Page 1

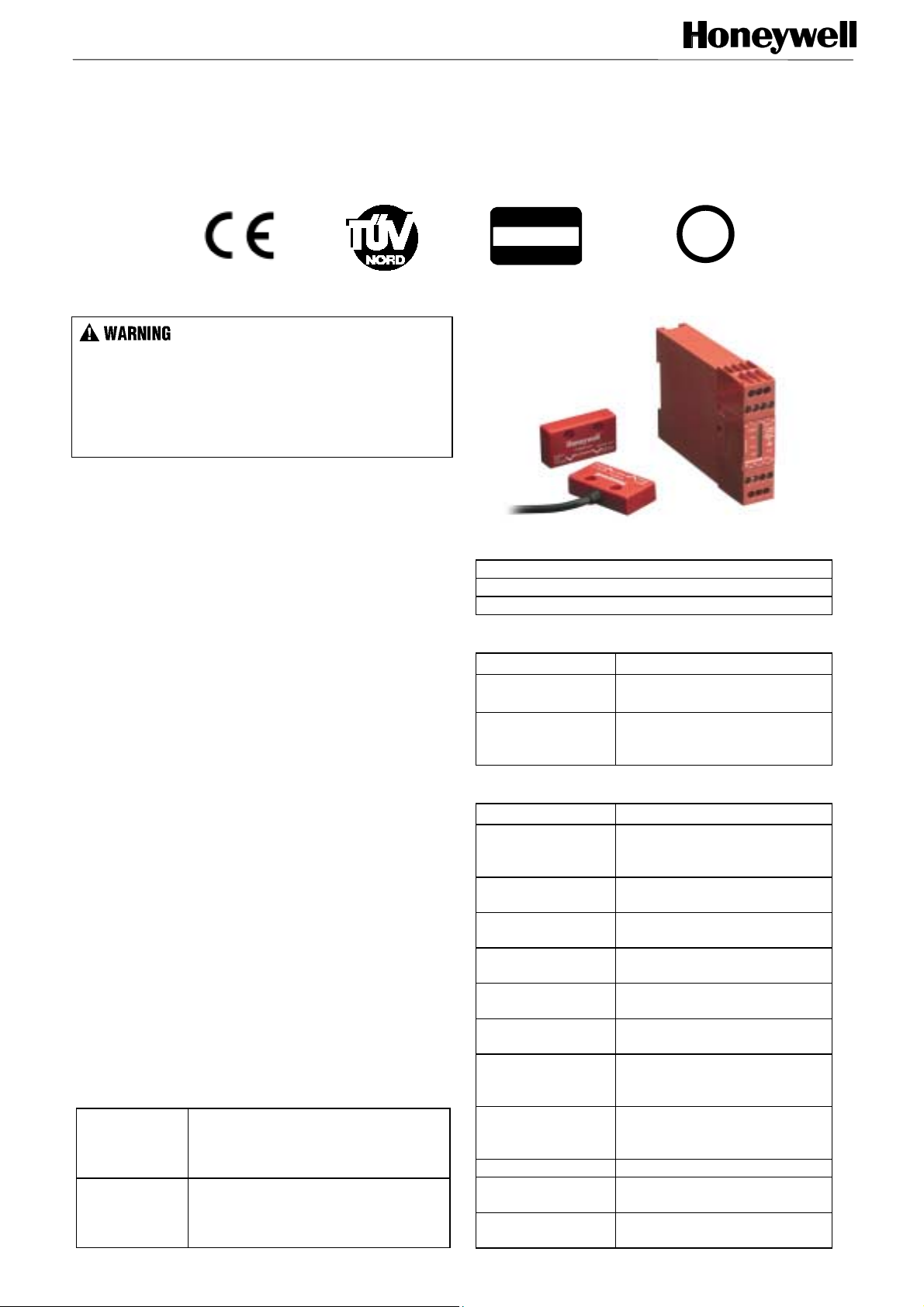

FF-SNC

Safety Non Contact Switch

Instructions for use

IMPROPER INSTALLATION

• Consult with US and/or European safety agencies and

their requirements when designing a machine control,

interface and all control elements that affect safety.

• Strictly adhere to all installation instructions.

Failure to comply with these instructions could result

in death or serious injury.

PRODUCT DESCRIPTION

The FF-SNC Honeywell safety non contact switch is a tamper

resistant safety system for monitoring machine guards. The

actuator being a passive component, the safety switch is the only

component that needs to be wired to the control unit and cannot be

defeated by a regular magnet.

