Page 1

HCE 80/HCE 80R

Underfloor Heating

Controller

Installation and Operation

Zoneregelaar

Montage en gebruik

HCC 80/HCC 80R

Page 2

Page 3

ENGLISH 3

NEDERLANDS 17

Page 4

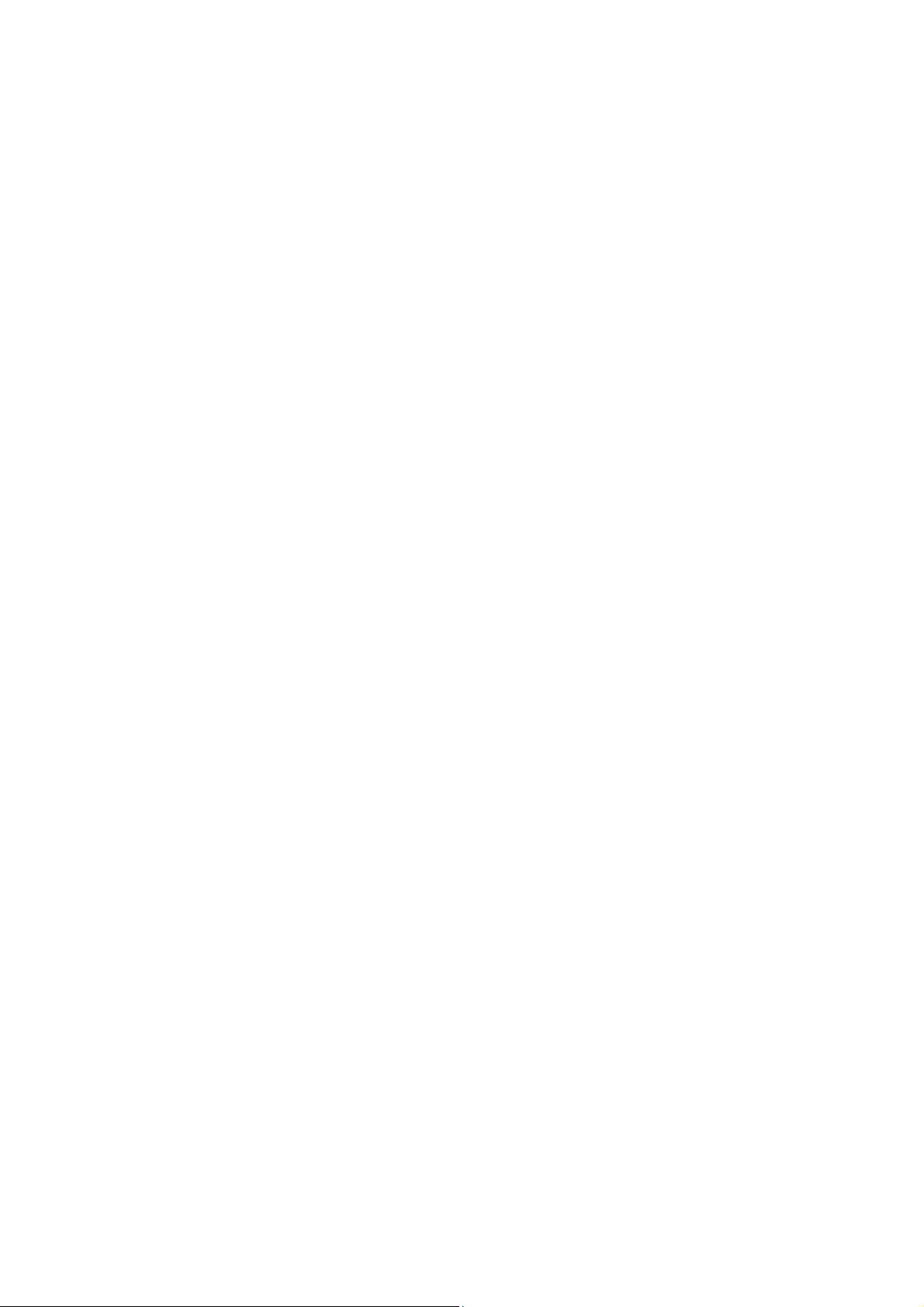

1x

8x

8x

1x

1x

1x

1x

Fig.1

Fig.2

B+ H/C TW

HRA80

MCR

Panther

Swite

9 10

Power

12

1

2

14

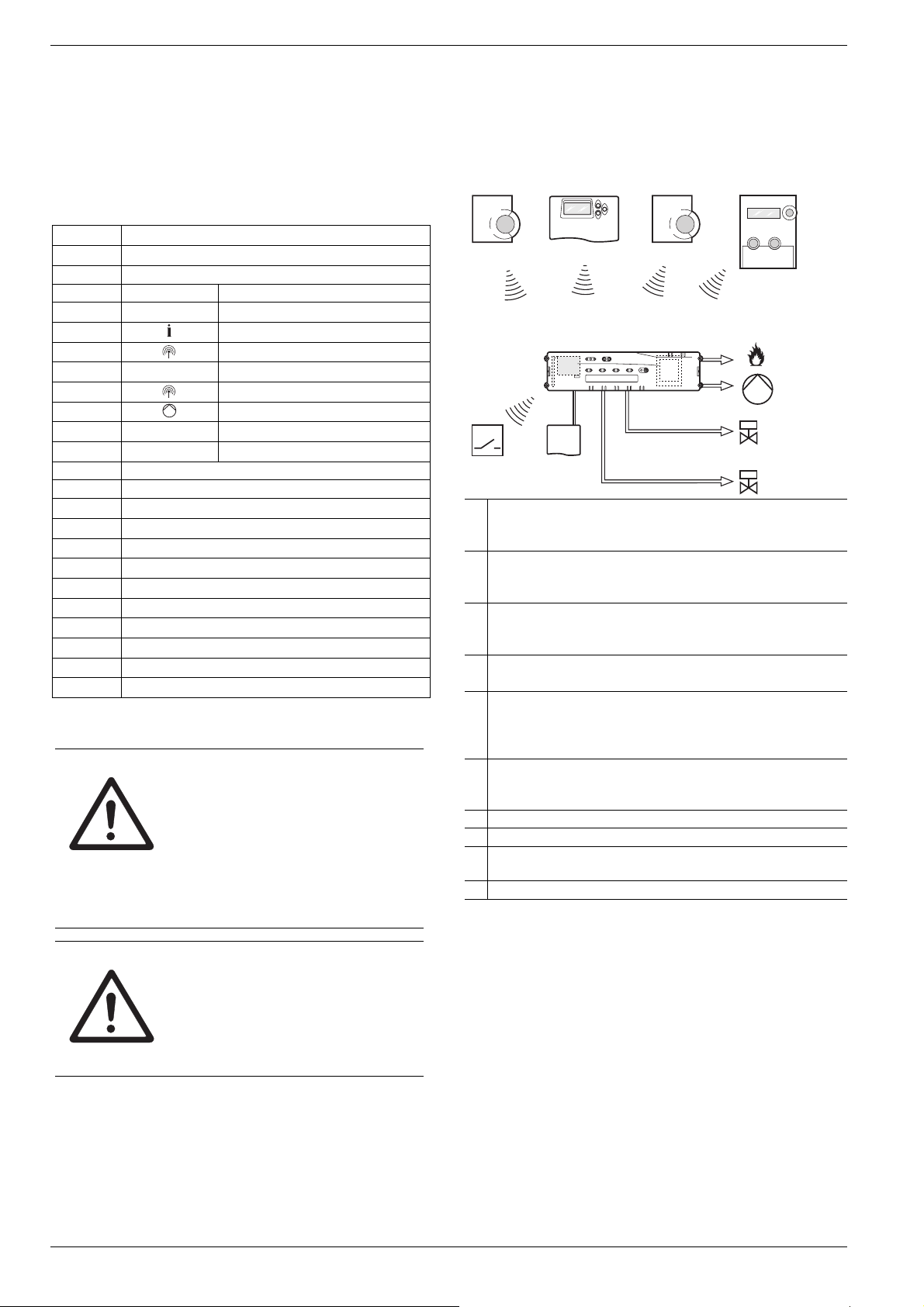

2 3 4 51

Mode

345678

3

4

5

6

Z3Z1 Z2 Z4 Z5 Z6 Z7 Z8

Fig.3

7

8

678

11

Fig.4

13

12

L

N

PE

L

L

PE

5.5mm

5.5mm

Fig.5 Fig.6 Fig.7

7mm

Page 5

Contents

1. About these instructions ........................................ 4

2. General safety instructions.................................... 4

3. Overview ............................................................... 4

3.1. Differences between the individual device types ... 5

3.2. Function overview ................................................. 5

4. Creating a zoning plan .......................................... 5

4.1. Specifying temperature zones ............................... 5

4.1.1. Example of zone divisions..................................... 5

5. Installation ............................................................. 5

5.1. Wall installation ..................................................... 6

5.2. DIN rail installation ................................................ 6

5.3. Installing components............................................ 6

6. Installation and configuration................................. 6

6.1. Opening the housing ............................................. 6

6.1.1. Plugging in the expansion module (optional)......... 6

6.1.2. Setting the thermal actuator type........................... 6

6.2. Cabling connections .............................................. 6

6.2.1. Permissible cable types and lengths ..................... 6

6.2.2. Connecting power cable........................................ 7

6.2.3. Connecting the thermal actuators.......................... 7

6.3. Boiler feedback...................................................... 7

6.3.1. Connecting the boiler feedback via an analog

output (only HCE 80/ HCC 80) to external

controllers.............................................................. 7

6.3.2. Implementing a boiler feedback via a wireless

connection (with HC60NG/R6660D)...................... 8

6.3.3. Implementing a boiler feedback with an

integrated relay 42 V AC, floating contact (only

HCE 80R/HCC 80R).............................................. 8

6.4. Pump..................................................................... 8

6.4.1. Pump control ......................................................... 8

6.4.2. Connecting a pump (230 V AC)............................. 8

6.4.3. Installing an external antenna................................ 8

6.4.4. Closing the housing of the underfloor heating

controller ............................................................... 8

7. Commissioning...................................................... 8

7.1.1. Commissioning the underfloor heating controller .. 8

7.2. LED indicators on underfloor heating controller..... 9

7.3. Checking the signal strength of the radio

transmission .......................................................... 9

7.4. Operating modes of the Underfloor Heating

controller ............................................................... 9

7.4.1. Normal mode......................................................... 9

7.4.2. Fault mode ............................................................ 9

7.4.3. Installation mode ................................................... 9

7.4.4. Device display ....................................................... 9

7.5. Cooling function..................................................... 9

7.5.1. Activating the cooling function............................... 9

7.5.2. Switching between heating and cooling ................ 9

7.5.3. Assigning room names.......................................... 9

8. Assigning zones and allocating room names

(teach-in) ............................................................... 9

8.1. Allocating the setpoint adjuster HCW 82, room

temperature sensor HCF 82.................................. 9

8.2. Allocating Hometronic Manager HCM 200D........ 10

8.3. Assigning the room control system CM67z ......... 10

8.3.1. Teach-in room temperature sensor ..................... 10

8.3.2. Teach-in time program CM67z (Zone 1)............. 10

8.3.3. Teach-in time program CM67z (Zone 2)............. 10

8.4. Time program for cooling function ....................... 11

8.5. Allocating relay modules for controlling the heat

generator ............................................................. 11

8.5.1. Teach-in for boiler feedback HC60NG/R6660D .. 11

8.6. Cancelling the assignment .................................. 11

8.6.1. Cancelling the assignment of the setpoint

adjuster to a temperature zone............................ 11

8.6.2. Cancelling assignment of the room name or

time program to the temperature zone ................ 11

8.7. Saving the settings on the Hometronic Manager . 11

9. Checking the configuration .................................. 11

9.1. Checking radio transmission ............................... 11

9.1.1. Sending test signals ............................................ 11

9.1.2. Receiving test signals.......................................... 11

10. Displaying faults ..................................................12

11. Completing commissioning.................................. 12

11.1. Note to installer.................................................... 12

11.2. Resetting underfloor heating controller to state

of delivery ............................................................ 12

12. Changing the fuse ............................................... 12

13. Appendix ............................................................. 12

13.1. Glossary .............................................................. 12

13.2. Help with problems.............................................. 13

13.3. Technical data ..................................................... 13

13.4. Device and function definition in accordance

with EN 60730-1.................................................. 13

13.5. Zoning plan (sample)........................................... 14

13.6. WEEE directive 2002/96/EC Waste Electrical

and Electronic Equipment directive .....................14

13.7. Brief instructions.................................................. 15

13.7.1. Navigation and function overview ........................ 15

Contents

3

Page 6

About these instructions

1. About these instructions

Fold out the left-hand cover. This shows all the operating

elements and connections. Leave the cover folded out while

reading further.

Technical terms are explained in the glossary (Page 12).

Legend for fold-out page

Fig. 1 Scope of delivery

Fig. 2 Opening housing

Fig. 3 Display and operating elements

Number Labelling Function

(1)

(2)

(3)

(4)

(5)

(6)

Power

Mode

