Page 1

Experion PKS

Release 516

Honeywell FSC Integration Reference

EPDOC-XX56-en-516A

August 2020

Page 2

DISCLAIMER

This document contains Honeywell proprietary information.

Information contained herein is to be used solely for the purpose

submitted, and no part of this document or its contents shall be

reproduced, published, or disclosed to a third party without the

express permission of Honeywell International Sàrl.

While this information is presented in good faith and believed to be

accurate, Honeywell disclaims the implied warranties of

merchantability and fitness for a purpose and makes no express

warranties except as may be stated in its written agreement with and

for its customer.

In no event is Honeywell liable to anyone for any direct, special, or

consequential damages. The information and specifications in this

document are subject to change without notice.

Copyright 2020 - Honeywell International Sàrl

2

Page 3

CONTENTS

Contents 3

Chapter 1 - Planning considerations for Honeywell FSC controllers 5

Devices supported by the Honeywell FSC interface 6

Other documentation for Honeywell FSC 7

FSC-specific terms 7

Differences between serial and Ethernet controllers 8

Architectures for Honeywell FSC 8

Serial connections for Honeywell FSC 8

Ethernet connections for Honeywell FSC 11

Contents

Communication settings for Honeywell FSC 13

Serial connection settings for Honeywell FSC 13

Ethernet connection settings for Honeywell FSC 14

Assigning SER numbers for sequence of events 15

Reserved SER numbers 16

Interpreting SOE lines 17

Chapter 2 - Honeywell FSC channel and controller reference 19

Main properties for a Honeywell FSC channel 20

Port properties for a Honeywell FSC channel 22

Main properties for a Honeywell FSC controller 25

About time synchronization on Honeywell FSC controllers 28

Optimizing Honeywell FSC scanning performance 29

Chapter 3 - Honeywell FSC points reference 31

Defining a Honeywell FSC address for a point parameter 32

Chapter 4 - Troubleshooting Honeywell FSC issues 37

Accessing diagnostics for an Ethernet controller 38

3

Page 4

Contents

Testing Honeywell FSC communications with the server 38

Troubleshooting Honeywell FSC communication errors for a serial

controller 41

Troubleshooting Honeywell FSC communication errors for an

Ethernet controller 41

Notices 43

4

Page 5

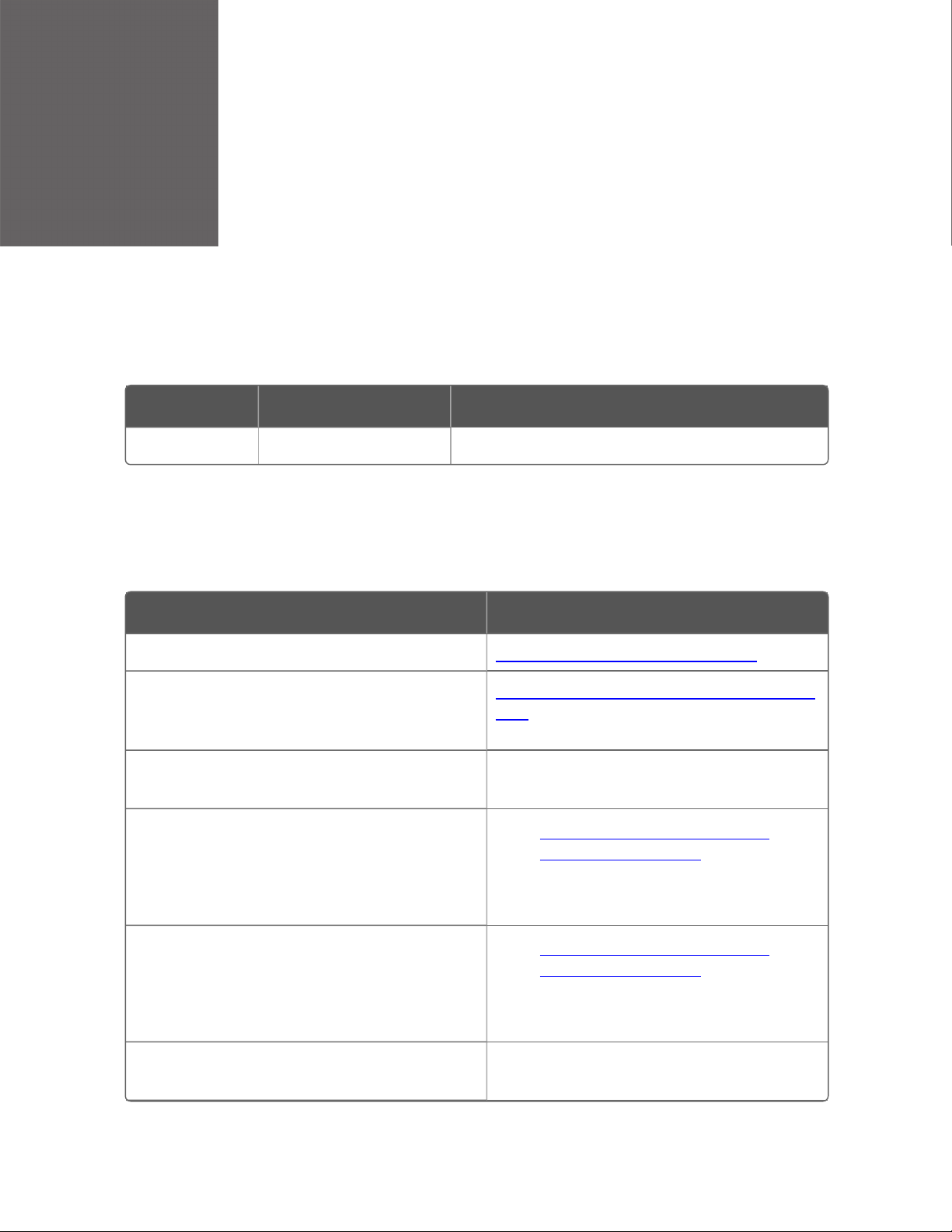

CHAPTER

PLANNING CONSIDERATIONS FOR

1

HONEYWELL FSC CONTROLLERS

This reference provides the information you need to set up, configure,

and test FSC controller communications with the server.

Revision history

Revision Date Description

A August 2020 Initial release of document.

How to use this guide

These are the steps for connecting and configuring a Honeywell FSC

controller. Complete each step before commencing the next.

