Page 1

Honeywell Process Solutions

ERX

Electronic Pressure Recorder

User Manual

October 2010

V 1.04

Honeywell

Page 2

Revisions

1.02 07/16/07

Changed item 780 text to 790, missed labeled item

Edited item 792 description

Change item 789 default to No 09/13/07

1.03

Add Audit Trail & Display list 2 for P3 Voltage monitoring 12/07/07

1.04 Honeywell 10/2010

2

www.honeywell.com

Page 3

Table of Contents

Introduction....................................................................................................................... 5

Warranty ........................................................................................................................... 6

Intrinsic Safety for Hazardous Locations....................................................................... 6

Warning.......................................................................................................................... 7

Modes of Operations......................................................................................................... 7

Sample Mode ................................................................................................................. 7

Display List Mode

.......................................................................................................... 7

Default Display Items and Live Enable....................................................................... 7

Serial Access Mode........................................................................................................ 8

Level 1...................................................

...................................................................... 8

Level 2......................................................................................................................... 8

Instrument Access ............................................................................................................. 9

How the ERX Recorder Works ............................................

........................................... 9

Pressure System ................................................................................................................ 9

Temperature System....................................................................................................... 11

Sample Interval .......................................................................................

........................ 11

Sample Interval Battery Life................................................................................... 11

Log Interval ..................................................................................................................... 11

Audit Trail ....................................................................................................................

... 12

Default Audit Trail Report Items .............................................................................. 12

Audit Trail Report Item 1-10.................................................................................. 12

Description of default Audit Trail items ................................................................... 12

Informational Display (LCD)...............................

.......................................................... 14

Installation and Operation of the ERX Recorder ........................................................ 15

Function Check............................................................................................................ 15

Instrument Setup.............................................................................................

............ 16

Instrument Configuration .......................................................................................... 16

Pressure .................................................................................................................... 16

Site IDs ......................................................................................................................... 16

Using Mas

terLink32 Software:...................................................................................... 17

• Date and Time ........................................................................................................... 17

• Sample Interval ......................................................................................................... 17

• Log Interval ............................

................................................................................... 17

• Start-of-Gas Day ....................................................................................................... 17

• Alarm Limits ................................................................................................................. 17

2-Point Pressure Calibration (Defined)......................

................................................... 18

2-Point Pressure Calibration (Gauge Transducers) .................................................... 18

2-point pressure calibration (procedure)...................................................................... 18

Two-Point Pressure Calibration (Absolute Transducers)........................................... 19

Two-point pressure calibration

(items required) ..................................................... 20

Two-point pressure calibration (procedure - absolute) ........................................... 20

Two-Point Temperature Calibration ............................................................................ 22

Alarm Pulses (Form-A) ................................................................................................

.. 23

Output Pulse Specifications............................................................................................ 23

Communicating to the ERX Recorder with a Modem ................................................ 24

Internal Modem Communications............................................................................. 24

3

Page 4

External Modem Communications without an External RS-232 Case Connector25

Internal or External Communications with a RS-232 Case Connector ................. 25

Automatic Call-In Feature ............................................................................................. 26

Alarm Call-In ............................................................................................................

...... 26

Pulse Method ................................................................................................................... 26

AT Commands Method .................................................................................................. 27

Scheduled Call-In Method.............................................................................................. 27

Alarm and Scheduled C

all-In ........................................................................................ 28

Modem Power Control--Call-out Window ................................................................... 28

30-Minute Window Interval ....................................................................................... 29

4-Hour Window Interval ............................................................

................................ 29

Multiple Windows- within the start and ending interval ........................................ 29

Digi-Span Fuel Switching Feature................................................................................. 31

Firmware Upgrade.......................................................................................................... 32

Procedure to Upgrade ERX Re

corder Firmware:....................................................... 32

Putting the ERX Recorder into “Shutdown” ............................................................... 35

Partial Shutdown......................................................................................................... 35

Complete Shutdown ...............................................................................

..................... 35

Taking the ERX Recorder “Un-Configured”............................................................... 36

Software method: ........................................................................................................ 36

Hardware method--if serial link cannot be established ........................................... 37

Parameter Item List..............................

.......................................................................... 38

Item Item Name & Description............................................................................... 38

P3 Pressure Coefficients....................................................................................... 38

Board Coefficients .................................................................................

.................. 38

P1 Pressure Coefficients................................................................................... 39

P2 Pressure Coefficients....................................................................................... 40

Board Coefficients ................................................................................................... 43

Audit Report Items-Default ........

................................................................................... 53

Pressure only default Audit Trail .............................................................................. 53

P3 Pressure Coefficients 1-26 ................................................................................ 54

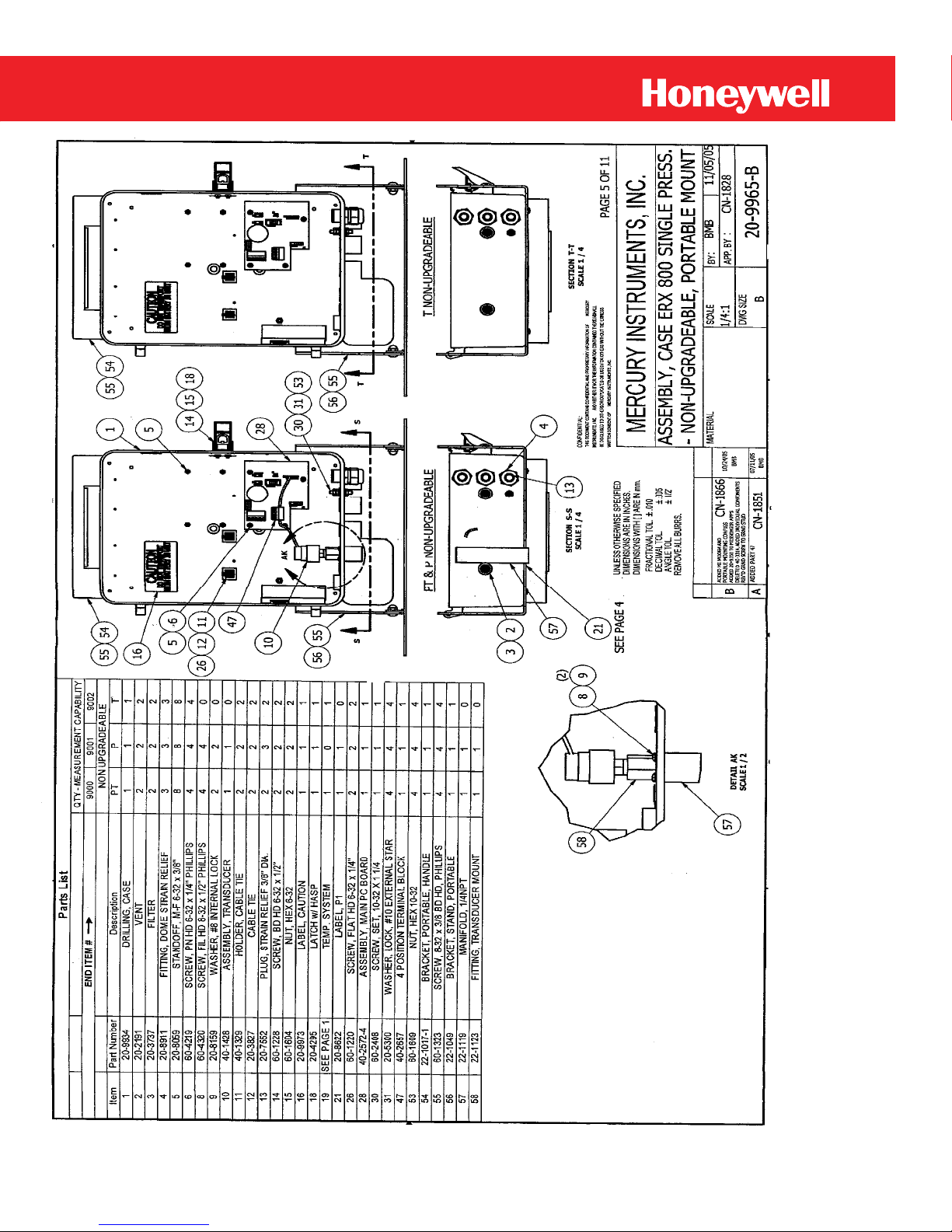

ERX Hazardous and Non-Hazardous Installation Drawings ..................................

... 67

4

www.honeywell.com

Page 5

Available Soon….

Introduction

Mercury Instruments ERX is a microprocessor-based, stand-alone, self-powered data recorder

that measures gas pressure(s), gas temperature, case temperature, and applied power supplies.

Sampled measurements, logged Audit Trail data, alarms, and operating parameters are stored in

non-volatile memory and may be retrieved directly with a laptop computer, Palm Pilot, Pocket

PC

, or remotely via modem. Pressure and Temperature, alarms, and other sampled parameters

may be displayed on an optional internal or external Alpha-Numeric LCD (Liquid Crystal

Display).

ERX Recorder is capable of sampling and recording up to three pressure transducers and ambient

and gas temperatures. At the time of manufacturing, the ERX may be fabricated as a wallmounted, pipe stand, or as a

Recorder (single pressure) or a Mini-AT (dual pressure) case.

Calibrating and serial accessing an ERX Recorder is accomplished by using Mercury

Instruments’ MasterLink32 version 3.50 or greater, Palm Suite, or Pocket PC software.

portable unit in an 800 series case, (three pressure default case) ERX

5

Page 6

MasterLink32 is a Window multifunctional software program that’s used to interface with an

ERX Recorder, via a serial cable, modem, or Bluetooth device.