Power supply on/off

Information display

Installation display

Operating mode button

Installation button

Pump on/off display

(7) 1...8 Zone LEDs

(8) Labelling of Zones 1...8

Fig. 4 Connections

Number Function

(9) I/O connector

(10) Switch for setting normally open/normally closed

(11) Slot for expansion module HCS 80

(12) Connector for supply voltage, pump

(13) Fuse

(14) Slot for internal antenna

(Z1 - Z8) Connector for Zones 1...8

Fig. 5 I/O connector

Fig. 6 Connector for Zones 1...8

Fig. 7 Connector for supply voltage, pump

2. General safety instructions

DANGER

WARNING

Danger to life through electric

shock!

Contacts that are open are live.

► Unplug the power plug before open-

ing the housing.

,

► Have all the work carried out by

authorised specialist personnel.

► Observe the valid VDE regulations

during the installation.

Damage to the underfloor heating

controller!

Short-circuiting through humidity and

moisture.

► Mount the device at a site that is

protected against humidity and moisture.

3. Overview

The floor hearing system is an intelligent system for individual room temperature control. The following overview shows

devices that can operate together with the underfloor heating controller.

(B)

(E)

(I)

(J)

(I)

A Setpoint adjuster HCW 82

Controls the setpoint temperature for each temperature

zone via adjustment dial

B Central operating device CM67z

Controls the room temperature via programmable time

programs

C Room temperature sensor HCF 82

Transmits room temperature information to underfloor

heating controller

D Hometronic Manager HCM 200D

Central operating unit of the house-automation system

E Underfloor heating controller

HCE 80/HCC 80/HCE 80R/HCC 80R

Controls actuators; communicates with setpoint adjusters

and room temperature sensors

F Boiler feedback,

Analog output (only HCE 80/HCC 80) or

Relay output (only HCE 80R/HCC 80R)

G Integrated pump relay

H Thermal actuators

I External antenna HCE 80/HCE 80R

Internal antenna HCC 80/HCC 80R

J Boiler feedback relay HC60NG/R6660D

(C)(A)

(D)

(F)

(G)

(H)

4

Page 7

Creating a zoning plan

3.1. Differences between the individual

HCE 80 HCE 80R HCC 80 HCC 80R

Antenna

Pump

relay

Analog

output

Boiler

feedback

radio

Boiler

feedback

relay

device types

External External Internal Internal

230 V AC

internal

Exists Does not

External

with

HC60NG/

R6660D

Does not

exist

The pump relay 230 V AC is not floating.

230 V AC

internal

exist

External

with

HC60NG/

R6660D

42 V AC/DC Does not

230 V AC

internal

Exists Does not

External

with

HC60NG/

R6660D

exist

230 V AC

internal

exist

External

with

HC60NG/

R6660D

42 V AC/DC

3.2. Function overview

• 5 controllable temperature zones, extendable to 8

• Up to 3 thermal actuators can be connected per zone

• Normally open and normally closed thermal actuators

can be used

• Integrated pump relay

• Boiler feedback

– Analog (only HCE 80/HCC 80)

– Integrated relay with floating contact 42 V AC/DC

(only at HCE 80R/HCC 80R)

– Wireless via relay HC60NG/R6660D

• Underfloor heating controller can be switched between

heating and cooling

• 1 antenna can be used for 3 controllers

• Internal or external antenna can be used

• Rapid mounting by screwless terminals of the thermal

actuators

• Intelligent controlling via fuzzy logic

• Simple diagnosis of the wireless transmission

• Operating state display via LEDs

4. Creating a zoning plan

Within a building rooms (zones) can be controlled with different room setpoint temperatures. The thermal actuators of

the allocated zone (room) are controlled depending on the

room setpoint temperature.

A maximum of 5 temperature zones can be set

for each underfloor heating controller. This number can be increased to 8 by using the expansion

module HCS 80.

A maximum of 3 actuators can be connected in

Temperature zones

(maximum)

8 24 1

16 48 2

24 72 3

Tab. 1: Overview of temperature zones/ underfloor heating controllers

each zone.

Actuators

(maximum)

No. of underfloor

heating controllers

4.1. Specifying temperature zones

► Specify the number of zones and corresponding rooms.

► Allocate the corresponding room device, for example

HCW 82, CM67z, and the required thermal actuators to

each zone.

► Label the room devices and thermal drives for the respec-

tive zone (refer to the fold-out page Fig. 4, Z1...Z8).

4.1.1. Example of zone divisions

kitchen

hall

dining room

living room

bathroom

Explanation of this example:

• The living area is covered by six temperature zones. The

additional module HCS 80 is required for this partitioning.

• The underfloor heating controller controls 8 actuators.

bedroom

toilet

5. Installation

WARNING Insufficient data transfer!

Interference of the radio receiver in the

device through metallic objects and

further radio devices.

► When selecting the operating site

ensure that the distance to radio devices such as radio headphones,

cordless phones, etc. according to

the DECT standard amounts to at

least 1 m.

► Ensure that there is sufficient dis-

tance to metallic objects.

► Select another installation site if the

WARNING

The underfloor heating controller was designed for installation in a distributor box. If insufficient space is available,

select an area where the underfloor heating controller can

communicate with the setpoint adjusters by radio without

interference and that is protected from moisture and water.

The underfloor heating controller can be installed in one of 2

ways:

• Wall installation

• DIN rail installation

radio interference cannot be rectified.

Damage to the underfloor heating

controller!

Short-circuiting through humidity and

moisture.

► Mount the device at a site that is

protected against humidity and moisture.

5

Page 8

Installation and configuration

5.1. Wall installation

Four 4.2 mm holes for installation are located on the underfloor heating controller.

Take the 52 mm installation height of the underfloor heating controller into account. If the underfloor heating controller is installed at a severe

angle, the transformer must be on top to allow for

ventilation.

57

52.0

337

∅

4.2

349.5

Dimensions of underfloor heating controller in mm

► Mark, drill and insert plugs into fastening holes.

► Screw on the underfloor heating controller.

5.2. DIN rail installation

► Place the housing on the DIN

rail from below (1).

► Press the housing upwards

until it snaps into place (2).

5.3. Installing components

Install the components as described in the accompanying

installation instructions.

6. Installation and configuration

DANGER

WARNING Damage to exposed components!

Danger to life through electric

shock!

Contacts that are open are live.

► Unplug the power plug before open-

ing the housing.

► Have all the work carried out by

authorised specialist personnel.

► All wiring must be in accordance with

IEE & Building Regulations.

Destruction of the electronic components through electrostatic discharges.

► Do not touch the components.

