Page 1

Category 3 Safety laser scanner

Two zone programmable area control

FF-SE Series

FEATURES

• No touch detection system in

compliance with the requirements of

IEC/EN 61496 part 1 and pr EN 61496

part 3 for Type 3 equipments

• Meets applicable parts of ANSI B11.191990 standard and OSHA 1910.212

regulations for Control Reliability

• Objects and people protection

2

• Surveillance area size up to 262 m

2

2820 ft

/

• Class 1 infrared Laser beam, invisible

and harmless to the eye

• Easy to install: a single device, a single

cable

• Detection of a unique inner failure per

EN 954-1

• Fast and accurate configuration of the

surveillance areas around the dangerous

zone with a computer and user friendly

software

• The shape of the protection zones fits

any environment (Teach-in option for

zone definition)

• Scanning angle: up to 300°

• Free rotating head, making it a self-

cleaning optical system

• Permanent self-checking of the beam

status with fixed test target

• External user defined test target

possibility to ensure correct positioning

of the laser during machine operation

• Response time: 0.280 s

• Surveillance range: 10 m / 32.8 ft

• Detection range: 6 m / 19.7 ft

• Resolution: 70 mm / 2.8 in

at 6 m / 19.7 ft

TYPICAL APPLICATIONS

• Horizontal detection (like a sensitive

mat) of people or objects

• Anti-collision system for AGVs

BIA

Berufsgenossenschaftliches

Institut für

Arbeitssicherheit

(Pending)

Approved as

Type 3

per IEC/EN 61496-1

The FF-SE laser scanner from Honeywell is a revolutionary product in the world of

industrial safety. This device combines radar and laser principles to scan pre-defined zones around dangerous machinery or moving vehicles. In case of intrusion

in these zones, output relays are immediately opened, eliminating the danger.

An infrared class 1 laser beam strikes a mirror rotating at 8 Hz, allowing it to sweep

a 300° area. Any object with a minimum reflectivity of 1,8% (black target) will be

detected in a 6 m / 19.7 ft radius. Two safety levels may be set through two zones

that can have any shape:

• “alarm zone”, in a 10 m / 32.8 ft radius around the FF-SE

• “safety zone” in a 6 m / 19.7 ft radius

These two zones are defined using the software (ordered separately), running on a

computer connected to the FF-SE, which allows the areas to be protected to be

displayed on the screen. The two zones correspond to two independent outputs,

allowing multiple applications:

• the alarm zone can be used to trigger an acoustic or light signal when a person

approaches, which indicates that there is a close danger, allowing the intruder to

withdraw without stopping the machine.

• the safety zone is used to trigger the immediate stopping of the machinery

(2 safety NO contacts).

Restart is automatic after clearing the zone. Use additional safety control module if

manual restart is needed.

This system is unique because of its small resolution (0,5° in angle) and its excellent precision, while covering a wide area (262 m2 / 2820 ft2). The FF-SE has been

designed in agreement with the pr EN 61496-3 that will soon be brought into effect

for this new kind of detecting device.

FF-SE Series

External and internal surveillance systems make it a Type 3 optoelectronic protective system. Its self-cleaning optical head and its good immunity to pollution guarantee a superior reliability.

!

WARNING

MISUSE OF DOCUMENTATION

• The information presented in this product sheet (or catalogue) is for reference only. DO NOT USE this document as system

installation information.

• Complete installation, operation and maintenance information is provided in the instructions supplied with each product.

Failure to comply with these instructions could result in death or serious injury.