MasterLink32 provides the following functions:

• Instrument configuration

• Date & Time

• Alarm limits

• Sample interval

• Log interval

• Audit Trail items (4 or 10 items)

• Display list (up to 18 displayable items)

• Units of mea

surement

• Pressure(s) and Temperature calibration

• Graph live pressure(s) or temperature

• Graph historical data retrieved for the ERX Recorder

• Audit Trail reports

• Serial Communications

• File management

• Instrument security

• See MasterLink32 ‘Help’ for additional functions and features

Warranty

Mercury instruments, Inc. warrants all instruments covered by this manual to be fr

ee from defects

in material and workmanship under normal use and service of this product. If returned to our

factory, transportation charges prepaid, within 4 years of the original purchase shipment date,

Mercury Instruments agrees to repair or replace any instrument, which its examination reveals to

have been defective due to faulty workmanship or material. All obligations or liabilities on

Mer

cury Instruments part is to repair or replace warranty instruments, and does not include any

other type of claims or damages, including but not limited to consequential damages following

the use of misuse of instruments sold by it. Mercury Instruments reserves the rights, at any time,

to make changes, modifications or enhancements to this product without prior notification. This

warranty is in l

ieu of all other warranties, express or implied. No agent is authorized to assume

for Mercury Instruments any liability except as set forth above

Intrinsic Safety for Hazardous Locations

Underwriter’s laboratories (UL) has listed the ERX Recorder as intrinsically safe for use in Class

I, Division 1, Group D hazardous locations and Canadian Standards Associations (CSA) for use

in Glass I, Divis

intrinsically safe instrument when installed in accordance with UL control drawing 40-3332 or

CSA control drawing 40-3332-A (see appendix).

ion 1, Groups C & D hazardous locations. The ERX Recorder is recognized as

6

www.honeywell.com

Page 7

Warning

Use only Mercury Instruments manufactured battery packs with part numbers as specified

on the certification label or control drawing. Use of third-party battery packs voids

product warranty, voids intrinsic safety certifications and may impair safety.

Modes of Operations

The ERX Recorder is in one of three operating modes. Each mode is well defined and suited to a

particular purpos

Operating Modes:

• Sample

• Display list

• Serial

Sample Mode

While in the sample mode, the instrument obtains, stores and compares pressure(s),

temperature(s), and power supply voltage readings with alarm limit set points. If reading

exceeds the alarm limit set points, the instrument outputs a single pulse out the alarm

channel, display ‘ALARM’ or customer configured message on inst

with an LCD, and if equipped with a modem, jumps into either a modem configured callin sub-routine or an instrument call-in sub-routine.

Display List Mode

An LCD is required for display list mode operation. A push button is used to scroll

through the pre-programmed items. Display list mode contains two lists (display list 1 &

display list 2) and live readings (live enabled).

display list 2 up to twelve items. Any of the instrument items maybe programmed in

either list. Live-enable is determined by the instrument installed hardware, number of

pressure transducers and whether equipped with a temperature probe. While in display

mode operation, no changes are possible that will affect the configuration of the ERX

Recorder; i

e.

ruments equipped

Display list 1 can contain up to six items,

t will only display the pre-selected items.

Default Display Items and Live Enable

Instrument Configuration

Item

Code

P PP PPP PT PPT PPPT T

Display List 1 Items 1-6

530 580 580 580 580 580 580 580

531 582 582 582 582 582 582 582

532 583 583 583 583 583 583 583

533 503 503 503 503 503 503 503

534 521 521 521 521 521 521 521

535 255 255 255 255 255 255 255

Live Display Enable

536 P PP PPP PT PPT PPPT T

Display List 2 Items 1-12

537 631 631 631 631 631 631 635

7

Page 8

537 255 255 255 255 255 255 255

538 255 255 255 255 255 255 255

539 255 255 255 255 255 255 255

540 255 255 255 255 255 255 255

541 255 255 255 255 255 255 255

542 255 255 255 255 255 255 255

543 255 255 255 255 255 255 255

544 255 255 255 255 255 255 255

545 255 255 255 255 255 255 255

546 255 255 255 255 255 255 255

547 255 255 255 255 255 255 255

548 255 255 255 255 255 255 255

Serial Access Mode

Serial access requires a serial cable, modem, or a Bluetooth device along with

MasterLink32, Palm Pilot, or Pocket PC software. In addition, the instrument must be

equipped with the same type of serial hardware that is accessing the instrument. While in

this the mode the instrument may be configured, calibrated, or data can be retrieved from

the instrument. Serial accesses co

8

www.honeywell.com

538 637 637 638 637 638 638 645

539 638 638 632 638 632 632 646

540 632 632 640 632 640 640 636

541 639 640 633 639 633 633 647

542 640 670 642 640 642 642 648

543 651 633 634 635 634 634 657

544 650 641 644 645 644 644 656

545 649 642 426 646 635 426 655

546 255 634 428 636 646 428 255

547 255 644 429 647 636 429 255

548 255 673 431 648 648 431 255

Display List 2 Items 1-12 P3 with Voltage Monitor

nsist of two levels, level one and level two.

Level 1

Level 1 software access is considered a lower level access to the instrument and

software functions and is gained through the use of a laptop computer, Palm

Pilot, or Pocket PC and appropriate serial hardware connected to the instrument’s

serial port. The user must enter a five-digit code access code (default 11111) to

enter level one. Leve

instruments parameters and its functionality is control and configurable by Level

2 access.

Level 2

Level 2 software is the highest available level access and has access to all

instrument and software functions and is gained through the use of a laptop

computer, Palm Pilot, or Pocket PC and appropriate serial hardware connected to

the i

nstrument’s serial port. The user must enter a five-digit code access code

(default 22222) to enter level two.

l one is limited in its ability to change or configure the

Page 9

Instrument Access

In addition, an instrument access code is necessary to maintain the instrument security and must

be entered or preprogrammed in appropriate software site list at the time of either successful level

one or level two serial links. Instrument default access code: 33333

How the ERX Recorder Works

The ERX Recorder utilizes a dedicated microprocessor in conjunction with precisi

on sensors to

measure gas pressure(s) and temperature(s) and records the measured values in memory. The

electronic circuits are powered by a battery pack located inside of recorder case or by an external

power source. The applied power regulated to voltages required by the connected circuits. While

in the sample mode, most of the electronic circuitry is in an un-powered state (sleep mode) to

co

nserve battery power. When an internal timer has reached the selected sample interval time,

the electronics are energized and a sample measurement cycle begins.

When the recorder wakes-up and enters the sample measurement mode, the programmable

firmware instructs the microprocessor to obtain analog measurements. The analog signals

(pressure(s), temperature(s) and power) are multiplexed through

the A/D converter and routed to

the microprocessor. The microprocessor converts and stores the digitized analog signals to an

equivalent numeric value, scaled to the selected engineering units. P1 pressure is stored in item

500; P2 pressure is stored in item 501; P3 pressure is stored in item 420; Gas temperature is

stored in item 502; Case temperature is stored in item 503: and power is stored

in item 521.

Once the all the measurements are obtained, the microprocessor compares the measured values to

the parameter limits already in memory, i.e., high and low limits of pressure(s), temperature,

power, etc; if any of the measured parameters are out-of-range, the firmware instructs the

microprocessor to jump into an alarm subroutine. The alarm subroutine activates the appropriate

alarm co

de item(s), turns on the alarm indicator, transmits an alarm pulse out the alarm channel

and if equipped, activates a call-in, via a Messenger modem, CDMA…etc.

If during a sample measurement cycle wake-up the power supply voltage falls below the low

limit set points, the microprocessor activates the alarm indicator, transmits an alarm pulse out the

alarm channel, and, if equipped, activates a mod

em call-in.

After the microprocessor has completed the sample measurement cycle wake-up, the

microprocessor will update memory, display the new samples data to the LCD, and return to the

‘sleep mode’ to conserve energy.

Other than time, the ERX Recorder will also wake-up due to either a serial link or push button

activation. A wake-up caused by a serial communication link allows the recorder

to

communicate with serial devices connected to J5 or through a COMS I/O port. A push button

activation access will cause the microprocessor to initiate the display list mode, as described on

page XXXXX. In all cases, the microprocessor will initiate a sample measurement cycle as

described earlier and continue to energize most circuits while the recorder is performing the userrequested tasks.

Pressure System

(1 to 5000 PSI)

The pressure-sensing system incorporates one, two or three precision strain gauge transducer. The

transducers are housed in the ERX Recorder case and exit the case via 1/1” NPT female

connector.

9

Page 10

Precision pressure transducers are characterized to 32 numeric points at the factory to determine

offset, linearity, repeatability, and hysteresis. The 32 points of characterization are unique to each

transducer and referred to as ‘Transducer Coefficients’. When replacing a transducer for any

reason, the coefficients must be reloaded with the proper coefficients for the replacement

transducer.

10

www.honeywell.com

Page 11

Temperature System

-40 to 150 (-40 to 65C)

The temperature system consists of a highly stable solid-state transducer connected to the ERX

main circuit board through a 6-foot Teflon cable. The stainless steel probe is ¼” in diameter and

six inches in length; however, longer or shorter probe lengths are available options as well as an

armor cable. A ½” NPT nylon slip-along fitting is also provi

ded for securing the temperature

probe within the thermo well. The temperature probe assembly is universally interchangeable

between ERX Recorders and electronic volume correctors.

Sample Interval

In the ERX Recorder sample-measurement mode applies power to the electronic circuit so the

pressure(s), temperature(s), and power voltage measurements may be obtained. After obtaining

new measureme

nts, the item values and LCD are updated, and then compared to alarm limits, if

the values exceed the alarm limit, the instrument will jump to alarm sub-routine. After

completion of these tasks, the circuitry will return to the sleep mode of operation.

Sample rates: 1, 5, 10, 30, and 60 seconds, default is 10 seconds

Note: the faster the sample rate, the quicker battery powered instruments power

is depleted.

Sample Interval Battery Life

1 second 1 year

10 seconds 3 years

60 seconds 4 years

Log Interval

The log interval is a user-selectable item, its value determines how often Audit Trail report items

are stored into the instrument’s memory. The choices are 1, 5, 10, 15, 30, 60, or 24 hours, 60

minutes as the default. At the selected time interval, the recorder will automaticall

sample measurement wake-up cycle and store the user-defined Audit Trail report items into the

instrument’s memory. The time-stamped record placed in memory will be identified with the log

trigger “Time.”