► Touch an earthed piece of metal to

discharge static electricity from your

body.

85

6.1. Opening the housing

► Open the housing as shown in Fig. 2 on the fold-out page.

6.1.1. Plugging in the expansion module

(optional)

The expansion module HCS 80 expands the number of

possible temperature zones of the underfloor heating controller from 5 through 8.

► Insert the expansion

module with the adapter

connector into the provided slot.

6.1.2. Setting the thermal actuator type

Only one thermal actuator type can be connected

per underfloor heating controller. If normally open

and normally closed actuators are to be operated, you require two underfloor heating control-

► Check the type of thermal actuator being used.

► Set the switches in accordance with the following table

Switch

position

lers.

The thermal actuators are protected by a ceramic

fuse.

(see the fold-out page, Fig. 4 (10)):

Thermal actuator type

Normally closed

Normally open

Property

Opens the heating circuit if

power is present at its control

input

Opens the heating circuit if

power is not present at its

control input

6.2. Cabling connections

6.2.1. Permissible cable types and lengths

Thermal actuators

Outer cable diameter

Cable length Max. 400 m

Cable cross-section Max. 1.0 mm²

Stripping length 4 mm

Terminal range of

the connectors

Power and pump connection 230 V AC

Outer cable diameter

Cable length Max. 100 m

Cable cross-section Max. 1.5 mm²

Stripping length 7 mm

Terminal range of

the connectors

Min. 3.5 mm/Max. 5.3 mm

0.07–1.33 mm²; flexible wire

Min. 8.0 mm/Max. 11 mm

0.50–2.50 mm²; flexible/fixed connection

0.50–1.50 mm²; flexible, with wire end

ferrule

6

Page 9

Installation and configuration

Antenna connection

Cable length Max. 30 m

Cable cross-section

JE-LiYCY 2x2x0.5 mm²;

JE-Y(St)Y ∅2x2x0.8 mm;

2x0.5 mm²

Stripping length 5.5 mm

Terminal range of

0.07–1.54 mm²

the connectors

Heating/cooling, boiler feedback

Cable length Max. 100 m

Cable cross-section

JE-LiYCY 2x2x0.5 mm²;

JE-Y(St)Y ∅2x2x0.8 mm;

2x0.5 mm²

Stripping length 5.5 mm

Terminal range of

0.07–1.54 mm²

the connectors

Tab. 2: Permissible cable types and lengths

6.2.2. Connecting power cable

DANGER

► Select a suitable cable in accordance with Table 2 for the

power supply.

► Strip the connections 7 mm (see fold-out page, Fig. 7).

Danger to life through electric

shock!

Contacts that are open are live.

► Ensure that the cable is deenergized.

► Lay the actuator cables to the distribution box.

► Connect the actuator wires.

► Break out the openings for

the cables on the housing

using a diagonal cutter.

► Strip the connections 5.5 mm (see

fold-out page, Fig. 6).

► Insert the connecting cables of the

actuators into the cable openings of

the connectors.

► Close the terminators.

► Plug the connectors into the sockets of the corresponding

zones (see the fold-out page, Fig. 4 (Z1 -Z8)).

► Clamp the cables into the stress relief clamp.

► Secure the cable with the cable clamp.

Installation Disassembling

► Connect the cable to the connector in

accordance with the graphics (see

L

fold-out page, Fig. 4 (12)).

► Plug the connector into Socket 12

(see the fold-out page, Fig. 4).

► Secure the cable with the cable clamp.

Installation Disassembling

6.2.3. Connecting the thermal actuators

WARNING

Damage to the underfloor heating

controller!

► Take the technical data into account

at thermal actuators: Total of 3 A

maximum current, 250 mA continuous current per zone.

Each zone can control up to 3 actuators. 3 actuators can be

connected directly for zone 1, 2 for zone 2 and 1 each for

zones 3 through 5. One connection for the expansion module is available for each of the zones 6 through 8.

If more than 11 thermal actuators are to be connected to the

underfloor heating controller, the cables of the actuator must

be wired in a distribution box.

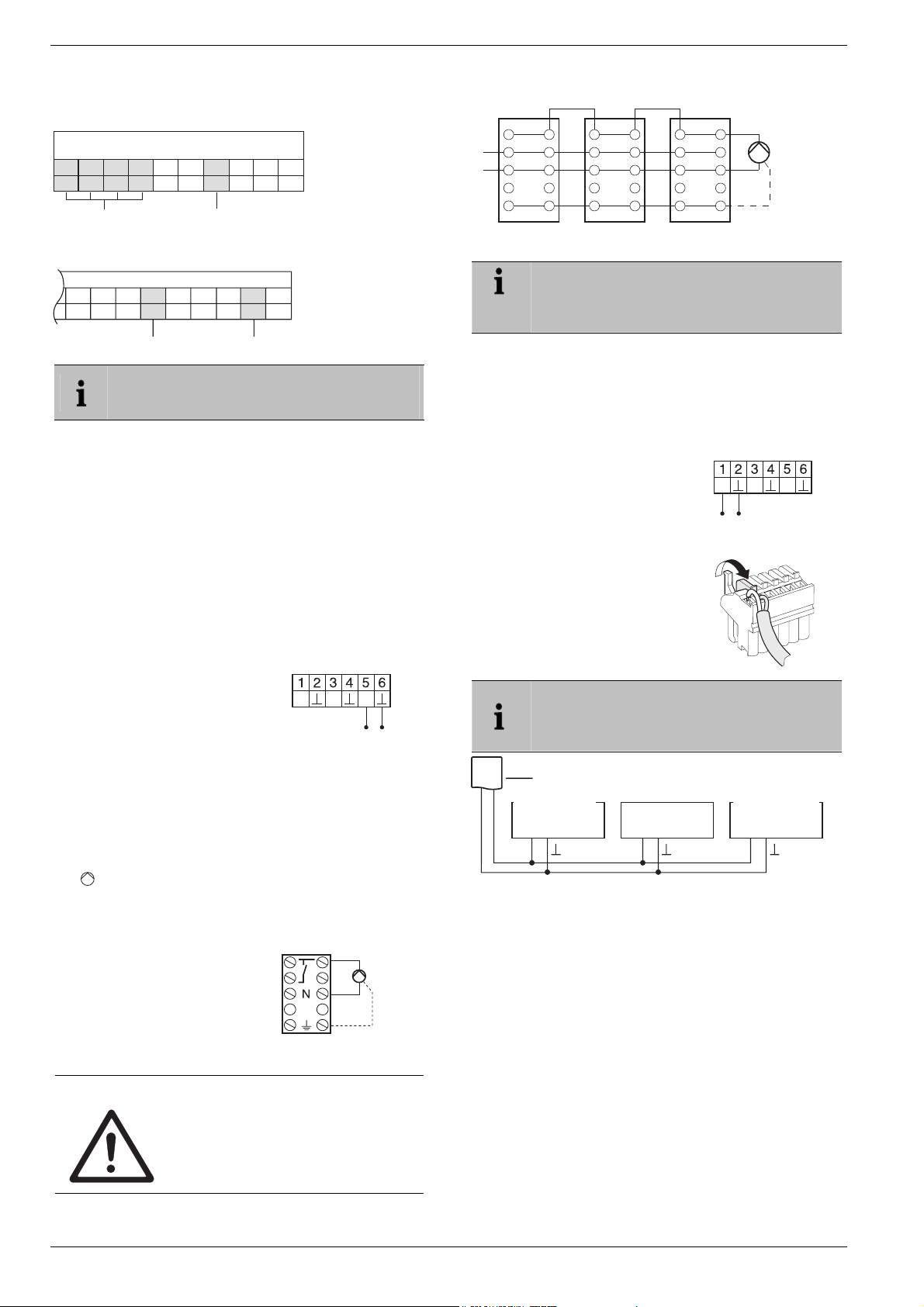

6.3. Boiler feedback

6.3.1. Connecting the boiler feedback via

an analog output (only HCE 80/

HCC 80) to external controllers

The analog output voltage changes depending on the valve

position.

► Strip the connections 5.5 mm (see fold-out page, Fig. 5).

► Connect the boiler feedback

in accordance with the following graphics (see the

fold-out page, Fig. 4 (9)).

Boiler feedback is possible with the controllers MCR 200,

MCR 40, ZG 252 N, Panther and Smile.

► Connect the controller inputs in accordance with the en-

closed instructions (earth input to Terminal 6, temperature

input to Terminal 5 of the underfloor heating controller).

TW

H/C

B+

7

Page 10

Commissioning

A

With controller MCR 40, the temperature and earth inputs

are located at the following terminals:

Earth input

MCR 40

Low-voltage side

Temperature input

TW

78910456123

With controller ZG 252 N, the temperature and earth inputs

are located at the following terminals:

ZG 252 N

456 10

789 1112

Earth input

TW

Temperature input

Depending on the design, the temperature selector and earth inputs are found on different terminals of the controller MCR 200.

6.3.2. Implementing a boiler feedback via

a wireless connection (with

HC60NG/R6660D)

The relay is switched on and off depending on the valve

setting.

6.3.3. Implementing a boiler feedback with

an integrated relay 42 V AC, floating

contact (only HCE 80R/HCC 80R)

The relay is switched on and off depending on the valve

setting.

► Strip the connections 5.5 mm (see fold-out page, Fig. 5).

► Connect the boiler feedback

in accordance with the following graphics (see the fold-out

page, Fig. 4 (9)).

B+

H/C

TW

6.4. Pump

6.4.1. Pump control

As soon as a zone is active, the pump is activated with a

time delay. The pump switches off as soon as all the valves

are closed.

LED (see fold-out page, Fig. 3 (6)) lights up green

The

when the pump is running.

6.4.2. Connecting a pump (230 V AC)

► Strip the connections 7 mm

(see fold-out page, Fig. 7).

► Connect the pump in accor-

dance with the following

graphics (see the fold-out

page, Fig. 4 (12)).

