Page 1

TrueSTEAM

69-2036EFS-07

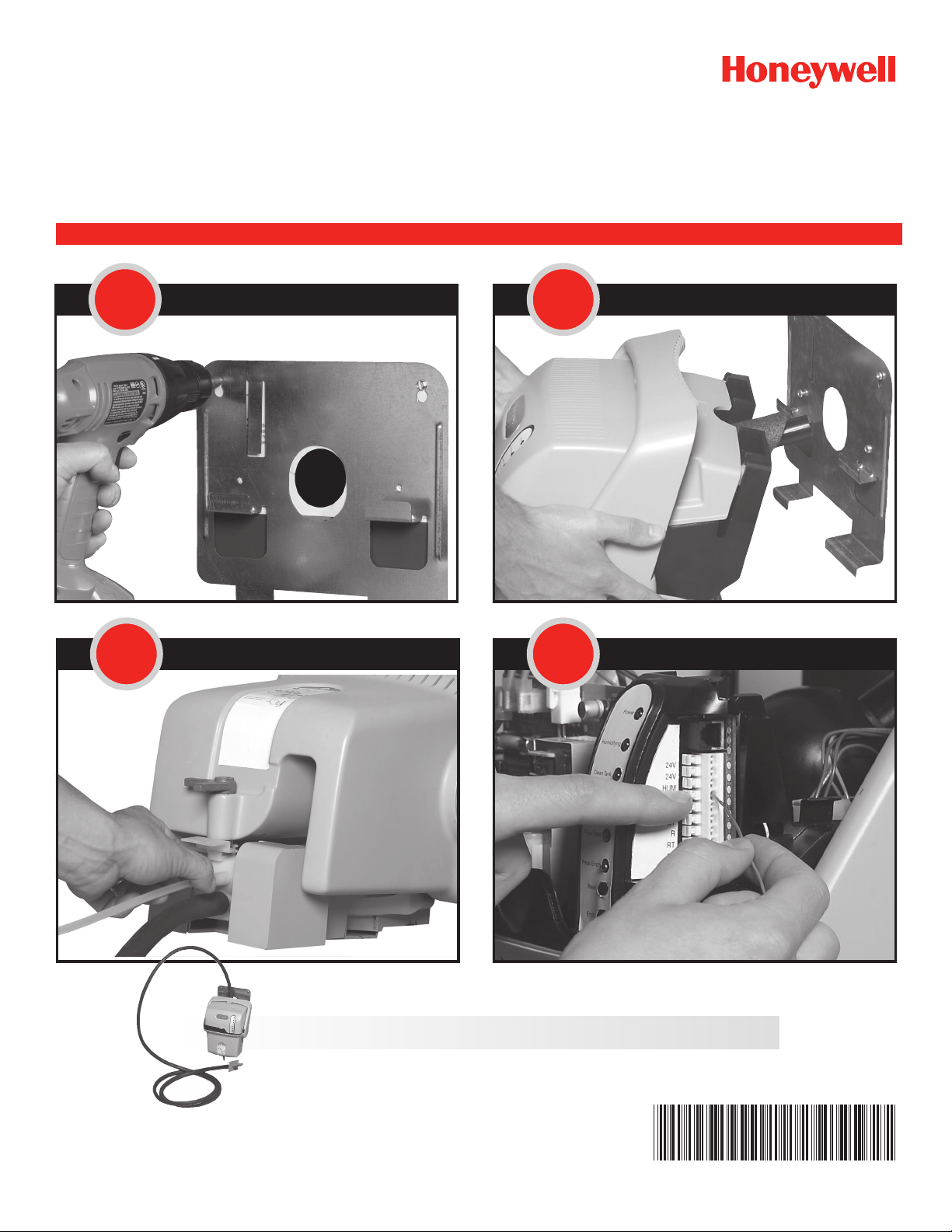

As Easy as 1-2-3-4

PROFESSIONAL INSTALLATION GUIDE

1

3

Mount

Plumb

2

4

Hang

Wire

See inside for detailed instruction and remote mounting options!

Page 2

Installation Guide

Table of ConTenTs

Installation Recommendations ...................................................... 1

List of tools/supplies ...................................................................... 2

Safety Precautions ......................................................................... 3

Duct Mount Instructions

Installation ....................................................................................... 4

Remote Mount Instructions

Installation ....................................................................................... 6

Plumbing and Wiring

Plumbing ....................................................................................... 12

Wiring ............................................................................................ 13

DIP Switch Selection .....................................................................17

Troubleshooting ............................................................................ 18

Cleaning and Seasonal or Vacation Maintenance ...................... 22

Additional Information

Parts List ....................................................................................... 24

Need Help?

For assistance with this product please visit http://yourhome.honeywell.com

or call Honeywell Customer Care toll-free at 1-800-468-1502

Read and save these instructions.

® U.S. Registered Trademark.

Patents pending.

Copyright © 2008 Honeywell International Inc. All rights reserved.

69-2036EFS—07 ii

Page 3

TrueSTEAM Humidification System

Make your TrueSTEAM installations accurate and efficient by addressing these commonly asked

questions:

Sizing for the Job

1. Selecting the appropriate humidifier for the job is critical:

The table below illustrates the square footage a TrueSTEAM humidifier can serve.

It is not recommended to install a 6 gallon device in a home larger than 2000 square feet.

Square Feet of Space 500 1000 1500 2000 2500 3000

ARI* Recommended Output Delivery (GPD) 0.1 2.2 4.4 6.5 8.6 11.7

TrueSTEAM HM512 - True 12 Gallons

TrueSTEAM HM509 - True 9 Gallons

TrueSTEAM HM506 - True 6 Gallons

* ARI Guideline F-2007 for maintaining 35% RH in a tight, residential four-person home with

8-ft. ceilings. Outdoor conditions = 20ºF and 70% RH.

Installation Check-out List

• Install the in-line water filter and back-flow prevention valve.

• Check that the main water supply line is open.

• Ensure there are no water leaks/drips at any of the water connections.

• Plug into a circuit with at least enough capacity to power the unit.

• Generate a call for humidity from the control and ensure TrueSTEAM fills and the Humidify

light turns on, indicating steam is being generated.

• Test the drain by pressing the EMPTY button until the Clean Tank light begins blinking,

indicating a drain cycle has begun.

NOTE: It may take approximately 10 minutes for the tank to fully flush and drain. TO BYPASS

AND DRAIN IMMEDIATELY, Press and hold the EMPTY button again while the Clean Tank light

is blinking. This will bypass the flush and immediately drain the tank. TO STOP draining, press

the Reset button.

• Mount the provided yellow tank service sticker on the duct/wall near the unit. Ensure the

drain hose is secured to prevent inadvertent disconnection. Check that the hose is plumbed

to a drain/condensate to prevent water spurting.

69-2036EFS—07

Page 4

Installation Guide

InsTallaTIon ReCommendaTIons

Setting Homeowner Expectations for the TrueSTEAM Experience:

It may take up to a week of continuous operation to achieve the humidity set point, depending

on weather, size of home, furnishings in the home, insulation, etc.

If using a six (6) gallon unit, the most appropriate setpoint is 30-35% or until there is condensation on the windows, then lower the setpoint (if not in frost protection mode). If the home can’t

achieve the setpoint, the unit may be under-sized (if home is under 2000 sq ft, this can also be

due to insulation, windows, arid climate, etc.) or the outdoor temperature may be too low to

maintain adequate humidity levels. Honeywell recommends waiting for the temperature to moderate closer to 20°F (-6°C).

If this occurs and the selected humidity levels are not achieved, then a larger capacity model

may be needed.

For the first week of operation, it is normal to experience a slight plastic odor in the home,

depending on the amount of supplied ventilation. If the remote hose is used, there may be a

slight rubber odor. These odors will dissipate within days of installation.

If the homeowner sees that TrueSTEAM is not humidifying but there is a call for humidity, it is

likely the unit is operating in drain cycle mode. Ask the homeowner to check again in an hour if

they are concerned the device may not be operating.

If the Call Service light is blinking, instruct the homeowner to press and hold the Reset button to

clear the fault. If the fault doesn’t clear, unplug the power to TrueSTEAM and plug back in to the

electrical outlet. Wait 24 hours prior to calling a contractor. The call service light may be blinking

due to a low voltage condition in the area and will reset to operate correctly when full power is

restored.

There may be a slight increase in the homeowner’s energy consumption. However, when operating correctly, TrueSTEAM will make the home feel warmer, allowing the homeowner to lower the

temperature setting on the thermostat. Every degree lower on the thermostat can save up to 3%

on heating costs.

69-2036EFS—07 2

Page 5

TrueSTEAM Humidification System

WhaT you WIll need To InsTall TRuesTeam

Tools/Hardware needed:

• Wire stripper/cutter

• Drill or duct-cutting tool

• 1-3/4-in. hole saw

• 1/8-in. drill bit

• Phillips and slotted (or Torx) screwdriver

• 18-gauge thermostat wire (5 or 2 conductor)

Material Provided:

• 1/4-in. copper or plastic water line

• 1/2-in. drain hose and clamps

• Mounting bracket and hardware

• In-line water filter* (50028044-001)

• Saddle valve

• Back-flow valve (50030142-001)

Options:

• Remote Installation Kits

– 10-foot hose and nozzle kit (50024917-001)

– 20-foot hose and nozzle kit (50024917-002)

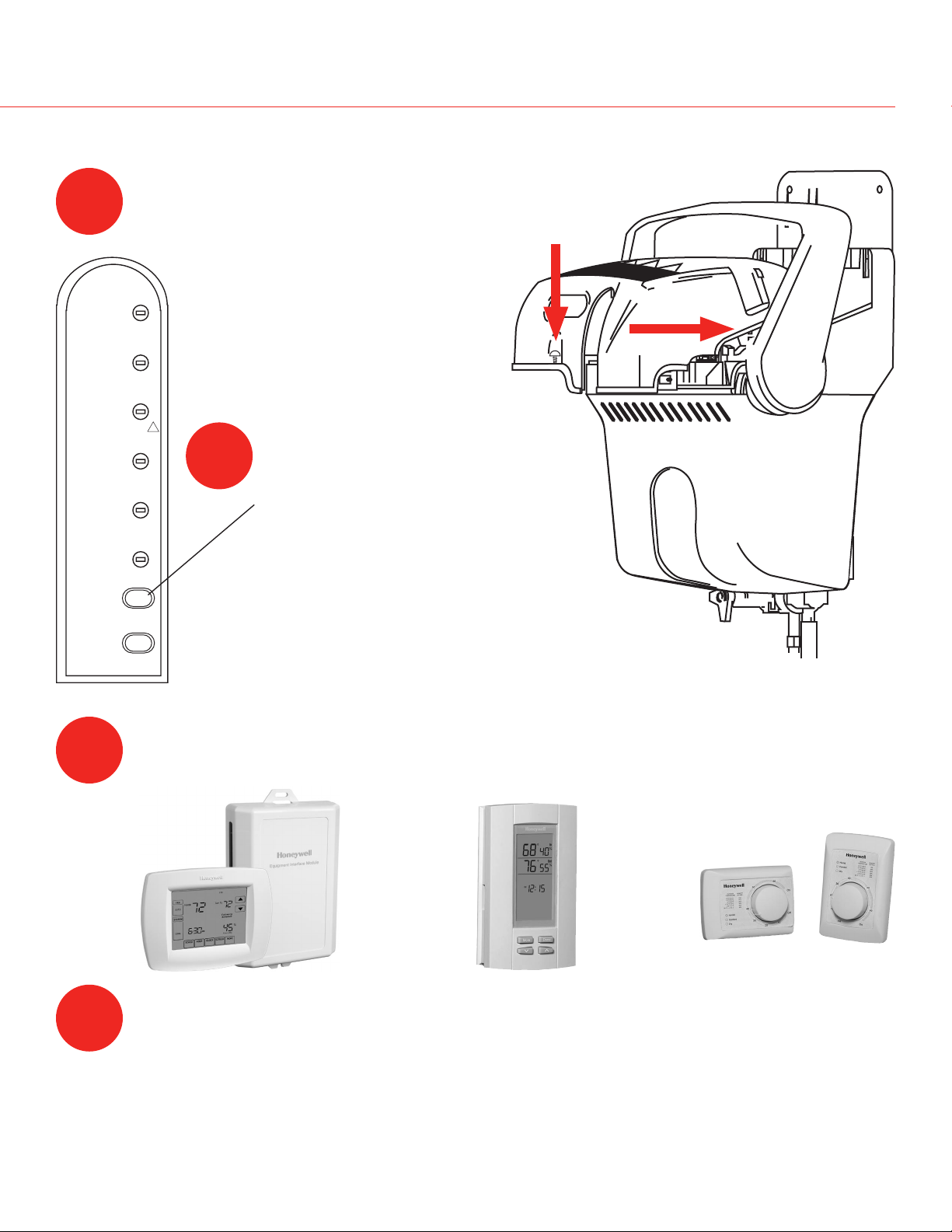

• Humidity Controls

– Manual Humidistat (H8908ASPST)

– TrueIAQ (DG115EZIAQ)

– VisionPRO IAQ (YTH9421C1010)

• Water line T-fitting

• Manual shut-off valve

• Remote hose P-trap

• Remote mount duct board adapter kit

(32005530-001)

• Differential pressure switch (50027910-001)

* Warranty requires in-line water filter installation with regular service.

3 69-2036EFS—07

Page 6

Installation Guide

safeTy PReCauTIons

CAUTION: Voltage Hazard.

Can cause electrical shock or equipment damage.

Disconnect HVAC equipment before beginning installation.

Safety Precautions

• Do not direct the steam nozzle at people.

• If used near a pool or spa, ensure the TrueSTEAM can not fall into the water or be splashed.

Also, ensure the TrueSTEAM is plugged into a GFI ground fault interrupt outlet.

• Water inside tank can be very hot. Follow installation instructions and service steps exactly

as given in the technical literature.

Warning: Electrocution, Heavy Equipment, and Chemical Hazard.

Can cause death, blindness, water damage to home and heating element failure.

• Do not cut into any air conditioning or electrical line

• Wear safety glasses when cutting or drilling.

• Mount the humidifier in a level position to avoid water damage or heating element failure.

• Reinforce duct as necessary to ensure stability.

The preferred installation location is on the warm or supply side of the furnace. If that location is

not possible, the steam nozzle should be inserted a minimum of 12 in. upstream of the furnace filter.

Depending on the location and the duct rigidity, additional duct reinforcement may be necessary.

Warning: Steam Condensation, Fire, and Freezing Water Hazard.

Can cause failure of fan or limit control or result in water damage to home.

• Do not install the humidifier where the ambient temperature is lower than 32°F (0°C) or higher

than 120°F (49°C).

• Do not install the humidifier through sidewalls of a return air duct made of wood (e.g., floor

joist).

• The mounting area must be strong enough to support the humidifier’s weight when it is full

of water (approximately 12 to 15 lbs.), and to hold the humidifier in a level position for safe,

reliable operation. Otherwise, additional duct or wall reinforcement will be necessary.

• If the ducting has exposed insulated materials on the interior, ensure the nozzle extends

beyond the insulation by clearing away excess insulation at the insertion point. You may wish

to replace a section of insulated duct (approximately 6 in. x 6 in.) with rigid, non-insulated

sheet metal to ensure effective installation.

• Mount the unit where it will have smooth air flow across the end of the steam nozzle.

• Allow at least 1 foot clearance to ventilation holes in humidifier’s cover. Do not cover these

holes. Covering them can increase the internal operating temperature of the humidifier and

shorten the humidifier’s life.

• Allow at least 4 inches of clearance between the steam nozzle insertion hole and the top of

the interior duct to avoid condensation forming. The mounting template is designed to allow

clearance if the top of the template is at or below the top surface of the interior duct.

• Do not mount directly to duct board. Remote mount nozzle attachment allowed only when

using with a duct board adapter kit (part #32005530-001).

• Do not install in completely enclosed spaces, such as a cabinet or unventilated closet.

Choose a location that is well ventilated.

