Page 1

Oxy-Fuel Burner PrimeFire FH

liable for any other injury, loss, damage or expenses, whether direct

or consequential, including but not limited to loss of use, income, or

damage to material arising in connection with the sale, installation,

use of, inability to use, or the repair or replacement of Honeywell’s

products.

Any operation expressly prohibited in this manual, any adjustment,

or assembly procedures not recommended or authorized in these

instructions shall void the warranty.

Document Conventions

There are several special symbols in this document. You must know

their meaning and importance.

CONTENTS

Safety ........................................1

Product description..............................2

Benefits.......................................2

Reference Information ............................2

Installation .....................................2

Maintenance ...................................4

SAFETY

Disclaimer Notice

In accordance with the manufacture’s policy of continual product

improvement, the product presented in this brochure is subject to

change without notice or obligation.

The material in this manual is believed adequate for the intended

use of the product. If the product is used for purposes other than

those specified herein, confirmation of validity and suitability must be

obtained. Eclipse warrants that the product itself does not infringe

upon any United States patents. No further warranty is expressed

or implied.

Liability and Warranty

We have made every effort to make this manual as accurate and

complete as possible. Should you find errors or omissions, please

bring them to our attention so that we may correct them. In this way

we hope to improve our product documentation for the benefit of

our customers. Please send your corrections and comments to our

Marketing Communications Manager.

It must be understood that Eclipse’s liability for its product, whether

due to breach of warranty, negligence, strict liability, or otherwise is

limited to the furnishing of replacement parts and Eclipse will not be

1 2 3 a b c

➔ = Instruction/Note

Audience and Purpose

The purpose of this manual is to ensure the installation and adjustment

of a safe, effective and trouble-free combustion system.

The audience is expected to have previous experience with this

type of equipment.

The purpose of this manual is to make sure that you carry out the

installation of a safe, effective, and trouble-free system.

Safety instructions

Information that is relevant for safety is indicated in the instructions

as follows:

DANGER

Indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.All interventions may only be

carried out by qualified gas technicians. Electrical interventions

may only be carried out by qualified electricians.

Safety

Important notices which help provide safe burner operation will be

found in this section. To avoid personal injury and damage to the

property or facility, the following warnings must be observed. All

involved personnel should read this entire manual carefully before

attempting to start or operate this system. If any part of the information

in this manual is not understood, contact Honeywell before continuing.

... = Action

OPERATING INSTRUCTIONS

Edition 11.19· ·

32-00255-01

D, GB, E, CN – www.docuthek.com

Page 2

DANGER

The burners covered in this manual are designed to mix fuel with

oxygen and burn the resulting mixture. All fuel burning devices

are capable of producing fires and explosions when improperly

applied, installed, adjusted, controlled or maintained.Do not

bypass any safety feature; fire or explosion could result.Never try

to light the burner if it shows signs of damage or malfunction.

WARNING

The burner is likely to have HOT surfaces. Always wear protec-

tive clothing when approaching the burner. Honeywell products

are designed to minimize the use of materials that contain

crystalline silica. Examples of these chemicals are: respirable

crystalline silica from bricks, cement or other masonry products

and respirable refractory ceramic fibers from insulating blankets, boards, or gaskets. Despite these efforts, dust created

by sanding, sawing, grinding, cutting and other construction

activities could release crystalline silica. Crystalline silica is

known to cause cancer, and health risks from the exposure to

these chemicals vary depending on the frequency and length of

exposure to these chemicals. To reduce the risk, limit exposure

to these chemicals, work in a well-ventilated area and wear approved personal protective safety equipment for these chemicals.

CAUTION

This manual gives information for the use of these burners for

their specific design purpose. Do not deviate from any instructions or application limits in this manual without written advice

from Honeywell.

Capabilities

Only qualified personnel, with good mechanical aptitude and experience with combustion equipment, should adjust, maintain, or

troubleshoot any mechanical or electrical part of this system.

Operator Training

The best safety precaution is an alert and trained operator. Train new

operators thoroughly and have them demonstrate an adequate understanding of the equipment and its operation. A regular retraining

schedule should be administered to ensure operators maintain a

high degree of proficiency.