WARNING

Damage to the underfloor heating

controller!

Short-circuit due to incorrect installation.

► Connect all the controllers to the

same phase.

L

Pump

PE

Controller 1

L

N

PE

6.4.3. Installing an external antenna

Controller 2 Controller 3

Pump

N

PE

Up to three underfloor heating controllers can be

connected to an antenna. When selecting the

operating site ensure that the function of the

antenna is not impaired.

► Only install the external antenna outside metal housings

(e.g. control cabinets).

► Install the antenna at a suitable location near the under-

floor heating controller. Ensure that a radio connection to

the setpoint adjuster exists.

► Strip the connections 5.5 mm (see fold-out page, Fig. 5).

► Connect the antenna in accor-

dance with the following graphics

(see the fold-out page, Fig. 4 (9)).

B+ H/C

TW

Shield to 2

Second conductor to 1

► Close the terminals.

If several underfloor heating controllers are operated simultaneously, an antenna (internal or

external) may only be connected to one controller.

ntenna

Controller 1

Regler 1 Regler 2 Regler 3

Controller 2

Controller 3

B+ B+ B+

6.4.4. Closing the housing of the underfloor heating controller

► Place the housing cover back on (see fold-out page).

► Snap the left and right snap lock back into place.

► Tighten the screws on the top.

7. Commissioning

During commissioning, setpoint adjusters – and the time

programs of the radio setpoint adjuster CM67z if applicable

– are assigned to the temperature zones of the underfloor

heating controller. A room name is defined for each temperature zone at the Hometronic Manager.

7.1.1. Commissioning the underfloor heating controller

► Switch on the operating voltage.

The mains voltage LED (POWER) lights up.

8

Page 11

Assigning zones and allocating room names (teach-in)

7.2. LED indicators on underfloor heating controller

The LEDs on the underfloor heating controller indicate the

operating mode of the Underfloor Heating controller and the

installed temperature zones.

Meaning of the 3 LEDs (see fold-out page, Fig. 3 (1,2,3)):

LED Display Meaning

POWER (green) Lights up Normal mode

(red)

Flashing Antenna fault display

(yellow)

Lights up Group alarm

Rapid

flashing

No device installed

7.3. Checking the signal strength of the

radio transmission

The signal strength of the radio transmission can be

checked for the transmitter and the receiver. Refer to Section "Checking radio transmission

" on Page 11.

7.4. Operating modes of the Underfloor

Heating controller

7.4.1. Normal mode

In normal mode the LEDs 1...8 show the position of the

actuators, see Fig. 3 (7) on the fold-out page:

Green Thermal drive opened

Off Thermal drive closed

7.4.2. Fault mode

The various faults are indicated by the zone LEDs in fault

mode. Refer to Section "Displaying faults" on Page 12.

7.4.3. Installation mode

In installation mode temperature zones are assigned to

the setpoint adjusters and the Hometronic Manager. Refer to Section "Assigning zones and allocating room

names (teach-in)" on Page 9.

7.4.4. Device display

The device display shows which devices are assigned to

the underfloor heating controller. Refer to Section

"Checking the configuration" on Page 11.

7.5. Cooling function

If the underfloor heating controller is used as a cooling regulator, this function has to be activated once during installation.

7.5.1. Activating the cooling function

► Keep the Mode button pressed for at least 4 seconds.

LED shows whether heating or cooling mode is

The

activated:

LED lights up green

LED lights up red

► Change the setting by pressing the installation button .

Cooling mode active

Heating mode active

The underfloor heating controller switches back

to normal mode automatically after 60 seconds.

You can also exit the installation mode by pressing the Mode button.

7.5.2. Switching between heating and

cooling

Switching between heating and cooling is carried

out via the changeover contacts 3 and 4.

► In order to activate the cool-

ing function connect the

changeover contacts 3

and 4, (see fold-out page,

Fig. 4 (9)), e.g. through an

external switch.

B+ H/C

External switch

TW

7.5.3. Assigning room names

► Enter the room names in the zoning plan.

► Press the installation button

flashes.

The LED of zone 1 flashes red.

► Allocate the setpoint adjuster.

► Press the installation button

The LED of zone 1 flashes green.

► Allocate a time program for Heating.

► Press the installation button .

The LED of zone 1 flashes yellow.

► Allocate a time program for Cooling.

Repeat the steps until two room names are assigned to all

the temperature zones.

until the LED of Zone 1

.

8. Assigning zones and allocat-

ing room names (teach-in)

The following section explains how you can assign the various components to a temperature zone and allocate room

names if a Hometronic Manager is used.

Only one setpoint adjuster can be assigned to a

temperature zone. If a room temperature sensor

HCF 82 is combined with a remote setpoint adjuster HCW 82, i.e. assigned to the same zone,

first assign the remote setpoint adjuster and then

the room temperature sensor.

If the installation button at the underfloor heating controller is not pressed for 4 minutes, the

underfloor heating controller reverts automatically

8.1. Allocating the setpoint adjuster

In the following example the setpoint adjuster HCW 82 is

assigned to Zone 1. Subsequently the room name "Living" is

assigned to Zone 1 in the time program of the Hometronic

Manager.

► Keep the zoning plan at hand.

► Keep the installation button

to normal mode.

HCW 82, room temperature sensor

HCF 82

at the underfloor heating

controller pressed for 2 seconds.

LED lights up. The LED of Zone 1 flashes red.

The

9

Page 12

Assigning zones and allocating room names (teach-in)

The underfloor heating controller is in installation mode

and waits for the signal from the setpoint adjuster.

In order to assign the setpoint adjuster to a different zone, press the installation button until

the LED of the desired zone flashes red.

► Press the Send button of the setpoint adjuster.

The setpoint adjuster is assigned to Zone 1.

The LED of the selected zone lights continuously red.

If no time program is active, the underfloor heating controller operates with a basic value of 20°C

(heating mode) or 26°C (cooling mode). Please

refer to Page 11 for information about checking

the configuration.

8.2. Allocating Hometronic Manager

► Press the installation button at the underfloor heating

► Select the desired room name, e.g. LIVING, in the Settings

► Press the Input button.

► Enter the room name in the zoning plan.

► Repeat the steps until a room name is assigned to all the

► Press the installation button

The underfloor heating controller is back in normal mode.

HCM 200D

For information on installing the device please

read the HCM 200D operating instructions.

controller again.

The LED of the selected zone flashes green. The underfloor heating controller waits for a signal from the

Hometronic Manager.

> Installation > Heating/Cooling menu

LIVING *

A * appears after "LIVING".

The LED on the underfloor heating controller in Zone 1

lights up green. The name "LIVING" has been assigned

to temperature zone 1.

temperature zones.

guishes.

If the installation button is not pressed for 4 minutes, the underfloor heating controller reverts to

normal mode.

The assigned temperature zones remain stored

in the underfloor heating controller, even after a

power failure.

DINING

KITCHEN

BEDROOM

until the LED extin-

8.3. Assigning the room control system

CM67z

8.3.1. Teach-in room temperature sensor

For information on installing the device please

read the CM67z operating instructions.

The CM67z operating unit has an integrated temperature

sensor for Zone 1. The function of the sensor is specified by

parameter 7:tS in the installation mode:

► Set parameter 7:tS to the setting "2".

► Set parameter 17:SU to the setting 0 (only HR 80) or 2

(HR 80 and R6660D).

The integrated sensor is now used to measure and control the room temperature in Zone 1.

10

Information about the parameter settings of the

CM67z can be found in the corresponding operating instructions.

► Move the slide switch at the operating unit CM67z to the

position OFF. Move the buttons TEMP

, TEMP and

PROG 1 together in order to activate the teach-in mode

for Zone 1.

The following is displayed at the

CM67z:

► Keep the installation button at the underfloor heating

controller pressed for 2 seconds.

LED lights up. The LED of Zone 1 flashes red.

The

The underfloor heating controller is in installation mode

and waits for the signal from the CM67z.

In order to assign the CM67z to a different zone,

press the installation button until the LED of

the desired zone flashes red.

► Send the teach-in signal by pressing the button .

8.3.2. Teach-in time program CM67z

(Zone 1)

► Press the installation button at the underfloor heating

controller again.

The LED of zone 1 flashes green.

► Send the teach-in-signal by pressing the button .

The LED of the selected zone lights continuously green.

8.3.3. Teach-in time program CM67z

(Zone 2)

No internal sensor is available at CM67z for Zone

2. You have to assign an external sensor

(HCF 82) to the zone (see Allocating the setpoint

adjuster HCW 82, room temperature sensor

► Move the slide switch at the operating unit CM67z to the

► Press the button MAN

► Press the installation button at the underfloor heating

► Send the teach-in-signal by pressing the button .

HCF 82, chapter 8.1).

position OFF. Move the buttons TEMP

, TEMP and

PROG 1 together in order to activate the teach-in mode

for Zone 1.

in order to switch the operating

unit CM67z to the teach-in mode for Zone 2.

The following is displayed at the

CM67z:

controller again briefly.

LED lights up. The LED of the selected zone

The

flashes green.

The underfloor heating controller is in installation mode

and waits for the signal from the CM67z.

In order to assign the CM67z to a different zone,

press the installation button until the LED of

the desired zone flashes green.

The LED of the selected zone lights continuously green.

Page 13

Checking the configuration

8.4. Time program for cooling function

If the cooling function was activated (see "Cooling function",

Page 9), a separate time program for heating and cooling

can be assigned for each zone (e.g. "Heat living", "Cool

living").

The time programs and setpoint values are activated by the

heating or cooling switchover contact.

The time program for heating is active when the connection

at terminal 3 and 4 is open at connector 9 (see fold-out

page, Fig. 4 (9)).

If terminals 3 and 4 are connected, time cooling time program becomes active.

If no time program for cooling is assigned to a

zone, the standard room setpoint temperature is

26°C.