69-2036EFS—07

Page 7

TrueSTEAM Humidification System

M24744

M24745

M24746

M24894

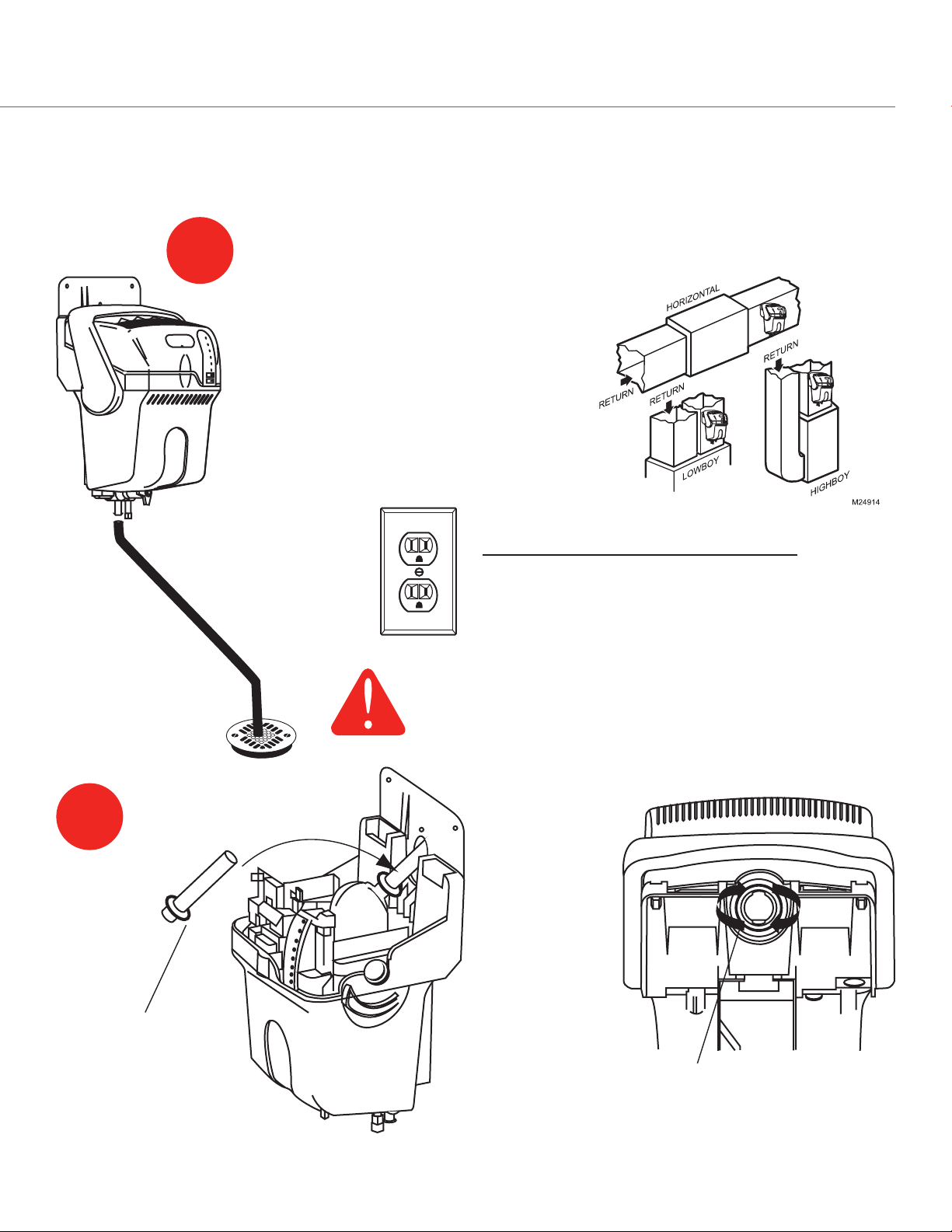

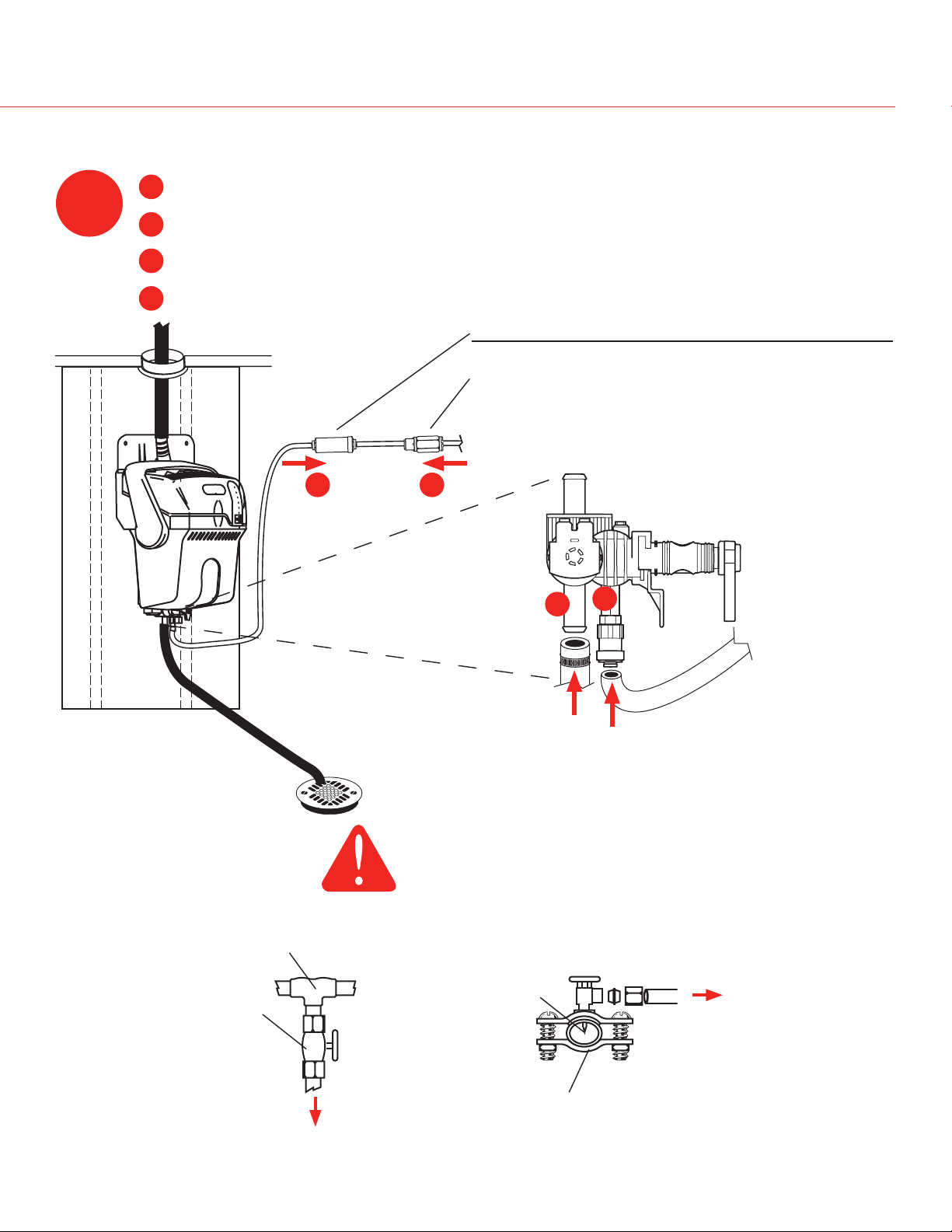

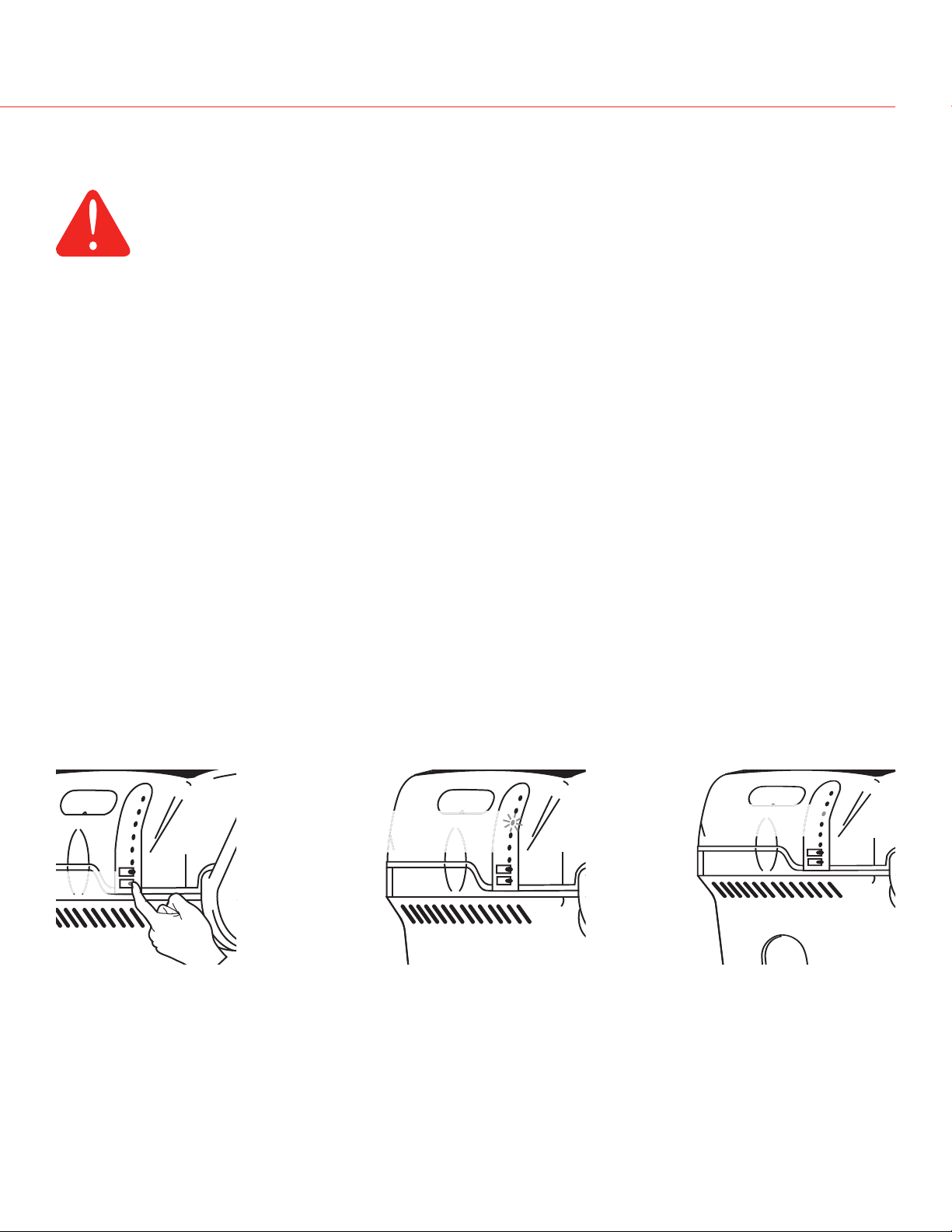

If installing the humidifier directly to the supply duct, follow steps on pages 5–6 and 13–18.

If mounting remote from the duct, follow steps on pages 7–18.

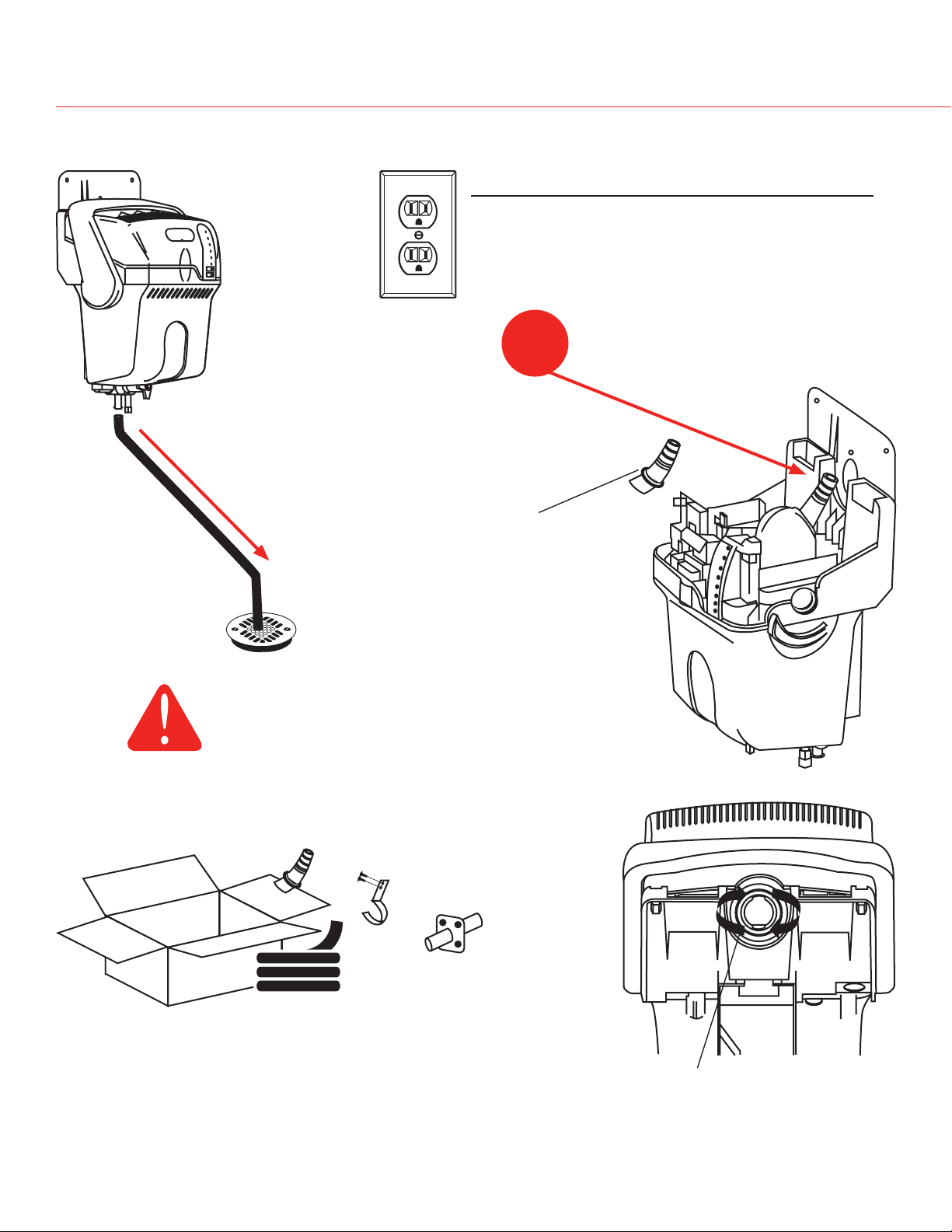

duCT mounT InsTallaTIon

Choose a location that has access to a:

1

Draining water

may be hot.

Ensure drain outlet not exposed.

• Drain allowing a slope of 1/4 in.

per foot of drain hose.

• Cold water line.

• Electrical circuit rated to your

humidifier.

• Vertical surface with adequate

clearances.

Continuous

downslope

Required Minimum

Model

Circuit Capacity

HM506 7 Amps

HM509 10 Amps

HM512 12 Amps

CAUTION

Hot water temperature above 120°F (49°C)

can cause burns from scalding.

2

Install duct nozzle.

Ensure o-ring gasket

is properly seated in

the groove.

Insert nozzle and twist clockwise to ensure tight seal of

nozzle to TrueSTEAM.

69-2036EFS—07

Page 8

Installation Guide

M24749

M24750

M24748

SUPPLY

12 INCHES

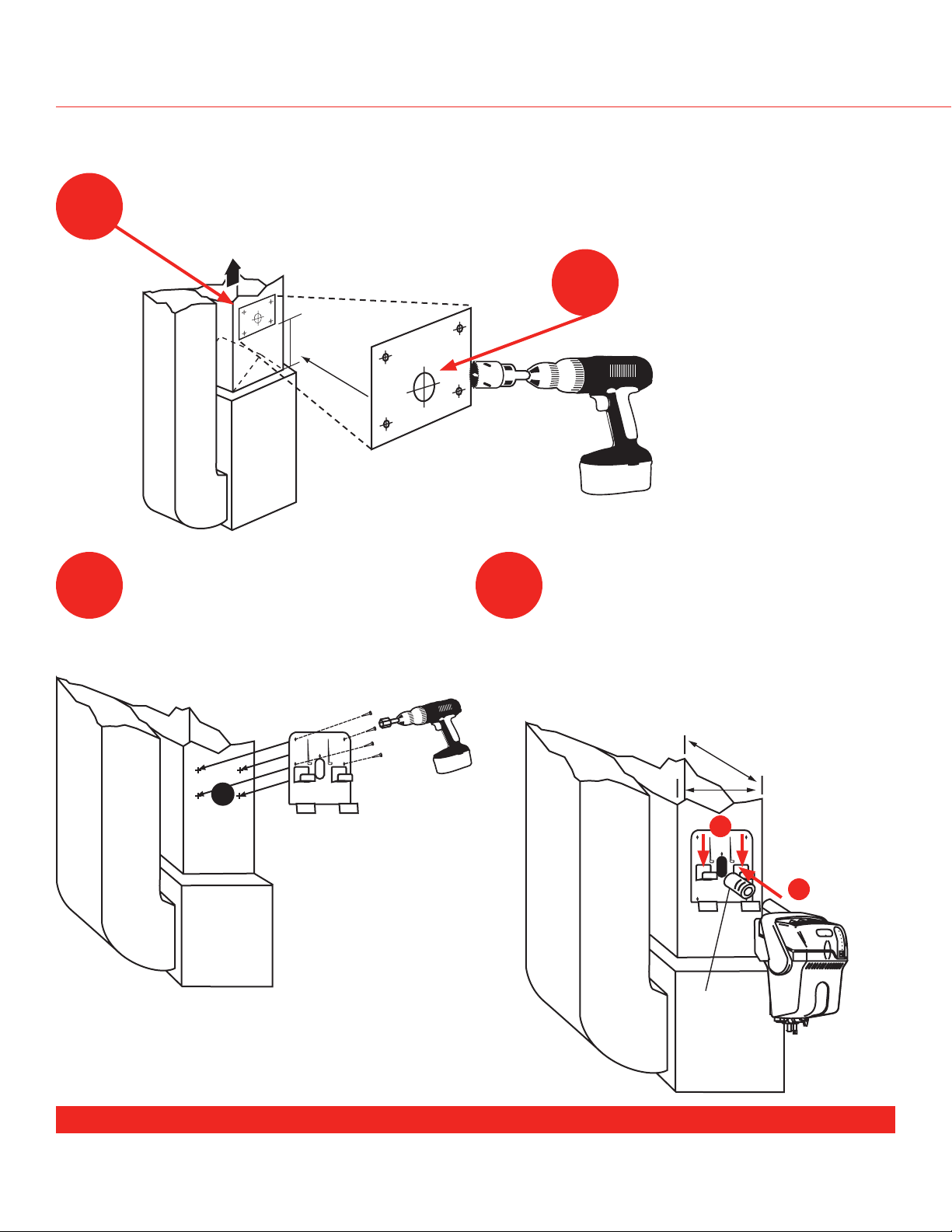

duCT mounT InsTallaTIon

Position template sticker on supply duct. For tall coils that do not have this

3

clearance available, refer to remote mounting instructions.

Secure bracket to duct using #8

5 6

self-drilling sheet metal screws (4).

4

Drill 1-3/4-in. hole.

A) Slide foam gasket over nozzle and

insert the nozzle into duct hole

(pictured).

B) Push down to secure humidifier to

bracket arms. Ensure gasket forms

tight seal in duct hole.

Allow 3 in. clearance from nozzle

outlet to duct wall.

Proceed to page 13 for plumbing and wiring instructions.