Hourly and daily time triggers will always occur at the top of the hour, at 00: 00: 00 zero minutes

and seconds. For log triggers less than 60 minutes, time triggers will occur at 1,

minutes with zero seconds. Log triggers other than time will appear randomly and are placed in

memory at the exact time the incident occurred.

y enter a

5, 10, 15, or 30

11

Page 12

Audit Trail

The ERX Recorder is capable of storing either 4 or 10 items in its Audit Trail. Any of the

recorder items may be placed in the Audit Trail. Default: 10 Audit Trail Items

Interval 10 items 4 items

1 minute 3 days 6 days

5 minutes 17 “ 30 “

10 minutes 34 “ 60 “

15 minutes 50 “ 110 “

30 minutes 90 “ 150 “

60 minutes 180 “ 36

24 hours 1000 “ 2000 “

5 “

Default Audit Trail Report Items

Audit Trail Report Item 1-10

Item

Code

P PP PPP PT PPT PPPT T

589 500 500 500 651 651 651 657

590 651 651 651 650 650 650 656

591 650 650 650 649 649 649 655

592 649 649 649 670 670 654 678

593 672 501 501 657 654 653 689

594 681 654 654 656 653 652 677

595 671 653 653 655 652 421 687

596 679 652 652 676 655 655 521

597 503 503 421 503 673 673 255

598 521 521 521 521 521 521 255

Description of default Audit Trail items

Item Description Item Description

421 P3 Average Pressure 656 Temperature Interval High

500 P1 Pressure 657 Temperature Interval Low

501 P2 Pressure 670 P1 Current Day Average

503 Case Temperature 671 P1 Current Day High

521 Battery Voltage 672 P1 Current Day Low

649 P1 Interval Average 673 P2 Current Day Average

650 P1 Interval High

651 P1 Interval Low 677 Temperature Current Day High

652 P2 Interval Average 678 Temperature Current Day Low

653 P2 Interval High 687 Temperature Current Day High

654 P2 Interval Low 681 P1 Current Day Low Time

655 Temperature Interval Average 687 P1 Current Day High Time

676 Temperature Current Day Average

12

www.honeywell.com

Page 13

Default Audit Trail with P3 Voltage Monitor

Audit Trail Report Item 1-10

589 500 501 500 500 501 651 657

590 651 654 651 651 654 650 656

591 650 653 650 650 653 649 655

592 649 652 649 652 652 654 423

593 423 423 501 423 423 653 423

594 422 422 654 421 421 652 422

595 421 421 653 502 502 423 421

596 503 503 652 651 651 651 503

597 255 255 423 657 657 657 255

598 255 255 503 503 503 503 255

Description of default Audit Trail items

Item Description Item Description

421 P3 Average Pressure 656 Temperature Interval High

422 P3 Interval High

423 P3 Interval Low

500 P1 Pressure 657 Temperature Interval Low

501 P2 Pressure 670 P1 Current Day Average

503 Case Temperature 671 P1 Current Day High

521 Battery Voltage 672 P1 Current Day Low

649 P1 Interval Average 673 P2

650 P1 Interval High 676 Temperature Current Day Average

651 P1 Interval Low 677 Temperature Current Day High

652 P2 Interval Average 678 Temperature Current Day Low

653 P2 Interval High 687 Temperature Current Day High

654 P2 Interval Low 681 P1 Current Day Low Time

655 Temperature Interval Average 687 P1 Current Day High Time

Current Day Average

13

Page 14

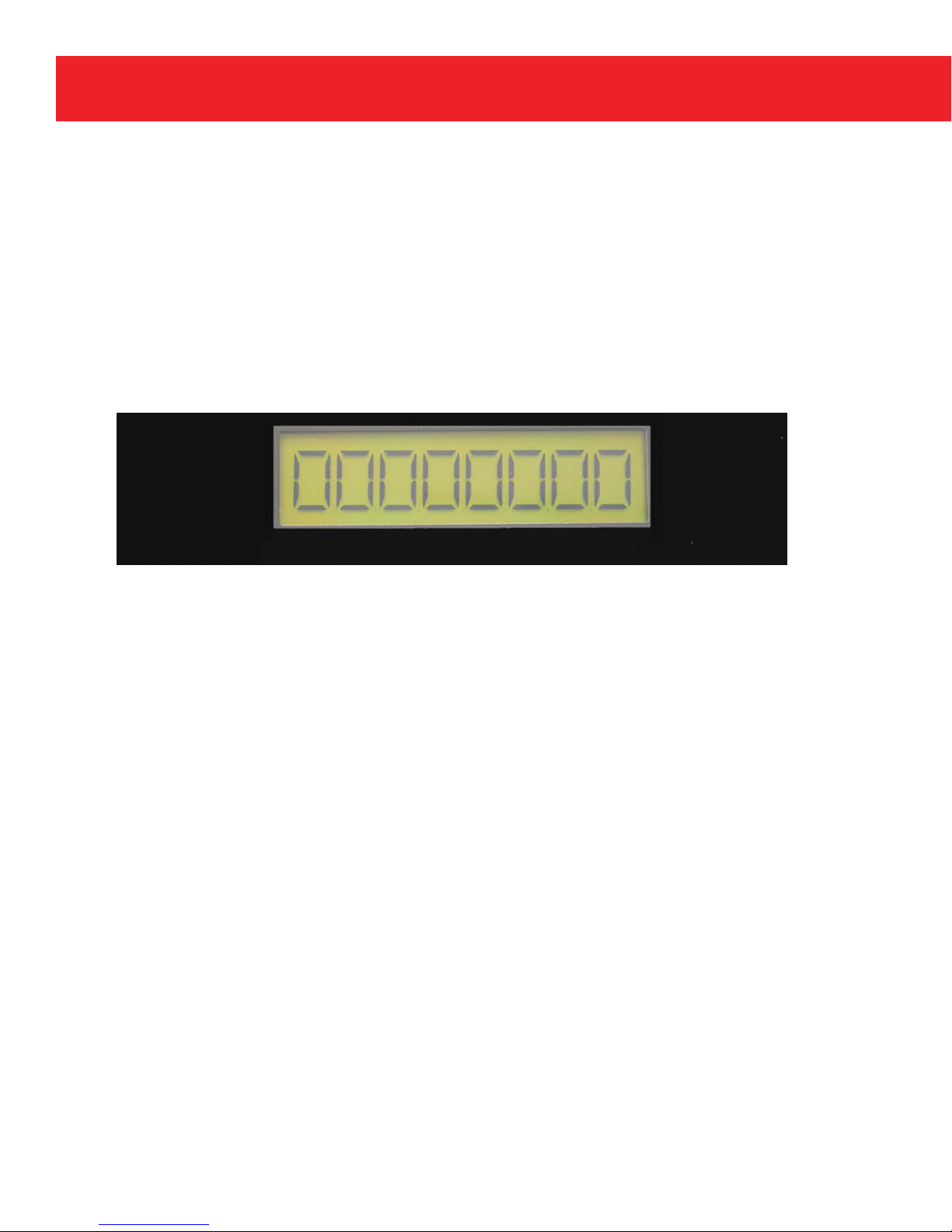

Informational Display (LCD)

A single 8-digit alphanumeric display (LCD) is a standard feature of the ERX. The LCD may be

mounted externally without a window cover, externally with a window cover, or internally. A

LCD is required for viewing the display lists 1 & 2 data and live readings. Normally the

instrument is in the sample measurement mode and the LCD displays the primary transducer (P1)

last sampled pressure, default setup. The default item (P1) displayed while in the sample mode

may be changed by changing the item entered in item 482, e.g. P2, P3, or etc. When activated by

a push button function, the LCD will display any alarm conditions, display list 1 & 2, and live

pressure(s) and temperature. If an instrument is in an alarm condition, the LCD will display

‘ALARM’ or a user

that’s entered in item 483 can contain any alphanumeric character, but is limited to eight

characters.

-defined message, control by what is entered in item 483. The alarm message

14

www.honeywell.com

Page 15

Installation and Operation of the ERX Recorder

Upon receiving the recorder, be sure that all items received are in good condition. Check the

packing list to make sure the shipment is complete. Report to your Mercury Representative any

damages and immediately file any shipping damage claims with the carrier who delivered the

shipment.