Each system is made up of one or several safety switches,

actuators and a control unit. The Honeywell FF-SNC safety non

contact switches are designed in compliance with the requirements

of the EN 954-1 European Standard for Category 3 Protective

Devices.

The FF-SNC is especially suited for applications where perfect door

alignment can not be attained. The FF-SNC Series can be

mounted on sliding, hinged or removable machine guards. The

output of the control unit is triggered as soon as the distance

between the safety switch and the actuator is greater or equal to

8 mm/0.32 in. This switching distance compensates for the

machine vibration or a minor issue with the installation alignment.

The sensor and actuator small size makes it usable under tight

space requirements. The safety switches and the actuators provide

excellent chemical and mechanical resistance. Stainless steel

housing versions fulfil the requirements of the Food and Beverage

industry.

The FF-SNC400 safety control unit comes in a 75 mm / 2.95 in

package and can monitor up to 4 sensors.

The FF-SNC200 safety control unit with its 22,5 mm / 0.89 in width

will easily find a place in the electrical cabinet and can monitor

2 sensors. Both control units can be placed up to 100 m / 328 ft

away from the safety non contact switches. The indicators located

on the front cover of both control units provide individual door status

information.

The FF-SNC1EXT extension module can be added to the

FF-SNC400 or FF-SNC200 control unit and allows the

connection of 5 additional sensors.

APPROVALS

CE The product, packaging and

documentation of FF-SNC Series

products is CE mark following an

examination by TÜV.

cULus This product is pending approval at

Underwriters Laboratories Inc.

According to Canadian and U.S. safety

requirements.

Suitable for interfaces

up to

CATEGORY 3

per EN 954-1

U

®

CUSSTEDLI

L

(pending)

DIRECTIVES COMPLIANCE

Machinery Directive 98/37/EC

Low Voltage Directive 73/23/EC

Electromagnetic Compatibility Directive 89/336/EC

REGULATIONS COMPLIANCE

Regulation Title

OSHA 29 CFR

1910.212

OSHA 29 CFR

1910.217

General Requirements for

(guarding of) all Machines

Requirements and

Safeguarding of Mechanical

Power Presses

STANDARDS COMPLIANCE

Standard Title

EN 292 Safety of Machinery – Basic

Concepts, General Principles

for Design

EN 60204 Safety of Machinery – Electrical

Equipment of Machines

EN 954-1 Safety of Machinery – Safety

related parts of control system

EN 1088 Interlocking Devices associated

with Guards

ANSI B11.1 Construction, Care and Use of

Mechanical Power Presses

ANSI B11.2 Construction, Care and Use of

Hydraulic Power Presses

ANSI B11.19 Safeguarding Performance

Criteria for the Design,

Construction, Care and Use

ANSI/RIA R15.06 Safety Requirements for

Industrial Robots and Robot

Systems

UL 508 Industrial Control Equipment

UL 991 Test for Safety related Controls

employing solid state devices

NFPA79 Electrical Standard for Industrial

Machinery

107099-10-EN FR26 GLO 602 Printed in England

Page 2

SPECIFICATIONS

Switch

Operating temperature -10 °C to +55 °C / 14 °F to 131 °F

Connection to the control unit Max. Cable length: 100 m / 328 ft

Material ABS (FF-SNC1SA03PA) or Stainless Steel and Resin filled (FF-SNC1SA03PS)

Sensing range 5-7 mm / 0.20 – 0.27 in On; 8-12 mm / 0.32 – 0.47 in Off

Optimum gap1 mm

Standard cable length 3 m / 9.84 ft or 5 m / 16.4 ft

Sealing IP 67

Fixing 2 x (M4x20 mm) Tamper proof screws (supplied with the product)

Control unit / Extension module

Category Category 3 according to EN 954-1

Supply voltage 24 Vdc/Vac ± 15 % / 110 Vac ± 15 % (FF-SNC400R4 only)

Response time of the control unit 15 ms (with or without extension module)

Power consumption (including

6 VA (with or without extension module)

sensors)

Operating temperature -10 °C to + 55 °C / 14 °F to 131 °F

Storage temperature -20 °C to 60 °C / -4 °F to 140 °F

Output 2 NO + 1 NC contacts (4 A / 250 Vac; 2 A / 30 Vdc)