Steps Go to

Determine FSC configuration Architectures for Honeywell FSC

Setting up the communications

parameters using the FSC configuration

software

Use FSC configuration software to set SER

numbers

Use Quick Builder to define channels

Use Quick Builder to define controllers

Download channel and controller

definitions to the server

Communication settings for Honeywell

FSC

Assigning SER numbers for sequence of

events

l Honeywell FSC channel and

controller reference

l "Build channels" topic in the Quick

Builder User’s Guide

l Honeywell FSC channel and

controller reference

l "Build controllers" topic in the

Quick Builder User’s Guide

"Downloading items" topic in the Quick

Builder User’s Guide

5

Page 6

Chapter 1 - Planning considerations for Honeywell FSC controllers

Steps Go to

Test communications Testing Honeywell FSC

communications with the server

Troubleshooting communication errors Troubleshooting Honeywell FSC

communication errors for a serial

controller

Use Quick Builder to define points Defining a Honeywell FSC address for a

point parameter

Devices supported by the Honeywell FSC interface

The server supports serial and Ethernet FSC controllers.

The server communicates with:

n Serial controllers using a point-to-point or multi-drop RS-232 link

and FSC Modbus protocol

n Ethernet controllers using a proprietary protocol based on the

Modbus protocol

Serial devices supported by the Honeywell FSC

interface

The server supports the following serial FSC controller configurations:

FSC-100 A single rack.

FSC-100R Two identical racks. Basically parallel FSC-100 configuration.

FSC-101 May consist of several racks.

FSC-102 Two Central parts and single I/O.

FSC-101R Two Central parts and redundant I/O.

FSC-202 Two Central racks and redundant I/O.

6

Page 7

Chapter 1 - Planning considerations for Honeywell FSC controllers

Ethernet devices supported by the Honeywell FSC

interface

The server supports the following Ethernet FSC controller

configurations.

FSC1oo1D

FSC1oo1D

FSC1oo2D

Single Central Part with single Ethernet connection

Single Central Part with redundant Ethernet connection

Redundant Central Parts with single Ethernet connection to each

Central Part

Other documentation for Honeywell FSC

This reference provides only supplemental information to interface

FSC controllers with the server. For detailed information about

installing and configuring FSC controllers, see the manufacturer's

documentation.

FSC-specific terms

FSC

Fail-safe controller.

SER

SER channel

SOE

BaseSER Number

Sequence of events recorder.

An FSC setting required so that the server can extract SOE data from

the controller. The server uses the SER channel to poll for SOE data.

Sequence of events.

The unique ID assigned to a serial (non-Ethernet) controller so that

the server can extract SOE data from that controller.

7

Page 8

Chapter 1 - Planning considerations for Honeywell FSC controllers

Differences between serial and Ethernet controllers

The server supports serial and Ethernet FSC controllers. However,

these two controller types are different, and following differences

apply:

n Serial controllers use Modbus; whereas Ethernet controllers use a

proprietary protocol based on Modbus.

n The diagnostic scan rate is not configurable in Ethernet

controllers.

n The Base SER is not required for Ethernet controllers.

n There is a separate test utility for each type of controller.

n System Information and Extended Diagnostics are available for

Ethernet controllers.

Architectures for Honeywell FSC

Honeywell FSC interface supports connection to the server via serial

or Ethernet connection.

Serial connections for Honeywell FSC

The server communicates with serial controllers using a point-topoint or multi-drop RS-232 link and FSC Modbus protocol.

