Page 1

Home

CAUTION

ERM5220R

Equipment Remote Module

WITH REDLINK™ WIRELESS TECHNOLOGY

Table of Contents

About the ERM5220R 2

Installation Checklist 3

Terminal Designations 4

Installation 6

Checkout 12

Troubleshooting 13

Specifications 15

5 Year Warranty 17

Read these installation instructions completely and follow them

carefully.

Installation must be performed by a qualified service technician

and must comply with local codes.

Disconnect power to all relevant devices before installing or

servicing the ERM.

Failure to connect the device according to these instructions may

result in damage to the device, the controls, and/or personal injury.

INSTALL GUIDE

33-00135EFS-07

Page 2

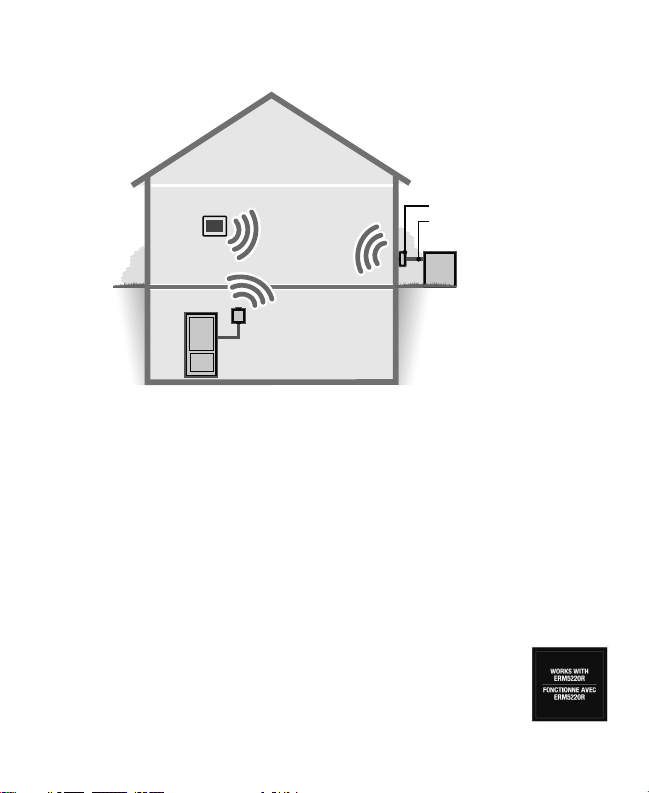

About the ERM5220R

THERMOSTAT

ERM

BOILER

ERM

WIRE

CONDENSING

UNIT

MCR35654

Fig. 1.

• Wireless RedLink™ communication between condensing unit/

compressor or boiler and thermostat.

• Eliminates the need to run additional wires to your equipment, for

example, during a heat pump upgrade.

• Suitable for outdoor use.

• Temperature sensor terminals for outdoor temp sensors or indoor

freeze protection.

• LEDs for easy installation checkout.

• May reduce damage to homes since wiring/drilling is eliminated.

NOTE: The ERM5220R is compatible with updated

models THX9421R5021, TH8321R1001,

TH8320R1003, and TH8110R1008.

THM5421R1021 EIM is also required with

THX9421R5021. Optional with other models.

33-00135EFS—07 2

Page 3

Installation Checklist

INSTALL GUIDE

33-00135EFS-03

ERM5220R

Equipment Remote Module

WITH REDLINK™ WIRELESS TECHNOLOGY

Table of Contents

About the ERM5220R 2

Installation Checklist 3

Terminal Designations 4

Installation 6

Checkout 12

Troubleshooting 14

Specifications 16

5 Year Warranty 18

CAUTION

Read these installation instructions completely and follow them

carefully.

Installation must be performed by a qualified service technician and

must comply with local codes.

Disconnect power to all relevant devices before installing or

servicing the ERM.

Failure to connect the device according to these instructions may

result in damage to the device, the controls, and/or personal injury.

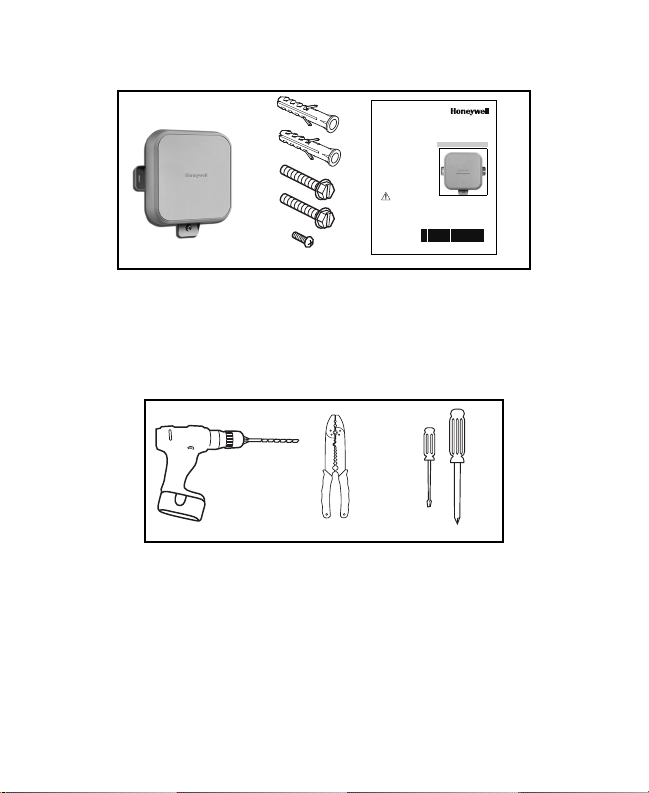

MATERIALS SUPPLIED:

M35671

• ERM5220R

• Wall Anchors (x2) and Mounting Screws (x2)

• Extra Cover Screw (optional)

• Installation Instructions

TOOLS NEEDED (NOT SUPPLIED):

M35669

M35672

•Drill

• Nut Driver Attachment for Drill

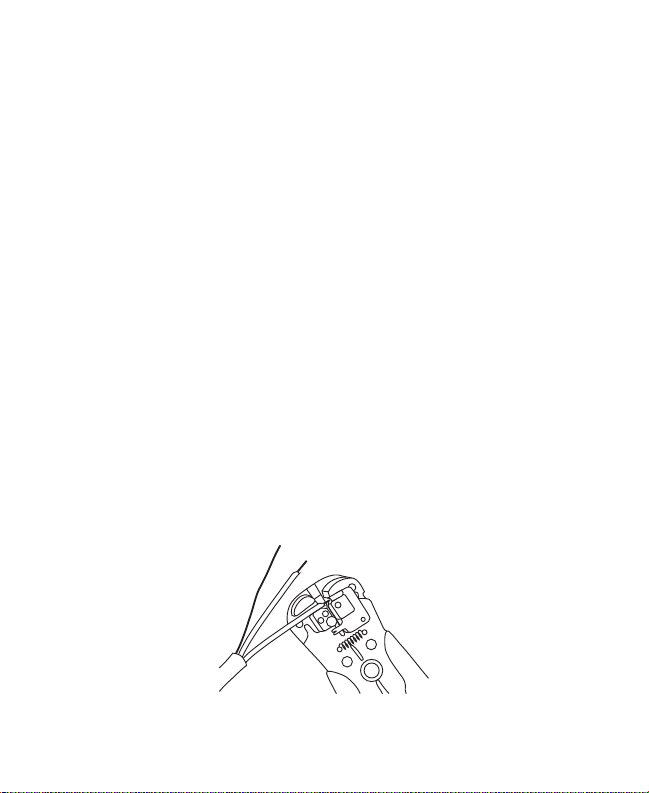

• Wire Stripper

• Small Flathead Screwdriver

• Phillips Screwdriver

• 120/240 V to 24 V Transformer (optional)

3 33-00135EFS—07

M35670

Page 4

Terminal Designations

M35655

J

R

C

Y

D

L

S1

S1

TERMINALS FOR 10K OHM TEMPERATURE SENSOR. CAN BE USED TO SENSE OUTDOOR TEMPERATURES WHICH WILL BE DISPLAYED

ON A COMPATIBLE RedLINK THERMOSTAT.

COMPRESSOR LINE FAULT TERMINAL. FAULT OCCURRENCE WILL BE COMMUNICATED TO COMPATIBLE RedLINK THERMOSTAT.

COMPRESSOR DEFROST TERMINAL. DEFROST OCCURRENCE WILL BE COMMUNICATED TO COMPATIBLE RedLINK THERMOSTAT.

O/B TERMINAL FOR REVERSING VALVE ON HEAT PUMP.

SECOND STAGE OF TWO STAGE COMPRESSOR.

FIRST STAGE OF TWO STAGE COMPRESSOR.

TERMINALS FOR 24VAC POWER.

TERMINAL FOR JUMPER. JUMPER BETWEEN J AND R SHOULD BE IN PLACE FOR COMPRESSOR USE.

THE “D” TERMINAL OPERATES AS AN INPUT FOR DEFROST. ACTIVE INPUT ON “D” TERMINAL WILL POWER AUX1. IF “D” TO AUX1 IS NOT DESIRED, DO NOT

CONNECT “D” TERMINAL TO THE ERM5220R. THIS FEATURE IS ONLY ACTIVE WHEN THE THE ERM5220R IS CONFIGURED FOR USE WITH A COMPRESSOR

TERMINAL DESIGNATIONS FOR COMPRESSOR

O/B

T

Y2

T

1

1

Fig. 2. Terminal Designations for Compressor.

