Page 1

HM700A1000

ELECTRODE STEAM HUMIDIFIER

Tools Needed

— Screwdriver

—Wrench

— Pliers

— Shut-off water valve

— Water line (LDPE or Copper)

Humidifier Configuration

The HM700 is configured at the factory to operate under most

conditions without the need to change its configuration.

NOTE: Because the humidifier is factory configured for

INSTALLATION INSTRUCTIONS

optimal performance, Honeywell strongly

discourages changes to the jumpers or the

potentiometer; doing so will void the warranty

and could damage the humidifier. Contact

Honeywell Customer Care for further

information.

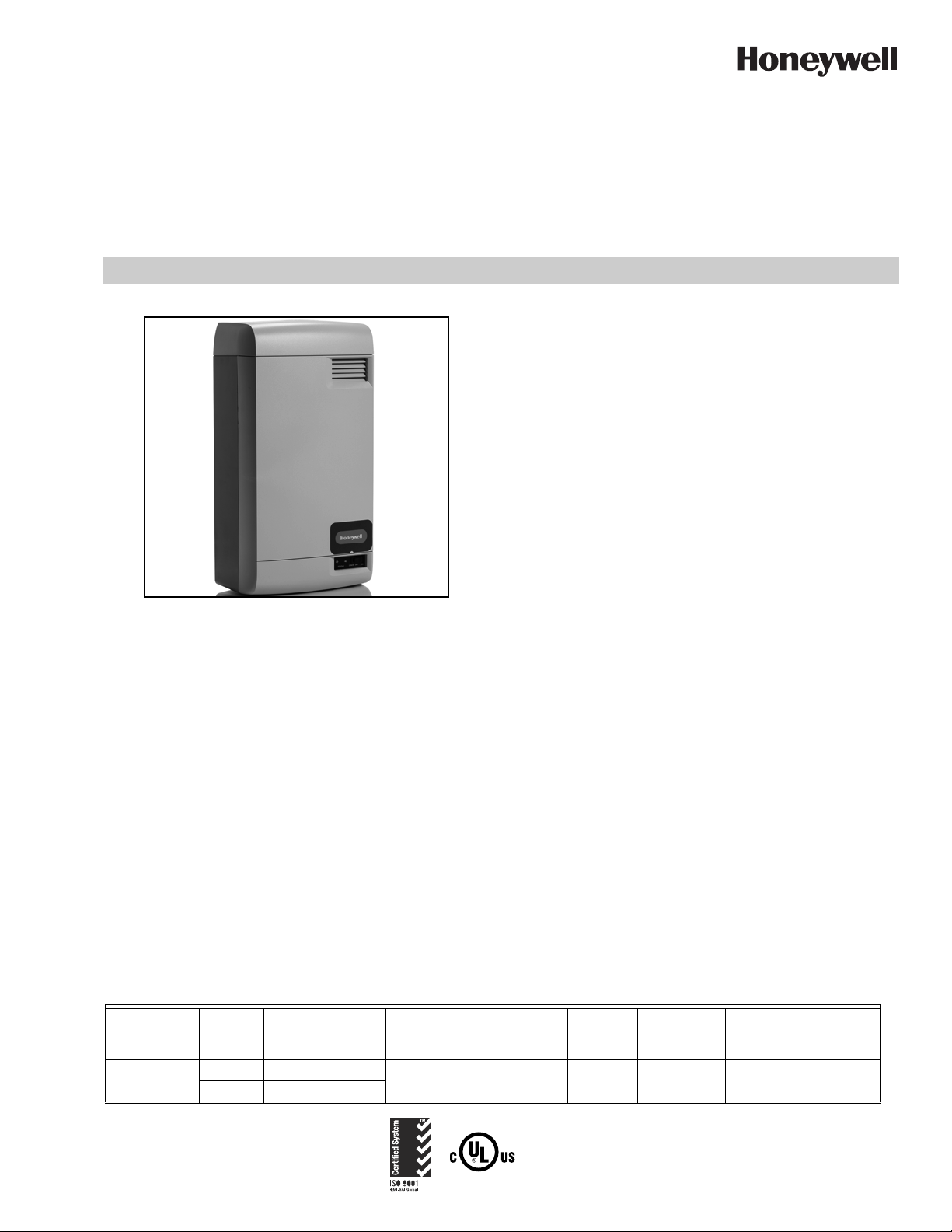

INTRODUCTION

The HM700 is the most advanced residential steam humidifier

available and provides steady and reliable humidification for a

home. The humidifier is designed for connection to a steam

distributor installed in a supply air duct for humidity on

demand.

IMPORTANT

Read and save these instructions. This guide should

be kept by the installer, and the Homeowner’s Guide

should be left with the equipment owner.

Included in the Box

— Steam Humidifier (HM700)

— Distribution Remote Mount Kit (HM700ADISTKIT)

— HumidiPRO Humidistat (H6062A1000)

— Steam Cylinder (one HM700ACYL2 included)

— Rubber drain hose

— Installation Instructions, Homeowner’s Guide and

Quick Start Guide

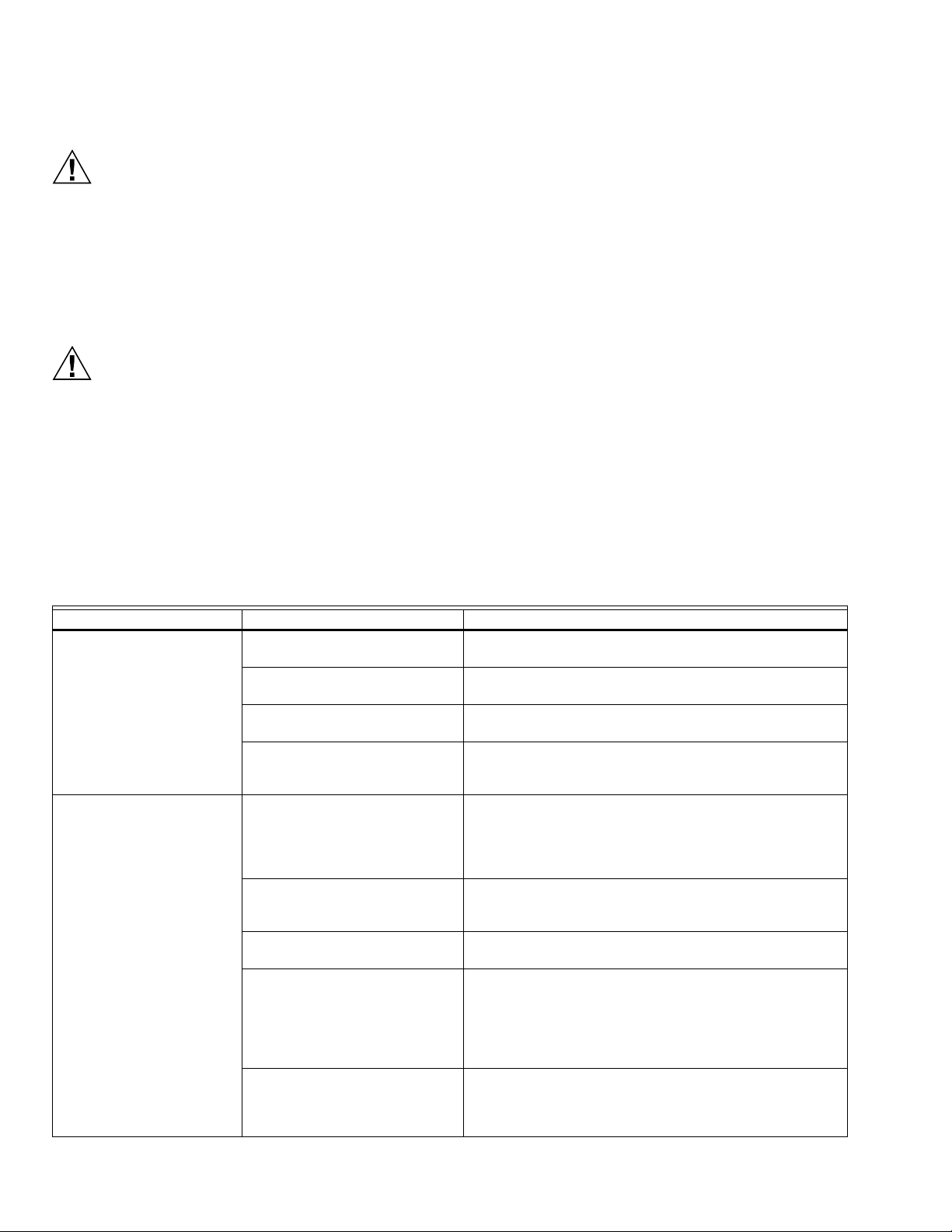

Table 1. Specifications.

Steam

Output

Part Number Volts

HM700A1000

110/120 11 1.4

220/240 22 2.8

GPD KW Amps Phase

12.0 1 15 A CYL2

Before Installation

1. Ensure that available voltage and phase corresponds

with humidifier voltage and phase as indicated on

humidifier’s specification label.

2. Ensure that the dedicated external fuse disconnect is of

sufficient size to handle the rated amps as indicated on

the specification label. Refer to local codes.

3. Ensure sufficient clearances will be available as

described in the Location section on page 5.

4. Ensure steam lines can be routed to duct distributor as

described in Steam Lines and Condensate Return

Instructions on page 8.

Dimensions

in inches

(L x W x H)

11.5 x 6.75 x 21.5

Max Ext

Fuse

Standard

Cylinder

Net/Full

Weight

lbs. (kg)

15 / 20

(7.0 / 9.5)

33-00118EFS-01

Page 2

HM700A1000

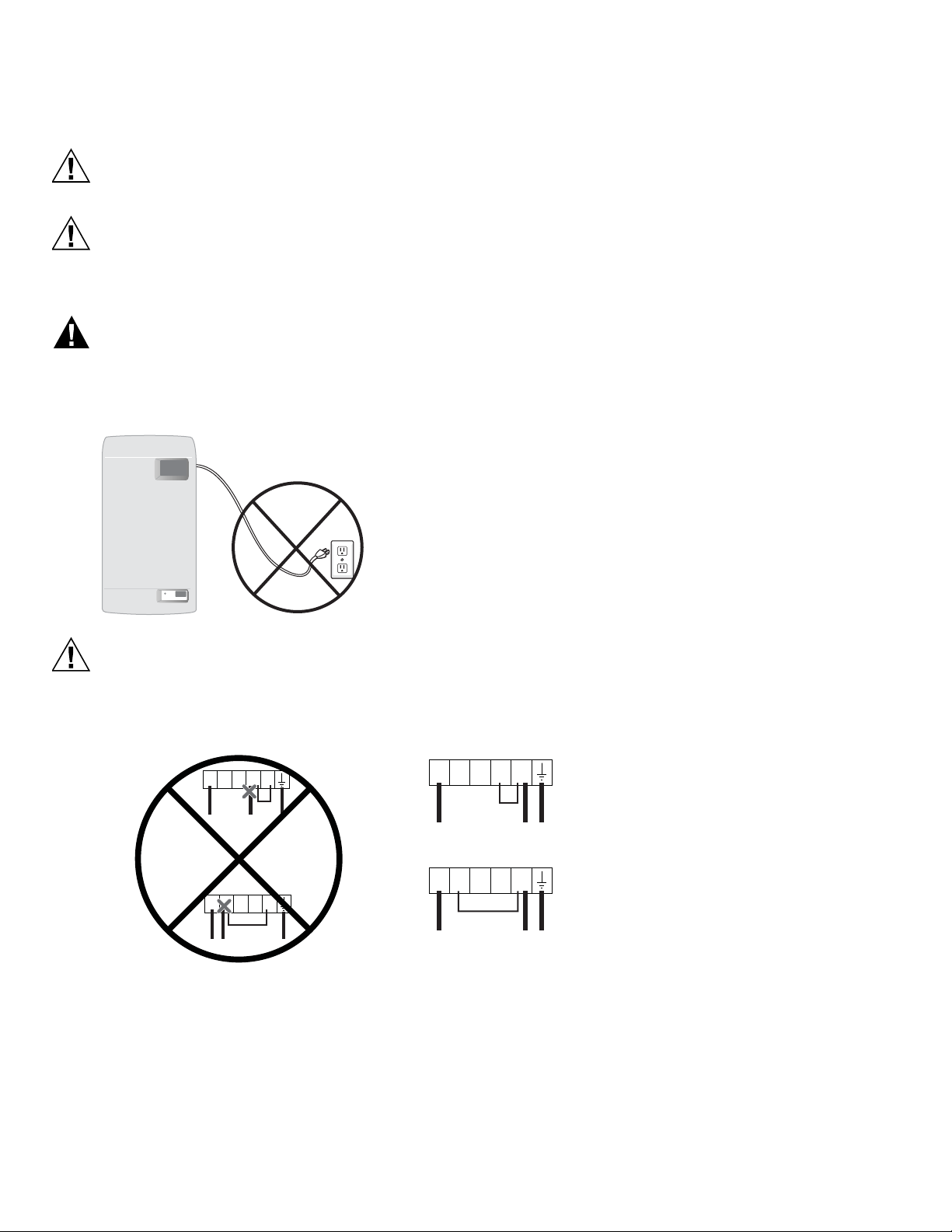

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

M35758

Golden Valley Minnesota 55422

MADE IN CANADA

MODEL:

VOLTS 1:

KW:

HM700A1000

S/N:

XXXXXXX

110-120

PHASE:

1

HZ:

60

1.4

DATE:

XXXXXXXXX

2583297A

220-240

VOLTS 2:

F.L.A: GPD:

12.0

F.L.A: GPD:

12.0

2.9

KW:

Auto-Adaptive

11

22

1

LISTED 205X

HUMIDIFIER

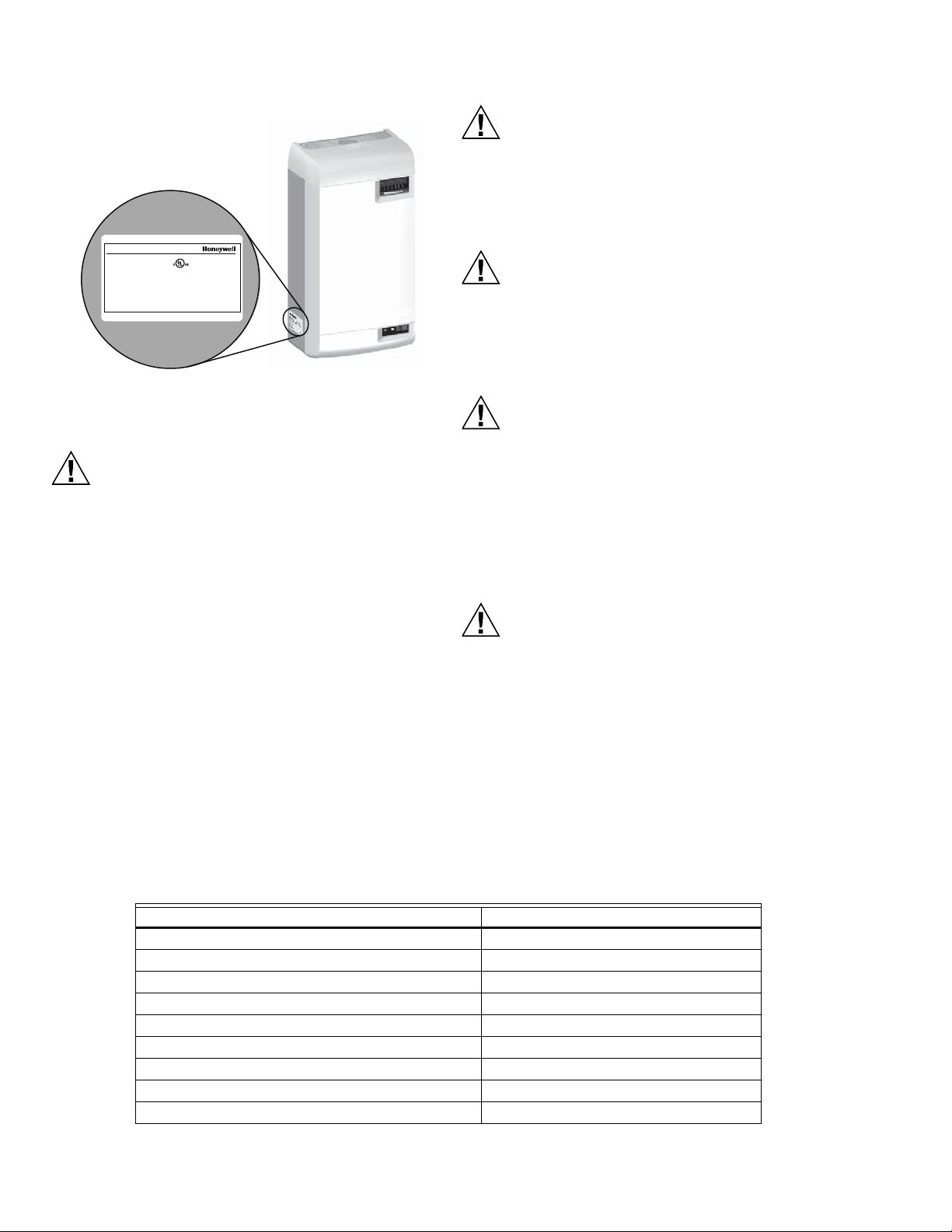

Servicing

Disconnect main power before any servicing.

The plumbing and electrical compartments contain

high voltage components and wiring. Access should

be limited to authorized personnel only.

During and following operation of the humidifier, the

steam and components in contact with the steam

such as the steam lines, steam distributors, and

condensate lines can become hot and can burn if

touched.

Honeywell does not accept any liability for installations

of humidity equipment installed by unqualified

personnel or the use of

parts/components/equipment that are not

authorized or approved by Honeywell.

To maintain warranty, only Honeywell approved parts

and cylinders may be used in the operation of the

product.

Electrical

All electrical work should be done according to local

and national electrical code.

Electrical connection to be performed by a licensed

electrician.

Unit must be powered by a dedicated GFI circuit.

Plumbing

Plumbing to be performed by a licensed plumber.

Drain water from humidifier can be very hot. Do not

drain to public sink.

All plumbing work should be done according to local

plumbing code.

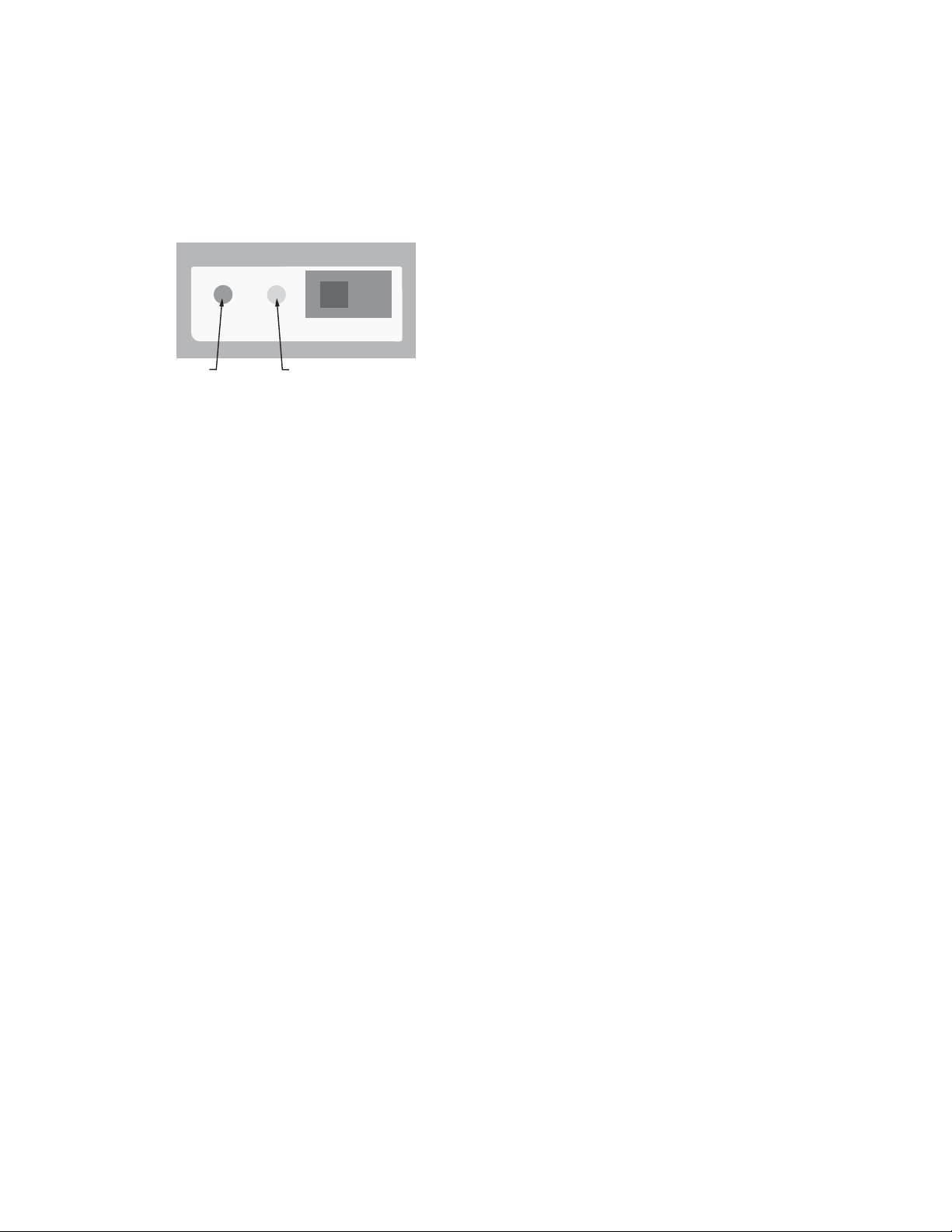

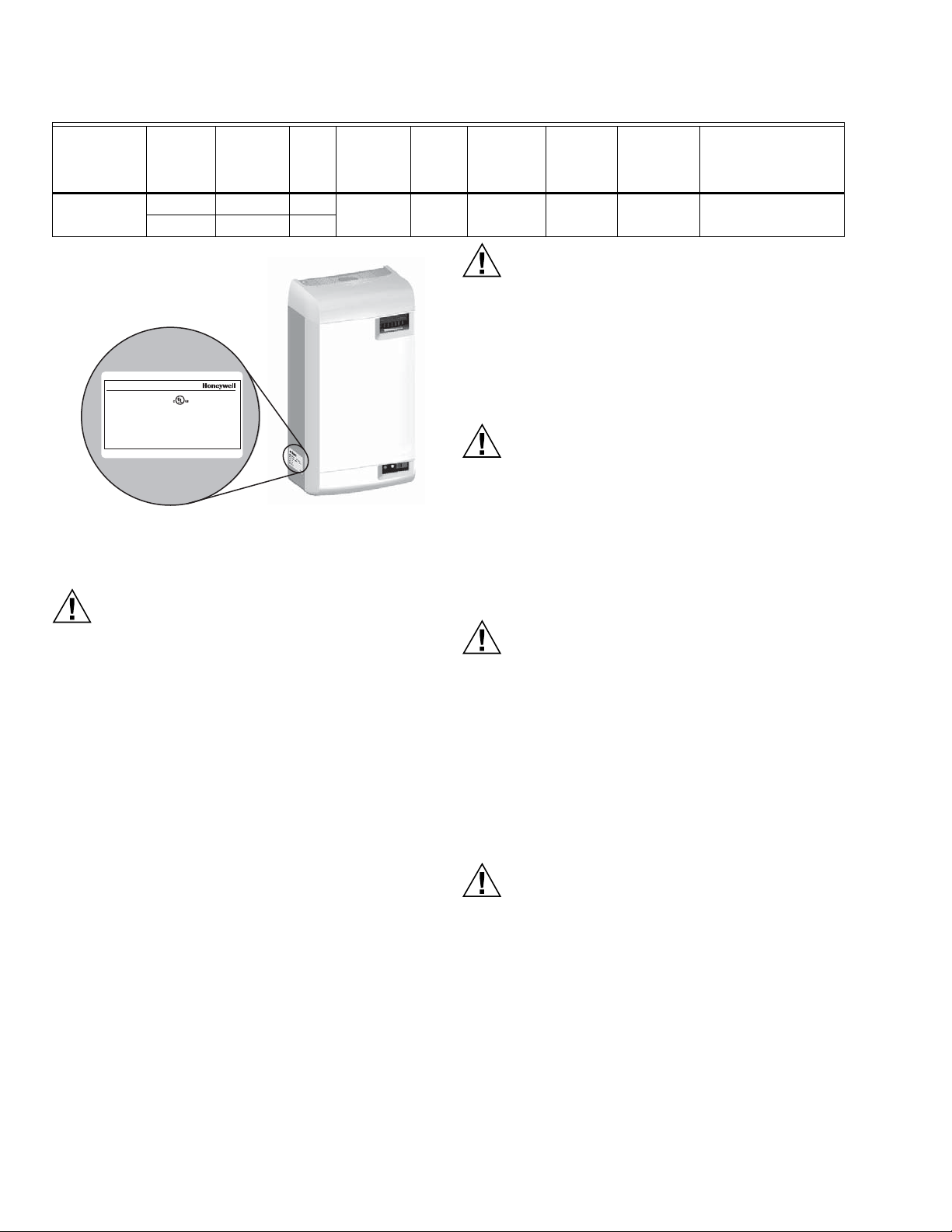

Fig. 1. Specification label location.

Installation

Do not mount on hot surfaces.

Do not mount in area where freezing can occur.

Do not mount on vibrating surface.

Do not mount on floor.