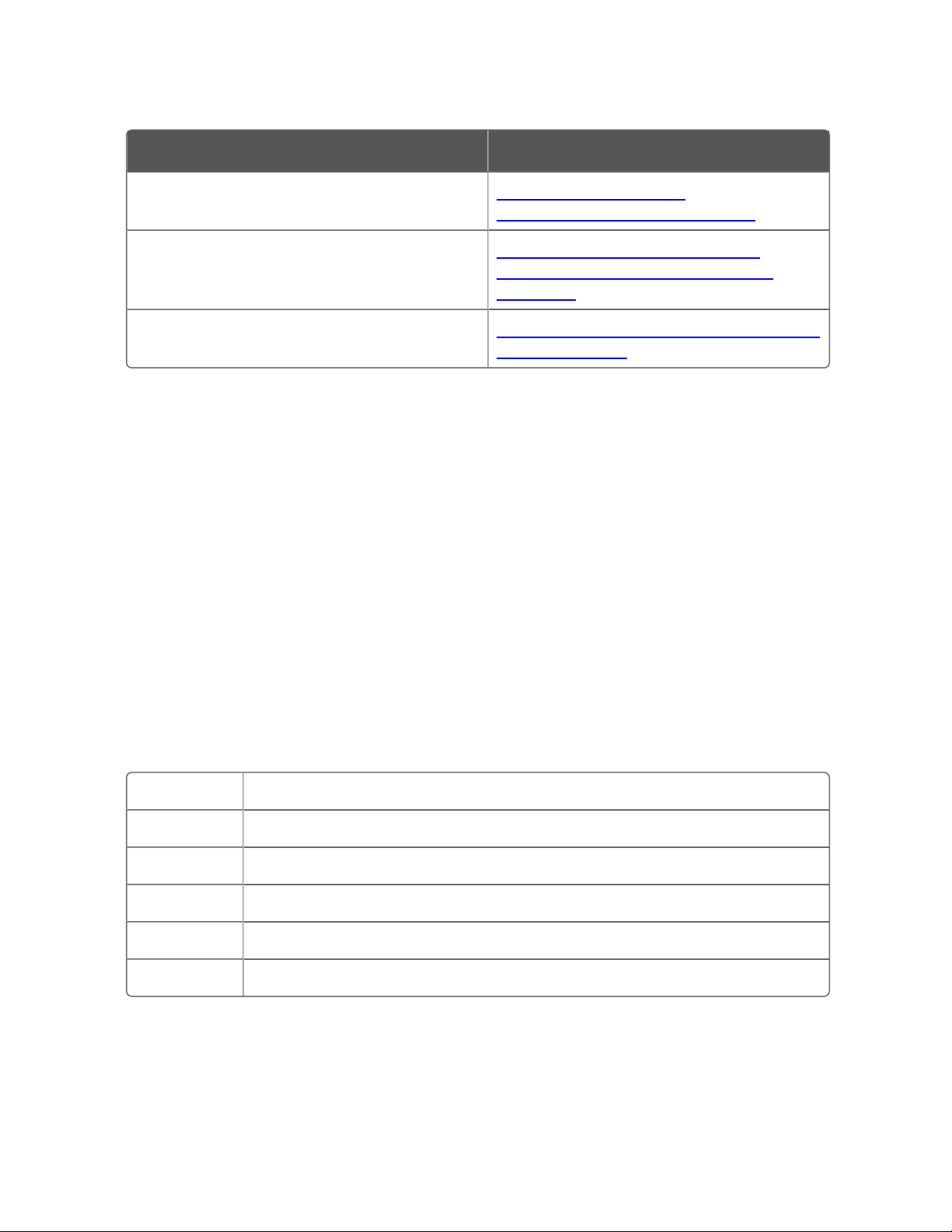

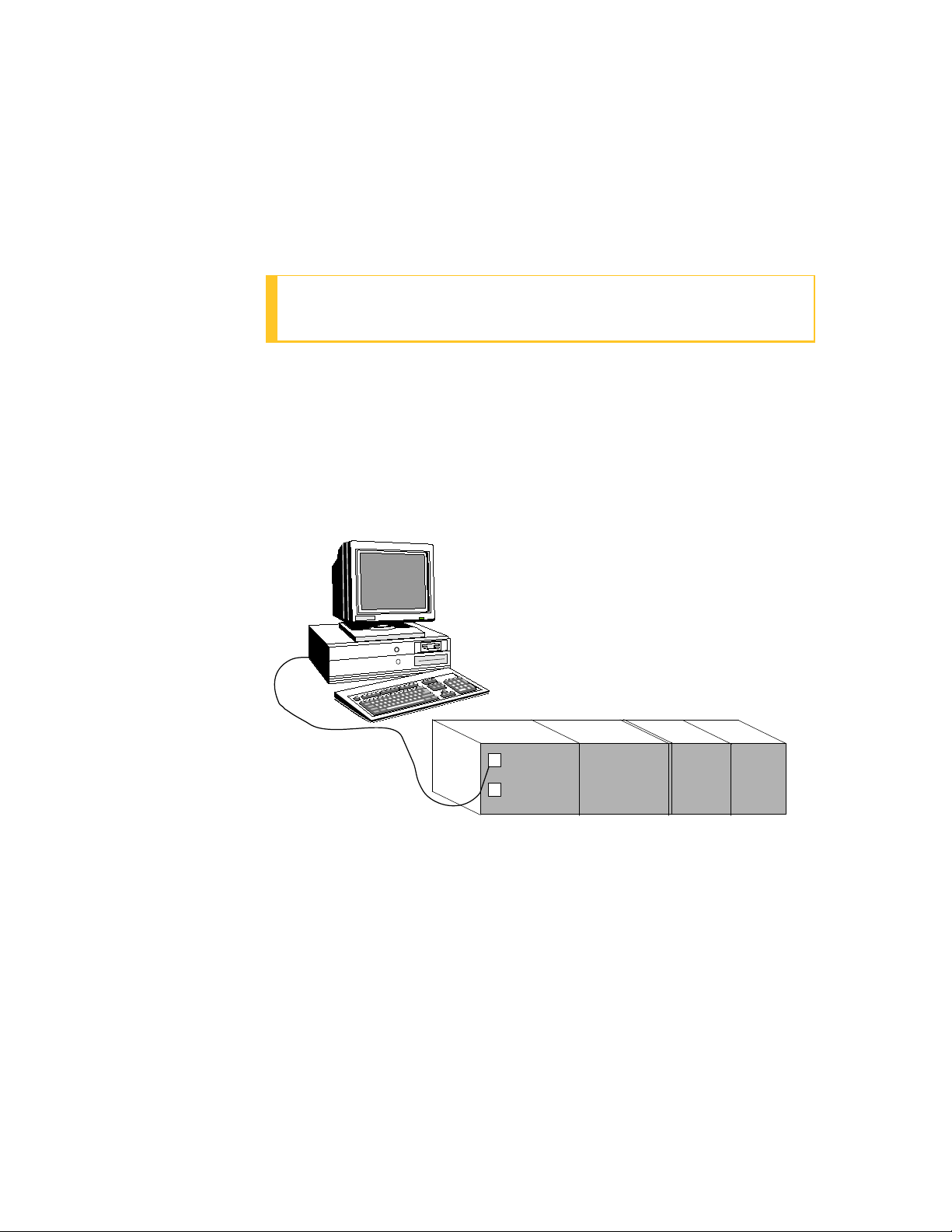

Point-to-point configuration

A point-to-point configuration consists of a controller with a single

COM module connected to a port on the server through a serial link.

