Page 1

M29857

68-0171EF-01

HR150, 200; ER150, 200 Perfect Window™

Fresh Air Ventilation Systems

PRODUCT DATA

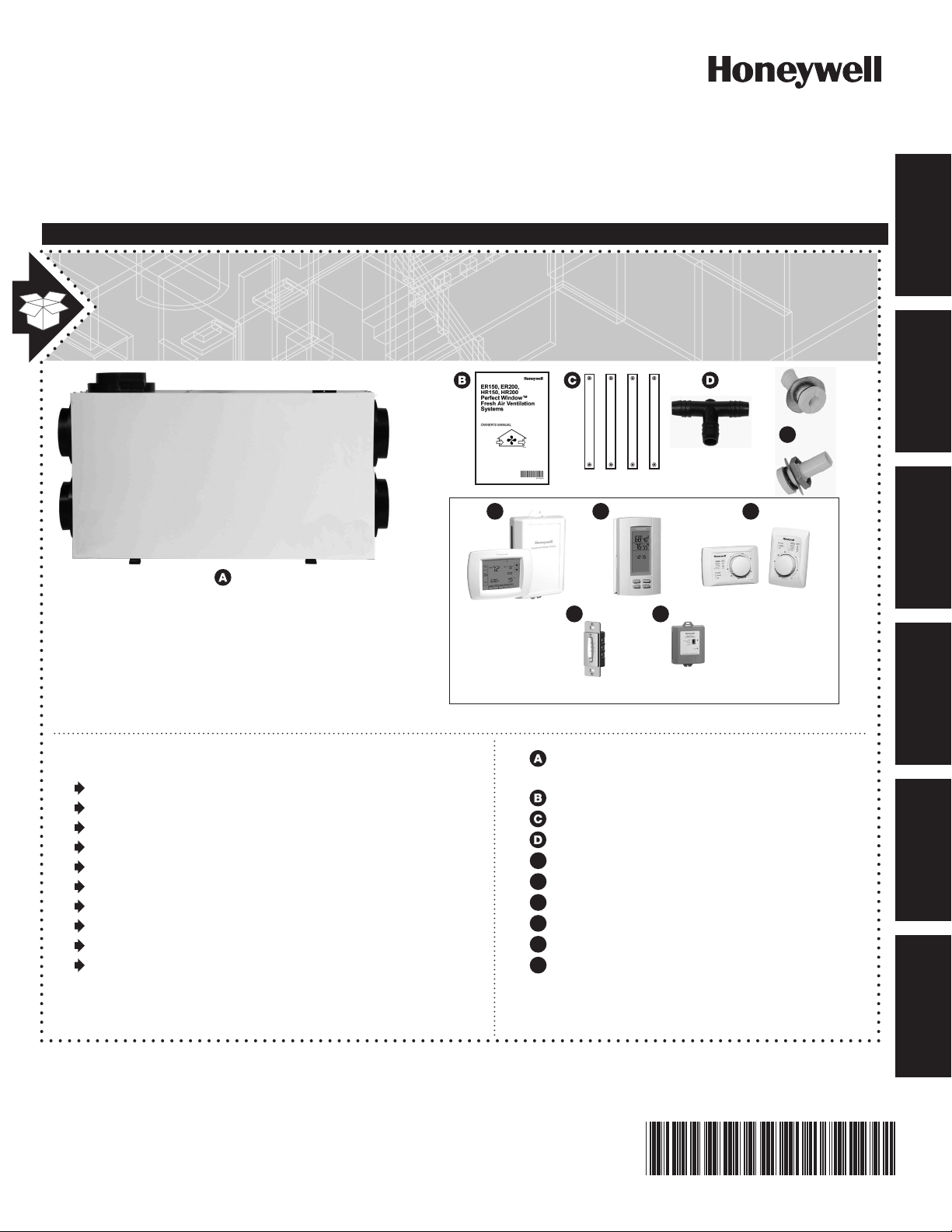

Included In thIs VentIlatIon system Box

*

e

STARTED

GETTING

MOUNTING PLUMBING WIRING APPENDICESDUCTING

*

Tools and accessories needed to install Perfect

Window™ Fresh Air Ventilation Systems

Wire cutter/stripper

18-gauge wire (up to 5 conductor)

Standard screwdriver

Insulated 6-inch round duct

Non-insulated 6-inch round duct

Two 6-inch weather hoods

Two 6-inch starter collars

1/2-inch I.D. drain hose

Airflow balancing kit

Foil tape

F1 F3

OPTIONAL CONTROLS SOLD SEPARATELY

e

F1

F2

F3

F4

F5

F2

F4 F5

HR150/200 or ER150/200 Perfect

Window™ Fresh Air Ventilation System

Owner’s Manual

Hanging straps

* T-fitting

* 2 drain spouts

VisionPRO IAQ control

TrueIAQ

Dehumidistat H8908

Digital fan timer

W8150 ventilation control

Not with “C” models.

*

Page 2

Page 3

Perfect Window Fresh Air Ventilation Systems

GETTING STARTED

Safety Definitions and Precautions . . . . . . . . . . . . . . 2

Application ................................. 3

Features .................................. 3

Planning the Installation . . . . . . . . . . . . . . . . . . . . . . 4

Sizing .................................. 5

Mounting Position and Location. . . . . . . . . . . . . . . . . 6

Balancing Airflow ............................ 9

MOUNTING

Installation ................................ 10

Suspended from Floor Joists ..................10

PLUMBING

Installing Drain Line and P-Trap . . . . . . . . . . . . . . . 11

STARTED

GETTING

MOUNTING PLUMBING WIRING APPENDICESDUCTING

WIRING

Heat Recovery Ventilator (HRV) and

Energy Recovery Ventilator (ERV) Connections . . . 12

Digital Fan Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DUCTING

Airflow Balancing ........................... 16

Balancing Procedure ........................ 16

APPENDICES

Startup and Checkout . . . . . . . . . . . . . . . . . . . . . . . 17

Cleaning Filters and Core .................. 17

Inspecting Exterior Hoods . . . . . . . . . . . . . . . . . 17

Troublshooting ............................. 18

Parts List ................................. 20

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

NEED HELP? For assistance with this product please visit http://yourhome.honeywell.com

?

or call Honeywell Customer Care toll-free at 1-800-468-1502.

Read and save these instructions.

® U.S. Registered Trademark. Patents pending. Copyright © 2010 Honeywell International Inc. All rights reserved.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

1

Page 4

GETTING

STARTED

Safety Definitions and Precautions

Safety Definitions

These safety terms identify information you must read.

CAUTION: Indicates a hazardous situation which, if not avoided, could cause bodily injury

or property damage.

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Safety Precautions

Make sure you read and understand the following safety and/or property hazards before installing,

using, or working with the Perfect Window™ Fresh Air Ventilation System:

All ducting to the outdoors must be terminated above anticipated snow lines and be fitted with a •

weather cap that incorporates bird screening.

CAUTION: Electrical shock hazard.

Can cause personal injury or equipment damage.

Disconnect power supply to prevent electrical shock or equipment damage.

CAUTION: Electrical Shock Hazard.

Can cause personal injury.

Be sure ventilator is correctly grounded. Confirm polarity of power line switched with safety (disconnect)

switch when cleaning or servicing unit.

CAUTION: Electrical Hazard.

Can cause equipment damage

Disconnect HRV/ERV from power source before connecting or disconnecting digital fan timer or other

device to HRV/ERV high-speed override terminals.

2

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 5

Application

The HR150B and HR200B Perfect Window™ Fresh Air Ventilation Systems provide proper levels of ventilation

with energy savings by transferring heat between the exhaust and fresh air streams.

The ER150B and ER200B Perfect Window™ Fresh Air Ventilation Systems provide proper levels of ventilation

with energy savings by transferring heat and moisture between the exhaust and fresh air streams.

The ER150C and ER200C Perfect Window™ Fresh Air Ventilation Systems are specifically designed for

installations in unconditioned spaces such as attics and garages in regions where the outdoor temperature does

not drop below freezing.

Features

Remotely control two-speed fan.•

Integral balancing dampers for quick installation.•

Provides ventilation that helps contractors meet ASHRAE 62.•

Automatic, economical built-in frost control available for operation to design temperatures of -40°F (-40°C).•

HR150 and HR200 models have an easy-to-clean aluminum cross-flow core.•

ER150 and ER200 models have an advanced energy heat and moisture recovery fixed core.•

Washable energy transfer core.•

Includes vibration isolation hardware and duct collars.•

Insulated cabinet made of rugged steel.•

Permanent (washable) prefilters.•

Quiet operation.•

Digital fan timer option on all models.•

Advanced ventilation algorithms available on VisionPRO IAQ, TrueIAQ and W8150 controls.•

Interlock the ERV/HRV to an air handler or furnace blower.•

Dehumidistat operation deactivated in summer.•

STARTED

GETTING

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

3

Page 6

GETTING

STALE

AIR FROM

INSIDE

DEFROST

PORT

FRESH

AIR TO

INSIDE

FRESH AIR

FROM OUTSIDE

STALE

AIR TO

OUTSIDE

M29739

BALANCING DAMPER

FILTERS

FILTERS (2)

DRAIN

M29853

MOTOR

BLOWERS

FRESH AIR

FROM OUTSIDE

DEFROST

PORT

DRAIN PANS

BALANCING

DAMPER

BALANCING

DAMPER

CORE

STALE

AIR FROM

INSIDE

FRESH

AIR TO

INSIDE

STALE

AIR TO

OUTSIDE

FRESH

AIR TO

INSIDE

FRESH AIR

FROM OUTSIDE

M29861

MOTOR

MOTOR

STALE AIR

FROM HOUSE

ENERGY

TRANSFER

CORE

BALANCING

DAMPER

CORE

STALE AIR

TO OUTSIDE

BALANCING

DAMPER

FILTERS (2)

STARTED

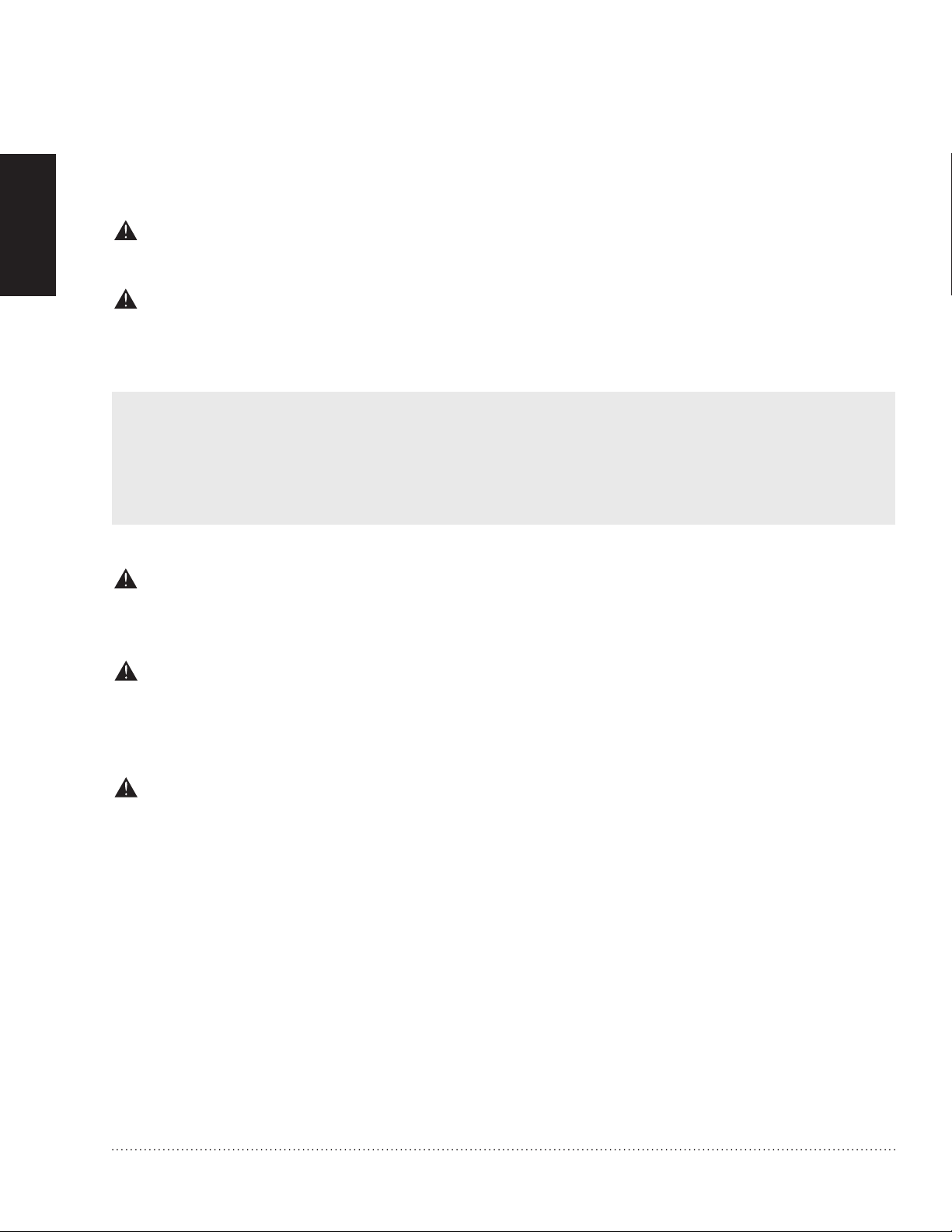

Planning the Installation

Failure to comply with these requirements will result in voided warranty, improper installation, and

service callbacks.