69-2036EFS—07 6

B

A

Foam

gasket

Page 9

M24896A

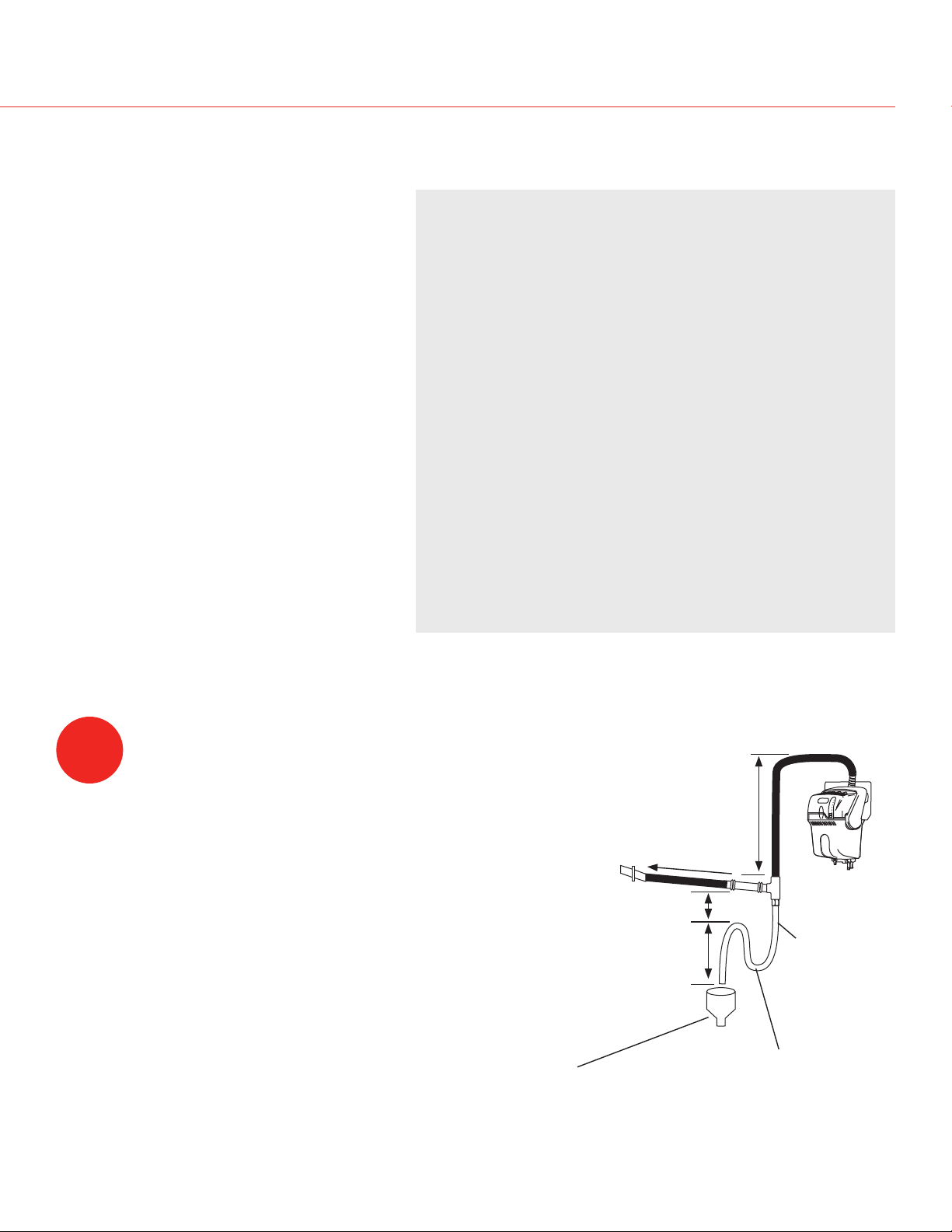

RemoTe mounT InsTallaTIon

Use for mounting to a location other than the supply duct.

TrueSTEAM Humidification System

Most operation problems are caused

by improper hose installation. Always

ensure an uphill flow when installing

the remote hose, and avoid kinks,

sharp turns, or low spots that could

restrict the flow of steam into the

injection nozzle or condensation back

into the humidifier.

If the remote hose cannot be installed

with an upward pitch of 2 in./ft., a

wetted drip tee must be installed.

Failure to do so can result in back

pressure on TrueSTEAM, which can

lead to duct nozzle water spitting or

leaking gasket. Remote hose must be

supported to prevent sagging or low

spots.

When remote mounting, also follow these critical

steps in sizing the proper TrueSTEAM:

If the steam distribution tube is going into an unconditioned air space (e.g., attic), insulate the tube to

ensure steam output efficiency:

• Honeywell recommends self-seal pipe insulation

for hot and cold water pipes. Insul-Tube 1-1/8 in. ID

x 1/2 in. wall 25/50 Factory Mutual 062411, flame

retardant added.

The 6-gallon model (HM506) can be remotely mounted up to:

• 5 feet without insulating the steam distribution tube

• 15 feet if insulating the steam distribution tube

The 9- and 12-gallon models (HM509 and HM512)

can be remotely mount up to 20 feet with or without

insulating the steam distribution tube.

Ensure at least 2 in. per foot slope if installing the

remote hose horizontally.

1

Choose a location for TrueSTEAM and the

remote duct nozzle (see remote installs on

pages 6–7).

It should have access for:

• Remote hose installation. Steam hose

must be installed with 2 in./ft. pitch on a

continuous uphill slope.

• Drain. Allow a continuous downslope to the

drain.

• Cold water line.

• Electrical circuit rated to your humidifier

(see circuit ratings on page 10).

Funnel or floor drain. Refer to governing

codes for drain pipe size and maximum

temperature requirements.

Maximum 3 ft.

2 in./ft. uphill

6 in.

8 in.

1/2 in.

minimum

diameter

Water in

elbow

7 69-2036EFS—07

Page 10

Installation Guide

M24786

M24781

M24785

M24936

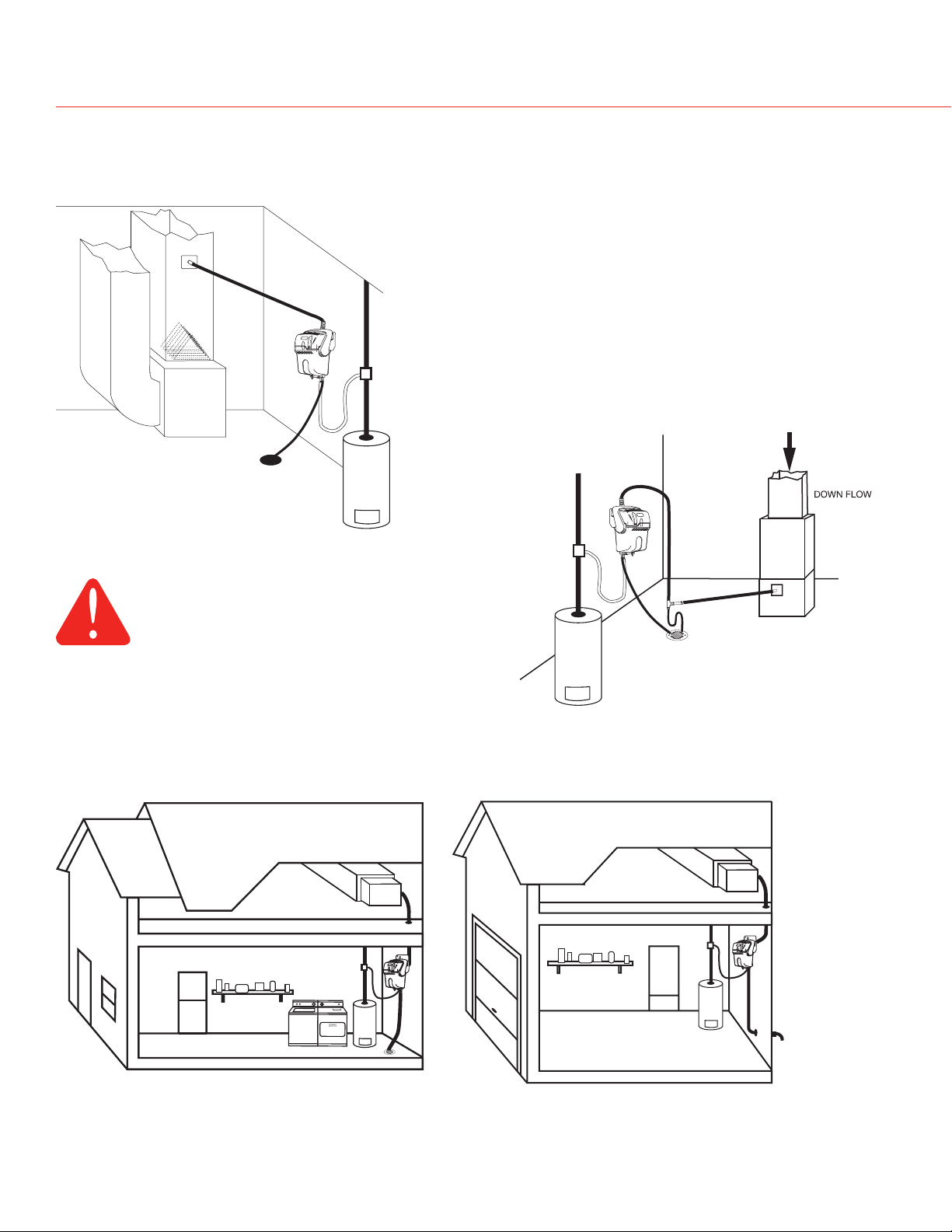

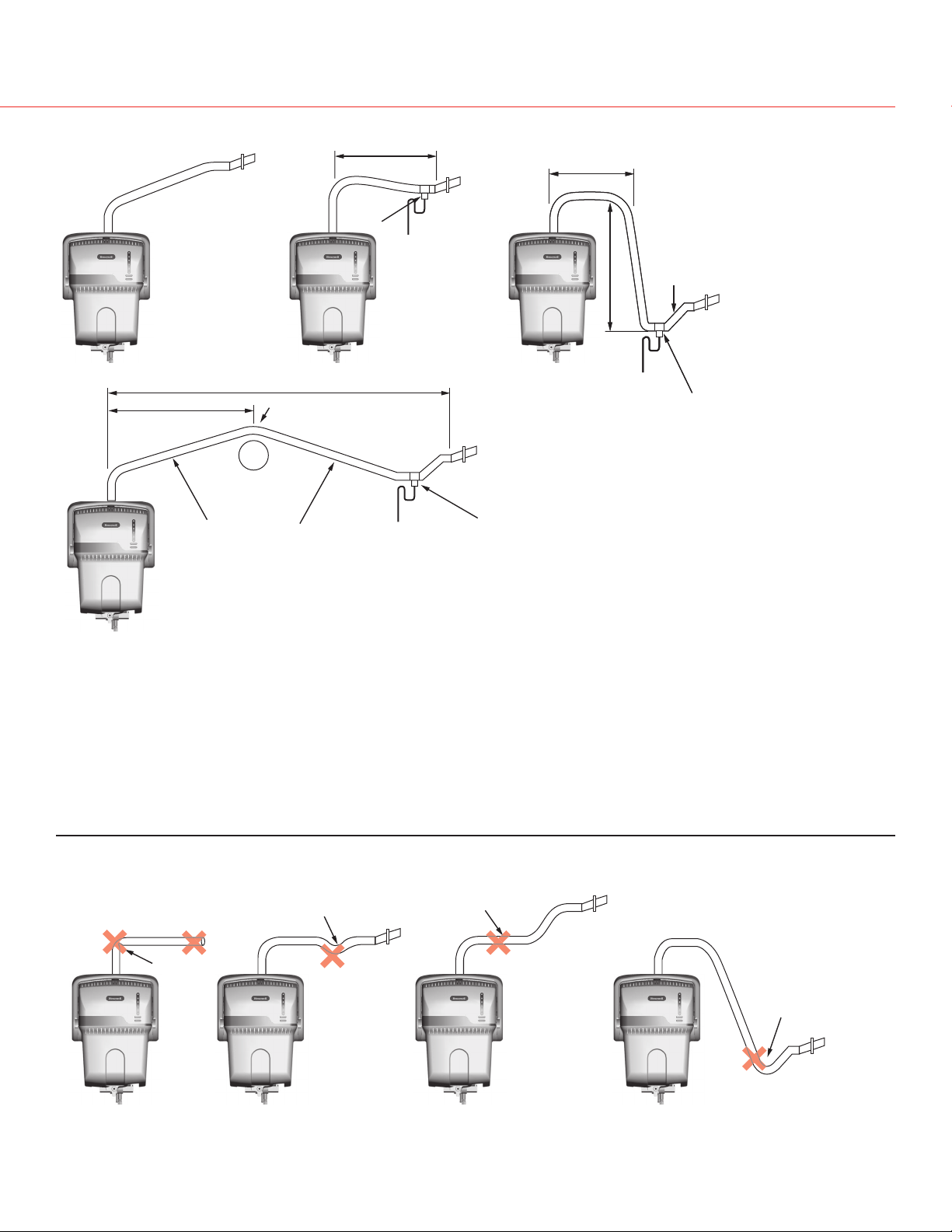

PRoPeR hose InsTalls

Furnace or Mechanical Room Remote

Note: If air handler location temperatures will drop

below freezing at any time, TrueSTEAM must be

mounted in a conditioned space, running a remote

hose to the duct.

Duct Mount Remote

CAUTION

Hot water temperature above 120°F (49°C)

can cause burns from scalding.

Living Area Remote Options

Garage Remote

Draining

water may

be hot.

Ensure

drain outlet not

exposed.

69-2036EFS—07

Page 11

2 IN. PER FT

2 IN. PER FT

2 IN. PER FT

2 IN. PER FT

20 FT MAX

P - TRAP

DRAIN

WITH TRAP

5 FT MAX

3 FT MAXIMUM

DRAIN

P - TRAP

IF NO SLOPE

10 FT MAX

GENTLE BEND

OBSTRUCTION

SUPPORTED REMOTE HOSE

20 FT MAX

DRAIN

WETTED P - TRAP

NOTE: HEIGHT OF TRAP MUST BE GREATER

THAN THE DUCT STATIC PRESSURE

DRAIN

P - TRAP

IF NO SLOPE

TYPICAL INSTALLATION

WHEN TrueSTEAM IS ABOVE

REMOTE NOZZLE

KINKED

SAG

NO SLOPE

NO SLOPE

M24915A

UNDRAINED

ELBOW

TrueSTEAM Humidification System

PRoPeR hose InsTalls

NOTES:

• Slope hose up in direction of steam flow at 2 in. per foot;

• Maximum length of remote steam hose is 20 ft.

• Slope hose down in direction of steam flow at 3/4 in. per foot;

• Height of P-traps must be greater than the duct static pressure. (Typical

3 in. will suffice.) P-trap must also be wetted (see page 7).

• Minimize sharp bends and elbows.

• Insulating the remote hose in unconditioned spaces will sustain

efficiency better than not insulating the hose.

AVOID THESE INSTALLATION MISTAKES.