Figure 1-1: Point-to-point configuration

8

Page 9

FSC Controller

Server

Central part 1

Server

FSC Controller

Central part 1

Central part 2

Chapter 1 - Planning considerations for Honeywell FSC controllers

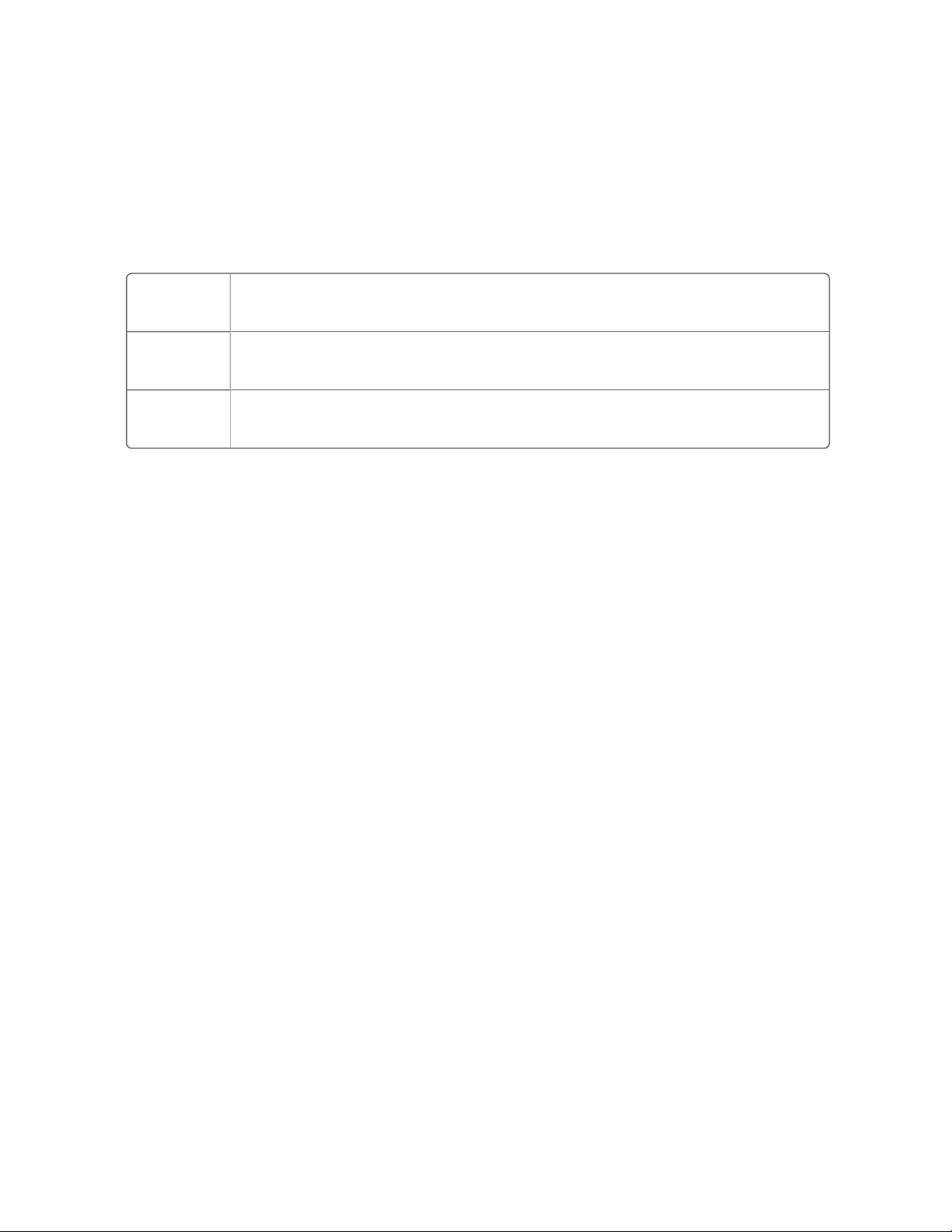

Multi-drop configuration

A multi-drop configuration consists of a redundant FSC controller

with two COM modules connected on the same serial link which

connects to a single port on the server.

Note that this type of configuration does not constitute server

communications redundancy, but it does provide a means of talking

to a redundant FSC system across a single channel.