8.5. Allocating relay modules for controlling the heat generator

Depending on the heat requirement of the installed rooms

the relay module HC60NG/R6660D controls the heat generator as a function of the valve setting.

8.5.1. Teach-in for boiler feedback

HC60NG/R6660D

► Press the button at the relay module HC60NG/R6660D for

5 seconds in order to activate the mode.

The red LED at the relay module flashes in the rhythm

0.5 sec on, 0.5 sec off.

► Press the installation button

controller briefly.

After successful allocation the red LED of the relay module extinguishes.

► Press the installation button

controller again when leaving the device display.

at the underfloor heating

at the underfloor heating

8.6. Cancelling the assignment

8.6.1. Cancelling the assignment of the

setpoint adjuster to a temperature

zone

► Keep the installation mode pressed for at least 2 sec-

onds in order to access the installation mode.

LED lights up. The LED of Zone 1 flashes red.

The

► Press the installation button

the zone to be removed flashes red.

► Press the Mode button for at least 4 seconds.

The LED of the selected zone extinguishes.

The assignment of the setpoint adjuster to the tempera-

ture zone has been cancelled.

8.6.2. Cancelling assignment of the room

name or time program to the temperature zone

► Keep the installation mode pressed for at least 2 sec-

onds in order to access the installation mode.

The LED

► Press the installation button

the zone to be removed flashes green.

► Press the Mode button for at least 4 seconds!

The LED of the selected zone extinguishes.

lights up. The LED of Zone 1 flashes red.

repeatedly until the LED of

repeatedly until the LED of

The assignment of the room name or the time program to

the temperature zone is cancelled.

8.7. Saving the settings on the Hometronic Manager

The settings at the Hometronic Manager have to be saved

before commissioning is completed.

See: Operating instructions of the Hometronic Manager,

"Adaptation" chapter.

9. Checking the configuration

► Press the installation button .

The LED flashes yellow.

The underfloor heating controller shows up in the device

display.

The colours of LEDs 1...8 always indicate the configuration

of the temperature zones.

Off No device installed

Red

Yellow

Green

► Press the installation button briefly again.

The colours of LEDs 1...8 indicate the assignment of the time

programs to the temperature zones.

Green Time program for cooling assigned

Red Time program for heating assigned

Yellow Time program for heating/cooling assigned

9.1. Checking radio transmission

9.1.1. Sending test signals

The underfloor heating controller can send a test signal to

all the allocated radio receivers in order to test the signal

strength.

► Keep the

You can exit the test mode by pressing any button. After 4

minutes the device changes automatically to normal mode.

9.1.2. Receiving test signals

► Send a test signal to the underfloor heating controller.

Room temperature sensor/setpoint adjuster is

installed

Time program, setpoint adjuster and room temperature sensor are installed

Hometronic Manager or radio setpoint adjuster

CM67z is installed

If the heating/cooling is enabled, information

about the current status can be called up.

Mode and buttons pressed simultaneously

for at least 4 seconds.

The

LED flashes green.

The underfloor heating controller sends a test signal

every 5 seconds to the allocated radio receivers. The

zone LEDs light up briefly during sending.

For information on sending a test signal to the

underfloor heating controller read the instructions

of the corresponding radio transmitter.

When a test signal is received, the LED flashes green.

The zone LED of the corresponding zone indicates the

strength of the received signal by flashing

(1=sufficient…5=strong).

11

Page 14

Displaying faults

10. Displaying faults

If the LED lights up, a fault exists in at least one temperature zone.

The colours of the zone LEDs 1...8 provide information on

the type of fault in the respective temperature zone:

Off No fault

Red

flashing

Yellow

flashing

No connection to the setpoint adjuster, room

temperature sensor

No connection to the setpoint adjuster and

Hometronic Manager HCM 200D or central

operating device CM67z

Green

flashing

No connection to the Hometronic Manager

HCM 200D or central operating device CM67z

The fault display extinguishes as soon as the fault has been

eliminated.

11. Completing commissioning

► Close the housing (see "Closing the housing of the under-

floor heating controller", Page 8).

► Hand over the completed zoning plan and the installation

instructions to the customer.

11.1. Note to installer

After the underfloor heating controller has been commissioned, inform your customer about the heating control

system.

► Explain the function and operation of all the components to

the customer.

► Point out particular features to the customer and ensure

that they are aware of the possibility of expanding their

system.

11.2. Resetting underfloor heating controller to state of delivery

All current assignments are lost if the underfloor

heating controller is reset to the state of delivery.

The underfloor heating controller retains its con-

► Keep the Mode and buttons at the underfloor heating

figuration after a power failure.

controller pressed simultaneously for at least 10 seconds.

After 4 seconds the controller changes over to

test mode Continue to keep the button pressed

until the LED flashes yellow.

The LED lights up yellow (flashes rapidly).

The underfloor heating controller is reset to the state of

delivery.

12. Changing the fuse

► Deenergize the device.

► Open the housing (see "Opening the housing", Page 6).

Only use ceramic fuses of the type 230 V AC;

2.5 A; fast; 5 x 20 mm.

► Remove the holder with the fuse

(Steps 1 to 3).

► Replace the fuse (4) by a new

one.

3

4

2

1

► Insert the holder again:

Inserting (1)

Turn to the right.

► Close the housing (see "Closing the housing of the under-

floor heating controller", Page 8).

13. Appendix

13.1. Glossary

Term Explanation

Boiler feedback

Heating circuit

Hometronic

Hometronic Manager

Integrated Pump

Relay

Room setpoint

temperature

Room temperature

sensor

Setpoint adjuster

Thermal actuator

Time program

The control of the heat generator is

dependent on the amount of heat required.

Totality of all the control and regulating

devices of a temperature zone.

Home automation system from Honeywell.

Central operating device of the Hometronic System.

Controls a pump that is connected to the

underfloor heating controller.

Room temperature that is to be reached.

Detects the room temperature and

transfers it to the underfloor heating

controller.

Detects the actual temperature, changes

the setpoint temperature. Installed in a

user-friendly location in each zone.

Opens and closes a heating circuit. Is

controlled by the underfloor heating

controller.

Pre-defined setpoints and switching

points adjustable at the Hometronic

Manager and at the CM67z.

12

Page 15

Appendix

13.2. Help with problems

Problem Cause/Solution

Power LED does

not light up when

the power is

switched on.

LEDs 1...8 of the

zones do not illuminate green continuously during startup.

LEDs 1...8 of the

zones do not illuminate red continuously during startup.

Rooms are not

heated/cooled.

The LED lights up

red after commissioning.

Room controlled

incorrectly.

The LED flashes

rapidly.

The LED flashes.

Mains voltage not connected.

► Check voltage of electrical outlet.

► Check fuse at underfloor heating

controller.

The room name is not assigned.

► Check whether or not the Hometronic

Manager is installed.

► Check whether or not a room name is

assigned to zone.

► Check the antenna connection.

► Reassign the zone, if applicable.

The setpoint adjuster cannot be assigned.

► Check whether or not batteries in

setpoint adjuster are inserted properly.

► Check wireless connection.

► Check the antenna connection.

► Check heating and inlet temperature.

► Check adaptation to thermal actuator

(see Page 6).

► Check fuse of underfloor heating

controller.

If fuse is defective:

► Check actuators for short circuit.

► Change the fuse.

There is a fault in one of the temperature zones (see Page 12).

► Check wireless connection.

► Check the antenna connection.

► Check whether or not zone is as-

signed correctly.

► Check the batteries of the allocated

devices.

► Check whether or not adjustment dial

of setpoint adjuster is at position 0.

► Check whether or not the adjusting

ring can be turned between -12 and

+12 with the housing cover removed.

► Check whether or not a setpoint

adjuster is assigned to room.

No device installed.

► Install the devices again.

No antenna connected or antenna

defective.

► Check whether or not an antenna is

connected.

If no antenna is connected:

► Connect an antenna.

If an antenna is connected:

► Check the antenna connection.

► If applicable, replace the antenna by

a new one.

13.3. Technical data

Input/Output voltage 230 V AC, 50 Hz

Power consumption

Pump relay

Boiler feedback relay

Thermal actuators

Ambient temperature 0 to 50°C

Storage temperature -20 to +70°C

Humidity 5 to 93 % relative humidity

Frequency 868.3 MHz (transmitter/receiver)

Dimensions 350x82x52 mm (WxHxD)

Weight 1 kg

Fuse

Material ABS

Degree of protection IP30

Fire class V0

Max. 1750 VA with connected pump

(max. 6 A)

Switching contact 230 V AC, max.

6 A (not floating) ; cosϕ ≥ 0.7

42 V AC; 1 V < U ≅ 42 V;

1 mA < I ≅ 100 mA; cosϕ = 1

2.7 A max. for 1 sec; 200 mA;

cosϕ ≥ 0.95

Ceramic fuse 5x20 mm, 230 V AC;

2.5 A; fast

13.4. Device and function definition in

accordance with EN 60730-1

• Purpose of the device is temperature controlling

• Device fulfils Protection class 1, EN60730-1,

EN60730-2-9

• Independently installable electronic control system with

fixed installation

• Type of action is Type 1.B (pump relay) and Type 1.C

(thermal actuator)

• Temperature for ball-thrust hardness test for housing

components 75 °C and for live parts such as, for example, terminals 125 °C

• EMC emitted interference test at 230 V AC +10/-15 %,

1750 VA maximum

• Pollution severity is 2

• Rated voltage is 4000 V (corresponding to Overvoltage

category III)

• Software class is A

13

Page 16

Appendix

13.5. Zoning plan (sample)

Zone Actuator

(type, location)

1 Heating

*Cooling

2 Heating

*Cooling

3 Heating

*Cooling

4 Heating

*Cooling

5 Heating

*Cooling

6 Heating

*Cooling

7 Heating

*Cooling

8 Heating

*Cooling

• Cooling optional

Setpoint adjuster (location)

Room name

13.6. WEEE directive 2002/96/EC

Waste Electrical and Electronic

Equipment directive

► At the end of the product life dispose of

the packaging and product in a corresponding recycling centre.

