Page 1

Fire and Smoke Damper Actuator

Field Replacement Guide

REPLACEMENT GUIDE

The following guidelines are crucial to keep fire and smoke

damper assemblies operating properly, and to stay in

adherence to standards and codes.

FIRE CODE REFERENCES AND INFORMATION

Honeywell Fire and Smoke Actuators are designed to meet

both UL555 and UL555S safety requirements for

combined fire and smoke applications, if applicable.

The following maintenance guidelines are a summary of

the National Fire Protection Association (NFPA) Codes as

well as Air Movement and Control Association (AMCA) and

Honeywell manuals. We recommend that you become

familiar with NFPA 80, 90A, 92A & B, and 105 and AMCA

publication 503. Be aware that other codes, such,

International Building Code (IBC), regional, state and local

codes, may also apply to your area.

APPLICATION

Safety should never be left to chance. Honeywell fire and

smoke actuators are designed to meet both UL-555 and

UL555S 350°F safety requirements for fire and smoke

applications, if applicable. Fast-acting actuators close

dampers in 15 seconds, and the integral spring return

ensures the consistent, proper level of torque. For the

highest level of occupant safety, you can count on

Honeywell.

Fire and Smoke actuators and assemblies must function

properly during a fire or life-safety emergency. Honeywell

Fire and Smoke Actuators provide fast action when

timeliness is key in preventing the spread of fire and

smoke. Proper installation and periodic performance

testing are required to ensure fire and smoke damper

assemblies will fully function should an emergency occur.

REPLACEMENT GUIDELINES

Actuator Specifications

UL555 and UL555S require fire and smoke actuators to be

tested to 20,000 close and reopen cycles and close within

75 seconds. UL555 also requires them to be rated to either

250°F or 350°F. If UL does not apply to your region, please

omit.

Honeywell fire and smoke actuators are rated to 30,000

cycles, operate within 15 seconds, and are rated to 350°F.

Applications

Combined Fire and smoke dampers are used to maintain

fire barrier ratings when walls and floors are penetrated by

ductwork.

Smoke dampers are used to prevent the passage of smoke

through the HVAC system or from one side of a fire-rated

separation to the other. They may be dedicated to this

function or also function as HVAC dampers.

38-00001-02

Page 2

FIRE AND SMOKE DAMPER ACTUATOR FIELD REPLACEMENT GUIDE

Damper Manufacturer’s Guidelines

When replacing actuators, it is important to follow the

guidelines that are provided by the damper manufacturer

for the damper assembly. When replacing a fire and smoke

actuator the replacement should be either like-for-like

with the original, factory-mounted actuator, or a

technically superior product where the total assembly has

passed UL testing with the damper manufacturer.

Please refer to the damper manufacturer’s guidelines for

details.

MAINTENANCE INFORMATION

Fire and Smoke damper assemblies must undergo

periodic performance testing to be properly maintained

and to ensure they are functioning and will function in a

fire or life-safety emergency.

The NFPA codes require combined fire and smoke

dampers be tested and inspected at the time the system is

commissioned, after it has been balanced, and one year

after installation. Then they need to be tested and

inspected every 4 years, except in hospitals, where they

need to be tested and inspected every 6 years. See "Option

1” and “Option 2” in this section for detailed test

instructions.

AMCA suggests that smoke dampers be tested at least

semi-annually. Smoke dampers should be operated, and

the correct outputs should be observed, to verify

operation. These tests need to also be conducted under

standby power, if used.

c. Use the signal from the damper’s position indi-

cation device to confirm that the damper reaches

its fully-closed position.

d. Re-apply electrical power to re-open the damper.

e. Use the signal from the damper’s position indi-

cation device to confirm the damper reaches its

fully-open position.

Option 2: Dampers without position indication:

a. Visually confirm that the damper is fully-open

position.

b. Ensure that all obstructions, including hands,

are out of the path of the damper blades.

c. Remove electrical power or air pressure from the

actuator to allow the actuator’s spring return fea-

ture to close the damper.

d. Visually confirm that the damper closes com-

pletely.

e. Re-apply electrical power to re-open the damper.

f. Visually confirm that the damper is in the fully

open position.