9 69-2036EFS—07

Page 12

Installation Guide

M24744

M24745

M24764

M24765

M24894

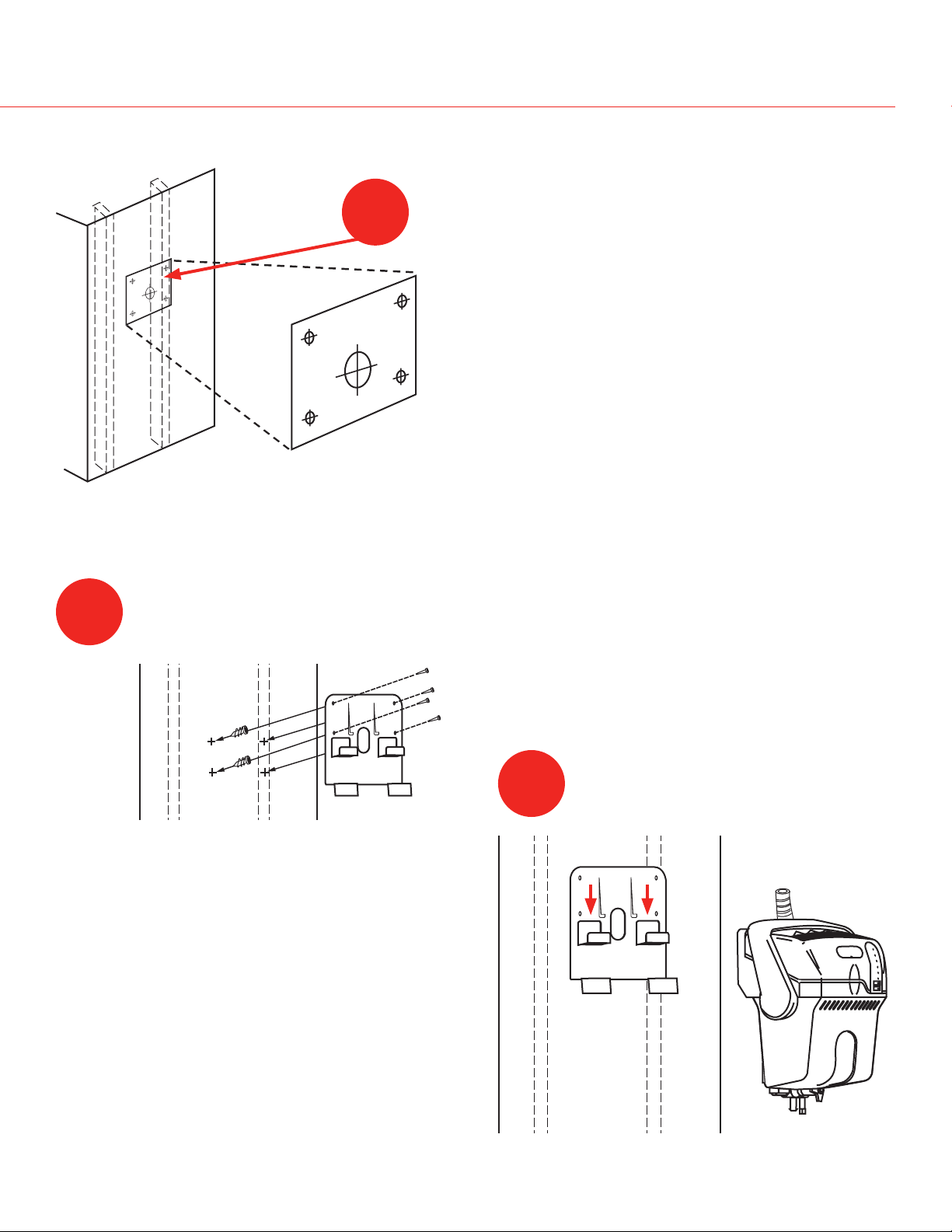

RemoTe mounT InsTallaTIon

Model Minimum Circuit Capacity

HM506 7 Amps

HM509 10 Amps

HM512 12 Amps

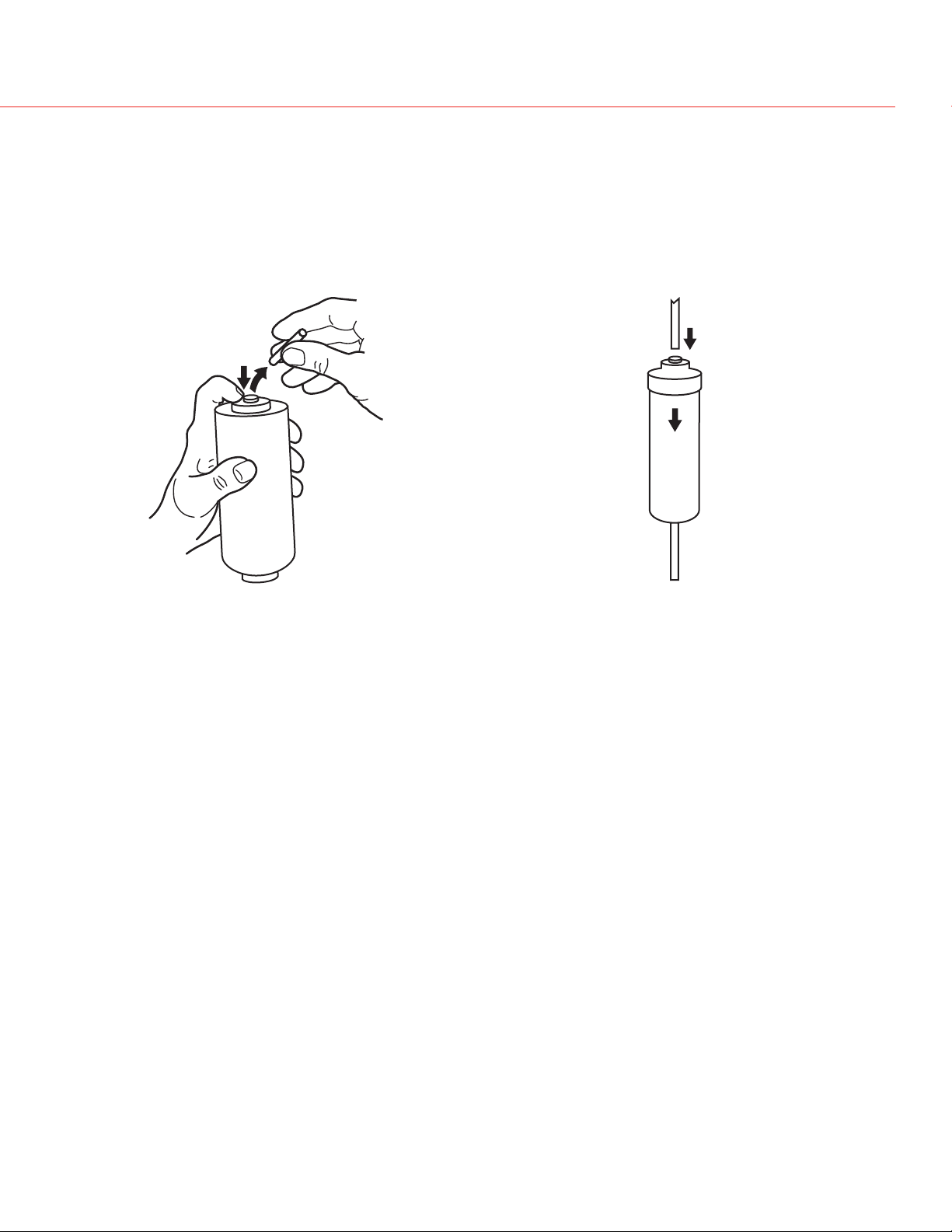

Install hose adapter from Remote

2

Mount Kit.

Draining water

may be hot.

Ensure drain outlet not exposed.

Remote Mount Kit

(sold separately)

Ensure o-ring gasket is

properly seated in the

Continuous

groove.

downflow

CAUTION

Hot water temperature above 120°F (49°C)

can cause burns from scalding.

Hose Adapter

Hose Clamps

Duct Nozzle

Remote Hose

• 50024917-001 = Ten Foot Hose Kit

• 50024917-002 = Twenty Foot Hose Kit

69-2036EFS—07 0

Insert hose adapter and twist

clockwise to ensure tight seal

of nozzle to TrueSTEAM.

Page 13

M24766

3

M24767A

M24768

TrueSTEAM Humidification System

RemoTe mounT InsTallaTIonRemoTe mounT InsTallaTIon

Position template sticker on remote location.

Note: TrueSTEAM will weigh 12–15 lbs. (+/- 2 lbs.) with

water, so if mounting onto drywall or plaster, position

one side over a wall stud.

4

Insert wall anchors (4) into pilot holes and secure

bracket to location.

5

Push down to secure TrueSTEAM to

bracket arms.

69-2036EFS—07

Page 14

Installation Guide

M24770

M24771

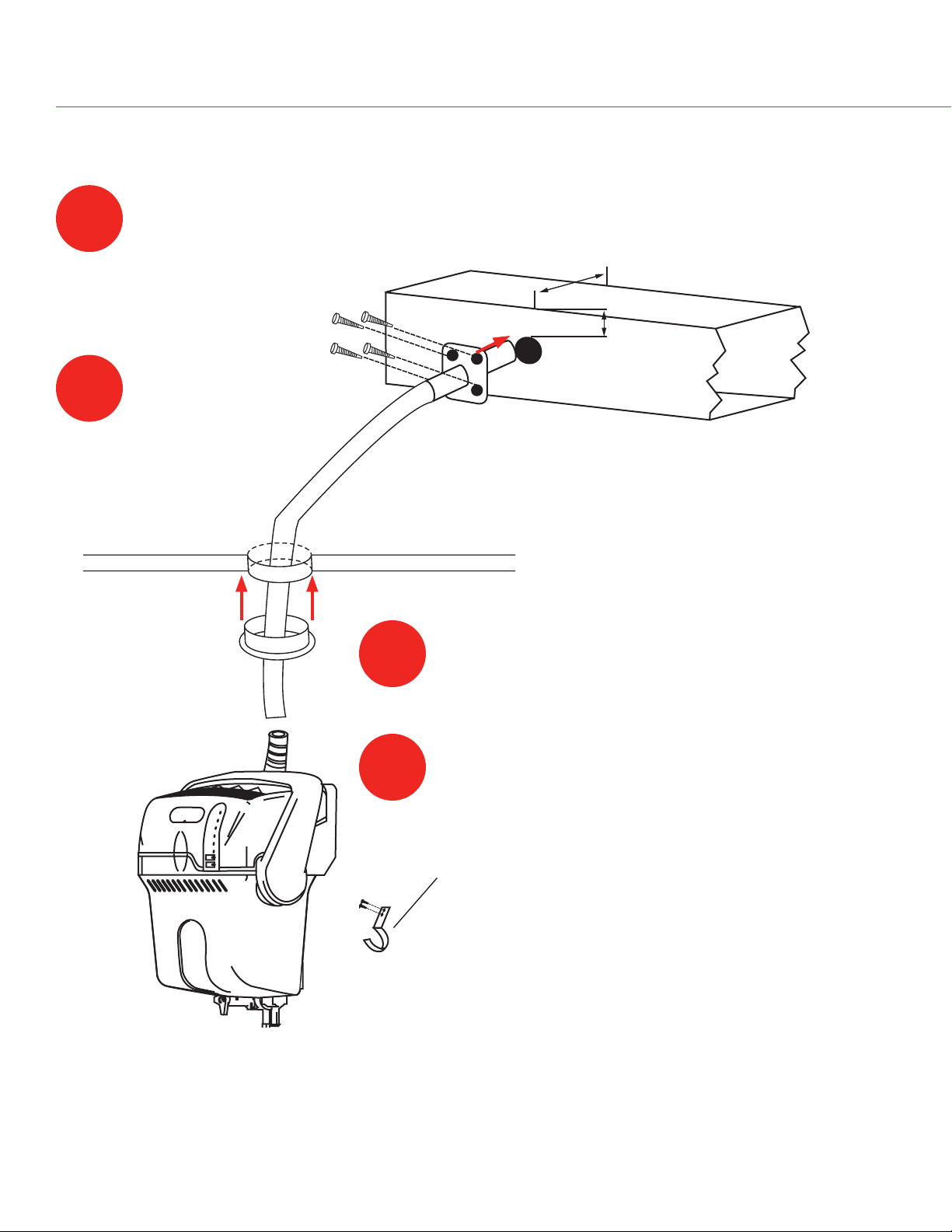

RemoTe mounT InsTallaTIon

Cut a 1-3/4 in. diameter duct hole, install the provided

gasket, and slide the remote nozzle up into the duct.

6

7

Secure remote nozzle to duct using #8 self-drilling

sheet metal screws (4).

Run remote hose from

the humidifier to the duct

nozzle location. Up to 20

ft. of hose can be used.

Minimum 3 in. clearance

required from nozzle outlet to

duct wall.

8

9

If mounting remotely requires running

hose through structural barriers (ie.

wall or ceiling), cut at least a 1-3/4 in.

hole and slide hose through.

Seal off unconditioned space with a

grommet (not provided) or caulk.

Attach remote hose by sliding over the nozzle

and adapter. Secure both hose ends with

clamps (provided).

IMPORTANT:

Run hose continuously uphill. For horizontal runs,

ensure a slope of 2 in. uphill per foot. Secure hose

every horizontal foot using clamps (provided).

For long horizontal runs, support the hose by first

securing a length of 2 x 4 lumber, U-channel, or

angle iron with the appropriate slope. Then attach

the hose to the top of this support. If remote hose

requires downward pitch, refer to pages 5 and 7 for

instruction.

69-2036EFS—07 2

Page 15

M24852

M24772

10

M27428

TrueSTEAM Humidification System

PlumbIng

A

Insert 1/4-in. water line into filter. Apply modest pressure to ensure a tight fit.

B

Insert 1/4-in. water line into back-flow valve. Apply modest pressure for a tight fit.

C

Connect 1/2-in. drain tube. Secure drain tube to barbed fitting with hose clamp.

D

Shut off the water supply. Secure 1/4-in. copper or plastic water feed tube.

Description Part Number

In-Line Water Filter (included)

(required for warranty)

Back-flow valve (included)

(required)

To water supply

50028044-001

50030142-001

A

B

1/4-in. copper

or plastic

Enlarged view

Continuous

downslope

1/2-in.

drain tube

D

C

1/4-in. water line

Draining water may be

hot. Ensure drain outlet

not exposed. Ensure

drain or condensate

pump is rated for at

least 120°F water.

CAUTION

Hot water temperature above 120°F (49°C)

can cause burns from scalding.

Water line tapping options. See instructions provided with the option you choose.

Manual shutoff

valve (sold

separately)

To humidifier

T-fitting

Piercing pin

Water supply line

Saddle valve (provided)

To humidifier

Check all water line connections to ensure no leaks once TrueSTEAM is operational.

3 69-2036EFS—07

Page 16

Installation Guide

M24754

M24895

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

M24893

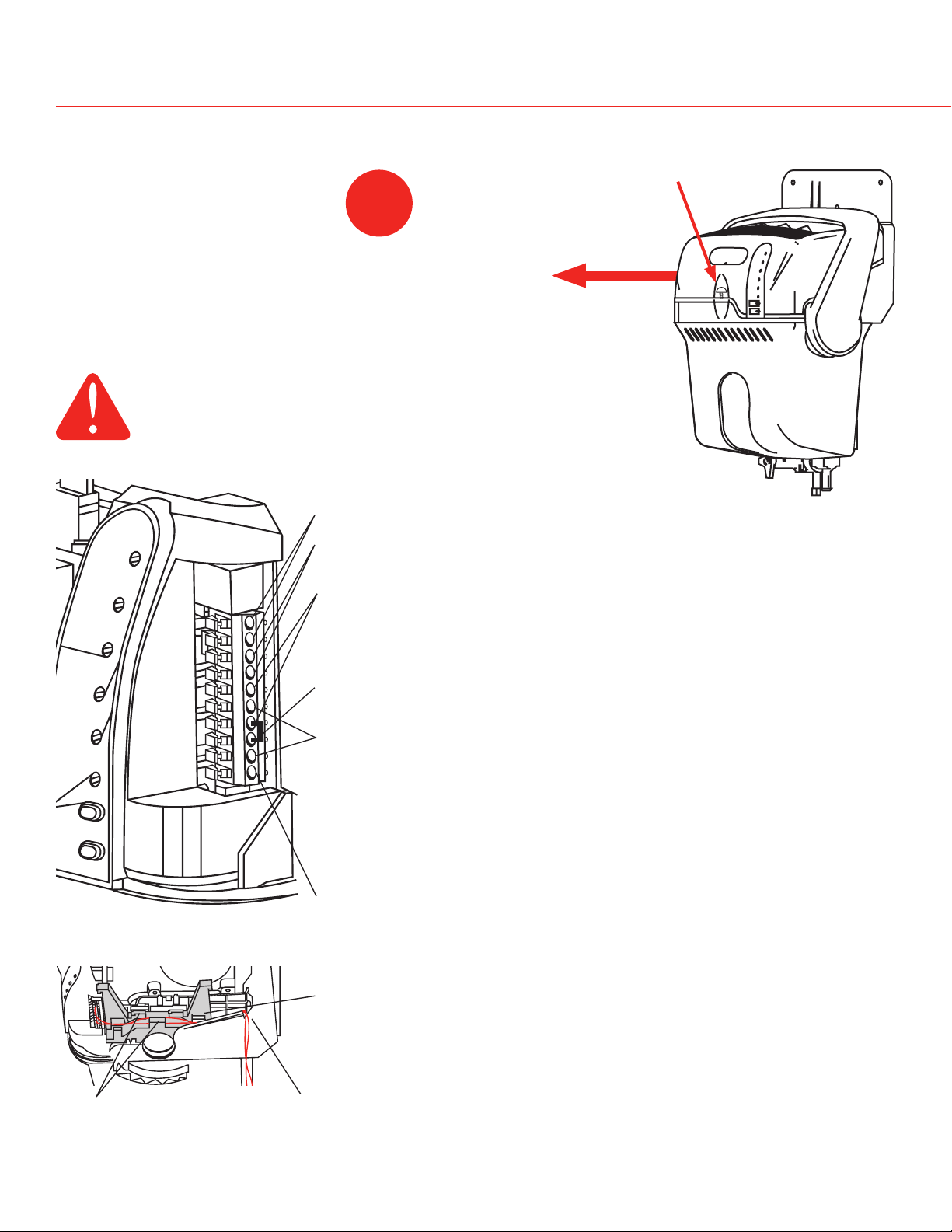

WIRIng

CAUTION: Voltage Hazard.

Before wiring to HVAC terminals, disconnect HVAC

equipment power. Ensure humidifier is not plugged in.

Loosen captive cover

11

screw. Slide cover out from

front.

Low-Voltage Terminals

24V AC power for electronic humidistat.

HUM Low-voltage humidistat (or thermostat) terminals control

C, R Connects to HVAC system transformer terminals (or relay

RT Connects to thermostat R terminal, which is normally

GT, GT connects to thermostat G terminal. GF connects to

GF

EXT When a 24-vac fan board is not used to control blower

Tabs Notch

Route wires through the raised harness tabs and out the notch at

the rear of the chassis. Ensure wires are secure and do not interfere with assembly of cover.

humidifier operation.

transformer fan control R and C) to ensure HVAC power

is present before humidifying. This can be disabled by

changing DIP switch 4 (see page 16).

switched to call for fan.

fan board G terminal. Thermostat G passes through the

normally-closed (NC) relay contacts to GF, allowing fan

activation. When TrueSTEAM is ready to provide humidity

to the home, it will take control of the fan by forcing power

from RT to GF (if not already activated).

(hydronic or cooling-only applications), this connection

with GF provides dry-contact closure for fan calls. EXT/

GF may be wired to a low-voltage relay control center to

provide line-voltage fan control.