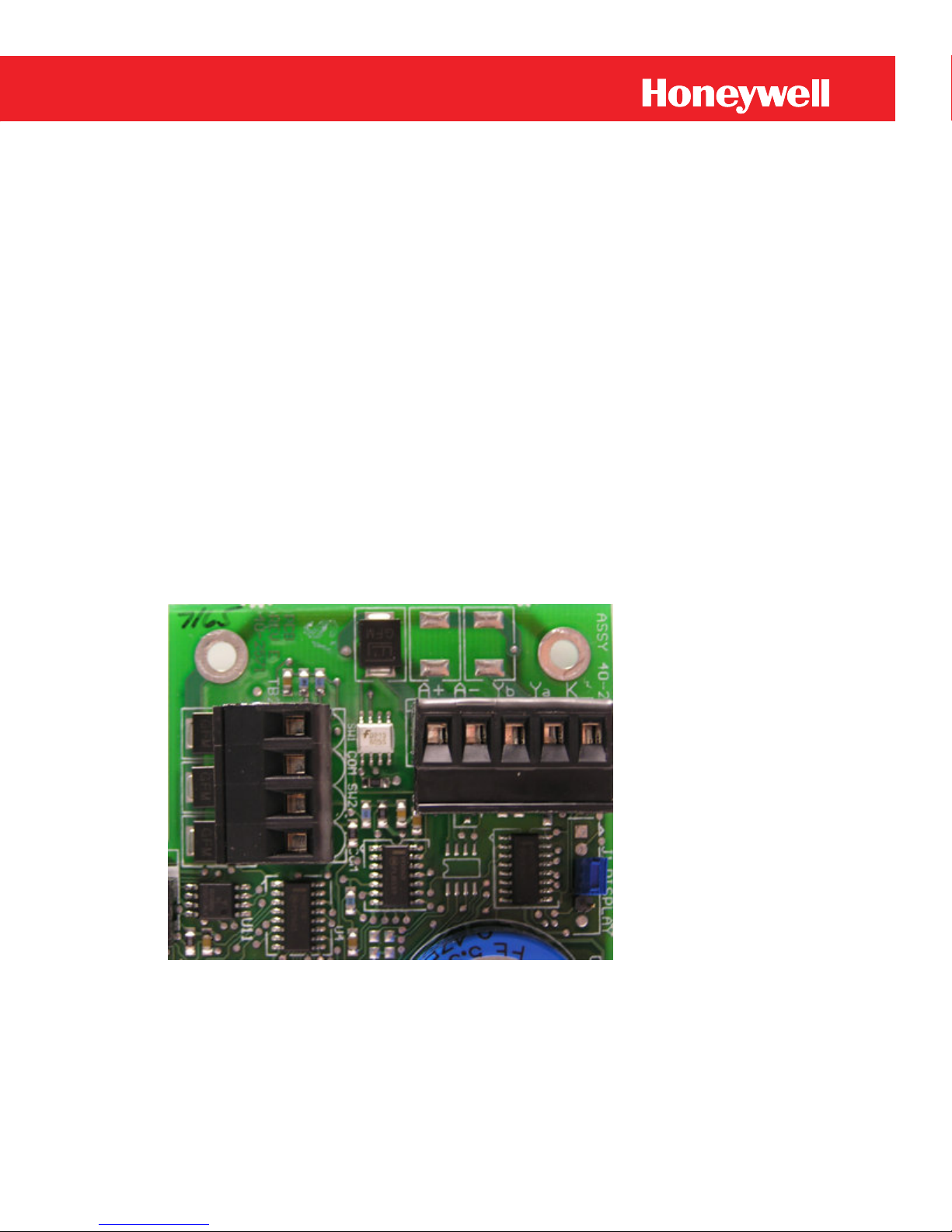

Function Check

1. Open the case door, check for any loo

seated.

2. • Ensure Super Cap jumper is installed onto both pins of J1

3. • Remove Velcro strap that secures the Alkaline Receptacle Battery Pack (default battery

pack)

4. • Remove battery pack; open the cover by pulling on the Velcro tab underneath pack

5. • Install four alkaline D-cell batteries, observe polarity, secure cover and replace

pack in the recorder, then secure with Velcro strap.

6. • Attach battery pack lead to either J3 or J4; J3 and J4 are parallel.

J1 Super Cap Jumper

Super Cap

Battery Velcro Strap J3 J4

se parts, and verify that all connectors are properly

battery

P1 P2 P3

15

Page 16

The LCD should display a pressure reading of close to ‘0.00. The recorder is now ready for

functional checks.

*Note: All of the function checks assume that the instrument has been configured with a

default setup.

Use the MI Logo (push button) or an optionally installed push button to scroll through the display

list(s) and stop at the live pressure reading. Without having made a pressure connec

will display a value very close to zero, typically, within +/- 0.4% of full scale.

Connect a pressure source to the external ¼” NPT pressure connector, apply a varying pressure

(less than full scale) and observe an increase or decease in the LCD’s reading as the pressure

varies. An automatic ten-minute time-out ensures that if a recorder left in a live reading, the

recorder will r

scroll through the remaining display list items until the recorder has returned to the sample

measurement mode.

eturn to the sample measurement mode to conserve battery power. Continue to

tion, the LCD

Instrument Setup

The following items are critical in the recorder’s operation and proper configuration.

Instrument Configuration

Item 576 configures what the recorder will record, that is, pressure(s) and te

equipped, e.g. P, PP, PPP, PT, or PPPT.

mperature data, if

Pressure

Transducer

Pressure (P1) 570

Pressure (P2) 571

Pressure (P3) 412

605~630

Temperature 551

Range

Xducer

Range Unit Coefficients

572

573

419

549 301~332 178~181

550 341~372 441~444

408 150~155 445~448

Board

Coefficients

Site IDs

Site identification items 580 and 581, used to identify the recorder to the associated software.

Items 580 and 581 Site IDs are preprogrammed using the recorder’s serial number, set by the

factory prior to shipping, but may be changed to meet company’s requirement. Site IDs must

remain unique, that is, no tw

o recorders should have the same Site ID numbers.

16

www.honeywell.com

Page 17

Using MasterLink32 Software:

• Date and Time

Instrument Set Inst. Date/Time via computer, ensure date and time is correct in the computer

before setting date and time via computer.

Or

Manually set time by entering the time in item 582

Manually set the date by entering the date in item 583

• Sample Interval

Item 586

• Log Interval

Item 585

• Start-of-Gas Day

Item 587

• Alarm Limits

Low Limit High Limit Low/Low High/High

Pressure (P1) 554 553 814 813

Pressure (P2) 556 555 818 817

Pressure (P3) 452 451 808 807

Temperature 564 563

Battery 565

17

Page 18

2-Point Pressure Calibration (Defined)

A 2-Point Pressure Calibration requires that two different pressures be applied to the instrument’s

pressure transducer and be sampled by the data acquisition circuits. A low pressure value,

usually 0.00 PSI, is applied to determine the Pressure Zero Calibration (offset). A higher pressure

value is applied to determine the Pressure Span Calibration (gain

). The default Calibration

Parameters require that the Span Pressure exceeds the Zero Pressure by at least 50% of the

transducer range, otherwise a “Points Too Close” error message is displayed.

To produce a linear pressure response for all rated pressures and temperatures, each transducer

has been factory characterized for ambient temperature effects. The characterization process

determines th

e proper compensation coefficients for each transducer. The 2-point calibration

process uses the coefficients when calculating the pressure offset and pressure span values. Once

these two points have been calculated and stored in the instrument’s memory, all other applied

pressures and temperature are automatically compensated by the coefficients.

2-Point Pressure Calibration (Gauge Transducers)

2-point pressure calibration (items required)

• ERX Recorder

• Pressure source and fittings (capable of providing pressures of at least 50% of the ERX

pressure transducer range)

• Pressure Reference (accuracy to equal or exceed the accuracy of the ERX pressure

system)

• Computer (IBM Compatible)

• MasterLink32 Software

• I/O cable, part number 40-1629 and a MPA, part number 40-2

620 or through the use

of I/O cable, part number 40-1629 only if the instrument is equipped with an external

case connector and a third option is through the use of I/O cable 40-2696 that connects

directly to J5 on the main circuit board.

2-point pressure calibration (procedure)

Make certain that the Pressure Compensation Coefficients listed are for the pressure transducer

installed. Also verify that Item Code 087 is

transducer serial number label and item 112 is set for Gauge type transducer. Since the two-point

calibration is mostly a software function, references to the appropriate sections in the

MasterLink32 Link software are included.

1. Connect the pressure source and pressure reference to the ERX pressure connector.

2. Make a serial connect from t

he computer’s serial port to the ERX serial port.

3. Start MasterLink32 software on the computer.

4. Enter the access code for Level 1 or Level 2 when requested. The default Level 1 Access

Code is “11111”, the default Level 2 Access Code is “22222”.

5. If a communications link has not yet been established, the screen will display a box

requesting the user to input the Instrument Access Code. Ent

box appears. The default code is “33333”

the desired pressure unit. Item Code 138 matches the

er the access code when this

18

www.honeywell.com

Page 19

6. Select “Calibrate” from the main menu.

7. Select “Pressure Calibration” from the sub-menu.

8. With zero pressure applied to the ERX pressure transducer, perform the “Pressure Zero

Calibration.” The pressure displayed in green on the computer’s screen is a live reading.

This permits the user to determine if the pressure has stabilized so that a sample may be

obtained. Click the AVERAGE PRES

SURE NOW button when it becomes active (text

changes from gray to black) to obtain a sample of the applied pressure.

9. When MasterLink32 displays “Average Pressure”, the value should be changed to match

the pressure reference by clicking the CHANGE button when it becomes active. Enter

the pressure value for the zero reference pressure (usually 0.00). The ERX will calculate

the required differe

nce offset, store this calculated value within the instrument before

returning to a live pressure reading.

10. Compare the displayed pressure to the reference pressure. If the ERX pressure reading is

not acceptable, click the AVERAGE PRESSURE NOW button again to obtain another

pressure sample. The program will continue to loop back to the live pressure reading.

Obtain as many pressure samples a

s necessary until an acceptable pressure reading is

displayed.

11. If the ERX zero pressure reading is acceptable, click the SPAN button to change to the

Span Calibration sequence.

12. The screen title should have changed to “Pressure Span Calibration.” At this point, the

software is waiting to sample the applied pressure. Increase the pressure applied to the

ERX to the span reference pressure.

This must be greater than 50% of the transducer

range.

Example #1: If the zero reference pressure on a 100 PSI transducer equals 0.00 PSI, then

the span reference pressure must be between 50.00 and 100.00 PSI.

Example #2: If the zero reference pressure on a 600 PSI transducer equals 0.00 PSI, then

the span reference pressure must be between 300.00 and 600.00 PSI.

13. The span calibration a

lso displays a live pressure reading to allow the user to determine if

the span reference pressure has stabilized. When the pressure has stabilized, click the

AVERAGE PRESSURE NOW button when it becomes active to obtain a pressure

sample.

14. If the average pressure reading is not equal to the span reference pressure, click the

CHANGE button when it becomes active. Enter the pressure value for t

he span reference

pressure. As the computer screen updates, the ERX will calculate the required span gain,

store this calculated value within the instrument before returning to a live pressure

reading. Obtain as many pressure samples as necessary until an acceptable span pressure

reading is displayed.

15) Compare the average pressure reading to the span reference pressure. If the average

pressu

re reading is acceptable, the pressure calibration process is complete. As a

suggestion, recheck the pressure zero reading and any number of pressure points within

the transducer range, or click DONE to exit the calibration sequence.

Two-Point Pressure Calibration (Absolute Transducers)

19

Page 20

20

Two-point pressure calibration (items required)

• ERX

• Pressure Source and fittings (capable of providing pressures of at least 50% of the ERX

pressure transducer range)

• Pressure Reference (accuracy to equal or exceed the accuracy of the ERX pressure system)

• Computer (IBM Compatible)

• I/O cable, part number 40-1629 and a MPA, part number 40-2620 or through the use of

I/O cable, part n

umber 40-1629 only if the instrument is equipped with an external case

connector and a third option is through the use of I/O cable 40-2696 that connects directly to

J5 on the main circuit board.