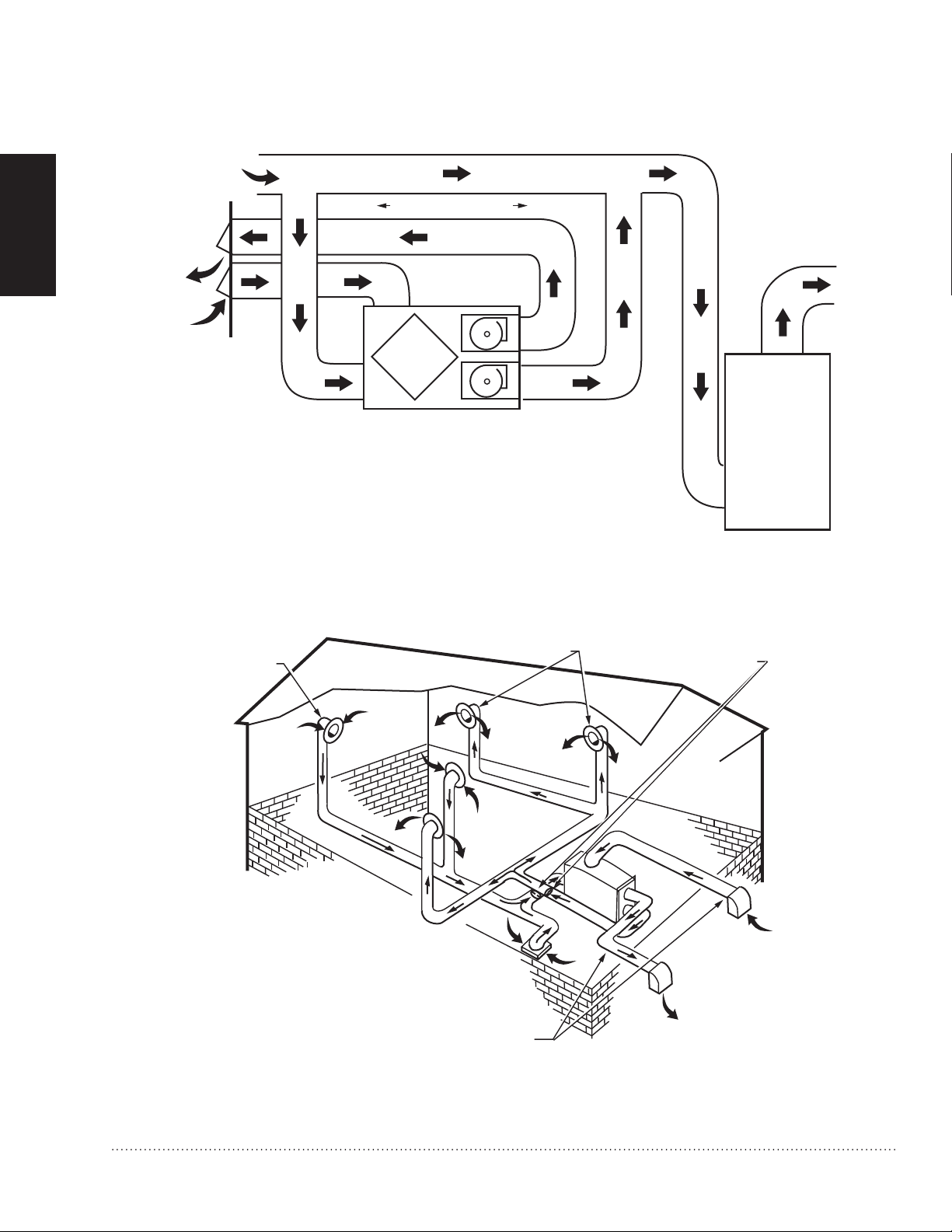

The Fresh Air Ventilation System is designed to

supply fresh air and exhaust stale air. The system

draws fresh outdoor air through the ventilator for

distribution throughout the house.

Heat Recovery Ventilator

Stale air is exhausted through the ventilator and to

the outdoors. Heat is transferred from one airstream

to the other as the air passes through the opposite

Duct connections and airflow (HR150B/HR200B).Fig. 1.

sides of the heat transfer core. See Fig. 1.

Energy Recovery Ventilator

Stale air is exhausted through the ventilator and to

the outdoors. Heat and moisture is transferred from

one airstream to the other as the air passes through

the opposite sides of the energy transfer core.

See Fig. 2 and 3.

4

Duct connections and airflow (ER150C/ER200C).Fig. 2.

Duct connections and airflow (ER150B/ER200B).Fig. 3.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 7

Sizing

ASHRAE 62.2

There are several methods that can provide

satisfactory results for sizing a ventilator to provide

adequate ventilation for a home. There is a new

residential ventilation standard, ASHRAE 62.2, that

suggests the following:

7.5 CFM per person (count people as 1 per •

bedroom plus 1) plus 1 CFM per 100 sq. ft.

Example:

2200 sq. ft. house with 4 bedrooms

= (7.5 CFM x (4 bedrooms + 1)) + (1 CFM x (2200 sq. ft. / 100))

= (7.5 x 5) + (2200 / 100)

= 37.5 + 22

= 59.5 CFM

In this case 60 CFM continuous would provide

satisfactory ventilation for this home.

ASHRAE 62.1

Some regions still use the previous standard, ASHRAE

62.1, as the code for ventilation in their region.

The ASHRAE Standard 62.1 Ventilation for Acceptable

Indoor Air Quality suggests the following:

Option 1: Fresh Air Ventilation System provides

continuous fresh air supply of 93 cfm, and intermittent

capacity for bathrooms of 150 cfm. A separate 100

cfm exhaust fan is used for the range hood.

Supply air flow required = 93 cfm

Exhaust air flow required = 150 cfm

Any Honeywell ventilation unit provides suitable

ventilation capacity. See Fig. 22.

Option 2: Fresh Air Ventilation System provides

continuous 93 cfm fresh air supply, 150 cfm

intermittent exhaust capacity for bathrooms and

continuous 50 cfm kitchen ventilation.

Supply air flow required = 93 cfm

Exhaust air flow required = 200 cfm

Honeywell HR200/ER200 have the exhaust capacity

required to meet the ventilation needs of this

application. See Fig. 22.

STARTED

GETTING

.35 air changes per hour (ach) but not less than 15 •

cfm per person for living areas = house size (sq ft)

x ceiling height (ft) / 60 (min) x.35 (ach)

Example:

= 2000 sq ft x 8 ft / 60 min x .35 ach = 93 cfm

50 cfm intermittent or 20 cfm continuous capacity •

for bathrooms

Example:

50 cfm intermittent x 3 bathrooms = 150 cfm

20 cfm continuous x 3 bathrooms = 60 cfm

100 cfm intermittent or 25 cfm continuous capacity •

for kitchens

Example:

100 cfm intermittent x 1 kitchen = 100 cfm

25 cfm continuous x 1 kitchen = 25 cfm

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

5

Page 8

GETTING

INSULATED

FLEX DUCT

COLLAR ON

VENTILATOR

SEAL INTERIOR LINING OF

FLEX DUCT TO INSIDE COLLAR

SEAL OUTER LINING OF FLEX

DUCT TO OUTER COLLAR

M6557

STARTED

Mounting Position and Location

The HR150/ER150 and HR200/ER200 can be

suspended from exposed ceiling joists, ceiling surface

or floor mounted. (Level ventilator so drains function

correctly.)

NOTE: ER150C and ER200C are specifically designed

for installations in unconditioned spaces such as

attics and garages in regions where the outdoor

temperature does not drop below freezing. (These

units are not equipped with drain kits.)

Locate fresh air intake 6 ft (2m) or more from stale •

air exhaust to prevent exhaust air from re-entering.

Locate ventilator where length of ducting required •

is minimal.

Install HR150/ER150 and HR200/ER200 in a

conditioned space using these guidelines:

Pipe drain line (ER150C and ER200C do not have •

drain kits) from the ventilator to a drain.

Use an existing electrical outlet with appropriate •

current rating (or install one) close to ventilator

power cord.

Allow space for drain line by placing the ventilator •

at least 10 in. (254 mm) off the floor.

For access and removal of ventilator core, allow at •

least 25 in. (635 mm) of open space in front of unit.

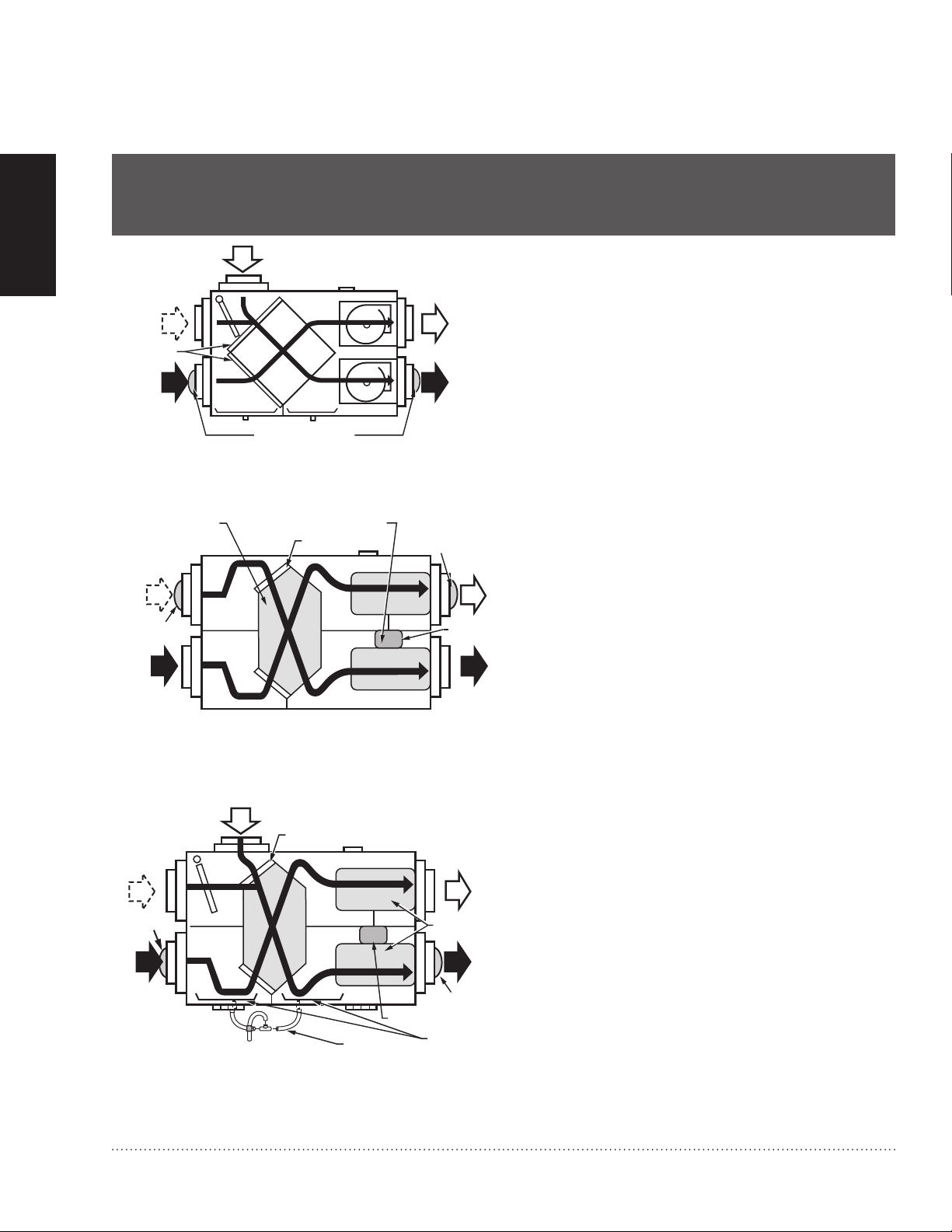

Ducting

Ducting between the ventilator and the outdoors must

be insulated and have a continuous air vapor barrier.

See Fig. 4.

IMPORTANT

All ducting to the outdoors must be terminated above

anticipated snow lines and be fitted with a weather cap

that incorporates bird screening.

Sealing insulated duct terminations.Fig. 4.

6

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 9

Design and installation of ductwork must be according to standard HVAC practice to deliver required quantities

COLD AIR

RETURN

EXHAUST AIR FROM

VARIOUS PARTS OF

HOME (BATHROOMS

IF REQUIRED; KITCHENS

IF REQUIRED; ROOMS

WITHOUT OPERABLE WINDOWS,

A

ND POTENTIALLY BASEMENTS).

FORCED AIR

FURNACE

COMBUSTION

OR ELECTRIC

M6549D

RETURN

AIR

OUTDOORS

NOTES:

1.

2.

3.

4.