69-2036EFS—07

Page 17

HVAC

RECOMMENDED

AIR FLOW SWITCH (AFS)

MECHANICAL

HUMIDISTAT

HVAC

POWER

MASTER

THERMOSTAT

HUM

HUM

GYWR Rc

GYWRC

TrueSTEAM - INTERNAL

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

M24756

12

FAN

FURNACE BOARD

EQUIPMENT INTERFACE MODULE (EIM)

G

C

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

CONV. HP

1

2

3

C

R

RC

RH

W1

W2

W3

Y

Y2

G

O/B

AUX

AUX2

Y

Y2

G

H1

U

M2

D1

H

M2

V1

N

T2

HEAT 1 RELAY

HEAT 2 RELAY

HEAT 3 RELAY

COOL 1 RELAY

COOL 2 RELAY

FAN RELAY

VISIONPRO IAQ

D-1

R-2

C-3

M24758

RECOMMENDED AIR FLOW SWITCH (AFS)

TrueSTEAM - INTERNAL

HVAC

TrueIAQ

THERMOSTAT

HUM

HUM

R

C

GYWR Rc

GYWR C

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

RECOMMENDED

AIR FLOW

SWITCH (AFS)

M27409

HVAC

POWER

MASTER

TrueSTEAM - INTERNAL

TrueSTEAM Humidification System

WIRIng

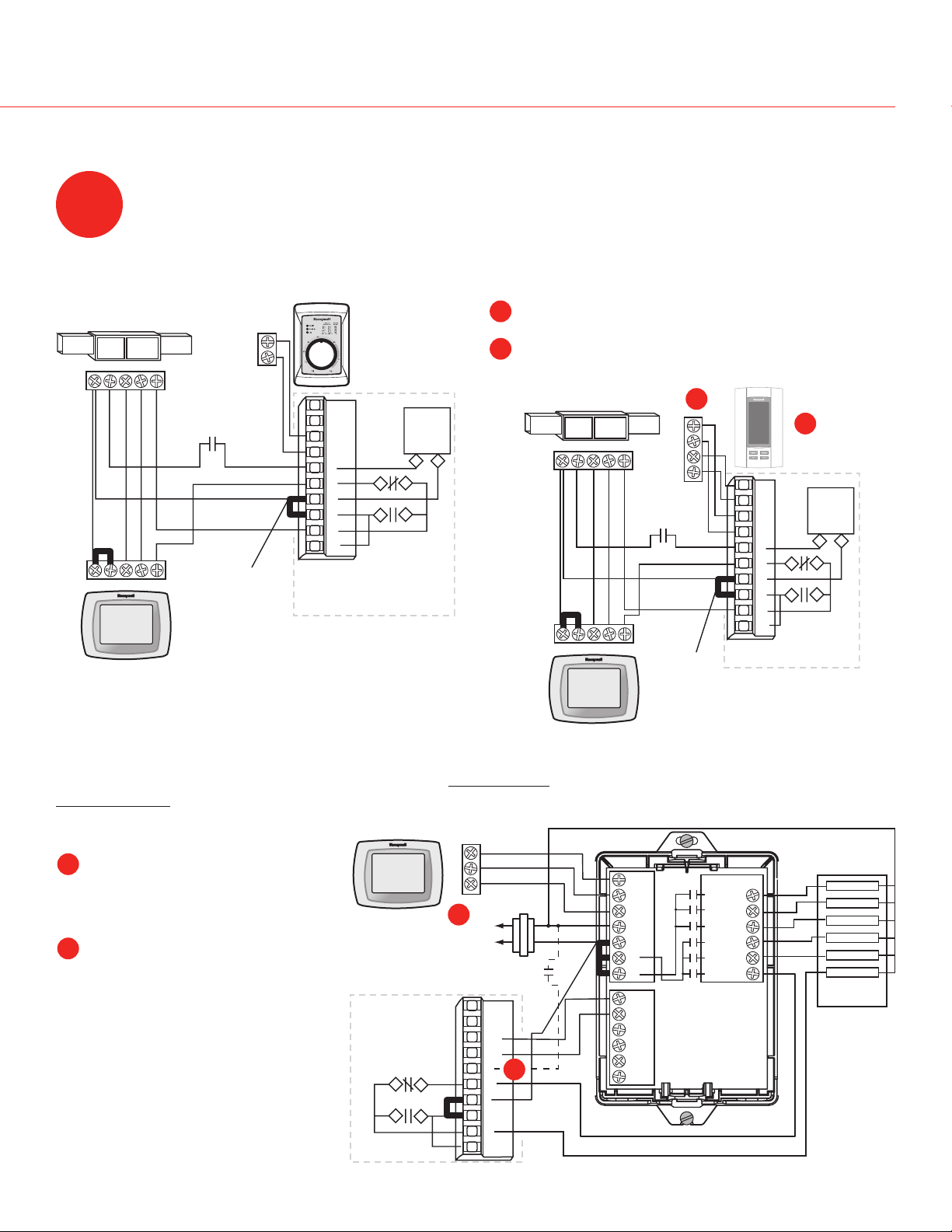

Wire the TrueSTEAM according to the diagram that applies to your humidity control.

Follow this diagram if using a mechanical humidistat

such as H8908ASPST or other.

Factory

installed

jumper

If AFS is used, ensure DIP 5

is in ON position.

Follow this diagram to wire TrueIAQ for manual

operation.

A

Set TrueIAQ ISU parameter 10 to 1, and ISU 25 to 2.

For auto-operation: also wire W and G to thermostat

B

W and G.

B

A

Factory

installed

jumper

Follow this diagram if using VisionPRO IAQTM for independent fan control. TrueSTEAM will

independently activate furnace fan (humidity on demand).

Set VisionPRO IAQTM ISU

A

parameter 374 to 3.

If operating TrueSTEAM without

B

monitoring HVAC power or

AFS, C wiring hookup is

optional, but ensure DIP 4 is in

ON position.

If AFS is used, ensure DIP 5

is in ON position.

69-2036EFS—07

A

If AFS is used, ensure DIP 5 is in ON position.

B

Page 18

Installation Guide

FAN

FURNACE BOARD

EQUIPMENT INTERFACE MODULE (EIM)

G

C

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

CONV. HP

1

2

3

C

R

RC

RH

W1

W2

W3

Y

Y2

G

O/B

AUX

AUX2

Y

Y2

G

H1

U

M2

D1

H

M2

V1

N

T2

HEAT 1 RELAY

HEAT 2 RELAY

HEAT 3 RELAY

COOL 1 RELAY

COOL 2 RELAY

FAN RELAY

HVAC

POWER

MASTER

VISIONPRO IAQ

D-1

R-2

C-3

M24761

RECOMMENDED

AIR FLOW SWITCH

(AFS)

TrueSTEAM - INTERNAL

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

HUMIDISTAT

HUM

HUM

HAC

HAC

MECHANICAL

HUMIDISTAT

HUM

HUM

HAC

HAC

RECOMMENDED

AIR FLOW SWITCH

(AFS)

TrueSTEAM - INTERNAL

HVAC

120 VAC

R8222

RED

BLACK

L1

L2

120

VAC

AT120

R C

M24760

HVAC POWER MASTER

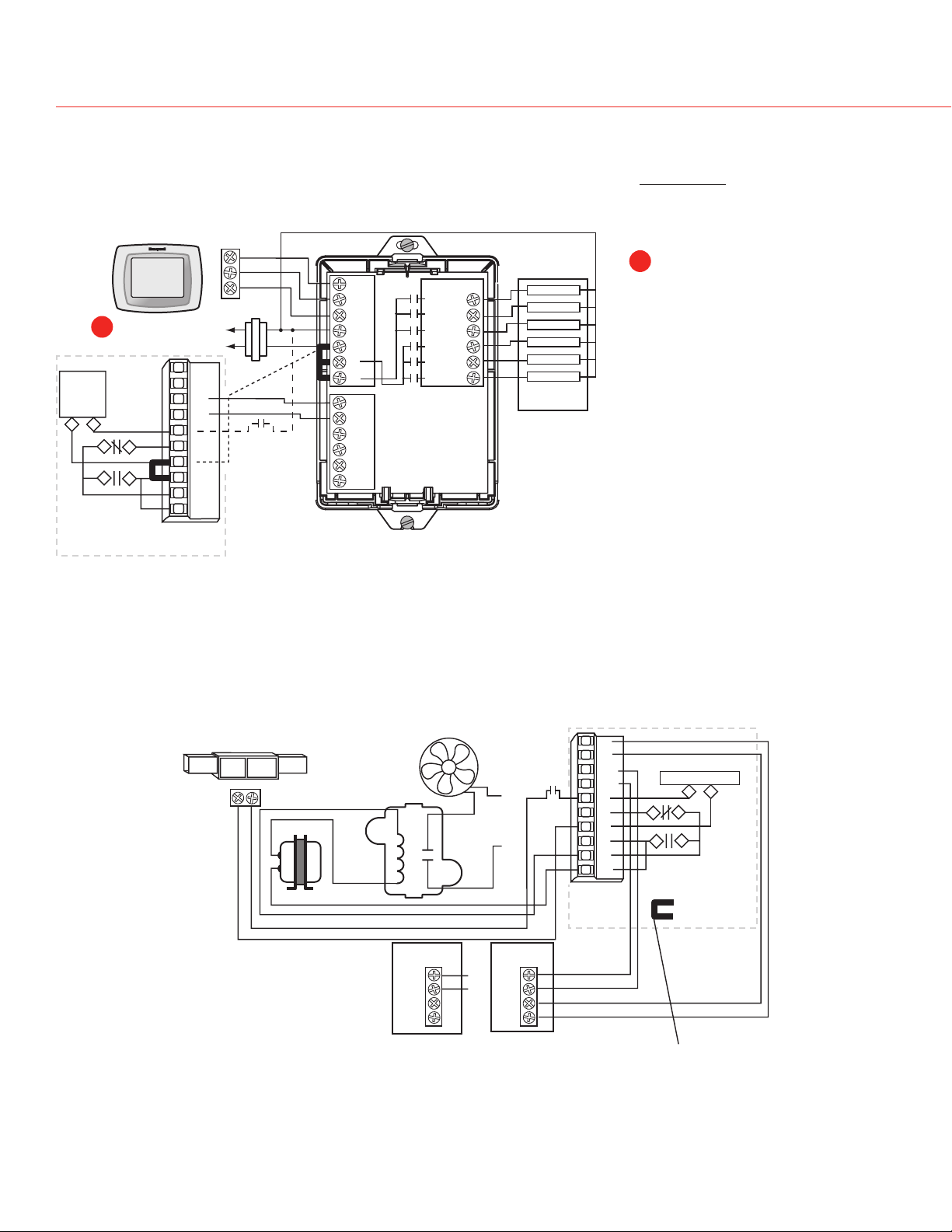

WIRIng

Follow this diagram for a system with the VisionPRO IAQTM with operation dependent on HVAC power

(humidification and fan call by thermostat).

Set VisionPRO IAQTM ISU

B

parameter 374 to 1. This

allows the thermostat to call

B

for fan at the same time as it

calls for humidification.

If AFS is not used, set DIP 4

ON and wire HUM terminals

only.

If AFS is used, set DIP 5 ON

and DIP 4 OFF and wire R, C,

and Hum terminals.

Follow this diagram if using a blower fan dedicated to the TrueSTEAM (a fan separate from the HVAC

equipment, as in hydronic or cooling-only applications).

69-2036EFS—07 6

If AFS is used, ensure DIP 5

is in ON position.

Remove Factory installed

jumper (R/RT)

Page 19

13

POWER

HUMIDIFYING

CLEAN TANK

CALL SERVICE

PRESS RESET

PRESS EMPTY

RESET

EMPTY

SEE LABEL BELOW

!

M24763

M24762

TrueSTEAM Humidification System

Slide the cover back into place and secure captive screw.

Turn on the water supply and plug in the humidifier.

The Press Reset light will blink when

14

power is applied.

Press/release the RESET button to

ready the TrueSTEAM. If not pushed,

TrueSTEAM will automatically move to

ready after five minutes.

WIRIngWIRIng

Turn the humidity control to the “Test” position. If the “Test” position is unavailable,

15

turn the control to a high setpoint (60% +). Be sure to turn this back down (or off) when

testing is complete. “Off” will turn TrueSTEAM off.

Confirm that the furnace blower turns on to circulate air. This will take about 10–15

16

minutes upon call for humidity.

Important for Remote Installation:

After TrueSTEAM has produced steam for 10–15 minutes, check the integrity of the

remote hose to ensure no sags have occurred. Add or adjust clamps if necessary to

ensure 2 in. per foot continuous slope.

7 69-2036EFS—07

Page 20

Installation Guide

M24853

OFF

ON

OFF

ON

OFF

ON

DIP 1

DIP 2

DIP 3

DIP 4

DIP 5

DIP 6

DIP 1

DIP 2

DIP 3

DIP 4

DIP 5

DIP 6

DIP 1

DIP 2

DIP 3

DIP 4

DIP 5

DIP 6

DIP

3

DIP

3

D

IP

3

D

IP

6

D

IP

6

DIP

6

M28181

DIP 1

DIP 2

DIP 3

DIP 4

DIP 5

DIP 6

DIP 1

DIP 2

DIP 3

DIP 4

DIP 5

DIP 6

OFF

ON

OFF

ON

DIP 1

DIP 2

DIP 3

DIP 4

DIP 5

DIP 6

OFF

ON

DIP

3

D

IP

3

DIP

3

D

IP

6

DIP

6

D

IP

6

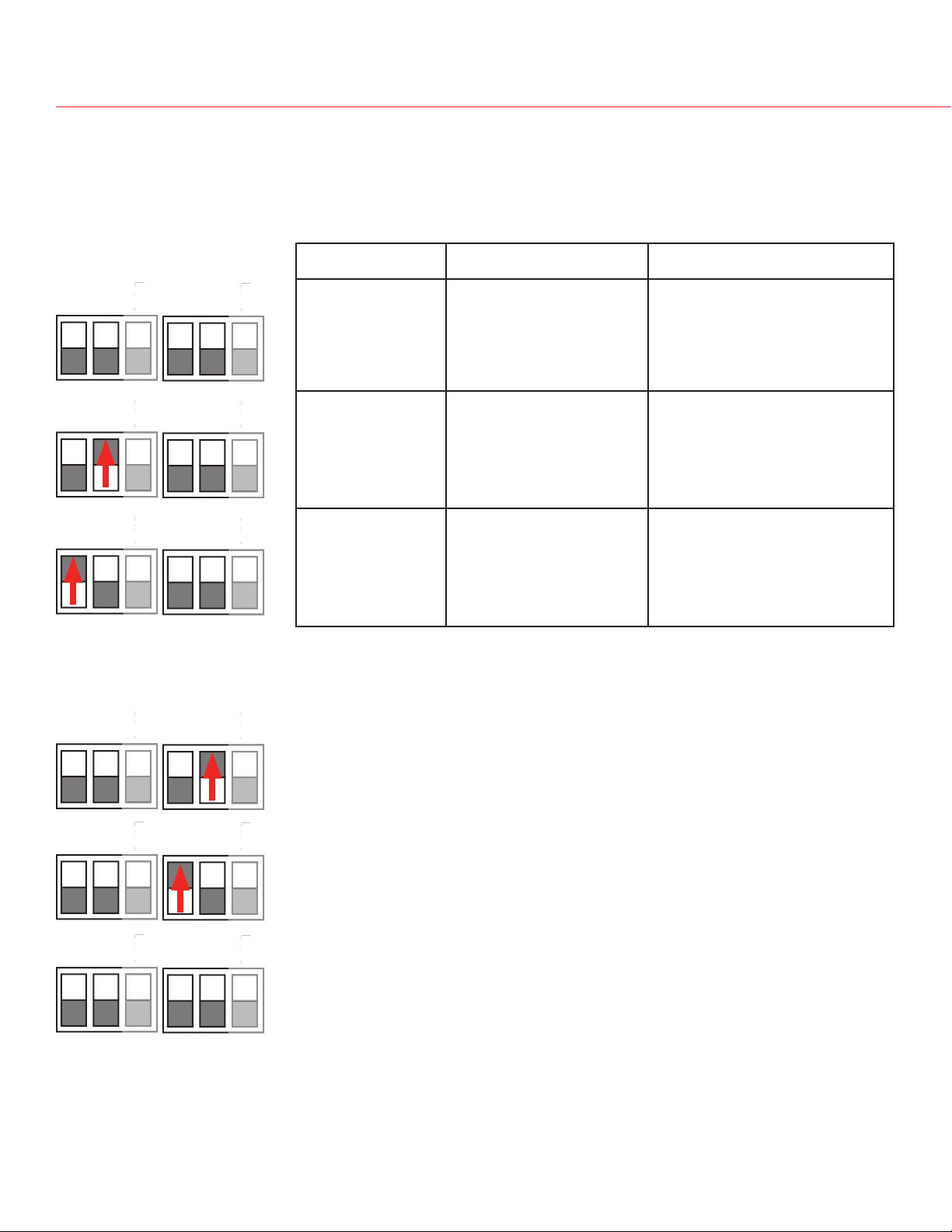

dIP sWITCh seleCTIon

Between the transformer and LED display on the circuit board are two sets of DIP switches. DIP

1 and 2 can be configured to adjust cleaning cycles. DIP 4 and 5 can simplify wiring. DIP 3 and 6

are not used at this time. Details below.

Run time (hrs) End-of-Season timer

(hrs)

10 hrs of humidifying before system

auto-flushes debris

48 hrs before system autodrains and remains empty

until next call for humidity.

from tank.

20 hrs of humidifying before system

auto-flushes debris

48 hrs before system autodrains and remains empty

until next call for humidity.

from tank.

30 hrs of humidifying before system

auto-flushes debris

48 hrs before system autodrains and remains empty

until next call for humidity.

from tank.

Clean tank indicator

1 year of total time (operational

and inactive) before the Press

Empty light will blink, indicating

it is time to manually clean the

water tank.

1 year of total time (operational

and inactive) before the Press

Empty light will blink, indicating

it is time to manually clean the

water tank.

1 year of total time (operational

and inactive) before the Press

Empty light will blink, indicating

it is time to manually clean the

water tank.

DIP 4 OFF, DIP 5 ON: If TrueSTEAM determines that no airflow*

is present two minutes after the blower fan call, it will shut down

steam output and activate a service light.

*Requires installation of air flow switch. See 'Wiring' section for details.

69-2036EFS—07

DIP 4 ON, DIP 5 either setting: TrueSTEAM will allow humidity

without HVAC power present and without airflow.

DIP 4 OFF, DIP 5 OFF: TrueSTEAM will not be allowed to humidify

without HVAC power being present.

Page 21

TrueSTEAM Humidification System

M24901

TRoubleshooTIng

TrueSTEAM has internal system diagnostics that monitor system operation, maintenance schedules,

and faults. If a system fault is detected, the system will attempt to recover itself up to five times in a

24 hour period. If unable to recover in that time, the red Call Service LED light will activate.

If the TrueSTEAM Call Service light is red, a system fault has occurred from which the humidifier can not recover by itself. The table below shows the possible faults, along with steps to fix

TrueSTEAM.