33-00135EFS—07 4

Page 5

M35656A

TERMINALS FOR 10K OHM TEMPERATURE SENSOR. CAN BE USED FOR FREEZE PROTECTION IN THE CASE OF THE THERMOSTAT

LOSING THE SIGNAL TO THE ERM. SENSOR MUST REMAIN INDOORS TO BE USED FOR FREEZE PROTECTION.

L

S1

S1

TERMINAL DESIGNATIONS FOR BOILER

TERMINAL FOR HEAT CALL.

TERMINAL FOR HEAT CALL.

T

T

D

Y2

O/B

TERMINALS FOR 24VAC POWER.

TERMINAL FOR JUMPER. JUMPER BETWEEN J AND R SHOULD BE REMOVED FOR BOILER USE.

J

C

R

Y

NOTE: ERM WILL NOT SUPPORT SERIES20 OPERA TION. WHEN CONFIGURED AS A BOILER, THE Y RELAY SHALL BE OFF AT ALL TIMES.

Fig. 3. Terminal Designations for Boiler.

5 33-00135EFS—07

Page 6

INSTALLATION

IMPORTANT

• The ERM is not compatible with RedLink Zone boards.

• To ensure that the ERM will receive a wireless signal at the

desired installation location, follow steps 1 to 5 in the Wiring

section.

• If your location has metal siding, the ERM’s signal may be

affected. If there is no communication or poor signal strength,

consider a different location.

• A Prestige (with EIM) or VisionPRO (with or without EIM) will

only allow one of the following configurations:

1) Enrolled with a single boiler configured ERM;

2) Enrolled with a single compressor configured ERM;

3) Enrolled with a single boiler configured ERM and enrolled

with a single compressor configured ERM.

Wiring

1. Make sure power to compressor/boiler is off.

2. Remove the front cover by loosening the cover screw and lifting

up from the bottom of the ERM.

3. Remove 3 to 4 inches of the cable’s outer sheathing, then

remove 3/8 to 1/2 inch of insulation from each wire.

M35674

Fig. 4. Cable prepared for wiring.

33-00135EFS—07 6

Page 7

4. For compressor applications: Leave the jumper between termi-

nals J and R in place.

For boiler applications

: Remove the jumper between terminals

J and R.

FOR COMPRESSOR:

Jumper J and R

FOR BOILER:

Remove Jumper

R

C

J

O/B

Y2

Y

T

T

S1

D

S1

L

MCR35657

Fig. 5. Terminal Designations showing the jumper

between J and R terminals.

5. For compressors and boilers:

Connect a 24 VAC power source

to the R and C terminals on the ERM.

O/B

Y2

J

24V CAN COME FROM AIR HANDLER

24

(COMPRESSOR APPLICATION)

VAC

V c.a.

OR EXTERNAL TRANSFORMER

T

T

Y

R

C

S1

D

S1

L

M35658

Fig. 6.

6. Connect terminals from the ERM to the appropriate terminals

on the compressor/boiler control board.

7 33-00135EFS—07

Page 8

COMPRESSOR

M35673

C

Y

D

L

S1 S1

J

R

O/B

T

Y2

T

T

EQUIPMENT

CONTROL

BOARD

10K OHM INDOOR

TEMPERATURE

SENSOR

(RECOMMENDED)

T

24

VAC

V c.a.

J

T

T

S1 S1

D

L

O/B

Y2

Y

R

C

24

VAC

V c.a.

C

R

Y

Y2

EQUIPMENT CONTROL BOARD

O/B

10K OHM OUTDOOR

TEMPERATURE

SENSOR (OPTIONAL)

D

L

M35668

Fig. 7.

BOILER

Fig. 8.

IMPORTANT

If the ERM was previously used with a compressor and will now

1) un-enroll the ERM at the thermostat;

be used with a boiler:

2) remove the jumper on the ERM;

33-00135EFS—07 8

3) designate Radiant Heat for Heating System Type

(ISU 2000) in your thermostat.

Page 9

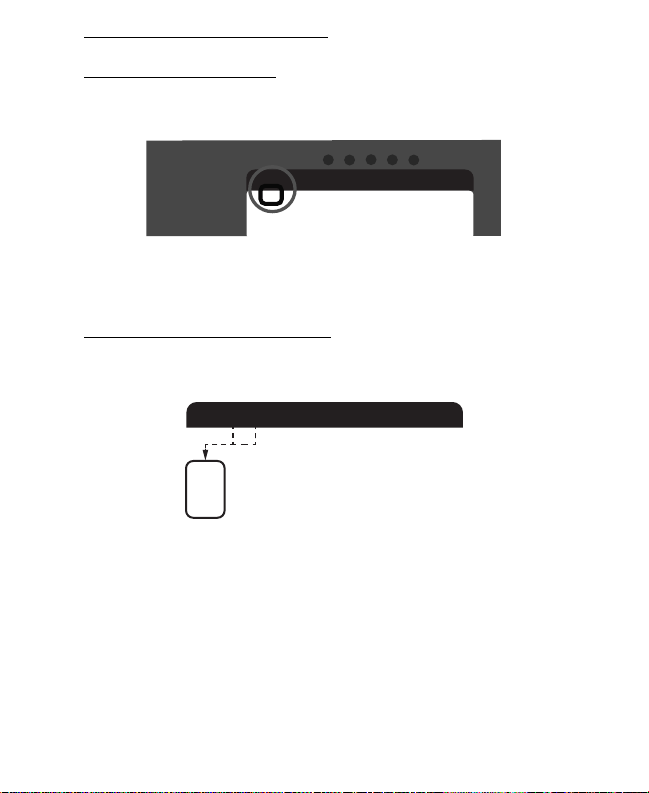

Once power is connected, the “Compressor” (or “Boiler”) LED should

OR

MCR35659

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

MCR35660

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

illuminate green. (Fig. 9)

Fig. 9.

7. For compressors and boilers:

Put the thermostat in pairing mode.

New thermostat installation: When going through the initial setup the

thermostat display will ask “TSTAT CONTROLS AN EQUIP MODULE”.

This refers to an EIM, not an ERM. See note below. The next screen

says “connect RedLINK Accessories?” The ERM is an accessory, so

select “yes”, and then “next”.

Existing thermostat installation

wireless manager - add device. See thermostat installation guide for

: Select menu - installer options -

assistance.

NOTE: The ERM (equipment remote module) is not an EIM

(equipment interface module).

• If using a Prestige IAQ thermostat, the EIM (THM5421R) is

always needed, whether the ERM is used or not.

• If using a RedLINK VisionPRO model, the EIM is not needed

if:

(a) there are wire connections to R and C at the

thermostat subbase and the thermostat controls hot

water heat only (no cooling).

(b) the R and C as well as furnace or air-handler wires are

connected to the subbase of the thermostat.

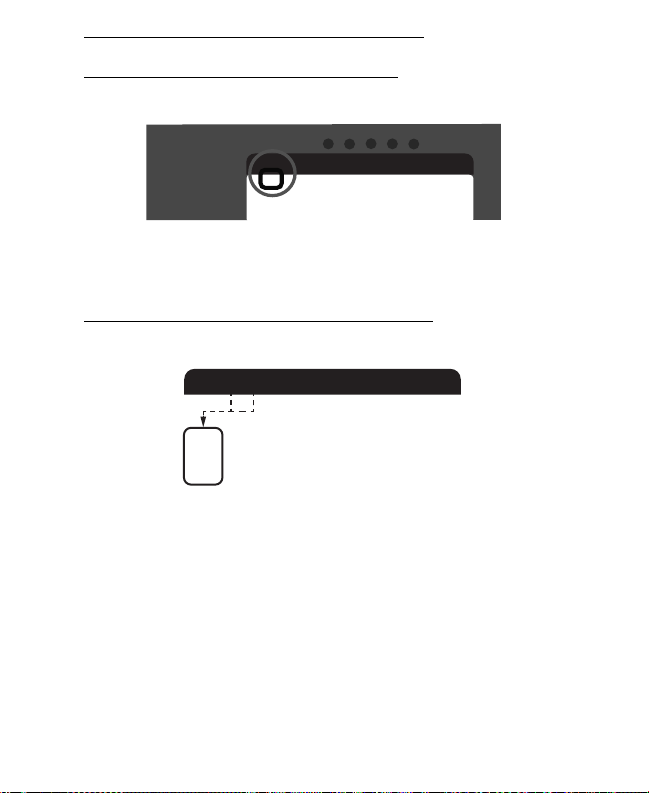

8. Once the thermostat is in pairing mode, press and quickly

release the “Connect” button on the ERM.