FURNACE BLOWER NEED NOT OPERATE TO PROVIDE GOOD AIR DISTRIBUTION/QUALITY WITH THIS SYSTEM.

IF FURNACE BLOWER OPERATION IS REQUIRED TO HELP DISTRIBUTE SUPPLY AIR: RUN CONTINUOUSLY

OR INTERLINK ELECTRICALLY (LOW VOLTAGE).

NO SEPARATION REQUIREMENTS ARE NECESSARY BETWEEN DIRECT CONNECTION POINT AND FURNACE.

WEATHER-HOOD ARRANGEMENT IS FOR DRAWING ONLY. 6 FT (2m) MINIMUM SEPARATION REQUIRED,

18 IN. (0.46m) ABOVE GRADE MINIMUM.

of fresh air to temperature-controlled space and exhaust equivalent quantities of room air to the outside.

Keep intake and exhaust duct runs as short as possible with few bends or elbows.

Keep duct sizes as large as possible throughout the installation.•

Use a 6 in. diameter round duct for all connections to and from the ventilator.•

Separate outside intake and exhaust vents by at least 6 ft (2m).•

NOTES: Do not locate the fresh air vent where it blows directly onto occupants or the thermostat.

Do not locate the fresh air intake close to known sources of pollutants such as automobile exhaust, a

dryer vent or chimney smoke.

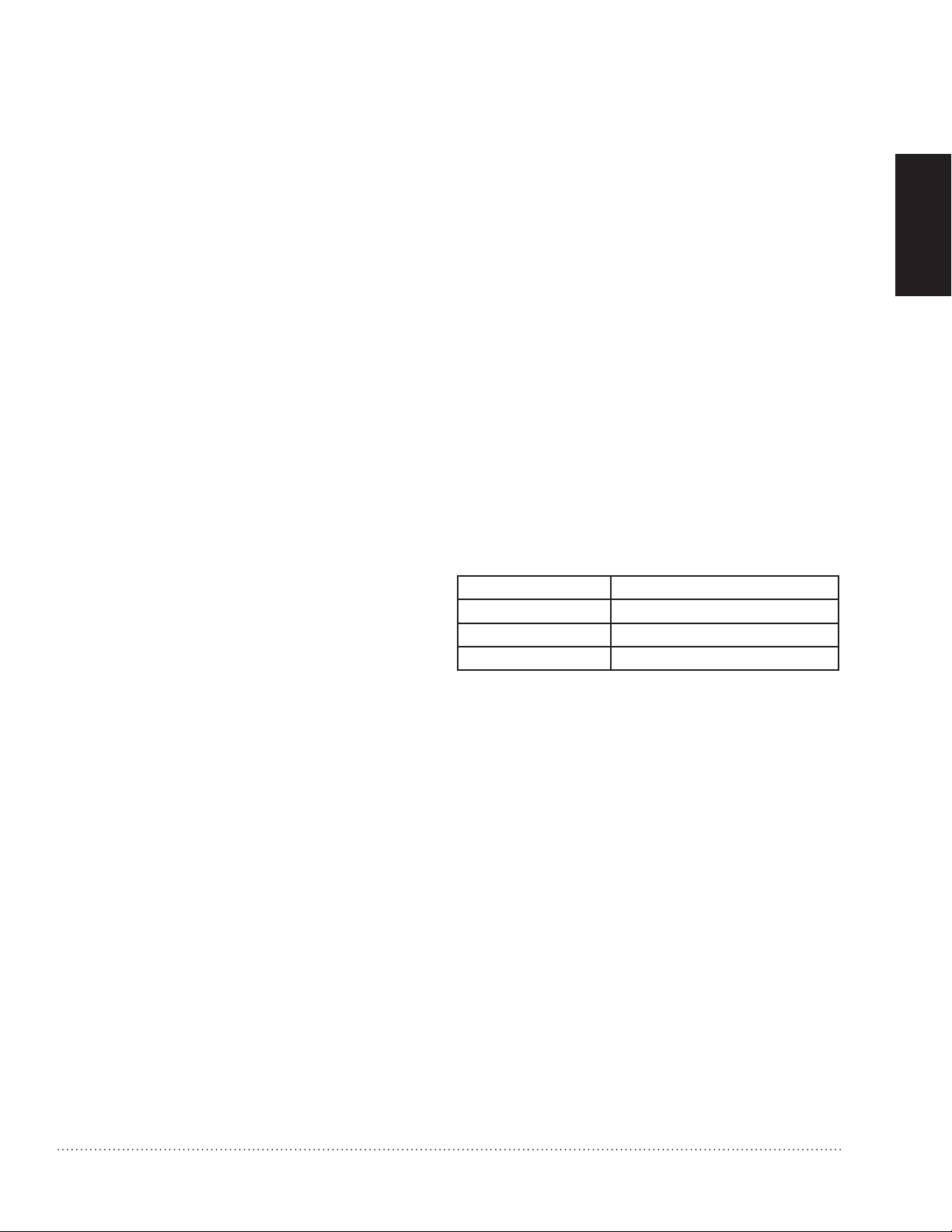

Ducting the supply outlet and/or the exhaust inlet of the ventilator to the return air plenum of the air handler •

is an excellent way to distribute fresh air and exhaust stale air from all parts of the house, while reducing

installation costs. When choosing this method, balance the ventilator when the air handler is running and

interlock the ventilator so that it can run only when the air handler runs. See Fig. 6. An alternate method is to

balance the ventilator when the air handler is not running and let the ventilator run whether the air handler is

running or not, see Fig. 5. An independent installation is shown in Fig. 7.

NOTE: When the home is occupied, continuous operation of the ventilator is recommended. When the furnace air handler

operates, fresh air is distributed through the heating/air conditioning supply registers. When the air handler is off,

fresh air is delivered through both supplies and returns.

STARTED

GETTING

An electrical interlock or an automatically powered damper must be used to prevent unwanted entry of •

outside air if the ventilator is turned off while the furnace air handler continues to operate.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Direct connection of supply air stream to furnace cold air return for HRV/ERV.Fig. 5.

7

Page 10

GETTING

40 IN. (1m) MINIMUM

COLD AIR

RETURN

FORCED AIR

FURNACE

COMBUSTION

OR ELECTRIC

M6548E

RETURN

AIR

OUTDOORS

NOTES:

1.

2.

3.

4.

FURNACE BLOWER IS REQUIRED TO OPERATE WHEN VENTILATION IS REQUIRED.

SET THE FURNACE BLOWER TO RUN CONTINUOUSLY, OR INTERLINK ELECTRICALLY

(LOW VOLTAGE).

MINIMUM SEPARATION OF 40 IN. IS REQUIRED BETWEEN THE TWO

DIRECT CONNECTIONS.

EXHAUST AIR CONNECTION SHOULD BE UPSTREAM OF THE SUPPLY

AIR CONNECTION TO PREVENT EXHAUSTING ANY FRESH AIR.

WEATHER-HOOD ARRANGEMENT IS FOR DRAWING ONLY. 6 FT. (2 m)

MINIMUM SEPARATION REQUIRED, 18 IN. (0.46m) ABOVE GRADE MINIMUM.

ADJUSTABLE FRESH

AIR SUPPLY

ADJUSTABLE DAMPERS FOR

BALANCING AIR FLOW INTO

AND OUT OF THE HOUSE

FRESH AIR

SUPPLY HOOD

STALE AIR

EXHAUST HOOD

FLEXIBLE INSULATED DUCTING

WITH A VAPOR BARRIER

VENTILATOR EXHAUSTS FROM KITCHEN AND/OR

BATHROOMS OR OTHER CENTRAL LOCATIONS

TO OUTDOORS.

VENTILATOR SUPPLIES OUTDOOR AIR DIRECTLY TO

EACH BEDROOM, TO EACH FLOOR WITHOUT A

BEDROOM, AND TO THE PRINCIPAL LIVING AREAS.

ADJUSTABLE

STALE AIR

RETURN

M4911A

NOTES:

1.

2.

STARTED

Direct connection of ventilator supply air stream and exhaust air stream to furnace cold air return.Fig. 6.

8

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Independent ventilator installation.Fig. 7.

Page 11

Balancing Airflow

Balancing the airflow verifies that the Fresh Air

Ventilation System is delivering the intended airflow

and energy performance. Use the Airflow Balancing

instructions in the Installation section to check and

balance the airflow.

Controls

Remote Override Switch Functions On/Off Control

If continuous ventilation is not required, an on/off

control can be used to activate the ventilator when it is

switched to Standby. Controls that can be used for this

function include dehumidistats, timers, wall switches

and the ventilate function of the VisionPRO IAQ and

TrueIAQ digital controls.

Dehumidistat

If moisture control in bathrooms is a primary function

of the system, a dehumidistat can be used to switch

the ventilator from a Low or Standby setting to the High

setting. Moisture removal throughout the entire home

can only be achieved when the outside air contains

less moisture than the inside air (typically during cold

weather conditions).

An HRV will override a call from the dehumidistat if

the outdoor temperatures exceed 60°F (15.6°C) for

a 24-hour period. The dehumidistat function will be

re-enabled if the unit is unplugged for 3 minutes or if

the outdoor temperature drops below 60°F (15.6°C)

for a 24-hour period. The dehumidistat function is

permanently enabled in ERVs.

IAQ Controls

The VisionPRO IAQ and TrueIAQ controls can

automatically control the ventilator by pressing the

Ventilate button on the control. See the control owner’s

guide for complete instructions.

Moisture Control

When a building is new, there is excess moisture in

the wood, plaster, cement and other construction

materials. When the new building is occupied, the

activities of the occupants also increase the moisture

level. There can also be high levels of formaldehyde

and other chemicals that were used in the building

materials. Running the ventilation system on high

speed provides optimum indoor air pollutant reduction.

High speed also provides maximum moisture removal

when the outside air contains less moisture than the

inside air. (Typically during cold weather conditions.)

Operating Damper Frost Control

Some models have an electronically-controlled damper

frost control mechanism to prevent frost buildup on the

core. Defrost timing will change based on incoming

outdoor air temperature.

Outdoor Temperauture Defrost Timer*

27 °F (-3 °C) 3 minute defrost/25 minute run

-4 °F (-20 °C) 4.5 minute defrost/17 minute run

-31 °F (-35 °C) 7 minute defrost/15 minute run

* The R2000 jumper on the control board can be

removed to meet R2000 program requirements.

Example:

When the outside temperature drops below 27 °F

(-3 °C), the defrost timer is activated. At the end of the

25 minute run cycle, when the core can experience

some nominal frost buildup, the timer activates a

motor-driven damper door that simultaneously opens

the defrost port and closes off the supply air port.

STARTED

GETTING

Digital Fan Timer

The ventilator controls are compatible with the Digital

Fan Timer. If more than one timer is activated, each

runs independently with the ventilator running at high

speed until all timers have timed out. Up to eight timers

can be installed in a system.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

9

Page 12

INSTALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow these instructions could damage the product or cause a

hazardous condition.

2. Check the ratings on the product to make sure the product is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

CAUTION: Electrical Shock Hazard.

Can cause personal injury or equipment damage.

Disconnect power supply to prevent electrical shock or equipment damage.

MOUNTING

Unpacking Fresh Air Ventilation System

Check that all the components are included. The Fresh Air Ventilation System is shipped assembled. The carton

contains the following:

Fresh Air Ventilation System.•

Vibration isolation straps (4).•

Drain fittings (2) and T fitting (1).•

Literature package.•

Except for the mounting hardware and drain fittings, the ventilator is ready for installation. Wiring, drain

connections and ducting are required to complete the installation.

Mounting

Suspended from Floor Joists

Mount the four vibration isolation straps (provided) to the side of the ventilator using the mounting screws located on the 1.

cabinet. See Fig. 23.

Securely fasten the other ends of the straps to the floor joists with wide-head nails (not supplied), making sure the unit 2.

is level. The straps are designed to reduce noise, resonance or harmonics; therefore, using the full length of the strap

between the ventilator and the floor joists is recommended.

NOTE: Removing door and core reduces the weight of the ventilator, making it easier to lift into place.

10

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 13

Installing Drain Line and P-Trap

M6552

DRAIN

PAN

O RING

HR

BOTTOM

WASHER

NUT

TO DRAIN

T FITTING

TAPE

M6551

Installing drain line.Fig. 8.

Installing P-trap.Fig. 9.

There are two holes at the bottom of the ventilator for

the drain pan connectors.

Insert the connectors through the hole in the drain pan 1.

and the bottom of the unit.

Place the washer and nut on the connector.2.

Hand tighten the nut. See Fig. 8.3.

Construct a P-trap using the plastic T-fitting provided.

Cut two lengths of 1/2 in. ID hose and connect each 1.

drain fitting to the end of the T-fitting.

Position the center leg of the T-fitting so it points upward.2.

Connect the drain line to the center leg and tape it in 3.

place to prevent any kinks. See Fig. 9.

This creates a trap that will hold some condensation

and prevent odors from being drawn up through the

drain hose into the unit. If the unit is installed during a

season when it is unlikely that condensation will form,

fill the trap with tap water.