If the red Call Service LED light is on, press/release the RESET button. The red Call Service LED

light will begin blinking in a series that indicates what fault occurred. Refer to the table below

for the fault signified by the number of blinks that occur. To clear the fault, press and hold the

RESET button for 5 seconds.

Press/hold the EMPTY button to clear the Service Timer light (i.e. the Press Empty button).

Press/release the EMPTY button to drain the tank.

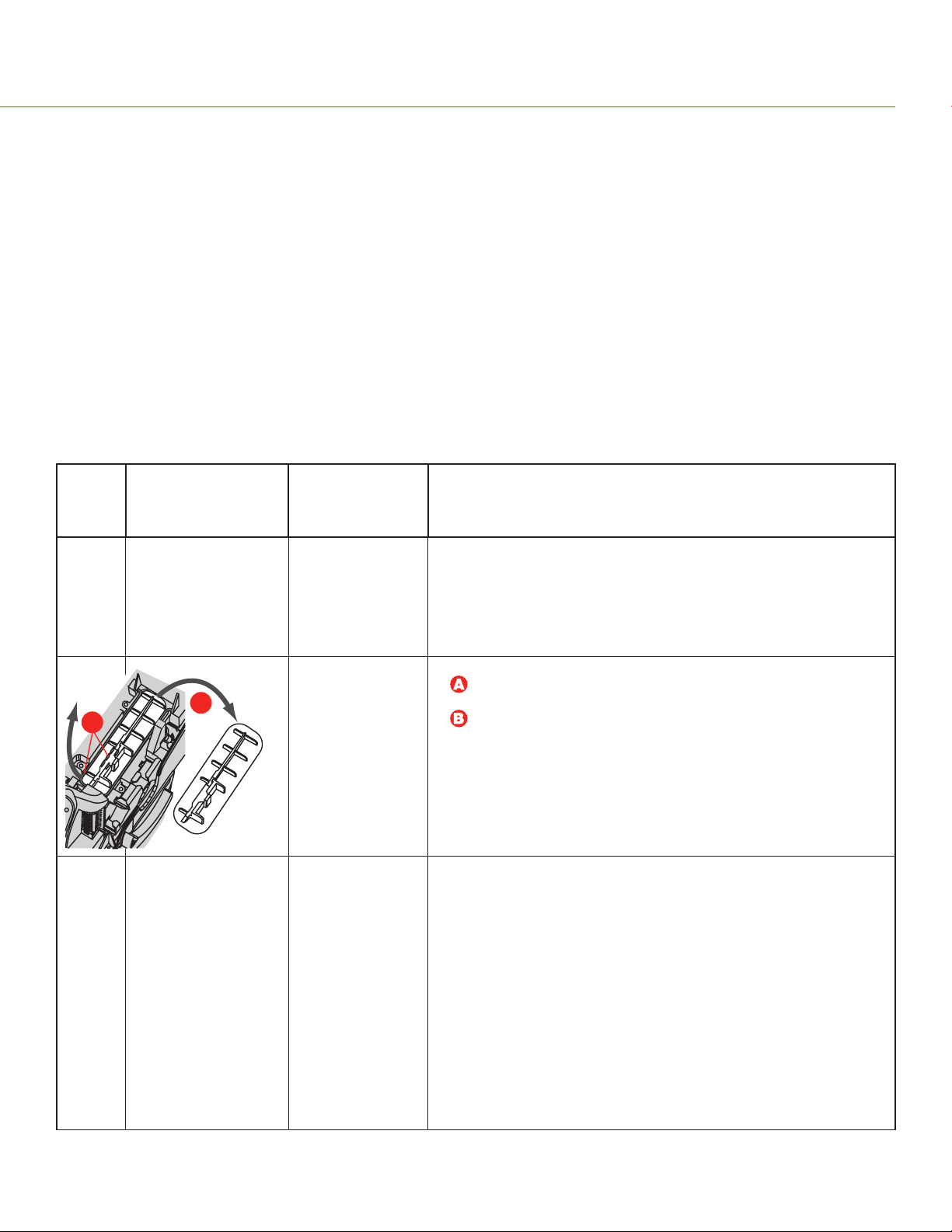

No. of

Red

Light

Blinks

1 Water/Heater temper-

2 Water sensors failed. Yes, system will

3 Failure to fill tank

Fault Description Auto-

ature sensor failed.

B

A

with water.

Recoverable?

Yes, system will

return to “Ready”

if fault no longer

exists in 1 hour.

return to “Ready”

if fault no longer

exists in 1 hour.

Will attempt to

reset itself 5 times

in 24 hours.

Yes, system will

return to “Ready”

if fault no longer

exists in 1 hour.

Steps to Fix

To be Performed by Professional HVAC Technician Only

• Unplug TrueSTEAM and remove cover.

• Check water sensor connection to electronic board.

• Reattach cover and plug TrueSTEAM in.

• If fault reappears, follow the cleaning steps on pages 23–24.

• Reassemble tank and press the RESET button.

• If fault returns, replace with applicable wattage heating

element.

• Unplug TrueSTEAM and remove cover.

• Disconnect water level sensor wiring, remove screen and

lift snap-hinge clamp.

Remove water sensor assembly.

• Clean water sensor probes using warm soapy water so that

the metal is exposed.

• Reassemble the sensor assembly in the unit, reattach and

secure cover.

• Plug unit back in and press the RESET button.

• If fault reappears, replace sensor assembly.

• Ensure inlet water is on.

• Check for leaks around the tank seal and solenoid.

• Turn off water supply and replace in-line water filter.

• Press/hold RESET button until the red Call Service light

turns off.

• If tank still fails to fill, press the EMPTY button (if unit fails to

drain, unplug unit and make sure water in tank is cool).

• Follow tank cleaning instructions on page 21. Ensure you

have a firm grip of the tank prior to releasing the tank,

especially if water is present.

• Clear any excess debris from the tank’s bottom orifice to

the solenoid.

• Reassemble tank and plug unit back in. Press the RESET

button.

• If water still fails to flush into the tank, replace the solenoid

valve.

9 69-2036EFS—07

Page 22

Installation Guide

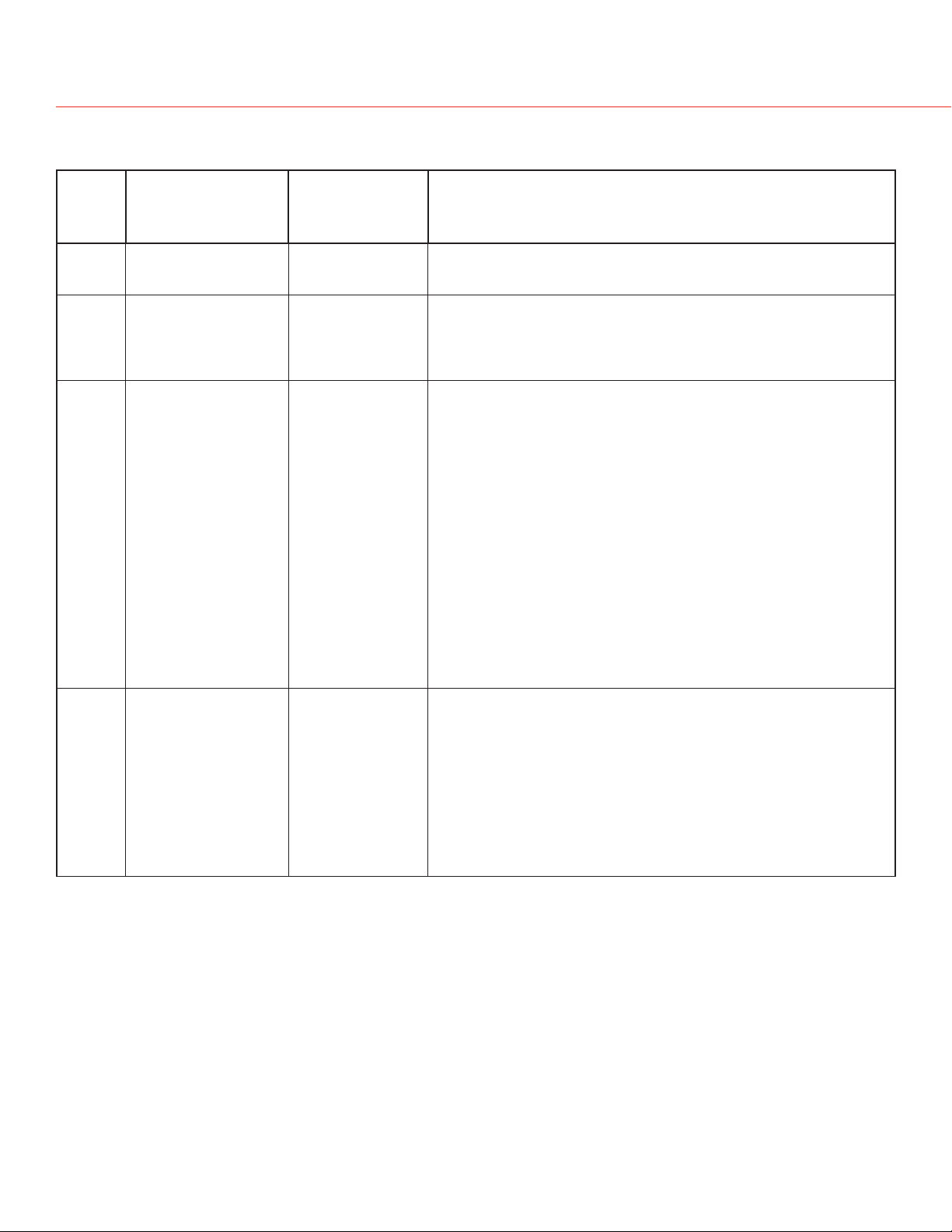

TRoubleshooTIng

No. of

Red

Light

Blinks

4 Heating element

5 Input voltage insuf-

6 Water overflow

7 HVAC power not

Fault Description Auto-

overheated.

ficient.

sensed.

present (monitor this

fault only when DIP 4

and 5 are OFF).

Steps to Fix

Recoverable?

No • Follow tank cleaning steps (pages 23–26).

Yes, system will

return to “Ready”

if fault no longer

exists in 1 hour.

Yes, system will

return to “Ready”

if fault no longer

exists in 1 hour.

Yes, system will

return to “Ready”

if fault no longer

exists in 1 hour.

To be Performed by Professional HVAC Technician Only

• Reassemble tank and press the RESET button.

• If fault returns, replace with applicable TrueSTEAM.

• Unplug and replug the unit in to see if the fault returns.

• If fault returns, unplug unit and remove cover.

• Ensure wiring connections are secure and attached.

• If fault returns, replace the TrueSTEAM with a new one (field

service is not recommended in the event line voltage is lost).

• Ensure drain hose is not kinked or submerged in water at

the drain. Check functionality of condensate pump if used.

• Check for water coming out of drain/overflow line. If

continuous water flow is present, follow the cleaning steps

on pages 23–26.

• Press EMPTY button to drain tank.

• Set humidistat RH setpoint to Test mode.

• If fault returns, unplug TrueSTEAM.

• Loosen cover screw and remove cover.

• Disconnect water level sensor wiring and lift snap-hinge clamp

to remove water sensor assembly. See image on page 17.

• Clean probes using warm soapy water so that the metal is

exposed.

• Reassemble the sensor assembly in the unit, reattach and

secure cover.

• Plug unit in, and press RESET button.

• If fault reappears, replace water sensor assembly and/or

solenoid valve.

• Unplug and replug the unit in to see if power returns.

• If not, ensure HVAC equipment has power. Check circuit

breaker and replace fuse if circuit is tripped.

• Unplug TrueSTEAM and remove cover.

• Ensure DIP 4 is ON and reattach cover.

• Plug unit in.

• If fault reappears, ensure the circuit being used has the

rating to support the unit. Unplug any additional equipment

plugged into this circuit. If fault disappears, the circuit

capacity is not properly sized to your unit.

• If fault returns, replace unit.

69-2036EFS—07 20

Page 23

TrueSTEAM Humidification System

TRoubleshooTIng

No. of

Red

Light

Blinks

8–11 The backup weld

12 Temperature of the

13 Tank failed to drain. No • Water in tank may be hot (>140ºF [60ºC]).

14 Heater failed to boil

15 No Airflow. Yes • Ensure Differential Pressure Switch is installed and wired

Fault Description Auto-

Recoverable?

No • Replace the unit.

monitor input is active

when the backup

heater relay is off.

Yes, system will

electronic circuit

board is too high.

water.

return to “Ready”

if fault no longer

exists in 1 hour.

Yes, system will

return to “Ready”

if fault no longer

exists in 1 hour.

Steps to Fix

To be Performed by Professional HVAC Technician Only

• Ensure ventilation holes in the cover are clear of

obstruction, and that 1 foot of clearance is maintained

around the cover’s vent holes.

• Ensure the TrueSTEAM is installed in a location with

conditioned air 32°F (0°C) to 104°F (40°C).

• Turn humidistat off and allow time for electronic board to cool.

• Turn humidistat on and press RESET button.

• Confirm humidity call starts by HUMIDIFYING light turning on.

• Allow unit to run and check for steam leaks around tank and

ventilation holes.

• If steam is present, replace TrueSTEAM.

• Press the EMPTY button.

• If unit fails to drain, wait for water in tank to cool. Ensure

tank water is cool before proceeding.

• Once cool, follow tank cleaning steps (pages 23–24).

• Reassemble tank and press the RESET button.

• If fault persists, replace the solenoid valve.

• Follow tank cleaning steps (pages 23–24).

• Reassemble tank and press the RESET button.

• If fault returns, replace the heating element with the

applicable wattage replacement part.

correctly. See the Wiring section for proper wiring.

• Ensure DIP switches are set correctly.

• If fault persists, replace AFS and/or unit.

2 69-2036EFS—07

Page 24

Installation Guide

sPeCIfICaTIons

Capacity:

HM512: 12 gallons per day (gpd) (45 liters per day [lpd])

HM509: 9 gpd (34 lpd)

HM506: 6 gpd (23 lpd)

Humidified Area:

House

Description

Loose Two 2000 ft21300 ft21000 ft

Average One 2500 ft21800 ft21500 ft

Tight One-half 3000+ ft22500 ft22000 ft

Air Changes

Per Hour

HM512 HM509 HM506

2

2

2

Weight:

Model Empty Filled with Water

HM512 9 lbs. 15 lbs.

HM509 9 lbs. 14.5 lbs.

HM506 8 lbs. 12 lbs.

• Dimensions: 11-1/4 in. W x 19 in. H x 9 in. D

• Humidifier Operating Temperature Range: 34ºF–

120ºF (1.1ºC–49ºC)

• Remote Hose/Nozzle Operating Temperature Range:

-50ºF–250ºF (-46ºC–121ºC)

• Operating Humidity Range: 0–95% RH, noncondensing

Drain Operation

• Auto flushing is configurable to 10, 20 or 30 hours of

operational time (heating element active).

• During auto flushing, cold water will enter the tank to

lower water temperature below 140ºF (60ºC) before

draining.

• During manual flush (performed by pressing the

EMPTY button) initial water temperature may be

above 140ºF (60ºC). Ensure drain outlet is not

exposed and use caution when pressing the EMPTY

button, and do NOT attempt to remove the tank with

water in it.

• Flush cycle takes approximately 15 minutes to

empty the tank completely. To override, press/hold

the EMPTY button while the “Clean Tank” light is

blinking.

• Drain Hose Operating Temperature Range: 34ºF–

212ºF (1.1ºC–100ºC)

Electrical Ratings and Tolerances

Input Ratings

• Power Supply: 120VAC +10/ -15%, 60Hz

- HM512: 1440W at 120VAC at full load

- HM509: 1200W at 120VAC at full load

- HM506: 840W at 120VAC at full load

• HM512: 12A, 120VAC

• HM509: 10A, 120VAC

• HM506: 7A, 120VAC

• 15A, 120VAC interlock switch

• Thermostat/HVAC power monitor (R to C): 10mA

resistive at 24VAC

• Field wiring terminals: 18–22 ga. solid

• HVAC power/airflow monitor: 10 mA resistive at 24

VAC

Output Ratings

• Relay output contacts:

- Fan: 1.5A full load, 7.5A locked rotor at 24VAC

- Heat and Backup: 15A resistive at 120VAC

• Fill Solenoid: 0.1A at 120VAC, 0.5 PF

• Drain Solenoid: 0.1A at 120VAC, 0.5PF

• Humidistat output contacts: 10mA resistive at 24VAC

• Humidistat power supply: 100mA at 24VAC

CAUTION

Hot water temperature above 140°F (60°C)

can cause burns from scalding.

Standards & Approval Body Requirements

Underwriters Laboratories: UL998, File no. E185662.

Federal Communications Commission: Class B compliance, File no. YU555.

Intended to be used in accordance with the National Electrical Code (NEC), ANSI/NFPA 70, and the rules of the

Canadian Electrical Code (CEC), Part 1, C22.1.

69-2036EFS—07 22

Page 25

TrueSTEAM Humidification System

EMPTY

M24774

CLEAN TANK

(BLINKING LIGHT)

M24775

M24776

CLEAN TANK

(ON SOLID)

CleanIng and seasonal oR VaCaTIon maInTenanCe

Maintenance is simple with TrueSTEAM—just remove the water tank for cleaning.

Warning: Scalding hazard.

Do not attempt to remove the humidifier from the mounting bracket during operation,

or when the humidifier’s water tank when full of water. Water heater could be hot when

tank is removed. Failure to comply could result in severe scalding or death.

Drain Operation

• Auto flushing is configurable to 10, 20 or 30 hours of operational time (heating element

active).

• During auto flushing, cold water will enter the tank to lower water temperature below 140°F

(60°C) before draining.

• During manual flush (performed by pressing the EMPTY button) initial water temperature may

be above 140°F (60°C). Ensure drain outlet is not exposed and use caution when pressing the

EMPTY button, and do NOT attempt to remove the tank with water in it.