3. If the damper is not operable, it must be repaired as

soon as possible. If the actuator has failed, replace it

with a UL approved actuator if required. See Table 1.

See Figs. 2-3 for mounting and installation information and Figs. 4-9 for wiring. After these repairs, the

damper should be tested again.

4. If there is a latch, verify that it is operable.

5. Perform any other damper manufacture recom-

mended maintenance such as lubrication.

6. Following the test and any repairs, document the

location of the damper, the date, the inspector, and

deficiencies or repairs. Keep the record for the life of

the damper, and have it available as you may need to

show it to an inspector.

Honeywell Fire and Smoke Actuators are found in

combination fire and smoke damper assemblies that use a

bi-metallic disc type thermostat to interrupt electrical

power to the actuator at a specified temperature. Once the

specified temperature is reached, power will be

interrupted and the spring return of the actuator will close

the damper. When these actuators are used in smoke

damper applications, they are usually controlled by smoke

detectors or fire alarms.

Periodic inspection includes:

1. Verify that there is full unobstructed access to the

damper

2. Test the damper with normal HVAC airflow and verify

that it opens following either Option 1 or Option 2.

There should be no interference due to rust, damaged frame or blades, or other moving parts.

Option 1: Dampers with Position Indication Wired to

indication Lights, or Control Panels:

Switches can be wired to local or remote control

panels or building automation systems (BAS) to

indicate that the damper is in the fully-open

position, fully-closed position, or neither.

a. Use the signal from the damper’s position indi-

cation device to confirm that the damper is in the

fully-open position.

b. Remove electrical power or air pressure from the

actuator to allow the actuator’s spring return feature to close the damper.

Fig. 1. Typical Fire and Smoke Damper Assembly.

Source: AMCA International: Guide for Commissioning

and Periodic Performance Testing of Fire, Smoke,

and other Life Safety Related Dampers, 2012.