The HM700 produces steam at atmospheric pressure.

No devices which could block steam output should

be connected to the steam outlet.

Steam lines must be installed so that no restriction can

produce backpressure in the humidifier.

Water quality

The Honeywell HM700 requires a cold water

connection from your home's main water supply

between 30-100 PSIG. A throttle valve may be

necessary, and a water shut-off valve is

recommended for safety. Reverse Osmosis (RO)

and Deionized (DI) water must not be used. Water

conductivity is important to ensure the electrode

humidifier operates effectively. Honeywell

recommends 150-1200 μS (microsiemens).

Parts and Accessories

The following parts and accessories are available and may have been included with your HM700 humidifier. The cylinder is the

only item that will need periodic replacement to maintain proper humidifier operation.

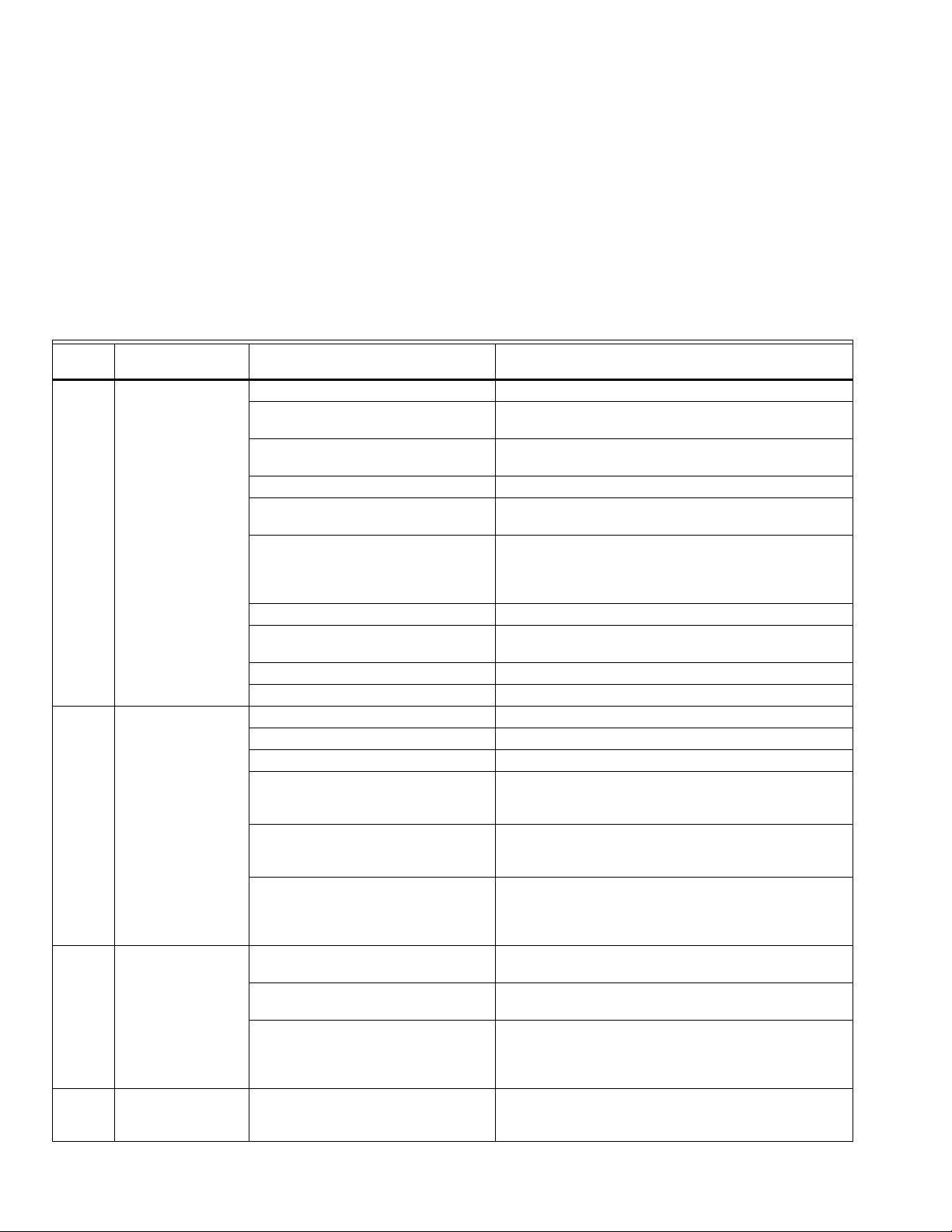

Table 2. Parts and accessories.

Part/Accessory Part Number

Replacement Cylinder HM700ACYL2

HumidiPRO Humidistat H6062A1000

Stainless Steel Distribution Remote Mount Kit HM700ADISTKIT

Replacement Drain Valve HM700ADVALVE

Replacement Fill Valve HM700AFVALVE

Replacement Transformer HM700ATX

Replacement PC Board HM700APCB

15 ft. Insulated Steam and Condensate Line Hose Kit HM700AHOSEKIT

33-00118EFS—01 2

Differential Pressure Switch for Air Proving 50027910-001

Page 3

How the Humidifier Works

The HM700 is an atmospheric steam generator that uses heat

generated by electrical current flowing between submerged

electrodes to generate steam. The HM700 is designed for ondemand air humidification via a steam distributor.

STEAM GENERATION

• Once the unit receives a demand signal and the safety loop

between terminal 1 and 2 is closed, the humidifier closes

the contactor and measures the electrical current.

• If the demand is lower than the actual output the inlet valve

is kept closed and output is reduced by letting the water

level in the cylinder decrease by evaporation.

• If demand is higher than the actual output, after a brief

delay the fill valve is activated and water flows into the fill

cup. Water from the fill cup flows into the bottom of the

cylinder through a hose connected to the drain valve

housing.

NOTE: The cylinder is gravity fed from the fill cup. If

backpressure from the steam line is too high it

will cause water to back up in the fill cup and

flow down the overflow line to the drain.

• As soon as the water in the cylinder comes in contact with

the energized electrodes, current flows through the water.

The resistance of the water to the electrical charge

generates heat and in turn steam. The electrical current

(and steam output) increases as the level of water

increases, as more of the electrode becomes submerged.

The unit continues to fill until the current matches demand

or the high water sensor detects a high water level.

• The HM700 repeats the fill and boil down cycle repeatedly

to match output to demand.

• Over time minerals in the water will adhere to the cylinder

electrodes. The humidifier will automatically fill to a higher

water level to maintain full capacity during the life of the

cylinder. Eventually because of scale formation it will no

longer be possible for the humidifier to reach its full

HM700A1000

capacity. The HM700 software monitors this condition and,

when detected, will stop operating and flash the yellow

LED in a repeating sequence of 4 flashes.

DRAINS

• As steam is produced, minerals are left behind, increasing

the conductivity of the water. The HM700 patented auto

adaptive cycle will monitor the water conductivity and

perform drains to maintain the water at optimal conductivity

for peak performance.

• The auto adaptive cycle ensures cylinder life is maximized.

It does this by keeping the tightest control and most

efficient use of water during the entire cylinder life.

STEAM DISTRIBUTION

Steam generated by the humidifier may be introduced into the

air in several different ways. The most common method for

adding the steam into the air is to mount a steam distributor

tube in a supply air duct.

STEAM LINE

The steam line between the cylinder steam outlet and the

distributor serves two purposes: it is used as a conduit to

transfer the atmospheric steam from the humidifier to the

distributor, as well as providing a means to remove

condensate. See “Steam Lines and Condensate Return

Instructions” on page 8 for information on selecting steam

lines.

CONDENSATE RETURN

Whenever steam is distributed condensate is formed in the

distribution system. Insulating steam lines is one important

way to reduce the amount of condensate formed. Steam lines

are sloped so that condensate does not collect in the lines and

create a restriction to steam flow. The condensate must be

collected and removed from the system so that it does not

build up and leak into the duct. Condensate can be returned to

the HM700 fill cup to reduce water waste or can be fed to

drain.

3 33-00118EFS—01

Page 4

HM700A1000

(OPTIONAL)

1 - R/HUM

2 - HUM

3 - C

4 - N/A

8 - AP

19 - Gf

20 - Rf

21 - N/A

1/8 NPT TO 1/4

COMPRESSION

OR LDPE

WATER LINE

HM700

OFF

ON

DEDICATED

CIRCUIT

BREAKER OR

DISCONNECT

COLD POTABLE WATER, 30-100PSIG, 1/2 IN. MIN.

NOTE: 240 V CONNECTION SHOWN

EXTERNAL

M35805

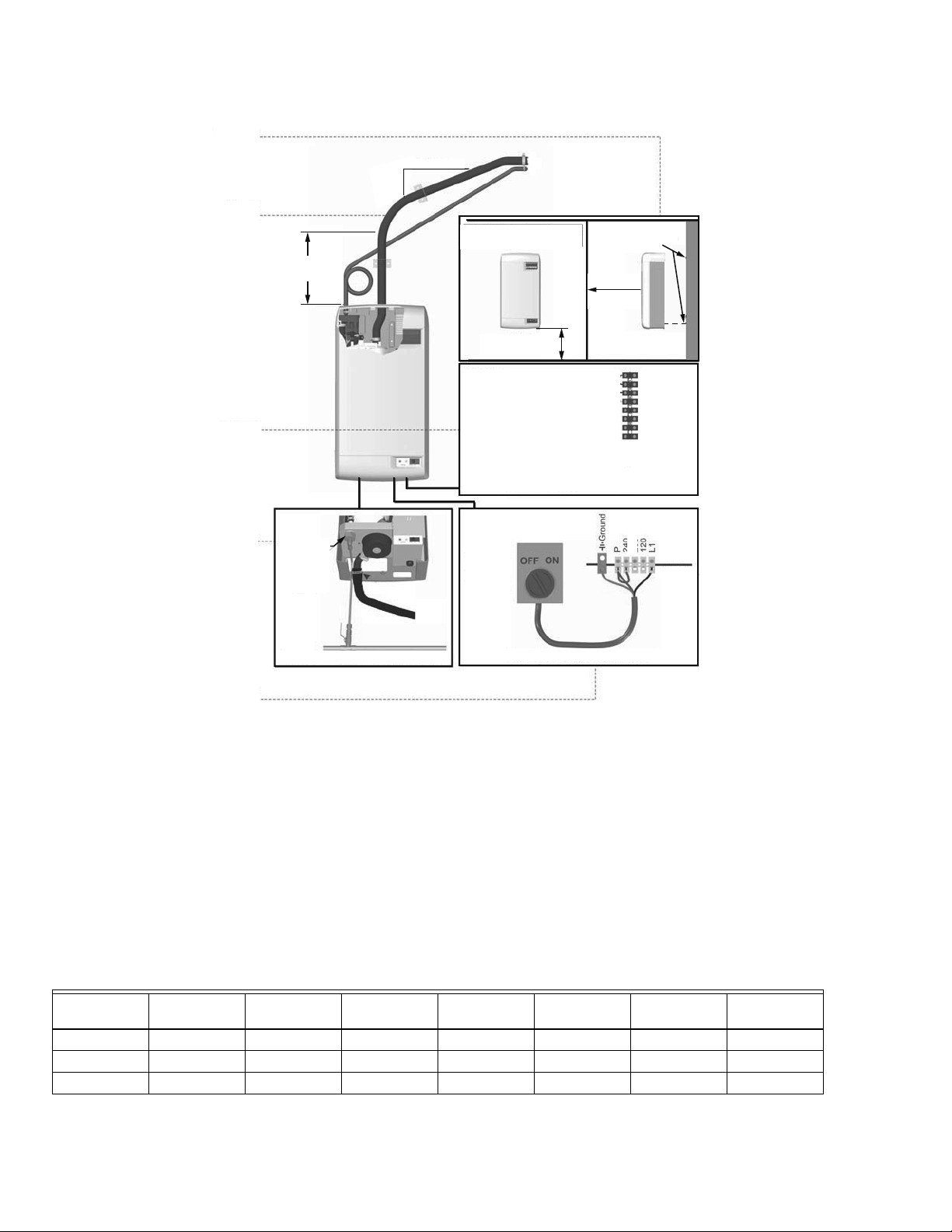

24 (610)

MINIMUM HEIGHT

36 (914)

MINIMUM

2 (51) SCREWS

12 (305)

MINIMUM

MOUNTING

STEAM

DISTRIBUTION

CONTROLS

PLUMBING

ELECTRICAL

2 (51)

MINIMUM

12 (305)

SIZING

IMPORTANT

The HM700 should only be installed if it has been

sized properly. Do not use square feet when sizing

a humidifier installation. Instead, cubic feet must

be used, since the humidity is filling a volume of

space (width x length x height). Also, take into

consideration the “tightness” of a home’s

construction.

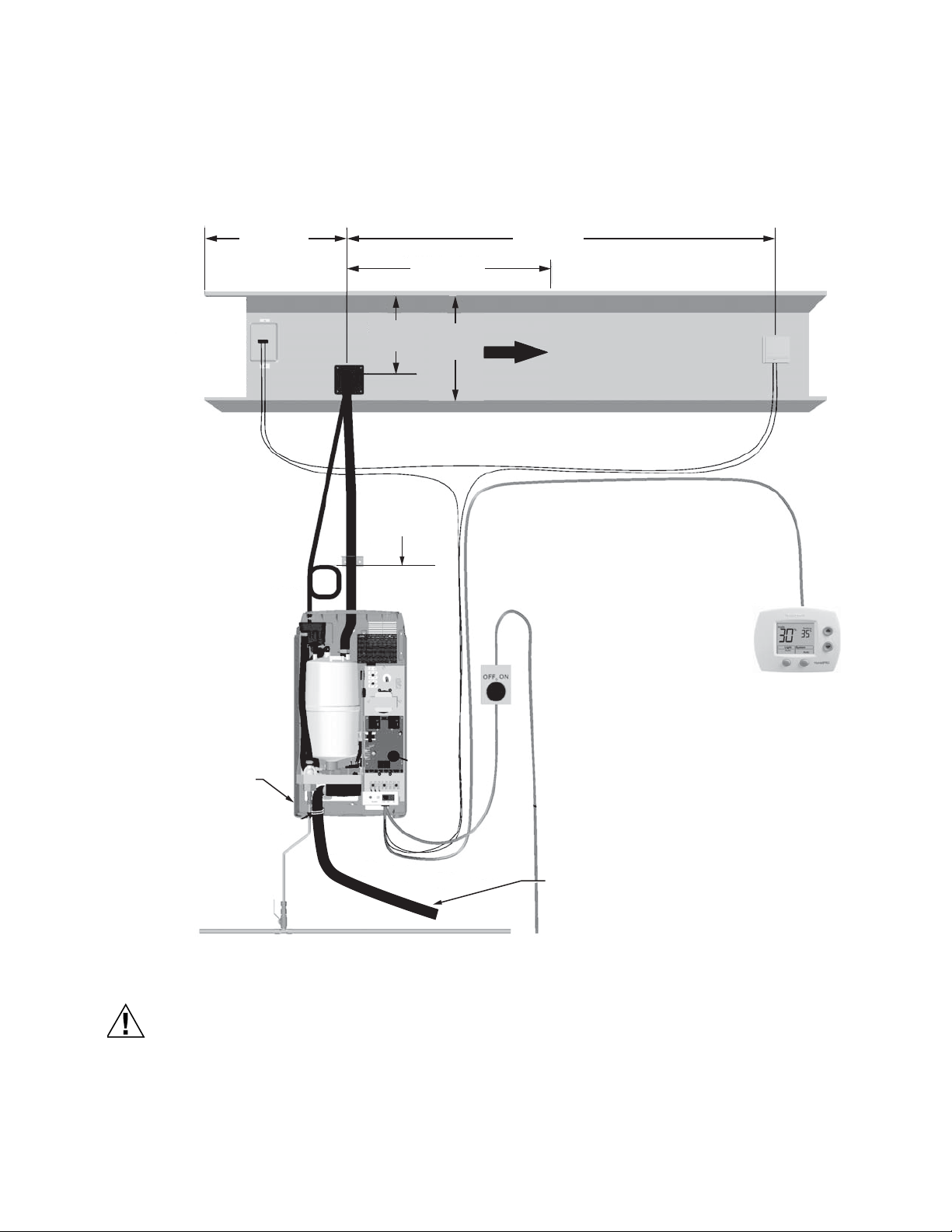

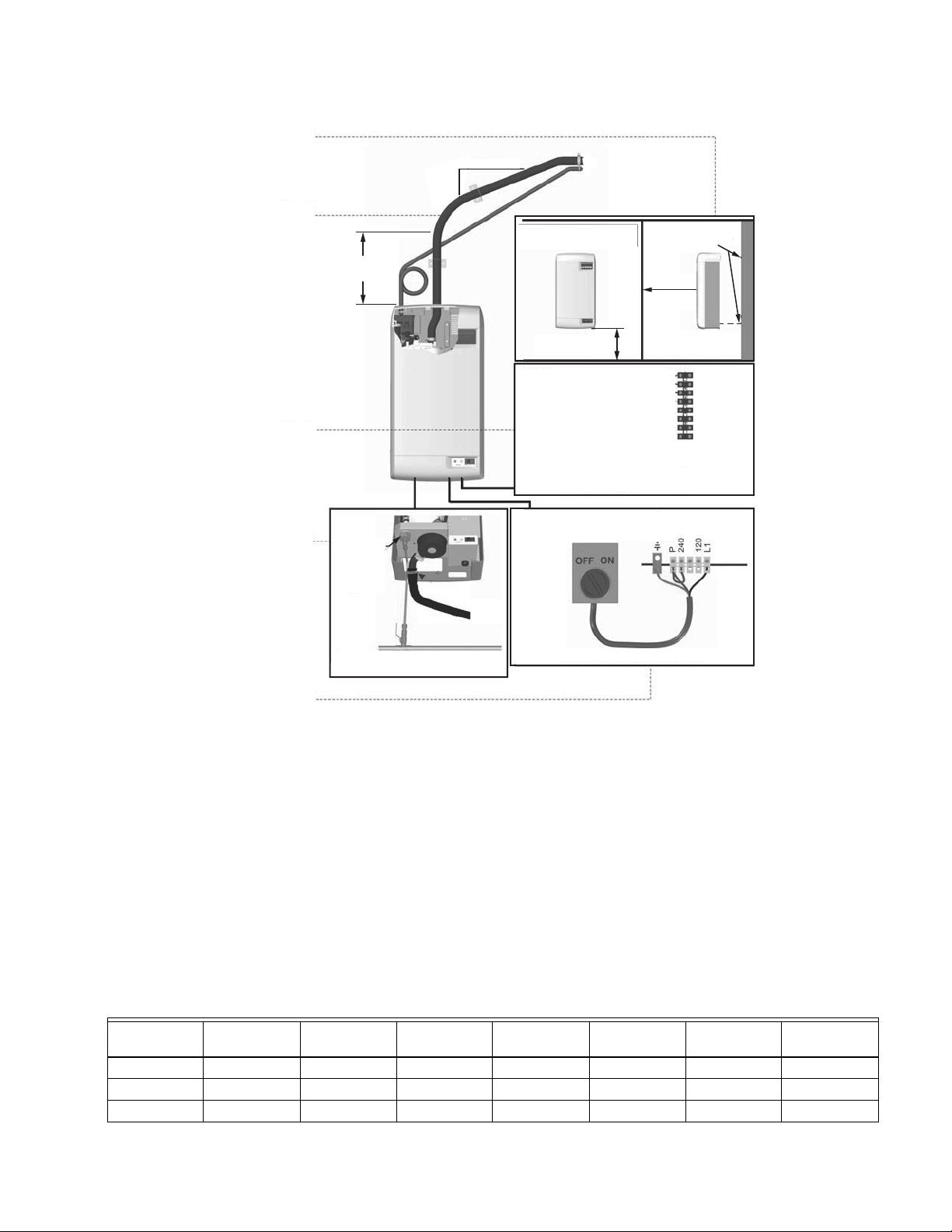

Fig. 2. Typical HM700 Installation.

Measurements in inches (mm).

The HM700 produces 11 gallons per day (GPD) when run on

120 V and 22 GPD when run on 240 V. See Figure 16 for

details on configuring the HM700 to run on a different voltage.

Table 3 contains AHRI recommendations for humidity

requirements and Table 4 shows what humidifiers and output

configuration will satisfy the humidification requirements.

Table 3. AHRI Recommended Humidity (in gallons per day).

Construction

Type 8,000 ft

Tight 3.3 4.3 5.4 7.5 9.6 11.7 16

Average 7.6 9.6 11.8 16 20.3 24.4 33

Loose 11.7 14.9 18.1 24.5 30.8 37.1 50

3

12,000 ft

3

16,000 ft

3

20,000 ft

3

24,000 ft

3

28,000 ft

3

32,000 ft

3

33-00118EFS—01 4

Page 5

HM700A1000

INSTALL SECOND

SCREW AFTER

HANGING

HUMIDIFIER

#8 X 2 IN. (5 CM)

WOOD SCREWS

INSERT SCREW LEAVING

1/4 IN. (6 MM) EXPOSED.

HANG UNIT, THEN

TIGHTEN SCREW.

2X4 OR OTHER

STRUCTURAL

MEMBER

KEYHOLE

M35759

HOLE

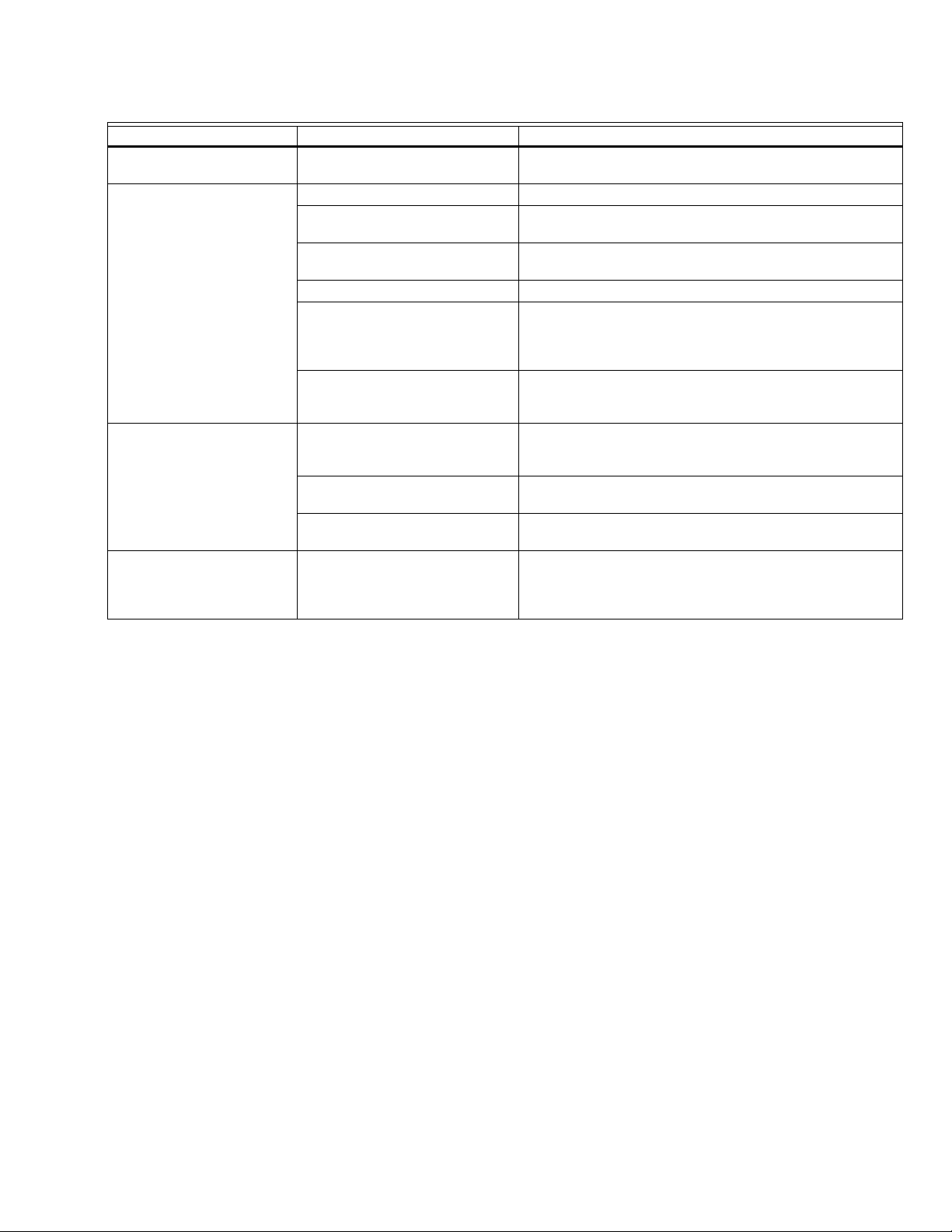

Table 4. Steam humidifier(s) necessary for application.

Construction

Type 8,000 ft

3

12,000 ft

3

16,000 ft

3

20,000 ft

3

24,000 ft

Tight 11 GPD 11 GPD 11 GPD 11 GPD 11 GPD

Average 11 GPD 11 GPD 22 GPD 22 GPD 22 GPD

11 GPD (x3)

Loose 22 GPD 22 GPD 22 GPD

or

22 GPD (x2)

a

In the table above, 11 GPD indicates a steam humidifier configured to run on 120 V and 22 GPD indicates a steam humidifier

11 GPD (x3)

or

22 GPD (x2)

a

3

28,000 ft

11 GPD (x2)

22 GPD (x1)

11 GPD (x3)

22 GPD (x2)

11 GPD (x4)

22 GPD (x2)

3

32,000 ft

3

11 GPD (x2)

or

or

22 GPD (x1)

11 GPD (x3)

or

or

22 GPD (x2)

11 GPD (x5)

or

or

22 GPD (x3)

configured to run on 240 V.