PLUMBING

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

11

Page 14

WIRING

M29806

HIGH SPEED

STATUS LIGHTS

SELECT BUTTON

INITIATES HIGH

SPEED VENTILATION

FOR 20, 40 OR 60

MINUTES

YELLOW

RED

GREEN

CAUTION: Electrical shock hazard.

Can cause personal injury.

Be sure ventilator is correctly grounded. Confirm polarity of power line switched with safety (disconnect)

switch when cleaning or servicing unit.

IMPORTANT

The hot line (black) is the correct line to switch. See Fig. 19. To confirm correct polarity, use voltmeter or test lamp to

verify there is no power after the switch when the door is open. Check between that point and ground (on cabinet). This

process must be used because occasionally some dwellings are incorrectly wired.

CAUTION: Electrical hazard.

Can cause equipment damage.

Disconnect HRV/ERV from power source before connecting or disconnecting digital fan timer or other

device to HRV/ERV high-speed override terminals.

WIRING

IMPORTANT

Do not connect external power sources to the highspeed override terminals.

Heat Recovery Ventilator (HRV) and Energy Recovery Ventilator (ERV) Connections

The connector is a three-prong, 120 Vac plug with ground. If further wiring is required, Honeywell recommends

that a licensed electrician make all electrical connections. It is very important that the unit be correctly grounded.

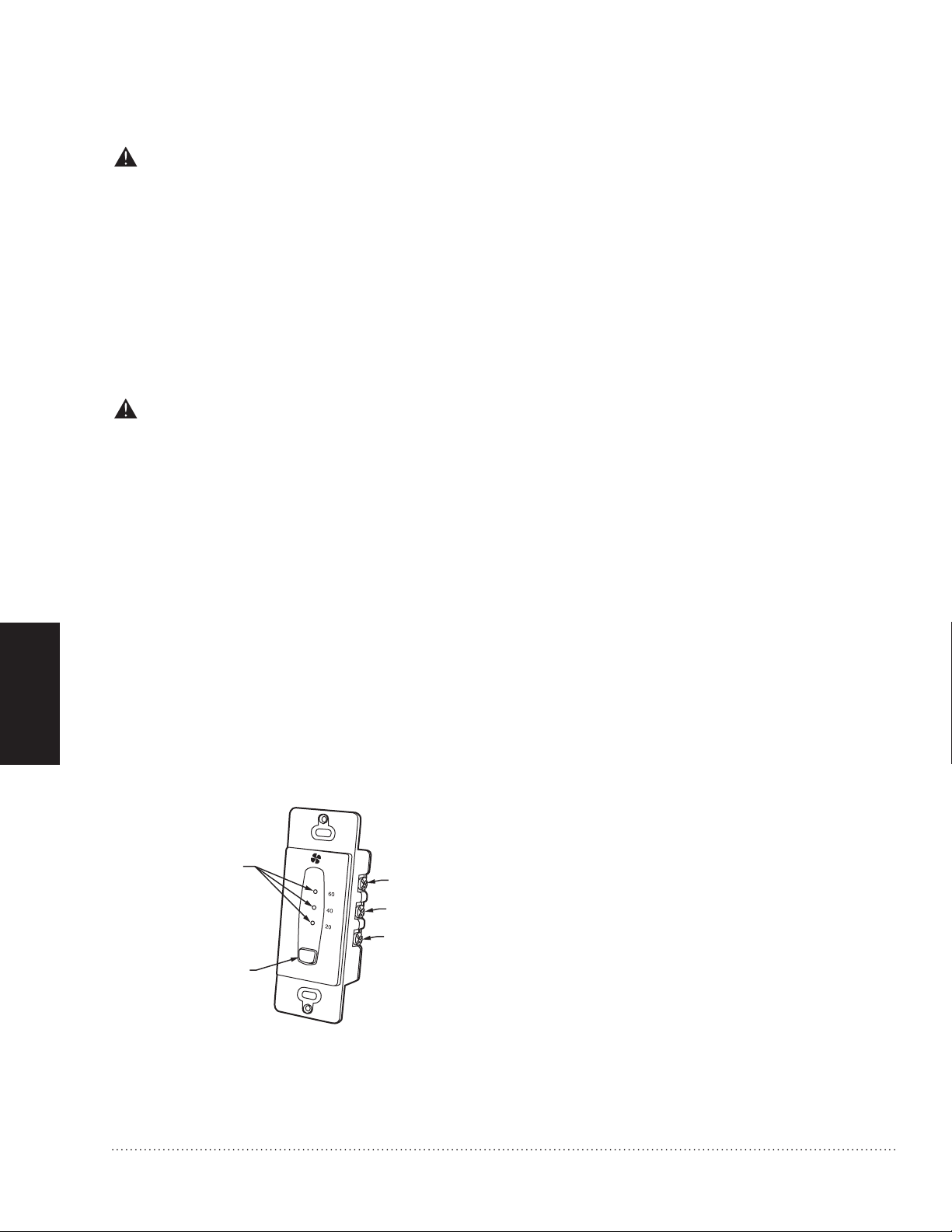

Digital Fan Timer

Mount digital fan timer in a full or one-half depth

electrical box in the living space. See Fig 10.

Press and release the Select Button to activate high

speed on the ventilator. Change between 20-, 40-, and

60-minute override times by pressing and releasing

the Select Button.

The status light will dim after 10 seconds of run time.

The status light will flash during the last 5 minutes of

override. All timers connected to the unit will illuminate

for the duration of the override.

Set the lockout mode by holding the Select Button for

5 seconds. Unlock by holding for 5 seconds.

12

Digital fan timer lights and Select Button.Fig. 10.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 15

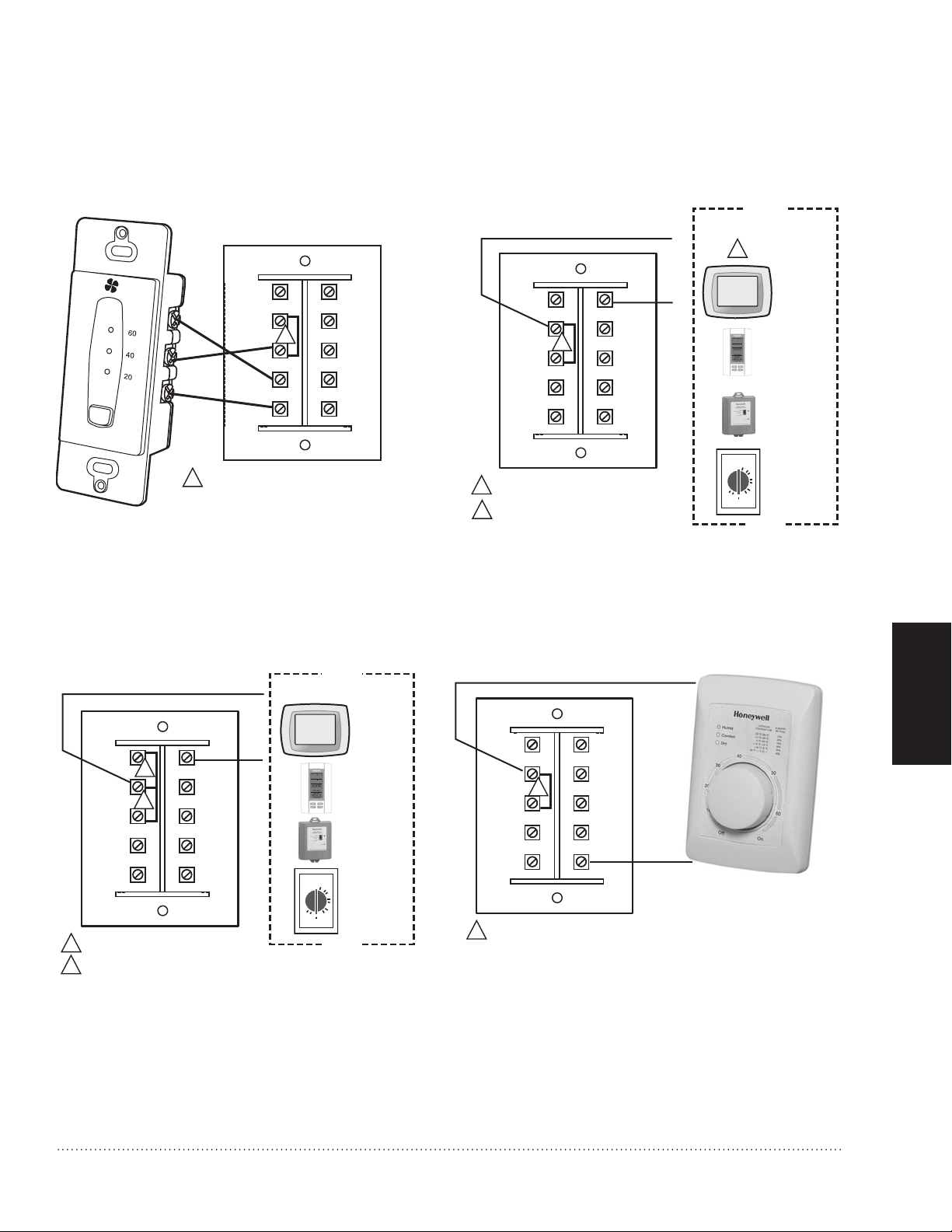

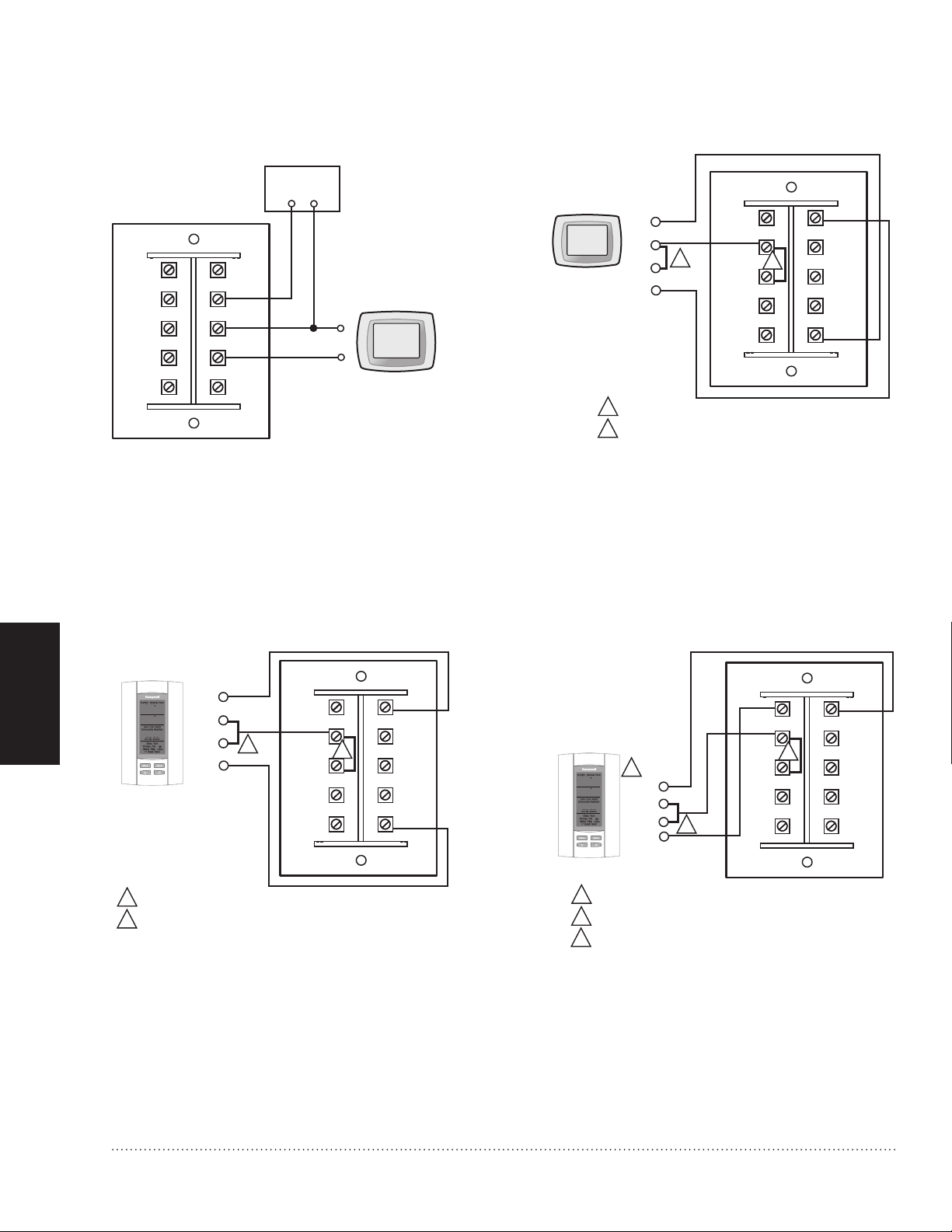

1

2

3

4

5

6

7

8

9

10

VNT

LOW

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

M29844

JUMPER BETWEEN VNT COM AND RED.

CHOOSE AMONG AVAILABLE CONTROLS.

ALL WIRE IDENTICALLY.