9 33-00135EFS—07

Page 10

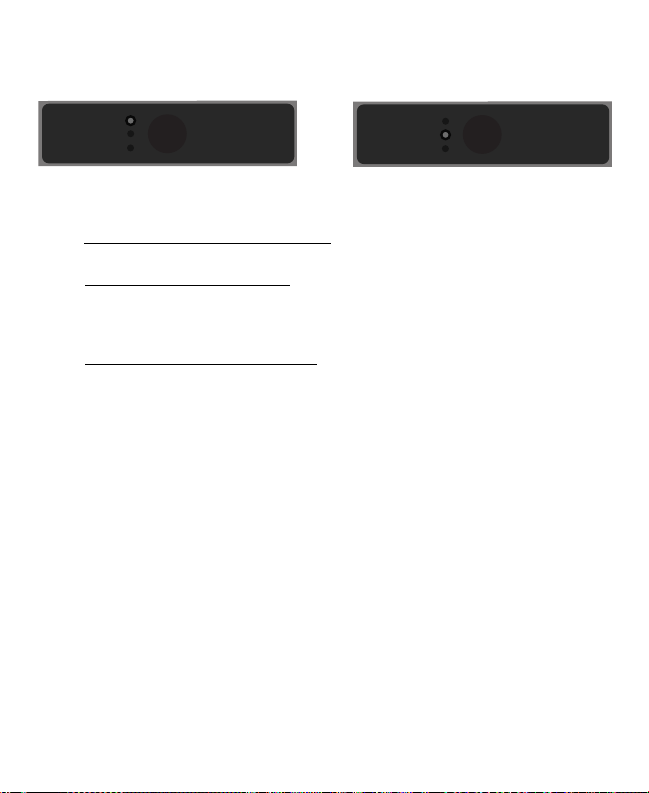

When the ERM is connected to the system, the ERM’s “Connected” LED will be

OR

MCR35661

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

MCR35662

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

MCR35665

MOUNTING

SCREWS

CORRECT

Equipment Remote Module I ERM5000R

Compressor

Boiler

Connected

Connect

CONNECTED LED STATUS

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor:

Jump J and R

Boiler:

Remove Jumper

J

R

C

Y1

Y2

T

O/B

T

D

L

S1

S1

INCORRECTINCORRECT

Equipment Remote Module I ERM5000R

Compressor

Boiler

Connected

Connect

CONNECTED LED STATUS

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor:

Jump J and R

Boiler:

Remove Jumper

J

R

C

Y1

Y2

T

O/B

T

D

L

S1

S1

Equipment Remote Module I ERM5000R

Compressor

Boiler

Connected

Connect

CONNECTED LED STATUS

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor:

Jump J and R

Boiler:

Remove Jumper

J

R

C

Y1

Y2

T

O/B

T

D

L

S1

S1

solid green and the thermostat will show “ERM” in its Wireless Manager. (Fig.

10)

Fig. 10.

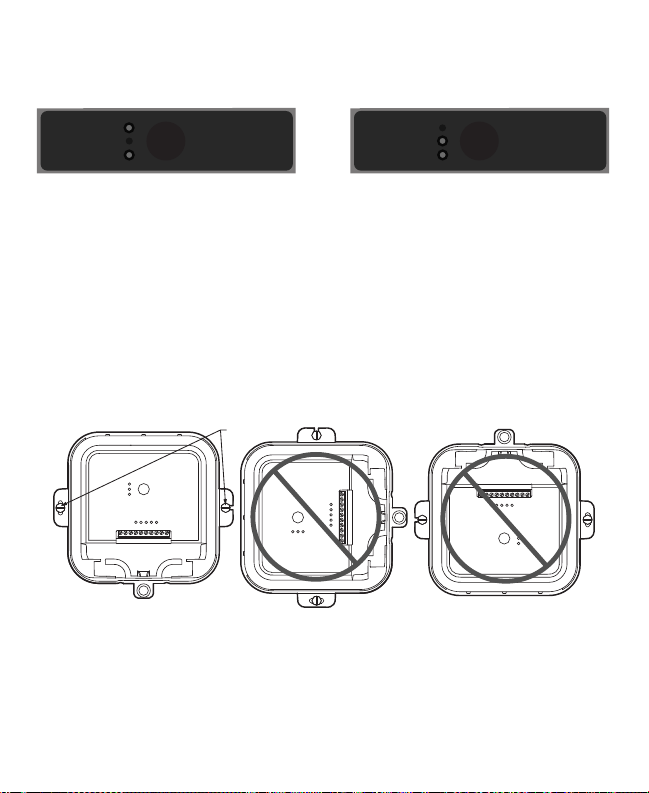

Mounting ERM

9. Use two screws and wall anchors to attach the ERM to the exterior wall near the compressor. The location should be at least

3 feet above ground and oriented with the two wire exits facing downward. See Figs. 11 and 12.

10. Attach cover and secure with bottom screw (Fig. 13).

33-00135EFS—07 10

Fig. 11. Mounting orientation.

Page 11

MINIMUM

1/4 INCH GAP

M35666

Fig. 12. If mounting on lap siding,

allow space for the cover to be removed.

M35667

Fig. 13.

11 33-00135EFS—07

Page 12

Checkout

M35680

Power the system on. Use the thermostat to start a cooling or heating cycle,

testing the ERM.

1. Restore power to the compressor/boiler as well as your RedLink

system.

2. Raise/lower the set point on the zone thermostat to initiate a

call for heat/cooling.

3. Observe all control devices to ensure operation and heat/cooling is active.

4. Lower/raise the set point on the thermostat to suspend the call

for heat/cooling.

5. If outdoor temperature sensor is used, check thermostat to see

the readings are active and accurate.

6. Be sure to set thermostat to the desired settings when checkout

is complete.

Fig. 14.

33-00135EFS—07 12

Page 13

TROUBLESHOOTING

NOTE: Disconnect RedLink™ when making changes to the device.

RESET PROCEDURE:

Hold down the “Connect” button on the ERM for 10 seconds. The

“Connection” LED should appear red for a few seconds and go out. This

indicates the unit is reset.

Symptom Possible Cause Action

Relays don’t switch as

expected

Connected LED is red Loss of

Connected LED is off Device is not enrolled

No LEDs are on No power to device Verify 24 VAC at R/C

Incorrect jumper

configuration

communication with

system

with system

Check jumper

configuration. If

incorrect, unenroll

from system, change

jumper, then re-enroll

with system.

Verify thermostat

and/or Equipment

Interface Module are

powered and

functioning correctly.

Enroll with system.

terminals.

13 33-00135EFS—07

Page 14

Symptom Possible Cause Action

No outdoor

temperature shown

on thermostat

No wired outdoor

temperature sensor

connected to ERM, or

device configured as

boiler

Thermostat shows “—”

for outdoor

temperature

Outdoor temperature

Wired outdoor

temperature sensor

failed

Sun load on sensor Verify outdoor

reading at thermostat

is too high

Compressor doesn’t

turn on, “Y” LED is

blinking

Emergency backup

control doesn’t

5-minute compressor

lockout after power

cycle

No valid indoor

temperature sensor

function

(if configured as

boiler)

Connect outdoor

temperature sensor

to S1/S1 terminals.

Device only reports

outdoor temperature

temperature when

configured as

compressor.

Check sensor for

short circuit or open

circuit.

temperature sensor is

not in direct sunlight.

May need to use

longer wire to mount

in ideal location.

Wait 5 minutes,

compressor will turn

on after safety

timeout.

Check sensor for

short circuit or open

circuit, or install

indoor temperature

sensor on S1/S1

terminals.

33-00135EFS—07 14

Page 15

SPECIFICATIONS

Operating Ambient Temperature Range:

Compressor: -40 to +155 ºF (-40 to +68 ºC)

Boiler: 30 to +130 ºF (-1 to +54 ºC)

Operating Relative Humidity Range: 0 - 99 %

Electrical:

24 VAC, 50/60 Hz.

Dimensions:

175 mm x 168 mm x 38 mm

Wireless capability via RedLink™ technology.

6-39/64

(168)

6-7/8 (175)

1-31/64

(38)

M35664

Fig. 15. Dimensions.

15 33-00135EFS—07

Page 16

SEPARABLE PARTS

ERM with TH8321R1001/U: YERM5220R8321

ERM with TH8321R1001/U and THM5421R1021: YERM5220RVPEIM

FCC REGULATIONS

§ 15.19 (A)(3)

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions:

1. This device may not cause harmful interference, and

2. this device must accept any interference received, including

interference that may cause undesired operation.

IC REGULATIONS

RSS-GEN

This device complies with Industry Canada’s licence-exempt RSSs.

Operation is subject to the following two conditions:

1. This device may not cause interference; and

2. This device must accept any interference, including interference

that may cause undesired operation of the device.

FCC WARNING

(§15.21) (USA ONLY)

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate

the equipment.

33-00135EFS—07 16

Page 17

5 YEAR WARRANTY

Honeywell warrants this product to be free from defects in the workmanship or

materials, under normal use and service, for a period of five (5) years from the

date of purchase by the consumer. If at any time during the warranty period the

product is determined to be defective or malfunctions, Honeywell shall repair

or replace it (at Honeywell's option).

If the product is defective,

(i) return it, with a bill of sale or other dated proof of purchase, to the place from

which you purchased it; or

(ii) call Honeywell Customer Care at 1-800-468-1502. Customer Care will

make the determination whether the product should be returned to the

following address: Honeywell Return Goods, Dock 4 MN10-3860, 1985

Douglas Dr. N., Golden Valley, MN 55422, or whether a replacement product

can be sent to you.

This warranty does not cover removal or reinstallation costs. This warranty

shall not apply if it is shown by Honeywell that the defect was caused by

damage which occurred while the product was in the possession of a

consumer.

Honeywell’s sole responsibility shall be to repair or replace the product within

the terms stated above. HONEYWELL SHALL NOT BE LIABLE FOR ANY LOSS

OR DAMAGE OF ANY KIND, INCLUDING ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING, DIRECTLY OR INDIRECTLY, FROM

ANY BREACH OF ANY WARRANTY, EXPRESS OR IMPLIED, OR ANY OTHER

FAILURE OF THIS PRODUCT. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so this limitation may not

apply to you.