Restart Manual or automatic

Sealing IP 40 Housing, Terminals IP 20

Mounting 35 mm / 1.37 in DIN rail

LED indicators

FF-SNC200R2 control unit: Power, Run and 2 guard status indicators

FF-SNC400R4 control unit: 4 guard status indicators and selection indicators

Material Polycarbonate, red

Ordering information: Description Weight

FF-SNC200R2 24 Vdc/Vac Control unit for monitoring up to 2 gates: 0,235 kg / 0.517 lb

FF-SNC400R2 24 Vdc/Vac Control unit for monitoring up to 4 gates: 0,49 kg / 1.078 lb

FF-SNC400RE 110 Vac Control Unit for monitoring up to 4 gates: 0,63 kg / 1.386 lb

FF-SNC1SA03PA Safety switch + actuator: 3 m / 9.84 ft cable: 0,169 kg / 0.371 lb

FF-SNC1SA05PA Safety switch + actuator: 5 m / 16.4 ft cable: 0,255 kg / 0.56 lb

FF-SNC1SA03PS Safety switch + actuator: 3 m / 9.84 ft cable –

0,265 kg / 0.583 lb

Stainless Steel Housing

FF-SNC1ACS Actuator Only: Stainless Steel Housing 0,077 kg / 0.169 lb

FF-SNC1ACA Actuator Only : ABS Housing 0,028 kg / 0.061 lb

FF-SNC1EXT Extension Module 0,135 kg / 0.297 lb

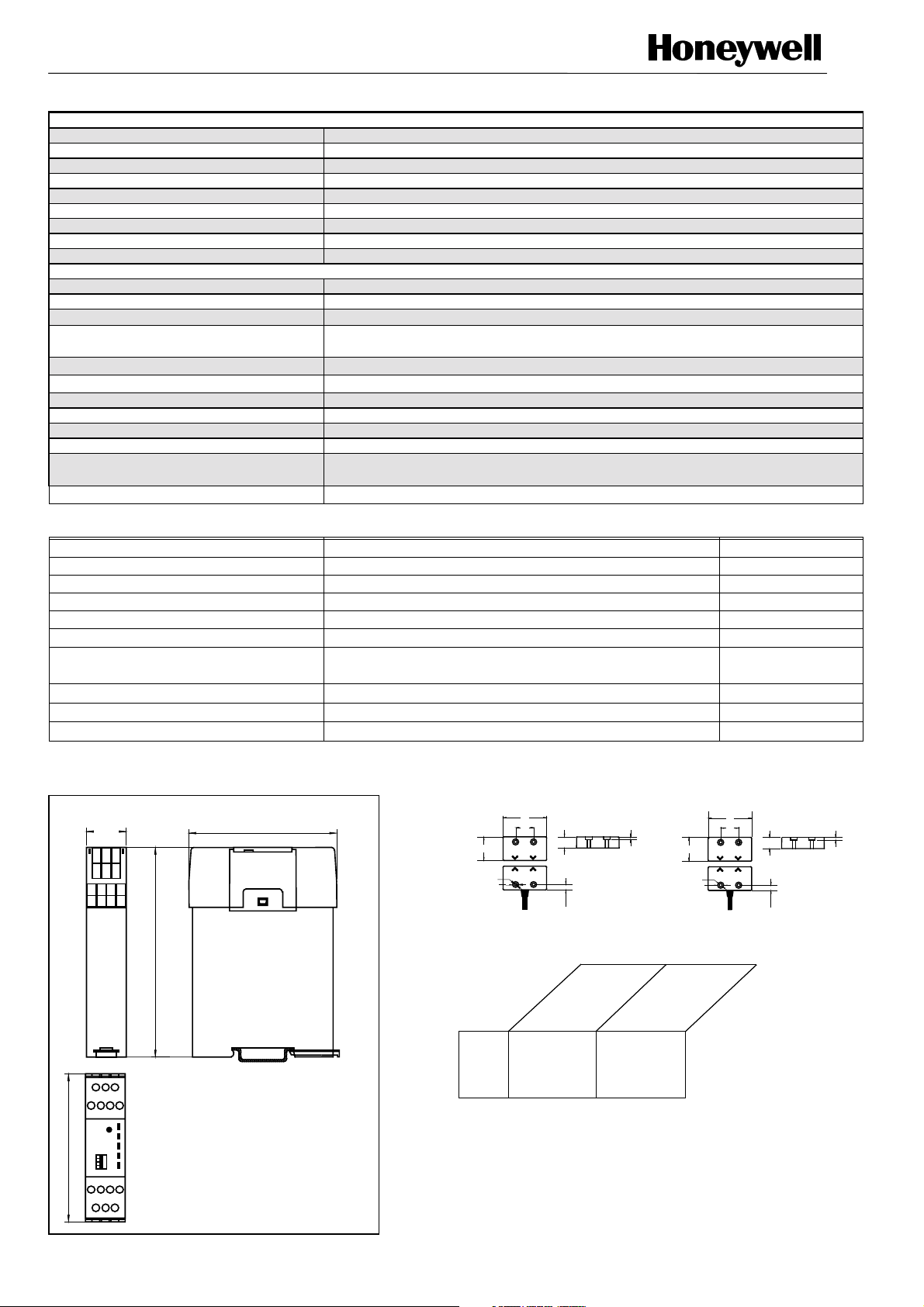

MOUNTING DIMENSIONS (mm/in) for reference only

FIG 1. FF-SNC Control unit

H

W

A1DRBLDRBLDRBL

GATE 2

GATE 1

GATE 4 GATE 5

A2DRBLDRBL BL

D

GATE 3

DR

H

FSNC_1

FIG. 2. FF-SNCS1A03PS - FF-SNCS1A03PA

29 / 1.14

ø 4,2 / 0.16

ø 8,1 / 0.32

W

H

D

53 / 2.08

22 / 0.86

FF-SNC200R2

22,5 / 0.88

84 / 3.30

119 / 4.68

13,5 / 0.53

SIDE

6,4 / 0.25

FF-SNC1EXT

119 / 4.68

3 / 0.11

ø 4,2 / 0.16

ø 8,1 / 0.32

FF-SNC400R2

FF-SNC400RE

75 / 2.95

74 / 2.91

28 / 1.10

52 / 2.04

22 / 0.86

(in mm/in)