•

Industrial Safety Products

• 153

FF-SE

Page 2

FF-SE

• Objects and people protection

BIA

Berufsgenossenschaftliches

Institut für

Arbeitssicherheit

• Scanning angle up to 300°

2

• Surveillance up to 262 m

/ 2820 ft

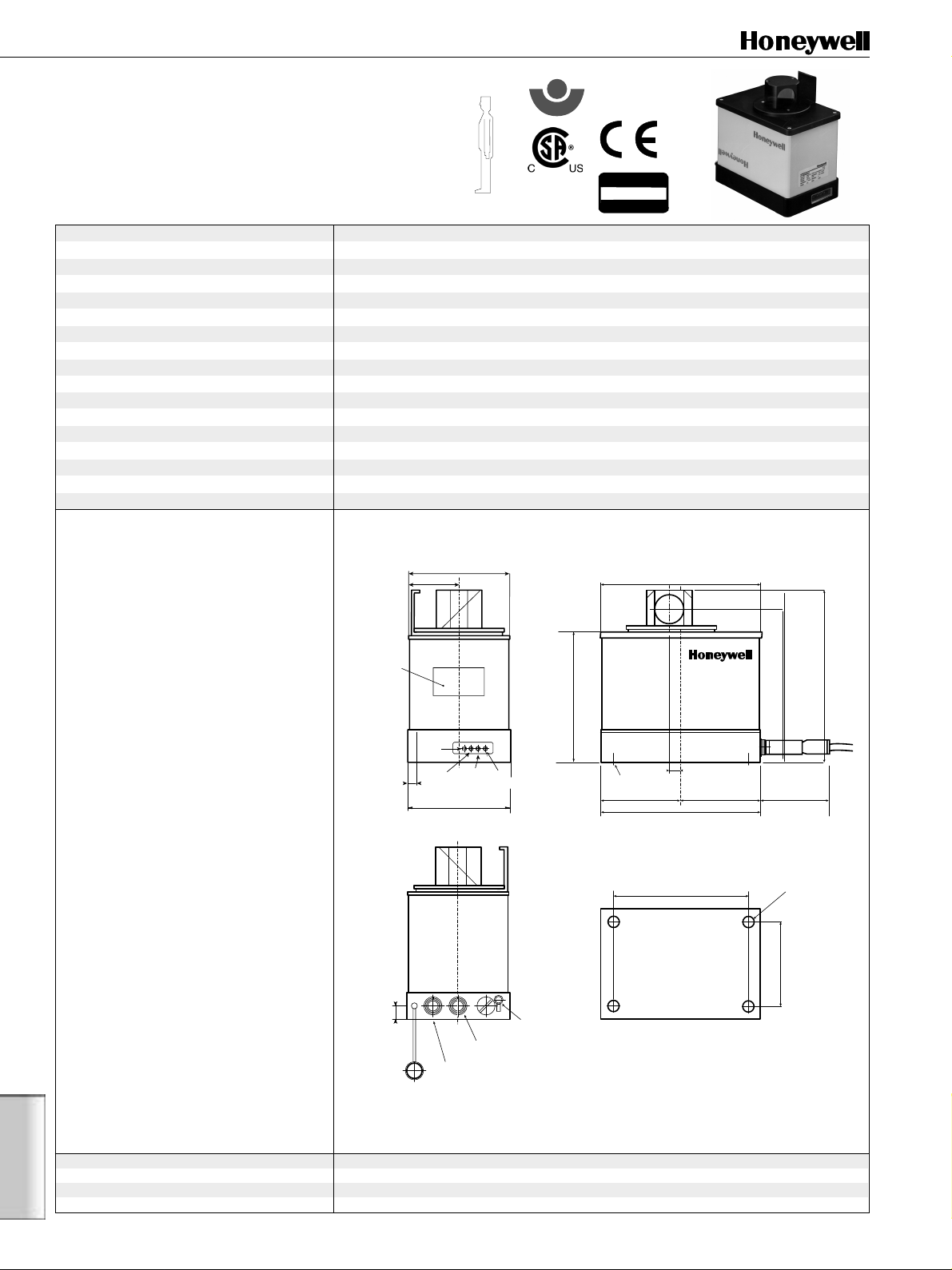

Dimensions in millimeters / inches, meters / feet, weights in kg / lbs

Features Power supply 24 Vdc, ± 15%

Consumption 0,75 A at 24 Vdc, rush at startup: 2 A during 100 ms

Measure and detection angle 300°

Detection distance Black target (1,8%): 6 m /19.7 ft

Head spinning frequency 8 Hz, ± 5%

Status display

Emitting source Infrared laser LED, 905 nm, ± 30 nm

Beam divergence 0,9°

Safety class

Protection class IP 65 (NEMA 4, 13)