Figure 1-2: Multi-drop configuration

9

Page 10

FSC “Master” Controller

Server

Central part 1

FSC Network - Slave and/or Master Controllers

Chapter 1 - Planning considerations for Honeywell FSC controllers

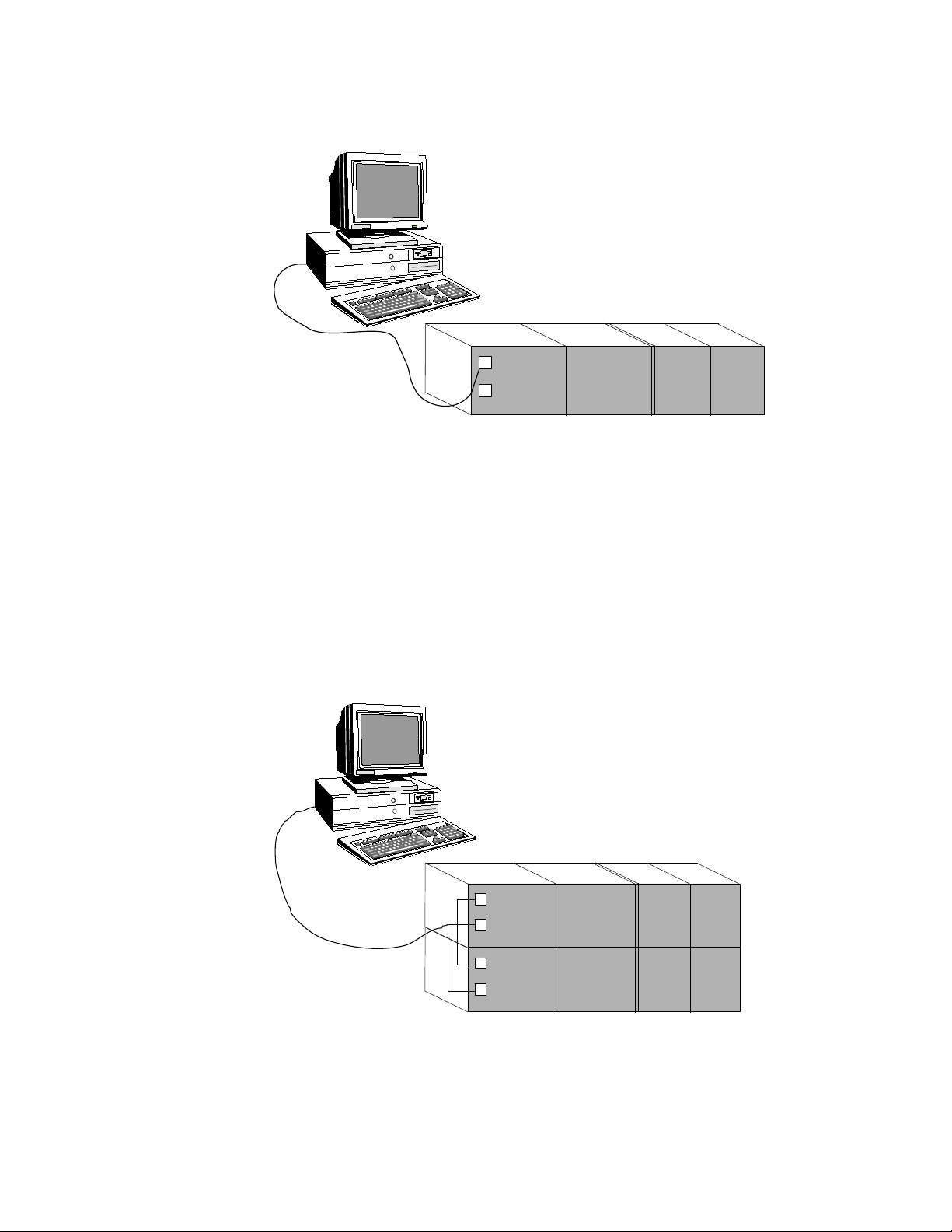

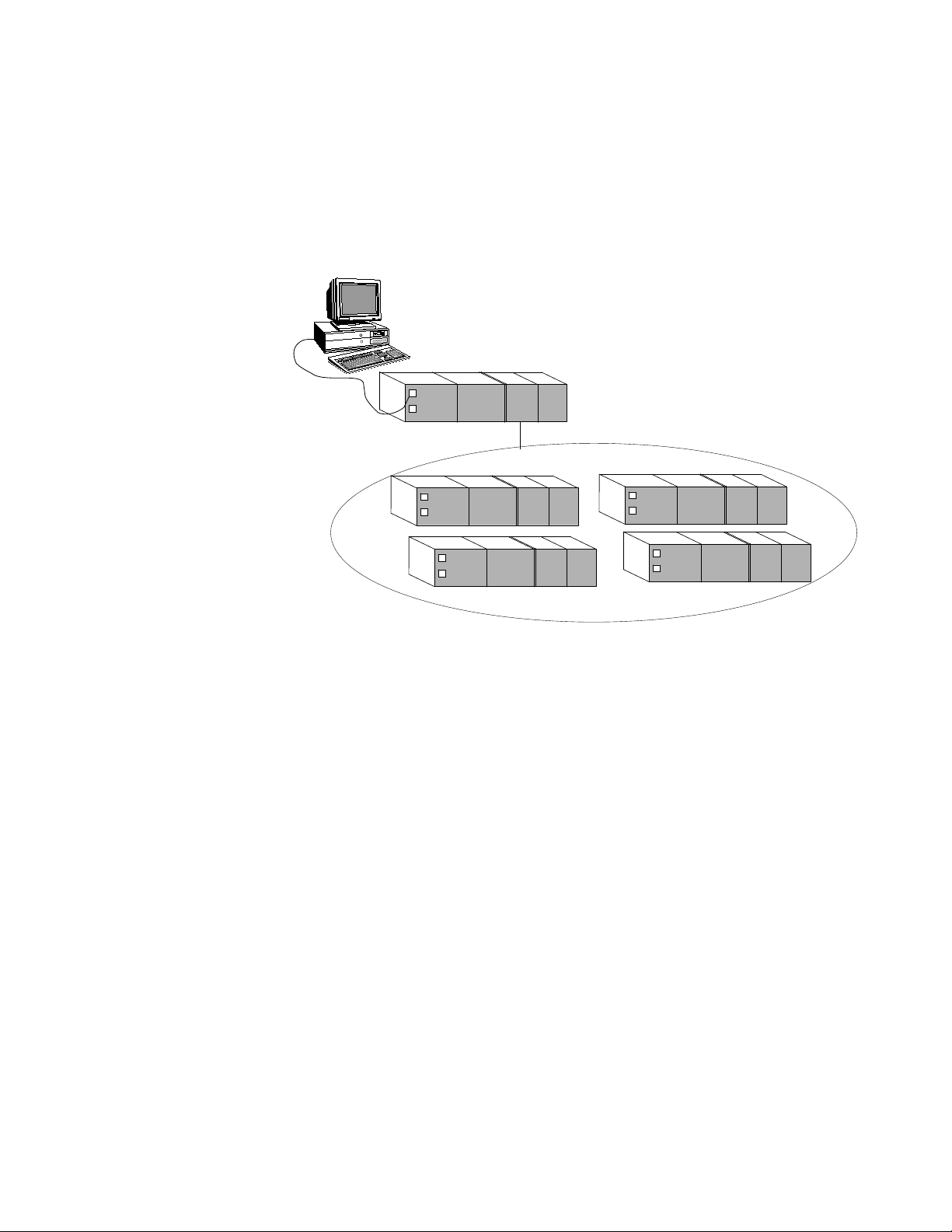

FSC network configuration

Using an FSC network configuration, a single FSC controller manages

the data that the server requests or controls. One controller,

designated as a 'master' controller, is responsible for gathering SOE

data from the FSC network. This enables SOE data from any

networked controller to be obtained from the master controller.

A master controller is also useful for time synchronization. The master

controller is responsible for time synchronization on the FSC

network—synchronizing the time on the master controller also

synchronizes the time on 'slave' controllers. See the topic titled "About

time synchronization on Honeywell FSC controllers" for more

information.

Figure 1-3: FSC network

10

Redundancy for serial controllers

Serial FSC controllers support communication redundancy. This is

not the same as the multi-drop configuration. Communication

redundancy involves a separate physical connection to communicate

with the FSC controller.

Page 11

FSC Controller

Server

Central part 1

Chapter 1 - Planning considerations for Honeywell FSC controllers

Ethernet connections for Honeywell FSC

The server communicates with Ethernet controllers using a

proprietary protocol based on the Modbus protocol. Process data

connections to the FSC are made on TCP port 51000. Information

scan connections to the FSC are made on TCP port 51001.

ATTENTION: Connecting or configuring a single FSC Ethernet

controller to multiple servers is not a supported configuration.

Point-to-point configuration

A point-to-point configuration consists of a controller with a single

COM module connected to a port on the server through an Ethernet

link.

Figure 1-4: Point-to-point configuration

FSC network configuration

Using an FSC network configuration, a single FSC controller manages

the data that the server requests or controls. One controller,

designated as a 'master' controller, is responsible for gathering SOE

data from the FSC network. This enables SOE data from any

networked controller to be obtained from the master controller.

A master controller is also useful for time synchronization. The master

controller is responsible for time synchronization on the FSC

11

Page 12

FSC “Master” Controller

Server

Central part 1

FSC Network - Slave and/or Master Controllers

Chapter 1 - Planning considerations for Honeywell FSC controllers

network—synchronizing the time on the master controller also

synchronizes the time on slave controllers. See the topic titled "About

time synchronization on Honeywell FSC controllers" for more

information.