14 / 0.55

SIDE

6,4 / 0.25

3 / 0.11

2 107099-10-EN FR26 GLO 602 Printed in England

Page 3

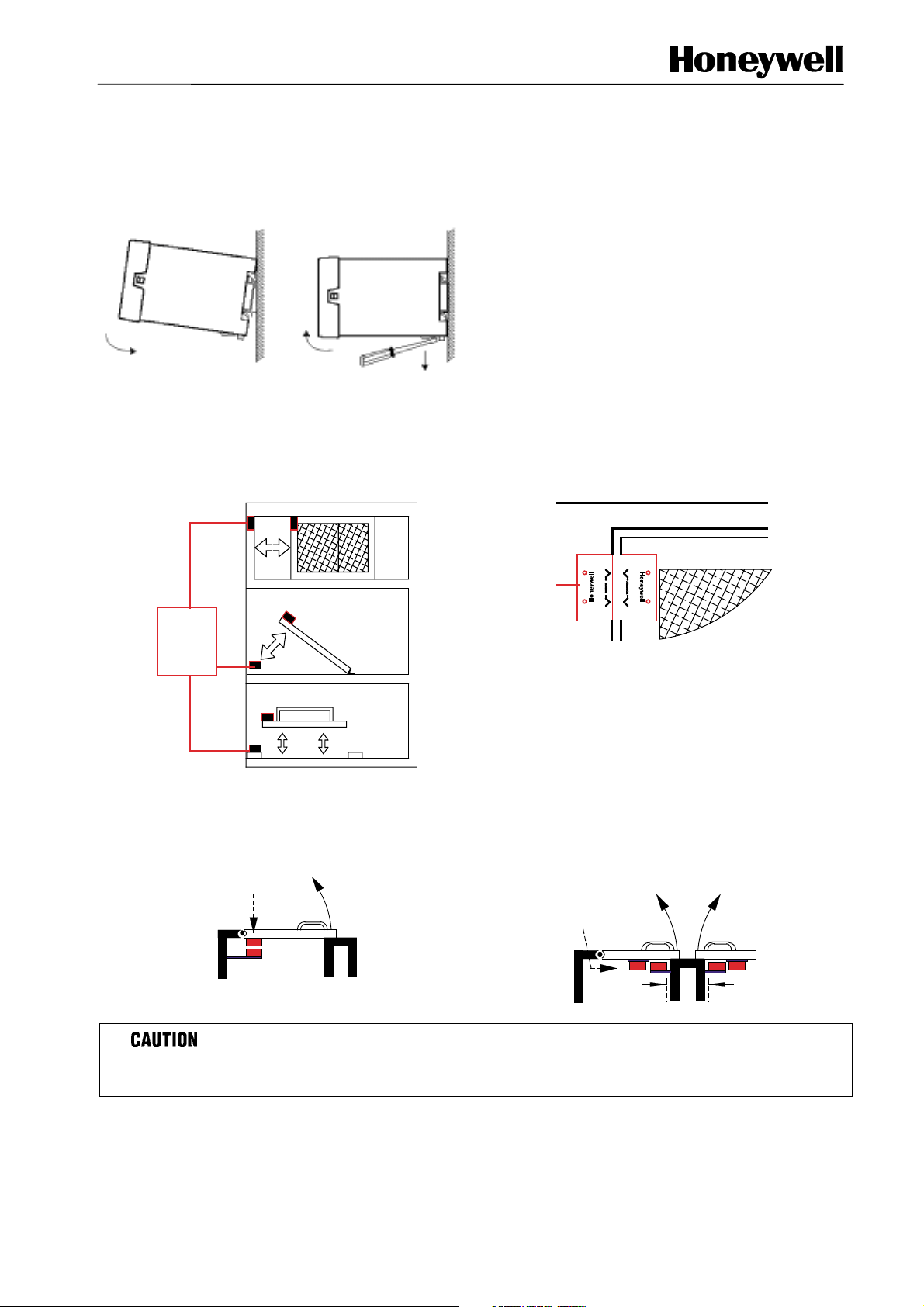

MECHANICAL INSTALLATION

The FF-SNC Control unit must be installed inside a NEMA 3 (IEC IP 54) rated enclosure or better. The module can be

clipped easily onto a 35 mm (1.38 in.) width DIN rail (see figure 3 for installation and removal).

FIG 3. INSTALLATION DIAGRAM

1. The FF-SNC control

unit is designed to fit

standard 35 mm /

1.37 in symmetric DIN

rail.

2. To remove: Place the tip

of a small screwdriver into

the white catch at the

bottom of the box (1) and

gently lever out.

This releases the retaining

clip and allows the unit to

be titled (2) and removed (3).

MOUNTING SAFETY SWITCH SENSORS

The FF-SNC safety swiches can be fitted to sliding, hinged or removable machine guards. Mount the fixed part of the

safety switch to the machine frame and the actuator on to the opening edge of the door ensuring that the targets on the

printed faces of the switches are aligned (see Fig. 4).

FIG. 4

FIG. 5

SLIDING DOOR

FF-SNC

HINGED DOOR

FF-SNC

FF-SNC

GUARD DOOR

LIFT OFF DOOR

FSNC_10EN

GUARD SWITCHES

The FF-SNC safety switch sensors have 2 fixing holes and are supplied with M4x20 mm Torx Proof screws to be specified.

FIG. 6. FIG. 7

WRONG

FSNC_4

CORRECT

Leave a 1 mm/0.039 in

gap to prevent damage

FSNC_3

FSNC_5

Min. 50 mm/1.97 in between actuators

as above

DO NOT enlarge the fixing holes!

Failure to comply with these instructions will result in product damage.

107099-10-EN FR26 GLO 602 Printed in England 3

Page 4