LOCATION

NOTE: Do not mount on hot surfaces, where freezing

can occur, vibrating surface, or floor.

Mount on a suitable wall or vertical surface. Do not sit the unit

on the floor. Allow clearances required for plumbing and

electrical connections. Clearance dimensions shown are for

reference only and are the minimum required for maintenance

of the humidifier. Consult local and national codes before final

location and installation. Honeywell does not accept

responsibility for installation code violations.

• Install only in areas with ambient temperature 41 to 104 °F

(5 to 40 °C) and relative humidity 5 to 95 %.

• When possible install below the steam distributor. Take

care to provide proper steam line routing and proper

condensate traps.

• DO NOT locate the humidifier any further then absolutely

necessary from the steam distributor location as net output

will be reduced as a result of heat loss through the steam

line.

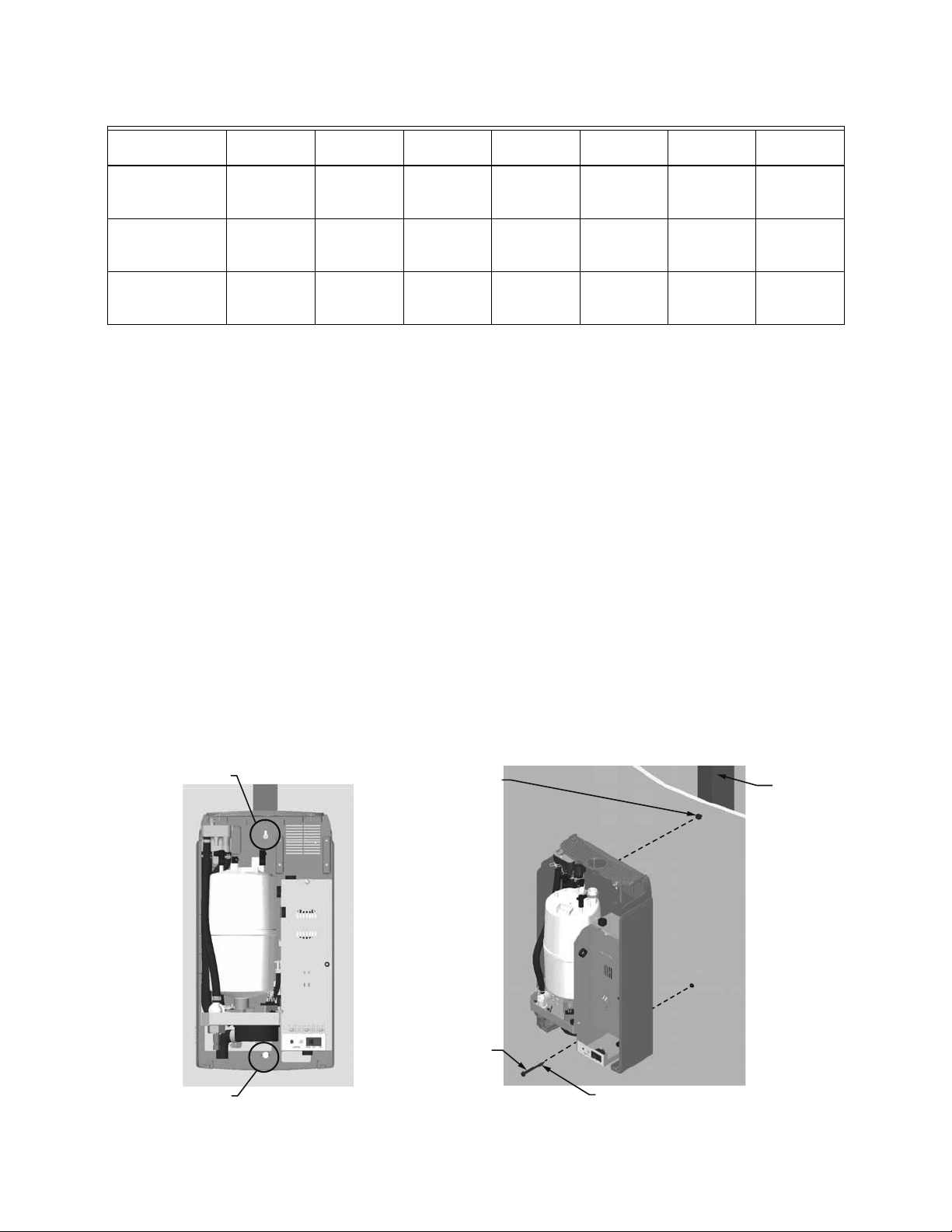

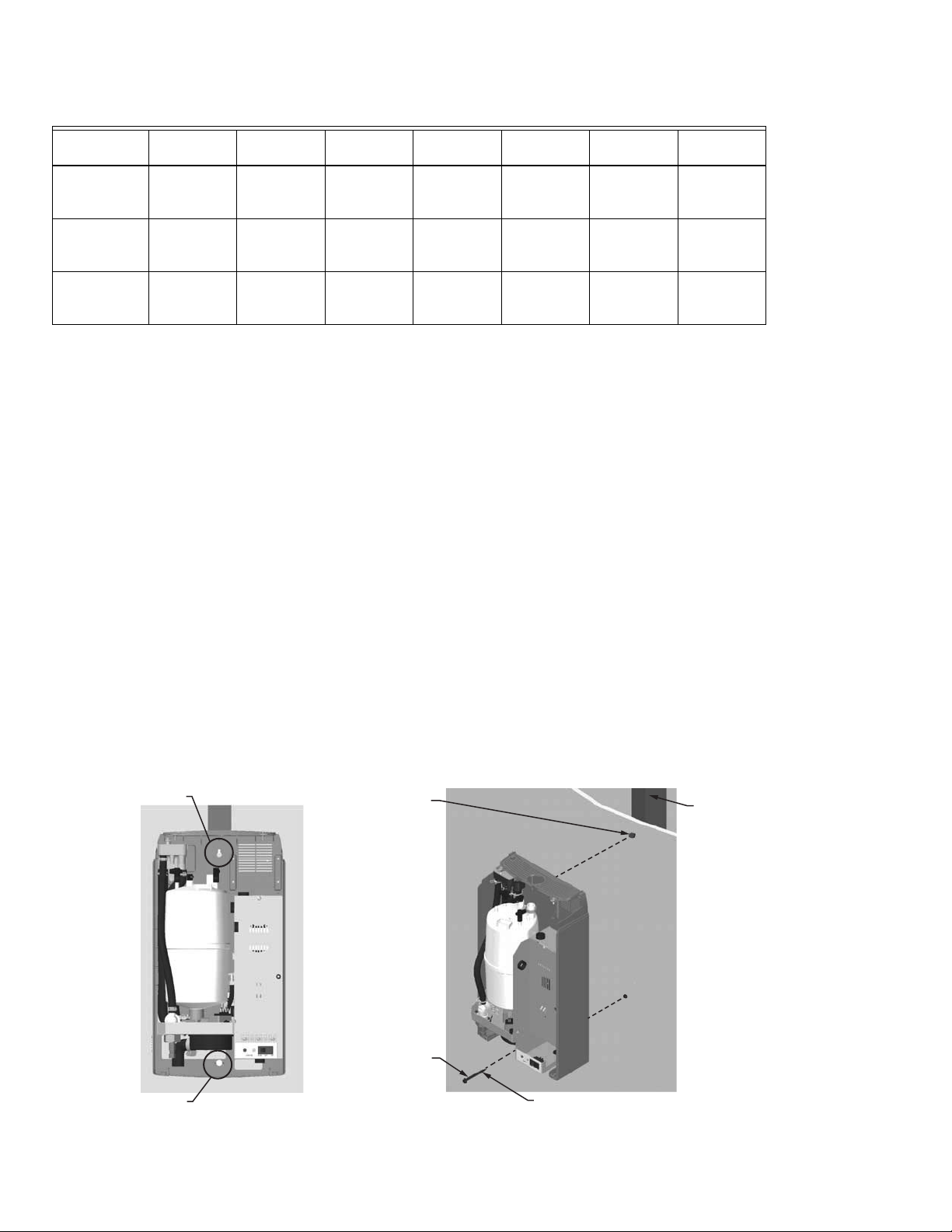

Mounting with Keyholes

1. The HM700 humidifier is wall mounted using a keyhole

located on the back of the unit cabinetry.

2. Use #8 x 2 in. (5 cm) screws mounted into 2x4 studs or

better. 2 screws are needed, one for hanging the unit

and one for securing so it will not lift off the keyhole.

3. Install the top screw so that 1/4 in. (6 mm) is exposed.

Raise the unit and place the screw head through the

keyhole.

4. Make sure the unit is level and then insert and tighten

the second screw through the bottom hole. Tighten the

top screw. See Fig. 3.

NOTE: Use screws longer than 2 in. (5 cm) if drywall or

other spacer is present.

• When possible, mount the HM700 humidifier at a height

convenient for servicing.

Fig. 3. Mounting with keyholes.

5 33-00118EFS—01

Page 6

HM700A1000

M35855

PLUMBING

USE 1/4 IN. COMPRESSION

FITTING (INCLUDED) TO

CONNECT WATER SUPPLY

LINE TO UNIT (LDPE PLASTIC

WATER SHUT-OFF VALVE.

OR COPPER).

1/2 IN. (30 MM) OD

ALWAYS INSTALL A

1

FILL AND DRAIN LINES CAN ALSO BE

1

ROUTED THROUGH OPENING IN BACK

OF CABINET.

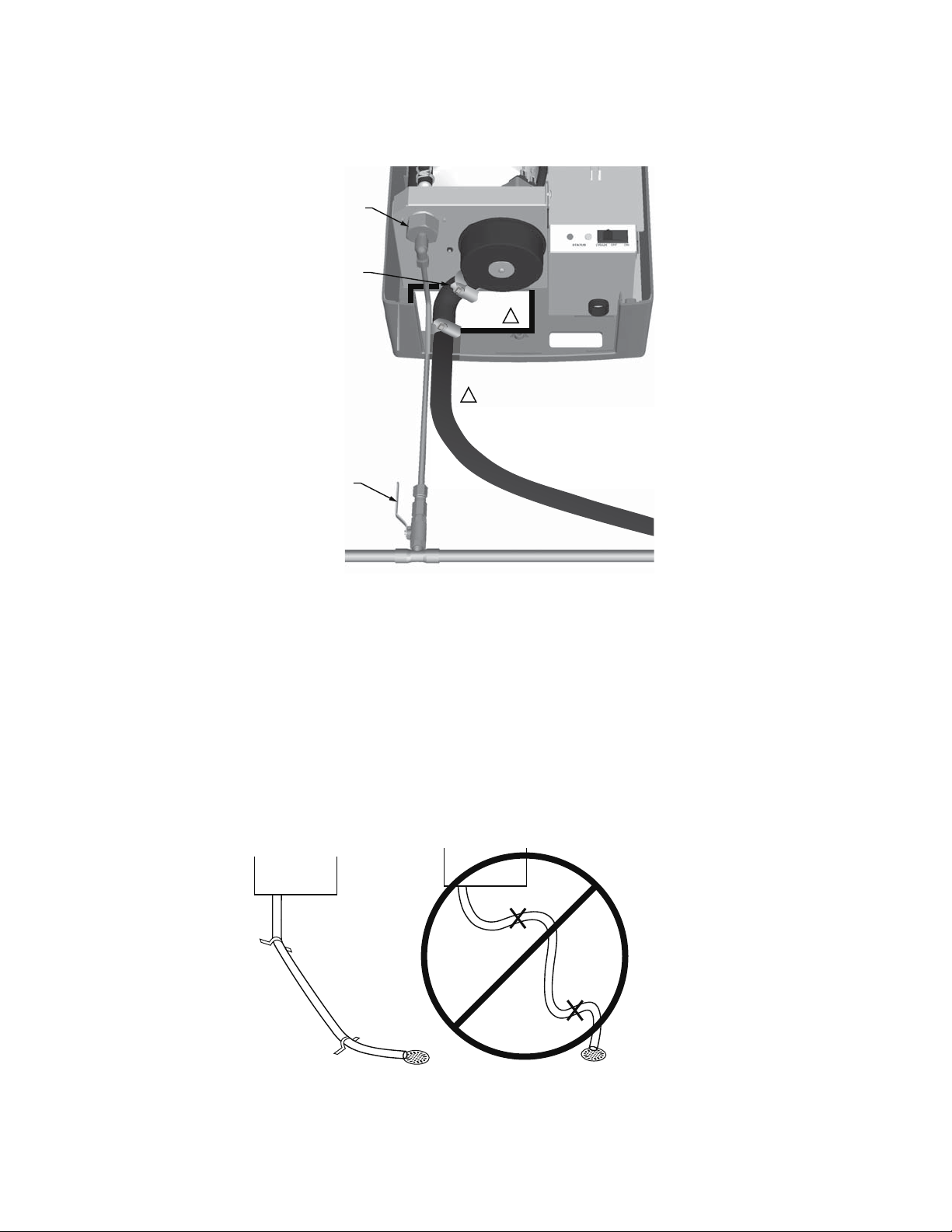

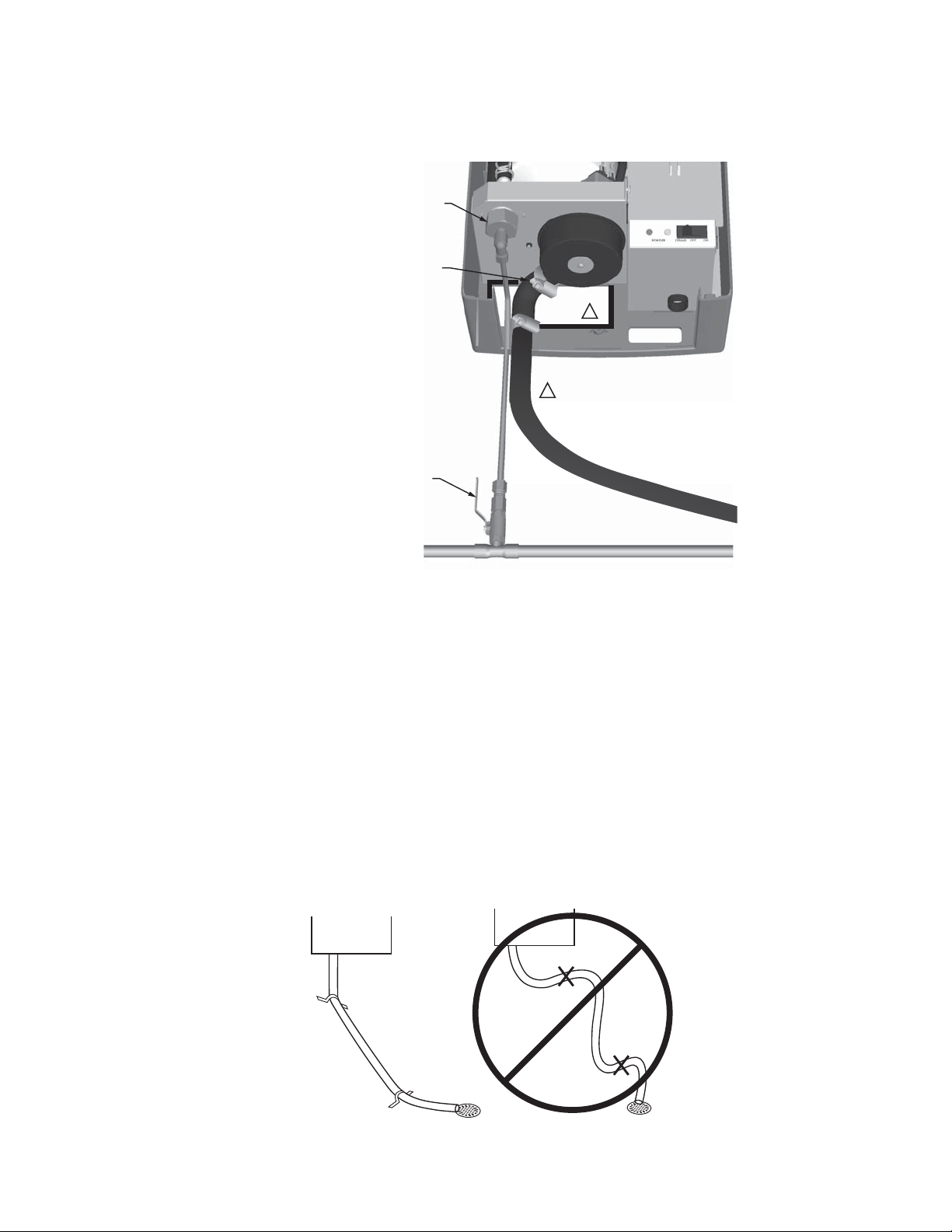

Fig. 4. Water supply and drain connection.

IMPORTANT

— All water supply and drain line connections should be

installed in accordance with local plumbing codes.

— Drain water is automatically cooled to 140 °F (60 °C)

when HM700 cycles a drain. When the manual drain

switch is used, temperature may be higher. The drain

material (tube and drain) must be rated for 200 °F

(93 °C).

• Supply water should be between 30 to 100 PSIG. A throttle

valve may be used if necessary.

• Do not use reverse osmosis or de-ionized water. Supply

water should be between 150-1200 μS (microsiemens) for

optimal conductivity.

USE 1/2 IN. OD COPPER TO

WITHIN 4 FT (1.2 M) OF HUMIDIFIER.

M35760

• Supply water should be cold, 34 to 68 ºF (1 to 20 ºC).

• Install water shut off valve before humidifier to facilitate

servicing.

• The drain line should not end in a sink used frequently by

personnel, or where plumbing codes prohibit it. Route to a

floor drain or equivalent for safety reasons.

• Drain line should be routed to allow free flow of water.

Ensure adequate slope, no traps, and no kinks. A restricted

drain can cause cylinder water to over concentrate and

result in poor operation.

• If a drain is not located near the humidifier use a

condensate pump rated for hot drain water.

Fig. 5.

33-00118EFS—01 6

Page 7

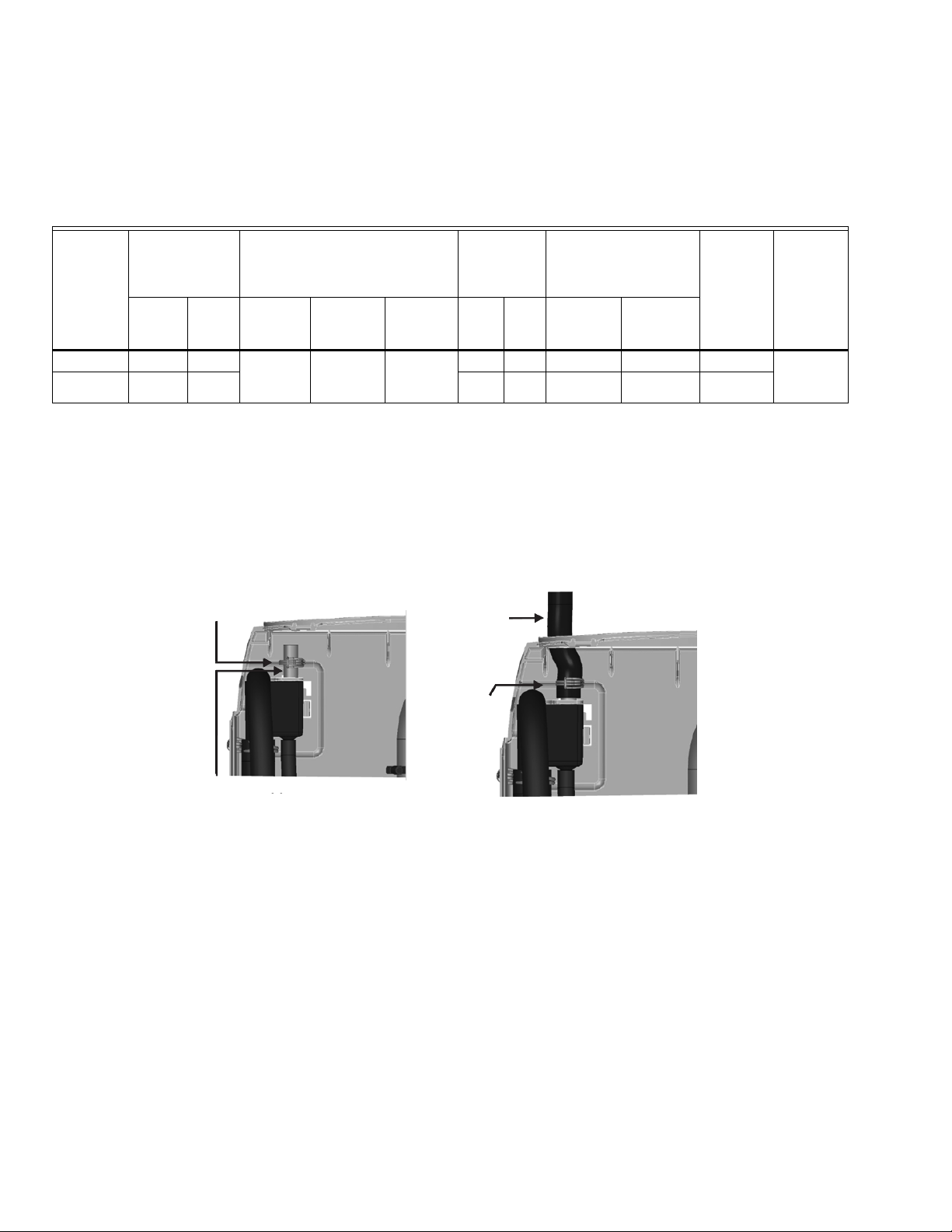

Steam Distributor

M35766

AIR FLOW

The HM700 requires a steam distributor installed in the

supply-side of ductwork. The HM700 can distribute steam into

a ventilation duct using the distributor shown in Table 5.

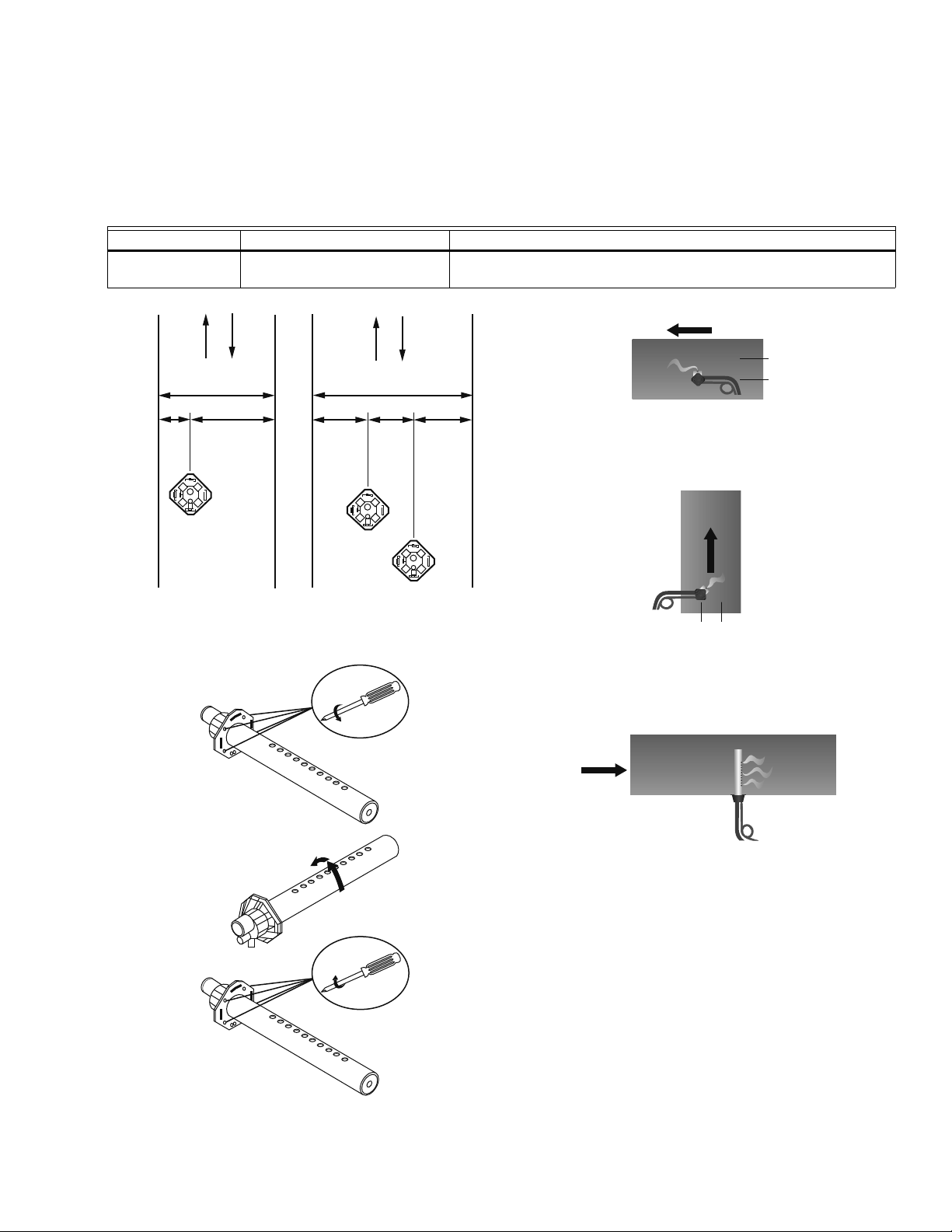

Table 5. Steam distributor.