THIS WARRANTY IS THE ONLY EXPRESS WARRANTY HONEYWELL MAKES

ON THIS PRODUCT. THE DURATION OF ANY IMPLIED WARRANTIES,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IS HEREBY LIMITED TO THE FIVE-YEAR DURATION

OF THIS WARRANTY.

Some states do not allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you. This warranty gives you specific

legal rights, and you may have other rights which vary from state to state.

If you have any questions concerning this warranty, please write Honeywell

Customer Care, 1985 Douglas Dr, Golden Valley, MN 55422 or call 1-800468-1502.

17 33-00135EFS—07

Page 18

33-00135EFS—07 18

Page 19

19 33-00135EFS—07

Page 20

Home and Building Technologies

In the U.S.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

® U.S. Registered Trademark

© 2017 Honeywell International Inc.

33-00135EFS—07 M.S. Rev. 09-17

Printed in United States

Page 21

ERM5220R

MISE EN GARDE

Module d'équipement à distance

(ERM)

AVEC TECHNOLOGIE SANS FIL REDLINK™

GUIDE D’INSTALLATION

Table des matières

À propos du module ERM5220R 2

Liste de vérification pour l’installation 3

Désignations des bornes 4

Installation 6

Vérification 13

Dépannage 15

Caractéristiques 17

Garantie de 5 ans 19

Lire cette notice d'installation dans son intégralité et bien respecter

les instructions.

L’installation doit être effectuée par un technicien d’entretien

qualifié et conformément aux codes locaux en vigueur.

Couper l’alimentation vers l’appareil avant d’installer ou de réparer

ce module ERM.

Un raccordement de cet appareil non conforme à ces instructions

peut endommager l’appareil ou les régulateurs et causer des

blessures.

Home

33-00135EFS-07

Page 22

À propos du module ERM5220R

THERMOSTAT

MODULE ERM

CHAUDIÈRE

MODULE ERM

FIL

UNITÉ DE

CONDENSATION

MFCR35654

Fig. 1.

• Communication sans fil RedLink™ entre le unité de

condensation/compresseur ou la chaudière et le thermostat.

• Élimine la nécessité d'acheminer des fils supplémentaires vers

l'équipement, pour la mise à niveau d'une thermopompe par

exemple.

• Compatible avec une utilisation à l'extérieur.

• Bornes de capteur de température pour capteurs de température

extérieure ou protection antigel intérieure.

• Témoins DEL pour une vérification aisée de l'installation.

• L'absence de câblage et de perçage peut minimiser les dommages

de l'habitation.

REMARQUE : Le module ERM5220R est compatible

avec les modèles THX9421R5021,

TH8321R1001, TH8320R1003 et

TH8110R1008 mis à jour. Le module de

l'interface de l'équipement

THM5421R1021 est également requis

avec le modèle THX-9421R5021. Il est

optionnel avec les autres modèles.

33-00135EFS—07 2

Page 23

Liste de vérification pour l’installation

M35671

INSTALL GUIDE

33-00135EFS-03

ERM5220R

Equipment Remote Module

WITH REDLINK™ WIRELESS TECHNOLOGY

Table of Contents

About the ERM5220R 2

Installation Checklist 3

Terminal Designations 4

Installation 6

Checkout 12

Troubleshooting 14

Specifications 16

5 Year Warranty 18

CAUTION

Read these installation instructions completely and follow them

carefully.

Installation must be performed by a qualified service technician and

must comply with local codes.

Disconnect power to all relevant devices before installing or

servicing the ERM.

Failure to connect the device according to these instructions may

result in damage to the device, the controls, and/or personal injury.

MATÉRIEL FOURNI :

• ERM5220R

• Ancres murales (2) et vis de montage (2)

• Vis de couvercle supplémentaire (en option)

• Notice d'installation

OUTILS REQUIS (NON FOURNIS) :

M35669

M35672

• Perceuse

• Douille tourne-écrou pour la perceuse

• Dénudeur de fils

• Petit tournevis plat

• Tournevis cruciforme

• Transformateur 120/240 V à 24 V (en option)

3 33-00135EFS—07

M35670

Page 24

Désignations des bornes

MF35655

J

R

C

Y

D

L

S1

S1

BORNES POUR CAPTEUR DE TEMPÉRATURE 10 K OHMS. PEUVENT ÊTRE UTILISÉES POUR DÉTECTER LES TEMPÉRATURES EXTÉRIEURES

QUI SERONT AFFICHÉES SUR UN THERMOSTAT RedLINK COMPATIBLE.

BORNE DE DÉFAILLANCE DE LIGNE DU COMPRESSEUR. L'OCCURRENCE DE LA DÉFAILLANCE SERA COMMUNIQUÉE AU THERMOSTAT RedLINK COMPATIBLE.

BORNE DE DÉGIVRAGE DU COMPRESSEUR. L'OCCURRENCE DU DÉGIVRAGE SERA COMMUNIQUÉE AU THERMOSTAT RedLINK COMPATIBLE.

BORNE O/B POUR LA VANNE D'INVERSION DE LA THERMOPOMPE.

DEUXIÈME ÉTAGE DU COMPRESSEUR À DEUX ÉTAGES.

PREMIER ÉTAGE DU COMPRESSEUR À DEUX ÉTAGES.

BORNES POUR ALIMENTATION 24 V C.A.

BORNE POUR CAVALIER. LE CAVALIER ENTRE J ET R DOIT ÊTRE EN PLACE POUR L'APPLICATION AVEC COMPRESSEUR.

LA BORNE D SERT D'ENTRÉE POUR LE DÉGIVRAGE. L'ENTRÉE ACTIVE SUR LA BORNE D ALIMENTE AUX1. SI CELA N'EST PAS SOUHAITÉ, NE PAS

BRANCHER LA BORNE D AU MODULE ERM5220R. CETTE FONCTION N'EST ACTIVE QUE LORSQUE LE MODULE ERM5220R EST CONFIGURÉ

POUR UNE UTILISATION AVEC UN COMPRESSEUR.

DÉSIGNATIONS DES BORNES POUR LE COMPRESSEUR

O/B

T

Y2

T

1

1

Fig. 2. Désignations des bornes pour le compresseur.

33-00135EFS—07 4

Page 25

MF35656

A

É

È

RE

Y

BORNES POUR ALIMENTATION 24 V C.A.

C

R

BORNE POUR CAVALIER. LE CAVALIER ENTRE J ET R DOIT ÊTRE RETIRÉ POUR L'APPLICATION AVEC CHAUDIÈRE.

J

REMARQUE : L'ERM N'EST PAS COMPATIBLE AVEC LA SÉRIE 20. POUR LES APPLICATIONS AVEC CHAUDIÈRE, LE RELAIS Y EST

DÉSACTIVÉ EN PERMANENCE.

BORNES POUR CAPTEUR DE TEMPÉRATURE 10 K OHMS. PEUT ÊTRE UTILISÉ POUR LA PROTECTION CONTRE LE GEL EN CAS

DE PERTE DE SIGNAL ENTRE LE THERMOSTAT ET LE MODULE ERM. LE CAPTEUR DOIT RESTER À L'INTÉRIEUR POUR ÊTRE

UTILISÉ COMME PROTECTION CONTRE LE GEL.

L

S1

SIGNATIONS DES BORNES POUR LA CHAUDI

S1

D

BORNE POUR APPEL DE CHAUFFAGE.

BORNE POUR APPEL DE CHAUFFAGE.

T

T

D

Y2

O/B

Fig. 3. Désignations des bornes pour la chaudière.

5 33-00135EFS—07

Page 26

INSTALLATION

IMPORTANT

• Le module ERM n'est pas compatible avec les tableaux de zone

RedLink.

• Pour s'assurer que le module ERM recevra un signal sans fil à

l'emplacement souhaité pour l'installation, suivre les étapes 1 à 5 de la

section Câblage.

• Si l'emplacement comporte un bardage métallique, le signal de l'ERM

peut en être affecté. En cas d'absence de communication ou d'intensité insuffisante du signal, considérer un autre emplacement.

• Les thermostats Prestige (avec EIM) ou VisionPRO (avec ou sans EIM)

ne permettront que l'une des configurations suivantes :

1) Enregistrement avec un ERM configuré pour une seule chaudière;

2) Enregistrement avec un ERM configuré pour un seul compresseur;

3) Enregistrement avec un ERM configuré pour une seule chaudière

et enregistrement avec un ERM configuré pour un seul compresseur.

Câblage

1. S'assurer que l'alimentation vers le compresseur/la chaudière

est coupée.

2. Retirer le couvercle avant en desserrant la vis du couvercle et en

le relevant du bas de l'ERM.

3. Retirer 3 à 4 pouces de la gaine extérieure du câble, puis retirer

3/8 à 1/2 pouce d'isolation de chaque fil.

M35674

Fig. 4. Câble préparé pour le raccordement.

33-00135EFS—07 6

Page 27

4. Pour les applications avec compresseur : Laisser le cavalier en

place entre les bornes J et R.

Pour les applications avec chaudière

: Retirer le cavalier entre

les bornes J et R.

FOR COMPRESSOR:

Jumper J and R

FOR BOILER:

Remove Jumper

R

C

J

O/B

Y2

Y

T

T

S1

D

S1

L

MCR35657

Fig. 5. Désignations des bornes montrant

le cavalier entre les bornes J et R.