• Always try to mount the switch and actuator on non-ferrous material. Ferrous materials will reduce the switching distance.

• The sensors should be mounted with a gap of approximately 1 mm/0.039 in (Fig 7). When the guard is closed, this gives a

good level of lateral tolerance to allow for “gate sag” and freedom from nuisance tripping due to machine / guard vibration.

• Leave a minimum gap of 50 mm/1.97 in between actuators as above (Fig. 7).

IMPROPER HINGED DOOR INSTALLATION

On a hinged door, do not mount the switch and actuator close to the hinge (Fig. 6) in order to prevent the door from

being opened while the switch is still in the scanning range specifications (State ON).

Failure to comply with these instructions will result in death or serious injury.

IMPROPER SWITCH INSTALLATION

EN 1088 provides some mounting suggestions, see examples below.

When fixing the switches to a sliding door (see Fig. 8), ensure that when the door is opened (see Fig. 9), the switch is

not easily accessible, helping prevent the system from being overridden.

Failure to comply with these instructions will result in death or serious injury.

FIG. 8. FIG. 9.

FSNC_6

FSNC_7

Refer to the European standards EN 811, EN 953, EN 294.

IMPROPER EXTENSION MODULE WIRING AND SET UP

• NEVER use the FF-SNC1EXT extension module as a stand alone module. It must be connected to the

FF-SNC400R2, FF-SNC400RE or FF-SNC200R2 master module, to operate correctly.

• Generally speaking, do NOT use the FF-SNC1EXT extension module if the master module (FF-SNC400R2,

FF-SNC400RE or FF-SNC200R2) can support all sensors needed in the application.