38-00001—02 2

Page 3

PRODUCT INFORMATION

FIRE AND SMOKE DAMPER ACTUATOR FIELD REPLACEMENT GUIDE

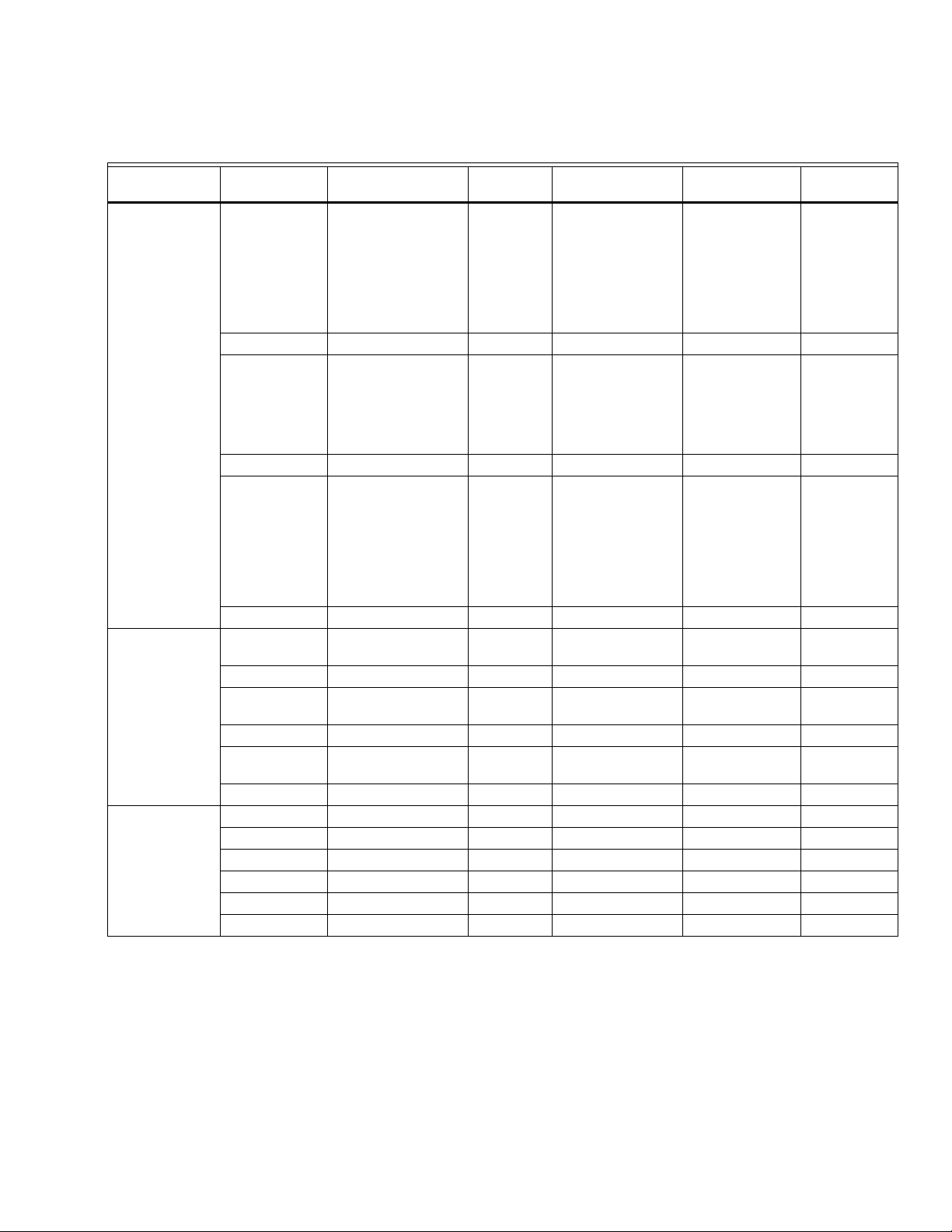

Tor que

30 lb-in

(3.4 Nm)

80 lb-in (9 Nm)

175 lb-in

(20 Nm)

Model

Number Voltage

120 Vac 0 ML4115A1009

MS4104F1010

MS4104F1210 120 Vac 2 Internal None FSLF120-S US None

MS4604F1010 230 Vac 0 ML4115C1007

MS4604F1210 230 Vac 2 Internal None FSLF230-S US None

MS8104F1010 24 Vac 0 ML8115A1005

MS8104F210 24 Vac 2 Internal None FSLF24-S US None

MS4109F1010

MS4109F1210 120 Vac 2 Internal None FSNF120-S US GND226.1U

MS4609F1010 230 Vac 0 MS4709F1014

MS4609F1210 230 Vac 2 Internal None FSNF230-S US GND326.1U

MS8109F1010 24 Vac 0 MS8209F1003

MS8109F1210 24 Vac 2 Internal None FSNF24-S US GND126.1U

MS4120F1006 120 Vac 0 None FSAF120 US GGD221.1U

MS4120F1204 120 Vac 2 Internal None FSAF120-S US None

MS4620F1005 230 Vac 0 None FSAF230 US GGD321.1U

MS4620F1203 230 Vac 2 Internal None FSAF230-S US None

MS8120F1002 24 Vac 0 None FSAF24 US GGD121.1U

MS8120F1200 24 Vac 2 Internal None FSAF24-S US None

120 Vac 0 MS4209F1007

SPST

Aux Switch

Legacy

Honeywell

ML4115A1017

ML4115B1008

ML4115B1016

ML4115H1002

ML4115J1009

ML4202F1000

ML4302F1008

ML4115C1015

ML4115D1006

ML4115D1014

ML4702F1009

ML4802F1007

ML8115A1013

ML8115B1004

ML8115B1012

ML8115H1008

ML8115J1005

ML8202F1006

ML8302F1004

MS4309F1005

MS4809F1012

MS8309F1001

Belimo

Cross

FSLF120 US None

FSLF230 US None

FSLF24 US None

FSNF120 US GND221.1U

FSNF230 US GND321.1U

FSNF24 US GND121.1U

Siemens

Cross

Table 1. Fire and Smoke Cross Reference.