►

Do not dispose of the unit with the usual

domestic refuse.

► Do not burn the product.

14

Page 17

13.7. Brief instructions

► Specify which heating circuits are to be controlled

by the underfloor heating controller.

See Section "Creating a zoning plan", Page 5.

► Mount the required components.

(B)

A Setpoint adjuster HCW 82

Controls the setpoint temperature for each temperature

zone via adjustment dial

B Central operating device CM67z

Controls the room temperature via programmable time

(E)

(I)

programs

C Room temperature sensor HCF 82

Transmits room temperature information to underfloor

(J)

(I)

heating controller

D Hometronic Manager HCM 200D

Central operating unit of the house-automation system

E underfloor heating controller

HCE 80/HCC 80/HCE 80R/HCC 80R

Controls actuators; communicates with setpoint adjusters

and room temperature sensors

F Boiler feedback,

Analog output (only HCE 80/HCC 80) or

Relay output (only HCE 80R/HCC 80R)

G Integrated pump relay

H Thermal actuators

I External antenna HCE 80/HCE 80R

Internal antenna HCC 80/HCC 80R

J Boiler feedback relay HC60NG/R6660D

See Section "Installation", Page 5.

► Set the underfloor heating controller to the corresponding

thermal actuator (normally open or normally closed), cable

the connections and interconnect the components.

See Section "Installation and configuration", Page 6.

► Assign the room temperature sensors, setpoint adjusters and

other control components to the temperature zones (teach-in).

If you use time programs:

► Assign room names at the Hometronic Manager, if applicable.

► Assign a time program of the CM67z to the temperature

zones, if applicable.

See Section "Commissioning", Page 8.

13.7.1. Navigation and function overview

Function Press button Status LED Zone LED Exit mode

Normal mode -

Teach-in

Delete allocated

devices

Device display

Cooling mode

> 2 s

Mode > 4 sec in

teach-in mode

Keep pressed

for < 2s

Mode > 4 s

Press button

in order to activate/de-activate

cooling mode

LED flashes yellow

LED lights up

yellow

LED lights up

yellow

LED flashes yellow

LED green = Cool-

ing mode active

LED red = Cooling

mode inactive

Lights up green = Valve open

LED off = Valve closed

Flashing 4 min after last action

Zone LED extinguishes 4 min after last action

Red = Room actual value

Green = Time program

Yellow = Room actual value/time

program

Red = Cooling active and cooling contact open

(Class 3 and 4)

Green = Cooling active and

cooling contact closed

(Class 3 and 4)

(C)(A)

Allocate device

(e.g. HCW 82)

• Automatically after 60 s

or

• Press other button

• Automatically after 60 s

or

• Press Mode button

Appendix

(D)

(F)

(G)

(H)

15

Page 18

Appendix

Function Press button Status LED Zone LED Exit mode

Send test signal

Boiler mode

Receive test signal

Communication error

Antenna error

Reset all settings

Keep and

Mode pressed

for 4 seconds

Mode > 6 sec

To change press

Keep and

Mode pressed for

10 seconds

LED flashes green

and LEDs flash

red alternatively =

Asynchronous mode

and LEDs flash

red simultaneously =

Synchronous mode

LED flashes green

LED lights up red

LED flashes red

LED flashes yellow

Light up red when the test signal

is sent

Signal strength of the assigned

device is indicated by flashing of

the respective green zone LED:

1x = Signal sufficient

5x = Signal strong

Flashing red = Room actual

value error

Flashing green = Time program

error

Flashing yellow = Room actual

value/time program error

Release button

• Automatically after

10 min

or

• Press other button

• Automatically after 60 s

or

• Press Mode button

10 s after last received test

signal

When error has been eliminated

When error has been eliminated

16

Page 19

Inhoud

1. De gebruiksaanwijzing ........................................ 18

2. Veiligheidsinstructies........................................... 18

3. Overzicht ............................................................. 18

3.1. Verschillen tussen de afzonderlijke toesteltypen . 19

3.2. Functieoverzicht .................................................. 19

4. Zoneschema opstellen ........................................ 19

4.1. Temperatuurzones vastleggen ............................ 19

4.1.1. Voorbeeld van een zone-indeling ........................ 19

5. Montage .............................................................. 19

5.1. Wandmontage ..................................................... 20

5.2. Montage op een DIN-rail ..................................... 20

5.3. Componenten monteren...................................... 20

6. Installatie en configuratie..................................... 20

6.1. Behuizing openen................................................ 20

6.1.1. Uitbreidingsmodule plaatsen (optioneel) ............ 20

6.1.2. Type thermische motor instellen.......................... 20

6.2. Aansluitingen bekabelen ..................................... 20

6.2.1. Toegestane typen en kabellengten ..................... 20

6.2.2. Netkabel aansluiten............................................. 21

6.2.3. Thermische motoren aansluiten .......................... 21

6.3. Ketelsturing ......................................................... 21

6.3.1. Ketelsturing via analoge uitgang (uitsluitend

HCE 80/HCC 80) op externe regelaars

aansluiten ............................................................ 21

6.3.2. Ketelsturing tot stand brengen via draadloze

verbinding (met HC60NG/R6660D)..................... 22

6.3.3. Ketelsturing tot stand brengen met geïntegreerd

relais 42 VAC, potentiaalvrij contact (uitsluitend

HCE 80R/ HCC 80R)........................................... 22

6.4. Pomp................................................................... 22

6.4.1. Pompaansturing .................................................. 22

6.4.2. Pomp aansluiten (230 VAC) ................................ 22

6.4.3. Externe antenne installeren................................. 22

6.4.4. Behuizing van de zoneregelaar sluiten................ 22

7. Inbedrijfstelling .................................................... 22

7.1.1. Inbedrijfstelling zoneregelaar............................... 23

7.2. LED's van de zoneregelaar ................................. 23

7.3. Sterkte van de signaaloverdracht controleren ..... 23

7.4. Bedrijfsstanden van de zoneregelaar .................. 23

7.4.1. Normaal bedrijf-modus ........................................ 23

7.4.2. Storingsmelding-modus....................................... 23

7.4.3. Installatie-modus ................................................. 23

7.4.4. Weergave-modus ................................................ 23

7.5. Koelfunctie........................................................... 23

7.5.1. Koelfunctie vrijgeven ........................................... 23

7.5.2. Omschakelen verwarmen/koelen ........................ 23

7.5.3. Zonenamen toewijzen ......................................... 23

8. Zones toewijzen en zonenamen toekennen

(Teach-in) ............................................................ 23

8.1. Temperatuurvoeler met instelknop HCW 82,

temperatuurvoeler HCF 82 toewijzen .................. 24

8.2. Hometronic Manager HCM 200D toewijzen ........ 24

8.3. Bedieningseenheid CM67z toewijzen.................. 24

8.3.1. Teach-in temperatuurvoeler ................................ 24

8.3.2. Teach-in tijdprogramma CM67z (zone 1) ........... 25

8.3.3. Teach-in tijdprogramma CM67z (zone 2) ........... 25

8.4. Tijdprogramma voor koelfunctie .......................... 25

8.5. Relaismodule voor aansturing van de

warmtebron toewijzen.......................................... 25

8.5.1. Teach-in ketelsturing HC60NG/R6660D.............. 25

8.6. Toewijzing ongedaan maken............................... 25

8.6.1. Toewijzing van afstandsregelaar aan

temperatuurzone ongedaan maken..................... 25

8.6.2. Toewijzing van zonenaam of tijdprogramma

aan temperatuurzone ongedaan maken.............. 25

8.7. Instellingen op de Hometronic Manager

beveiligen ............................................................25

9. Configuratie controleren ...................................... 26

9.1. RF communicatie controleren.............................. 26

9.1.1. Testsignalen zenden ........................................... 26

9.1.2. Testsignalen ontvangen ...................................... 26

10. Storingen weergeven........................................... 26

11. Inbedrijfstelling beëindigen .................................. 26

11.1. Aanwijzingen voor de installateur ........................ 26

11.2. Zoneregelaar resetten naar de fabrieksinstelling. 26

12. Zekering vervangen............................................. 27

13. Appendix ............................................................. 27

13.1. Verklarende woordenlijst ..................................... 27

13.2. Storingen oplossen.............................................. 27

13.3. Technische gegevens.......................................... 28

13.4. Toestel- en functiedefinities conform EN 60730-

1 ..........................................................................28

13.5. Zoneschema (sjabloon) ....................................... 28

13.6. WEEE-richtlijn 2002/96/EG ................................. 28

13.7. Verkorte gebruiksaanwijzing................................ 29

13.7.1. Navigatie- en functieoverzicht ............................. 29

Inhoud

17

Page 20

De gebruiksaanwijzing

1. De gebruiksaanwijzing

Sla de linker omslagpagina open. Daarop worden alle

bedieningselementen en aansluitingen afgebeeld. Laat deze

omslagpagina tijdens het doorlezen van de

gebruiksaanwijzing open liggen.

Vaktermen worden toegelicht in de Verklarende woordenlijst

(pagina 27).

