Page 1

Construction

The sludge and air separator consists of:

•Housing

• Connection piece incl. couplings and seals

• Quick bleeder

• Blind plug including magnetic separator

• Foam insulation jacket

•Ball valve

HF49

Sludge and Air Separator

Product specification sheet

Application

The sludge and air separator serves to separate sludge and air

from the heating system. It is equipped with a sludge and contamination reduction feature that functions according to the

cyclone principle. This guarantees an effective separation of the

particles.

There is an optional phosphate cartridge available to prevent

corrosion in aluminium-free heating systems.

Special Features

• swivel connection for vertical or horizontal installation

• quality insulation shell to prevent heat loss

• integrated quick bleeder

• integrated magnet for separation of ferromagnetic metals

Range of Application

The sludge and air separator is installed in the heating circuit (feed

and return line) and serves to separate sludge and air from the

heater water.

Technical Data

Connection diameter DN25

Nominal pressure (PN) 10 bar

Operating pressure max. 10 bar

Nominal flow 3,6 m³/h

Pressure loss during nominal flow rate 0,2 bar

k

-value 7,8 m³/h

vs

Operating temperature max. 90°C

Materials

• Dezincification resistant brass housing

• Connection piece made of dezincification-resistant brass

• Quick bleeder made of dezincification-resistant brass

• Foam insulation made of PE foam

• EPDM sealing washers

EN0H-1547GE23 R1009 • Subject to change

www.honeywell.com 1

Page 2

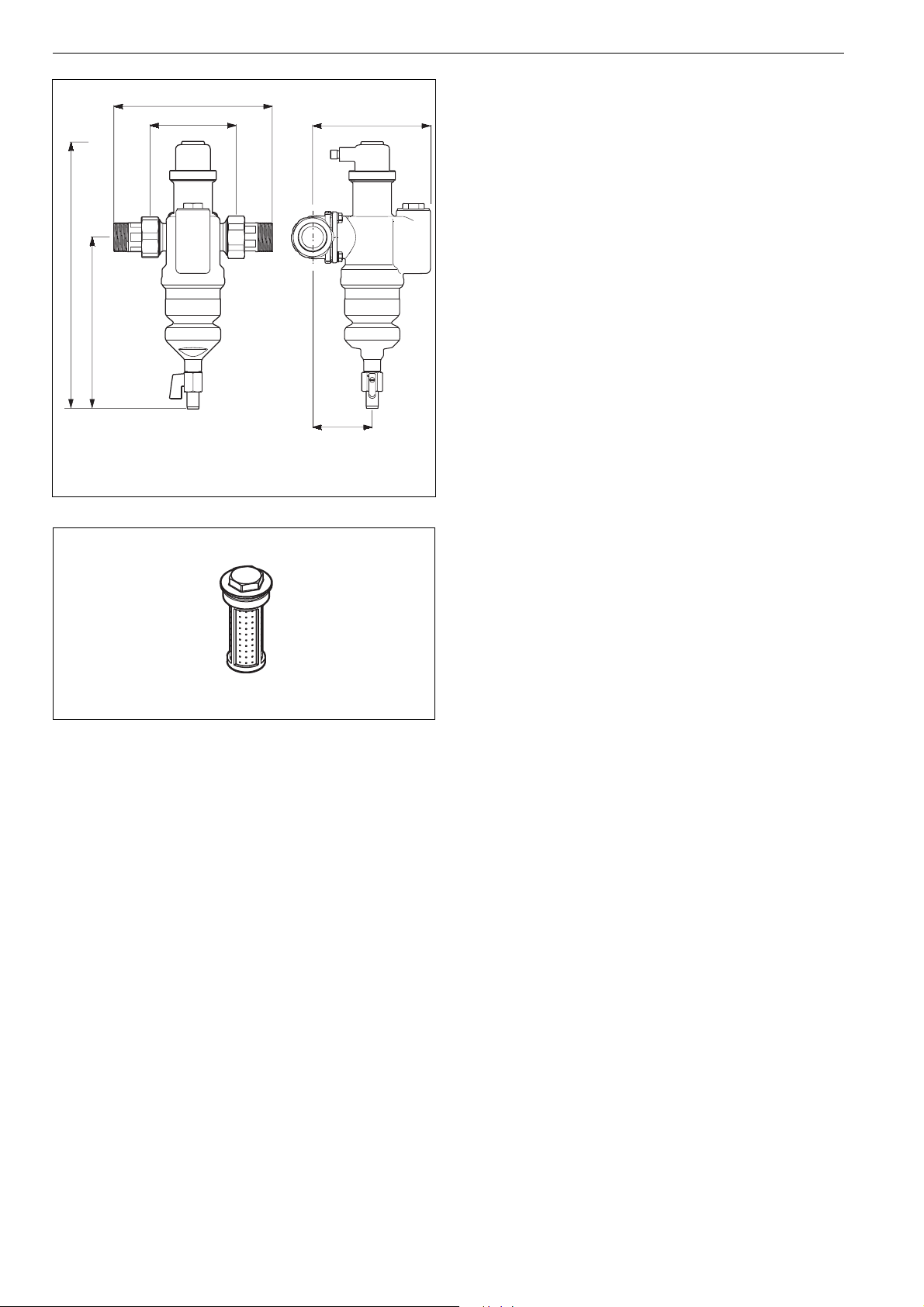

HF49 Sludge and Air Separator

184

100

138

Method of Operation

The heater water separator serves to separate sludge and air

from the heater system.

It is equipped with a sludge and contamination reduction that

functions according to the cyclone principle. This guarantees an

effective separation of the particles.

The heater water separator is equipped with a quick bleeder for

the air separation. If there is air in the system, it will rise to the

highest point of the heater water separator. The water level drops

there, the integrated floater pulls the floater arm down and

330

thereby opens the sealed area. The air bleeds out whereby the

water level rises again and the sealed area is closed again.

310

The optionally available phosphate cartridge counters the corrosion in the heater system. This dosing serves as an additional

protection of the heater system; not as a replacement of the