5. Pour les compresseurs et les chaudières :

Brancher une source

d'alimentation de 24 V c.a. sur les bornes R et C du module ERM.

O/B

Y2

J

24 V PROVENANT DU SYSTÈME DE

TRAITEMENT DE L'AIR (APPLICATION

24

V c.a.

AVEC COMPRESSEUR) OU D'UN

TRANSFORMATEUR EXTERNE

T

T

Y

R

C

S1

D

S1

L

MF35658

Fig. 6.

6. Connecter les bornes du module ERM aux bornes appropriées

du tableau de contrôle du compresseur/de la chaudière.

7 33-00135EFS—07

Page 28

COMPRESSEUR

MF35668

C

Y

D

L

S1 S1

J

R

O/B

T

Y2

T

C

Y

D

L

R

Y2

O/B

24

V c.a.

CAPTEUR DE TEMPÉRATURE

EXTÉRIEURE 10 K OHMS

(EN OPTION)

TABLEAU DE CONTRÔLE

DE L'ÉQUIPEMENT

CHAUDIÈRE

J

Fig. 7.

O/B

Y2

Y

R

C

T

T

S1 S1

D

L

24

V c.a.

T

T

TABLEAU DE

CONTRÔLE DE

L'ÉQUIPEMENT

CAPTEUR DE TEMPÉRATURE

INTÉRIEURE 10 K OHMS

(RECOMMANDÉ)

MF35673

Fig. 8.

33-00135EFS—07 8

Page 29

IMPORTANT

OU

MCR35659

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

MCR35660

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

Si le module ERM a précédemment été utilisé avec un compresseur

et est maintenant destiné à être utilisé avec une chaudière :

1) annuler l'enregistrement du module ERM sur le thermostat;

2) retirer le cavalier du module ERM;

3) indiquer Radiant Heat for Heating System Type (ISU 2000)

(Chauffage rayonnant pour type de système de chauffage) sur

le thermostat.

Une fois l'alimentation connectée, le témoin DEL « Compressor »

(Compresseur) ou « Boiler » (Chaudière) devrait s'allumer en vert. (Fig.

9)

Fig. 9.

7. Pour les compresseurs et les chaudières :

Mettre le thermostat en mode d'appairage.

Installation d'un nouveau thermostat

: Lors de la configuration

initiale, l'écran du thermostat demandera « TSTAT CONTROLS

AN EQUIP MODULE ». Ceci fait référence à un module EIM, et

non à un module ERM. Voir la remarque ci-dessous. L'écran

suivant invitera à « Connect RedLINK Accessories? »

(Brancher les accessoires RedLINK?), Le module ERM est un

accessoire, sélectionner « yes » (oui), puis « next » (suivant).

Installation d'un thermostat existant

: Sélectionner menu options de l'installateur - gestionnaire des dispositifs - ajouter

un dispositif. Voir la notice d'installation du thermostat pour

obtenir de l’aide.

9 33-00135EFS—07

Page 30

REMARQUE : Le module ERM (module à distance d'équipement) n'est

OU

MCR35661

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

MCR35662

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

pas un module EIM (module d'interface d'équipement)..

• Lors de l'utilisation d'un thermostat Prestige IAQ, un module

EIM (THM5421R) est toujours nécessaire, qu'un module

ERM soit utilisé ou non.

• Lors de l'utilisation du modèle RedLINK VisionPRO, le

module EIM n'est pas nécessaire si :

(a) il y a des connexions de câblage à R et C à la plaque

de raccordement et que le thermostat ne contrôle

que le chauffage de l'eau (pas de refroidissement).

(b) les fils R et C ainsi que ceux de l'appareil de

chauffage ou de traitement de l’air sont connectés à

la plaque de raccordement du thermostat.

8. Une fois le thermostat en mode d'appairage, appuyer rapide-

ment sur le bouton « Connect » (Connexion) sur le module

ERM.

Une fois le module ERM connecté au système, son témoin DEL de

connexion s'allume en vert en continu et le thermostat indique

« ERM » dans le gestionnaire des dispositifs sans fil. (Fig. 10)

Fig. 10.

33-00135EFS—07 10

Page 31

Montage du module ERM

9. Utiliser deux vis et deux ancres murales pour fixer le module

ERM sur le mur extérieur près du compresseur. L'emplacement

doit être situé à au moins 3 pieds au-dessus du sol et orienté

avec les deux sorties de fil face vers le bas. Voir les Figs. 11 et

12.

10. Attacher le couvercle et le fixer avec la vis inférieure (Fig. 13).

VIS DE MONTAGE

Equipment Remote Module I ERM5000R

Compressor

CONNECTED LED STATUS

Remove Jumper

Flashing: Device Connecting

Connect

Boiler

Green: Device Connected

Red: Not Communicating

Connected

O/B

Y2

Compressor:

R

C

J

Y1

D

S1

S1

L

T

T

Jump J and R

Boiler:

Equipment Remote Module I ERM5000R

CONNECTED LED STATUS

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Connect

Boiler

Connected

Compressor

S1

S1

L

D

T

O/B

T

Y2

Y1

C

R

J

Boiler:

Compressor:

Jump J and R

Remove Jumper

S1

S1

T

L

D

O/B

Red: Not Communicating

Green: Device Connected

Flashing: Device Connecting

CONNECTED LED STATUS

T

Y1

J

C

R

Y2

Connect

Remove Jumper

Boiler:

Jump J and R

Compressor:

Connected

Boiler

Compressor

Equipment Remote Module I ERM5000R

CORRECTE

INCORRECTEINCORRECTE

MFCR35665

Fig. 11. Orientation de montage.

11 33-00135EFS—07

Page 32

Fig. 12. Si le montage a lieu sur un bardage à clin, laisser

ESPACEMENT

MINIMUM 1/4 PO

suffisamment d'espace pour permettre le retrait du couvercle.

M35667

Fig. 13.

33-00135EFS—07 12

Page 33

Vérification

Mettre le système sous tension. Utiliser le thermostat pour lancer un

cycle de chauffage ou de refroidissement pour tester le module ERM.

1. Restaurer l'alimentation vers le compresseur/la chaudière ainsi

que vers le système RedLink.

2. Hausser/réduire le point de consigne sur le thermostat de zone

pour lancer un appel de chauffage/refroidissement.

3. Observer tous les dispositifs de régulation pour vérifier qu'ils

fonctionnent bien et que le chauffage/refroidissement est actif.

4. Réduire/hausser le point de consigne sur le thermostat pour

lancer un appel de chauffage/refroidissement.

5. Si le capteur de température extérieure est utilisé, vérifier que

les valeurs indiquées sur le thermostat sont actives et précises.

6. Veiller à régler le thermostat aux réglages désirés une fois la

vérification terminée.

13 33-00135EFS—07

Page 34

Fig. 14.

M35680

33-00135EFS—07 14

Page 35

DÉPANNAGE

REMARQUE : Débrancher le système RedLink™ avant de procéder à

des modifications sur le dispositif.

PROCÉDURE DE RÉINTIALISATION :

Appuyer pendant 10 secondes sur le bouton « Connect » (Connexion)

du module ERM. Le témoin DEL de connexion doit s'allumer en rouge

pendant quelques secondes, puis s'éteindre. Ceci indique que l'unité a

été réinitialisée.

Symptôme Cause possible Action

Les relais ne

s'enclenchent pas

comme prévu

Le témoin DEL de

connexion est rouge

Le témoin DEL de

connexion est éteint

Aucun témoin DEL

n'est allumé

Le thermostat

n'affiche pas la

température

extérieure

Configuration incorrecte

du cavalier

Perte de

communication avec le

système

L'appareil n'est pas

enregistré dans le

système

L'appareil n'est pas

alimenté

Aucun capteur de

température extérieure

n'est connecté au

module ERM, ou

l'appareil est configuré

sur chaudière

Contrôler la configuration

du cavalier. Si elle est

incorrecte, annuler

l'enregistrement, modifier

le cavalier, puis enregistrer

de nouveau l'appareil.

Vérifier que le thermostat

et/ou le module d'interface

d'équipement sont

alimentés et fonctionnent

correctement.

Enregistrer l'appareil dans

le système.

Vérifier que 24 V c.a. sont

présents aux bornes R/C.

Brancher le capteur de

température extérieur aux

bornes S1/S1.

L'appareil n'indique que la

température extérieure

lorsqu'il est configuré sur

compresseur.

15 33-00135EFS—07

Page 36

Symptôme Cause possible Action

Le thermostat indique

«—» pour la

température

extérieure

La température

extérieure indiquée

sur le thermostat est

trop élevée

Le compresseur ne se

met pas en marche, le

témoin DEL « Y »

clignote

La régulation de

secours en cas

d'urgence ne

fonctionne pas (si

configurée comme

chaudière)

Défaillance du capteur

de température

extérieure avec fil

Charge solaire sur le

capteur

Verrouillage du

compresseur de 5

minutes après le cycle

de mise sous tension

Pas de capteur de

température intérieure

valide

Contrôler le capteur pour

s'assurer qu'il n'y a ni courtcircuit ni circuit ouvert.

Vérifier que le capteur de

température extérieure

n'est pas directement

exposé à la lumière solaire.

Un fil plus long peut être

requis pour assurer une

installation adéquate.