• Barometer

Two-point pressure calibration (procedure - absolute)

Make certain that the Pressure Compensation Coefficients loaded in the instrument are for the

pressure transducer installed. Also ve

Since the two-point calibration is mostly a software function, references to the appropriate

sections in the MasterLink32 software are included.

1. Connect the pressure source and pressure reference to the ERX pressure connector.

2. Make a serial connect from the computer’s serial port to the ERX serial port.

3. Start MasterLink32 softw

4. Enter the access code for Level 1 or Level 2 when requested. The default Level 1 Access

Code is “11111”, the default Level 2 Access Code is “22222”.

5. If a communications link has not yet been established, the screen will display a box

requesting the user to input the Instrument Access Code. Enter the access code when this

box appears. The default code is “33333”.

6. Se

lect “Calibrate” from the main menu.

7. Select “Pressure Calibration” from the sub-menu.

8. With zero pressure applied to the ERX pressure transducer, perform the “Pressure Zero

Calibration.” The pressure displayed in green on the computer’s screen is a live reading.

This permits the user to determine if the pressure has stabilized so that a sample may be

obtained. Click the AVERAGE PRESSURE NO

changes from gray to black) to obtain a sample of the applied pressure.

9. Obtain the current local atmospheric pressure reading using a barometer or by some other

means. When MasterLink32 displays “Average Pressure”, the value should be changed

to match the current atmospheric pressure value by clicking the CHANGE button when it

becomes active. Enter the c

comparable, i.e., PSIA. The ERX will calculate the required difference offset, store this

calculated value within the instrument before returning to a live absolute pressure

reading.

10. Compare the displayed pressure to the reference pressure. If the ERX absolute pressure

reading is not acceptable, click the AVERAGE PRESSURE NOW butt

another pressure sample. The program will continue to loop back to the live pressure

reading. Obtain as many pressure samples as necessary until an acceptable pressure

reading is displayed.

11. If the ERX absolute pressure reading is acceptable, click the SPAN button to change to

the Span Calibration sequence.

12. The screen title should have changed to “Pressure Span Calibrat

software is waiting to sample the applied pressure. Increase the pressure applied to the

ERX Recorder to the span reference pressure that exceeds the zero reference pressure by

at least 50% of the rated transducer range.

www.honeywell.com

rify that instrument is setup for the desired pressure unit.

are on the computer.

W button when it becomes active (text

urrent atmospheric pressure value, making sure the units are

on again to obtain

ion.” At this point, the

Page 21

Example #1: If the zero reference pressure on a 100 PSIA transducer equals 14.73 PSIA,

then the span reference pressure must be between 64.73 and 100.00 PSI.

Example #2: If the zero reference pressure on a 100 PSIA transducer equals 13.25 PSIA,

then the span reference pressure must be between 63.25 and 100.00 PSI.

Example #3: If the zero reference pressure on a 600 PSIA transducer equals

14.73 PSIA,

then the span reference pressure must be between 314.73 and 600.00 PSI.

13. The span calibration also displays a live pressure reading to allow the user to determine if

the span reference pressure has stabilized. When the absolute pressure has stabilized,

click the AVERAGE PRESSURE NOW button when it becomes active to obtain a

pressure sample.

NOTE: The span reference pressure is

equal to the sum of the dead weight tester

pressure, and the atmospheric pressure obtained in step 9 above.

14. If the average pressure reading is not equal to the span reference pressure, click the

CHANGE button when it becomes active. Enter the pressure value for the span reference

pressure. As the computer screen updates, the ERX will calculate the required span gain,

and store this calculat

ed value within the instrument before returning to a live pressure

reading. Obtain as many pressure samples as necessary until an acceptable span pressure

reading is displayed.

15. Compare the average, absolute pressure reading to the span reference pressure. If the

average pressure reading is equal to the sum of the applied pressure plus the atmospheric

pressure, the pressure calibration proces

s is complete. As a suggestion, recheck the

pressure zero reading and any number of pressure points within the transducer range, or

click DONE to exit the calibration sequence.

21

Page 22

Two-Point Temperature Calibration

A Two-point Temperature Calibration requires that two different temperatures be applied to the

instrument's temperature probe and be sampled by the data acquisition circuits. A low

temperature source, usually a 32 degrees F ice bath is used to determine the Temperature Zero

Calibration. A higher temperature source is used to determine the Temperature Span Ca

(gain). The default calibration parameters require the Span Temperature exceed the Zero

Temperature by at least 15% of the instrument temperature range.

The temperature probe provides a nonlinear, but very predictable temperature response for all

rated temperatures. The instrument's firmware chip contains the required information to produce

a linear temperature response for any connec

ted temperature probe. The Two-Point Calibration

process uses the temperature offset and temperature span values to adjust for individual

variations. Once these two points have been calculated and stored in memory, all other applied

temperatures can be determined by a linear interpolation.

libration

22

www.honeywell.com

Page 23

Alarm Pulses (Form-A)

The alarm output pulse is available as a Form-A output only. The alarm output pulse width is

fixed at 50 mS and there is no need for pulse scaling. An alarm pulse output is a one-time

occurrence, at the time any alarm becomes active. Subsequent alarm pulses will not occur until

all previous alarms have been cleared.

Output Pulse Specifications

1.

2. Outputs are rated for DC only, from 3.0 volts to 10.0 volts. Observe polarity.

3. The alarm output will sink up to 5 mA. Pulse duration is 50 mS minimum.

4. Form-A contact closures are between the A- and A+ terminals. The contact closures are

All outputs are isolated from ground and each other.

held for 50 mS. Note: Observe polarity.

Note: A- and A+ output channel is also used to power (on/off) an internal

communication devices, i.e. cellular phones, modem, radio...etc.

or external

23

Page 24

Communicating to the ERX Recorder with a Modem

The ERX Recorder has a single I/O serial port that is used for local serial connections and for

modem connections. The I/O serial port baud rate is controlled by item 588, is set to “Auto baud”

and automatically adjusts from the 38400, the starting baud rate to match the baud rate of

connecting serial device. However, it is highly recommended when

communicating with the

recorder via a modem to adjust item 588 (serial baud) to match the baud rate of the connecting

modem’s RS-232 port. The serial port will support the following lines: TX, RX, and COM,

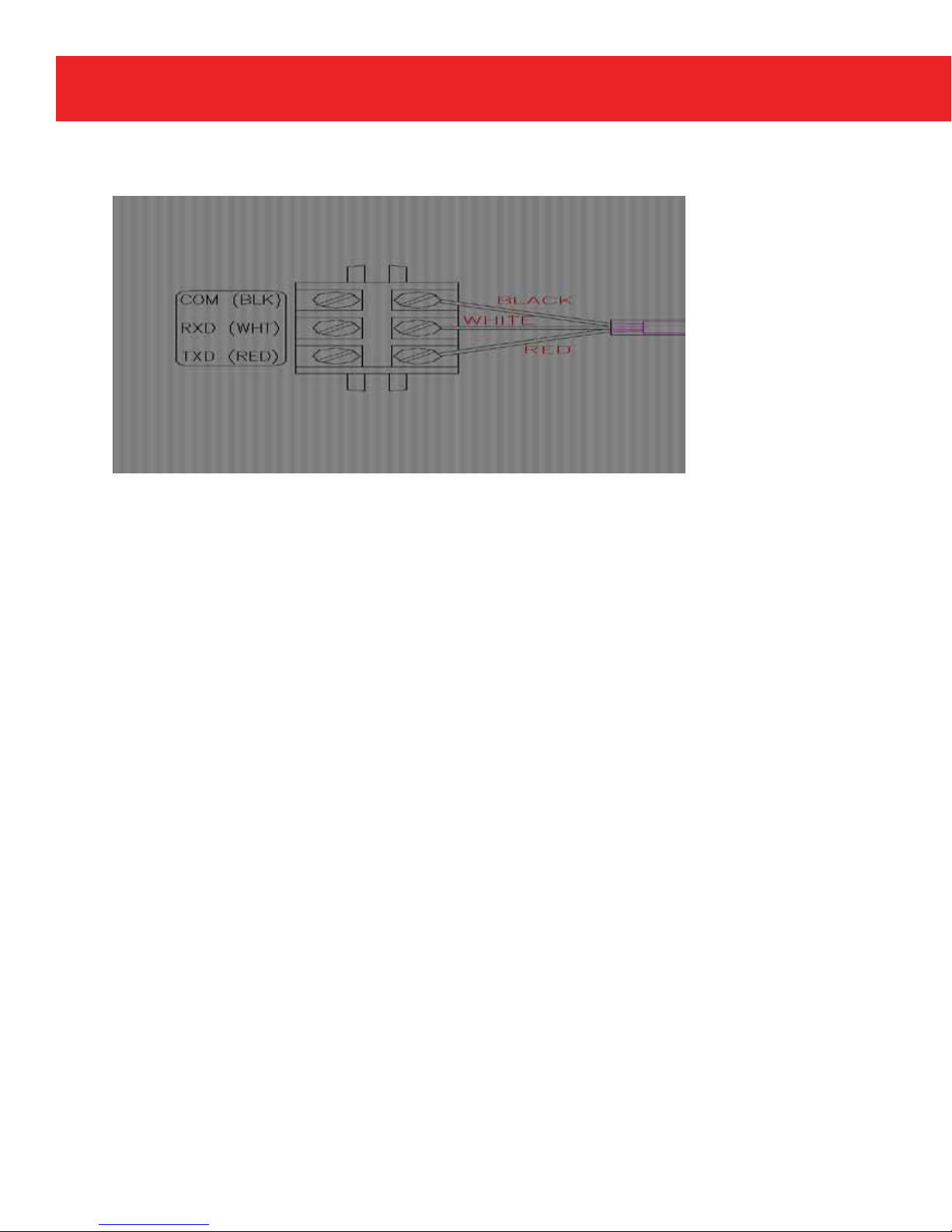

Internal Modem Communications

Mercury Instruments manufactures a low power modem designed to be installed within the case

of the ERX Recorder, the Messenger Modem. The Messenger Modem can

ERX via a ribbon cable, which is used for internal Messenger Modem installations that do not

have an external case connector. See Messenger Modem manual for additional information.

communicate with the

24

Pin1

RS-232 to CMOS I/O port, use to connect serially to the recorder

using an IBM compatible computer or PDA and a communication cable 40-2696-1 technician

cable.

www.honeywell.com

Page 25

External Modem Communications without an External RS-232 Case Connector

Requires the use of an optional RS-232 to CMOS I/O Board, 40-2717-2:

See Messenger Modem manual for additional information.