basic conditioning of the heater water by inhibitors.

Options

70

HF49-1A= Standard version

Accessories

PE49 Phosphate cartridge

Phosphate cartridge for protection of the heater system

against corrosion.

Use only in heater systems without aluminium materials.

PE49

EN0H-1547GE23 R1009 • Subject to change

2 www.honeywell.com

Page 3

Installation examples

HF49 Sludge and Air Separator

HF49 in feed line

Installation Guidelines

• The sludge and air separator is not suited for:

o the separation of oils greases, solvents, soaps and other

lubricating media

o the separation of water-solvent materials

• The sludge and air separator is installed in the heating circuit

(feed and return line)

• The heating system needs to be rinsed and filled

• The national installation regulations, general guidelines and

technical data must be observed during the assembly

• The installation site has to be frost-free and the protection of

the device from chemicals, paints, solvents, vapours and

environmental influences must be guaranteed

• A course dirt separator needs to be installed up front for

water with course dirt particles

• To ensure the bleeding of the air, the sludge and air separator

has to be installed with the quick bleeder upwards

• The separator has to stand vertically; the connection piece

can be built into horizontal and vertical lines

• Make sure the seals fit properly. The pressure-sealing tightening of the screws has to be done cross-wise

• Install stop valves ahead and following the sludge and air

separator

o This makes it possible to maintain the sludge and air sepa-

rator easily without draining the heating system

• Mount the sludge and air separator at easily accessible

points in the system

HF49 in return line

Typical Applications

For installation in the heating circuit to filter out dirt and sludge

particles and bleed off air.

This prevents malfunctions and damage to radiators, valves,

pumps, and heat generators.

A high efficiency is ensured for the whole heating system.

EN0H-1547GE23 R1009 • Subject to change

www.honeywell.com 3

Page 4

HF49 Sludge and Air Separator

1

Spare Parts

Sludge and Air Separator HF49 (from 2008 onwards)

1 Venting insert EE49

2 Ball valve KH49

available as

accessorie

2

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Rolle, Z.A. La

Pièce 16, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1547GE23 R1009

Subject to change without notice

© 2009 Honeywell GmbH

Loading...

Loading...