Part Number Description Notes

HM700ADISTKIT

1/3W

Stainless Steel Distribution

Remote Mount Kit

W

2/3W

1/3W

H

1/3W

Includes a steam distributor, 5 ft. insulated steam hose, condensate

hose, and installation hardware.

1/3W

The steam distributor should be installed as close as possible

to the humidifier. Short steam distribution lines minimize

condensate loss and the possibility of generating

backpressure in the steam distribution line.

Fig. 8. Distributor installed horizontally

HM700A1000

AIR FLOW

2/3

1/3

M35764

in a horizontal duct.

MIN. W=8 (203)

1

2

3

Fig. 6.

+45˚

1 TURN

–45˚

M35755

AIR FLOW

1/3

2/3

M35765

Fig. 9. Distributor installed horizontally in a vertical duct.

Rotate the distributor 45º so that steam is discharged

toward the center of duct, in the direction of the air flow.

Fig. 10. Distributor installed vertically in a horizontal duct.

This configuration is not recommended.

M35756

Fig. 7.

7 33-00118EFS—01

Page 8

HM700A1000

M35761

SPRING CLAMP

3/8” OD COPPER TUBE

SPRING

CLAMP

INSERT HOSE OVER

COPPER TUBE AND

FASTEN WITH

SPRING CLAMP

Steam Lines and Condensate Return Instructions

The following instructions must be followed for installation of steam lines for the HM700. Failure to use recommended material

and exceeding maximum recommended length in Table 6, or failure to follow any other steam line installation instructions will

result in improper operation and could void the warranty.

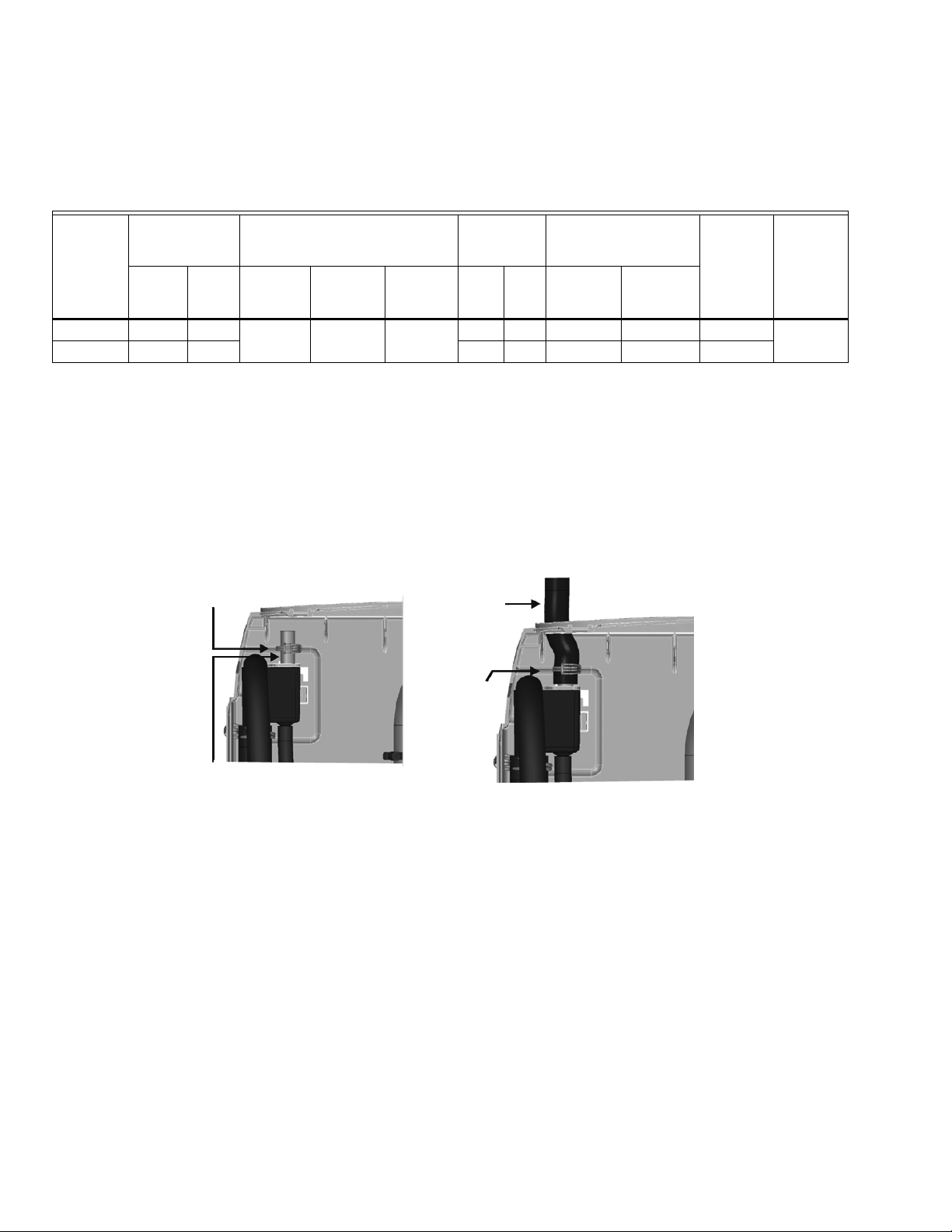

Table 6. Recommended Steam Line Material for HM700 Duct.

Maximum

Steam Line

Length Possible Losses

Minimum

7 (2) 0.5 (0.2) 115

Airflow

CFM

Max

Static

Pressurelbs/hr (kg/hr)

3.0 in. w.c.

MED-L

Tube

*

Stainless

Steel

Tube ft (m) lbs/hr (kg/hr)

0.875 x

0.049W

Steam Output Material

Steam

Voltag e

110/120V 3.85 (1.75)

220/240V 7.7 (3.5) 12 (3.5) 1.5 (0.7) 230

Hose

7/8 in. 3/4 in.

Copper

* The use of steam line other than copper, stainless steel tube or Honeywell supplied steam line will void the warranty and may

adversely affect the operation of the humidifier.

* When using copper or stainless steel tubing (other than the supplied tubing), insulation is recommended due to high

temperature safety as well as reduced condensate.

To return condensate for HM700, insert copper tube (supplied with equipment) half way into the condensate opening of the fill cup

along with the spring clamp (supplied with equipment).

Insert the condensate hose into the condensate return hole at the top of the HM700, and over the copper tube. Fasten in place

with the spring clamp.

Fig. 11. Condensate return.

MAIN RULES FOR ATMOSPHERIC STEAM LINES

• Steam lines must not have any restrictions which could result in back pressure.

• Follow recommended materials, size and length, see tables.

• Install steam line in a vertical (upwards) fashion from the HM700 to the distribution nozzle. Consult Figures 12-14 for other

installation options.

• Insulate with 1.0 in. (2.5 cm) pipe insulation.

• Trap condensate (Use full size ‘T’ for Traps)

• Do not over tighten hose clamp at cylinder steam outlet. The maximum torque is 12 in-lbs.

• Support steam line so weight is not on cylinder.

• Condensate traps must be a minimum of 6 in. (15 cm) in height or duct static pressure +2 in. (5 cm), whichever is greater.

• Trapping by P-trap or pigtail. Support line as necessary to ensure it remains free of kinks.

33-00118EFS—01 8

Page 9

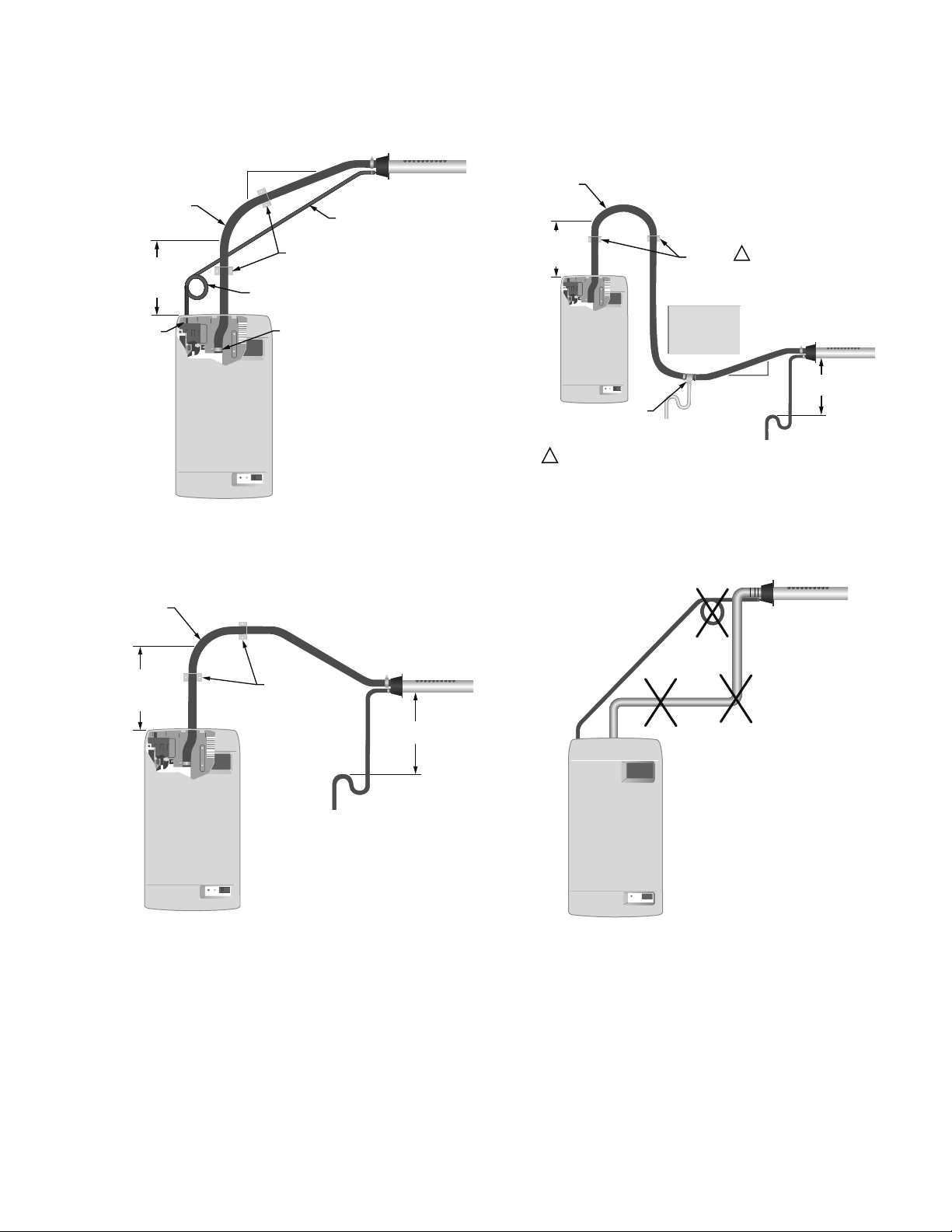

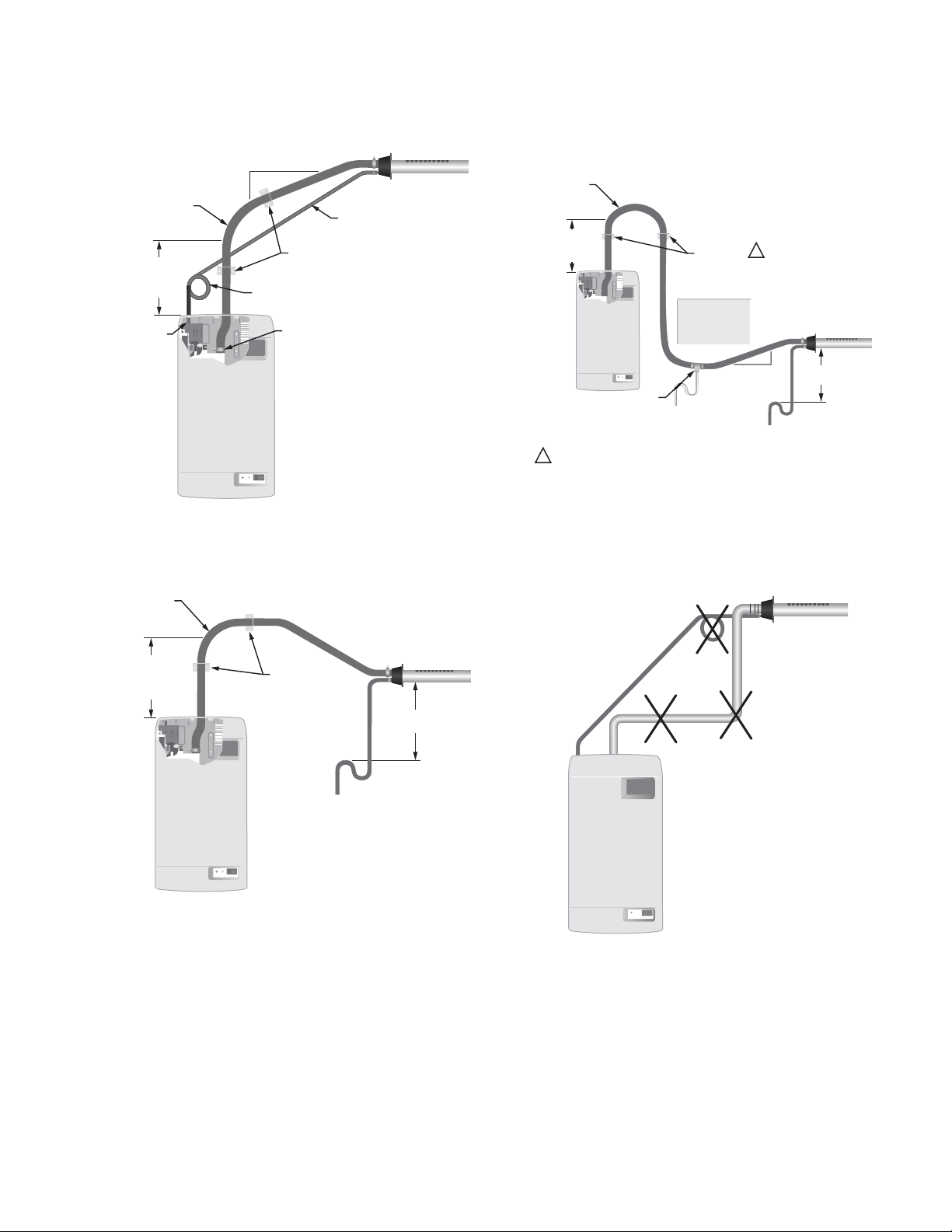

Steam Line Installation Examples

12 (305)

MINIMUM

M35718

SUPPORT

BRACKETS

CONDENSATE

TRAP

TO DRAIN

12 (305)

MINIMUM

RADIUS

12 (305)

MINIMUM

BEFORE

ANY BEND

A

M35720

NO

CONDENSATE

TRAP AT

VERTICAL

TRANSITION

STEAM LINE

NOT SLOPED

CONDENSATE

TRAP NOT 12

(305) BELOW

DISTRIBUTOR

HM700A1000

12 (305)

SUPPORT

BRACKETS

CONDENSATE

LINE

CONNECT

STEAM

HOSE TO

CYLINDER

CONDENSATE

LINE

M35717

12 (305)

MINIMUM

RADIUS

12 (305)

MINIMUM

BEFORE

ANY BEND

CONNECT

CONDENSATE

HOSE TO FILL

CUP

2 (51)

MINIMUM

Fig. 12. Steam distributor above humidifier (hose).

Measurements in inches (mm).

12 (305)

MINIMUM

RADIUS

12 (305)

MINIMUM

BEFORE

NY BEND

USE FULL SIZE CONDENSATE

TEE AT LOW POINT. SLOPE

LINES UP TO “T” AND

IMMEDIATELY AFTER IT.

HOSE WILL SOFTEN OVER TIME. PROPER SUPPORT IS NECESSARY.

1

OBSTRUCTION

TO DRAIN

SUPPORT

BRACKETS

1

2 (51)

MINIMUM

TO DRAIN

12

(305)

MIN.

12 (305)

MINIMUM

M35719

Fig. 14. Steam distributor below humidifier with

obstruction (hose). Measurements in inches (mm).

Fig. 13. Steam distributor below humidifier (hose).

Measurements in inches (mm).

Fig. 15. Common steam line installation errors.

Measurements in inches (mm).

9 33-00118EFS—01

Page 10

HM700A1000

CAUTION

CAUTION

WARNING

CAUTION

M35779

240 VAC

L1 N/A P120 240

120 VAC

Hot

Hot

Jumper

L1 N/A P120 240

Hot

Neutral

Ground Ground

Jumper

240 VAC

L1 N/A P120 240

120 VAC

Hot

Hot

Jumper

L1 N/A P120 240

Hot

Neutral

Ground

Ground

Jumper

M35850

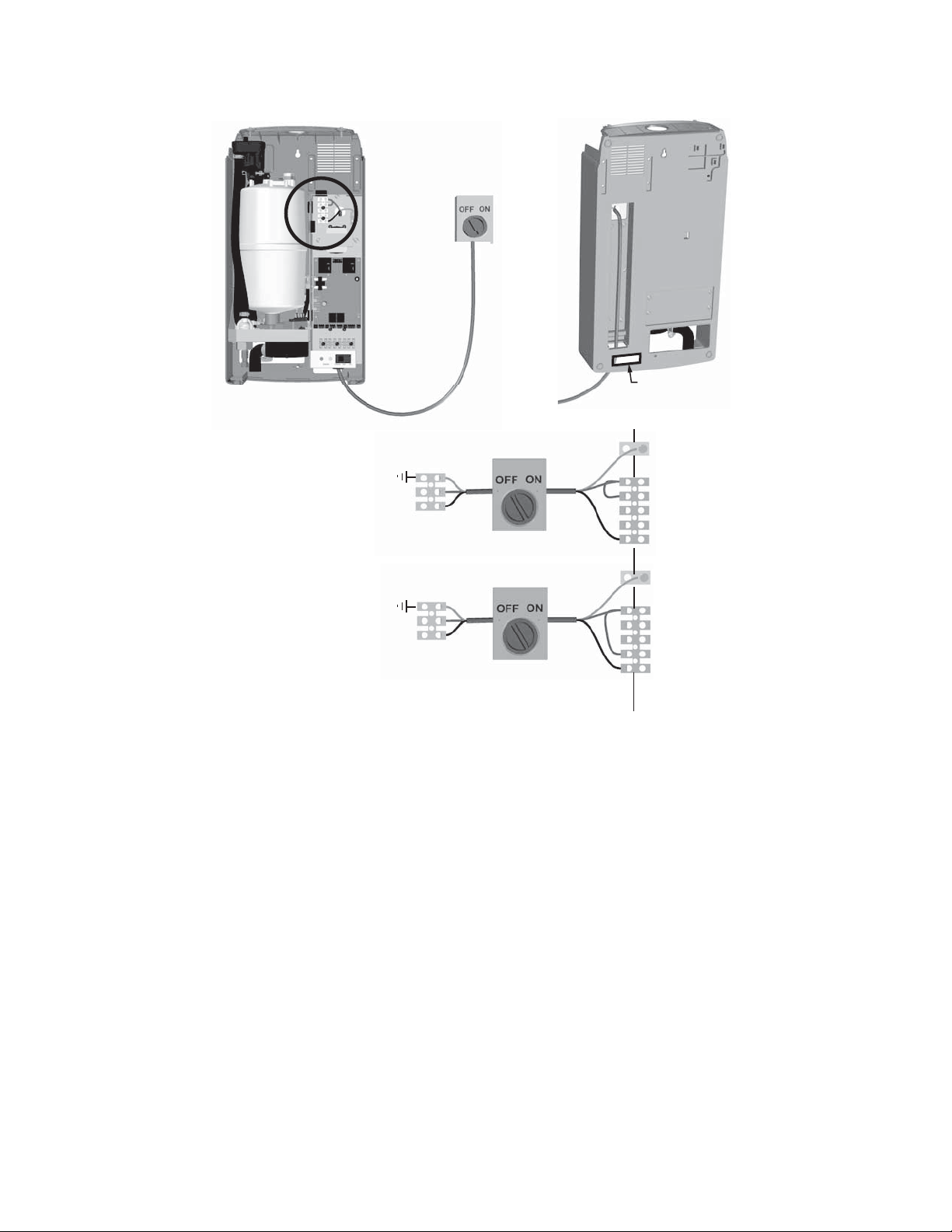

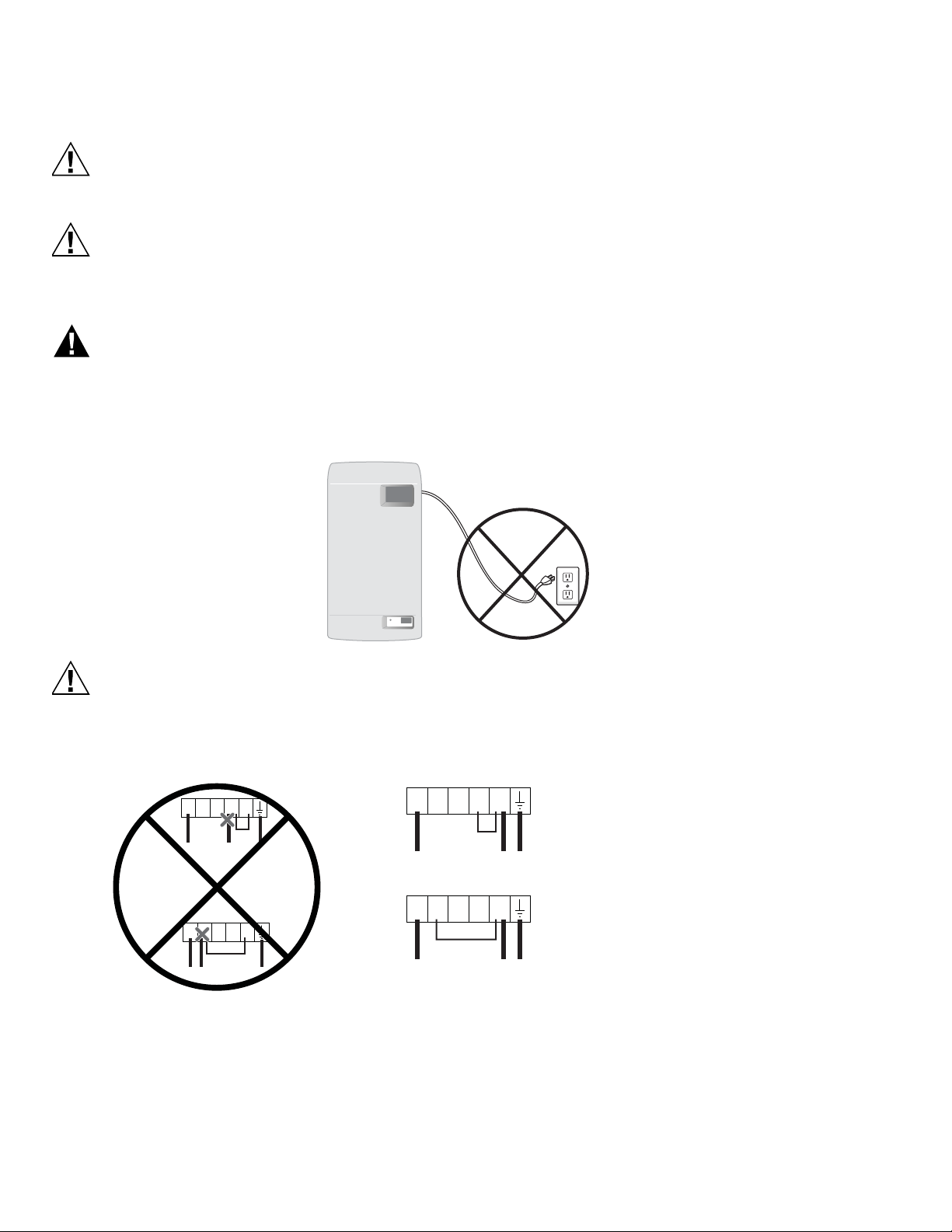

ELECTRICAL

Wiring to be performed by a licensed electrician. This unit must be installed on a GFI Circuit.

Equipment Damage Hazard

Failure to wire the humidifier in accordance with the wiring instructions could cause permanent damage.

Such errors will void the warranty.

HM700A Humidifier must be installed using a dedicated 15 amp circuit breaker and hardwired directly to comply

with UL product listing. All wiring must be done per governing electrical codes.

Electrical line cord plugs can overheat and result in risk of damage to property and/or personal injury. Note: Product

warranty will be voided if these instructions are not followed.

JUMPER WIRE INSTALLATION

• DO NOT install mains voltage wire (hot or neutral) into 120 or 240 terminal.

• DO install mains wires into L1 terminal (hot) and P terminal (hot/neutral).

• DO install jumper from P to 120 or 240 terminal (according to mains voltage).

Installation Steps

1. Unit requires a dedicated circuit with GFI protection. Bring circuit to a disconnect near the device to protect from electrical

shock when servicing.