Internal or External Communications with a RS-232 Case Connector

Requires the use of an optional RS-232 to CMOS I/O Board with shorting plug, 40-2717-3:

(Shorting plug not shown)

25

Page 26

External Modem Communications with a RS-232 CMOS I/O Board with shorting plug and

stripped wires, 40-2717-8, same as 40-2717-3 but instead of three stripped wires it has a terminal

block to facilitate external modem connection.

Automatic Call-In Feature

Alarm Call-In

Pulse Method

The ERX Recorder has the capability to initiate a modem-to-modem call. There are two

circumstances where the ERX Recorder will initiate a call, Alarm Call-In and a Schedule Call-In.

The Alarm Call-In feature can be configured to call in two ways: 1is to use the alarm pulse output

of the ERX Recorder to trigger the automatic call-in featur

alarm condition has been detected by the recorder, the recorder will generate an alarm pulse, that

will cause the MI Modem to jump into an alarm subroutine that has been pre-programmed in the

MI Modem program.

To use this method, set the following items:

Item Code Set to

333 Call-In Trigger 1 Alarm Call-In

484 Alarm Channel Control 0 Alarm Pulse Out

789 Modem AT Enable 0 Call-In via Alarm Pulse

Note: The MI Modem must be configured properly for this method to work; see MI Modem

installation guide for more information.

e of the MI Modem. Once and an

put

26

www.honeywell.com

Page 27

AT Commands Method

The AT command method is accomplished by sending Hayes AT-type commands out the serial

I/O port to a generic-type modem, such as the Messenger Modem. This method has the ERX

recorder controlling the Hayes compatible modem.

To use this method, set the following items:

Item Code Set to

333 Call-In Trigger 1 Alarm Call-In only

789 Modem AT Enable 1 Call-In via A

T commands

780 Modem Init String Initialization command of the Modem

Default: ATE0Q0V0X4

781 Modem Dial String Command sent to indicate dialing

Default: ATDT

782 Modem Hang-up String Command sent to modem for hang-up

Default: ATH

784 Alarm Call-In Phone# Phone number to call due to an alarm

786 Modem Retry Interval A Time (minutes) between short-term retries

Default: 5

787 Modem Retry Interval B Time (minutes) to wait before trying again if all

short-term retries have failed

Default: 1440

788 Modem Retry Count A Number of short-term retries

Default: 3

Scheduled Call-In Method

The Scheduled Call-In feature requires the ERX Recorder to issue AT commands to a generic

modem or to a Messenger modem. This feature, design

applications that can accept a scheduled call-in from a remote site.

To use this method, set the following items:

Item Code Set to

333 Call-In Trigger 2 Scheduled Call-In only

334 Scheduled Call-In Date Date of call

335 Scheduled Call-In Time Time of call

339 Scheduled Call-In Phone # Phone number to call at schedule time

789 Modem AT En

able 1 Call-In via AT commands

780 Modem Init String Initialization command of the Modem

Default: ATE0Q0V0X4

781 Modem Dial String Command sent to indicate dialing

Default: ATDT

784 Alarm Call-In Phone# Phone number to call due to an alarm

782 Modem Hang-up String Command sent to modem for hang-up

Default: ATH

786 Modem Retry Interval A Time (minutes) between sho

ed to interface with third party software

rt-term retries

27

Page 28

28

Default: 5

787 Modem Retry Interval B Time (minutes) to wait before trying again if all

short-term retries have failed

Default: 1440

788 Modem Retry Count A Number of short-term retries

Note: Item 334 must be reset after a Scheduled Call-In; otherwise, the recorder will not call

again.

Alarm and Scheduled Call-In

The ERX Recorder, if configured, can initialize a call-

in due to an alarm and a scheduled-call-in.

In this method, item 338 (Scheduled Call-In Occurred) may be used by the host system to

determine whether the call-in was triggered by an alarm or due to a scheduled call-in. A

scheduled call-in will have changed item 338 from ‘0’ to ‘1’ indicating that a scheduled call-in

occurred and not an alarm. Item 338 must have its value reset to a value of ‘0’

and item 334 must

be reset for the next scheduled call-in date after a Scheduled Call-In; otherwise, the recorder will

not call again.

To use this method, set the following items:

Item Code Set to

333 Call-In Trigger 3 Alarm & Scheduled Call-In

334 Scheduled Call-In Date Date of call

335 Scheduled Call-In Time Time of call

339 Scheduled Call-In Phone # Phone number to call at sc

hedule time

789 Modem AT Enable 1 Call-In via AT commands

780 Modem Init String Initialization command of the Modem

Default: ATE0Q0V0X4

781 Modem Dial String Command sent to indicate dialing

Default: ATDT

784 Alarm Call-In Phone# Phone number to call due to an alarm

782 Modem Hang-up String Command sent to modem for hang-up

Default: ATH

786 Modem Retry Interval

A Time (minutes) between short-term retries

Default: 5

787 Modem Retry Interval B Time (minutes) to wait before trying again if all

short-term retries have failed

Default: 1440

788 Modem Retry Count A Number of short-term retries

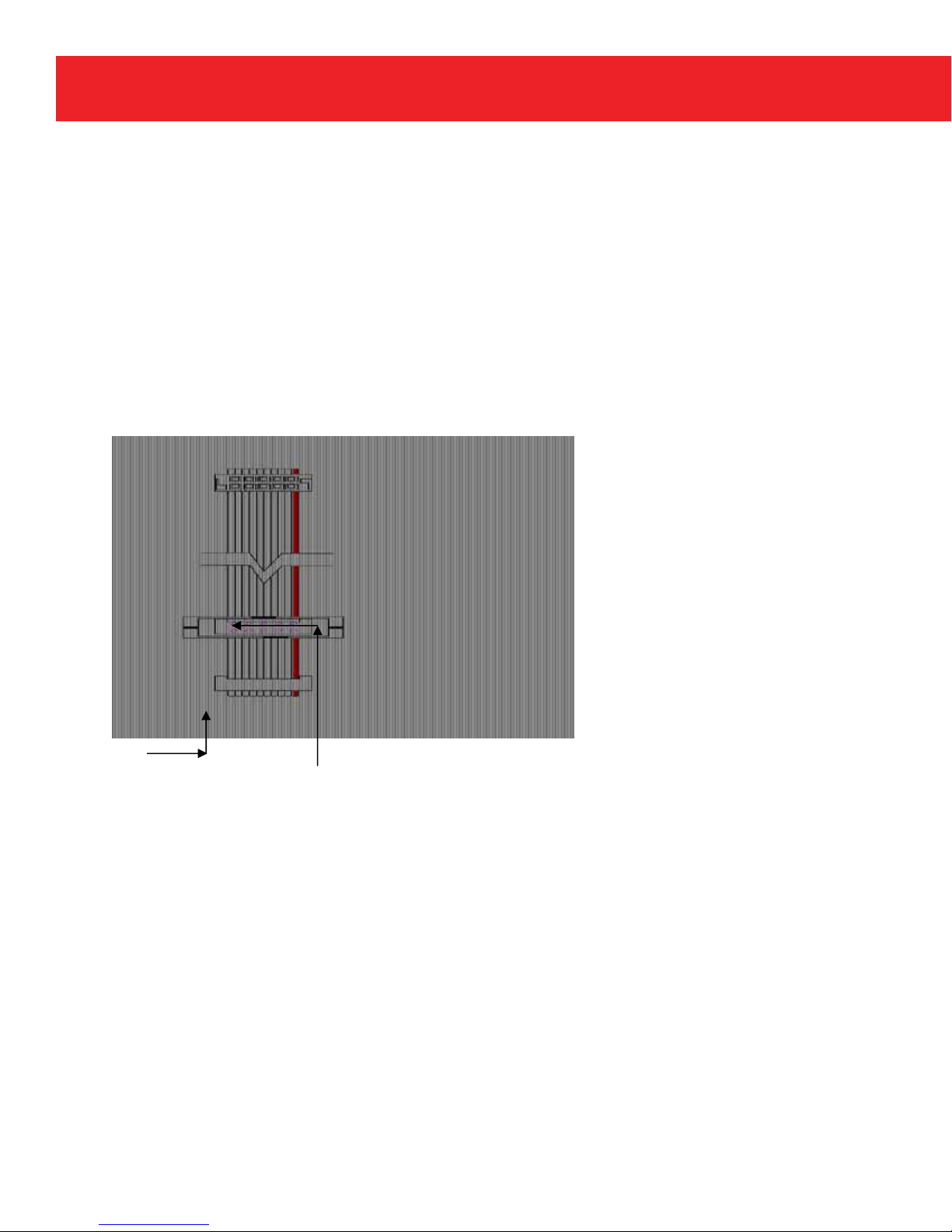

Modem Power Control--Call-out Window

Modem power control is used to conserve battery power by only applying power to a

communication device wi

power control utilizes the alarm output channel of TB1; A- and A+ to control the power applied

to a communication device, such as, a modem, CDPD, or radio, etc.

Item 484, Alarm-Channel-Control must be configured to Modem Power control instead of the

default Alarm Pulse output. This action defeats Alarm Pulse output.

The period that

the communications device is powered is controled by item 791 Call-out Start

Time and item 783 Call-out Stop Time and further defined by item 792 Call-out Repeat

Interval and item 793 Call-out Keep Alive Time.

www.honeywell.com

thin an operating window when communication is desired. Modem

Page 29

If both items 792 or 793 is set to zero disables modem power control.

30-Minute Window Interval

To power a communication device for a thirty-minute period that starts at 9:00 AM and ends at

9:30 AM, configure item 791 to 09 00 00 and item 783 to 09 30 00 and items 792 & 793 to 30

minutes.