Attendre 5 minutes. Le

compresseur se met en

marche après le délai de

sécurité.

Contrôler le capteur pour

vérifier qu'il n'y a pas de

court-circuit ni de circuit

ouvert, ou installer le

capteur de température

intérieure sur les bornes

S1/S1.

33-00135EFS—07 16

Page 37

CARACTÉRISTIQUES

M35664

6-7/8 (175)

6-39/64

(168)

1-31/64

(38)

Gamme de température ambiante de service :

Compresseur : -40 à +68 °C (-40 à +155 °F)

Chaudière : -1 à +54 °C (30 à +130 °F)

Plage d'humidité relative de service : 0 - 99 %

Spécifications électriques :

24 V c.a., 50/60 Hz.

Dimensions :

175 mm x 168 mm x 38 mm

Capacité sans fil via technologie RedLink™.

Fig. 15. Dimensions.

17 33-00135EFS—07

Page 38

PIÈCES SÉPARABLES

ERM avec TH8321R1001/U : YERM5220R8321

ERM avec TH8321R1001/U et THM5421R1021 :

YERM5220RVPEIM

RÈGLEMENTS DE LA FCC

§ 15.19 (A)(3)

Ce dispositif est conforme à la Partie 15 du règlement de la FCC. Le

fonctionnement est soumis aux deux conditions suivantes :

1. Ce dispositif ne doit pas causer d’interférences nuisibles, et

2. Ce dispositif doit accepter toutes les interférences reçues, y

compris celles pouvant causer un fonctionnement non

souhaité.

RÉGLEMENTATION IC

RSS-GEN

Le présent appareil est conforme aux CNR d’Industrie Canada

applicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes :

1. l’appareil ne doit pas produire de brouillage;

2. l’utilisateur de l’appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d’en

compromettre le fonctionnement.

AVERTISSEMENT DE LA FCC

(§15.21) (ÉTATS-UNIS UNIQUMENT)

Toute modification qui n'est pas autorisée expressément par la partie

responsable de la conformite de l'appareil peut rendre l'utilisateur

inapte a faire fonctionner l'équipment.

33-00135EFS—07 18

Page 39

GARANTIE DE 5 ANS

Honeywell garantit ce produit contre tout vice de fabrication ou de matériau dans la

mesure où il en est fait une utilisation et un entretien convenables, et ce, pour cinq

(5) ans à partir de la date d’achat par le consommateur. En cas de défaillance ou de

mauvais fonctionnement pendant la période de garantie, Honeywell remplacera ou

réparera le produit (à sa discrétion).

Si le produit est défectueux,

(i) le renvoyer avec la facture ou une autre preuve d’achat date au lieu d’achat; ou

(ii) appeler le service à la clientèle de Honeywell en composant le 1-800-468-1502.

Le service à la clientèle déterminera si le produit doit être retourné à l’adresse

suivante : Honeywell Return Goods, Dock 4MN10-3860, 1985 Douglas Dr. N.,

Golden Valley, MN 55422, ou si un produit de remplacement peut être expédié.

La présente garantie ne couvre pas les frais de retrait ou de réinstallation. La

présente garantie ne s’appliquera pas s’il est démontré par Honeywell que la

défaillance est due à un endommagement du produit qui s'est produit lorsque le

consommateur l’avait en sa possession.

La responsabilité exclusive de Honeywell se limite à réparer ou à remplacer le produit

conformément aux modalités susmentionnées. HONEYWELL N’EST EN AUCUN

CAS RESPONSABLE DES PERTES OU DOMMAGES, Y COMPRIS LES DOMMAGES

INDIRECTS OU ACCESSOIRES DÉCOULANT DIRECTEMENT OU INDIRECTEMENT

D’UNE VIOLATION QUELCONQUE D’UNE GARANTIE, EXPRESSE OU TACITE,

APPLICABLE AU PRÉSENT PRODUIT, OU TOUTE AUTRE DÉFAILLANCE DU

PRÉSENT PRODUIT. Certains états ou provinces ne permettent pas de limiter la

durée des garanties tacites et, par conséquent, la présente limitation peut ne pas

s’appliquer.

CETTE GARANTIE EST LA SEULE GARANTIE EXPRESSE FAITE PAR HONEYWELL

POUR CE PRODUIT. LA DURÉE DE TOUTE GARANTIE IMPLICITE, INCLUANT LES

GARANTIES DE QUALITÉ MARCHANDE OU D’ADAPTATION À UNE UTILISATION

PARTICULIÈRE, EST LIMITÉE PAR LES PRÉSENTES À LA PÉRIODE DE CINQ ANS

DE LA PRÉSENTE GARANTIE.

Certaines provinces ne permettent pas de limiter la durée des garanties tacites et,

par conséquent, la présente limitation peut ne pas s’appliquer. La présente garantie

donne au consommateur des droits spécifiques et certains autres droits qui peuvent

varier d’une province à l’autre.

Pour toute question concernant la présente garantie, prière d’écrire aux Services à la

clientèle de Honeywell à l’adresse suivante : Honeywell Customer Relations, 1985

Douglas Dr, Golden Valley, MN 55422, ou composer le 1-800-468-1502.

19 33-00135EFS—07

Page 40

Home and Building Technologies

Aux États-Unis :

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

® Marque de commerce déposée aux États-Unis

© 2017 Honeywell International Inc.

33-00135EFS—07 M.S. Rev. 09-17

Imprimé aux États-Unis

Page 41

Módulo de acceso remoto al

PRECAUCIÓN

equipo ERM5220R

CON TECNOLOGÍA INALÁMBRICA REDLINK™

Home

Índice

Sobre el ERM5220R 2

Lista de verificación para la instalación 3

Designación de los terminales: 4

Instalación 6

Verificación 13

Localización y solución de problemas 14

Especificaciones 16

Garantía de 5 Años 19

Lea todas las instrucciones de instalación y cumpla con estas

atentamente.

La instalación la debe realizar un técnico de servicio calificado y

debe cumplir con los códigos locales.

Desconecte el suministro de energía eléctrica hacia todos los

dispositivos relevantes antes de instalar o prestar servicio al ERM.

No conectar el dispositivo según estas instrucciones, puede

ocasionar daños al dispositivo, los controles y/o lesiones

personales.

GUÍA DE INSTALACIÓN

33-00135EFS-07

Page 42

Sobre el ERM5220R

MSCR35654

ERM

CABLE

UNIDAD DE

CONDENSACIÓN

TERMOSTATO

ERM

CALDERA

Fig. 1.

• Comunicación inalámbrica RedLink™ entre el unidad de

condensación/compresor o la caldera y el termostato.

• Elimina la necesidad de pasar cables adicionales a su equipo, por

ejemplo, durante una actualización de la bomba de calor.

• Apto para uso exterior.

• Terminales de sensor de temperatura para protección de los

sensores de temperatura exteriores o de congelamiento en

interiores.

• Los LED para revisión fácil de la instalación.

• Puede disminuir el daño a los hogares debido a que se elimina el

cableado/las perforaciones.

NOTA: El ERM5220R es compatible con los modelos

33-00135EFS—07 2

actualizados THX9421R5021, TH8321R1001,

TH8320R1003, y TH8110R1008. El

THM5421R1021 EIM también es necesario con

el modelo THX-9421R5021. Opcional con otros

modelos.

Page 43

Lista de verificación para la instalación

INSTALL GUIDE

33-00135EFS-03

ERM5220R

Equipment Remote Module

WITH REDLINK™ WIRELESS TECHNOLOGY

Table of Contents

About the ERM5220R 2

Installation Checklist 3

Terminal Designations 4

Installation 6

Checkout 12

Troubleshooting 14

Specifications 16

5 Year Warranty 18

CAUTION

Read these installation instructions completely and follow them

carefully.

Installation must be performed by a qualified service technician and

must comply with local codes.

Disconnect power to all relevant devices before installing or

servicing the ERM.

Failure to connect the device according to these instructions may

result in damage to the device, the controls, and/or personal injury.

MATERIALES PROPORCIONADOS:

M35671

• ERM5220R

• Tarugos de pared (2) y tornillos de montaje (2)

• Tornillo para cubierta adicional (opcional)

• Instrucciones de instalación

HERRAMIENTAS NECESARIAS (NO SE SUMINISTRAN):

M35669

M35672

•Taladro

• Accesorio de inserción de tuercas para uso con el taladro

• Pelacables

• Destornillador pequeño de hoja plana

• Destornillador de estrella

• Transformador de 120/240 V a 24 V (opcional)

3 33-00135EFS—07

M35670

Page 44

Designación de los terminales:

MS35655

J

R

C

Y

D

L

S1

S1

TERMINALES PARA EL SENSOR DE TEMPERATURA DE 10K OHMIOS. SE PUEDE UTILIZAR PARA DETECTAR LAS TEMPERATURAS

EXTERIORES QUE SE MOSTRARÁN EN UN TERMOSTATO RedLINK COMPATIBLE.

TERMINAL DE FALLA DE TUBERÍA DEL COMPRESOR . LA FALLA SERÁ COMUNICADA AL TERMOSTATO RedLINK COMPATIBLE.

TERMINAL DE DESCONGELACIÓN DEL COMPRESOR. LA DESCONGELACIÓN SERÁ COMUNICADA AL TERMOSTATO RedLINK COMPATIBLE.

TERMINAL O/B PARA INVERTIR LA VÁLVULA EN LA BOMBA DE CALOR.