Replacement Parts

Order replacement parts from Honeywell only. Any customersupplied valves or switches should carry UL, FM, CSA, CGA and/or CE

approval where applicable.

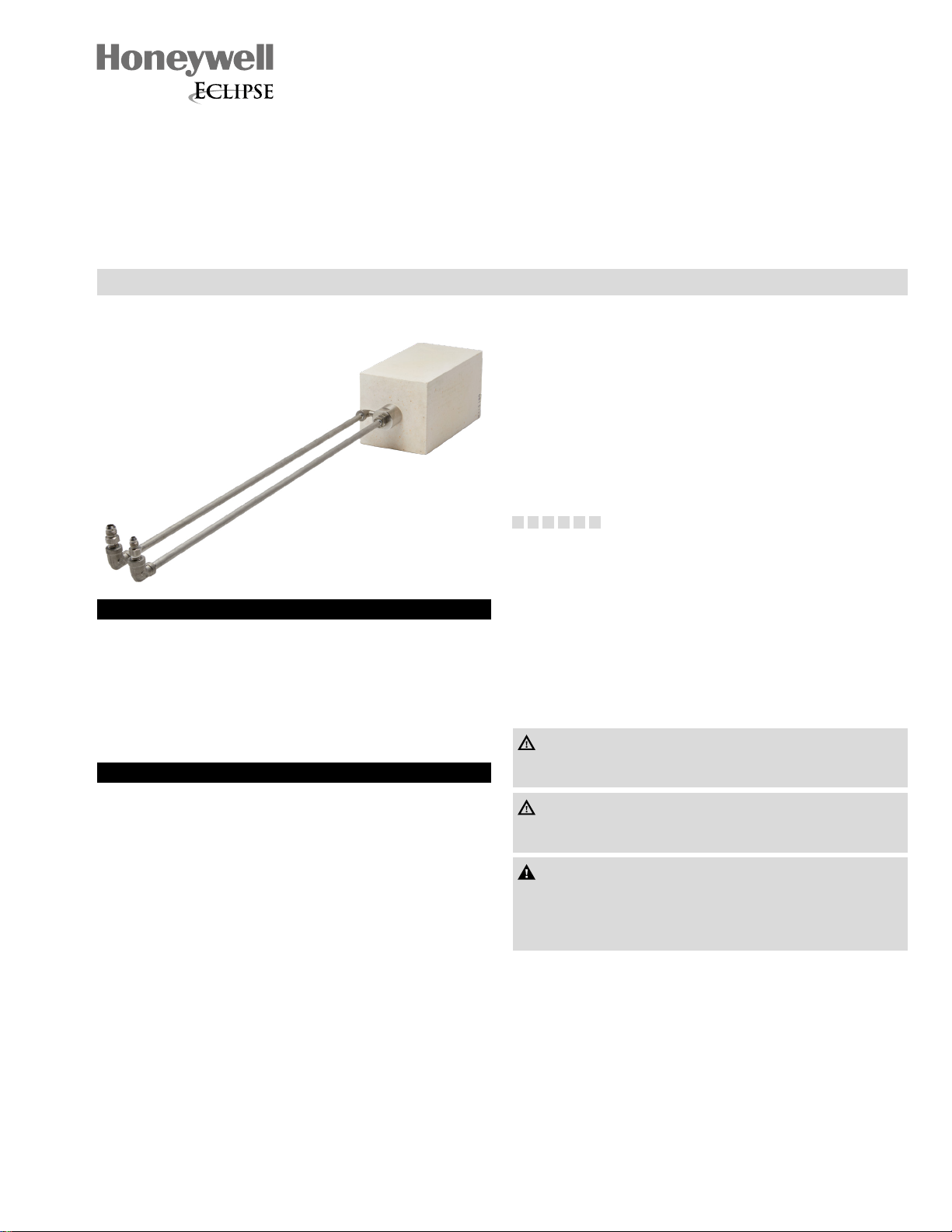

PRODUCT DESCRIPTION

Forehearth oxygen gas burners are small, nozzle mixing burners designed to be inserted into the forehearth to provide temperature homogeneity throughout the glass by increasing the heat of the glass melt

in the area near the forehearth wall where cooling occurs more rapidly.