Legenda bij de uitklappagina

Fig. 1 Inhoud van de verpakking

Fig. 2 Behuizing openen

Fig. 3 Weergave- en bedieningselementen

Nummer Opschrift Functie

(1)

(2)

(3)

(4)

(5)

(6)

Power

Mode

Voeding aan/uit LED

Informatie LED

Installatie/RF LED

Bedrijfsstandenknop

Installatieknop

Pomp aan/uit LED

(7) 1...8 Zone LED's

(8) Opschrift van de zones 1...8

Fig. 4 Aansluitingen

Nummer Functie

(9) I/O-aansluitklem

(10)

Schakelaar voor instelling spanningsloos open/

gesloten

(11) Insteekplaats voor uitbreidingsmodule HCS 80

(12) Aansluitklem voor voedingsspanning pomp

(13) Zekering

(14) Insteekplaats voor interne antenne

(Z1...Z8) Aansluitklem voor zone 1...8

Fig. 5 I/O-aansluitklem

Fig. 6 Aansluitklem voor zone 1...8

Fig. 7 Aansluitklem voor voedingsspanning pomp

2. Veiligheidsinstructies

GEVAAR

WAARSCHUWING

Levensgevaar door elektrische

schok!

Bij het installeren liggen nietgeïsoleerde contacten met netspanning

vrij. Het aanraken van een onder

,

spanning staand contact kan

levensgevaarlijk letsel veroorzaken.

► Verwijder de netstekker voor het

openen van de behuizing.

► Laat alle werkzaamheden uitvoeren

door erkend en opgeleid personeel.

► Houdt u bij de installatie aan de

geldende elektrotechnische

voorschriften.

Beschadiging van de

zoneregelaar!

Kortsluiting door vocht.

► Monteer het toestel op een tegen

vocht beschermde locatie.

3. Overzicht

Het vloerregelsysteem is een intelligent systeem voor

individuele ruimtetemperatuurregeling. Onderstaand

overzicht toont de toestellen, die samen met de

zoneregelaar kunnen worden gebruikt.

(B)

(E)

(I)

(J)

(I)

A Temperatuurvoeler met instelknop HCW 82

regelt met een instelknop de ingestelde temperatuur per

temperatuurzone

B Bedieningseenheid CM67z

regelt met instelbare tijdprogramma's de

zonetemperatuur

C Temperatuurvoeler met instelknop HCF 82

geeft de ruimtetemperatuur door aan de zoneregelaar

D Hometronic Manager HCM 200D

centraal bedieningstoestel van het

woningautomatiseringssysteem

E Zoneregelaar HCE 80/HCC 80/HCE 80R/HCC 80R

stuurt thermische motoren aan; communiceert met

zoneregelaars, Hometronic manager en

temperatuurvoelers

F Ketelsturing,

analoge uitgang (uitsluitend HCE 80/HCC 80) of

relaisuitgang (uitsluitend HCE 80R/HCC 80R)

G Geïntegreerd pomprelais

H Thermische motor

I Antenne extern HCE 80/HCE 80R

Antenne intern HCC 80/HCC 80R

J Ketelrelais HC60NG/R6660D

(C)(A)

(D)

(F)

(G)

(H)

18

Page 21

Zoneschema opstellen

3.1. Verschillen tussen de afzonderlijke

HCE 80 HCE 80R HCC 80 HCC 80R

Antenne

Pomp-

relais

Analoge

uitgang

Ketelsturing

draadloos

Ketelrelais

toesteltypen

Extern Extern Intern Intern

230 VAC

intern

Aanwezig Niet

Extern

met

HC60NG/

R6660D

Niet

aanwezig

Het pomprelais 230 VAC is niet potentiaalvrij.

230 VAC

intern

aanwezig

Extern met

HC60NG/

R6660D

42 V AC/DC Niet

230 VAC

intern

Aanwezig Niet

Extern met

HC60NG/

R6660D

aanwezig

230 VAC

intern

aanwezig

Extern met

HC60NG/

R6660D

42 V AC/DC

3.2. Functieoverzicht

• 5 regelbare temperatuurzones, uit te breiden tot 8

• Per zone maximaal 3 thermische motoren aan te sluiten

• Spanningloos open en spanningloos gesloten thermische

motoren te gebruiken

• Geïntegreerd pomprelais

• Ketelsturing

– analoog (uitsluitend HCE 80/HCC 80)

– geïntegreerd relais met potentiaalvrij contact

42 V AC/DC (uitsluitend bij HCE 80R, HCC 80R)

– draadloos met relais HC60NG/R6660D

• Zoneregelaar omschakelbaar op verwarmen/koelen

• 1 antenne voor 3 regelaars te gebruiken

• Interne of externe antenne te gebruiken

• Snelle montage door schroefloze klemmen van de

thermische motoren

• Intelligente besturing door Fuzzy Logic

• Eenvoudige diagnose van de signaaloverdracht

• Aanduiding van de bedrijfstoestand met LED's

4. Zoneschema opstellen

In een gebouw kunnen ruimtes (zones) met verschillend

ingestelde ruimtetemperaturen worden geregeld. Afhankelijk

van de ingestelde temperatuur worden de thermische

motoren van de toegewezen zone (ruimte) aangestuurd.

Per zoneregelaar kunnen maximaal

5 temperatuurzones worden gedefinieerd. Met de

uitbreidingsmodule HCS 80 kan dit aantal

worden verhoogd tot 8.

Per zone kunnen maximaal 3 thermische

Temperatuurzones

(maximaal)

8 24 1

16 48 2

24 72 3

Tabel 1: Overzicht temperatuurzones/zoneregelaars

motoren worden aangesloten.

Thermische

motoren

(maximaal)

Aantal

zoneregelaars

4.1. Temperatuurzones vastleggen

► Bepaal het aantal zones en de ruimtes die daarbij horen.

► Wijs aan elke zone de betreffende temperatuurvoelers,

b.v. HCW 82, CM67z, en de benodigde thermische

motoren toe.

► Markeer de temperatuurvoelers en motoren

voor de betreffende zone (zie uitklappagina Fig. 4,

Z1...Z8).

4.1.1. Voorbeeld van een zone-indeling

kitchen

hall

dining room

living room

bathroom

Uitleg bij dit voorbeeld:

• De woning is verdeeld in 6 temperatuurzones. Voor deze

indeling is uitbreidingsmodule HCS 80 nodig.

• De zoneregelaar stuurt 8 thermische motoren aan.

bedroom

toilet

5. Montage

WAARSCHUWING

WAARSCHUWING

De zoneregelaar is bedoeld voor montage in de verdeelkast.

Wanneer daar niet voldoende ruimte is, kies dan de locatie

zo, dat de zoneregelaar zonder signaalstoringen draadloos

kan communiceren met de temperatuurvoelers en

beschermd is tegen vocht.

De zoneregelaar kan op 2 manieren worden bevestigd:

• wandmontage

• montage op een DIN-rail

Voorkom interferentie van

de RF communicatie!

Neem de volgende punten

in acht:

► Let bij de keuze van de

montagelocatie op een afstand

van minimaal 1 m tot draadloze

apparatuur zoals radiografische

(RF) koptelefoons, DECTtelefoons etc

► Zorg voor een voldoende afstand

tot metalen voorwerpen.

► Kies een andere montagelocatie,

wanneer storingen in de

gegevensoverdracht blijven

optreden.

Beschadiging van de

zoneregelaar!

Kortsluiting door vocht.

► Monteer het toestel op een tegen

vocht beschermde locatie.

19

Page 22

Installatie en configuratie

5.1. Wandmontage

Voor de wandmontage zijn op de zoneregelaar 4

bevestigingsgaten met een diameter van 4,2 mm

aangebracht.

Houd rekening met de montagehoogte van

52 mm van de zoneregelaar! Wanneer de

zoneregelaar verticaal wordt gemonteerd, moet

de transformator aan de bovenzijde zitten, zodat

de warmte optimaal kan worden afgevoerd.

57

52.0

337

∅

4.2

349.5

Afmetingen van de zoneregelaar in mm

► Teken de bevestigingsgaten af, boor de gaten en steek er

geschikte wandpluggen in.

► Schroef de zoneregelaar vast.

5.2. Montage op een DIN-rail

► Bevestig de DIN-rail

► Plaats de zoneregelaar van

onderen op de DIN-rail (1).

► Druk de zoneregelaar naar

boven tot deze vastklikt (2).

5.3. Componenten monteren

Zie voor bevestiging van de diverse componenten de

betreffende installatie instructies.

6. Installatie en configuratie

GEVAAR

WAARSCHUWING

Levensgevaar door elektrische

schok!

Niet-geïsoleerde contacten met

netspanning.

► Verwijder de netstekker voor het

openen van de behuizing.

► Laat alle werkzaamheden uitvoeren

door erkend en opgeleid personeel.

► Houdt u aan de geldende

elektrotechnische voorschriften.

Beschadiging van printplaat

componenten!

De elektronische componenten van

de zoneregelaar en de uitbreidingsmodule kunnen door elektrostatische ontladingen defect raken!

► Raak de componenten niet aan.

► Raak een geaard metalen deel

aan om uzelf te ontladen.

85

6.1. Behuizing openen

► Open de behuizing zoals afgebeeld in Fig. 2 op de

uitklappagina.

6.1.1. Uitbreidingsmodule plaatsen

(optioneel)

De uitbreidingsmodule HCS 80 verhoogt het mogelijke

aantal temperatuurzones van de zoneregelaar van 5 naar 8.

► Plaats de

uitbreidingsmodule met

de aansluitklem in de

hiervoor bedoelde

insteekplaats.

6.1.2. Type thermische motor instellen

Per zoneregelaar kan slechts één type

thermische motor worden aangesloten. Wanneer

spanningsloos open en spanningsloos gesloten

thermische motoren worden gebruikt, hebt u

► Controleer welk type thermische motor u hebt.

► Stel de schakelaar in conform onderstaande tabel (zie

Schakelaarstand

twee zoneregelaars nodig.