1

1

2

2

VISIONPRO

IAQ VNT1, 2

TERMINALS

O

10

20

30

40

50

60

W8150

AUX

TERMINALS

CONTROL OPTIONS

MECHANICAL

TIMER DRY

CONTACTS

TRUE IAQ VENT

TERMINALS

68

40

55

1215

:

76

%

%

In

Out

PM

VNT

COM

1

2

3

4

5

6

7

8

9

10

VNT

LOW

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

M29846

JUMPER BETWEEN VNT COM AND RED.

1

1

20 40 60 TIMER

FAN INTERLOCK

VNT

COM

1

2

3

4

5

6

7

8

9

10

VNT

LOW

VNT

COM

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

M29845

JUMPER BETWEEN VNT COM AND RED.

JUMPER BETWEEN VNT COM AND VNT LOW.

1

1

VISIONPRO

IAQ VNT1, 2

TERMINALS

O

10

20

30

40

50

60

W8150

AUX

TERMINALS

MECHANICAL

TIMER DRY

CONTACTS

2

TRUE IAQ VENT

TERMINALS

2

68

40

55

1215

:

76

%

%

In

Out

PM

20 40 60 TIMER

FAN INTERLOCK

CONTROL OPTIONS

1

2

3

4

5

6

7

8

9

10

VNT

LOW

VNT

COM

RED

YEL

GRN

VNT

HI

G

F

R

G

T

DSTAT

20 40 60 TIMER

FAN INTERLOCK

M29838

YEL

RED

GRN

JUMPER BETWEEN VNT COM AND RED.

1

1

NOTE: Turn power to ventilator OFF during wiring. A static discharge to the wiring terminals while powered

could cause unit to reset or require power cycling.

Wiring digital fan timer.Fig. 11.

Wiring IAQ or ventilation control.Fig. 12.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Wiring for continuous low speed and high Fig. 13.

speed override.

WIRING

Wiring dehumidistat.Fig. 14.

13

Page 16

WIRING

1

2

3

4

5

6

7

8

9

10

VNT

LOW

VNT

COM

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

M29848

JUMPER BETWEEN VNT COM AND RED.

JUMPER BETWEEN DHM2 AND VNT1.

1

1

2

2

DHM 1

DHM 2

VNT 1

VNT 2

VisionPRO IAQ

20 40 60 TIMER

FAN INTERLOCK

1

2

3

4

5

6

7

8

9

10

VNT

LOW

VNT

COM

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

M29849

JUMPER BETWEEN VNT COM AND RED.

JUMPER BETWEEN VENT AND DEHUM.

1

1

2

2

VENT

VENT

DEHUM

DEHUM

68

40

55

1215

:

76

%

%

In

Out

PM

TrueIAQ

20 40 60 TIMER

FAN INTERLOCK

1

2

3

4

5

6

7

8

9

10

VNT

LOW

VNT

COM

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

M29850

JUMPER BETWEEN VENT AND DEHUM.

JUMPER BETWEEN VNT COM AND RED.

LOW SPEED WILL OPERATE IF TrueIAQ IS CONFIGURED TO

LOWER VENTILATION BASED ON OUTDOOR CONDITIONS

(SETUP NUMBER 115=2).

1

2

2

68

40

55

1215

:

76

%

%

In

Out

PM

VENT

VENT

DEHUM

DEHUM

TrueIAQ

1

3

3

20 40 60 TIMER

FAN INTERLOCK

1

2

3

4

5

6

7

8

9

10

VNT

LOW

VNT

COM

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

M29847

THERMOSTAT

R

G

FURNACE

G

R

20 40 60 TIMER

FAN INTERLOCK

Wiring for fan interlock.Fig. 15.

Wiring VisionPRO IAQ for ventilation and Fig. 16.

dehumidification.

Wiring TrueIAQ for ventilation and Fig. 17.

14

dehumidification.

Wiring TrueIAQ for high and low speed Fig. 18.

ventilation.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 17

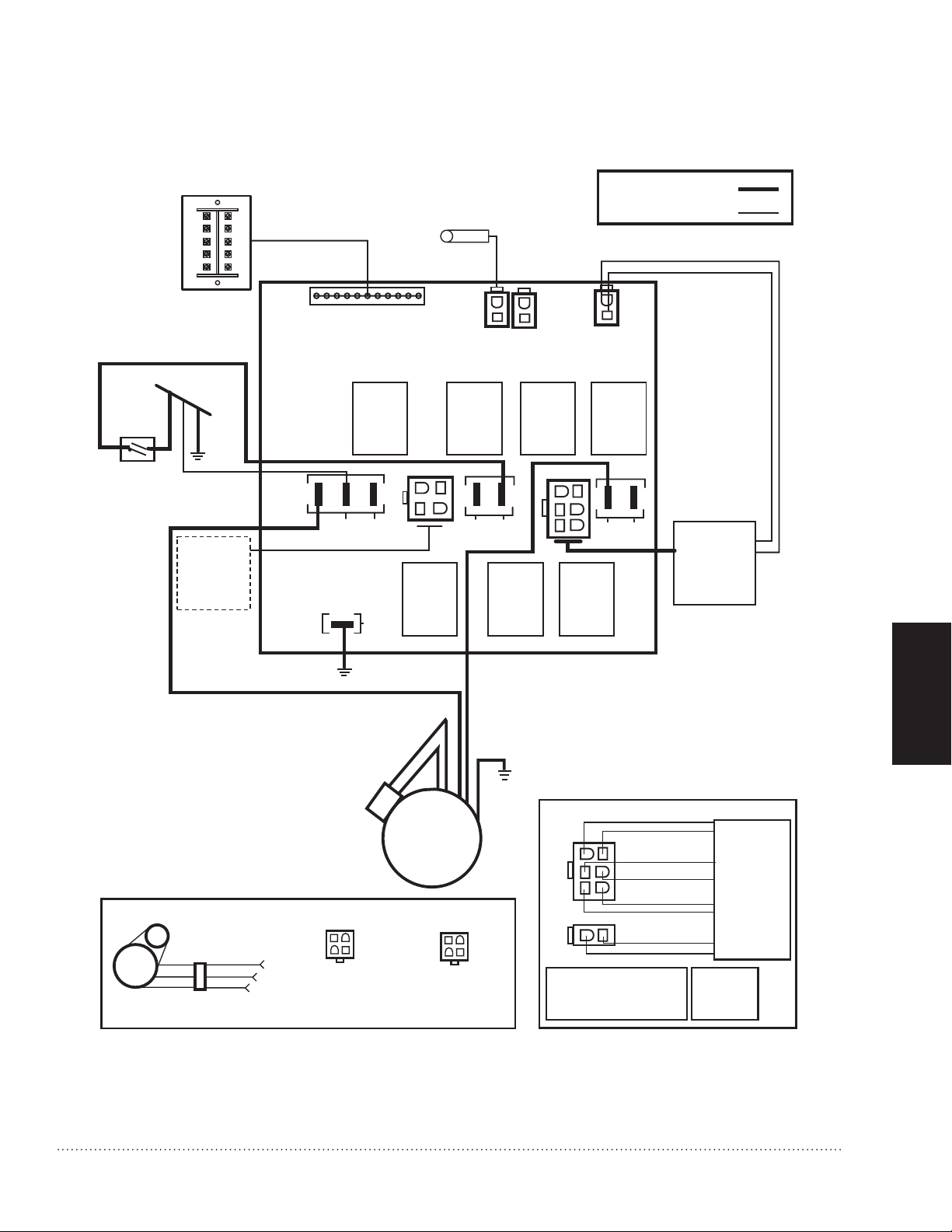

LEGEND

HIGH VOLTAGE

12V LOW VOLTAGE

M29742

K7K2 K3

P2

RED

THERMISTOR

(NOT ON ALL UNITS)

BLACK

GREEN

NEUTRAL

LINE

AUTOTRANSFORMER

SEE

DEFROST

DETAIL

WHITE

P4

BLUE

K4

K6 K1

P3

FAN O/P

T8T7

P1

T3T2

T9

T1

K5

DIRECT

MOUNTED

CAPACITOR

CAPACITOR

DEFROST DETAILS

PCB PLUG-IN

PLUG IN

CONNECTOR

BLACK

RED

ORANGE

ORANGE

12

P1

34

PIN 1–BLACK

PIN 2–ORANGE

PIN 3–RED

PIN 4–SPARE

RED

BLACK

BI-DIRECTIONAL

DAMPER MOTOR

PCB PLUG-IN

12

P1

34

PIN 1–RED

PIN 2–ORANGE

PIN 3–BLACK

PIN 4–SPARE

FAN

MOTOR

BROWN

BROWN

GREEN

BLACK

WHITE

VNT

LOW

VNT

COM

RED

YEL

GRN

VNT HI

G

F

R

G

T

DSTAT

AUTO-TRANSFORMER DETAIL

PIN 1–BLUE

PIN 2–YELLOW

PIN 3–BROWN

PIN 4–RED

PIN 5–WHITE

PIN 6–BLACK

PIN 1–GREEN

PIN 2–GREEN

P5

AUTO

TRANSFORMER

4

5

6

1

2

3

1

2

P6

P5

PLUG-IN CONNECTOR

P6

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Internal schematic for fresh air ventilation systems.Fig. 19.

WIRING

15

Page 18

Airflow Balancing

PUSH AND TURN WITH

SLOTTED SCREWDRIVER.

DAMPER AUTO MATICALLY

LOCKS WHEN PRESSURE

IS RELEASED.

M13462

Volume-balanced airflow in the ventilator is required. Volume of outside air brought in must equal the volume of

air the unit exhausts. If airflow is not correctly balanced:

unit does not operate at its maximum efficiency.•

negative or positive air pressure can occur in the house.•

unit will not defrost properly.•

warranty can be voided.•

Excessive positive pressure can drive moist indoor air into building external walls where it can condense (in cold

weather) and degrade structural components. Moist indoor air can also cause keyholes to freeze.

Excessive negative pressure can have several undesirable side effects; in some geographic locations, soil

gases such as methane and radon can be drawn into the home through basement/ground contact areas.

Excessive negative pressure can also cause back drafting of vented combustion equipment when adequate

combustion air supply is not provided.

Balancing Procedure

Six-inch (150 mm) diameter flow collars connected to inclined or digital manometer, or magnehelic, with

range of 0 to.25 in. (0 to 62.5 Pa) of water are recommended for accurate airflow measurements. To avoid

airflow turbulence and incorrect readings, flow stations should be located at a distant point of at least five duct

diameters; for example, 6 in. (150 mm) duct requires five diameters x 6 in. (150 mm) = 30 in. (76 cm) from

nearest valve or flow restriction. This requirement applies to both stale air to exchanger duct and fresh air to

house duct.

DUCTING

Before balancing, make sure:

all sealing of the ductwork system is completed.•

all of the ventilator system components are in place and functioning properly.•

balancing dampers are fully open.•

unit is on High speed.•

airflows in branch lines to specific areas of house are adjusted before balancing the unit. (A smoke pencil •

used at the grilles is a good indicator of relative airflow for each branch line.)

HVAC fan is on for models ducted into HVAC system.•

After taking readings in stale air and fresh air ducts,

duct with lower cfm (L/s) velocity reading should

remain as is, while duct with higher reading should be

dampered back to match lower reading. See Fig. 20.

Return unit to appropriate fan speed for normal

operation.

Balancing airflow.Fig. 20.

16

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 19

STARTUP AND CHECKOUT

When the ventilator is powered up it will go through a self-test and turn on both fan speeds and check damper

operation.

LED on Terminal Board of Ventilator

The terminal board has an LED that flashes to indicate the current mode of the ventilator.

Ventilator Mode Flashing Sequence Description

Standby, Ventilating,

or Off*

Self-Test 2-½ sec. on followed by ½ sec. off Self-test will turn on both fan speeds and check damper

Defrost ½ sec. on followed by ½ sec. off See page 9 for defrost operation

* In Off mode the ventilator will not come on. The ventilator is in Off mode when there is no jumper between

VNT COM and RED. The jumper can be replaced with an ON/OFF light switch to provide an easy positive off

switch.

½ sec. on followed by 10 sec. off This is the normal operation of the ventilator.

operation.

SERVICE

CAUTION: Electrical shock hazard.

Can cause personal injury or equipment damage.

Disconnect power to unit before starting

maintenance.

For maximum efficiency, the Fresh Air Ventilation

System must be maintained on a regular basis.

Honeywell recommends checking and cleaning at

least twice a year, preferably at the beginning of each

heating and cooling season.

Cleaning Filters and Core

Open ventilator door by loosening draw latches on top of 1.

unit and swinging door open. For easier access, remove

door by moving it right to disengage hinges.

Carefully grip ends of core, (be careful not to damage 2.

aluminum fins); then pull evenly outward. Core fits tightly,

but slides out of channels.

Once core is removed, filters can be removed by 3.

removing clips holding them in place. Note clip

installation for reassembly.

ERV core: Vacuum the ERV core or rinse with cold water. 4a.

Do not use soap, dishwasher, or a pressure washer.

HRV core: Soak and rinse the HRV core in warm soapy 4b.

water. Do not use cleaning solutions, dishwasher or a

pressure washer.

Wash the filters in warm soapy water.5.

Place the clean filter (wet or dry) over the core and 6.

secure it in place with the clips.

Reinstall core by sliding it into the four corner channels. 7.