These burners consist of a 300-series stainless steel gas tip

and a 300-series stainless steel or oxygen nozzle. They produce a short, bright flame intended to keep the temperature of the glass near the forehearth wall, where cooling is

most rapid, at the same level as the middle of the glass bed.

Forehearth burners use one size body for all nozzle sizes making for

easier maintenance and greater capacity flexibility. They fire natural

gas and come with a unique block to fit the exact requirements of

the burner.

BENEFITS

– Cooler running burner and block for increased reliability and

product life

– No maintenance design for less downtime and lower mainte-

nance costs

– Simple design, easy to configure and order for your specific

application

– Easy to set up and operate

– 60% reduction in fuel consumption*

– 80% NOx reduction*

– Fewer total burners required*

– No blowers required for the combustion process*

*as compared with Air-Fuel Pre-Mix solutions

REFERENCE INFORMATION

For further information about Oxy-Fuel Burner PrimeFire FH see:

– Technical Information for Oxy-Fuel Burner PrimeFire FH.

– Honeywell Combustion Engineering Guide

INSTALLATION

Introduction

In this section you will find the information and instructions needed

to install the burner and system components.

Handling and Storage

Handling

➔ Make sure the area is clean.

Protect the components from weather, damage, dirt and moisture.

➔

➔

Protect the components from excessive temperatures and humidity.

Storage

➔ Make sure the components are clean and free of damage.

➔ Store the components in a cool, clean, dry room.

After making sure everything is present and in good condition,

➔

keep the components in original packages as long as possible.

Approval of Components

Limit Controls and Safety Equipment

All limit controls and safety equipment must comply with all applicable

local codes and/or standards and must be listed for combustion

safety by an independent testing agency. Typical application examples include:

– American: NFPA 86 with listing marks from UL, FM, CSA

– European: EN 746-2 with CE mark from TuV, Gastec, Advanti-

ca

Electrical Wiring

All the electrical wiring must comply with all applicable local codes

and/or standards such as:

– NFPA Standard 70

– IEC 60364

– CSA C22

– BS7671

Gas Piping

All the gas piping must comply with all applicable local codes and/

or standards such as

– NFPA Standard 54

– ANSI Z223

– EN 746-2

Where to Get the Standards?

The NFPA Standards are available from:

National Fire Protection Agency

Batterymarch Park

Quincy, MA 02269

www.nfpa.org

The ANSI Standards are available from

American National Standard Institute

1430 Broadway

New York, NY 10018

www.ansi.org

The UL Standards are available from

333 Pfingsten Road

Northbrook, IL 60062

www.ul.com

2

PrimeFire FH · Edition 11.19 · EN

Page 3

5 inch

127 mm

1.6 inch

40.6 mm

5 inch

127 mm

10.956 inch

278 mm

9 inch

229 mm

1.958 inch

49.7 mm

10.455 inch

266 mm

2

1

1

Oxygen Inlet

Fuel Inlet

2

The FM Standards are available from

1151 Boston-Providence Turnpike

PO Box 9102

Norwood, MA 02062

www.fmglobal.com/approvals

Information on the EN standards and where to get them is

available from

Comité Européen de Normalisation

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196811

Fax: +32-25196819

www.cen.eu

Comité Européen de Normalisation Electronique

Stassartstraat 36

B-1050 Brussels

Phone: +32-25196871

Fax: +32-25196919

www.cenelec.org

Forehearth Oxy/Gas and Air/Gas Burners

➔ The oxy/gas forehearth burners consist of a stainless steel body

that is universal for all oxygen and gas nozzle sizes.

Forehearth burners are mounted directly into the forehearth burner

➔

blocks with no special mounting equipment required.

Burner Installation and Operation

Initial Forehearth Start-Up

➔ Burners should be out of the forehearth during furnace heatup.

1

Connect the oxygen (or air) and gas supply lines to fittings on the

burner.

2

Make sure all systems are checked and ready.

3

Make sure all burner isolation valves are closed.