To clean the TrueSTEAM:

1. Press and hold the EMPTY button for 3 seconds. Wait for the CLEAN TANK light to be

on solid (not blinking). The flush cycle takes approximately 15 minutes to empty the tank

completely. To override the flush cycle press/hold the EMPTY button a second time for 3

seconds. The tank will drain immediately.

Wait

Go to Step 2

23 69-2036EFS—07

Page 26

Installation Guide

M24777

M24778

M24779

M24856

M24857

CleanIng and seasonal oR VaCaTIon maInTenanCe

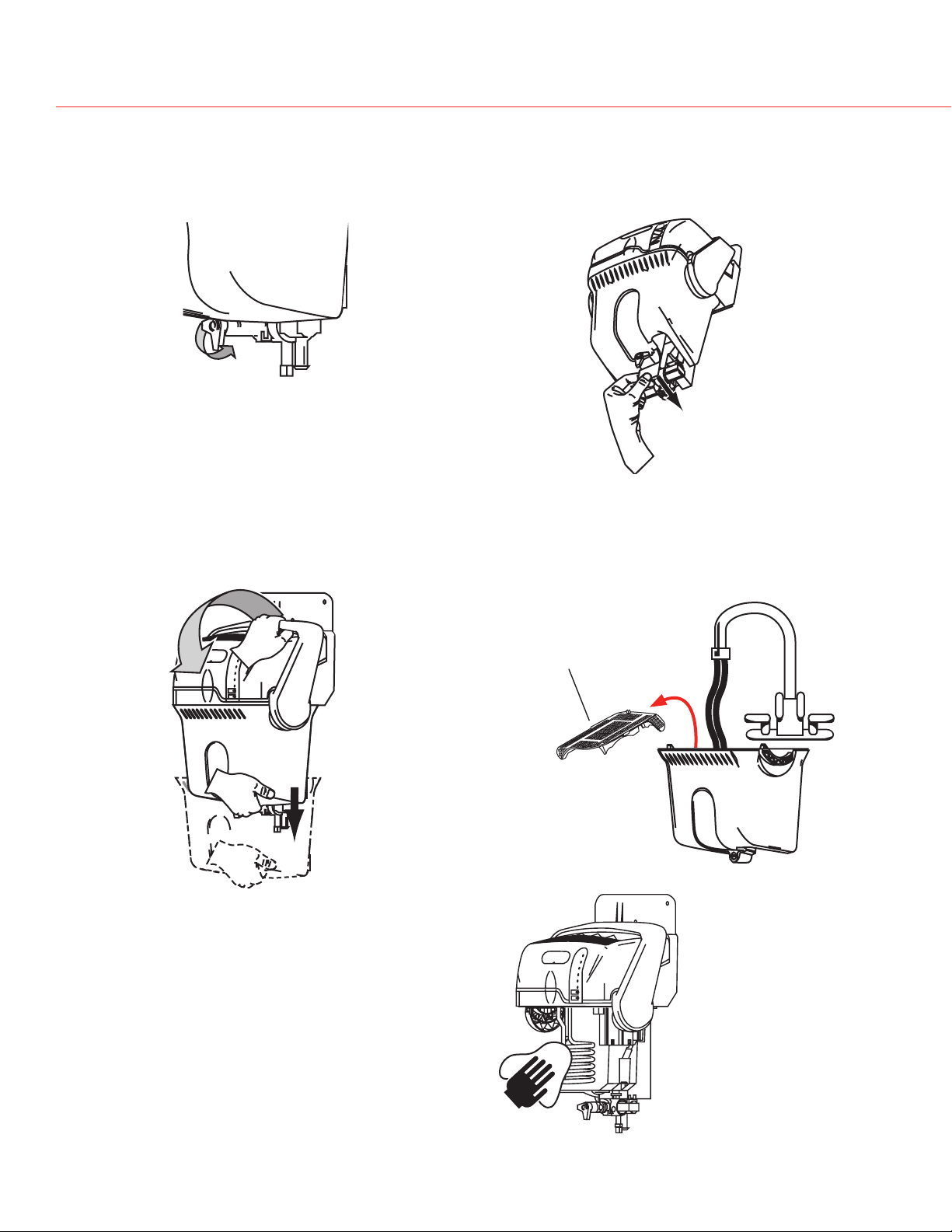

2. Turn the manual shut-off valve at the

bottom of the tank to the “Unlock”

position.

4. Firmly grip the tank bottom. Push down

the cover's safety button and pull the latch

forward to release the tank.

Note: Latch does not come off humidifier

with tank.

3. Grip the white water valve arm and slide it

back within the bracket to disengage from

the tank.

5. Use tap water to flush loose minerals from

the tank. Sediment screen at tank's bottom

is removable. For a more thorough cleaning,

soak tank in warm, soapy water, then rinse

clean. Tank is also dishwasher-safe.

6. Carefully rub minerals off of the heating

element, reservoir walls, and sensors. Scouring

pads suitable for non-stick pots or pans are

suitable for cleaning the TrueSTEAM reservoir

walls and components within the tank.

Sediment screen

69-2036EFS—07 2

Page 27

TrueSTEAM Humidification System

M27410

M27411

7. Replace inline filter once per year. Turn water supply off before replacing.

Press down filter collar ring and pull

out 1/4 in. water line from each side.

Insert 1/4 in. lines into new filter. Apply

modest pressure to ensure a tight fit.

Once clean, reattach tank by securing the latch. Engage the water valve to the cam shaft, and

“Lock” the shut-off valve. The “Press Reset” light will blink at start-up. Push the RESET button

to ready the humidifier.

2 69-2036EFS—07

Page 28

Installation Guide

CleanIng and seasonal oR VaCaTIon maInTenanCe

Automatic End of Season Shutdown

Your TrueSTEAM humidifier has the built-in intelligence to shut down when humidity is not needed for an extended period. After 48 hours of inactivity, TrueSTEAM will drain and remain empty

until humidity is needed again. This prevents water from stagnating within the tank. The tank will

refill with water upon next humidity call.

There are a few house-cleaning steps to follow to keep your TrueSTEAM operating at peak

efficiency:

1. Follow steps 1–6 in the Cleaning section on page 23 at least once per year, or when the

“Press Empty” light is blinking.

2. Clear ventilation holes in the humidifier’s cover.

3. Clear the water drain tube.

4. Make sure the water tank gasket seal is not cracked or split before reattaching the humidifier

water tank.

5. Check that the humidifier is still mounted level.

Extended Vacation

When you leave on extended vacations, it is recommended you turn off the humidifier’s water

supply and turn off the humidity control. When you return, turn on the humidifier water supply

and reset your humidity control to a comfortable position.

69-2036EFS—07 26

Page 29

TrueSTEAM Humidification System

M24787A

PaRTs lIsTCleanIng and seasonal oR VaCaTIon maInTenanCe

Part Part Number Fig. Reference

10-foot Remote Hose and Nozzle Kit 50024917-001 1

20-foot Remote Hose and Nozzle Kit 50024917-002 1

Cover 50028004-001 2

Duct Nozzle 50028003-001 3

Remote Nozzles 50028001-001 4

Mounting Bracket 50020012-001 5

Solenoid Valve 50027997-001 6

In-Line Water Filter 50028044-001 7

HM512/HM509 Water Tank 50033181-001 8

HM506 Water Tank 50033182-001 9

Water Level Sensor Assembly 50027998-001 10

Saddle Valve 32001616-001 11

Back-flow Water Valve 50030142-001 12

Differential Pressure Switch 50027910-001

13

13

12

1

2

8

3

4

5

6

11

10

9

7

27 69-2036EFS—07

Page 30

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

http://yourhome.honeywell.com

® U.S. Registered Trademark.

© 2008 Honeywell International Inc.

69-2036EFS—07 M.S. Rev. 05-08

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Page 31

Humidificateur TrueSTEAM

Simple comme 1, 2, 3, 4

GUIDE D’INSTALLATION PROFESSIONNELLE

1

3

Monter

Mettre de niveau

2

4

Suspendre

Raccorder

Consulter les pages suivantes pour des instructions détaillées et des options de montage à distance.

Page 32

Guide d’installation

Table des maTIèRes

Recommandations d’installation ................................................. 31

Outils et matériel nécessaires ..................................................... 33

Consignes de sécurité ................................................................. 34

Instructions de montage sur gaine

Installation ..................................................................................... 35

Instructions de montage à distance

Installation ..................................................................................... 37

Plomberie et câblage

Plomberie ...................................................................................... 43

Câblage ......................................................................................... 44

Réglage des commutateurs DIP .................................................. 48

Dépannage .................................................................................... 49

Nettoyage, entretien saisonnier et

avant les absences prolongées ............................................. 53

Renseignements supplémentaires

Nomenclature des pièces ............................................................ 57

Besoin d’aide?

Pour toute assistance concernant ce produit, visitez le site http://yourhome.honeywell.com

ou communiquez avec les Services à la clientèle au numéro sans frais 1-800-468-1502

Veuillez lire les présentes instructions et les

garder à portée de main.

® Marque de commerce enregistrée aux États-Unis.

Brevets en instance.

Copyright © 2007 Honeywell International Inc. Tous droits réservés.

69-2036EFS—07 30

Page 33

Humidificateur à injection directe TrueSteam

ReCommandaTIons d’InsTallaTIon

Pour effectuer correctement l’installation du TrueSTEAM et assurer son bon fonctionnement, il

est important de tenir compte des points suivants :

Capacité de l’appareil

1. Choisir l’humidificateur qui convient à l’application est crucial :

Le tableau ci-dessous indique la superficie en mètres carrés (pieds carrés) qu’un appareil

TrueSTEAM peut humidifier.

Un appareil de 23L (6 gall.) n’est pas recommandé pour les maisons d’une superficie supérieure

à 185 mètres carrés (2000 pieds carrés).

Aire en mètres carrés (pieds carrés)

LPJ (GPJ) recommandés par l’ARI*

TrueSTEAM HM512 - 45 L (12 gall.) réels

TrueSTEAM HM509 - 34 L (9 gall.) réels

TrueSTEAM HM506 - 23 L (6 gall.) réels

* Recommandation F-2007 de l’ARI pour le maintien d’un taux d’humidité relative de 35 % dans une

maison étanche avec plafonds de 2,4 m (8 pi), habitée par quatre personnes. Température de -6 ºC

(20 ºF) et taux d’humidité relative de 70 % à l’extérieur.

45

(500)

0,4

(0,1)

90

(1000)

8,3

(2,2)

140

(1500)

16,6

(4,4)

185

(2000)

24,6

(6,5)

230

(2500)

32,6

(8,6)

280

(3000)

44,3

(11,7)

Liste des vérifications au moment de l’installation

• Installer le filtre de tuyau à eau et la vanne anti-refoulement.

• Vérifier si le tuyau d’alimentation principale en eau est ouvert.

• S’assurer qu’il n’y aucune fuite ni gouttes d’eau à l’un ou l’autre des raccordements d’eau.

• Vérifier si le circuit est suffisant pour alimenter l’appareil.

• Provoquer une demande d’humidification à l’aide du régulateur et vérifier si le TrueSTEAM se

remplit et si le voyant d’humidification s’allume, ce qui indique la production de vapeur.

• Vérifier le fonctionnement du drain en appuyant sur le bouton EMPTY (VIDANGE) jusqu’à ce

que le voyant Clean Tank (Nettoyage du réservoir) commence à clignoter pour indiquer la

mise en marche du cycle de vidange.

REMARQUE : Le nettoyage et la vidange du réservoir peuvent prendre une dizaine

de minutes. Pour sauter l’étape du nettoyage et effectuer la vidange immédiatement,

maintenir enfoncé le bouton EMPTY (VIDANGE) lorsque le voyant Clean Tank (Nettoyage du

réservoir) clignote. Le cycle de nettoyage est annulé et la vidange du réservoir commence

immédiatement. Pour arrêter la vidange, appuyer sur le bouton Reset (Réarmement).

• Apposer l’étiquette d’entretien du réservoir fournie sur la gaine ou le mur près de l’appareil.

Cette étiquette autocollante est jaune. Vérifier si le tuyau de drain est fixé de manière qu’il

ne peut se séparer accidentellement. Vérifier si le tuyau est bien inséré dans le drain ou la

pompe à condensats; autrement l’eau pourrait gicler.

3 69-2036EFS—07

Page 34

Guide d’installation

ReCommandaTIons d’InsTallaTIon

Réglage de l’appareil TrueSTEAM pour un fonctionnement efficace et pour répondre aux

besoins des utilisateurs :

Le point de consigne de l’humidification n’est parfois atteint qu’au bout d’une semaine de

fonctionnement continu de l’appareil, compte tenu de facteurs comme l’aire de la maison, son

contenu et son isolation.

Avec un appareil de 23 L (6 gall.), le meilleur réglage est entre 30 et 35 % ou jusqu’à ce qu’il y ait

de la condensation dans les fenêtres. Il faut alors abaisser le point de consigne (à condition que

l’appareil ne soit pas réglé au mode protection contre le givre). Si le point de consigne n’est pas

atteint, l’appareil n’est peut-être pas assez puissant (si la superficie de la maison est inférieure

à 185 mètres carrés ou 2000 pieds carrés, l’isolation, les fenêtres ou le climat aride peuvent en

être la cause); il est aussi possible que la température extérieure soit trop basse et qu’elle ne

permette pas d’assurer le maintien de niveaux d’humidité adéquats. Il est préférable d’attendre

que la température soit près de -6 °C (20 °F).

Si la température est de cet ordre mais que les niveaux d’humidification sélectionnés ne sont

pas atteints, il faut utiliser un appareil d’une plus grande capacité.

Pendant la première semaine de fonctionnement de l’appareil, il est normal de sentir une légère

odeur de plastique, selon le degré de ventilation dans la maison. Si un tuyau à distance est

utilisé, il peut y avoir une légère odeur de caoutchouc. Ces odeurs disparaîtront dans les jours

suivant l’installation.

Si le TrueSTEAM ne se met pas en marche malgré une demande d’humidification, c’est

probablement parce qu’il est en mode vidange. Demander au propriétaire de revérifier le

fonctionnement de l’appareil au bout d’une heure.

Si le voyant Call Service (Appel de service) clignote, demander au propriétaire de maintenir

enfoncé le bouton de réarmement pour corriger le problème. Si le problème dure, débrancher

l’appareil, puis le rebrancher dans la prise de courant. Attendre 24 heures avant d’appeler un

entrepreneur. Le voyant d’appel de service clignote peut-être parce que la tension est basse

dans les environs; l’appareil devrait recommencer à fonctionner correctement une fois le courant

revenu à la normale.

La consommation d’énergie peut augmenter légèrement. Par contre, comme la maison semble

plus chaude lorsque le TrueSTEAM fonctionne efficacement, il est possible d’abaisser le point

de consigne du thermostat. Une diminution du point de consigne d’un degré permet de réaliser

des économies de coûts de chauffage pouvant atteindre 3 %.

69-2036EFS—07 32

Page 35

Humidificateur à injection directe TrueSteam

ouTIl eT maTéRIel néCessaIRes PouR l’InsTallaTIon de l’humIdIfICaTeuR TRuesTeam

Outils et quincaillerie nécessaires :

• Pince à dénuder et à couper les fils

• Perceuse ou outil pour découper la gaine

• Scie-cloche de 44 mm (1 3/4 po)

• Foret de 3 mm (1/8 po)

• Tournevis à point cruciforme et tournevis

droit (ou Torx)

• Fil de thermostat de calibre 18 (à 5 ou

à 2 conducteurs)

Matériel fourni :

• Tuyau de 64 mm (1/4 po), en cuivre ou en

plastique

• Tuyau d’évacuation de 127 mm (1/2 po) et

colliers

• Support de montage et quincaillerie

• Filtre de tuyau à eau* (50028044-001)

• Robinet-vanne à étrier

• Vanne anti-refoulement (50030142-001)

Matériel facultatif :

• Ensemble d’installation à distance

– Ensemble tuyau de raccordement de

3 m (10 pi) et buse (50024917-001)

– Ensemble tuyau de raccordement de

6 m (20 pi) et buse (50024917-002)

• Régulateur d’humidité

– Humidistat manuel (H8908ASPST)

– TrueIAQ (DG115EZIAQ)

– VisionPRO IAQ (YTH9421C1010)

• Raccord de tuyau en T

• Robinet de sectionnement

• Siphon de tuyau à distance

• Interrupteur à pression différentielle

(50027910-001)

• Nécessaire de montage à distance pour une

gaine à panneaux (32005530-001)

* La garantie stipule que l’installation d’un filtre à eau en ligne et son entretien à intervalles

réguliers sont obligatoires.

33 69-2036EFS—07

Page 36

Guide d’installation

ConsIgnes de séCuRITé

MISE EN GARDE : Risques liés au courant électrique.

Peut causer des chocs électriques ou endommager l’équipement. Couper

l’alimentation du système CVCA avant de commencer l’installation de l’appareil.

Consignes de sécurité

• Ne pas diriger la buse de vapeur vers des personnes.

• Si l’humidificateur TrueSTEAM est installé près d’une piscine ou d’un spa, s’assurer qu’il ne

peut tomber dans l’eau, ni être éclaboussé. S’assurer également qu’il est branché dans une

prise de courant à disjoncteur de fuite à la terre (DFT).

• L’eau contenue dans le réservoir peut être très chaude. Suivre à la lettre les directives

d’installation et les étapes d’entretien telles qu’elles figurent dans la documentation technique.

Avertissement : Dangers reliés à l’électricité, à l’équipement lourd et aux

produits chimiques

Peut causer la mort, la cécité, des dégâts d’eau et provoquer la panne de élément chauffant.

• Ne couper aucun tuyau de climatiseur, ni aucun fil électrique.

• Porter des lunettes de sécurité pour couper ou percer.

• Installer l’humidificateur de niveau pour éviter les dégâts d’eau ou la panne de l’élément

chauffant.

• Si nécessaire, renforcer la gaine pour assurer la stabilité de l’installation.