2. Hard wire humidifier to disconnect according as shown at right.

3. Install factory-supplied jumper between the P terminal and the terminal that corresponds to supply voltage.

4. Remove green wire attached to case body and drain valve (remove canister for access).

5. Clip ground wire as close to drain valve as possible and remove excess.

33-00118EFS—01 10

Page 11

HM700A1000

HOT

HOT

GROUND

P

240

120

L1

GROUND

E

X

T

I

N

T

240 VAC (1 PHASE)

120 VAC (1 PHASE)

NEUTRAL

HOT

GROUND

P

240

120

L1

GROUND

NOTE: CONNECT 120 VAC,

“HOT”, TO L1

(OPTIONAL)

(OPTIONAL)

NOTE: POWER WIRES

CAN ALSO BE ROUTED

THROUGH OPENING IN

BACK OF CABINET

M35806

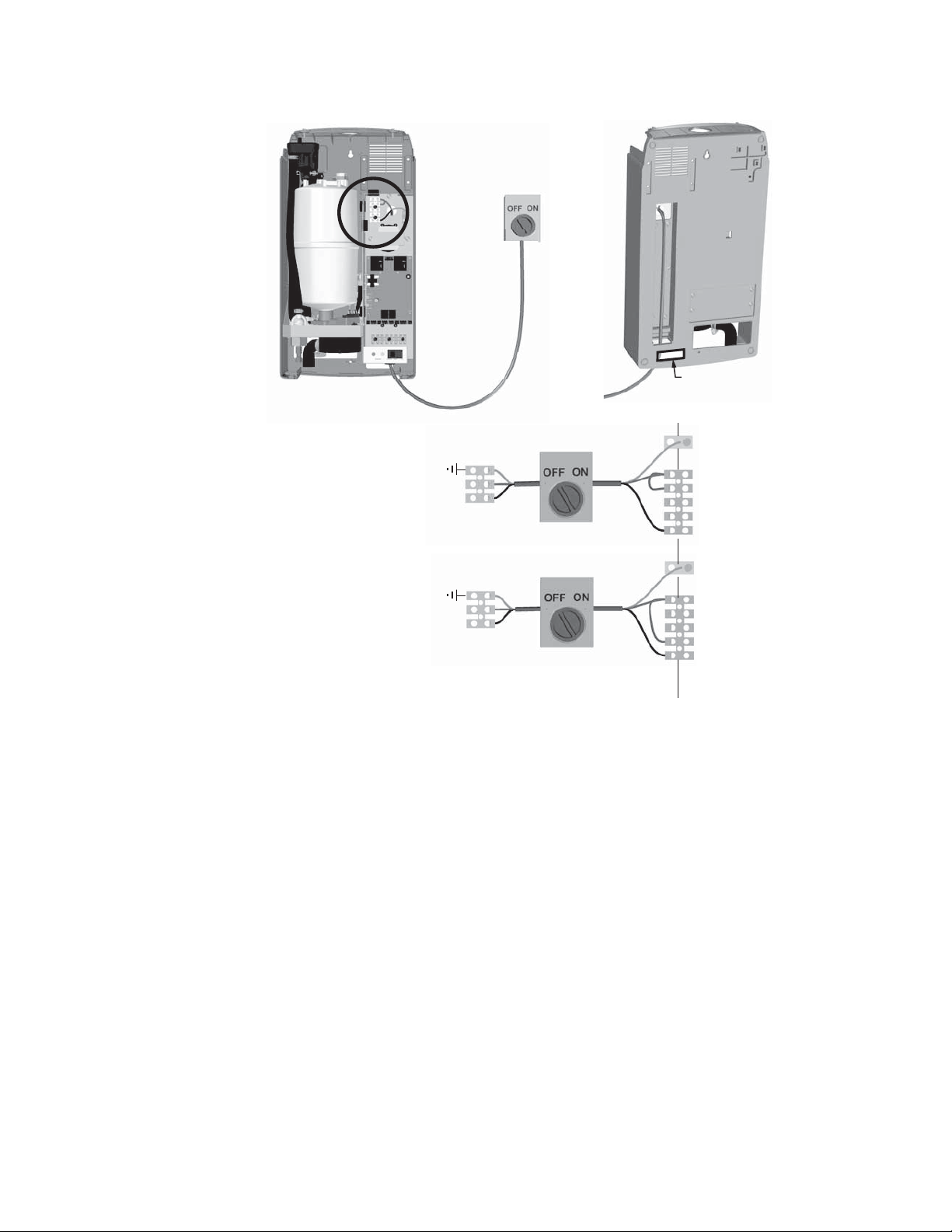

Fig. 16. Primary power connection.

NOTES:

— Honeywell requires the use of a GFI circuit on this device to protect the homeowner from electrical shock.

— When installed correctly, the green wire should be removed from the drain valve. The green wire comes pre-installed

from the factory to protect the homeowner in case of an improper installation or when it is not possible to retrofit a GFI

circuit. See Fig. 24 for the location of green wire on the drain valve.

— Ensure that adequate power is available to carry full humidifier amp draw as indicated on the specification label.

— Do not use neutral wire as a ground; connect a dedicated ground to ground termination.

— All wiring to be in accordance with national and local electrical codes.

11 33-00118EFS—01

Page 12

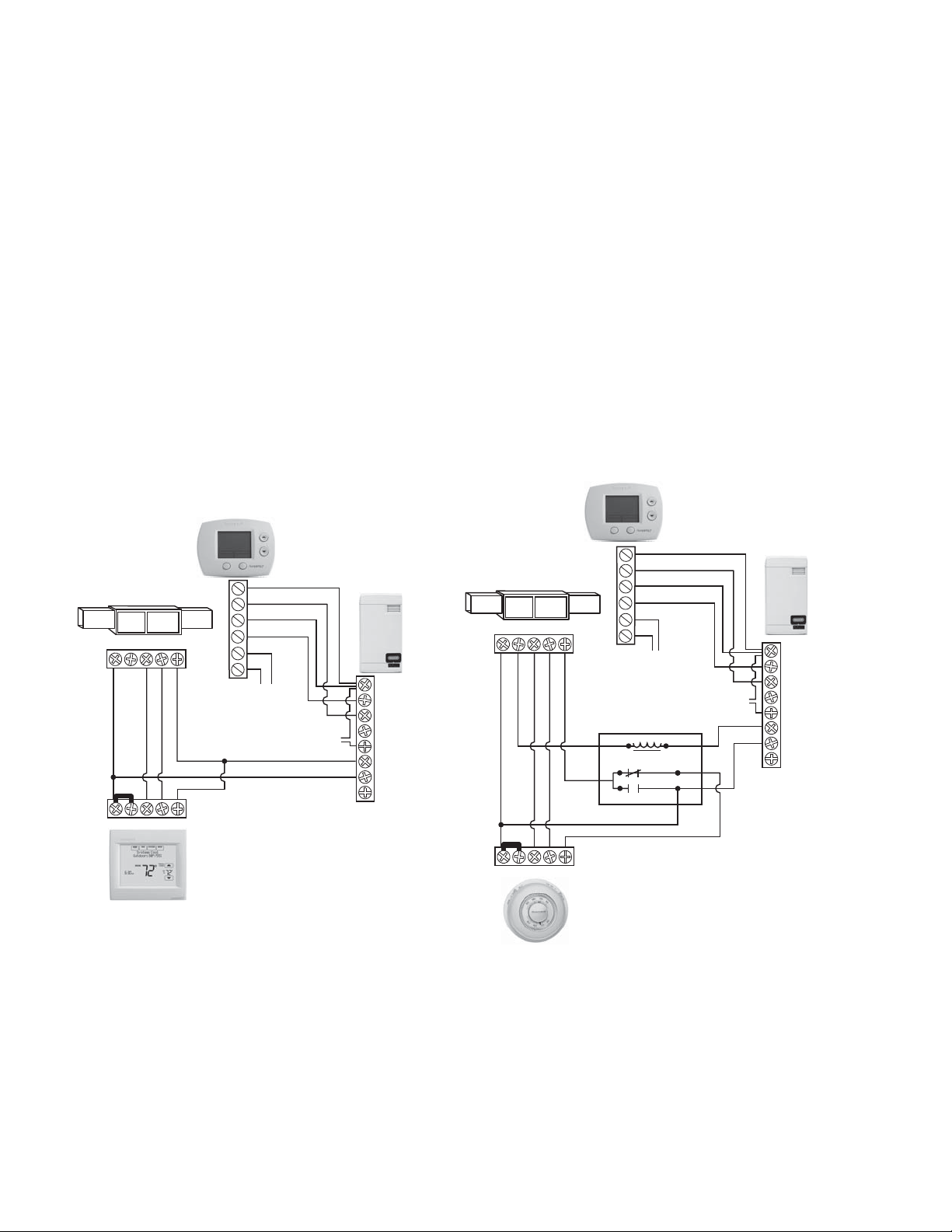

HM700A1000

HVAC

THERMOSTAT

R

C

U

U

S

S

GYWRRc

GYWR C

R/HUM

HUM

C

N/A

AP

G

F

R

F

N/A

M35754

OUTDOOR

SENSOR

AIR PROVING

OR JUMPER

EXTERNAL CONTROLS

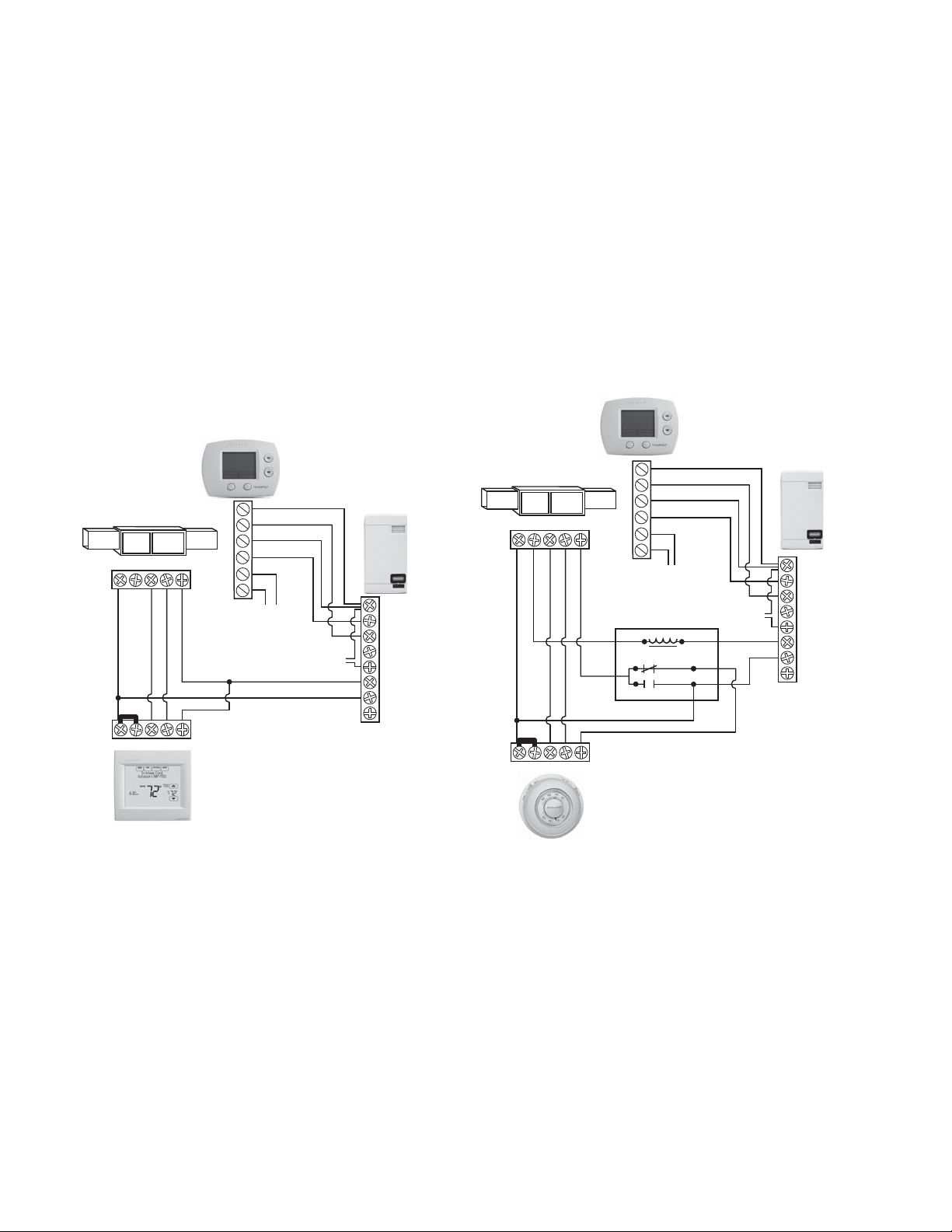

Fan Interlock Wiring with HumidiPRO

When distributing steam into a duct, there could be a call for

humidity when there is no air flow. The HM700 with

HumidiPRO control or some other thermostat (such as the

Honeywell Prestige of VisionPRO

fan on a call for humidity. If using another thermostat, consult

that control’s manual for wiring instructions to enable the fan

with a powered humidification device.

NOTE: Humidifier will not start producing steam until

fan security loop is closed.

®

) can be used to enable a

This information is relevant to all controls, factory supplied or

otherwise. For wiring use minimum 18 AWG solid wire and

keep as short as possible.

Humidity Control

• Can be located either in return air duct (preferred) or in

room being humidified.

• Avoid placing near discharge diffuser of humidified air.

• Mount in area representative of room humidity (drafts,

doorways, sunlight, or an overhang such as a shelf can

affect reading).

Optional Outdoor Temperature Sensor (not shown; included

with HumidPRO)

• Mount outside in area representing air temperature.

HVAC

R

C

U

U

GYWR C

S

S

SPDT RELAY

COM

OUTDOOR

SENSOR

NC

NO

AIR PROVING

OR JUMPER

R/HUM

HUM

C

N/A

AP

G

F

R

F

N/A

NOTE:

SPDT RELAY IS NECESSARY TO PREVENT

ENERGIZING THE Y TERMINAL IF THE

GYWRRc

THERMOSTAT DOES NOT ISOLATE Y AND G.

Fig. 17. Wiring the steam humidifier with a digital thermostat.

THERMOSTAT

Fig. 18. Wiring the steam humidifier with a mechanical

M35730

thermostat.

NOTE: If a Prestige, VisionPRO, Lyric (or similar) are used to control humidity, wire the two HUM contacts to terminals 1 and 2

33-00118EFS—01 12

on the HM700. With the jumper in place between terminals 1 and 8 on the HM700, only these two wires are necessary

to control humidity. Be sure to configure the control to force fan on with a call for humidity, or run on a heat cycle if the fan

enable wiring is not used.

Page 13

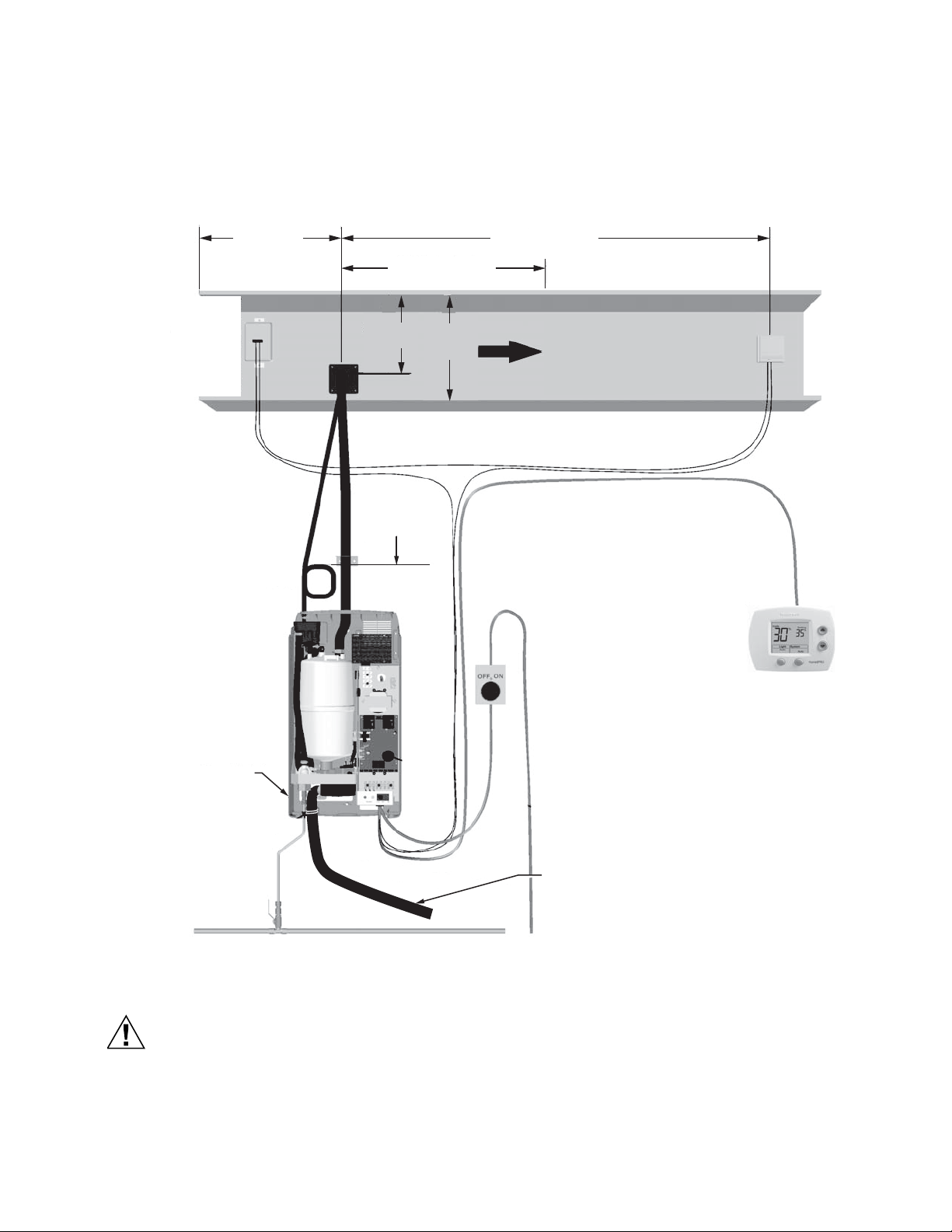

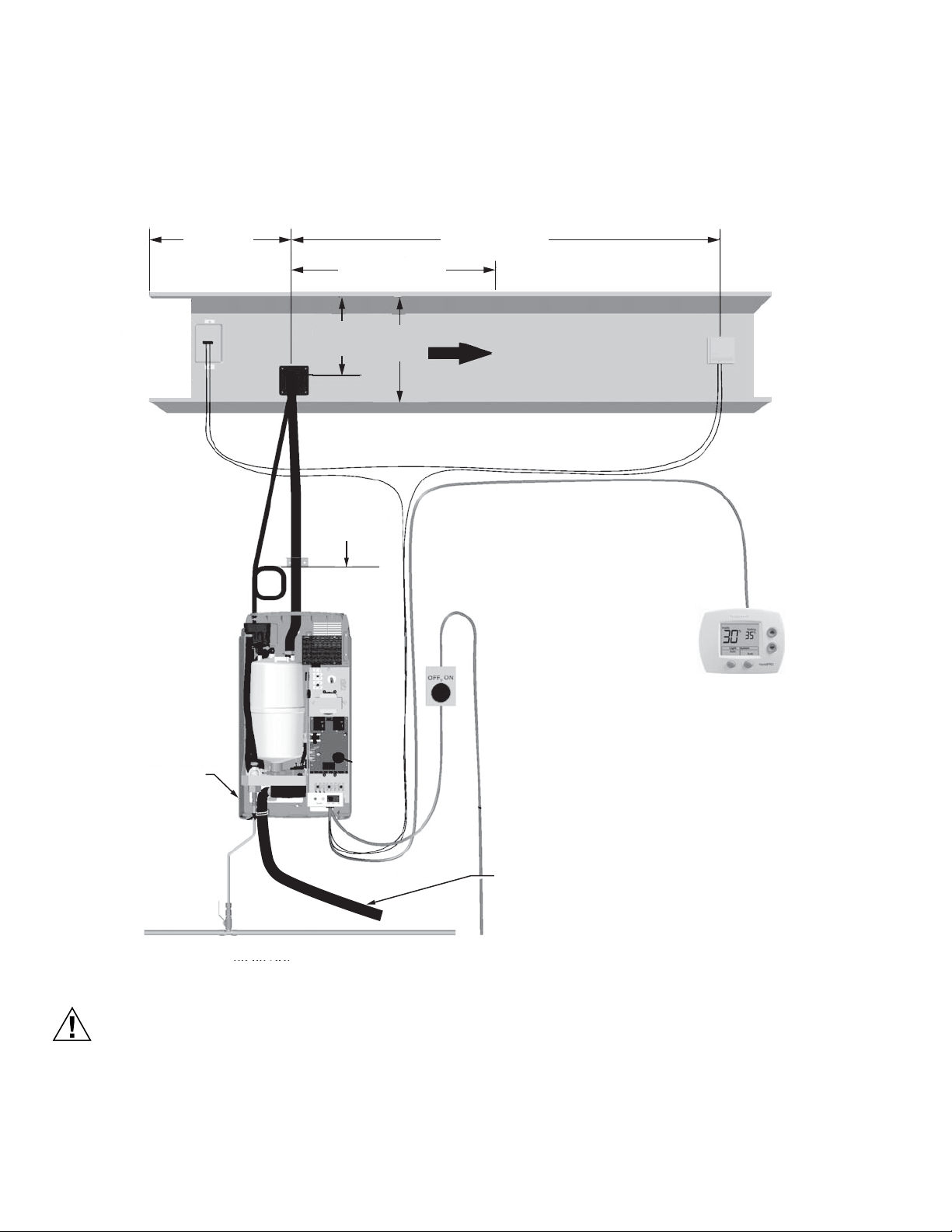

START UP

CAUTION

FUSED DISCONNECT

CORRECT VOLTAGE / AMPS /

PHASE PER SPEC LABEL

(OPTIONAL)

MOUNTING

- UNIT LEVEL

- SCREWS INTO

STRUCTURAL

MEMBER

STEAM LINE

- ADEQUATE SLOPE

- NO RESTRICTIONS

- NO KINKS IN HOSE

- CONDENSATE TRAPS

ON LONG RUNS

HUMIDITY CONTROL

IN RETURN DUCT OR

LOCATION WHICH

REPRESENTS HUMIDIFIED

SPACE (NO DRAFTS, NOT

BY DOOR, NOT BY DIFFUSER)

1/2 IN. LINE (MINIMUM) TO WITHIN 4 FT (1.2 M). 30-100 PSIG

SPEC LABEL

AIR GAP

P TRAP

WITH 12 IN (30 CM)

MINIMUM DROP

BEND, OR OTHER

OBSTRUCTION

NOTE: U OR HUM TERMINALS IN SERIES BETWEEN TERMINALS 1 AND 2

AIR PROVING

(OPTIONAL)

IN SERIES BETWEEN

TERMINALS 1 AND 2.

JUMPER BETWEEN

TERMINALS 1 AND 8

MUST BE REMOVED.

2X DUCT HEIGHT

FROM FAN OR

TRANSITION

10 FEET (3 M) MINIMUM

4 FEET (1219) MINIMUM

2/3 DUCT

HEIGHT

8

(20 CM)

MINIMUM

HIGH LIMIT

ON/OFF

(OPTIONAL)

IN SERIES BETWEEN

TERMINALS 1 AND 2.

JUMPER BETWEEN TERMINALS

1 AND 8 MUST BE REMOVED.

M35807

DRAIN LINE SHOULD BE ROUTED TO ALLOW FREE FLOW OF

WATER. ENSURE ADEQUATE SLOPE, NO TRAPS, AND NO KINKS.

Installation Check

Before turning on power to the HM700, inspect the installation to ensure that it was carried out correctly.

HM700A1000

Fig. 19. Installation check.

Equipment Damage Hazard

Do not leave the On/Off/Drain switch in the drain

position for more than one complete drain cycle. The

drain valve solenoid may heat up and result in damage

to the valve and its wiring.

Do not attempt to drain with no water in system.

On/Off

The HM700 is factory-configured to operate as an On/Off

humidifier. It will run when 24 VAC from terminal 1 is fed back

into terminal 2 through an On/Off humidistat and other

security devices in series.

13 33-00118EFS—01

Page 14

HM700A1000

WARNING

Start Up Procedure

1. Examine the humidifier and installation for damage

and/or improper installation.

2. Ensure the cylinder is properly seated in the drain valve

and that the electrode plugs are pushed all the way

down on the cylinder pins.

3. Ensure that the front cover is in place and secured with

its retaining screws.

4. Open the supply water shut off valve.

5. Turn on the main power using the installed disconnect.

Personal Injury Hazard.

Damaged or improperly installed units must not be

operated. Damaged or improperly installed units may

present a danger to persons and property.

6. Turn the On/Off switch on the front of the humidifier to

On.

• The humidifier will perform a self-diagnostic

sequence during which the LED’s and internal

components will be momentarily activated. See

“LED Status Lights” on page 15 for an explanation

of the LEDs and sequences.

• If an error is detected during the self-diagnostic

sequence the humidifier will not start. The yellow

status LED will flash in sequence to indicate the

detected fault. See Tables 7 and 8 for information

on diagnosing and correcting faults.

• After the system test the humidifier is in normal

operation mode.

7. Check and adjust the control setpoint on the control and

high limit humidistat.

8. When the external humidistat generates a demand for

humidity and the security loop is closed the green

humidifying LED on the front of the humidifier will light

up, the power relay on the control board will engage, the

fill valve will activate (after a delay) and the cylinder will

slowly fill with water.

NOTE: While the cylinder is filling with water there

should be no water flowing down the drain. If

water is flowing down the drain it can indicate

excessive backpressure or a leaking drain valve.

See Troubleshooting.

9. If a fan enable relay is used, the green LED will continue

to flash until the air proving closes. Once the air closes,

the flashing green LED will become solid and the

humidifier will start steam production as described in

step 8.