4

Open oxygen and gas to the zone controls.

5

Allow oxygen and gas to flow through the burner to ensure gas

and oxygen lines are purged.

6

Allow chamber to reach a minimum temperature of 1500 ºF (816

ºC) to ensure the auto-ignition point of natural gas has been

reached before inserting burners and opening oxygen and gas

valves.

➔ For oxygen burner starts, it is best to allow the furnace to rise to

a temperature between 1652 ºF (900 ºC) to 1832 ºF (1000 ºC),

if possible.

➔

It is suggested that this initially be in an area away from the

heat-up burner.

7

Open the oxygen valve for the burners installed in step 7.

➔ With oxygen flowing, set the oxygen flow per burner to the flow

in the following table based on burner model:

Oxygen Flow Chart

Model Oxygen Flow, scfh (Nm3/hr)

FH1350 70 (1.99)

FH0935 50 (1.42)

FH0517 24 (0.684)

➔ Turndown is 4:1 on all models

8

Open the natural gas valve.

9

Start the natural gas flow and bring up to a flow per burner from

the following table based on the burner model:

Model Fuel Flow, scfh (Nm3/hr)

FH1350 35 (0.997)

FH0935 25 (0.712)

FH0517 12 (0.342)

10

Check burners to verify ignition and listen for a “screaming” or

“squealing” sound. If the burners are making these sounds, open

or close the gas to the burner until the sound goes away. If the

sound persists, shut off gas flow to the zone and check burners

PrimeFire FH · Edition 11.19 · EN

for damage as well as to verify gas and oxygen/air connections

are not reversed.

➔

During the initial light off/heat-up, it is better to run the flame

slightly gas rich.

11

Ensure heat-up burner flame is not pushing forehearth burner

flame into the side of the block bore.

12

Add or reduce gas and oxy/air to keep the furnace temperature

on the heat up curve.

13

Heat-up burner turndown and removal

– It is recommended to start with burners away from the heat-up

burner first.

– As forehearth burners are turned on, lower the gas flow to the

heat-up burner.

– When the flow to the heat-up burner is low enough, shut off the

gas flow and remove the burner.

➔

Pay attention to the forehearth pressure during this procedure

and close off the stack as needed.

➔ With oxy firing, the pressure will drop off significantly. Add fuel/

oxygen to hold temperature, then add burners as necessary.

14

Repeat steps 3-15 for each zone.

15

Remove a burner and check the appearance of the flame.

16

Add burners as needed but ensure the flow of oxygen and gas

remain below the maximum and above the minimum flow rates

for each burner.

Burner Mounting

The block must rest flat on the sill or wall without rocking to allow

the weight to be evenly distributed. Failure to do so could result in

cracking or block failure. If burner openings are too large, shims

may be used to align the burner. Avoid applying any compressive or

tensile forces to the ceramic portions of the burner as this may cause

premature failure. The burner opening should provide a minimum of

1/16” clearance on all three sides. High temperature furnace sealant

or packing should be used between the burner and wall.

