ref

.396

.015

Min

.054

.004

.014

.387

.150

.050 ref

.197

.015

ref

Max

.104

.011

.019

.509

.292

ref

.416

.030

Max

.068

.010

.019

.443

.157

.209

.030

HMC1021D—8-Pin Ceramic DIP

A1

E1

A

Q

D

8 7 6 5

1 2 3 4

L

b

E

e

HMC1021S—8-Pin SOIC

D

E

H

1

A1

A

•

e

HMC1022—16-Pin SOIC

D

H

E

1

•

e

h x 45°

B

916

8

h x 45°

B

A1

Millimeters Inches

—

Min

.054

.004

.014

.189

.150

.229

.015

Min

Max

0.012

0.020

0.405

0.298

0.310

0.060

0.175

Max

.068

.010

.019

.196

.157

.244

.030

Max

.068

.010

.019

.443

.157

.244

.030

Symbol

A

A1

b

D

E

E1

e

Q

L

Symbol

A

A1

B

D

E

e

H

h

Symbol

A

A

A1

B

D

E

e

H

h

Min Max

2.718 ref

7.163

7.366

2.54 ref

3.175

1.270 ref

1.371

0.101

0.355

9.829

3.810

1.270 ref

5.816

0.381

0.305

0.229

0.508

0.406

10.287

—

7.569

7.874

1.524

0.381

4.445

Millimeters Inches

Min

1.371

0.101

0.355

4.800

3.810

5.816

0.381

Min

Max

1.728

0.249

0.483

4.979

3.988

6.198

0.762

Millimeters Inches

Max

1.728

0.249

0.483

11.253

3.988

6.198

0.762

Min

0.107 ref

0.009

0.016

0.282

0.290

0.100 ref

0.015

0.125

.050 ref

.054

.004

.014

.387

.150

.050 ref

.229

.015

14

Page 15

DESIGN / PACKAGE OPTIONS

LINEAR MAGNETIC FIELD SENSORS

Honeywell offers a range of magnetic microcircuit products.

Two different sensor designs and five package

configurations are available:

• HMC1001/1002 series offers a higher sensitivity and

lower field resolution.

• HMC1021/1022 series offers a wider field range, lower

set/reset current and has a lower cost for higher volume

applications.

20/1001CMH22/1201CMHstinU

ytivitisneS1.30.1G/V/Vm

noituloseR7258ssuagµ

egnaR2±6±ssuag

tnerruCtsR/teS0.35.0spmA

tsoCemulovhgihnirewoL

Two-axis parts contain two sensors for the x- and y- field

measurements. Single-axis variations include a SIP package

for mounting through the circuit board to create a 3-axis

solution, a SOIC for direct surface mount, and a ceramic DIP

for high performance military and high temperature

applications.

ORDERING INFORMATION

rebmuNtraPrebmuNsixAytivitisneSelytSegakcaP

1001CMHelgniSG/V/Vm3PISniP-8

2001CMHowTG/V/Vm3CIOSniP-02

D1201CMHelgniSG/V/Vm1PIDcimareCniP-8

Z1201CMHelgniSG/V/Vm1PISniP-8

S1201CMHelgniSG/V/Vm1CIOSniP-8

2201CMHowTG/V/Vm1CIOSniP-61

Solid State Electronics Center • 12001 State Highway 55, Plymouth, MN 55441 • (800) 323-8295 • www.magneticsensors.com

Additional Product Details:

Customer Service Representative

(612) 954-2888 fax: (612) 954-2257

E-Mail: clr@mn14.ssec.honeywell.com

Honeywell reserves the right to make changes to any products or technology herein to improve reliability, function or design. Honeywell does not assume any liability

arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent rights nor the rights of others.

900248 Rev. B

4-00

15

Loading...

Loading...