De thermische motoren zijn beveiligd met een

glaszekering.

uitklappagina Fig. 4 (10)):

Type

Eigenschap

thermische

motor

Spanningsloos

gesloten

Opent het verwarmingscircuit

wanneer er spanning staat op

de regelingang

Spanningsloos

open

Opent het verwarmingscircuit

wanneer er geen spanning

staat op de regelingang

6.2. Aansluitingen bekabelen

6.2.1. Toegestane typen en kabellengten

Thermische motoren

Uitwendige

kabeldiameter

Kabellengte max. 400 m

Kerndiameter max. 1,0 mm²

Striplengte 4 mm

Klembereik van de

aansluitklem

Net- en pompaansluiting 230 VAC

Uitwendige

kabeldiameter

Kabellengte max. 100 m

Kerndiameter max. 1,5 mm²

Striplengte 7 mm

Klembereik van de

aansluitklem

min. 3,5 mm/max. 5,3 mm

0,07–1,33 mm²; flexibele aders

min. 8,0 mm/max. 11 mm

0,50–2,50 mm²; flex ibele/massieve

aansluiting

0,50–1,50 mm²; flexibel, met

adereindhulsen

20

Page 23

Installatie en configuratie

Antenneaansluiting

Kabellengte max. 30 m

Kerndiameter

JE-LiYCY 2x2x0,5 mm²;

JE-Y(St)Y ∅2x2x0,8 mm; 2x0,5 mm²

Striplengte 5,5 mm

Klembereik van de

0,07–1,54 mm²

aansluitklem

Verwarmen/koelen, ketelsturing

Kabellengte max. 100 m

Kerndiameter

JE-LiYCY 2x2x0,5 mm²;

JE-Y(St)Y ∅2x2x0,8 mm; 2x0,5 mm²

Striplengte 5,5 mm

Klembereik van de

0,07–1,54 mm²

aansluitklem

Tabel 2: Toegestane typen en kabellengten

6.2.2. Netkabel aansluiten

GEVAAR

► Kies conform Tabel 2 een geschikte kabel voor de

netaansluiting.

► Strip de aansluitingen over 7 mm

(zie uitklappagina Fig. 7).

► Sluit de kabel conform onderstaande

afbeelding aan op de aansluitklem

(zie uitklappagina Fig. 4 (12)).

► Steek de aansluitklem in bus 12

(zie uitklappagina Fig. 4).

Levensgevaar door elektrische

schok!

Bij het installeren liggen nietgeïsoleerde contacten met netspanning

vrij.

► Verzekert u ervan, dat de kabel niet

onder spanning staat.

L

kabels van de motoren in een verdeeldoos worden

aangesloten.

► Trek zonodig de kabels van de motoren naar de

verdeeldoos.

► Sluit de kabels van de motoren aan.

► Breek de openingen voor

de kabels in de behuizing

uitsluitend uit met een

zijkniptang.

► Strip de aansluitingen over 5,5 mm

(zie uitklappagina Fig. 6).

► Steek de aansluitkabels van de

thermische motoren in de

kabelopeningen van de stekkers.

► Sluit de klemmen.

► Steek de stekkers in de contacten van de bijbehorende

zones (zie uitklappagina Fig. 4 (Z1…Z8)).

► Klem de kabels in de trekontlastingen.

► Borg de kabel met de kabelklem.

Montage Demontage

► Borg de kabel met de kabelklem.

Montage Demontage

6.2.3. Thermische motoren aansluiten

WAARSCHUWING

Elke zone kan maximaal 3 thermische motoren aansturen.

Voor zone 1 kunnen 3 motoren, voor zone 2 kunnen 2 en

voor de zones 3 tot en met 5 kan telkens 1 thermische

motor rechtstreeks worden aangesloten. Met de

uitbreidingsmodule is telkens 1 aansluiting voor de zones 6

tot en met 8 beschikbaar.

Wanneer meer dan 11 thermische motoren op de

zoneregelaar moeten worden aangesloten, moeten de

Beschadiging van de

zoneregelaar!

► Let bij de thermische motoren op

de technische gegevens: totaal

3 A piekstroom, 250 mA

continustroom per zone.

6.3. Ketelsturing

6.3.1. Ketelsturing via analoge uitgang

(uitsluitend HCE 80/HCC 80) op

externe regelaars aansluiten

De analoge uitgangsspanning is afhankelijk van de stand

van de zoneventielen.

► Strip de aansluitingen over 5,5 mm

(zie uitklappagina Fig. 5).

► Sluit de ketelsturing conform

onderstaande afbeelding aan

(zie uitklappagina Fig. 4 (9)).

Bij de regelaars MCR 200, MCR 40, ZG 252 N, Panther en

Smile is ketelsturing mogelijk:

► Sluit de ingangen conform de meegeleverde

gebruiksaanwijzing aan (massa-ingang op klem 6, TWingang op klem 5 van de zoneregelaar).

Bij regelaar MCR 40 liggen TW- en massa-ingang op de

volgende klemmen:

TW

H/C

B+

21

Page 24

Inbedrijfstelling

A

MCR 40

Laagspanningszijde

TW

78910456123

Massa-ingang

TW-ingang

Bij regelaar ZG 252 N liggen TW- en massa-ingang op de

volgende klemmen:

ZG 252 N

456 10

789 1112

Massa-ingang

TW

TW-ingang

Bij regelaar MCR 200 zijn de klemmen, waarop

de TW- en massa-ingangen liggen, afhankelijk

van de uitvoering.

6.3.2. Ketelsturing tot stand brengen via

draadloze verbinding (met

HC60NG/R6660D)

Afhankelijk van de stand van de zoneventielen wordt het

relais in- en uitgeschakeld.

6.3.3. Ketelsturing tot stand brengen met

geïntegreerd relais 42 VAC,

potentiaalvrij contact (uitsluitend

HCE 80R/ HCC 80R)

Afhankelijk van de stand van de zoneventielen wordt het

relais in- en uitgeschakeld.

► Strip de aansluitingen over 5,5 mm

(zie uitklappagina Fig. 5).

► Sluit de ketelsturing conform

onderstaande afbeelding aan

(zie uitklappagina Fig. 4 (9)):

TW

H/C

B+

6.4. Pomp

6.4.1. Pompaansturing

Zodra een zone actief is, wordt de pomp met tijdvertraging

ingeschakeld. Zodra alle kranen zijn gesloten, schakelt de

pomp uit.

De LED

groen, wanneer de pomp loopt.

6.4.2. Pomp aansluiten (230 VAC)

► Strip de aansluitingen over

7 mm (zie uitklappagina

Fig. 7).

► Sluit de pomp conform

onderstaande afbeelding aan

(zie uitklappagina Fig. 4 (12)):

WAARSCHUWING

(zie uitklappagina Fig. 3 (6)) brandt continu

L

Pomp

PE

Beschadiging van de

zoneregelaar!

Kortsluiting bij onjuiste installatie.

► Sluit alle regelaars aan op

dezelfde fase.

Regelaar 1

L

N

PE

6.4.3. Externe antenne installeren

Regelaar 2 Regelaar 3

Pomp

N

PE

Er kunnen maximaal drie zoneregelaars op een

antenne worden aangesloten. Verzekert u er bij

de keuze van de montagelocatie van, dat de

werking van de antenne hierdoor niet negatief

► Installeer de externe antenne uitsluitend buiten metalen

wordt beïnvloed.

behuizingen (b.v. schakelkasten).

► Monteer de antenne op een geschikte plaats in de buurt

van de zoneregelaar. Let er daarbij op, dat er een goede

RF communicatie met de temperatuurvoeler tot stand is

gebracht.

► Strip de aansluitingen over 5,5 mm

(zie uitklappagina Fig. 5).

► Sluit de antenne conform

onderstaande afbeelding aan

(zie uitklappagina Fig. 4 (9)):

B+ H/C

TW

afscherming op 2

tweede ader op 1

► Sluit de klemmen.

Bij gelijktijdig gebruik van meerdere

zoneregelaars mag slechts op één regelaar een

antenne zijn aangesloten (intern of extern).

ntenne

Regelaar 1

Regler 1 Regler 2 Regler 3

Regelaar 2

Regelaar 3

B+ B+ B+

6.4.4. Behuizing van de zoneregelaar

sluiten

► Plaats het deksel van de behuizing (zie uitklappagina).

► Laat de kliksluitingen links en rechts vastklikken.

► Draai de schroef aan de bovenzijde vast.

7. Inbedrijfstelling

Bij het inbedrijfstellen worden afstandsregelaars aan de

temperatuurzones van de zoneregelaar toegewezen (en

zonodig de tijdprogramma's van de draadloze

bedieningseenheid CM67z). Op de Hometronic Manager

wordt voor elke temperatuurzone een zonenaam

vastgelegd.

22

Page 25

Zones toewijzen en zonenamen toekennen (Teach-in)

A

r

7.1.1. Inbedrijfstelling zoneregelaar

► Schakel de bedrijfsspanning in.

De LED voor de netspanning (POWER) brandt.

7.2. LED's van de zoneregelaar

De LED's van de zoneregelaar geven de bedrijfsstanden

aan van de zoneregelaar en van de geïnstalleerde

temperatuurzones.

Betekenis van de 3 LED's (zie uitklappagina Fig. 3 (1,2,3)):

LED Weergave Betekenis

POWER (groen) Brandt Normaal bedrijf

(rood)

Brandt

lgemene storing

Knippert Storingsmelding

(geel)

Knippert

Geen toestel geïnstalleerd

snel

7.3. Sterkte van de signaaloverdracht

controleren

De sterkte van de signaaloverdracht kan zowel voor de

zender als voor de ontvangers worden gecontroleerd.

Zie paragraaf "RF communicatie controleren" op pagina 26.

7.4. Bedrijfsstanden van de

zoneregelaar

7.4.1. Normaal bedrijf-modus

In normaal bedrijf geven de LED's 1...8 de stand van de

thermische motoren aan, zie Fig. 3 (7) op de

uitklappagina:

Groen Thermische motor open

7.4.2. Storingsmelding-modus

In de storingsmelding-modus worden de diverse

storingen aangegeven door de zone-LED's.

Zie paragraaf "Storingen weergeven" op pagina 26.

7.4.3. Installatie-modus

In de installatie-modus wijst u aan de