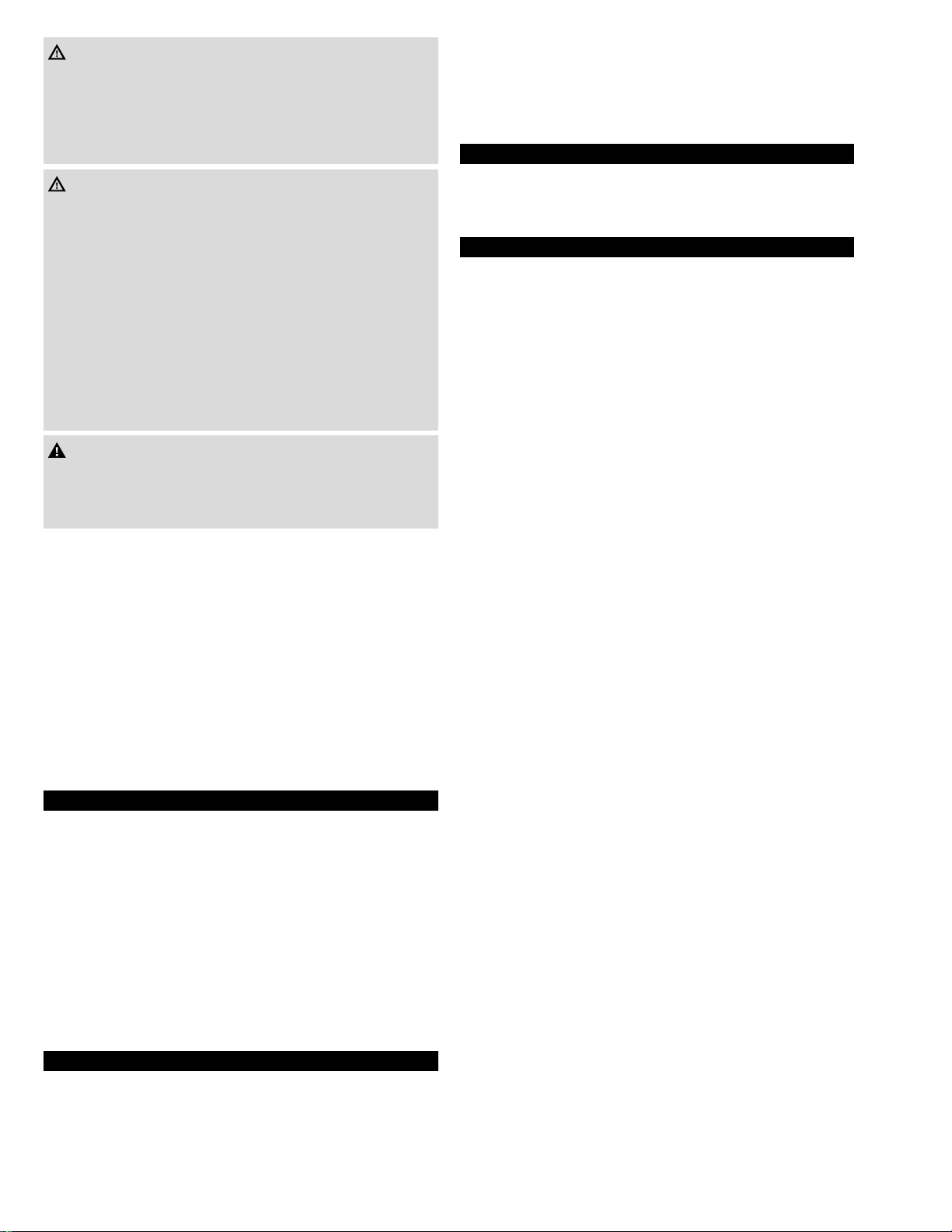

Basic dimensions of the PrimeFire FH, showing both the Oxygen

Inlet and Fuel Inlet orientation to the burner and block

assembly.

➔ It is recommended that the PrimeFire FH be mounted such that

the piping is anchored to a fixture to allow pressure on the burner/

block connection in order to ensure ideal performance.

2

1

3

Oxygen Supply line, Fuel Supply Line and pipe clamp.

1 Oxygen Supply Line - 3/8 Stainless Steel Braided Hose

(Part Number: 10057031)

3

Page 4

2 Fuel Supply Line - 1/4 Stainless Steel Braided Hose

(Part Number: 10057032)

3 Pipe clamp to keep pressure on the burner and block connec-

tion

Cooling Air Flow

Removal of the burner nozzle is recommended when the burner is

out of service. If removal is not possible, or not chosen, cooling flow,

either clean, dry air, nitrogen or oxygen, must be used. Typical compressed air systems contain lubrication oils, which will contaminate

oxygen-clean environments and cannot be used for cooling flows

without special treatment. Cooling air provided by plant process air

fans is one possible source.

Hot Installation

➔ Minimum temperature of 1500º F (816º C))

Failure to follow the proper installation sequence noted below

➔

could result in damage or destruction of vital burner components.

Cooling oxygen or air flows should be present at all times when

the burner nozzle is inserted.

1

Connect gas and oxy (or air) supply lines to burner fittings.

2

Make sure all systems are checked and ready.