SEGUNDA ETAPA DEL COMPRESOR DE DOS ETAPAS.

PRIMERA ETAPA DEL COMPRESOR DE DOS ETAPAS.

TERMINALES PARA ALIMENTACIÓN DE 24 V CA.

TERMINAL DEL PUENTE. EL PUENTE ENTRE J Y R DEBE ESTAR EN SU LUGAR PARA EL USO DEL COMPRESOR.

EL TERMINAL "D" FUNCIONA COMO UNA ENTRADA PARA DESCONGELACIÓN. ACTIVAR LA ENTRADA EN EL TERMINAL "D" ALIMENTARÁ EL AUX1.

SI NO SE DESEA "D" A AUX1, NO CONECTE EL TERMINAL "D" AL ERM5220R. ESTA FUNCIÓN ESTÁ ACTIVA ÚNICAMENTE CUANDO EL ERM5220R

ESTÁ CONFIGURADO PARA USO CON UN COMPRESOR.

DESIGNACIÓN DE LOS TERMINALES PARA EL COMPRESOR

O/B

T

Y2

T

1

1

Fig. 2. Designación de los terminales para el compresor.

33-00135EFS—07 4

Page 45

MS35656A

Ó

N DE LOS TERMINALES PARA LA CALDERA

Y

TERMINALES PARA ALIMENTACIÓN DE 24 V CA.

TERMINAL PARA EL PUENTE. EL PUENTE ENTRE J Y R DEBE ESTAR EN SU LUGAR PARA EL USO DE LA CALDERA.

J

C

R

NOTA: EL ERM NO ADMITE EL FUNCIONAMIENTO CON LA SERIE 20. CUANDO SE CONFIGURA COMO UNA CALDERA, EL RELÉ "Y"

DEBE ESTAR APAGADO EN TODO MOMENTO.

TERMINALES PARA EL SENSOR DE TEMPERATURA DE 10K OHMIOS. SE PUEDE UTILIZAR PARA PROTECCIÓN CONTRA CONGELACIÓN

EN CASO DE QUE EL TERMOSTATO PIERDA LA SEÑAL AL ERM. EL SENSOR DEBE PERMANECER EN INTERIORES PARA SER UTILIZADO

COMO PROTECCIÓN CONTRA CONGELACIÓN.

L

S1

S1

DESIGNACI

Fig. 3. Designación de los terminales para la caldera.

TERMINAL PARA DEMANDA DE CALEFACCIÓN.

TERMINAL PARA DEMANDA DE CALEFACCIÓN.

T

T

D

Y2

O/B

5 33-00135EFS—07

Page 46

INSTALACIÓN

M35674

IMPORTANTE

• El módulo de acceso remoto al equipo (ERM) no es compatible

con los tableros de zona RedLink.

• Para garantizar que el ERM reciba una señal inalámbrica en el

lugar de instalación deseado, siga los pasos 1 al 5 en la sección

de Cableado.

• Si el lugar tiene paneles de revestimiento de metal, la señal del

ERM puede verse afectada. Si no hay comunicación o la señal

tiene poca potencia, considere una ubicación diferente.

• Un Prestige (con EIM) o VisionPRO (con o sin EIM) solo permitirá

una de las siguientes configuraciones:

1) Incorporado con un ERM configurado a una sola caldera;

2) Incorporado con un ERM configurado a un solo compresor;

3) Incorporado con un ERM configurado a una sola caldera e

incorporado con un ERM configurado a un solo compresor.

Cableado

1. Compruebe que el suministro de energía eléctrica hacia el compre-

sor/caldera esté desconectado.

2. Retire la cubierta frontal aflojando el tornillo de la cubierta y

extrayéndola de la parte inferior del ERM.

3. Retire 3 o 4 pulgadas (7.6 cm o 10.2 cm) del revestimiento del

cable, seguidamente retire de 3/8 a 1/2 pulgada del aislante de

cada cable.

Fig. 4. Cable preparado para el cableado.

33-00135EFS—07 6

Page 47

4. Para aplicaciones en el compresor: Deje el puente entre los

terminales J y R en su lugar.

Para aplicaciones en la caldera

: Retire el puente entre los

terminales J y R.

FOR COMPRESSOR:

Jumper J and R

FOR BOILER:

Remove Jumper

R

C

J

O/B

Y2

Y

T

T

S1

D

S1

L

MCR35657

Fig. 5. Designaciones de terminales mostrando

el puente entre los terminales J y R.

5. Para compresores y calderas:

Conecte a una toma de energía

de 24 V CA a los terminales R y C en el ERM.

O/B

Y2

J

LOS 24 V PUEDEN PROCEDER DE UN

CONTROLADOR DE AIRE (APLICACIÓN

24

VAC

DEL COMPRESOR) O DE UN

V c.a.

TRANSFORMADOR EXTERNO

T

T

Y

R

C

S1

D

S1

L

MS35658

Fig. 6.

6. Conecte los terminales del ERM a los terminales adecuados del

tablero de control del compresor/caldera.

7 33-00135EFS—07

Page 48

COMPRESOR

MS35668

C

Y

D

L

S1 S1

J

R

O/B

T

Y2

T

C

Y

D

L

R

Y2

O/B

24

VAC

V c.a.

SENSOR DE 10K OHM

DE TEMPERATURA EXTERIOR

(OPCIONAL)

PANEL DE CONTROL

DEL EQUIPO

CALDERA

Fig. 7.

O/B

Y2

Y

R

C

J

T

T

S1 S1

D

L

24

VAC

V c.a.

T

T

PANEL DE

CONTROL DEL

EQUIPO

SENSOR DE 10K OHM

DE TEMPERATURA INTERIOR

(RECOMENDADO)

MS35673

Fig. 8.

IMPORTANTE

utilizará con una caldera:

Si el ERM se utilizó previamente con un compresor y ahora se

1) Desincorpore el ERM en el termostato;

33-00135EFS—07 8

2) Retire el puente en el ERM;

3) Designe calefacción radiante para el tipo de sistema

de calefacción (ISU 2000) en su termostato

Page 49

Una vez que la electricidad está conectada, el LED del "compressor"

O

MCR35659

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

MCR35660

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

(compresor) o del "boiler" (caldera) se debe iluminar en verde. (Fig. 9)

Fig. 9.

7. Para compresores y calderas:

Coloque el termostato en el modo de conexión.

Instalación de termostato nuevo

: Cuando ejecute los pasos de

la configuración inicial la pantalla del termostato mostrará

“TSTAT CONTROLS AN EQUIP MODULE” (el termostato

controla un módulo de equipo). Esto se refiere a un EIM no a

un ERM. Consulte la nota que se encuentra a continuación.

¿La siguiente pantalla indica "connect RedLINK Accessories?”

(¿conectar los accesorios RedLINK?) El ERM es un accesorio,

de modo que seleccione "yes" (sí) y luego "next" (siguiente).

Instalación en termostato existente

: Seleccione el menú opciones del instalador - administrador inalámbrico - añadir

dispositivo. Consulte la guía de instalación del termostato

para obtener asistencia.

9 33-00135EFS—07

Page 50

NOTA: El ERM (módulo de acceso remoto al equipo) no es un EIM

O

MCR35661

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

MCR35662

CONNECTED LED STATUS

Connect

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Compressor

Boiler

Connected

(módulo de interfaz del equipo).

• Si utiliza un termostato Prestige IAQ, el EIM (THM5421R) se

necesita siempre, independientemente de si el ERM se

utiliza o no.

• Si utiliza un modelo RedLINK VisionPRO, no se necesita el

EIM si:

(a) hay conexiones de cable a R y C en la subbase del

termostato y el termostato controla la calefacción por

agua caliente únicamente (no la refrigeración).

(b) El R y el C, así como los cables del sistema de

calefacción o la unidad de manejo del aire están

conectados a la subbase del termostato.

8. Una vez que el termostato esté en el modo de conexión, presi-

one y suelte rápidamente el botón "Conectar" en el ERM.

Cuando el ERM está conectado al sistema, el LED "conectado" del

ERM estará verde fijo y el termostato mostrará "ERM" en su

Administrador inalámbrico. (Fig. 10)

Fig. 10.

33-00135EFS—07 10

Page 51

Monte el ERM

9. Utilice dos tornillos y tarugos de pared para fijar el ERM a la

pared exterior cerca del compresor. La ubicación debe estar por

lo menos a 3 pies (91 cm) por encima del suelo y orientada

con las dos salidas de cable hacia abajo. Vea las Figs. 11 y 12.

10. Fije la cubierta y asegúrela con el tornillo inferior (Fig. 13).

TORNILLOS DE

MONTAJE

Equipment Remote Module I ERM5000R

Compressor

CONNECTED LED STATUS

Flashing: Device Connecting

Connect

Boiler

Green: Device Connected

Red: Not Communicating

Remove Jumper

Connected

O/B

Y2

Compressor:

R

C

J

Y1

D

S1

S1

L

T

T

Jump J and R

Boiler:

Equipment Remote Module I ERM5000R

CONNECTED LED STATUS

Flashing: Device Connecting

Green: Device Connected

Red: Not Communicating

Connect

Boiler

Connected

Compressor

S1

S1

L

D

T

O/B

T

Y2

Y1

C

R

J

Boiler:

Compressor:

Jump J and R

Remove Jumper

S1

L

S1

D

Red: Not Communicating

Green: Device Connected

Flashing: Device Connecting

CONNECTED LED STATUS

T

T

Y1

J

C

R

Y2

O/B

Boiler

Connect

Remove Jumper

Boiler:

Jump J and R

Compressor:

Connected

Compressor

Equipment Remote Module I ERM5000R

CORRECTA

INCORRECTAINCORRECTA

MSCR35665

Fig. 11. Orientación de montaje.