(Water cannot damage gasket and label on core ends,

so it is not necessary to remove them from the core.)

Inspecting Exterior Hoods

Inspect exterior hoods at least monthly. Be sure

exhaust and fresh air supply hoods are not blocked

or restricted by leaves, grass or snow. In winter, be

sure snow does not block hoods and frost does not

accumulate on wire mesh bird screen.

IMPORTANT

Blocked hoods can cause house/building pressure

change that can lead to possible combustion product

spillage from heating appliances.

APPENDICES

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

17

Page 20

TROUBLESHOOTING

Table 1. Troubleshooting Guide.

Symptom Cause Solution

Poor airflow Plugged outside hood 1/4 in. (6 mm) mesh.• Clean exterior hoods or vents•

Filters plugged.• Remove and clean filter.•

Core obstructed.• Remove and clean core.•

House grilles closed or blocked.• Check and open grilles.•

Dampers (if installed) are closed.• Open and adjust dampers•

Poor power supply at site.• Have electrician check supply voltage at house.•

Ductwork is restricting airflow.• Check duct installation.•

Improper speed control setting.• Increase speed of ventilator.•

Ventilator airflow improperly balanced.• Have contractor balance ventilator airflow.•

Supply air

feels cold

Dehumidistat

is not

operating

Poor location of supply grilles, airflow can •

irritate the occupant.

Outdoor temperature extremely cold.• Turn down ventilator supply speed.•

Ventilator airflow can be incorrectly balanced.• Have a contractor balance ventilator airflow.•

Incorrect connection to external 24-volt control.•

Staple/nail is shorting out external low voltage.•

Check dehumidistat setting; it could be at Off.• Set dehumidistat at the desired setting.•

Dehumidistat is disabled when the outdoor •

temperature is above 60F for 24 hours.

Locate grilles high on walls or under baseboard •

heaters; install ceiling-mounted diffuser or

grilles to avoid blowing directly on occupants

(example: over a sofa).

Use a small duct heater (1 kW) to temper the •

supply air.

Placement of furniture or closed doors is •

restricting movement of air in the home.

If supply air is ducted in furnace return, run •

furnace fan continuously to distribute ventilation

air comfortably.

Check that correct wires were used.•

Check external wiring for a short.•

Check the LED on the terminal block for long •

flash followed by a short flash.

APPENDICES

18

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 21

Symptom Cause Solution

Humidity

levels are

too high;

condensation

appears on

windows

Dehumidistat is set too high. Set dehumidistat lower.

Undersized ventilator to handle hot tub, indoor •

Cover pools and hot tubs when not in use.•

pool, etc.

Lifestyle of occupants.• Avoid hanging clothes to dry, storing wood and •

venting clothes dryer inside. Consider moving

wood outside.

Humidity

levels too low

Ventilator and/

or ducts have

frost buildup

Condensation

or ice buildup

in insulated

duct to

outside

Water in

ventilator

bottom

Moisture coming into home from crawl space •

not vented or heated.

Moisture is remaining in bathroom and kitchen •

areas.

Condensation is forming in spring and fall.• On humid days, as seasons change, •

Ventilator speed is set too low.• Increase speed of ventilator.•

Ventilator airflow can be incorrectly balanced.• Have a contractor balance ventilator airflow.•

Dehumidistat control set too low.• Set dehumidistat higher.•

Blower speed of ventilator is too high.• Decrease ventilator blower speed.•

Lifestyle of occupants.• Increase humidity with humidifiers.•

Ventilator airflow can be incorrectly balanced.• Have a contractor balance ventilator airflow.•

Ventilator airflow is incorrectly balanced. • NOTE: Minimal frost build-up is expected on •

Malfunction of ventilator defrost system.• Have HVAC contractor check defrost system.•

Incomplete vapor barrier around insulated duct.• Tape and seal all joints.•

Hole or tear in outer duct covering.• Ensure vapor barrier is completely sealed.•

Drain pans are plugged.•

Improper connection of ventilator drain lines.•

Ventilator is not level.• Level ventilator.•

Drain lines are obstructed.• Check water drain connections.•

Ventilator heat exchange not correctly installed.• Make sure water drains correctly from pan.•

Vent crawl space and place vapor barrier on •

floor of crawl space.

Size bathroom ducts to remove moist air as •

effectively as possible; use bathroom fan to

remove additional moisture.

condensation appears but air quality remains

high with some ventilator use. Use a control that

provides ventilation in all seasons.

cores before unit initiates defrost cycle functions.

Have HVAC contractor balance ventilator.•

Tape any hole or tears made in outer duct •

covering.

Ensure O-ring on drain nozzle adjusted correctly.•

Look for kinks in line.•

APPENDICES

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

19

Page 22

PARTS LIST

HR/ER Parts List

Item

Number

(Fig. 21)

1 209746 Heat Transfer Core, Aluminum with Plastic Frame

2 208359 208359 208359 Blower Motor with Capacitor

3 50002341-001 50002341-001 50002341-001 Blower Housing Kit, includes upper and lower housing, no

4 209723 50050728-001 50050728-001 Foam Prefilter, Set of 2

5 209722 Included with

6 209715 209715 N/A Defrost Damper Motor, Bi-directional

7 50048693-001 50048693-001 N/A Drain Spouts and “T” Kit

8 50048694-001 50048694-001 50048694-001 Door latch, double wide

9 50050832-001 50050832-001 50050832-001 Electronic Control Kit (Control Board and Auto Transformer)

* Date can be determined by serial number which includes date in MMDDYY format.

Shaded items are obsolete — available while supplies last.

Part Number for Description

HR150B/

HR200B

ER150B/

ER200B

32002074-001 32002074-001 Cross-Flow Energy Transfer Core, with Guide Channels,

50048918-001 50048918-001 Universal Energy Transfer Core with guide channels to fit

Prefilter

ER150C/

ER200C

Included with

Prefilter

diamond shape made before August 2005*

diamond and square shape.

wheels or motor.

Clip for HRV Foam Prefilter

APPENDICES

Accessory Items Parts List Not Shown—All Models

Item

Number

6 W8150A1001 Fresh Air Ventilation Control

7 50050477-001 Digital Fan Timer, 20, 40, 60 minutes

Part Number Description

20

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 23

M29855

2

3

7

9

8

4

5

6

1

1

HR150/HR200 and ER150/ER200 exploded view of parts keyed to HR/ER Parts List.Fig. 21.

APPENDICES

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

21

Page 24

Specifications

IMPORTANT

TRADELINE® Models

TRADELINE models are selected and packaged to

provide ease of stocking, ease of handling and maximum

replacement value.

TRADELINE Models Available:

Color

White

Electrical Ratings

APPENDICES

The specifications given in this publication do

not include normal manufacturing tolerances.

Therefore, this unit might not exactly match the

listed specifications. Also, this product is tested

and calibrated under closely controlled conditions,

and some minor differences in performance can be

expected if those conditions are changed.

HR150 and HR200 Fresh Air Ventilation Systems: •

Includes heat transfer core, prefilters, fan and blower

assembly and frost control.

ER150, ER200 Fresh Air Ventilation Systems: Includes •

enthalpic heat and moisture transfer core, prefilters, fan

and blower assembly and frost control (frost control on B

models only).

HR150B: 150 cfm, aluminum cross flow core, manual •

control and frost control.

HR200B: 200 cfm, aluminum cross flow core, manual •

control and frost control.

ER150B: 150 cfm, heat and moisture transferring core, •

manual control and frost control.

ER150C: 150 cfm, heat and moisture transferring core, •

manual control and without frost control.

ER200B: 200 cfm, heat and moisture transferring core, •

manual control and frost control.

ER200C: 200 cfm, heat and moisture transferring core, •

manual control and without frost control.

Power Rating: 120 Vac, 60 Hz•

Amp Rating: 1.4 A•

Consumption:•

Watts

Mode

Low speed 63 70

High speed 173 182

HR150/ER150 HR200/ER200

Mounting

Most models mount in conditioned space such as a

basement, utility room, hallway or closet. Can also be

mounted in conditioned attic space.

NOTE: ER150C and ER200C models can be installed in

unconditioned spaces such as attics and garages

in regions where the outdoor temperature does not

drop below freezing.

Approvals

Home Ventilation Institute (HVI): Certified.•

Canadian Standards Association: Approved.•

ETL: Certified to UL1812.•

Installed Weight

HR150/HR200: 70 lb (32 kg).•

ER150/ER200: 70 lb (32 kg).•

HVI Certified

HR150, HR200, ER150, ER200

Ventilation Performance

See Fig. 22 and 24.

Dimensions

See Fig. 23 and 25.

Accessories

See the Accessory Items Parts List that follows the

Troubleshooting Guide.

HR150, HR200

Performance ratings based on CAN/CSA-C439-88.

Maximum Temperature Recovery

78%

Sensible Effectiveness

HR150 at 67 cfm (32 L/s) at 32°F (0°C): 76%.

HR200 at 119 cfm (56 L/s) at 32°F (0°C): 67%.

ER150, ER200

Sensible Effectiveness

ER150 at 64 cfm (30 L/s) at 32°F (0°C): 81%.

ER200 at 116 cfm (55 L/s) at 32°F (0°C): 76%.

Total Recovery Efficiency

ER150 at 65 cfm (30 L/s) at 95°F (35°C): 47%.

ER200 at 117 cfm (30 L/s) at 95°F (35°C): 50%.

22

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 25

M29743B

25

50

75

100

125

150

175

.1

.2

.3

.4

.5

.6

.7

83

77

73

67

58

47

18

177

164

156

143

123

100

38

EXT STATIC

PRESSURE

(Pa)(in. wg)(L/s) (cfm)

NET SUPPLY

AIR FLOW

HR150 VENTILATION PERFORMANCE (HV1)

20

40

60

80

100

120

140

160

180

200

00.1 0.20.3 0.40.5 0.60.7 0.8

STATIC PRESSURE (IN W.G.)

AIR FLOW (CFM)

MANUFACTURER’S DATA

1

1

HIGH SPEED

LOW SPEED

M29744B

.1

.2

.3

.4

.5

.6

.7

101

97

91

87

80

73

65

214

206

193

184

170

155

137

EXT STATIC

PRESSURE

(Pa)(in. wg)(L/s) (cfm)

NET SUPPLY

AIR FLOW

HR200 VENTILATION PERFORMANCE (HVI)

25

50

75

100

125

150

175

20

40

60

80

100

120

140

160

180

200

220

240

00.1 0.20.3 0.40.5 0.60.7 0.8

STATIC PRESSURE (IN W.G.)

AIR FLOW (CFM)

MANUFACTURER’S DATA

1

HIGH SPEED

LOW SPEED

1

STALE

AIR FROM

INSIDE

DEFROST

PORT

FRESH

AIR TO

INSIDE

FRESH AIR

FROM OUTSIDE

STALE

AIR TO

OUTSIDE

M29741

A

DEFROST

DAMPER

CONDENSATE

DRAINS

BALANCING

DAMPER

BLOWERS

FILTERS

14-3/4

(375)

19

(483)

FRONT CLEARANCE OF 25 INCHES (635 MM)

IS RECOMMENDED FOR SERVICING UNIT.

ALL DUCT

CONNECTIONS

6 (150)

MOUNTING

SCREWS

1

1

BALANCING

DAMPER

33-5/8

(850)

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

HR150 and HR200 Ventilation performance.Fig. 22.

HR150 and HR200 dimensions in in. (mm).Fig. 23.

APPENDICES

23

Page 26

HIGH SPEED

LOW SPEED

220

200

180

160

140

120

100

80

60

40

20

0

0 0.1 0.2 0.3

0.4

0.5

0.6

0.7

0.8

AIR

FLOW

(CFM)

STATIC PRESSURE (IN. W.G.)

M29836

0.1 (25)

0.2 (50)

0.3 (75)

0.4 (100)

0.5 (125)

0.6 (150)

0.7 (175)

0.8 (200)

E.S.P.

(EXTERNAL STATIC PRESSURE)

INCHES (Pa)

CFM (Ls)

ER150 VENTILATION PERFORMANCE

NET SUPPLY AT LOW IN CFM (L/s) AGAINST EXTERNAL STATIC PRESSURE

151 (71)

141 (67)

132 (62)

124 (59)

107 (50)

98 (46)

81 (38)

60 (28)

MANUFACTURER’S DATA .

1

1

M29837

0.1 (25)

0.2 (50)

0.3 (75)

0.4 (100)

0.5 (125)

0.6 (150)

0.7 (175)

0.8 (200)

E.S.P.

(EXTERNAL STATIC PRESSURE)

INCHES (Pa)

CFM (Ls)

ER200 VENTILATION PERFORMANCE

NET SUPPLY AT LOW IN CFM (L/s) AGAINST EXTERNAL STATIC PRESSURE

180 (85)

169 (80)

157 (74)

146 (69)

132 (62)

118 (56)

101 (48)

82 (39)

MANUFACTURER’S DATA .

1

HIGH SPEED

LOW SPEED

220

200

180

160

140

120

100

80

60

40

20

0

0 0.1 0.2 0.3

0.4

0.5

0.6

0.7

0.8

AIR

FLOW

(CFM)

STATIC PRESSURE (IN. W.G.)