Operating temperature 0 °C to 50 °C / 32 °F to 122 °F

Storage temperature -20 °C to 70 °C / -4 °F to 158 °F

Shock and vibration resistance According to IEC 68

2

(Pending)

Outputs 3 relay outputs, free of potential: 2 A / 48 V

Green:

safety zone free •

Red

: safety zone occupied •

Interface RS 232, V.24, 19200 Baud

Sensor:

Type 3 according to IEC/EN 61496-1

Material

Casing

: Aluminium •

Colour Yellow paint RAL 1021

Approved as

Type 3

per IEC/EN 61496-1

(1)

•

Laser

Connector

Yellow:

alarm zone occupied - Diagnostic

(2)

: Class 1

according to IEC 825-1

: Steel

Ordering information

FF-SEDGE6G2-1 Sensor kit

112 / 4.41 in

54 / 2.13 in

172 / 6.77 in

(Sensor + power cable)

and

FF-SEZ6SOFT2 Software kit (Diskette + PC cable)

Type plate

Accessories:

FF-SEZ6BRAC3 Mounting bracket

FF-SEZ6PLAT Mounting plate

FF-SEZ6POST Post supporting the bracket

Remarks

(1) Category 3 per EN 954-1.

FF-SE

(2) No special limitation of use in the USA or in

13,5 /

0.53 in

10 / 0.39 in

Protection cap

Interface

interface

Green

SAFETY

Red

SAFETY

Binder

Yellow

ALARM

LED

112 / 4.41 in

24 Vdc

Signal Fuse

Binder

Yellow

DIAGNOSTIC

3.15 A

PE connection

Type 132,5 ± 1 / 5.22 in

Mounting holes

M4 x 10 (4x)

View from the bottom

Position of the mounting holes

144 ± 0,2 / 5.67 in

Europe.

Infrared beam radius At 6 m / 19.7 ft: 100 mm / 3.9 in • At 10 m / 32.8 ft: 170 mm / 6.7 in

Beam Increment 0,5°

Response time t1 280 ms (including relays)

Device weight 3 kg / 6.61 lbs

Optical axis

10,5 / 0.41 in

172 / 6.77 in

155,5 ± 1 / 6.13 in

175,5 ± 1 / 6.91 in

==

approx. 60 / 2.36 in

ø 4,5 / 0.17

± 0,2

86 ± 0,2 / 3.39 in

154 •

Industrial Safety Products

•

FF-SE Series

Page 3

RS232

14 pins

PC RS232 FF-SE

1

White

Brown

Pink

Black

Yellow

Green

E

6

2

7

3

8

4

9

5

G

P

R

L

O

S

J

N

T

M

U

A

C

CTS

TxD

RxD

RESTART

RESET

GND

RTS

Tolerance and detection distances

i

n

w

g

e

i

V

Alarm zone

o

i

n

t

c

z

e

t

e

D

Safety zone

FF-SE

User defined

test target

60˚

Fixed test target

Installation distance

S

z

o

n

e

o

n

e

6 m/

19.7 ft

10 m/

32.8 ft

300˚

The protection zone is made up of 600 beams. Each beam receives a signal corresponding to a distance measured using the

light time of flight principle, whatever the reflectivity of the target. If this signal goes below a user defined threshold during

the surveillance, it means that an object is present in the protection area. Consequently, the corresponding relay is opened.

The surveillance area includes an alarm zone and a safety zone,

that are user-defined. Both may have an irregular shape which

corresponds to the environment.

Applications: a greater flexibility

The FF-SE being an optoelectronic detecting device, it has a no

touch detection and therefore brings more flexibility on site. Its

principle of diffuse reflection simplifies the installation, compared to the traditional emitter/receiver pair of light curtains.

The protection zones do not need any additional fixture (wall,

fence, door...) since the FF-SE covers a 300° angle and adapts

to existing obstacles. Installation costs are reduced to a minimum and the working position is easily accessible since the

protection is a no-touch type.