10. It can take 5 – 10 minutes for the water to be heated up

by the submerged electrodes and for steam to be produced.

NOTE: If operated on low conductivity water it may take

several hours for the HM700 to reach full output

capacity. This is normal. During this time the

humidifier will not perform any drains and the

conductivity of the water in the cylinder will

increase. To expedite this process, add a

1/4 teaspoon of salt to the cylinder. This will

immediately increase water conductivity and

initiate heating.

33-00118EFS—01 14

Page 15

OPERATION

M35828

STATUS

DRAIN OFF ON

YELLOWGREEN

HM700A1000

LED Status Lights

The HM700 user interface includes 2 LEDs that provide

information about the humidifier status.

Fig. 20. LED status indicator lights.

Yellow and Green LED Flashing

Indicates there is no request for humidity.

Yellow LED Flashing

Fault detected, humidifier has stopped operating. Count

the number of flashes and see Table 8 for info.

Green LED Flashing

Indicates the humidifier is powered, but there is not a

request for humidity. Security loop (1-2) is open.

Yellow LED On

Indicates that water level is high.

When the yellow LED is steady on (not flashing) it indicates that the high water sensor has interrupted filling of

the cylinder. The LED is on for information only and

unless it persists for an extended period of time, it does

not require any action.

Green LED On

Indicates steam is being produced.

Selecting a Relative Humidity Setpoint

The optimum humidity setpoint depends on the reasons that a

space is being humidified. The “ASHRAE Handbook HVAC

Applications” recommends specific design relative humidity for

specific applications.

Health and Comfort – The benefit of humidity is most

pronounced for health and comfort in the 40-60% range. A

humidity setting of 45-50% is recommended for this purpose

to prevent over humidifying.

Temperature Setback – In cold climates it is often necessary

to reduce the humidity level in a conditioned environment to

prevent build-up of condensation on the inside of exterior

walls, windows, and trim. It is highly recommended that the

humidity setback function of the HumidiPRO control be used

under these conditions to prevent damage from condensation.

The digital control with an outdoor temperature sensor

installed will automatically setback the humidity setpoint to

correspond with outdoor temperature.

15 33-00118EFS—01

Page 16

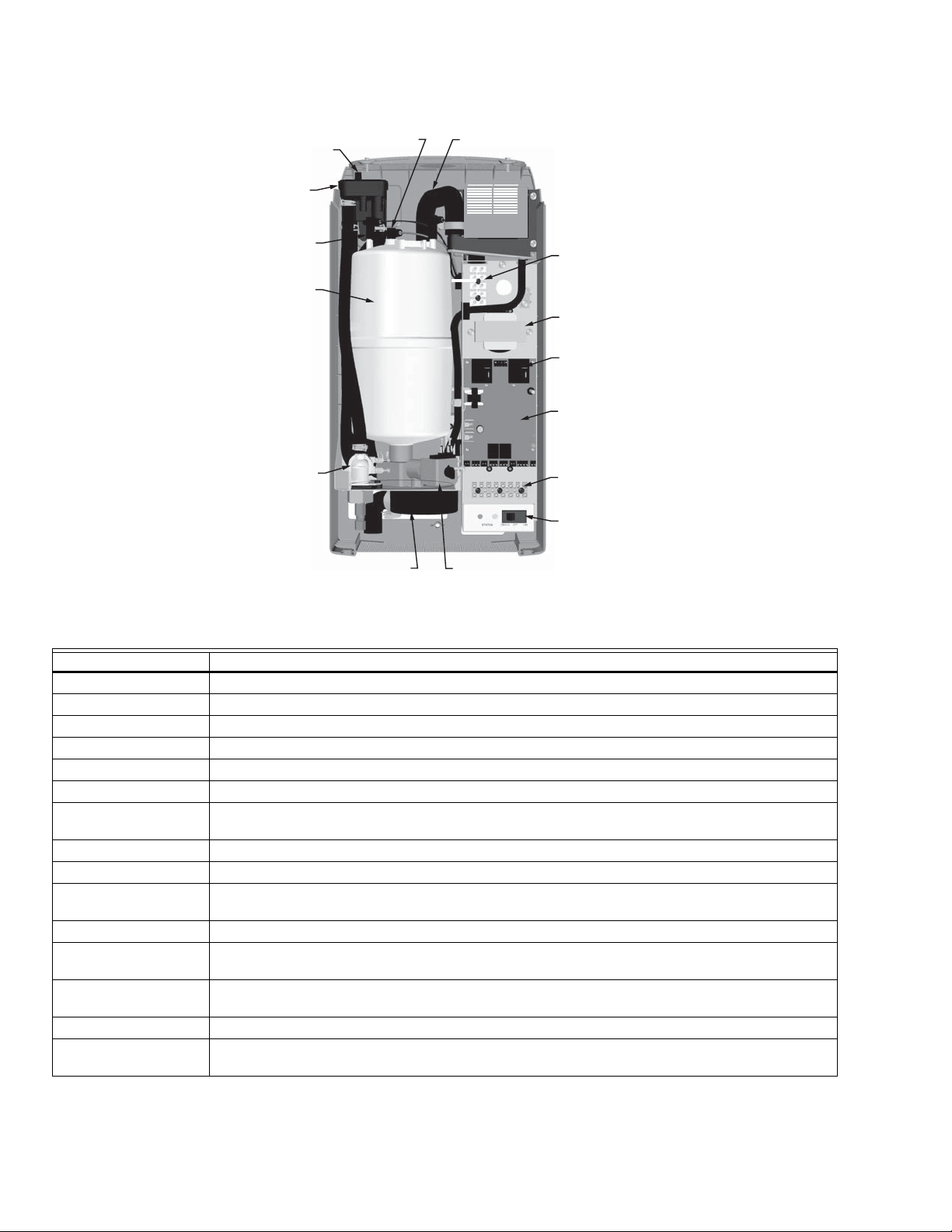

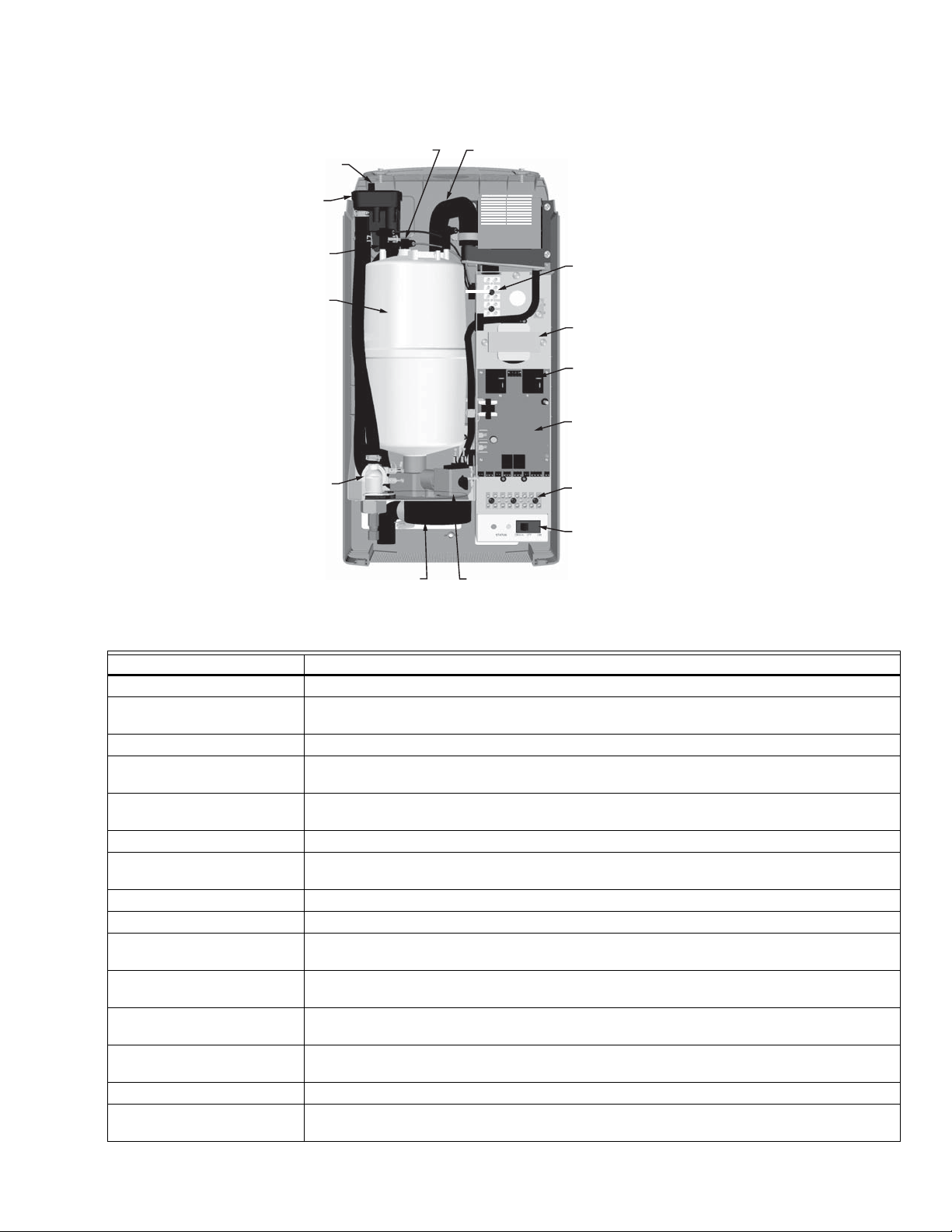

HM700A1000

STEAM

OUTLET

CONDENSATE

RETURN

FILL CUP

DRAIN VALVEDRAIN CANAL

FILL VALVE

CYLINDER

CYLINDER

PLUG

HIGH WATER

SENSOR PLUG

ON/OFF/DRAIN

SWITCH

CONTROL

BOARD

POWER RELAY

HIGH VOLTAGE

TE RM IN A L

BLOCK

TRANSFORME R

CONTROL

TE RM IN A L

STRIP

M35827

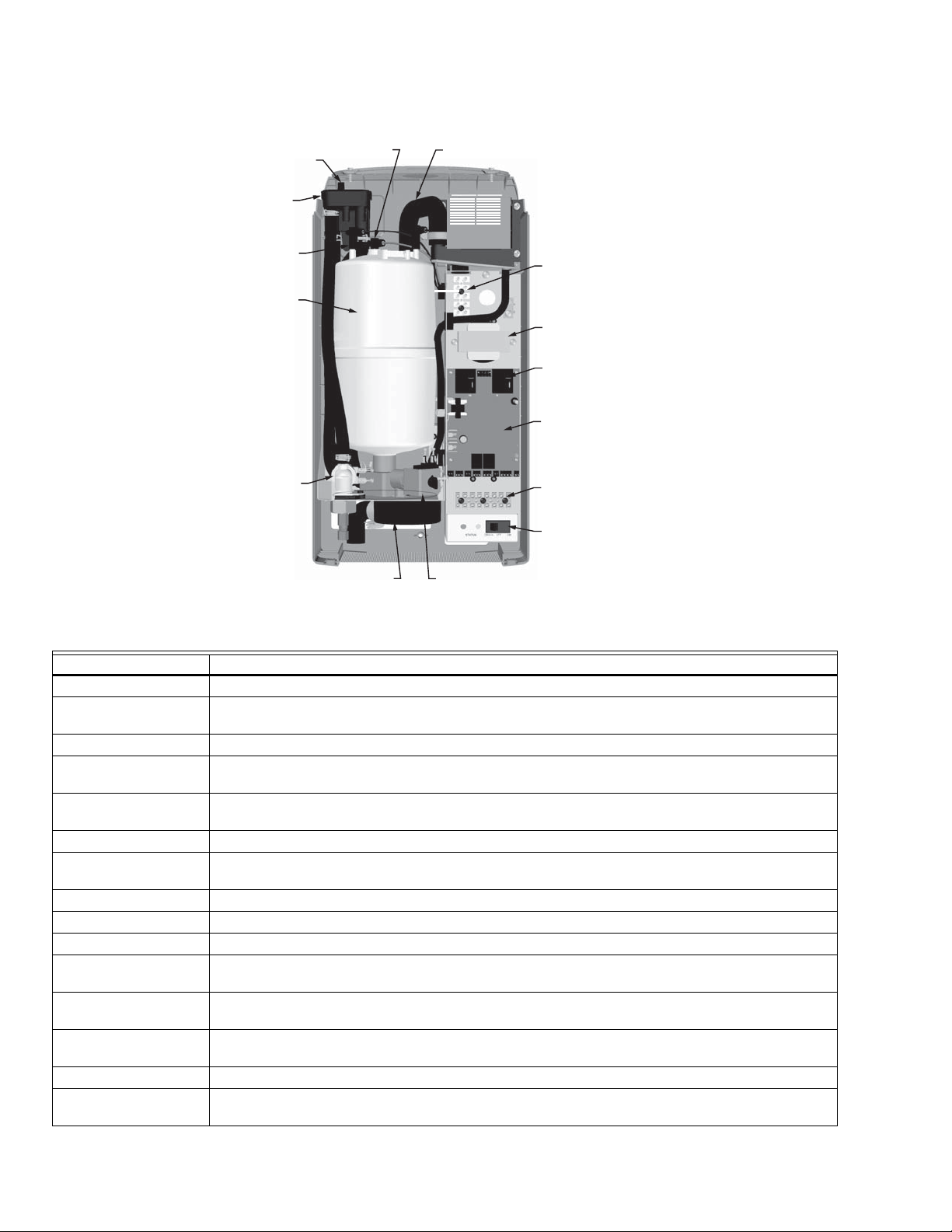

Fig. 21. Humidifier components.

Component Function

Condensate Return Provides a connection to return condensate to humidifier.

Control Terminal Strip Terminal strip for connecting external controls to humidifier and interfacing with other equipment.

Cylinder Plug Power connectors to electrodes in cylinder.

Cylinder Holds electrodes in water. Current between electrodes generates heat used to generate steam.

Drain Canal Combines cylinder drain water and fill cup overflow into a single drain outlet.

Drain Valve Drains water from humidifier.

Control Board Controls all functions of the humidifier operation and provides input and output connections to

humidifier components.

Fill Cup Provides an air gap for backflow prevention.

Fill Valve Controls flow of water into humidifier.

High Voltage Terminal

Block

High Water sensor Plug Used to detect max water level in cylinder.

Primary power connection from remote disconnect to humidifier.

On/Off/Drain Switch Turns power on/off to humidifier controller and drains the cylinder for servicing. Note: Turn off

humidifier disconnect to shut off primary power to the humidifier.

Power Relay Turns on/off power to cylinder electrodes based on a signal from the humidifier’s controller (mounted

on control board).

Steam Outlet Connect to steam line with steam hose.

Transformer Steps primary voltage down to 24 VAC for the controller and internal components such as the fill valve

and drain valve.

33-00118EFS—01 16

Page 17

MAINTENANCE AND SERVICING

CAUTION

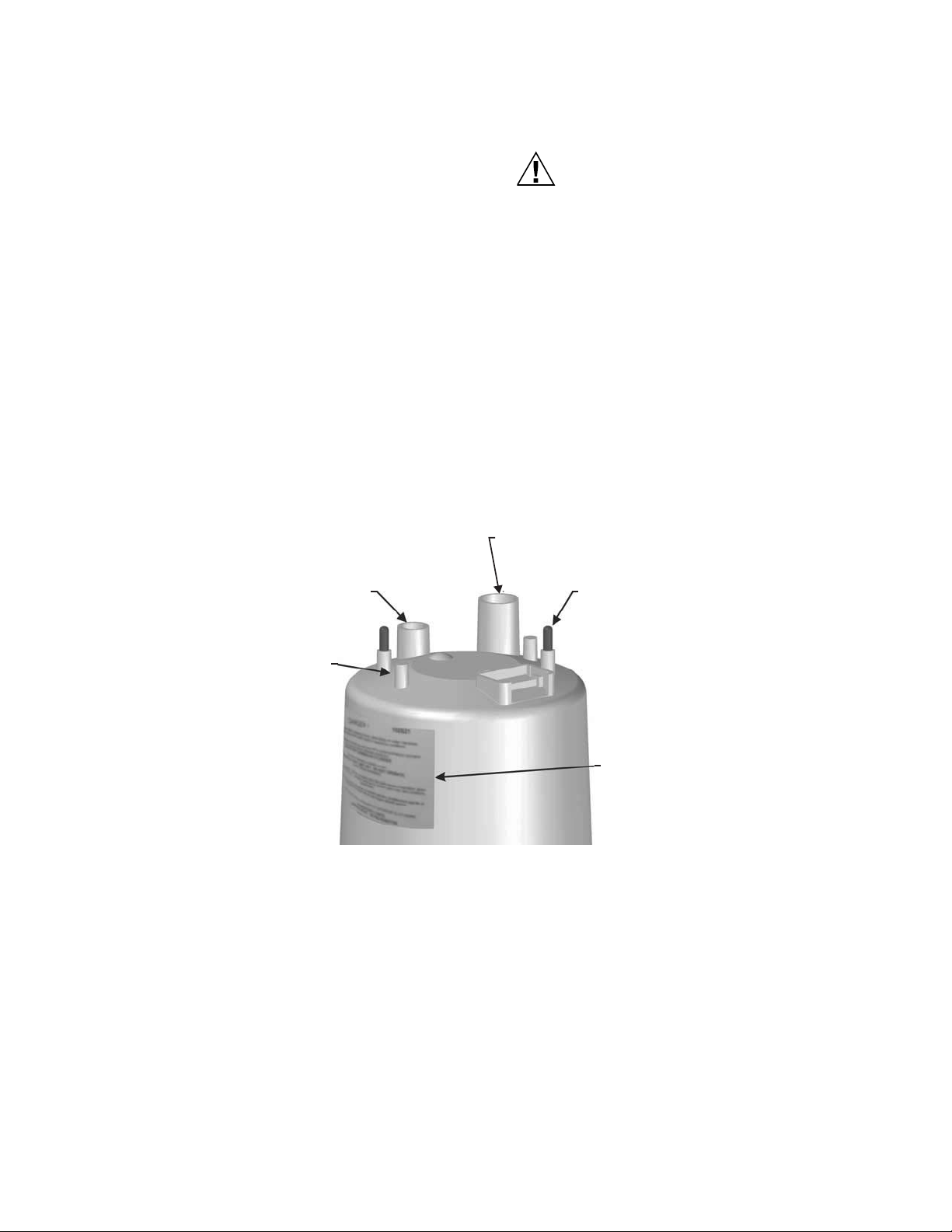

M35704

ELECTRODE INTERNAL

MOUNTING POINT.

HIGH WATER SENSOR PIN HAS

A PLASTIC COLLAR AROUND IT.

CONNECT ORANGE HIGH WATER

SENSOR WIRE HERE.

STEAM OUTLET

SECURE STEAM HOSE TO

OUTLET WITH HOSE CLAMP.

ELECTRODE PIN

CONNECT COLOR CODED CYLINDER

PLUGS TO PIN WITH CORRESPONDING

COLOR LABEL. THE SPRING LOADED

PLUG SHOULD FIT SNUGLY ON THE PIN.

REPLACE IF LOOSE OR ANY SIGNS OF

DAMAGE.

LABEL

IDENTIFIES CYLINDER INFORMATION.

ALSO INCLUDES SAFETY INFORMATION

AND CONTACTS.

Required Maintenance

The HM700 humidifier has been designed to require very little

maintenance. Regular maintenance consists of checking the

humidifier to ensure it is in good condition, replacing the

cylinder when the software advises that the cylinder is spent

and cleaning out the drain valve whenever the cylinder is

replaced.

CYLINDER SPENT FAULT

When the cylinder is spent the HM700 will stop operating and

the yellow LED will flash in a repeating pattern of 4 flashes.

See Table 8 on page 22 for more information on other flash

sequences. At this time the cylinder must be replaced.

The steam cylinder is disposable and must be replaced at end

of cylinder life. Cylinder life is dependent on water supply

conditions and humidifier usage.

HM700A1000

Failure to replace the cylinder at the end of

cylinder life will result in improper operation and

may result in damage to the humidifier. Honeywell

is not responsible for any damages resulting from,

or attributed to, the failure to replace a spent

cylinder (see Manufacturer’s Warranty).

NOTE: Honeywell recommends keeping a replacement

cylinder in stock throughout the humidification

season. This will prevent possible downtime

when the humidifier reports cylinder end of life.

REPLACEMENT CYLINDER

The label on the existing cylinder identifies the cylinder type in

its top left corner. When ordering a cylinder always quote the

three or five digit model number on the label, the humidifier’s

serial number and the humidifiers voltage. Serial number and

voltage are located on the specification label on the left side of

the humidifier.

Fig. 22. HM700 cylinder (HM700ACYL2).

17 33-00118EFS—01

Page 18

HM700A1000

WARNING

HOSE CLAMP

CYLINDER PLUG

LIFT VERTICALLY

ON/OFF/DRAIN SWITCH

CYLINDER

COVER SCREWS

TILT CYLINDER

FORWARD TO CLEAR

HOSE AND THEN

LIFT FROM DRAIN

VALVE.

TILT COVER

FORWARD TO

REMOVE.

M35705

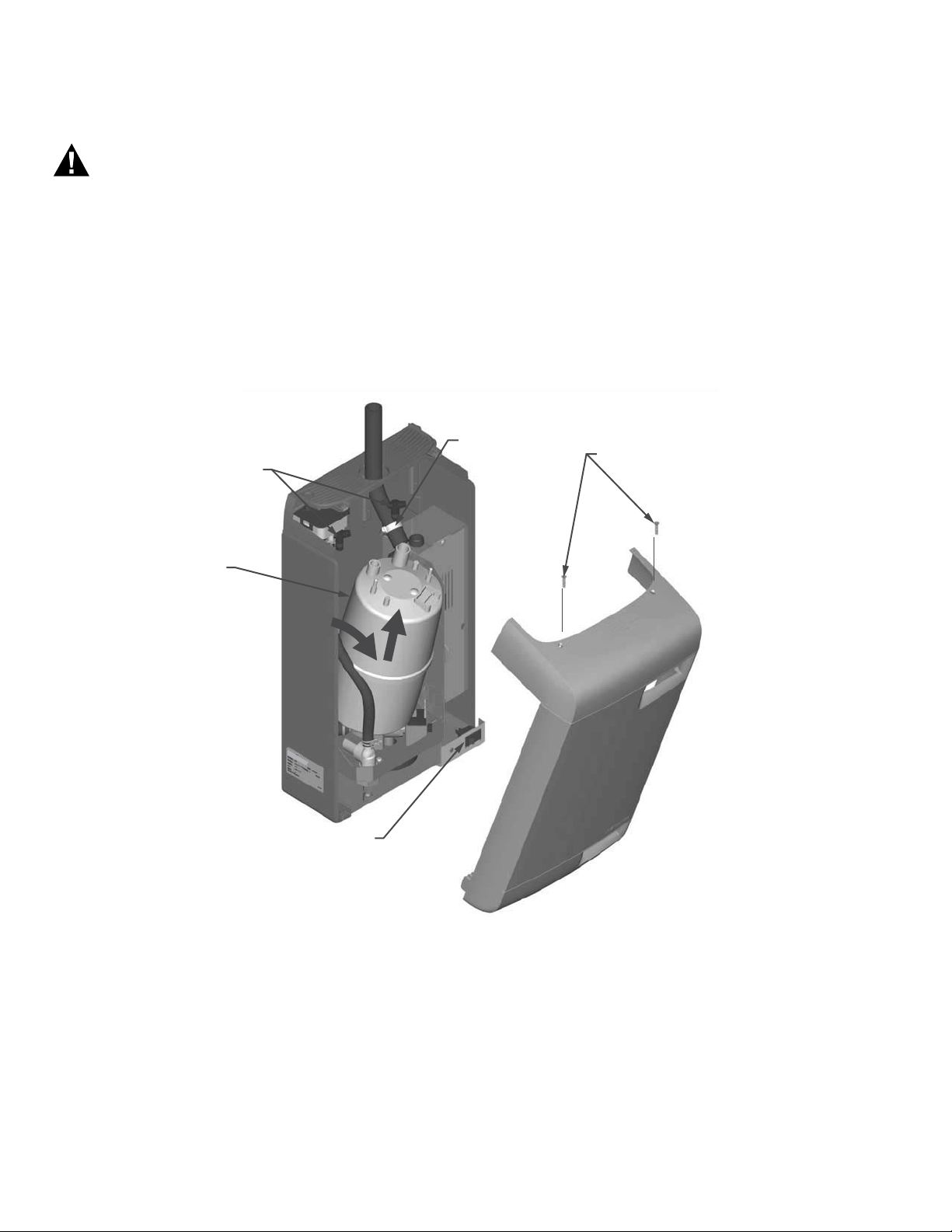

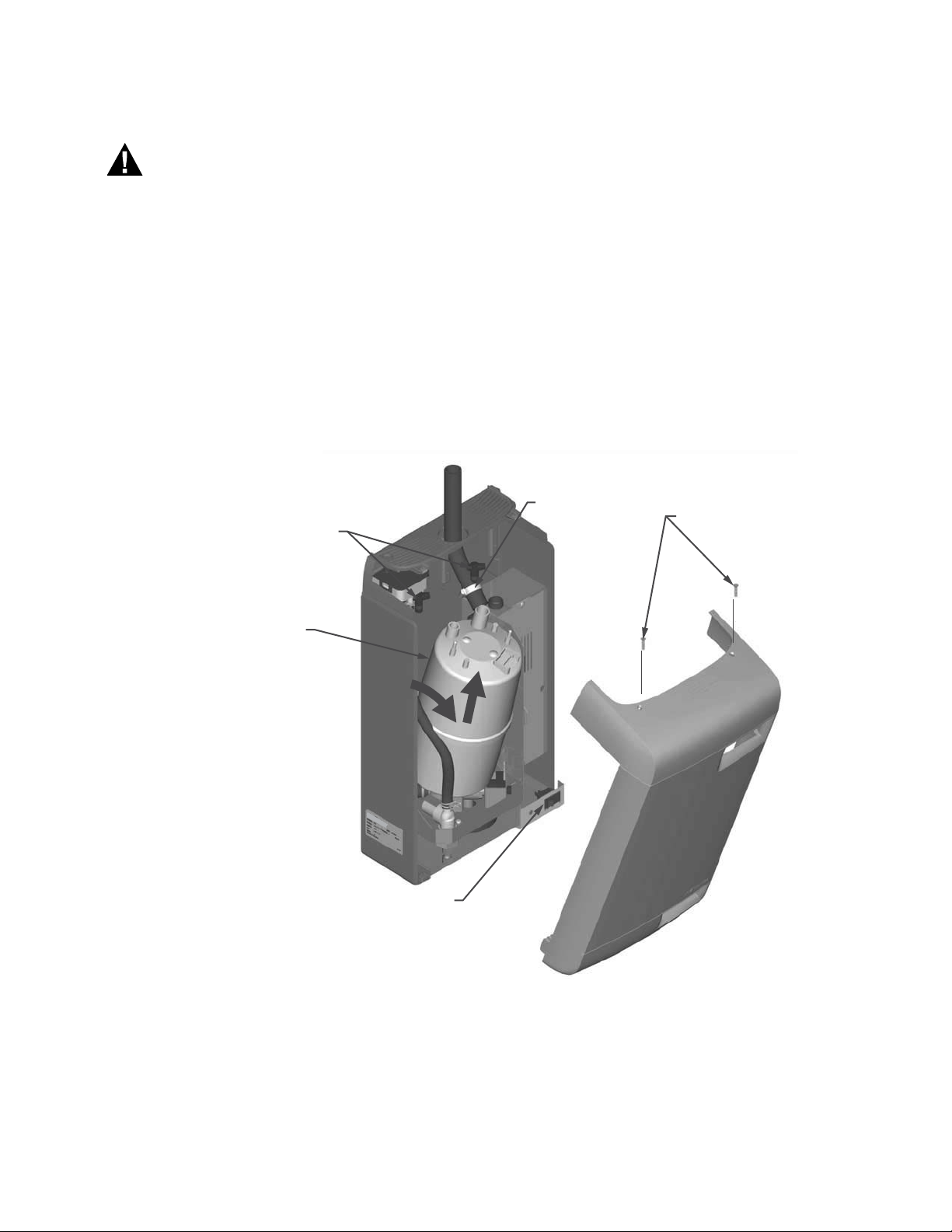

Removing the Cylinder

Disconnect main power at the external disconnect

before any servicing.