1

FILTERS (2)

M29856

MOTOR

BLOWERS

ENERGY

TRANSFER

CORE

BALANCING

DAMPER

19

(483)

14-3/4

(375)

33-5/8

(850)

CORE

BALANCING

DAMPER

FRONT CLEARANCE OF 25 INCHES (635 MM)

IS RECOMMENDED FOR SERVICING UNIT.

ALL DUCT CONNECTIONS ARE 6 (150).

1

2

1

2

MOUNTING

SCREWS

DEFROST

PORT

STALE

AIR FROM

INSIDE

FRESH

AIR TO

INSIDE

STALE

AIR TO

OUTSIDE

FRESH AIR

FROM

OUTSIDE

APPENDICES

24

ER150 and ER200 Ventilation performance.Fig. 24.

ER150 and ER200 dimensions in in. (mm).Fig. 25.

HR150, 200; ER150, 200 Perfect Window™ Fresh Air Ventilation Systems 68-0171EF—01

Page 27

Page 28

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited–Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

http://yourhome.honeywell.com

® U.S. Registered Trademark

© 2010 Honeywell International Inc.

68-0171EF—01 M.S. 03-10

Printed in U.S.A.

Page 29

M29857

68-0171EF-01

Systèmes de ventilation à apport d’air frais

Perfect Window™ HR150, 200; ER150, 200

DONNÉES SUR LE PRODUIT

Inclus dans la Boîte du système

COMMENCER

POUR

de VentIlatIon

F1 F3

COMMANDES EN OPTION VENDUES SÉPARÉMENT

Outils et accessoires requis pour l’installation des

systèmes de ventilation à apport d’air frais Perfect

Window™

Coupe-fil/outil à dénuder

Fil de calibre 18 (jusqu’à 5 conducteurs))

Tournevis normal

Conduit rond isolé de 6 po

Conduit rond non isolé de 6 po

Deux hottes anti-intempéries de 6 po

Deux collets de départ de 6 po

Tuyau d’évacuation de ½ po de dia. int.

Nécessaire d’équilibrage du débit d’air

Ruban métallique

*

F2

F4 F5

Système de ventilation à apport d’air

frais Perfect Window™ HR150/200 ou

ER150/200

Manuel du propriétaire

Brides de suspension

* Raccord en T

* 2 becs d’évacuation

e

Régulateur VisionPRO IAQ

F1

TrueIAQ

F2

Déshumidistat H8908

F3

F4

Minuterie de ventilateur numérique

F5

Régulateur de ventilation W8150

MONTAGE PLOMBERIE CÂBLAGE ANNEXESTUYAUTERIE

e

*

Pas pour les modèles « C ».

*

Page 30

Page 31

Systèmes de ventilation à apport d’air frais Perfect Window

POUR COMMENCER

Définitions et précautions relatives à la sécurité .... 2

Application ................................. 3

Caractéristiques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Préparation de l’installation .................... 4

Dimensionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Position et emplacement de montage ............ 6

Équilibrage du débit d’air ...................... 9

MONTAGE

Installation ................................ 10

Suspension aux solives de plancher ............ 10

PLOMBERIE

Installation du tuyau d’évacuation et du siphon P . . 11

CÂBLAGE

Raccordements du ventilateur à récupération de

chaleur (VRC) et du ventilateur à récupération

d’énergie (VRE) ............................ 12

Minuterie de ventilateur numérique ............. 12

COMMENCER

POUR

MONTAGE PLOMBERIE CÂBLAGE ANNEXES

TUYAUTERIE

Équilibrage du débit d’air ..................... 16

Procédure d’équilibrage ...................... 16

ANNEXES

Démarrage et vérification . . . . . . . . . . . . . . . . . . . . 17

Nettoyage des filtres et du noyau ............ 17

Inspection des hottes extérieures ............ 17

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Liste des pièces ............................ 20

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

BESOIN D’AIDE? Pour de l’assistance au sujet de ce produit, merci de consulter le site

?

http://yourhome.honeywell.com ou d’appeler le numéro gratuit du service à la clientèle de

Honeywell au 1-800-468-1502.

TUYAUTERIE

Lire et conserver ces instructions.

® Marque déposée américaine. Brevets en instance. Copyright © 2010 Honeywell International Inc. Tous droits réservés.

Systèmes de ventilation à apport d’air frais Perfect Window™ HR150, 200; ER150, 200 68-0171EF—01

1

Page 32

Définitions et précautions relatives à la sécurité

Définitions relatives à la sécurité

L’information portant sur l’identification des termes de sécurité doit être lue.

POUR

COMMENCER

MISE EN GARDE : Indique une situation dangereuse qui, si elle n’est pas évitée, risque d’endommager le

produit ou de causer des blessures corporelles.

AVERTISSEMENT : Indique une situation dangereuse qui, si elle n’est pas évitée, risque de causer des

blessures graves, voire mortelles.

Précautions relatives à la sécurité

Veiller à lire et à comprendre les avertissements relatifs à la sécurité et aux dommages matériels

suivants avant d’installer, d’utiliser ou de travailler sur le système de ventilation à apport d’air frais

Perfect Window™ :

Toute la tuyauterie en direction de l’extérieur doit se terminer au-dessus des lignes de limites de neige •

prévues et être munie de bouchons anti-intempéries équipés d’un grillage aviaire.

MISE EN GARDE : Risque de choc électrique.

Peut causer des blessures et des dommages matériels.

Débrancher l’alimentation pour éviter les chocs électriques et les dommages matériels.

MISE EN GARDE : Risque de choc électrique.

Peut causer des blessures.

Veiller à ce que le ventilateur soit correctement mis à la masse. Confirmer la polarité des lignes électriques

utilisant un interrupteur de sécurité (déconnexion) lors du nettoyage ou de l’entretien de l’unité.

MISE EN GARDE : Risque de choc électrique.

Peut endommager l’équipement

Débrancher le VRC/VRE de l’alimentation avant de connecter ou de déconnecter la minuterie du ventilateur

numérique ou un autre appareil des bornes de dérivation haute vitesse du VRC/VRE.

2

Systèmes de ventilation à apport d’air frais Perfect Window™ 68-0171EF—01

Page 33

Application

HR150B et HR200B de Honeywell procurent une ventilation adéquate tout en réduisant la consommation

d’énergie; ils transfèrent en effet à l’air neuf la chaleur contenue dans l’air extrait.

Le système de ventilation par apport d’air frais Perfect Window™ ER150B et ER200B de Honeywell procure une

ventilation adéquate tout en réduisant la consommation d’énergie; il transfère en effet la chaleur et l’humidité

contenue entre les flux d’air d’évacuation et d’air frais.

Les systèmes de ventilation à apport d’air frais Perfect Window™ ER150C et ER200C sont spécifiquement

conçus pour les installations dans les espaces non climatisés, tels que les greniers et les garages dans les

régions où la température extérieure ne descend pas en dessous de 0 °C (32 °F).

Caractéristiques

Ventilateur à deux vitesses à commande à distance.•

Registres d’équilibrage intégrés pour une installation rapide.•

Fournit une ventilation qui permet aux entrepreneurs d’assurer une ventilation conforme à la norme ASHRAE •

62

Commande de dégivrage intégrée, automatique et économique disponible pour un fonctionnement aux •

températures de calcul de -40 °C (-40 °F).

Les modèles HR150 et HR200 ont un noyau à débit croisé en aluminium facile à nettoyer.•

Les modèles ER150 et ER200 ont un noyau fixe à récupération d’énergie, de chaleur et d’humidité de •

technologie avancée

Noyau de transfert d’énergie lavable. Inclut le matériel d’isolation des vibrations et des collets de conduit.•

Armoire isolée en acier robuste•

Préfiltres permanents (lavables)•

Fonctionnement silencieux•

Option de minuterie de ventilateur numérique sur tous les modèles•

Algorithmes de ventilation avancés disponibles sur les régulateurs VisionPRO IAQ, TrueIAQ et W8150•

Raccorder le VRC/VRE sur la soufflante de la section de traitement de l’air ou de l’appareil chauffage•

Fonctionnement du déshumidistat désactivé l’été•

COMMENCER

POUR

Systèmes de ventilation à apport d’air frais Perfect Window™ 68-0171EF—01

3

Page 34

POUR

AIR

RANCE DE

L’INTÉRIEUR

ORIFICE DE

DÉGIVRAGE

AIR FRAIS

VERS

L’INTÉRIEUR

AIR FRAIS DE L’EXTÉRIEUR

AIR RANCE

VERS

L’EXTÉRIEUR

MF29739

REGISTRE D’ÉQUILIBRAGE

FILTRES

FILTRES (2)

ÉVACUATION

MF29853

MOTEUR

SOUFFLANTES

AIR FRAIS DE

L’EXTÉRIEUR

ORIFICE DE

DÉGIVRAGE

BACS DE RÉCUPÉRATION

REGISTRE

D’ÉQUILIBRAGE

REGISTRE

D’ÉQUILIBRAGE

CORE

AIR

RANCE DE

L’INTÉRIEUR

AIR FRAIS

VERS

L’INTÉRIEUR

AIR RANCE

VERS

L’EXTÉRIEUR

AIR FRAIS DE

L’EXTÉRIEUR

MF29861

MOTEUR

MOTEUR

AIR RANCE

DE LA

MAISON

NOYAU DE

TRANSFERT

D’ÉNERGIE

NOYAU

REGISTRE

D’ÉQUILIBRAGE

REGISTRE

D’ÉQUILIBRAGE

FILTRES (2)

AIR FRAIS

VERS

L’INTÉRIEUR

AIR RANCE

VERS

L’EXTÉRIEUR

COMMENCER

Préparation de l’installation

Le non-respect de ces exigences annulera la garantie, nuira à l’installation et entraînera des appels

de service injustifiés.

Le système de ventilation à apport d’air frais est

conçu pour apporter de l’air frais et évacuer l’air

rance. Le système aspire l’air frais extérieur par le

ventilateur pour le distribuer dans la maison.

Ventilateur à récupération d’énergie

L’air rance est évacué à l’extérieur par le

ventilateur. La chaleur est transférée d’un flux d’air

à l’autre pendant que l’air passe par les côtés

Raccordement des conduits et débit d’air Fig. 1.

(HR150B/HR200B).

opposés du noyau de transfert de chaleur. Voir la

Fig. 1.

4

Raccordement des conduits et débit d’air Fig. 2.

Raccordement des conduits et débit d’air Fig. 3.

(ER150C/ER200C).

(ER150B/ER200B).

Ventilateur à récupération d’énergie

L’air rance est évacué à l’extérieur par le

ventilateur. La chaleur et l’humidité sont

transférées d’un flux d’air à l’autre pendant que

l’air passe par les côtés opposés du noyau de

transfert d’énergie. Voir les Fig. 2 et 3.

Systèmes de ventilation à apport d’air frais Perfect Window™ 68-0171EF—01

Page 35

Dimensionnement

ASHRAE 62.2

Plusieurs méthodes peuvent donner des résultats

satisfaisants pour dimensionner le ventilateur requis

pour fournir une ventilation adéquate à l’habitation. La

nouvelle norme de ventilation résidentielle ASHRAE

62.2 donne les suggestions suivantes :

3

7,5 pi•

/min. par personne (compter le nombre de

personnes tel que 1 par chambre à coucher plus 1)

plus 1 pi3/min. par 100 pi

2

Exemple :

Maison de 2200 pi2 avec 4 chambres à coucher

= (7,5 pi3/min. x (4 chambres à coucher + 1)) + (1 pi3/min. x (2200

pi2 / 100))

= (7,5 x 5) + (2200 / 100)

= 37,5 + 22

= 59,5 pi3/min.

Dans ce cas, une capacité de 60 pi3/min. continus

fournirait une ventilation adéquate pour cette

habitation.

ASHRAE 62.1

Certaines régions utilisant la norme plus ancienne

ASHRAE 62.1 en tant que code de ventilation pour leur

région.

La norme de ventilation ASHRAE 62.1 relative à

la qualité de l’air intérieur acceptable donne les

suggestions suivantes :

0,35 changement d’air par heure (cah) mais pas •

moins de 15 pi3/min. pour les zones habitables =

taille de l’habitation (pi2) x hauteur du plafond (pi) /

60 (min) x 0,35 (cah)

Exemple :

= 2000 pi2 x 8 pi / 60 min x 0,35 cah = 93 pi3/min.

Exemple :

50 pi3/min. intermittents x 3 salles de bains = 150 pi3/

min.

20 pi3/min. continus x 3 salles de bains = 60 pi3/min.

Capacité de 100 pi•

3

/min. intermittents ou 25 pi3/min.

continus pour les cuisines

Exemple :

100 pi3/min. intermittents x 1 cuisine = 100 pi3/min.

25 pi3/min. continus x 1 cuisine = 25 pi3/min.

Option 1 : Le système de ventilation à apport d’air frais

fournit une alimentation en air frais continue de 93 pi3/

min. et une capacité intermittente de 150 pi3/min. pour

les salles de bains. Un ventilateur d’aspiration séparé

de 100 pi3/min. est utilisé pour la hotte de la cuisinière.

Débit d’air fourni requis = 93 pi3/min.

Débit d’air évacué requis = 150 pi3/min.