• When use of the FF-SNC1EXT extension module is required, it should be connected to the last input available on

the master module, ie "gate 4" for the FF-SNC400R2 or FF-SNC400RE or "gate 2" on the FF-SNC200R2.

• If exceptionaly the FF-SNC1EXT extension had to be used although inputs available on the master module are not

all used, make sure the extension module is connected to the next available input. For example, if only 2 sensors

are connected on the FF-SNC400R2 4-gate master module, the sensors would have to be connected to "gate 1"

and "gate 2" inputs and the extension module would have to be connected to "gate 3".

• Selector switches on the extension module and on the master module should always be positioned to reflect and

match the exact number of inputs in use, whatever is connected to these inputs (a sensor or an extension module).

• When installing or modifying an FF-SNC system, ALWAYS test correct operation by opening and closing each gate

separately. When all gates are closed and the master module reset, the master module safety outputs 13-14 & 2324 should be ON. When any of the gates is opened, the safety outputs 13-14 & 23-24 should go OFF.

Failure to comply with these instructions will result in death or serious injury.

4 107099-10-EN FR26 GLO 602 Printed in England

Page 5

LID REMOVAL AND SWITCH SELECTION

MODE SETTING LED INDICATORS

FIG. 15. FF-SNC400R❏

❏ active gate selection

❏❏

ELECTRICAL SHOCK

• Remove power from FF-SNC switches and before

setup. Ensure that installation is performed by

qualified personnel.

Failure to comply with these instructions could

result in death or serious injury.

This module offers the capability to function in the

automatic start mode or manual start mode. To set the

desired mode of operation, insert the start pushbutton between terminals X1/X2 for manual start

mode or insert a jumper between X1/X2 for

automatic start mode to function.

LID REMOVAL

The central part of the

FF-SNC lid (1) is

FIG. 10.

removable. Using a small

screwdriver in the recess

(2) gently prise the lid

upwards.

21

This allows access to the

Guard Selector Switch (See

Fig. 11 to 13) and to the

automatic and restart mode

selector switch.

SWITCH SELECTION

Using the GATE SWITCH

SELECTOR Switch, set the

FF-SNC to the required

number of inputs.

NOTE: the number of

Active Gate Selection

A1

G2

G1

FF-SNC200R2

31 13BL23

DR

A131X113BL23DR

GATE 1

GATE 1

G2

G1

inputs (safety switches)

must match the gate

selector setting. Any

difference will prevent the

system from operating.

A132X214BL DR

FIG. 11.

Selector

switch

down for 1

GATE 2

24

GATE 2

A132X214BL DR

24

FIG. 12.

Selector switch

up for 2 gate

operation

gate

operation

Automatic/Manual

restart:

Using the AUTOMATIC /

MANUAL SELECTOR

Switch, set the FF-SNC to

the required restart mode.

31 13BL23

A1

A

M

GATE 2

A132X214BL DR

GATE 1

DR

A131X113BL23DR

GATE 1

A

M

GATE 2

A132X214BL DR

24

24

Auto

Manual

FF-

SNC200

A

(up)

M

FF-

SNC400

A

(down)

FIG. 13.

Selector

switch up for

automatic

restart

FIG. 14.

Selector

switch down

for manual

restart

(down) M (up)

Gate

Selector

Operation

Switch

1 Gate Operation

Yellow LED No.1 will illuminate when

234

gate switch 1 is closed

When no Green LED's are illuminated

only the first gate input is activated

2 Gate Operation

2

3

Yellow LED's No.1 & No.2 will illuminate

when the corresponding gate switch is closed

4

The top Green LED will be illuminated

to show 2 gate inputs are activated

3 Gate Operation

23

Yellow LED's No.1, 2 & 3 will illuminate

when the corresponding gate switch is closed

4

The top 2 Green LED's will be illuminated

to show 3 gate inputs are activated

4 Gate Operation

234

FSNC_9

Yellow LED's No.1,2,3 & 4 will illuminate

when the corresponding gate switch is closed

All three Green LED's will be illuminated

to show all 4 gate inputs are activated

FIG 16. FF-SNC1EXT active gate selection*

Gate

Selector

Operation

Switch

1 Gate Operation

G2

Yellow LED No.1 will illuminate when

G3

gate switch 1 is closed

G4

When no Green LED's are illuminated

only the first gate input is activated

G5

G2

FSNC_24

FSNC_25

*If an extension module is connected, it has to be taken

into account when selecting active gates.