11 33-00135EFS—07

Page 52

MÍNIMO 1/4 DE PULGADA

(6.3 mm) DE SEPARACIÓN

MS35666

Fig. 12. Si está montado sobre paneles de revestimiento,

deje espacio para que se pueda retirar la cubierta.

M35667

Fig. 13.

33-00135EFS—07 12

Page 53

Verificación

M35680

Active el suministro de energía eléctrica hacia el sistema. Utilice el

termostato para comenzar el ciclo de refrigeración o calefacción,

probando el ERM.

1. Restituya el suministro de energía eléctrica al compresor/

caldera así como al sistema RedLink.

2. Eleve/baje el punto de referencia del termostato de zona para

iniciar una demanda de calefacción/refrigeración.

3. Observe todos los dispositivos de control para garantizar que el

funcionamiento y la calefacción/refrigeración estén activas.

4. Baje/eleve el punto de referencia del termostato de zona para

suspender la demanda de calefacción/refrigeración.

5. Si se utiliza el sensor de temperatura exterior, revise el

termostato para ver si las lecturas están activas y son precisas.

6. Verifique que el termostato esté en las configuraciones

deseadas cuando finalice la revisión.

Fig. 14.

13 33-00135EFS—07

Page 54

LOCALIZACIÓN Y SOLUCIÓN DE PROBLEMAS

NOTA: Desconecte RedLink™ cuando haga cambios al dispositivo.

PROCEDIMIENTO PARA REINICIAR:

Presione el botón "Connect" (conectar) en el ERM durante 10

segundos. El LED de la "conexión" debe aparecer en rojo durante unos

segundos y después se apaga. Esto indica que la unidad está

reiniciada.

Síntoma Causa posible Acción

Los relés no

cambian como se

espera

El LED conectado

está rojo

El LED conectado

está apagado

Ninguno de los LED

está encendido

Configuración

incorrecta del puente.

Pérdida de

comunicación con el

sistema

El dispositivo no está

incorporado al

sistema

No llega electricidad

al dispositivo

Revise la configuración

del puente. Si está

incorrecta, desincorpore

a nivel del sistema,

cambie el puente y

vuelva a incorporar al

sistema.

Verifique que el

termostato y/o el módulo

de acceso remoto están

alimentados y

funcionando

correctamente.

Incorpórelo al sistema.

Verifique que haya

24 V CA en los

terminales R/C

33-00135EFS—07 14

Page 55

Síntoma Causa posible Acción

No se muestra la

temperatura

exterior en el

termostato

No hay sensor de

temperatura de

exterior cableado

conectado al ERM, ni

dispositivo

configurado como

caldera

Conecte el sensor de

temperatura exterior a

los terminales S1/S1.

El dispositivo solo

reporta la temperatura

exterior cuando está

configurado como

compresor.

El termostato

muestra “—” para la

temperatura

Falla en el sensor de

temperatura

cableado exterior

Revise el sensor en

busca de cortocircuito o

circuito abierto.

exterior

La lectura de

temperatura

exterior del

termostato es

demasiado alta

Carga de sol en el

sensor

Verifique que el sensor

de temperatura exterior

no esté bajo la luz solar

directa. Puede necesitar

utilizar un cable más

largo para montarlo en

un lugar ideal.

El compresor no se

activa, el LED "Y"

está parpadeando

El control de

respaldo de

emergencia no

funciona (si se

configura como

caldera)

Bloqueo del

compresor durante 5

minutos después del

ciclo de encendido

No hay sensor de

temperatura válido en

interiores

Espere 5 minutos, el

compresor se activará

después del apagado

por seguridad.

Revise el sensor en

busca de cortocircuito o

circuito abierto o instale

el sensor de temperatura

en interiores en los

terminales S1/S1.

15 33-00135EFS—07

Page 56

ESPECIFICACIONES

M35664

6-7/8 (175)

6-39/64

(168)

1-31/64

(38)

Rango de temperatura ambiente de funcionamiento:

Compresor: De -40 a +155 °F (-40 a +68 °C)

Caldera: De 30 a +130 ºF (-1 a +54 ºC)

Rango de humedad relativa de funcionamiento: 0 - 99 %

Características eléctricas:

24 V CA, 50/60 Hz.

Dimensiones:

175 mm x 168 mm x 38 mm

Habilitación inalámbrica mediante la tecnología RedLink™.

Fig. 15. Dimensiones.

33-00135EFS—07 16

Page 57

PARTES SEPARABLES

ERM con TH8321R1001/U: YERM5220R8321

ERM con TH8321R1001/U y THM5421R1021: YERM5220RVPEIM

REGULACIONES DE LA FCC

§ 15.19 (A)(3)

Este dispositivo cumple con la Sección 15 de las regulaciones la FCC.

El funcionamiento está sujeto a las dos condiciones siguientes:

1. Este dispositivo no debe causar interferencia perjudicial y

2. este dispositivo deberá aceptar cualquier interferencia que se

reciba, incluyendo la interferencia que pudiese causar el

funcionamiento no deseado.

REGULACIONES IC

RSS-GEN

Este dispositivo cumple con la(s) norma(s) RSS exentas de licencia de

la industria de Canadá. El funcionamiento está sujeto a las dos

condiciones siguientes:

1. Este dispositivo no debe causar interferencia, y

2. Este dispositivo deberá aceptar cualquier interferencia, incluso

la interferencia que pudiese causar el funcionamiento no

deseado del dispositivo.

17 33-00135EFS—07

Page 58

ADVERTENCIA DE LA FCC

(§15.21) (SOLO EN LOS EE.UU.)

Los cambios o las modificaciones que no hayan sido expresamente

aprobados por la parte responsable del cumplimiento de las

regulaciones podrían anular la autoridad del usuario para hacer

funcionar el equipo.

33-00135EFS—07 18

Page 59

GARANTÍA DE 5 AÑOS

Honeywell garantiza que este producto no tiene defectos en la mano de obra ni en

los materiales en condiciones de uso y servicio normales durante un período de

cinco (5) años desde la fecha de compra por parte del consumidor. Si en cualquier

momento, durante el período de vigencia de la garantía, se determina que el

producto está defectuoso o no funciona adecuadamente, Honeywell lo reparará o lo

reemplazará (a elección de Honeywell).

Si el producto está defectuoso,

(i) llévelo al lugar donde lo compró, junto con la factura de compra u otra prueba de

compra que incluya la fecha en la que compró el producto; o

(ii) comuníquese con el Servicio de atención al cliente de Honeywell, llamando al 1800-468-1502. En el Servicio de atención al cliente determinarán si el producto

debe ser devuelto a la siguiente dirección: Honeywell Return Goods, Dock 4 MN103860, 1985 Douglas Dr. N., Golden Valley, MN 55422, o si se le puede enviar un

producto de reemplazo.

Esta garantía no cubre los gastos de remoción ni de reinstalación. Esta garantía no

se aplicará si Honeywell demuestra que el defecto fue causado por daños que se

produjeron mientras el producto estuvo en posesión de un consumidor.

La única responsabilidad de Honeywell será la de reparar o reemplazar el producto

dentro de los términos mencionados anteriormente. HONEYWELL NO SERÁ

RESPONSABLE POR LA PÉRDIDA NI EL DAÑO DE NINGÚN TIPO, QUE INCLUYE

CUALQUIER DAÑO INCIDENTAL O CONSECUENTE QUE RESULTE, DIRECTA O

INDIRECTAMENTE, DE CUALQUIER INCUMPLIMIENTO DE CUALQUIER

GARANTÍA, EXPRESA O IMPLÍCITA, O DE CUALQUIER OTRA FALLA DE ESTE

PRODUCTO. Algunos estados no permiten la exclusión o limitación de los daños

incidentales o consecuentes, por lo que esta limitación podría no aplicarse en su

caso.

ESTA GARANTÍA ES LA ÚNICA GARANTÍA EXPRESA QUE HONEYWELL REALIZA

SOBRE ESTE PRODUCTO. LA DURACIÓN DE CUALQUIERA DE LAS GARANTÍAS

IMPLÍCITAS, INCLUYENDO LAS GARANTÍAS DE COMERCIABILIDAD O DE APTITUD

PARA UN FIN DETERMINADO, ESTÁN LIMITADAS A LOS CINCO AÑOS DE

DURACIÓN DE ESTA GARANTÍA.

Algunos estados no permiten limitaciones en relación a la duración de una garantía

implícita, de manera tal que la limitación anterior puede no aplicarse en su caso.

Esta garantía le otorga derechos legales específicos, pero es posible que usted goce

de otros derechos que varían de un estado a otro.

Si tiene preguntas acerca de esta garantía, escriba a Honeywell Customer Relations,

1985 Douglas Dr. Golden Valley, MN 55422 o llame al 1-800-468-1502.

19 33-00135EFS—07

Page 60

Home and Building Technologies

En los EE. UU.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

® Marca Registrada en los Estados Unidos

© 2017 Honeywell International Inc.

33-00135EFS—07 M.S. Rev. 09-17

Impreso en Estados Unidos

Loading...

Loading...