The inside of the humidifier cabinet contains high

voltage components and wiring. Access should be

limited to authorized personnel.

1. Drain the existing cylinder by switching the On/Off/Drain

switch to the Drain position. Let the humidifier drain until

no more water is flowing out to drain (usually not more

than 10 minutes).

2. Turn the humidifier On/Off/Drain switch to off.

3. Close supply water shut off valve.

4. Turn off power to the humidifier with the external discon-

nect.

5. Remove the two screws securing the front cover.

6. Remove the cylinder plugs from the cylinder pins by

pulling vertically.

7. Using a flat screwdriver loosen the hose clamp where

the hose is connected to the cylinder.

8. Tip the top of the cylinder forward to pivot it out of the

steam hose. When free of steam hose lift the cylinder

out.

NOTE: The HM700 has a re-usable tie strap to secure the

cylinder for transit as well as home installation.

This must be removed or loosened to remove the

cylinder. Secure when new cylinder is installed.

33-00118EFS—01 18

Fig. 23. Cylinder removal.

Page 19

HM700A1000

CAUTION

CYLINDER PORT

AND O-RING

GROUND

WIRE

SOLENOID

SPADE

CONNECTORS

BRASS NUT

(ACTUATOR)

SCREWS

HOSE AND

HOSE CLAMP

M35700

M35707

SLEEVE AND

SOLENOID

SPRING

(NOTE ORIENTATION)

PLUNGER

ACTUATOR

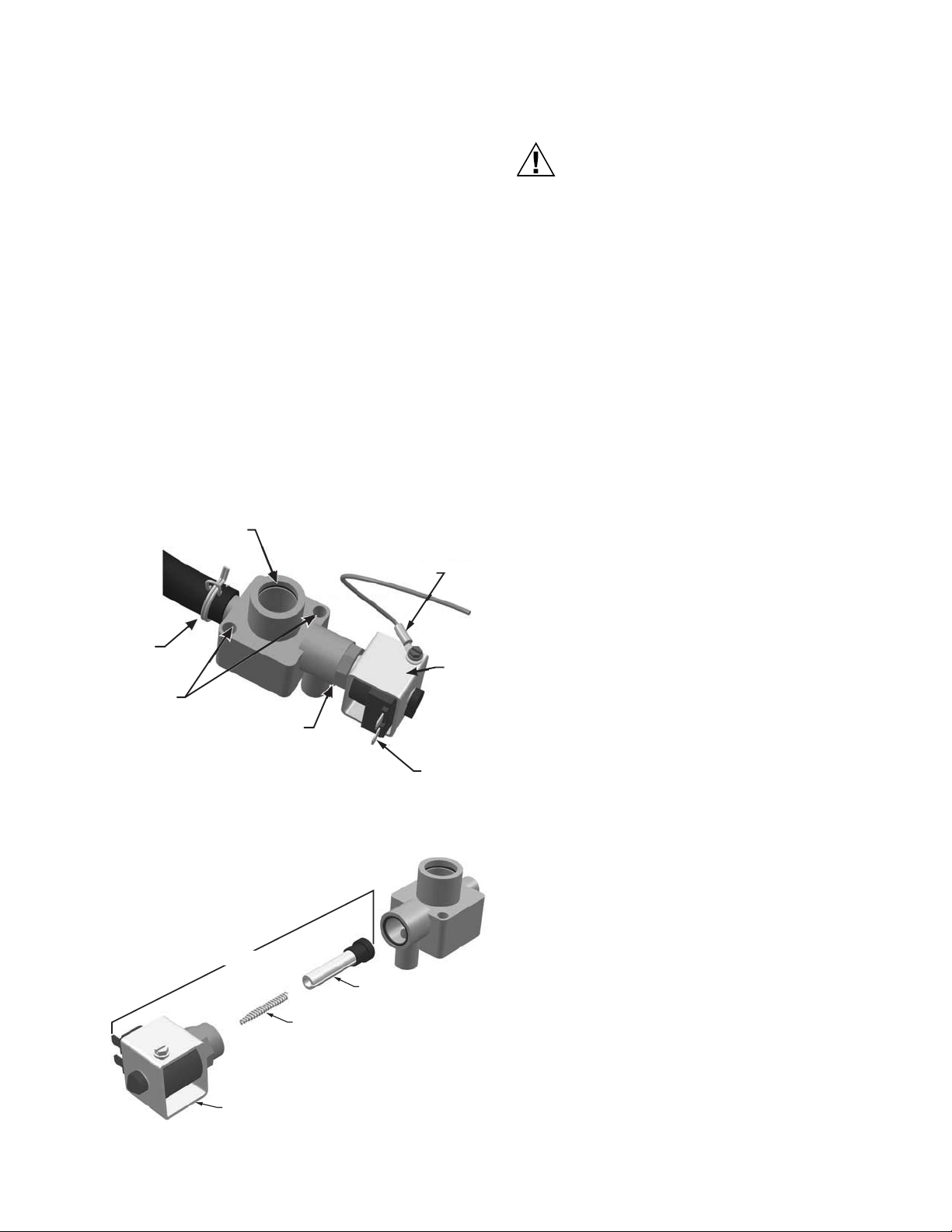

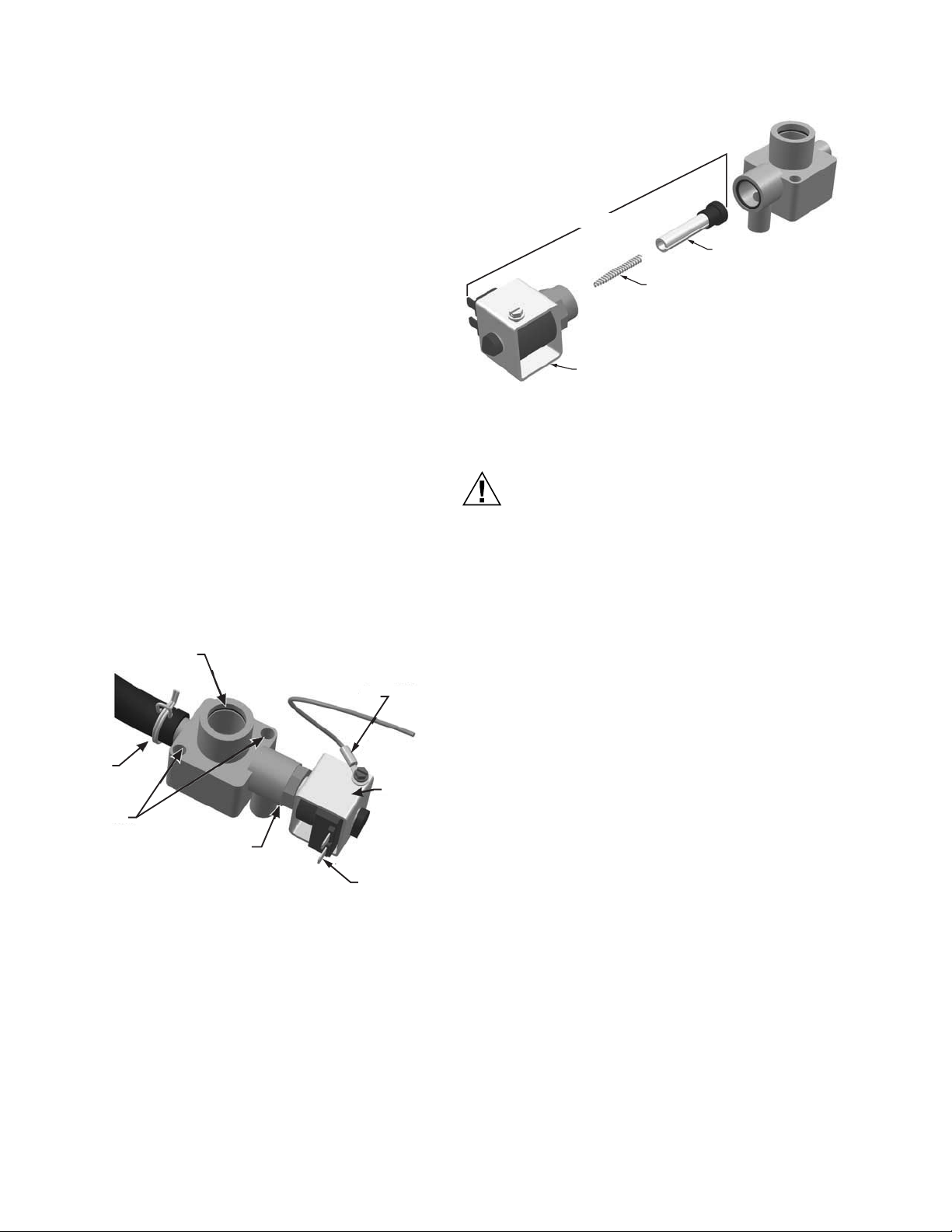

Drain Valve Cleaning

Always clean the drain valve before installing a new cylinder.

Scale from the spent cylinder may have fallen into the drain

valve and could prevent its proper operation. To properly clean

the drain valve it must be removed and disassembled.

1. Disconnect spade terminals from the drain valve.

2. Remove the two screws holding the valve to the drain

pan.

3. Squeeze the tabs of the spring clamp holding the hose

to the drain valve and slide it up the hose. Pull hose

from drain valve. Lift the drain valve from the drain pan.

4. Unsnap red coil cap on solenoid and remove the sole-

noid from the valve.

5. Loosen brass nut holding actuator to plastic housing

with a wrench and disassemble actuator.

6. Clean actuator components and valve housing (inlet

port, outlet port, and cylinder port). Put new o-ring that

was supplied with new cylinder into valve.

7. Reassemble actuator making sure tapered end of

spring is oriented as shown in Fig. 25. Tighten brass nut

1/4 turn past hand tight.

8. Clean out end of hose and reattach to valve. Slide hose

clamp back in place and place valve into drain pan.

9. Secure valve with 2 screws to drain pan.

Installing the New Cylinder

Make sure the new cylinder is a HM700ACYL2. Use

of any other model or remanufactured cylinders

will void the HM700 warranty.

1. Insert cylinder into drain valve. Tilt cylinder forward and

fit end of steam hose to steam outlet. Tip cylinder back

into place.

2. Tighten hose clamp being careful not to over tighten and

crush the plastic cylinder steam outlet.

3. Attach color-coded cylinder plugs to the corresponding

color-coded cylinder pin. Push down completely.

Connect high water sensor plug. Spring-loaded plugs

should fit snuggly onto the cylinder pin. Replace if they

are loose or damaged.

4. Re-fasten tie strap.

5. Replace the humidifier cover and secure with two

screws.

6. Turn on power to humidifier with the external

disconnect.

7. Open supply water shut off valve.

8. Turn the humidifier On/Off /Drain switch to On.

Extended Shutdown

Should it be required to disconnect power to the humidifier for

a period of extended shut-down, always drain the cylinder first.

Fig. 24. Drain valve.

1. Switch the On/Off/Drain Switch to the Drain position.

2. Wait until the humidifier is completely drained (usually

takes less than 10 minutes).

3. Turn the On/Off /Drain switch to the off position.

4. Shut off power to the humidifier with the external

disconnect.

5. Close the supply water shut-off valve.

NOTE: As long as the HM700 is powered, it will

automatically drain the cylinder when there has

not been a call for humidity for an extended

period of time. This feature will reduce or prevent

the possibility of corrosion of the electrodes and

the accumulation of algae and bacteria growing

in the cylinder. The cylinder will remain empty

until there is a call for humidity at which time the

fill valve will open and refill the cylinder. The unit

will go through its normal process for optimum

operation.

STARTING AFTER EXTENDED SHUTDOWN

1. Check to see the humidifier has not been damaged and

the installation has not been altered. See “Start Up

Procedure” on page 14.

2. Turn on the power to the humidifier with the external

disconnect.

3. Turn the On/Off/ Drain switch to the Drain position.

4. Wait until there is no water flowing to drain. It usually

takes less than 10 minutes.

5. Follow the start up procedure on page 14.

Fig. 25. Drain valve actuator assembly.

19 33-00118EFS—01

Page 20

HM700A1000

CAUTION

CAUTION

TROUBLESHOOTING

High Voltage Hazard.

Be aware, when troubleshooting, that the humidifier is

powered by high voltage and familiarity with both good

practices and wiring of the humidifier is recommended.

Any troubleshooting that requires opening the cabinet

should be done by qualified personnel.

Burn and Scalding Hazard.

Hot water or steam with a temperature above 120 °F

(49 °C) can cause burns from scalding.

NOTE: Most humidifier faults are not caused by faulty

equipment but rather by improper installation. A

complete fault diagnosis always involves a

thorough examination of the entire system.

Often, the steam hose connection has not been

properly executed, or the fault lies with the

humidity control system.

TROUBLESHOOTING REQUIREMENTS

• Ensure the installation meets the installation requirements

outlined in the Installation Chapter of this manual.

• Familiarize yourself with the operation of the humidifier by

reading the Operation Chapter of this manual.

• Wiring diagram for specific for your humidifier is installed

on the inside of the humidifier door. A generic copy of the

HM700 wiring diagram is also included at the end of this

chapter for reference purposes.

• When contacting your local representative or Honeywell for

troubleshooting assistance, please ensure the serial

number has been obtained for reference purposes.

The following section provides general guidelines for

troubleshooting the HM700 humidifier and auxiliary

components. For detailed troubleshooting information refer to

the manuals that were provided with the auxiliary equipment

and to Table 8, “Troubleshooting HM700 Faults,” on page 22.

Symptom Cause Corrective Action(s)

Nothing happens when On/Off

switch is turned on.

Humidifier will not humidify or not

reaching HM700 setpoint

Humidifier has faulted and yellow

LED is flashing

Table 7. General troubleshooting.

Fuse blown Check inline fuse between transformer and

control board.

Incorrect Voltage Check voltage against spec label and correct.

Step Down Transformer not outputting

24VAC

Incorrect primary power jumper Check that jumper on high voltage terminal block

Safety loop open Check if there is 24 VAC at terminal 2.

No demand signal Check voltage between terminal 3 and 4. For

Capacity has been manually limited Check Manual Capacity adjustment

Low conductivity water Check if yellow LED is on. If operated on low

No airflow in duct Check that humidifier fan enable (terminals 19-20)

Software has detected an abnormal

condition

Replace the transformer.

is connected between P and terminal

corresponding to supply voltage. See Fig. 16.

Check wiring and operation of On/Off devices

connected to terminal 1 and 2.

Check jumper is installed in air proving safety

loop, terminal 1 and 8.

demand configuration 35% of full-scale signal

must be present for humidifier to start.

potentiometer. Clockwise increases capacity.

conductivity water it may take several hours for

the HM700 to reach full output capacity. This is

normal. During this time the humidifier will not

perform any drains and the conductivity of the

water in the cylinder will increase. Conductivity

can be increased more quickly by adding

1/4 teaspoon of salt.

are properly wired to furnace. Check air proving

wired to terminal 8.

Refer to Table 8 on page 22.

33-00118EFS—01 20

Page 21

HM700A1000

Table 7. General troubleshooting. (Continued)

Symptom Cause Corrective Action(s)

Distributor spitting out water Distributor not level Use support at end of distributor to ensure it is

level.

“P” Trap too close to distributor “P” Trap must be a minimum of 12 in (30 cm)

below the distributor to ensure flow. Relocate if

required.

Condensate line not sloped sufficiently Sufficient slope to ensure flow is required.

Reinstall if required.

Trap blocked Check that water flows through trap. Clear out if

blocked.

Steam line not insulated If steam line is long, condensate build up could

overload distributor condensate port. Insulate line

to improve efficiency and install additional

condensate traps as required.

Incorrect steam line installation Check that steam line has been installed with

condensate traps and slope. See “Steam Lines

and Condensate Return Instructions” on page 8.

Condensation in duct Installation clearances not observed Refer to distributor installation manual for required

clearances. Relocate distributor if required.

Design conditions changed Check supply air temperature and humidity to

determine if conditions have changed.

High limit not functioning Check setting and operation of high limit. Replace

if defective.

Humidifier is tripping the GFI. Humidifier is wired to a GFI circuit.

Drain valve ground wire is not

disconnected.

Review the Electrical Installation Steps and Notes

on page 10 for GFI guidelines and ground wire

removal information.

21 33-00118EFS—01

Page 22

HM700A1000

HM700 Faults

The self-diagnostic system built into the HM700 is continually

monitoring the operation of the humidifier. When an abnormal

condition occurs that cannot be self-corrected by the software

the HM700 will turn off power to the cylinder, drain the

cylinder, and annunciate the fault using the yellow status LED.

LED Flash Sequence

To differentiate between different fault conditions the yellow

LED is flashed in different sequences. Table 8 lists the fault

sequences that can be displayed, their meaning, possible

cause and suggested corrective actions.

Clearing a Fault

• Check the flash sequence against the list of fault messages

and take any necessary actions to correct the cause(s) as

outlined in Table 8 on page 22.

• Power cycle the humidifier with the On/Off switch waiting

10 seconds between turning it off and on.

Table 8. Troubleshooting HM700 Faults.

Yellow

LED Symptom Cause Corrective Action(s)

1 flash Excess Current

Current has

exceeded 130% of

max

2 flashes No Current

Fill valve activated

for long time but

high water level not

reached.

Fill should be faster

than 1” per minute.

3 flashes No Current, High

Water

Water level at top of

cylinder with no

current

4 flashes Cylinder Spent

Electrodes covered

with scale.

Drain blocked water over concentrated Clean the drain line

Drain solenoid not energized, water

over concentrated

Filling too fast, fill valve damaged and

leaking

Filling too fast, wrong fill valve Fill valve may be defective - replace if necessary

Water supply too conductive a) Change the water supply

Humidifier short cycling a) Check if high limit or other On/Off control is cycling

Wrong cylinder installed Install correct cylinder model

Cylinder Spent but not detected by

software

Condensate from other source Remove condensate returns other than from steam line.

Back pressure Eliminate back pressure

Drain valve leaking or stuck open Clean drain valve or replace (see maintenance chapter)

Water shut off valve closed Open shut off valve

Fill Valve strainer blocked Clean out strainer on fill valve inlet.

High system back pressure a) Check for kinked hose

High water sensor not connected Check that cylinder plug with white marker is connected

Low water conductivity a) Check if potable water supplied to unit, not treated

Primary wire not looped through

current transformer.

High water sensor plug is on an

electrode pin.

Cylinder plugs installed incorrectly Check that cylinder plugs colors match markers next to

Cylinder electrodes are covered with

scale and humidifier cannot meet

demand

Check and correct wiring to drain valve.

Replace the fill valve

b) Contact Honeywell representative for recommendation

On/Off in less than 5 minutes. Check location and setting

of high limit.

b) Reduce the output by turning down the potentiometer

Replace the cylinder (see maintenance chapter)

b) Check for proper condensate removal (see

installation)

to short electrode with a plastic well around it and to

control board.

water (RO or DI).

b) Check conductivity of water. If less than 150 μS, add

1/4 teaspoon of salt to fill cup and restart unit.

Rewire primary wire through current transformer.

Install high water senor plug on cylinder pin with shroud

around it.

electrodes on cylinder and that white marked cylinder

plug is connected to short electrode located in plastic

well.

Replace cylinder with same model number (see

maintenance chapter).

33-00118EFS—01 22

Page 23

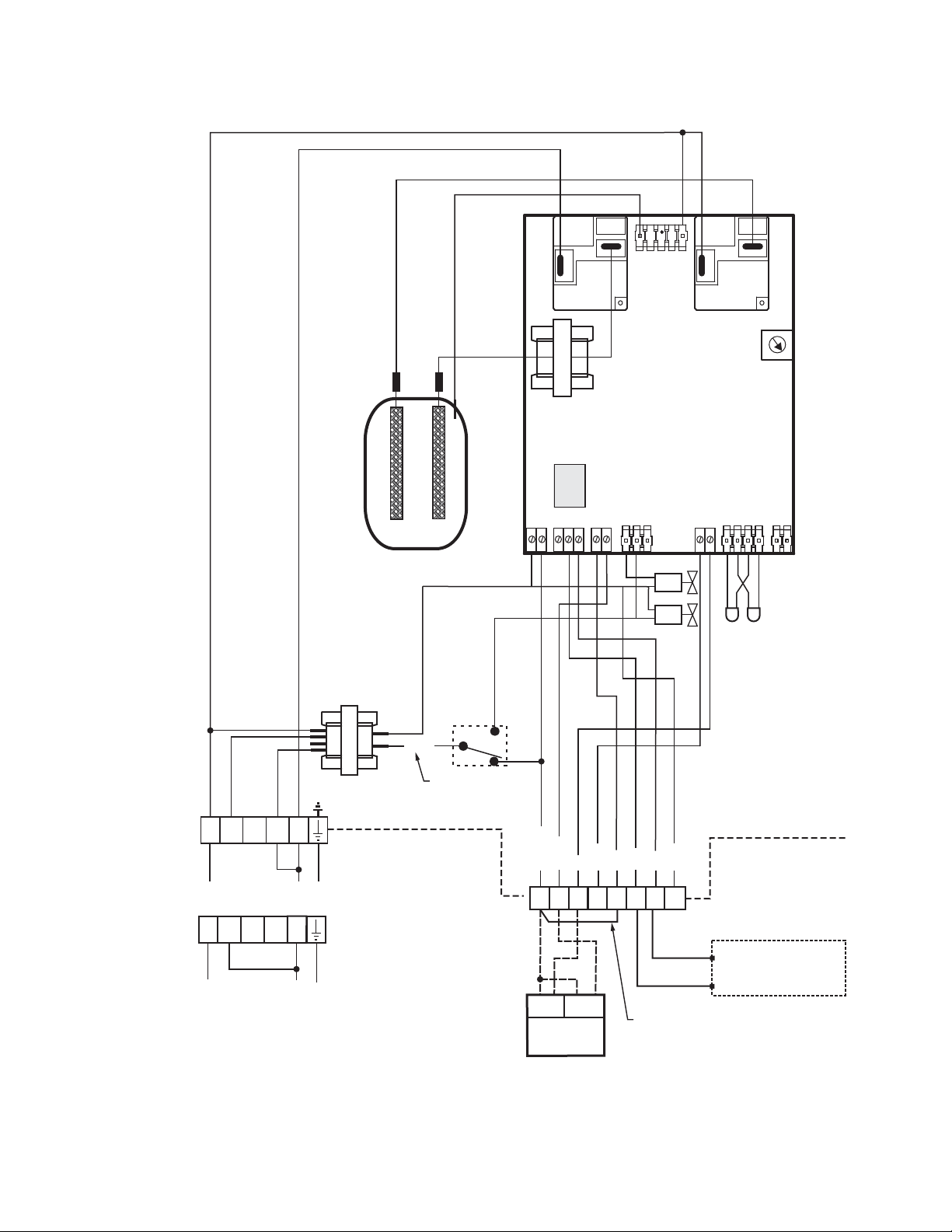

POTENTIOMETER

P8

HIGH WATER

K2

K3

P1 P2 P3 P4 P5 P6 P7

240/208/

120 VAC

24 VAC

1.5 AMPS

CYLINDER

FILL V

DRAIN V

1

2

3

4

8

19

20

21

R / HUM

AP

GF

RF

C

HUM

N/A

N/A

120L1

EXTERNAL

INTERNAL

240 P

ON/OFF/

DRAIN

SWITCH

TRANSFORMER

N/A

120L1

240 P

S

STATUS

LAMPS

G

Y

NOTE: INSTALL JUMPER FROM PTO TERMINAL

CORRESPONDING TO MAINS VOLTAGE.