2 Gate Operation

Yellow LED's No.1 & No.2 will illuminate

G3

when the corresponding gate switch is closed

G4

The top Green LED will be illuminated

to show 2 gate inputs are activated

G5

G2

3 Gate Operation

Yellow LED's No.1, 2 & 3 will illuminate

G3

when the corresponding gate switch is closed

G4

The top 2 Green LED's will be illuminated

to show 3 gate inputs are activated

G5

4 Gate Operation

G2

Yellow LED's No.1,2,3 & 4 will illuminate

G3

when the corresponding gate switch is closed

G4

All three Green LED's will be illuminated

to show all 4 gate inputs are activated

G5

5 Gate Operation

G2

Yellow LED's No.1,2,3,4 & 5 will illuminate

G3

when the corresponding gate switch is closed

G4

All four Green LED's will be illuminated

to show all 5 gate inputs are activated

G5

FSNC_14

FSNC_15

107099-10-EN FR26 GLO 602 Printed in England 5

Page 6

Safety Distance Calculations per US ANSI / OSHA standard

Ds = K(Ts + Tc + Tr ) + Dpf

With:

Ds = minimum safe distance between safeguarding device and hazard

K = speed constant: 1,6 m/sec (63 in/sec) minimum based on the movement being the hand/arm only and the body

being stationary (a greater value may be required in specific applications and when body motion must also be

considered)

Ts = worst stopping time of the machine/equipment

Tc = worst stopping time of the control system

Tr = response time of the safeguarding device including its interface (Tr for interlocked barrier may include a delay

due to actuation. This delay may result in Tr being a deduct– negative value).

Dpf = the “Depth penetration factor” is the maximum travel towards the hazard if the guard can be opened a certain

width or amount before a stop is signaled.

Dpf values from OSHA O-10 Table

If the maximum width or diameter of the opening is less

than or equal to (mm/in):

6,4 / 0.25 12,7 / 0.5

9,5 / 0.375 38,1 / 1.5

12,7 / 0.5 63,5 / 2.5

15,9 / 0.625 88,9 / 3.5

19,1 / 0.75 139,7 / 5.5

22,2 / 0.875 165,1 / 6.5

31,8 / 1.25 190,5 / 7.5

38,1 / 1.5 317,5 / 12.5

47,6 / 1.875 393,7 / 15.5

54,0 / 2.125 444,5 / 17.5

152,4 / 6 800 / 31.5

Above 152,4 / 6 Not allowed

Example: Dpf = 0,5 when the guard can be opened up to, but less than 6,4 mm / 0.25 in before issuing a stop

command. Dpf = 444,5 mm / 17.5 in if the guard can be opened 54 mm / 2.125 in. At no time can the opening be

greater than 152,4mm / 6 in before issuing a stop command.

For more information, refer to the US regulations and standards (OSHA 29 CFR 1910.212 & 1910.217, ANSI B11.19

and ANSI/RIA R15.06).

Dpf equals (mm/ in.)

6 107099-10-EN FR26 GLO 602 Printed in England

Page 7

WIRING DIAGRAMS

(B)

y

FIG. 17.

24 V

(+)

24 V

(-)

FIG. 19.

FF-SNC200R2 FF-SNC400R2/FF-SNC400RE

FIG. 18.

+

GS1

F1

A1 X1 BL DR 31 13 23

GATE 1

POWER

IND 1

IND 2

RUN

GATE 2

A2 X2 BL DR 32 14 24

GS2

K1 K2

F2

K1

K2

(B)

Mechanical

Safety

Switches

Emergency

Stop

-

or

Manual

reset

K1

K2

(A)

FSNC_16EN

A1

S13 S23

X1 BL DR BL DR 31 13

POWER

RUN

A2

S14 S24

X2 BL DR BL DR 32 14 24

GS1 GS2

GATE 2 GATE 1

DE-SELECT

GATE 2

GATE 3

GATE 4

GATE 4 GATE 3

GS3 GS4

F1

F2

23

K1 K2

Wiring diagram with FF-SNC1EXT Extension Module

FF-SNC400R2

Control Unit (24 Vdc)

GS1 GS2

A1

S13 S23

X1 BL DR BL DR 31 13 23

GATE 2 GATE 1

1

POWER

DE-SELECT

GATE 2

2

RUN

3

GATE 3

4

GATE 4

S14 S24

X2 BL DR BL DR 32 14 24

GATE 4 GATE 3

A2

GS3

F1

K1 K2

F2

K1

K2

(A)