Toutes les unités de ventilation de Honeywell

fournissent une capacité de ventilation adéquate. Voir

la Fig. 22.

Option 2 : Le système de ventilation à apport d’air frais

fournit une alimentation en air frais continue de 93 pi3/

min., une capacité d’évacuation de l’air intermittente de

150 pi3/min. pour les salles de bains et de 50 pi3/min.

pour les cuisines.

Débit d’air fourni requis = 93 pi3/min.

Débit d’air évacué requis = 200 pi3/min.

Les modèles HR200/ER200 de Honeywell ont la

capacité d’évacuation requise pour les besoins en

ventilation de cette application. Voir la Fig. 22.

COMMENCER

POUR

Capacité de 50 pi•

3

/min. intermittents ou 20 pi3/min.

continus pour les salles de bains

Systèmes de ventilation à apport d’air frais Perfect Window™ 68-0171EF—01

5

Page 36

Position et emplacement de montage

CONDUIT

FLEXIBLE

ISOLÉ

COLLET SUR

VENTILATEUR

ÉTANCHÉISER LE REVÊTEMENT INT.

DU CONDUIT FLEXIBLE SUR LE COLLET INT.

É

TANCHÉISER LE REVÊTEMENT EXT.

DU CONDUIT FLEXIBLE SUR LE COLLET EXT.

MF6557

POUR

COMMENCER

Les modèles HR150/ER150 et HR200/ER200 peuvent

être suspendus aux solives de plafond exposées, à

la surface du plafond ou montés au sol. (Mettre le

ventilateur à niveau pour que l’évacuation fonctionne

correctement.)

REMARQUE : Les modèles ER150C et ER200C sont

spécifiquement conçus pour les installations dans

les espaces non climatisés, tels que les greniers

et les garages dans les régions où la température

extérieure ne descend pas en dessous de 0 °C

(32 °F). (Ces unités ne sont pas équipées de

nécessaires d’évacuation.)

Situer l’arrivée d’air frais à 2 m (6 pi) ou plus de •

l’évacuation d’air rance pour éviter que l’air évacué

ne pénètre de nouveau.

Situer le ventilateur à l’endroit nécessitant le moins •

de longueur de tuyauterie.

Installer les modèles HR150/ER150 et HR200/

ER200 dans les endroits climatisés en respectant les

instructions suivantes :

Raccorder le conduit d’évacuation (les modèles •

ER150C et ER200C ne sont pas munis de

nécessaires d’évacuation) du ventilateur à un

orifice d’évacuation.

Utiliser une prise électrique existante au courant •

approprié (ou en installer une) près du cordon

d’alimentation du ventilateur.

Prévoir l’espace pour le conduit d’évacuation en •

plaçant le ventilateur à au moins 254 mm (10 po)

du sol.

Pour l’accès et le retrait du noyau du ventilateur, •

prévoir un espace ouvert d’au-moins 635 mm (25

po) à l’avant de l’unité.

Tuyauterie

Étanchéisation des extrémités de tuyaux isolésFig. 4.

La tuyauterie entre le ventilateur et l’extérieur doit être

isolée et avoir une barrière de vapeur d’air continue.

Voir la Fig. 4.

IMPORTANT

Toute la tuyauterie en direction de l’extérieur doit se

terminer au-dessus des lignes de limites de neige

prévues et être munie de bouchons anti-intempéries

équipés d’un grillage aviaire.

6

Systèmes de ventilation à apport d’air frais Perfect Window™ 68-0171EF—01

Page 37

La conception et l’installation de la tuyauterie doivent être conformes aux pratiques de CVCA standard pour

RETOUR

D’AIR FROID

A

IR D’ÉVACUATION DE

DIVERSES ZONES DE

L’HABITATION (SALLES

DE BAINS OU CUISINES SI

REQUIS; PIÈCES SANS

FENÊTRES FONCTIONNELLES ET

ÉVENTUELLEMENT SOUS-SOLS).

APPAREIL DE

CHAUFFAGE À

AIR PULSÉ

À COMBUSTION

OU ÉLECTRIQUE

MF6549

AIR DE

RETOUR

EXTÉRIEUR

REMARQUES :

1.

2.

3.

4.

IL N’EST PAS NÉCESSAIRE QUE LA SOUFFLANTE DE L’APPAREIL DE CHAUFFAGE FONCTIONNE POUR

ASSURER UNE BONNE DISTRIBUTION/QUALITÉ DE L’AIR AVEC CE SYSTÈME.

S’IL EST REQUIS QUE LA SOUFFLANTE DE L’APPAREIL DE CHAUFFAGE FONCTIONNE POUR FACILITER LA

DISTRIBUTION DE L’AIR FOURNI : FAIRE TOURNER EN CONTINU OU INTERCONNECTER ÉLECTRIQUEMENT

(BASSE TENSION).

PAS DE SÉPARATION REQUISE ENTRE LE POINT DE CONNEXION DIRECT ET L’APPAREIL DE CHAUFFAGE.

LA DISPOSITION DE LA HOTTE ANTI-INTEMPÉRIES EST UNIQUEMENT FOURNIE POUR L’ILLUSTRATION.

UNE SÉPARATION DE 2 M (6 PI) MINIMUM EST REQUISE, 0,46 M (18 PO) SUPÉRIEUR À LA SURÉLÉVATION MINIMUM.

fournir les quantités d’air frais requises à l’espace à température contrôlée et permettre l’évacuation vers

l’extérieur de quantités d’air ambiant équivalentes.

Garder les tuyauteries d’arrivée et d’évacuation aussi courtes que possible et réduire au minimum le nombre de

coudes.

Garder la taille des tuyaux aussi grande que possible sur toute l’installation.•

Utiliser des conduits ronds de 6 po de diamètre pour tous les raccords vers le ventilateur ou depuis celui-ci.•

Séparer les évents d’arrivée et d’échappement externes d’au moins 2 m (6 pi).•

REMARQUES : Ne pas situer l’évent d’air frais à un endroit où il serait dirigé vers les personnes ou le thermostat.

Ne pas situer l’arrivée d’air frais près de sources connues de polluants, tels que les gaz d’échappement

automobiles, le ventilateur d’un séchoir ou la fumée d’une cheminée.

Le raccordement de la sortie de l’arrivée et/ou de l’arrivée de l’évacuation du ventilateur au plénum d’air de •

retour de la section de traitement de l’air est une excellente méthode de distribution d’air frais et d’évacuation

de l’air rance de toutes les zones de l’habitation, et permet aussi de réduire les coûts d’installation. Si cette

méthode est utilisée, équilibrer le ventilateur de façon à ce que la section de traitement de l’air fonctionne

et soit raccordée au ventilateur pour qu’il ne fonctionne que lorsque la section de traitement de l’air est en

marche. Voir la Fig. 6. Une autre méthode consiste à équilibrer le ventilateur lorsque la section de traitement

de l’air n’est pas en marche et de laisser le ventilateur tourner indépendamment de la section de traitement

de l’air, voir la Fig. 5. Une installation indépendante est illustrée à la Fig. 7.

REMARQUE : Lorsque l’habitation est occupée, un fonctionnement continu du ventilateur est recommandé.

Lorsque la section de traitement de l’air de l’appareil de chauffage fonctionne, de l’air frais est distribué

dans les registres d’alimentation du chauffage/climatiseur. Lorsque la section de traitement de l’air est

arrêtée, l’air frais est délivré par l’arrivée et le retour.

Un système de verrouillage électrique ou un registre alimenté automatiquement doit être utilisé pour éviter •

la pénétration non souhaitée de l’air extérieur si le ventilateur n’est pas en marche et que la section de

traitement de l’air continue à fonctionner.

COMMENCER

POUR

Systèmes de ventilation à apport d’air frais Perfect Window™ 68-0171EF—01

Connexion directe du flux d’air fourni au retour d’air froid de l’appareil de chauffage pour le VRC/VRE.Fig. 5.

7

Page 38

POUR

1 M (40 PO) MINIMUM FROID

RETOUR

D’AIR

FROID

MF6548

AIR DE

RETOUR

EXTÉRIEUR

REMARQUES :

1.

2.

3.

4.

IL EST NÉCESSAIRE QUE LA SOUFFLANTE DE L’APPAREIL DE CHAUFFAGE FONCTIONNE LORSQUE

LA VENTILATION EST REQUISE. RÉGLER LA SOUFFLANTE DE L’APPAREIL DE CHAUFFAGE SUR

FONCTIONNEMENT CONTINU OU EFFECTUER UNE INTERCONNEXION ÉLECTRIQUE (BASSE TENSION).

UNE SÉPARATION MINIMUM DE 40 PO EST REQUISE ENTRE LES DEUX

CONNEXIONS DIRECTES.

LA CONNEXION DE L’AIR D’ÉVACUATION DOIT ÊTRE EN AMONT DE LA

CONNEXION DE L’AIR FOURNI POUR ÉVITER D’ÉVACUER DE L’AIR FRAIS.

LA DISPOSITION DE LA HOTTE ANTI-INTEMPÉRIES EST UNIQUEMENT FOURNIE POUR L’ILLUSTRATION.

UNE SÉPARATION DE 2 M (6 PI) MINIMUM EST REQUISE, 0,46 M (18 PO) SUPÉRIEUR À LA SURÉLÉVATION MINIMUM.

APPAREIL DE

CHAUFFAGE À

AIR PULSÉ

À COMBUSTION

OU ÉLECTRIQUE

ARRIVÉE AIR FRAIS

RÉGLABLE

REGISTRES R

É

GLABLES POUR

L’ÉQUILIBRAGE DU DÉBIT D’AIR

ENTRANT ET SORTANT

HOTTE D’ARRIVÉE

D’AIR FRAIS

HOTTE D’ÉVACUATION

D’AIR RANCE

TUYAUTERIE ISOLÉE FLEXIBLE

AVEC BARRIÈRE DE VAPEUR

L’ÉVACUATION DU VENTILATEUR SE FAIT PAR LA

CUISINE ET/OU LES CHAMBRES À COUCHER OU

D’AUTRES EMPLACEMENTS CENTRAUX, VERS L’EXTÉRIEUR.

LE VENTILATEUR FOURNIT L’AIR EXTÉRIEUR DIRECTEMENT

À CHAQUE CHAMBRE À COUCHER, CHAQUE ÉTAGE SANS

CHAMBRE, ET AUX PIÈCES HABITABLES PRINCIPALES.

RETOUR AIR

RANCE

RÉGLABLE

MF4911

REMARQUES :

1.

2.

COMMENCER

Connexion directe du flux de l’air fourni et du flux de l’air d’évacuation du ventilateur au retour d’air froid de Fig. 6.

l’appareil de chauffage.

Installation indépendante du ventilateur.Fig. 7.

8

Systèmes de ventilation à apport d’air frais Perfect Window™ 68-0171EF—01

Page 39

Équilibrage du débit d’air

L’équilibrage du débit d’air permet de vérifier que le

système de ventilation à apport d’air frais fournit le débit

d’air et la performance énergétique prévus. Utiliser les

instructions d’équilibrage du débit d’air de la section

Installation pour vérifier et équilibrer le débit d’air.

Commandes

Commande marche/arrêt des fonctions de

l’interrupteur de dérivation à distance

Si une ventilation continue n’est pas requise, une

commande marche/arrêt peut être utilisée pour

activer le ventilateur lorsqu’il est en mode de veille.

Les commandes pouvant être utilisées pour cette

fonction incluent les déshumidistats, les minuteries, les

interrupteurs muraux et la fonction de ventilation des

régulateurs numériques VisionPRO IAQ et TrueIAQ.

Déshumidistat

Si la régulation de l’humidité dans les salles de

bains est une fonction principale du système, un

déshumidistat peut être utilisé pour faire passer le

ventilateur du réglage Bas ou Veille au réglage Haut.

Le retrait de l’humidité dans toute l’habitation ne peut

se faire que lorsque l’air extérieur contient moins

d’humidité que l’air intérieur (généralement par temps

froid).

Un VRC annulera l’appel d’un déshumidistat si la

température extérieure dépasse 15,6 °C (60 °F)

pour une période de 24 heures. La fonction du

déshumidistat sera réactivée si l’unité est débranchée

pendant 3 minutes ou si la température extérieure

chute en dessous de 15,6 °C (60 °F) pour une période

de 24 heures. La fonction du déshumidistat est activée

en permanence sur les modèles VRE.

Régulateurs IAQ

Les régulateurs VisionPRO IAQ et TrueIAQ peuvent

réguler automatiquement le ventilateur en appuyant

sur le bouton Ventiler du régulateur. Vor le guide

du propriétaire du régulateur pour les instructions

complètes.

Minuterie de ventilateur numérique

Les régulateurs du ventilateur sont compatibles

avec la minuterie de ventilateur numérique. Si plus

d’une minuterie est activée, chacune fonctionne

indépendamment avec le ventilateur en marche

à haute vitesse jusqu’à ce que la durée de

fonctionnement de toutes les minuteries se soit

écoulée. Huit minuteries au maximum peuvent être

installées sur un système.

Régulation de l’humidité

Lorsqu’un bâtiment est neuf, le bois, le plâtre, le

ciment et les autres matériaux de construction