HOT

NEUTRAL

GROUND

HOT

HOT

GROUND

240 VAC

120 VAC

NOTE:

DRY POINTS FOR FURNACE

FAN ENABLE.

24 V PILOT CONTROL ONLY

N/A

FACTORY INSTALLED TERMINAL

HUMIDITY

CONTROL

24V

HUM

CALL

M35721

HM700A1000

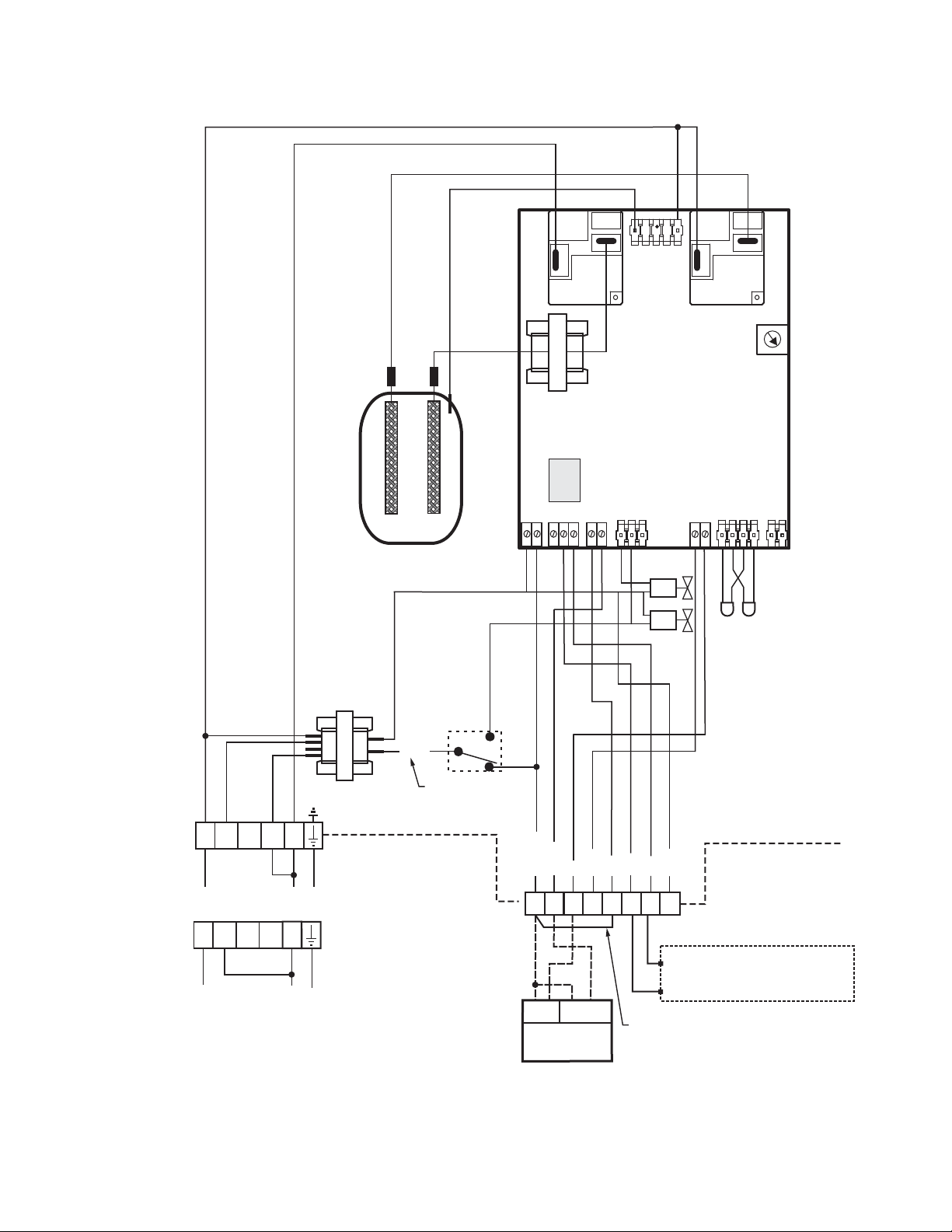

Fig. 26. Wiring diagram.

23 33-00118EFS—01

Page 24

HM700A1000

5 YEAR WARRANTY

Honeywell warrants this product to be free from defects in the workmanship or materials, under normal use and service, for a

period of five (5) years from the date of purchase by the consumer. If at any time during the warranty period the product is

determined to be defective or malfunctions, Honeywell shall repair or replace it (at Honeywell's option).

If the product is defective,

(i) return it, with a bill of sale or other dated proof of purchase, to the place from which you purchased it; or

(ii) call Honeywell Customer Care at 1-800-468-1502. Customer Care will make the determination whether the product should be

returned to the following address:

Honeywell Return Goods, Dock 4 MN10-3860, 1985 Douglas Dr. N., Golden Valley, MN 55422,

or whether a replacement product can be sent to you.

This warranty does not cover removal or reinstallation costs. This warranty shall not apply if it is shown by Honeywell that the

defect was caused by damage which occurred while the product was in the possession of a consumer.

Honeywell’s sole responsibility shall be to repair or replace the product within the terms stated above. HONEYWELL SHALL NOT

BE LIABLE FOR ANY LOSS OR DAMAGE OF ANY KIND, INCLUDING ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

RESULTING, DIRECTLY OR INDIRECTLY, FROM ANY BREACH OF ANY WARRANTY, EXPRESS OR IMPLIED, OR ANY

OTHER FAILURE OF THIS PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential

damages, so this limitation may not apply to you.

THIS WARRANTY IS THE ONLY EXPRESS WARRANTY HONEYWELL MAKES ON THIS PRODUCT. THE DURATION OF

ANY IMPLIED WARRANTIES, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, IS HEREBY LIMITED TO THE FIVE-YEAR DURATION OF THIS WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you. This

warranty gives you specific legal rights, and you may have other rights which vary from state to state.

If you have any questions concerning this warranty, please write Honeywell Customer Care, 1985 Douglas Dr, Golden Valley, MN

55422 or call 1-800-468-1502.

IMPORTANT

To maintain warranty, only Honeywell approved parts and cylinders may be used in the operation of the product.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

33-00118EFS—01 M.S. 03-16

Printed in United States

Page 25

HM700A1000

HUMIDIFICATEUR ELECTRODE STEAM

— Tuyau de vidange en caoutchouc

— Notice d'installation, Guide du propriétaire et Guide de

démarrage rapide

Outils requis

—Tournevis

— Clé

— Pinces

— Robinet de coupure d'eau

— Conduite d'eau (PEbd ou cuivre)

Configuration de l'humidificateur

Le modèle HM700 est configuré en usine pour fonctionner

dans la plupart des conditions sans avoir à modifier sa

configuration.

NOTICE D’INSTALLATION

INTRODUCTION

Le modèle HM700 est l'humidificateur à vapeur résidentiel le

plus sophistiqué du marché et fournit une humidification

résidentielle constante et fiable. L'humidificateur est conçu

pour être raccordé à un distributeur de vapeur installé dans un

conduit d'alimentation en air pour assurer une humidité à la

demande.

IMPORTANT

Lire et conserver ces instructions. Ce guide doit être

conservé par l'installateur, et le Guide du propriétaire

doit être laissé avec le propriétaire de l'équipement.

Inclus dans la boîte

— Humidificateur à vapeur (HM700)

— Nécessaire de distribution à montage à distance

(HM700ADISTKIT)

— Humidistat HumidiPRO (H6062A1000)

— Bouteille de vapeur (une bouteille HM700ACYL2

incluse)

Tableau 1. Spécifications.

Débit de

Référence de

pièce Volts

HM700A1000

110/120 11 1,4

220/240 22 2,8

vapeur en

gal./jour KW Ampères Phase

12,0 1 15 A CYL2

REMARQUE : L'humidificateur étant configuré en usine

pour produire des performances optimales,

Honeywell décourage vivement de modifier

les cavaliers ou le potentiomètre; cela

pourrait annuler la garantie et endommager

l'humidificateur. Contactez le service

clientèle de Honeywell pour de plus amples

informations.

Avant l'installation

1. Assurez-vous que la tension et la phase disponibles

correspondent à la tension et à la phase de

l'humidificateur indiquées sur l'étiquette des

spécifications de l'humidificateur.

2. Assurez-vous que le sectionneur à fusible externe dédié

est de taille suffisante pour gérer l'intensité nominale

indiquée sur l'étiquette des spécifications. Consultez les

codes locaux.

3. Assurez-vous qu'il y a suffisamment d'espace, tel que

décrit dans la section Emplacement à la page 5.

4. Assurez-vous que les conduites de vapeur peuvent être

acheminées vers distributeur, tel que décrit dans les

Instructions relatives aux conduites de vapeur et au

retour du condensat à la page 8.

Fusible

ext.

max.

Bouteille

standard

Poids

net/intégral

en lb (kg)

15 / 20

(7,0 / 9,5)

Dimensions en

pouces (L x l x H)

11,5 x 6,75 x 21,5

Page 26

HM700A1000

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

M35758

Golden Valley Minnesota 55422

MADE IN CANADA

MODEL:

VOLTS 1:

KW:

HM700A1000

S/N:

XXXXXXX

110-120

PHASE:

1

HZ:

60

1.4

DATE:

XXXXXXXXX

2583297A

220-240

VOLTS 2:

F.L.A: GPD:

12.0

F.L.A: GPD:

12.0

2.9

KW:

Auto-Adaptive

11

22

1

LISTED 205X

HUMIDIFIER

Fig. 1. Emplacement de l'étiquette des spécifications.

Entretien

Débranchez l’alimentation principale avant l’entretien.

Les compartiments de plomberie et d'électricité

contiennent des composants et des câbles haute

tension. L'accès doit être réservé au personnel

autorisé.

Pendant et après le fonctionnement de l'humidificateur,

la vapeur et les composants en contact avec la

vapeur tels que les conduites de vapeur, les

distributeurs de vapeur et les conduites de

condensats peuvent devenir brûlants et causer des

brûlures en cas de contact.

Honeywell n'accepte aucune responsabilité lorsque

les humidificateurs sont installés par un personnel

non qualifié ou lorsque des

pièces/composants/équipements non autorisés ou

approuvés par Honeywell sont utilisés.

Pour conserver la garantie, utilisez uniquement des

pièces et des bouteilles approuvées par Honeywell.

Électricité

Tous les travaux électriques doivent être effectués

conformément au code électrique local et national.

Les connexions électriques ne doivent être réalisées

que par un électricien qualifié.

L'unité doit être alimentée par un circuit muni d'un

disjoncteur de fuite à la terre dédié.

Plomberie

Les travaux de plomberie ne doivent être réalisés que

par un plombier qualifié.

L'eau qui sort de l'humidificateur peut être brûlante. Ne

la vidangez pas dans un évier public.

Tous les travaux de plomberie doivent être effectués

conformément au code de plomberie local.

Installation

Ne montez pas l'équipement sur des surfaces

chaudes.

Ne montez pas l'équipement dans des zones

soumises au gel.

Ne montez pas l'équipement sur des surfaces qui

vibrent.

Ne montez pas l'équipement sur le sol.

Le modèle HM700 produit de la vapeur à la pression

atmosphérique. Aucun appareil pouvant bloquer le

débit de vapeur ne doit être connecté à la sortie de

vapeur.

Les conduites de vapeur doivent être installées de

manière à ce qu'aucune restriction ne puisse

produire une contre-pression dans l'humidificateur.

Qualité de l’eau

Le modèle HM700 de Honeywell nécessite un

raccordement à l'eau froide provenant de

l'approvisionnement en eau principal du domicile

entre 30-100 psig. Une vanne d'étranglement peut

être nécessaire, et un robinet de coupure de l'eau

est recommandé pour la sécurité. N'utilisez pas

d'eau à osmose inverse ou déionisée. La

conductivité de l'eau est importante pour que

l'humidificateur à électrodes fonctionne

efficacement. Honeywell recommande 150-1200 μS

(microsiemens).

Pièces et accessoires

Les pièces et accessoires suivants sont nécessaires et sont

peut-être inclus avec l'humidificateur HM700. La bouteille est

le seul élément nécessitant un remplacement périodique pour

maintenir le bon fonctionnement de l'humidificateur.

Tableau 2. Pièces et accessoires.

Pièce/accessoire Référence de pièce

Bouteille de rechange HM700ACYL2

Humidistat HumidiPRO H6062A1000

Nécessaire de distribution à montage à distance en acier inoxydable HM700ADISTKIT

Vanne de vidange de rechange HM700ADVALVE

Vanne de remplissage de rechange HM700AFVALVE

Transformateur de rechange HM700ATX

Carte PC de rechange HM700APCB

Nécessaire de tuyau de conduite de condensat et de vapeur isolé de 15 pieds HM700AHOSEKIT

33-00118EFS—01 2

Contacteur de pression différentielle pour vérification de la présence d'air 50027910-001

Page 27

Fonctionnement de l’humidificateur

Le modèle HM700 est un générateur de vapeur

atmosphérique qui utilise la chaleur générée par le courant

électrique circulant entre les électrodes immergées pour

produire de la vapeur. Le modèle HM700 est conçu pour

l'humidification de l'air à la demande via un distributeur de

vapeur.

PRODUCTION DE VAPEUR

• Lorsque l'appareil reçoit un signal de demande et que la

boucle de sécurité entre les bornes 1 et 2 est fermée,

l'humidificateur ferme le contacteur et mesure le courant

électrique.

• Si la demande est inférieure à la production réelle, la

vanne d'admission est maintenue fermée et la production

est réduite en laissant le niveau d'eau dans la bouteille

diminuer par évaporation.

• Si la demande est supérieure à la production réelle, la

vanne de remplissage est activée après un bref délai et

l'eau pénètre dans la cuvette de remplissage. L'eau de la

cuvette de remplissage s'écoule dans le bas de la bouteille

par un tuyau connecté au carter de la vanne de vidange.

REMARQUE : La bouteille est alimentée par gravité

depuis la cuvette de remplissage. Si la contre-pression de la conduite de vapeur est

trop élevée, l'eau est renvoyée dans la

cuvette de remplissage et s'écoule par la

conduite de trop-plein jusqu'au drain.

• Dès que l'eau dans la bouteille entre en contact avec les

électrodes activées, le courant circule à travers l'eau. La

résistance de l'eau à la charge électrique génère de la

chaleur puis de la vapeur. Le courant électrique (et la

production de vapeur) augmente au fur et à mesure que le

niveau de l'eau augmente, au fur et à mesure de

l'immersion de l'électrode. L'unité continue de se remplir

jusqu'à ce que le courant corresponde à la demande ou

que le capteur de niveau d'eau élevé détecte un haut

niveau d'eau.

• Le modèle HM700 recommence le cycle de remplissage et

de condensation jusqu'à ce que la production corresponde

à la demande.

• Au fil du temps, les minéraux dans l'eau adhèrent aux

électrodes de la bouteille. L'humidificateur se remplit

automatiquement à un niveau d'eau supérieur pour

maintenir la pleine capacité pendant la durée de vie de la

HM700A1000

bouteille. À la longue, la formation de tartre empêchera

l'humidificateur d'atteindre sa pleine capacité. Le logiciel

HM700 surveille cet état et une fois détecté, le

fonctionnement s'arrête et le voyant jaune clignote à une

séquence répétitive de 4 clignotements.

VIDANGES

• La vapeur produit des minéraux qui augmentent la

conductivité de l'eau. Le cycle auto-adaptatif breveté du

système HM700 surveille la conductivité de l'eau et

effectue des vidanges pour maintenir l'eau à un niveau de

conductivité optimal et assurer une performance de pointe.

• Le cycle auto-adaptatif garantit que la durée de vie de la

bouteille est maximisée. Il procède en maintenant un strict

contrôle et une utilisation optimale de l'eau pendant toute

la durée de vie de la bouteille.

DISTRIBUTION DE VAPEUR

La vapeur produite par l'humidificateur peut être introduite

dans l'air de plusieurs manières. La méthode d'ajout de

vapeur dans l'air la plus courante consiste à monter un tube

distributeur de vapeur dans un conduit d'arrivée d'air.

CONDUITE DE VAPEUR

La conduite de vapeur entre la sortie de vapeur de la bouteille

et le distributeur remplit deux fonctions : elle est utilisée

comme conduit pour transférer la vapeur atmosphérique de

l'humidificateur au distributeur, ainsi que pour fournir un

moyen d'éliminer le condensat. Voir « Instructions relatives

aux conduites de vapeur et au retour du condensat » à la

page 8 pour plus d'informations sur la sélection de conduites

de vapeur.

RETOUR DU CONDENSAT

Lorsque de la vapeur est distribuée, un condensat se forme

dans le système de distribution. L'isolation des conduites de

vapeur est une méthode efficace permettant de réduire la

formation de condensat. Les conduites de vapeur sont

inclinées pour que le condensat ne se recueille pas dans les

conduites et ne restreigne pas le débit de vapeur. Le

condensat doit être recueilli et éliminé du système afin qu'il ne

s'accumule pas pour passer dans le conduit. Le condensat

peut être retourné à la cuvette de remplissage du système

HM700 pour réduire le gaspillage de l'eau, ou il peut être

vidangé.

3 33-00118EFS—01

Page 28

HM700A1000

(EN OPTION)

1 - R/HUM

2 - HUM

3 - C

4 - N/A

8 - AP

19 - Gf

20 - Rf

21 - N/A

CONDUITE

D'EAU

1/8 NPT À 1/4

COMPRESSION

OU PEBD

HM700

OFF

ON

DISJONCTEUR

OU

SECTIONNEUR

DÉDIÉ

EAU POTABLE FROIDE, 30-100 PSIG, 1/2 PO MIN.

REMARQUE : CONNEXION 240 V ILLUSTRÉE

EXTERNE

MF35805

24 (610)

HAUTEUR MIN.

36 (914)

MIN.

VIS 2 (51)

12 (305)

MIN.

MONTAGE

DISTRIBUTION

DE VAPEUR

RÉGULATEURS

RACCORDEMENT

DE PLOMBERIE

RACCORDEMENT

ÉLECTRIQUE

2 (51)

MIN.

12 (305)

TERRE

DIMENSIONNEMENT

IMPORTANT

Étanchéité supérieure 3,3 4,3 5,4 7,5 9,6 11,7 16

Étanchéité moyenne 7,6 9,6 11,8 16 20,3 24,4 33

Étanchéité inférieure 11,7 14,9 18,1 24,5 30,8 37,1 50

Fig. 2. Installation typique du modèle HM700.

Mesures en po (mm).

Le modèle HM700 produit 11 gallons par jour (gal./jour)

Le modèle HM700 ne doit être installé que s'il a été

correctement dimensionné. N'utilisez pas une

mesure en pieds carrés pour dimensionner une

installation avec humidificateur. Utilisez une

mesure en pieds cubes, car l'humidité remplit un

volume d'espace (largeur x longueur x hauteur).

Considérez également l'étanchéité de la construction

de l'habitation.

lorsqu'il fonctionne sur 120 V et 22 gallons par jour lorsqu'il

fonctionne sur 240 V. Voir la Figure 16 pour plus de détails sur

la configuration du modèle HM700 pour une tension

différente.

Le Tableau 3 contient des recommandations de l'AHRI

(Institut de climatisation, chauffage et réfrigération) en matière

d'humidité et le Tableau 4 montre les humidificateurs et la

configuration de sortie qui satisfont au exigences

d'humidification.

Tableau 3. Humidité recommandée par l'AHRI (Institut de climatisation, chauffage et réfrigération) (en gallons/jour).

Type de

construction 8000 pi

3

12 000 pi316 000 pi320 000 pi324 000 pi328 000 pi332 000 pi

3

33-00118EFS—01 4

Page 29

HM700A1000

Tableau 4. Humidificateur(s) à vapeur nécessaire(s) à l'application.

Type de

construction 8000 pi

Étanchéité

supérieure

Étanchéité

moyenne

Étanchéité

inférieure

a

Dans le tableau ci-dessus, 11 gallons/jour indique un humidificateur à vapeur configuré pour fonctionner sur 120 V et

11 gallons/jour 11 gallons/jour 11 gallons/jour 11 gallons/jour 11 gallons/jour

11 gallons/jour 11 gallons/jour 22 gallons/jour 22 gallons/jour 22 gallons/jour

22 gallons/jour 22 gallons/jour 22 gallons/jour

3

12 000 pi316 000 pi

3

20 000 pi

11 gallons/jour (x3)

ou

22 gallons/jour (x2)

3

24 000 pi

11 gallons/jour (x3)

22 gallons/jour (x2)

3

11 gallons/jour (x2)

22 gallons/jour (x1)

11 gallons/jour (x3)

22 gallons/jour (x2)

11 gallons/jour (x4)

ou

22 gallons/jour (x2)

a

28 000 pi

ou

ou

ou

3

32 000 pi

11 gallons/jour (x2)

22 gallons/jour (x1)

11 gallons/jour (x3)

22 gallons/jour (x2)

11 gallons/jour (x5)

22 gallons/jour (x3)

ou

ou

ou

22 gallons/jour indique un humidificateur à vapeur configuré pour fonctionner sur 240 V.

EMPLACEMENT

Montez sur une surface horizontale ou verticale adaptée. Ne

REMARQUE : Ne montez pas l'appareil sur des surfaces

chaudes ou soumises au gel ou à des

vibrations, ni sur le sol.

posez pas l'unité sur le sol. Allouez les dégagements requis

pour les raccordements de plomberie et électriques. Les

dimensions des dégagements sont indiquées à titre de

référence uniquement et constituent le minimum requis pour

l'entretien de l'humidificateur. Consultez les codes locaux et

nationaux avant de déterminer l'emplacement final et de

procéder à l'installation. Honeywell n'accepte aucune

responsabilité en cas de violations du code d'installation.

• Installez uniquement dans des zones à température

ambiante de 41 à 104 °F (5 à 40 °C) et humidité relative de

5 à 95 %.

• Dans la mesure du possible, installez sous le distributeur

de vapeur. Prenez soin de bien acheminer la conduite de

vapeur et d'utiliser des purgeurs de condensat adéquats.

• Placez l'humidificateur LE PLUS PRÈS POSSIBLE du

distributeur de vapeur. Plus l'humidificateur est éloigné,

Montage avec boutonnières

1. L'humidificateur HM700 peut être monté sur un mur en

utilisant la boutonnière située à l'arrière de l'armoire de

l'appareil.

2. Utilisez des vis n°8 x 2 po (5 cm) installées dans des

montants de 2x4 po ou plus. Deux vis sont requises,

une pour suspendre l'unité, et l'autre pour la fixer de

manière à ce qu'elle ne se relève pas dans la

boutonnière.

3. Installez la vis supérieure de manière à en exposer

1/4 po (6 mm). Relevez l'unité et placez la tête de vis

dans la boutonnière.

4. Assurez-vous que l'unité est à niveau puis insérez et

serrez la deuxième vis dans la boutonnière. Serrez la

vis supérieure. Voir la Fig. 3.

plus la production sera réduite en raison de la perte

thermique qui a lieu dans la conduite de vapeur.

• Lorsque c'est possible, montez l'humidificateur HM700 à

une hauteur qui facilitera l'entretien.

REMARQUE : Utilisez des vis d'une longueur supérieure à

2 po (5 cm) si une cloison sèche ou une

autre entretoise est présente.

3

BOUTONNIÈRE

TROU

INSÉREZ UNE VIS

EN LAISSANT

1/4 PO (6 MM)

DÉPASSER.

ACCROCHEZ L'UNITÉ

PUIS SERREZ LA VIS.

INSTALLEZ UNE

DEUXIÈME VIS

APRÈS AVOIR

ACCROCHÉ

L'HUMIDIFICATEUR

VIS À BOIS N° 8 x 2 PO (5 CM)

Fig. 3. Montage avec boutonnières.

5 33-00118EFS—01

MONTANT 2x4 PO

OU AUTRE MEMBRE

DE CHARPENTE

MF35759

Page 30

HM700A1000

M35855

PLOMBERIE

UTILISEZ UN RACCORD À COMPRESSION

DE 1/4 PO (INCLUS) POUR RACCORDER LA

CONDUITE D'ARRIVÉE D'EAU À L'UNITÉ

(PLASTIQUE PEBD OU CUIVRE).

DIA. EXT. 1/2 PO (30 MM)

INSTALLEZ TOUJOURS UN

ROBINET DE COUPURE D'EAU.

1

LES CONDUITES DE REMPLISSAGE ET

1

DE VIDANGE PEUVENT AUSSI ÊTRE

ACHEMINÉES PAR L'OUVERTURE À

L'ARRIÈRE DE L'ARMOIRE.

Fig. 4. Raccords d’arrivée et de vidange d’eau.

IMPORTANT