Figure 1-5: FSC network

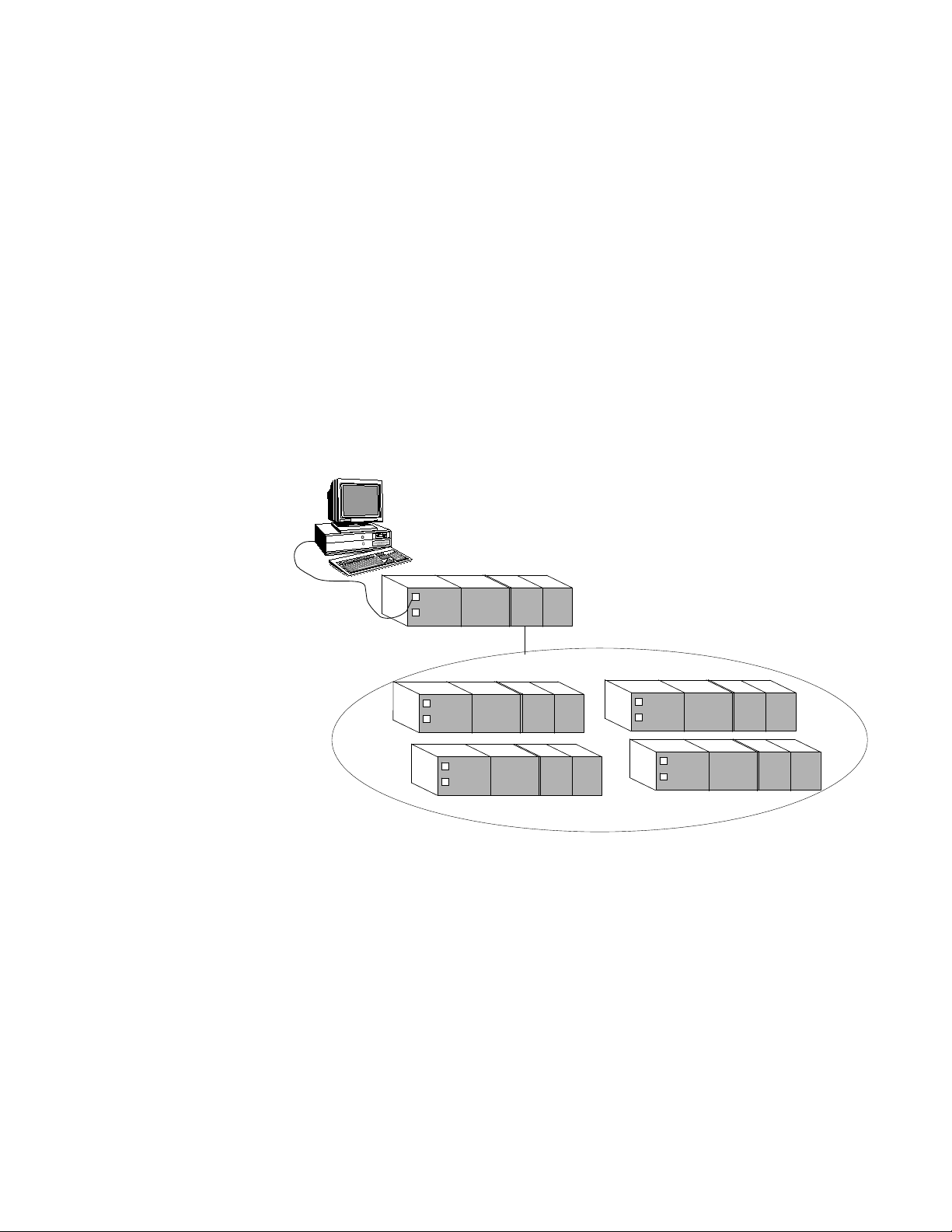

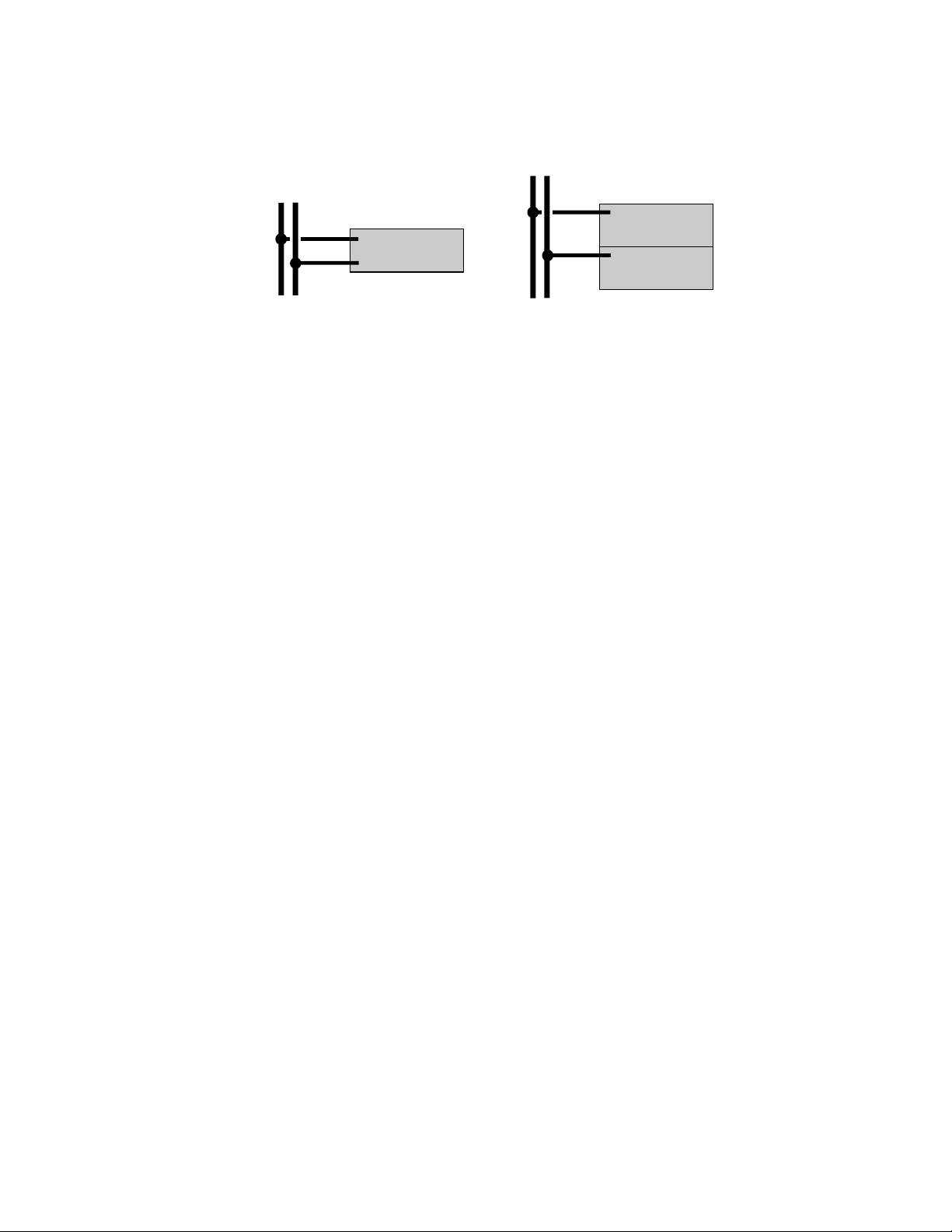

Redundancy for Ethernet controllers

Ethernet FSC controllers support communication redundancy.

Communication redundancy involves a separate physical connection

to communicate with the FSC controller.

The server supports the following redundancy options:

n Redundant connection to a single Central Part via a single,

redundant 10018/E/E COM module

n Redundant connection to redundant Central Parts via a single,

non-redundant 10018/E/1. COM module on each Central Part

Figure 1-6: Redundancy options

12

Page 13

CP

A

A B

B

CP1

CP2

A

A B

B

Chapter 1 - Planning considerations for Honeywell FSC controllers

Communication settings for Honeywell FSC

The communication settings are specific to the controller type (serial

or Ethernet).

Serial connection settings for Honeywell FSC

The RS-232 connection is made to the controller's COM module,

which can be of the following types:

n 10004/./.

n 10014/./.