9:00 |---------------ON----------------| 9:30

791 783

Start End

Item 792: 30 minu

tes

Item 793: 30 minutes

Setting the above items to the values shown will keep a communication device on for a period of

30 minutes.

Note: that extending the time that the recorder controls the power applied to the communication

device will reduce the battery reserve. It is recommended, that if the Modem Power control

interval is greater than 15 minutes per day, that the recorder has either, a

dual battery pack, a

Solar power supply, or an AC to DC power supply with battery backup.

4-Hour Window Interval

To power a communication device for a four hour interval that starts at 8 00 AM and ends at 12

00 PM, configure item 791 to 08 00 00 and item 783 to 12 00 00 and items 792 & 793 to 30

minutes.

8:00 |---------------On-----------------| 12:00

791 783

Start Time Endin

g Time

Item 792: 30 minutes

Item 793: 30 minutes

Setting the above items to the values shown will keep a communication device powered for a

interval of four hours. Take note that items 792 and 793 have the same value and having the same

value will force the recorder to apply power to the communication device for the entire interval.

Note: that extending the time that the recorder controls the

power applied to the communication

device will reduce the battery reserve. It is recommended, that if the Modem Power control

interval is greater than 15 minutes per day, that the recorder has either, a dual battery pack, a

Solar power supply, or an AC to DC power supply with battery backup.

Multiple Windows- within the start and ending interval

29

Page 30

Configure the recorder the same as the 30-minute window and adjust items 791 and 783, as

needed, and change items 792 and 793 to create the amount of time the communication device is

powered within the interval.

Item 792 Call-out Repeat Interval

Item 793 Call-out Keep Alive Time

Example: 2-Hour interval with repeating 5 minute windows

Item 791 = 09 00 00

Item 783 = 11 00 00

Item 793 = 5 minut

es

Item 792 = 20 minutes

Will power the communication device starting 9: 00 Am and ends at 11: AM

On 9:00~9:05

Off 9:05~9:20

On 9:20~9:25

Off 9:25~9:40

On 9:40~9:45

Off 9:45~10:00

On 10:00~10:05

Off 10:05~10:20

On 10:20~10:25

Off 10:25~10:40

On 10:40~10:45

Off 10:45~11:00

Window repeats the next-day

Start time: 09:00:00 Ending time: 11:00:00

| |

00:00:00

On On On On On On 23:59:59

Note that the recorder is applying power to the communication device for a total of 30 minutes.

Note: that extending the time that the recorder controls the power applied to the communication

device will reduce the battery reserve. It is recommended, that if th

e Modem Power control

interval is greater than 15 minutes per day, that the recorder has either, a dual battery pack, a

Solar power supply, or an AC to DC power supply with battery backup.

30

www.honeywell.com

Page 31

Digi-Span Fuel Switching Feature

An ERX connected to a Digi-Span module provides an automatic or manual fuel switching

function when item 340 is enabled. This feature requires ERX’s Pulser-A output to be connected

to the Digi-Span’s “Gas Override” terminal, the Pulser-B output connected to the “Oil Override”

terminal, and the common terminal ‘K’ connected to the Digi-Span common. When item cod

340 is configured for Automatic mode, a pre-selected temperature at the Digi-Span module

determines which fuel is ‘switched on’. Item 340 may also be configured for either a manual

“Gas Override” or a manual “Oil Override”, which results in a continuous ON at one of the pulse

outputs channels.

Although not an original design consideration, there may be other applications that could make

use of

a continuous ON from either pulse output channel besides the Digi-Span module. Care

must be taken to be certain that the connected device can be actuated with 5 mA of current, or

less. Regardless of the connected device, enabling item 340 places a heavier burden on the

battery, which will decrease battery life.

e

31

Page 32

Firmware Upgrade

ERX Recorder firmware (instrument operating instructional program) is stored in flash memory.

Adding new features, capabilities, and correction of firmware issues to the instrument is simply a

matter of uploading a text file containing a newer version of firmware, via a MPA

Flash Access Security is provided by the use of the Serial Port Adapter (MPA). To upgrade flash

memor

y, use the free software application Firmware Upgrade Manager available through your

Mercury representative or by contacting Mercury Instruments.

Important

Before performing a firmware upgrade procedure download an item file and Audit Trail data

using MasterLink32 software only. All data and configuration information is lost and the

recorder is in a firmware default configuration after upgrading

the firmware.

NOTE: If the ERX has an optional pressure expansion board installed, discount the expansion

board’s ribbon cable from J2 of recorder’s main circuit board prior to upgrading firmware

Procedure to Upgrade ERX Recorder Firmware:

1. Connect the MPA (40-2620) to J5 I/O port on the printed circuit board.

2. Connect the Serial Cable (40-1629) from the MPA to the computer COM port.

3.

4. From the Menu bar select SetupCommunications, adjust port and baud rate as required

Start Firmware Upgrade Manager

The following steps reference Min-Max command buttons; the ERX and ERX Recorder… based

on the operating platform.

32

www.honeywell.com

Page 33

5. Click Mini-Max, which generates the Open screen prompting for a location of the

firmware text file and then drill to the file location by using Windows conventions.

6. Once you have drilled to the location of the file, highlight the desired file and click Open,

producing a Modal screen:

7. Click Ok to establish a serial link to the recorder

8. Click Begin, but do not select Pre-Firmware Upgrade Data Collection or Post-

Firmware Upgrade Data Restoration check boxes.

33

Page 34

10. Click Ok to the following Modal screen to continue

11.A number of status screens will appear:

Connecting to MPA

Erasing Current Firmware

Sending New Firmware

Verifying Firmware Upgrade

12. Finally, if the upgrade procedure was successful, the following screen will display the newly

installed firmware version

13. Click Close

14. Discount link and re-link to recorder using MasterLink32 software and upload the item file

created previously, then load Non-Cal Items and Cal Items to restore the configuration and

calibration items.

15. Reset the date and time in recorder.

16. Verify the ERX Recorder has the proper configuration.

34

www.honeywell.com

Page 35

Putting the ERX Recorder into “Shutdown”

Shutdown is a mode of operation invoked by the user prior to placing the instrument into storage

or prior to performing some type of board maintenance. The MasterLink32 Link software

manual describes the procedure for putting the ERX Recorder into shutdown. There are two

types of “Shutdown” that can be induced into the ERX Recorder; Partial and Complet

e. The

connection status of the battery packs determines which type of Shutdown the instrument

assumes.

Partial Shutdown

To put the ERX Recorder into “partial shutdown”, from MasterLink32 Link software, select and

confirm “SHUTDOWN” from the “Instrument” menu. Leave the main battery plugged-in.

In partial shutdown, the recorder’s real-time clock will continue to update; however, the sampling

of pressure or temperature of the gas no longer occurs. The LCD will show dashes “- - - - - - - “across the display. The recorder still draws normal background current from the main battery

when placed in partial shutdown, and it preserves all item values and audit trail information.

To recover from a partial shutdown, i.e., return to Sample Mode, simply press the MI button.

Complete Shutdown

To put the ERX Recorder into “complete shutdown”, from MasterLink32 Link software, select

and confirm “SHUTDOWN” from the “Instrument” menu, then unplug the main battery, and

remove the super cap jumper. In complete shutdown, the clock of the recorder will stop working

and the sampling of pressure or temperature of the gas no longer occurs. The configuration data

of the recorder and all item va

the batteries are unplugged.

In order to bring the ERX Recorder out of a complete shutdown, simply plug in the main battery

and replace the super cap jumper. It will be necessary to reset the date, time, and other items that

are not current.

lues are retained in E2PROM. The LCD display will go blank once

35

Page 36

Taking the ERX Recorder “Un-Configured”

“Un-Configured” refers to resetting the instrument’s items to a firmware default.

Firmware defaults are different from the default values in the “Parameter Item List” section.

The default values listed in “Parameter Item List” are a combination of firmware and factory

defaults.

Once the ERX Recorder is “un-configured” Audit Trail, calibration informatio

n, and instrument

settings are all cleared. Therefore, it is important to record (down load an item file) this

information before taking the ERX Recorder un-configured. Specific information about

downloading an item file is available in MasterLink32 software.

There are two methods to put an ERX Recorder in un-configured state. The first is with

MasterLink32 Software, and the second is a hardwar

e method that is useful if a serial link cannot

be established.

Software method:

1. Make a physical connection to the ERX Recorder via serial link.

2. Start MasterLink32

3 Select form the Menu bar SetupAdvanceRaw Instrument AccessRaw Item

Access left click Raw Item Access

36

www.honeywell.com

Page 37

This generates the modal screen:

3. Enter the 264 in the Item Number field

4. Enter 20141465 in the Item Value field

5. Click Write

6. Perform a software disconnect link, see MasterLink32 Help, for details

Prior to commissioning the recorder again, reset the date and time and operating

parameters by downloading an item file to the recorder or through individual items.

Hardware method--if serial link cannot be established

1

. Remove the jumper on JP1, (removes the SuperCap from circuits)

2. Disconnect the power supply from the recorder and allow the LCD to go blank (within 15

seconds)

3. While holding in the MI button, connect the battery and continue to hold the

MI button for at least 10 seconds. You should see Button Down on the display.

4. To reset the recorder to ERX firmware defaults, release the MI button whe

reads REL 4D FLT or to restore the recorder to its preconfigured configuration continue

to hold the MI button until the display reads DISPLAY TEST, then RESTORE, release

MI button.

5. Replace JP1, reconnects Super Cap to circuits

Prior to commissioning the recorder again, reset the date and time and operating

parameters by downloading an item file to the recorder or through indiv

n the display

idual items.

37

Page 38

38

Parameter Item List

All items that make up the operating parameters, codes, alarms, calibration references, voltage

levels and other information relative to operation or configuration of the Mercury Instruments

ERX Recorder are listed below. When connected and linked to a computer, all ERX Recorder

items can be displayed or changed in the Display/Item by Function of MasterLink32 software.

Item

Item Name & Description

061 Display Test

A test pattern generated by the microprocessor that gives a visual indication of the status

of LCD; pattern energizes all segments of LCD.