De préférence, installer l’appareil sur le côté air chaud ou approvisionnement en air de l’appareil

de chauffage. S’il n’est pas possible de l’installer à cet endroit, la buse de vapeur doit être installée à au moins 30 cm (12 po) en amont du filtre de l’appareil de chauffage. Si nécessaire, selon

l’emplacement et le degré de rigidité de la gaine, installer un renfort de gaine.

Avertissement : Dangers reliés à la condensation de vapeur, au feu et au gel de l’eau.

Peut causer des pannes du ventilateur et des limiteurs ou des dégâts d’eau.

• Ne pas installer l’appareil à un endroit où la température ambiante est inférieure à 0 °C (32 °F) ou

supérieure à 49 °C (120 °F).

• Ne pas installer l’humidificateur sur les parois latérales d’une gaine de retour d’air fabriquée en

bois (p. ex. des solives de plancher).

• La surface de montage doit être assez résistante pour supporter le poids de l’humidificateur

rempli d’eau (approximativement entre 5,4 kg et 6,8 kg [12 et 15 lb]) et pour maintenir l’appareil

de niveau afin d’assurer un fonctionnement sécuritaire et fiable. Sinon, renforcer la gaine ou le

mur.

• Si l’intérieur de la gaine est garni de matériel isolant exposé, enlever l’excès d’isolant au point

d’insertion de manière à bien dégager la buse. Il peut être préférable de remplacer une section

de la gaine isolée (approximativement 15 cm x 15 cm [6 po x 6 po]) par une section de tôle non

isolée pour rendre l’installation adéquate.

• Monter l’appareil à un endroit où le débit d’air est régulier, à l’extrémité de la buse de vapeur.

• Laisser un espace d’au moins 30 cm (1 pi) au dessus des orifices de ventilation dans le couvercle

de l’humidificateur. Ne pas recouvrir ces orifices, ce qui pourrait faire augmenter la température

interne de fonctionnement et raccourcir la durée de vie de l’humidificateur.

• Laisser au moins 10 cm (4 po) de dégagement entre l’orifice d’insertion de la buse de vapeur et le

haut de l’intérieur de la gaine pour éviter la formation de condensation à l’intérieur de la gaine. Le

gabarit de montage est conçu pour assurer ce dégagement si sa partie supérieure est placée à

égalité ou en dessous de la surface supérieure de l’intérieur de la gaine.

• Ne pas monter l’appareil directement sur une gaine à panneaux. L’adaptateur de buse à distance

ne peut être utilisé qu’avec le nécessaire d’adaptation pour une gaine à panneaux (pièce

32005636-001).

• Ne pas installer l’appareil dans un espace totalement clos comme une armoire ou un placard non

aéré. Choisir un emplacement bien ventilé.

69-2036EFS—07 3

Page 37

Humidificateur à injection directe TrueSteam

M24744

M24745

M24746

M24894

MF24914

Pour une installation sur la gaine de soufflage, suivre les instructions aux pages 35 et 36 et aux

pages 43 à 48. Pour une installation à distance, suivre les instructions aux pages 37 à 48.

InsTallaTIon suR gaIne

Choisir un emplacement qui donne

1

accès à :

• un drain permettant de donner au

tuyau d’évacuation une pente de

2 cm par mètre (1/4 po par pied);

• un tuyau d’eau froide;

• un circuit électrique de capacité

suffisante;

• une surface verticale offrant un

dégagement suffisant.

Pente

régulière

L’eau de vidange

peut être chaude.

S’assurer que la

sortie du drain

n’est pas exposée.

2

Installer la buse de gaine.

Capacité minimale du

Modèle

circuit électrique

HM506 7 ampères

HM509 10 ampères

HM512 12 ampères

AVERTISSEMENT

L’eau chaude à une température qui dépasse 120 °F

(49 °C) peut causer des brûlures par ébouillantage.

S’assurer que le

joint torique est

bien posé dans sa

rainure.

Insérer la buse et la tourner dans le

sens horaire pour que le joint entre la

buse et le TrueSTEAM soit étanche.

3 69-2036EFS—07

Page 38

Guide d’installation

M24749

M24750

MF24748

APPROVISIONNEMENT

30 CM (12 PO)

InsTallaTIon suR gaIne

Placer le gabarit autocollant sur la gaine de soufflage. Dans le cas où les

3

grands serpentins ne permettent de laisser un dégagement suffisant, suivre les

instructions de montage à distance.

4

Percer un trou de 4,5 cm

(1 3/4 po).

Fixer le support à la gaine avec 4

5 6

vis à métal autotaraudeuses no 8

A) Glisser le joint en mousse par-dessus la

buse et insérer la buse dans l’orifice de

la gaine (voir l’illustration).

B) Pousser l’humidificateur vers le bas de

manière à bien le fixer sur le support.

S’assurer que le joint en mousse dans

l’orifice de la gaine est bien étanche.

Allouer un

dégagement de

3 po entre la sortie

de la buse et la

paroi de la gaine.

B

A

Joint en

mousse

Passer à la page 43 pour les directives concernant la plomberie et le câblage.

69-2036EFS—07 36

Page 39

Humidificateur à injection directe TrueSteam

M24896A

InsTallaTIon à dIsTanCe

Suivre ces instructions pour installer l’appareil ailleurs que sur la gaine de soufflage.

La plupart des problèmes de

fonctionnement sont causés par une

mauvaise installation du tuyau. Dans une

installation à distance, toujours s’assurer

qu’il y a une pente ascendante. Éviter

la formation de plis, d’angles aigus ou

points bas qui peuvent restreindre le

flux de la vapeur dans la buse d’injection

ou provoquer sa condensation dans

l’humidificateur.

S’il est impossible d’installer le tuyau

d’installation à distance avec une pente

ascendante de 10,5 cm par mètre (2 po

par pi), installer un raccord en T pour

l’égouttement. Autrement, la pression de

retour dans l’humidificateur TrueSTEAM

peut entraîner la projection d’eau dans la

gaine par la buse ou une fuite du joint. Le

tuyau d’installation à distance doit être

soutenu pour prévenir son affaissement et

les points bas.

Choisir l’emplacement de

1

l’humidificateur TrueSTEAM et

de la buse de gaine à distance.

(Consulter l’installation à distance

aux pages 32 et 33.)

Il faut avoir accès à :

• un endroit permettant d’installer

le tuyau de vapeur avec une

pente ascendante continue de

10,5 cm par mètre (2 po par

pied);

• un drain permettant une pente

descendante continue;

• un tuyau d’eau froide;

Dans le cas d’un montage à distance,

suivre également les étapes suivantes car elles

permettent de choisir l’appareil TrueSTEAM

approprié :

Si le tuyau de distribution de vapeur passe dans

un endroit non chauffé, par exemple un grenier,

isoler ce tuyau pour assurer la sortie efficace de

la vapeur :

• Un isolant autoscellant pour tuyaux d’eau

chaude et d’eau froide est recommandé. Tuyau

isolé de 29 mm (1 1/8 po) de diam. int. x 38

mm (1,5 po), homologué Factory Mutual 25/50,

no 062411, ignifuge.

Le modèle HM506 de 23 L (6-gall.) peut être

monté à une distance maximale de :

• 1,5 mètre (5 pieds) avec tuyau de distribution

de vapeur non isolé

• 4,5 mètres (15 pieds) si le tuyau de distribution

de vapeur est isolé

Les modèles HM509 et HM512, respectivement

de 34 L (9 gall.) et 45 L (12-gall.) peuvent être

montés jusqu’à une distance de 6 mètres (20

pieds) avec un tuyau de distribution de vapeur

isolé ou non isolé.

Prévoir une pente ascendante d’au moins 10,5

cm par mètre (2 po par pi) si le tuyau à distance

est installé à l’horizontale.

Maximum de 90 cm (3 pi)

Pente ascendante

de 10,5 cm/m (2 po/pi)

• un circuit électrique de

capacité suffisante (consulter

l’information sur les capacités

du circuit à la page 40).

Entonnoir ou drain de plancher. Consulter les codes

de construction pour connaître les exigences

relatives à la dimension et la température maximale.

37 69-2036EFS—07

15 cm (6 po)

20 cm (8 po)

Diamètre

minimum de

1,3 cm (1/2 po)

Water in elbow

Page 40

Guide d’installation

M24786

M24781

M24785

MF24936

FLUX DESCENDANT

InsTallaTIon CoRReCTe du Tuyau

À distance dans la pièce de chauffage

ou des installations mécaniques

Remarque : Si la température à l’endroit où est

situé l’appareil de conditionnement de l’air peut

descendre en dessous du point de congélation, il

faut installer l’humidificateur TrueSteam dans un

endroit chauffé et amener un tuyau jusqu’à la gaine.

Montage sur gaine à

distance

AVERTISSEMENT

L’eau chaude à une température qui

dépasse 120 °F (49 °C) peut causer

des brûlures par ébouillantage.

Installation dans des pièces habitées

À distance dans le garage

L’eau de

vidange peut

être chaude.

S’assurer

que la

sortie du

drain n’est

pas exposée.

69-2036EFS—07 3

Page 41

10,5 CM/M (2 PO/PI)

10,5 CM/M (2 PO/PI) 10,5 CM/M (2 PO/PI)

10,5 CM/M

(2 PO/PI)

MAX 6 M (20 PI)

AVEC SIPHON

MAX 1,5M (5 PI)

SI AUCUNE PENTE

SIPHON

SIPHON

VIDANGE

MAX 90 CM (3 PI)

MAX 3 M (10 PI)

COURBE FAIBLE

OBSTRUCTION

TUYAU D’INSTALLATION À DISTANCE SOUTENU

MAX 6 M (20 PI)

VIDANGE

SIPHON

REMARQUE : LA HAUTEUR DU SIPHON DOIT ÊTRE

SUPÉRIEURE À LA PRESSION STATIQUE DE LA GAINE.

VIDANGE

INSTALLATION TYPE SI

LE TrueSTEAM EST INSTALLÉ

AU-DESSUS DE LA BUSE À DISTANCE

PLI

POINT BAS

PAS DE PENTE

PAS DE PENTE

MF24915

COUDE

SANS VIDANGE

Humidificateur à injection directe TrueSteam

InsTallaTIon CoRReCTe du Tuyau

REMARQUES :

• Diriger le tuyau vers le haut avec une pente de 10,5 cm par mètre (2 po par pi)

dans le sens du flux de vapeur.

• Diriger le tuyau vers le bas avec une pente de 4 cm par mètre (3/4 po par pi).

• Le tuyau d’installation à distance POUR la vapeur doit avoir une longueur

maximale de 6 m (20 pi)

• La hauteur du siphon doit être supérieure à la pression statique de la gaine.

Normalement, une hauteur de 8 cm (3 po) est suffisante. Le siphon doit aussi

être muni d’un dispositif d’égouttement (voir à la page 37).

• Réduire au minimum les angles aigües et les coudes.

• Dans des espaces sans chauffage ni refroidissement, l’efficacité du tuyau

d’installation à distance sera plus grande si celui-ci est isolé.

ÉVITER CES ERREURS D’INSTALLATION.

39 69-2036EFS—07

Page 42

Guide d’installation

M24744

M24745

M24764

M24765

M24894

InsTallaTIon à dIsTanCe

Capacité minimale du

Modèle

circuit électrique

HM506 7 ampères

HM509 10 ampères

HM512 12 ampères

Installer l’adaptateur de tuyau four-

2

ni dans l’ensemble d’installation à

distance.

L’eau de vidange

peut être chaude.

S’assurer que la

Pente

Régulière

sortie du drain

n’est pas exposée.

AVERTISSEMENT

L’eau chaude à une température qui dépasse 120 °F

(49 °C) peut causer des brûlures par ébouillantage.

Ensemble d’installation à distance

(vendu séparément)

Adaptateur de tuyau

S’assurer que le joint

torique est bien installé

dans sa rainure.

Colliers de tuyau

Buse de gaine

Tuyau d’installation

à distance

• 50024917-001 = Ensemble de tuyau de

raccordement de 3 m (10 pi)

• 50024917-002 = Ensemble de tuyau de

raccordement de 6 m (20 pi)

69-2036EFS—07 0

Insérer la buse et la tourner dans le

sens horaire pour que le joint entre la

buse et le TrueSTEAM soit étanche.

Page 43

M24766

3

M24767A

M24768

Humidificateur à injection directe TrueSteam

InsTallaTIon à dIsTanCeInsTallaTIon à dIsTanCe

Placer le gabarit autocollant à l’emplacement

d’installation à distance.

Remarque : L’humidificateur TrueSTEAM pèse entre

5,4 à 6,8 kg (+/- 1 kg) (12 à 14 lb (+/- 2 lb) une fois

qu’il est rempli d’eau. S’il est monté sur un mur de

plâtre ou de placoplâtre, installer un des côtés de

l’humidificateur sur un montant du mur.

4

Poser 4 ancrages de mur dans des trous pilotes et

fixer le support en position.

5

Pousser l’humidificateur vers le bas

pour bien le fixer sur le support.

69-2036EFS—07

Page 44

Guide d’installation

M24770

M24771

InsTallaTIon à dIsTanCe

Découper un trou de 4,4 cm (1 3/4 po) dans la

gaine. Installer le joint fourni. Insérer la buse à

6

7

distance dans la gaine. Fixer la buse à la gaine

avec 4 vis à métal autotaraudeuses no 8.

Installer le tuyau

d’installation à distance

entre l’humidificateur et la

buse. Ce tuyau doit avoir

une longueur maximale

de 6 m (20 pi).

Un dégagement minimal de 3 po

est requis entre la sortie de la

buse et la paroi de la gaine

8

9

Si le tuyau à distance doit passer

dans un élément de structure (par. ex.

un mur ou un plafond), découper un

trou d’au moins 4,4 cm (1 3/4 po) pour

l’installer.

Sceller les espaces sans chauffage

ni refroidissement avec une rondelle

(non fournie) ou du calfeutrage.

Fixer le tuyau d’installation à distance à la buse

et à son adaptateur en le glissant par-dessus l’un

et l’autre. Fixer le tuyau aux deux bouts avec les

colliers fournis.

IMPORTANT :

Installer le tuyau avec une pente ascendante continue. Dans le cas d’une installation horizontale,

s’assurer de conserver une pente ascendante de

10,5 cm par mètre (2 po par pied). Fixer le tuyau à

tous les 30 cm (12 po) avec les colliers fournis.

Dans le cas d’un long circuit horizontal, soutenir le

tuyau en le fixant sur un montant de 61 x 122 cm

(2 x 4 po), un profilé en U ou une cornière, installés

selon la pente appropriée. Si une section du tuyau

doit être installée avec une pente descendante,

consulter les instructions aux pages 35 et 37.

69-2036EFS—07 2

Page 45

Humidificateur à injection directe TrueSteam

M27428

M24852

M24772

10

A

PlombeRIe

Insérer le tuyau d’eau de 64 mm (¼ po) dans le filtre. Appliquer une légère pression

pour assurer l’étanchéité.

B

Insérer le tuyau d’eau de 64 mm (¼ po) dans la vanne anti-refoulement. Appliquer

une légère pression pour assurer l’étanchéité.

C

Raccorder un tuyau d’évacuation de 1,3 cm (1/2 po). Fixer le tuyau d’évacuation au

raccord cannelé avec un collier à tuyau.

D

Couper l’alimentation en eau. Installer un tuyau d’alimentation en eau en cuivre ou

en plastique de 0,64 cm (1/4 po).

A

1/4-in. copper

or plastic

Description Numéro

Filtre de tuyau à eau (compris)

(requis pour la garantie)

Vanne anti-refoulement

(comprise) (requise)

Vers l’alimentation en eau

B

50028044-001

50030142-001

C D

Vue agrandie

Pente

continue

L’eau de vidange peut

être chaude. S’assurer

que la sortie du drain

n’est pas exposée. Vérifier

Tuyau

d’évacuation

de 1,3 cm

(1/2 po)

Tuyau d’alimentation

en eau de 0,64 cm

(1/4 po)

si le drain et la pompe à

condensats sont conçus

pour les applications où

la température de l’eau

peut atteindre 49 °C

AVERTISSEMENT

L’eau chaude à une température qui dépasse 120 °F

(49 °C) peut causer des brûlures par ébouillantage.

(120 °F).

Autres options de raccordement du tuyau d’alimentation en eau. Voir les instructions correspondant à l’option choisie.

Raccord en T

Pointeau

Robinet de

sectionnement

(vendu séparément)

Robinet-vanne à étrier

Vers l’humidificateur

Vers l’humidificateur

Tuyau d’alimentation en eau

Vérifier tous les raccords des tuyaux pour s’assurer qu’il n’y a aucune fuite, une fois le

TrueSTEAM en marche.

3 69-2036EFS—07

Page 46

Guide d’installation

M24754

M24895

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

M24893

CÂblage

Desserrer la vis imperdable du

11

MISE EN GARDE : Risque de chocs électriques.

Avant d’effectuer le raccordement aux bornes de l’appareil

CVCA, débrancher l’appareil. S’assurer que l’humidificateur

est débranché.

Bornes basse tension

24V Alimentation c.a. pour un humidistat électronique.

HUM Bornes basse tension de l’humidistat ou du thermostat

C, R Se raccordent aux bornes du transformateur de l’appareil

RT Se raccorde à la borne R du thermostat, qui sert

GT, La borne GT se raccorde à la borne G du thermostat.

GF

EXT Si la mise en marche du ventilateur n’est pas commandée

Pattes

Faire passer les fils entre les pattes ouvertes de l’attache-fil et dans l’encoche à l’arrière du

Encoche

boîtier. S’assurer que les fils sont bien fixés et ne nuisent pas au montage du couvercle.

couvercle. Enlever le couvercle

en le glissant vers l’avant.

commandant le fonctionnement de l’humidificateur.

CVCA ou aux bornes R et C du transformateur du relais de

commande du ventilateur. Permet d’assurer que l’appareil

CVCA est en marche avant de faire fonctionner l’humidificateur.

Cette fonction peut être désactivée en changeant le réglage du

commutateur DIP 4 (voir à la page 46).