Communication address

To communicate with a serial FSC controller, the server uses a

communicationaddress, which can be calculated using the

FSCSystem number specified when configuring the controller.

You use the FSC configuration utility, FSC Navigator, to specify the

FSCSystem number, which must be unique within a system of FSC

controllers.

The communicationaddress is equal to four times the FSCSystem

number.

Modbus data tables and function codes

Serial FSC controllers use the following Modbus data tables and

function codes.

In Quick Builder, you need to define a separate 'logical' controller for

each data table to which the server needs access. For example, if the

server needs access to the Discrete Output table and the and Input

Register table, you need to define two logical controllers.

13

Page 14

Chapter 1 - Planning considerations for Honeywell FSC controllers

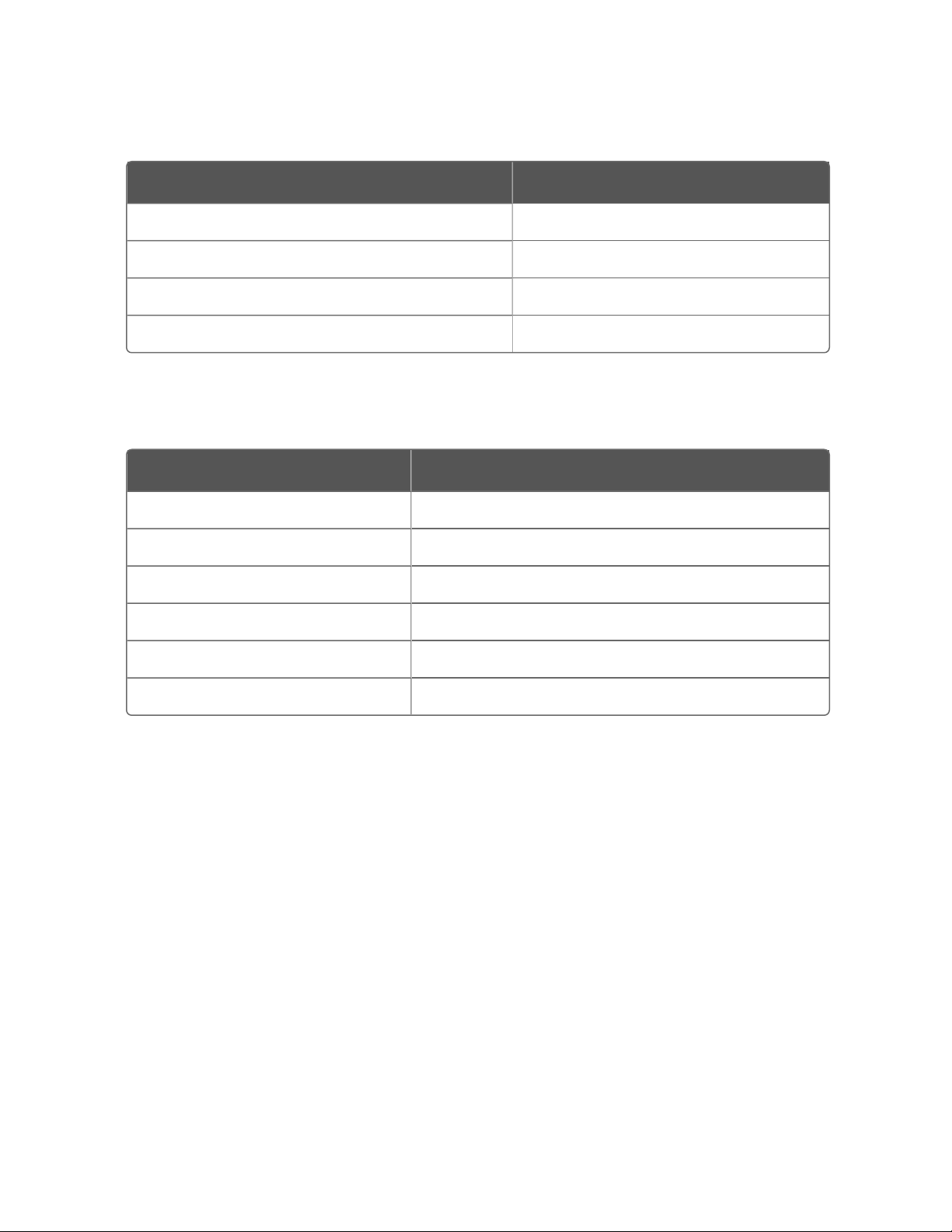

Table 1-1: Modbus data tables

Data table Server addressable range

Discrete (digital) Output (coils) 00001–08192 (read/write)

Discrete (digital) Input (contacts) 10001–18192 (read only)

Input Register 30001–38192 (read only)

Holding Register 40001–48192 (read/write)

Serial FSC controllers support the following Modbus protocol

function codes:

Table 1-2: Modbus function codes

Function code Description

01 Read output status

02 Read input status

03 Read output registers

04 Read input registers

05 Force Single Coil

06 Preset Single Register

Ethernet connection settings for Honeywell FSC

The Ethernet connection is made to the controller's 10018/E/1 or

10018/E/E COM modules.

Communication address

To communicate with an Ethernet FSC controller, the server uses a

communicationaddress, which can be calculated using the

FSCSystem number specified when configuring the controller.

You use the FSC configuration utility, FSC Navigator, to specify the

FSCSystem number, which must be unique within a system of FSC

controllers.

14

The communicationaddress is equal to four times the FSCSystem

number.

Page 15

Chapter 1 - Planning considerations for Honeywell FSC controllers

Ethernet data tables

Ethernet FSC controllers use the following Modbus data tables.

In Quick Builder, you need to define a separate 'logical' controller for

each data table to which the server needs access. For example, if the

server needs access to the Coils table and the Registers table, you

need to define two logical controllers.

ATTENTION: The following points can only be built on an SOE

only controller:

l FSC variables with a SER sequence number, but without a DCS

address. This includes FSC variables with a SER sequence

number which are located in a FSC network. See the section

"FSC network configuration" in the topic titled "Ethernet

connections for Honeywell FSC" for more information.

l FSC system events. See the topic titled "Reserved SER

numbers" for more information.

Table 1-3: Ethernet data tables

Data Table Server Addressable Range (DCS address)

Coils (FSC types: I, O) 1–8192

SOE Only N/A

Registers (FSC types: BI, AI, BO, AO) 10001–18192

Assigning SER numbers for sequence of events

FSC controllers have SOE (Sequence of Events) capabilities. If you

want the server to record a controller's SOEs in its SOE log, you need

to assign an SER (Sequence of Events Recorder) number to each

internal address.