Manual

Reset

(Momentary

Push-Button)

K1

K2

24 Vdc

FF-SNX1EXT+

FF-SNC400R2

8 Gate safety system

with optional

mechanical switch

or E-Stop input

and Manual Reset

24 Vdc

+

-

FF-SNC1EXT

Extension Module

GS1

GS2 GS3

A1 BLDR

BLDR BLDR

GATE 1

GATE 2 GATE 3

POWER

2

3

4

5

GATE 4

GATE 5

A2 BLDR

BLDR BLDR

GS4

GS5

(B)

Mechanical

IND 1

safety switch

or E-Stop

IND 2

IND 3

IND 4

IND 5

K1

K2

(A)

Manual

Reset

K1

K2

FSNC_17EN

FF-SNC1EXT

Extension Module

GS1

GS2 GS3

A1 BLDR

BLDR BLDR

GATE 1

GATE 2 GATE 3

POWER

GATE 4

GATE 5

A2 BLDR

BLDR BLDR

GS4

FF-SNC200R2

Control Module

GS1

F1

F2

A1 X1 BL DR 31 13 23

IND 1

IND 2

IND 3

IND 4

IND 5

GATE 1

POWER

IND 1

IND 2

RUN

GATE 2

A2 X2 BL DR 32 14 24

K1 K2

K1

K2

(A)

Manual

Reset

(Momentary

Push-Button)

K1

K2

24 Vdc

+

FF-SNC400R2

2 x FF-SNC1EXT

10 Gate safety system

with Manual Reset

24 Vdc

-

FF-SNC1EXT

Extension Module

GS1

GS2 GS3

A1 BLDR

BLDR BLDR

GATE 1

GATE 2 GATE 3

IND 1

POWER

IND 2

IND 3

IND 4

IND 5

GATE 4

GATE 5

A2 BLDR

BLDR BLDR

GS4

GS5

(A) if the automatic restart is set, X1 and X2 must be jumpered for correct operation.

If a Mechanical Safet

operation.

Switch or an Emergency Stop is not used, S13/S14 and S23/S24 must be jumpered for correct

APPLICATION NOTES

Up to 28 gates can be protected, using extension modules.

The extension module must be connected to the BL/DR terminals corresponding to the last gate on the master module.

FSNC_23EN

107099-10-EN FR26 GLO 602 Printed in England 7

Page 8

WARRANTY AND REMEDY

Honeywell warrants goods of its manufacture as being

free of defective materials and faulty workmanship.

Contact your local sales office for warranty information.

If warranted goods are returned to Honeywell during

the period of coverage, Honeywell will repair or replace

without charge those items it finds defective. The

foregoing is Buyer’s sole remedy and is in lieu of all

other warranties, expressed or implied, including

those of merchantability and fitness for a particular

purpose.

While we provide application assistance, personally

and through our literature and the Honeywell Website,

it is up to the customer to determine the suitability of

the product in the application.

Specifications may change at any time without notice.

The information we supply is believed to be accurate

and reliable as of this printing. However, we assume no

responsibility for its use.

SALES AND SERVICE

For application assistance, current specifications,

pricing or name of the nearest Authorized Distributor,

contact a nearby sales office or call:

TELEPHONE

+ 61 (0) 2 9370 4500 Australia

+ 1-800-737-3360 Canada

+ 33 (0) 1 60 19 80 40 France

+ 49 (0) 69 8064 444 Germany

+ 34 91 313 61 00 Spain

+ 1-815-235-6847 International

+ 44 (0) 1698 481 481 UK

+ 1-800-537-6945 USA

FAX

+ 61 (0) 2 9370 4525 Australia

+ 1-800-565-4130 Canada

+ 33 (0) 1 60 19 81 73 France

+ 49 (0) 69 8064 442 Germany

+ 34 91 313 61 29 Spain

+ 44 (0) 1698 481 276 UK

+ 1-815-235-6545 USA

INTERNET

http://www.honeywell.com/sensing/

info.sc@honeywell.com

EC DECLARATION OF CONFORMITY

© 2002 Honeywell International Inc. All rights reserved

Honeywell

21, chemin du vieux chêne

38240 Meylan

9OO1ISO

AFAQ N 1994/2213

France

107099-10-EN FR26 GLO 702 Printed in England

E

C

E Net

Q

U

A

L

I

F

T

I

R

E

D

M

E

T

S

I

T

Y

S

Y

Loading...

Loading...