3

Make sure burner isolation valves are closed.

4

Open oxygen or air valve to the burner.

5

Slowly open the gas valve to the burner to ignite the flame.

6

Open gas valve to the burner to set flow to desired rate.

Burner Ignition

CAUTION

The PrimeFire FH burner does not have self ignition capability.

It is the responsibility of the end user and service personnel

attempting start-up to confirm that ignition temperatures appropriate for the fuel used are present inside the furnace where the

burner is located. In cases where manual ignition from the outside is required, provisions shall be made in the furnace wall adjacent to the burner. Burners should be started up at minimum

fuel and oxygen flows (see page 3 (Burner Installation and

Operation) to prevent sudden pressure rise in the fired chamber.

➔

Set correct gas and oxygen flow before attempt of burner ignition.

Flow meters for oxygen and gas flow measurement should be

used for proper burner adjustment.

CAUTION

Oxygen should only be used with approved materials, properly

cleaned pipe and equipment, and specially designed systems.

Ordinary materials can be extremely flammable in the presence

of oxygen and air enriched with oxygen.

Flame Lengths

Flame lengths are given at high fire and minimum fire for each capacity. The flame length in this design has a linear relationship with

the fuel flow rate. The higher the fuel flow rate at a given capacity

the longer the flame

Model

FH0517

FH0935

FH1350

Fuel Flow Rate, scfh

(Nm3/hr)

5 (0.142)

17 (0.484)

9 (0.256)

35 (0.997)

13 (0.37)

50 (1.425)

Flame Length, inches

(meters)

3 (0.076)

7 (0.178)

5 (0.127)

10 (0.254)

7 (0.178)

12 (0.305)

Flame Lengths

12

10

8

6

4

Flame Length [inch]

FH0517

2

0

0 4 8 12 16 20 24 28 32 36 40 44 48 52

FH1350

FH0935

Fuel Flow Rate (SCFH)

MAINTENANCE

➔

The PrimeFire FH requires very little maintenance, if any. However,

preventative maintenance is the key to a reliable, safe and efficient system. The following are suggested guidelines for periodic

maintenance. Burners in severe environments or operational

conditions should be checked more frequently. Spare burners

not in use should be completely drained and stored vertically to

prevent rusting.

➔

NOTE: The periodic, monthly, and yearly lists are an average

interval. If your environment is dirty, the intervals may be shorter.

Check with local authorities having jurisdiction regarding their

recommended maintenance schedules.

Periodic Checklist

1

Continuously monitor gas and oxygen flows.

2

Check flame shape to ensure there is nothing blocking the gas

or oxygen nozzles which could cause damage to the burner and

the burner block.

3

Remove burners and inspect tips for signs of carbon build-up as

well as checking for any damage to the burner blocks that could

result from dirty nozzles/ incorrect flows, or loose oxygen nozzles

at least four times per year.

4

Clean all burner nozzles on a routine basis once per month and

when required by flame appearance.

5

Check for proper oxygen/gas pressures (refer to Technical Infor-

mation for Oxy-Fuel Burner PrimeFire FH).

6

Test all the system alarms for proper response signals.

7

Test the manual gas shut-off valves for proper operation.

Yearly Checklist

1

Test (leak test) safety shut-off valves for tightness of closure.

2

Test pressure switch settings by checking switch movements

against pressure settings and comparing these with the actual

impulse pressure.

3

Inspect impulse piping for leaks.

4

Clean and inspect all burners.

FOR MORE INFORMATION

The Honeywell Thermal Solutions family of products includes Honeywell

Combustion Safety, Eclipse, Exothermics, Hauck, Kromschröder and

Maxon. To learn more about our products, visit

www.ThermalSolutions.honeywell.com or contact your Honeywell Sales

Engineer.

Eclipse Inc.

1665 Elmwood Rd. · Rockford, IL 61103

United States

www.eclipsenet.com

www.ThermalSolutions.honeywell.com

© 2019 Eclipse Inc.

4

PrimeFire FH · Edition 11.19 · EN

We reserve the right to make technical modifications in the interests of progress.

Loading...

Loading...