3 38-00001—02

Page 4

FIRE AND SMOKE DAMPER ACTUATOR FIELD REPLACEMENT GUIDE

M34622

2 (51)

1 (25)

90

°

0

°

11/16

(17)

6-3/8

(161)

8-15/16

(227)

4 (102)

2 (51)

1/16

(2)

3-1/4 (83)

5-1/8 (130)

9/16 (14)

INSTALLATION AND WIRING

M20051A

3-15/16 (100)

2 (50)

1-9/16

(40)

8-5/8

(220)

10-11/16

(271)

2-15/16 (75)1/4 (6)

Fig. 2. Dimensions for MS4104, MS4109, MS4604,

MS4609, MS8104, and MS8109 Series actuators.

See the following literature for further details and

mounting instructions:

• Product Data and Installation Instructions: 63-2740

• Specification data: 38-00006

Fig. 3. Dimensions for MSXX20F actuators.

See the following literature for further details and

mounting instructions:

• Product Data and Installation Instructions: 63-2584

• Specification Data: 63-2592

38-00001—02 4

Page 5

Wiring

M34624

24 VAC

BLACK

RED

L1

( )

L2

( )

YELLOW

YELLOW

BLUE

7° AUXILIARY

SWITCH

85° AUXILIARY

SWITCH

BLUE

WHITE

BLACK

GREEN

L1

( )

L2

( )

YELLOW

YELLOW

BLUE

BLUE

7° AUXILIARY

SWITCH

85° AUXILIARY

SWITCH

120 VAC

M34625

M34626

BLUE

BROWN

GREEN

230 VAC

L1

( )

L2

( )

YELLOW

YELLOW

BLUE

BLUE

7° AUXILIARY

SWITCH

85° AUXILIARY

SWITCH

M20053B

24 VAC

BLACK

RED

GREEN

MS8120F

L1

( )

L2

( )

YELLOW

YELLOW

BLUE

7° AUXILIARY

SWITCH

85° AUXILIARY

SWITCH

BLUE

FIRE AND SMOKE DAMPER ACTUATOR FIELD REPLACEMENT GUIDE

For 30 lb-in and 80 lb-in (3.4 Nm, 9 Nm)

models:

Fig. 4. Typical 24 Vac wiring.

For 175 lb-in (20 Nm) models:

Fig. 7. Typical 24 Vac wiring

MS4120F

( )

L2

120 VAC

( )

L1

WHITE

BLACK

GREEN

Fig. 5. Typical 120 Vac wiring.

Fig. 6. Typical 230 Vac wiring.

7° AUXILIARY

85° AUXILIARY

M20056B

( )

L2

230 VAC

( )

L1

7° AUXILIARY

85° AUXILIARY

BLUE

SWITCH

SWITCH

BLUE

YELLOW

YELLOW

Fig. 8. Typical 120 Vac wiring.

MS4620F

BLUE

BROWN

GREEN

BLUE

SWITCH

SWITCH

BLUE

YELLOW

YELLOW

Fig. 9. Typical 230 Vac wiring.

M20057B

5 38-00001—02

Page 6

FIRE AND SMOKE DAMPER ACTUATOR FIELD REPLACEMENT GUIDE

38-00001—02 6

Page 7

FIRE AND SMOKE DAMPER ACTUATOR FIELD REPLACEMENT GUIDE

7 38-00001—02

Page 8

FIRE AND SMOKE DAMPER ACTUATOR FIELD REPLACEMENT GUIDE

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any

liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Home and Building Technologies

In the U.S.:

Honeywell

3992

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

38-00001—02 M.S. Rev. 11-16

Printed in United States

Loading...

Loading...