H

S ≥ V (t1 + t2) + (L - 0.4 H) + E

Where:

• S: Distance (mm / in)

• t1: Response time of the FF-SE (See technical

specifications)

• t2: Stopping time of the machine (s); i.e. the time interval

necessary to stop the machine, after the protection

device has emitted the stop signal

• L: 1200 mm / 47.28 in

• H: Height of the beam from the ground,

300 ≤ H ≤ 1000 mm / 11.82 ≤ H ≤ 39.4 in

• V: Penetration velocity (mm / s or in / s)

( V = 1600 mm / s in Europe) V = 63 in / s in USA

• E: Maximum Error in measurement (see technical

specifications)

2

4

5

13

8

7

6

In case of a change in the machine or production floor layout,

the FF-SE can adapt very quickly by a re-configuration. The

FF-SE is not linked to any particular set up or machine: it is

exchangeable just by programming.

Compared to a usual safety device (light curtain, safety mat,

door...), the FF-SE includes two protection zones which is a

great asset: the alarm zone, used as an early warning zone,

allows a signal to an intruder that he is close to a dangerous

zone and that his movement is about to stop the machine.

There is still time for the individual to change direction and

avoid a stoppage of the equipment that can be costly if it

occurs often. By avoiding unnecessary stoppage, the FF-SE

increases the production lines productivity without decreasing

the safety: it protects just what is needed.

Computer connection

G

E

RP

O

S

JC

T

N

UM

L

A

Pin number Signal Function

1 24 V Power 24 Vdc supply

2 GND24 Ground 0 Vdc supply

3 SAFETY 2.1 DETEC2 Safety 2 relay output

4 SAFETY 2.2 DETEC2 Safety 2 relay output

5 SAFETY 1.1 DETEC1 Safety 1 relay output

6 SAFETY 1.2 DETEC1 Safety 1 relay output

7 ALARM1 ALARM relay output

8 ALARM2 ALARM relay output

SHIELD PE Protection earth

FF-SE Series

•

Industrial Safety Products

FF-SE

• 155

Page 4

Software

The Honeywell software kit allows the protection zones to be

easily programmed into the sensor. This software runs under

any PC (286 or more), under MS DOS. The FF-SE is linked to the

PC through the serial port (RS232 format) and a cable supplied

with the software kit. The custom zone definition can be

achieved through 3 different methods that can be combined:

• with the mouse, by clicking on end points forming the limit of

the protection field;

• with the keyboard, by plotting points with the cursor keys;

• with a text editor in which the end points are defined by their

coordinates;

Defining the protection zones is easy since obstacles are displayed on the screen: they are seen in real time.

Using a PC also allows to store several configurations on a disk,

that can be retrieved in a few seconds into the sensor. One can

therefore define different shapes according to different situations and transmit them into the sensor whenever needed.

Once the settings are downloaded into the sensor, it is a

standalone device that will keep all zone definitions and parameters in a permanent memory, even if the power is cut. Access

to this memory and to zone definition is protected by a password. The program also has other features: real time profile

measurement, sensor simulation to get familiar with it, surveillance of the zones with intrusion time display.

Graphic screen

Defining the zones with the editor

Self-check

A fixed test target is mounted on top of the housing to ensure

the beam self-check: this takes away 60° off the scanning angle

to perform various checks: contamination of the lens, accuracy

of the distance measurements, status of the beam...

An external test target possibility ensures the correct positioning of the sensor and guarantees the safety if its position is

changed since the definition of the zones depend on the position of the sensor. The rotating head is self-cleaning and therefore is much less sensitive to pollution as other fixed-window

devices. The internal angular coder is controlled by a “surveillance circuitry”, as are the relays.

FF-SE

156 •

Example of electrical connection

Dangerous

machine

FF-SE

Industrial Safety Products

Alarm device

Switching device

SAFETY signals

ALARM signal

Interface

•

Switching device

Serial port

PC

FF-SE Series

Page 5

Connection diagram

(+)

Emergency

Stop P/B

Honeywell FF-SE

1

Safety Laserscanner

Safety

Safety

Output 1

Output 2

3456 7 8

Alarm

Output

2

PE

Signalling

K3

K3

A1

(+)S11S12S22

FF-SRS5935:

Setting of internal switches S1

and S2:

S1: "With cross fault detection"

Power

K2

K3

S2:"Manual restart" mode

A2

S33S

(-)

(-)

Start

Installation

The FF-SE can be installed in various configurations. It does

not need any receiver nor separated reflector. When mounted

horizontally, it replaces light curtains or safety mats by offering

a better coverage and an increased flexibility. Its small size

allows installations in most of existing sites. The laser beam is

an invisible Class 1 laser, therefore it is not harmful and does

not disturb workers. A unique connector links the sensor to the

power supply and the devices connected to the 3 output relays

(alarm, safe 1 and safe 2), making connections with the sensor

very easy.