104 A/D FAULT

This item indicates if an alarm for the A/D Converter was generated. If the

microprocessor detects an A/D fault (Analog to Digital), an alarm is initiated and is

indicated by placing dots on

104 indicates there is no A/D Converter Alarm. The alarm indicators will remain active

until manually cleared (by software). Unlike other instrument alarms, an A/D Fault is

usually a hardware failure that requires factory replacement of a component on the main

circuit board, or a field replacement of the main board.

Default = 00000000

118

Reference Number 1 000000000

119 Reference Number 2 00000000

127 Instrument Type 10

P3 Pressure Coefficients

150 P3 Pressure Coefficient 27 0.000000

151 P3 Pressure Coefficient 28 0.000000

152 P3 Pressure Coefficient 29 0.000000

153 P3 Pressure Coefficient 30 30.00000

154 P3 Pressure Coefficient 31 0.000000

155 P3 Pressure Coefficient 32 0.000000

156 P3 Interval High Pressu

157 P3 Interval High Pressure Date 01-01-04

158 P3 Interval Low Pressure Time 00 00 00

159 P3 Interval Low Pressure Date 01-01-04

173 AT Reset Log Trigger 1

Board Coefficients

178 P1 Board Coefficients A 0.0000

179 P1 Board Coefficients B 1.0000

180 P1 Board Coefficients C 0.0000

181 P1 Board Coefficients D 1.0000

265 Reserved MA 00000000

266 Reserved M

D 00000000

267 Reserved MC 00000000

Item Item Name & Description

www.honeywell.com

the LCD and “11111111” at Item 104. “00000000” at Item

re Time 00 00 00

Page 39

P1 Pressure Coefficients

301 P1 Pressure Coefficient 1 0.000000

302 P1 Pressure Coefficient 2 30.00000

303 P1 Pressure Coefficient 3 0.000000

304 P1 Pressure Coefficient 4 0.000000

305 P1 Pressure Coefficient 5 0.000000

306 P1 Pressure Coefficient 6 30.00000

307 P1 Pressure Coefficient 7 0.000000

308 P1 Pressure Coefficient 8 0.000000

309 P1 Pressure Coefficient 9 0.000000

310

P1 Pressure Coefficient 10 30.00000

311 P1 Pressure Coefficient 11 0.000000

312 P1 Pressure Coefficient 12 0.000000

313 P1 Pressure Coefficient 13 0.000000

314 P1 Pressure Coefficient 14 30.00000

315 P1 Pressure Coefficient 15 0.000000

316 P1 Pressure Coefficient 16 0.000000

317 P1 Pressure Coefficient 17 0.000000

318 P1 Pressure Coefficient 18 30.00000

319 P1 Pressure Coefficien

t 19 0.000000

320 P1 Pressure Coefficient 20 0.000000

321 P1 Pressure Coefficient 21 0.000000

322 P1 Pressure Coefficient 22 30.00000

323 P1 Pressure Coefficient 23 0.000000

324 P1 Pressure Coefficient 24 0.000000

325 P1 Pressure Coefficient 25 0.000000

326 P1 Pressure Coefficient 26 30.00000

327 P1 Pressure Coefficient 27 0.000000

328 P1 Pressure Coefficient 28 0.000000

329 P1

Pressure Coefficient 29 0.000000

330 P1 Pressure Coefficient 30 30.00000

331 P1 Pressure Coefficient 31 0.000000

332 P1 Pressure Coefficient 32 0.000000

333 Call-In Trigger

Selection to determine what activity will cause an instrument call-in.

Select:

0 - No Call-in

Default: 1 - Alarm Call-in only

2 - Scheduled Call-in only

3 - Alarm & Scheduled Call-In

334 Scheduled Call-In Date

Date of next scheduled call-in. The host software must reset this after each call.

Default = 01-01-00

39

Page 40

40

Item Item Name & Description

335 Scheduled Call-In Time

Time of next scheduled call-in. The host software may reset as needed or be reused for

next call-in.

Default = 01:00:00

338 Scheduled Call-In Alarm

Status of scheduled call-in activity, ‘11111111’ indicates call-in activity since last

interrogation and is intended to be reset to zero after each read. ‘00000000’ indicates no

activity s

ince last interrogation.

Default: 00000000

339 Scheduled Call-In Phone #

Phone number used for scheduled call-in.

340 Digi-Span Mode

Selection that determines what mode the ERX Recorder pulse output channels are set to.

Default: 0 = No Digi-Span--Standard Pulse Out

1 = Gas Override--Pulse Channel A on

2 = Oil Override--Pulse Channel B on

3 = Automatic--Both Channels off

P2 Pressure Coefficients

341 P2 Pressure Coefficient 1 0.000000

342 P2 Pressure Coefficient 2 30.00000

343 P2 Pressure Coefficient 3 0.000000

344 P2 Pressure Coefficient 4 0.000000

345 P2 Pressure Coefficient 5 0.000000

346 P2 Pressure Coefficient 6 30.00000

347 P2 Pressure Coefficient 7 0.000000

348 P2 Pressure Coefficient 8 0.000000

349 P2 Pressure Coefficient 9 0.000000

350

P2 Pressure Coefficient 10 30.00000

351 P2 Pressure Coefficient 11 0.000000

352 P2 Pressure Coefficient 12 0.000000

353 P2 Pressure Coefficient 13 0.000000

354 P2 Pressure Coefficient 14 30.00000

355 P2 Pressure Coefficient 15 0.000000

356 P2 Pressure Coefficient 16 0.000000

357 P2 Pressure Coefficient 17 0.000000

358 P2 Pressure Coefficient 18 30.00000

359 P2 Pressure Coefficien

t 19 0.000000

360 P2 Pressure Coefficient 20 0.000000

361 P2 Pressure Coefficient 21 0.000000

362 P2 Pressure Coefficient 22 30.00000

363 P2 Pressure Coefficient 23 0.000000

364 P2 Pressure Coefficient 24 0.000000

365 P2 Pressure Coefficient 25 0.000000

Item Item Name & Description

www.honeywell.com

Page 41

366 P2 Pressure Coefficient 26 30.00000

367 P2 Pressure Coefficient 27 0.000000

368 P2 Pressure Coefficient 28 0.000000

369 P2 Pressure Coefficient 29 0.000000

370 P2 Pressure Coefficient 30 30.00000

371 P2 Pressure Coefficient 31 0.000000

372 P2 Pressure Coefficient 32 0.000000

408 P3 Pressure Unit

Selection for the unit-of-measure for P2 pressure item 501, if changed to a diff

all P2 pressure-related items are converted and displayed to the new unit-of-measure.

See below for possible pressure unit choices.

Default: 0-PSIG

1-PSIA

2-kPA

3-mPa

4-Bar

5-mBar

6-KGcm2

7-in WC

8-in HG

9-mm HG

10-Oz

410 P3 Pressure Calibration Date

Date of the most recent P3 calibration

Default: 01-01-04

411 P3 Pressure Transducer Serial Number

Default: 00000000

412 P3 Pressure Range

P3 transducer in PSI

Default: 333.00

414 P3 Pressure Zero Offset

The most recent span value for P3 pressure transducer and obtained during a pressure

span calibration. A value that is normally ver

Pressure Span Calibration

Default = 0.0000

.

y close to 0.0000 and recalculated on each

415 P3 Pressure Previous Zero Offset

The previous P3 zero offset value recorded in item 414, updated on each calibration.

Default: 0.0000

erent type,

41

Page 42

Item Item Name & Description

417 P3 Pressure Span Factor

The most recent span value factor for P3 pressure transducer and obtained during a

pressure span calibration. The value is normally very close to 1.0000 and recalculated on

each pressure span calibration.

Default = 1.0000

418 P3 Pressure Previous Span Factor

The previous P3 span factor recorded in item 417, updated on each calibrat

Default: 1.0000

419 P3 Pressure Range User

The upper pressure range limit, automatically scaled to the pressure units selected at item

408. If PSI is the selected pressure units, then item 419 will be the same as item 412.

NOTE: The value at Item 419 and maybe manually edited to a rounded-off number, if

desired.

Default = 333.00

420 P3 Gas Pressure

Gas pressure measured at the las

t wake-up. The pressure reading is scaled to the unit of

measure selected at item 408.

421 P3 Average Pressure

P3 average pressure that occurred during the log interval

422 P3 Interval High Pressure

Highest P3 pressure reading recorded during the log interval.

423 P3 Interval Low Pressure

Lowest P3 pressure reading recorded during the log interval.

424 P3 Current Day Average Pressure

Av

erage P3 pressure readings recorded for the current day.

425 P3 Previous Day Average Pressure

Previous value recorded in item 424

426 P3 Maximum Pressure

Maximum P3 pressure reading recorded since the recorder was last reset.

Default: 0.000

427 P3 Maximum Pressure Time

Time of maximum P3 pressure reading was recorded since the recorder was last reset.

Default: 00 00 00

428 P3 Maximum Press

ure Date

Date of the maximum P3 pressure reading since the recorder was last reset.

Default: 01-01-04

ion.

42

www.honeywell.com

Page 43

Item Item Name & Description

429 P3 Minimum Pressure

Minimum P3 pressure reading recorded since the recorder was last reset.

Default: 333.00

430 P3 Minimum Pressure Time

Time of minimum P3 pressure reading was recorded since the recorder was last reset.

Default: 00 00 00

431 P3 Minimum Pressure Date

Date of the minimum P3 pressure reading since the recorder was last reset.

Default: 01-01

-04

Board Coefficients

441 P2 Board Coefficients A 0.0000

442 P2 Board Coefficients B 1.0000

443 P2 Board Coefficients C 0.0000

444 P2 Board Coefficients D 1.0000

445 P3 Board Coefficients A 0.0000

446 P3 Board Coefficients B 1.0000

447 P3 Board Coefficients C 0.0000

448 P3 Board Coefficients D 1.0000

451 P3 High Alarm

Binary indication whether a P3 high alarm occurr

ed.

Default: 00000000, No alarm

11111111, Alarm

452 P3 Low Alarm

Binary indication whether a P3 low alarm occurred.

Default: 00000000, No alarm

11111111, Alarm