13 23 33 41

S1

S2

Internal Switches

S21

14 24 34 42

PE

34

Machine Control

Minimum distance

Honeywell

FF-SRS5935

Minimum distance

above the floor

B

e

z

e

i

c

h

T

y

p

N

r

.

S

e

r

.

N

r

.

150 mm /

5.91 in

n

u

n

g

LA

04

D

85

AR

00

2

00

D

0

0

/D

O

06

W

0

R

S

e

6

v

.

A

B

j

.

9

6

Scanning range

10 m / 32.8 ft

For AGVs

Weight and speed of AGVs in industrial environments can represent a certain danger for the workforce. The FF-SE can be

installed on these AGVs to ensure people safety: due to its long

range, it can stop the AGV before the obstacle, even if its speed

is high.

The two distinct zones can be used in an elegant way:

The alarm zone, with its 10 m / 32.8 ft range, acts as a slowing

down system: if something is detected in the zone, the AGV will

slow down and emit a warning signal to make the way free

again.

The safety zone, with its 6 m / 19.7 ft range, acts as an emergency stop: the AGV will immediately be stopped when an object is detected in this zone.

Knowing the AGV stopping distance and the response time of

the safety chain, it is possible to calculate the limits of these

zones optimally.

FF-SE Series

•

Industrial Safety Products

Normal speed

Slowing down

Complete stop

• 157

Safety zone

Alarm zone

Safety zone

Alarm zone

No intrusion

Intrusion

in the alarm zone

Intrusion

in the safety zone

Safety zone

Alarm zone

FF-SE

Page 6

Accessories

•FF-SEZ6BRAC3 Mounting bracket: It reinforces the

protection in installations where the sensor could be reached

by humans or vehicles. It allows head up or down mounting.

The bracket can be mounted on a vertical surface from behind

thanks to 4 M6 holes. There are 2 adjustable screws that allow

an adjustment of the scanning plane (±8°) in X, ± 4° in Y, so as

to allow an accurate placement of the beam, especially in

multiple device configurations.

Dimensions in millimeter/inches

200 / 7.88

50 /

1.97

89,5 /

r=10

30 /

95 / 3.74

105 /

165 / 6.50

13 /

0.51

1.18

4.13

3.52

89,5 / 3.52

200 / 7.88

2xr=10

42 /

1.65

90 /

3.54

60 /

116

42 /

1.65

4 M12 holes

4 ø6 holes for wall mounting

110,5 / 4.35

4xr = 10

1 ø6 hole

95 /

3.74

2 ø9 holes

2xr=11

±8˚ ±4˚

125 / 4.92

230 / 9.06

110 / 4.33

28/

1.10

60 /

60 /

30 /

1.18

2.36

2.36

135 / 5.32

mini. r

4 ø6 holes

1 ø 6 hole

86 / 3.38

5 /

0.19

•FF-SEZ6PLAT Mounting plate: Mounting plate to mount the

scanner on horizontal ground.

•FF-SEZ6POST:

This post is designed to support the mounting bracket

FF-SEZ6BRAC3. This allows an adjustment of the scanning

plane height. The scanning plane can be adjusted from

300 mm up to 700 mm / 11.82 in to 27.58 in. The bracket can

also be rotated around the post. A collar holds the bracket to

the post and slides on the post. The bracket can be mounted

up or down, so that the laser scanner head is either up or

down.

226 / 8.90

130 / 5.12

ø295 /11.62

overall: 700 / 27.58

FF-SE

•FF-SEZ6SOFT2: The Honeywell software kit allows sensor

programming and setup. It is supplied with a manual

explaining how to use it and an RS232 cable for PC

connection.

158 •

Industrial Safety Products

300 / 11.82

•

FF-SE Series

Loading...

Loading...