ATTENTION: In the case of a serial FSC controller, you need to

define a BaseSER for the controller.

15

Page 16

Chapter 1 - Planning considerations for Honeywell FSC controllers

To record a controller's SOEs in its SOE log

1. Assign an SER number to each internal address you want the

server to record. (It is recommended that you assign SER numbers

in a tight block for each controller.)

You use the FSC configuration utility, FSC Navigator, to assign SER

numbers.

2. When defining the controller in Quick Builder, select the SOE

Enable check box. (If you define several logical controllers, only

select this for one controller.) See the topic titled "Main properties

for a Honeywell FSC controller" for more information.

3. Assign a separate point, in Quick Builder, to each SER number. A

point can only have one SER number associated with it.

Reserved SER numbers

FSC controllers reserve the following SER numbers for system events.

If you want the server to log these system events, you need to assign

points to them that are reserved for system events.

SER Number (serial) SER Number (Ethernet) System Event

BaseSER 0 All forces cleared

BaseSER + 1 1 FSC System Fault

BaseSER + 2 2 SER Buffer Full

BaseSER + 3 3 SER Buffer Empty

BaseSER + 5 5 Force Event

ATTENTION:

l BaseSER + 4 (4 in the case of Ethernet) is not a valid event.

l The 'SER Buffer Empty' event cannot be stored in server SOE.

If a point is defined with this SER number, it is ignored.

l To be logged on to the SOE display when using an Ethernet

FSC controller, the System Events must be built on a SOE only

controller. This is because System Events have no DCS address

associated with them.

16

Page 17

Interpreting SOE lines

The following fields of the server's SOE file are populated for each

SOE with a matching SER number:

Field Description

Chapter 1 - Planning considerations for Honeywell FSC controllers

Date &

Time

Source The server's point ID that corresponds with this SOE.

Condition The SER number associated with this SOE.

Action Only applicable to Ethernet controllers. Information indicator

Description The server's point description.

Value The value returned in the SOE (if applicable).

The date and time given to the SOE by the controller.

dependent on the types of SER. See the section below titled "Action

descriptions."

For a status point built against a coil, this displays the appropriate state

descriptor for that point. Indeterminate values display either blank or

zero.

Action descriptions

Event Type FSC Data Type

FSC

Description

Server-action

Field

Event Report

Process Variable Event Boolean True to False F

1

System events. See the topic titled "Reserved SER numbers.“

2

Actions that are not applicable or indeterminate appear as --.

1

Any N/A

False to True T

Analog Low LO

Healthy HLT

High HI

2

17

Page 18

Chapter 1 - Planning considerations for Honeywell FSC controllers

Event Type FSC Data Type

Process Variable Force

Boolean Force Set SET

Event

Analog Force Set SET

Diagnostic Event Diagnostic

Event

FSC

Description

Server-action

Field

Force Cleared CLR

Force Cleared CLR

N/A

18

Page 19

CHAPTER

HONEYWELL FSC CHANNEL AND

2

CONTROLLER REFERENCE

This section describes the configuration and addressing information

specific to Honeywell FSC channels and controllers.

In this section:

Main properties for a Honeywell FSC channel 20

Port properties for a Honeywell FSC channel 22

Main properties for a Honeywell FSC controller 25

Optimizing Honeywell FSC scanning performance 29

19

Page 20

Chapter 2 - Honeywell FSC channel and controller reference

Main properties for a Honeywell FSC channel

The Main tab defines the basic properties for a Honeywell FSC

channel.

For information about how to create a channel, see "Building

controllers and channels" in the Quick Builder User’s Guide.

ATTENTION: If you use both serial and Ethernet Honeywell FSC

controllers, you need to create a separate channel for each type

of controller.

Property Description

Name The unique name of the channel. A maximum of 10 alphanumeric

characters (no spaces or double quotes). Note: In Station displays,

underscore characters ( _ ) appear as spaces.

Description (Optional) A description of the channel. A maximum of 132

alphanumeric characters, including spaces.

Associated

Asset

Marginal

Alarm Limit

The Tag Name of the Asset to be associated with the controller.

The communications alarm marginal limit at which the channel is

declared to be marginal. When this limit is reached, a high priority

alarm is generated. To change the priority of the alarm system wide,

see the topic titled "Configuring system alarm priorities" in the Server

and Client Configuration Guide. To change the priority of the alarm for

one channel, see the topic titled "About configuring custom system

alarm priorities for an individual channel or controller" in the Server

and Client Configuration Guide.

A channel barometer monitors the total number of requests and the

number of times the controller did not respond or response was

incorrect. The barometer increments by two or more, depending on

the error, and decrements for each good call.

To calculate an acceptable marginal alarm limit, use the formula:

Square root of the number of controllers on the channel × Marginal

Alarm Limit defined on those controllers (Normally, you specify the

same value for all controllers on a channel).

20

For example, if there are 9 controllers on the channel and their

Page 21

Property Description

Marginal Alarm Limit is set to 25, the value would be 3 (which is the

square root of 9) × 25 = 75.

Chapter 2 - Honeywell FSC channel and controller reference

Fail Alarm

Limit

Connect

Timeout

Read

Timeout

The communications alarm fail limit at which the channel is declared

to have failed. When this barometer limit is reached, an urgent alarm

is generated. To change the priority of the alarm system wide, see the

topic titled "Configuring system alarm priorities" in the Server and

Client Configuration Guide. To change the priority of the alarm for one

channel, see the topic titled "About configuring custom system alarm

priorities for an individual channel or controller" in the Server and

Client Configuration Guide.

Set this to double the value specified for the channel Marginal Alarm

Limit.

The time (in seconds) the server waits to connect to the Port and the

Redundant Port of the controller before abandoning the connection.

The default is 10 seconds for both the Port and the Redundant Port.

You can set different values for these two ports.

Use the default values unless the communications lines have a high

error rate or you are using modems.

The time (in seconds) that the server waits for a reply from the Port

and the Redundant Port of the controller. The default is 2 seconds for

both the Port and the Redundant Port. You can set different values for

these two ports.

Use the default values unless the communications lines have a high

error rate or you are using modems.

Item Type The type of channel specified when this item was created.

Last

The date and time the channel properties were modified.

Modified

Last

The date and time the channel was last downloaded to the server.

Downloaded

Item

Number

The unique item number currently assigned to this channel, in the

format CHNcccc, where cccc is the channel number.

You can change the Item Number if you need to match your current

server database configuration. The number must be between 0001 and

21

Page 22

Chapter 2 - Honeywell FSC channel and controller reference

Property Description

the maximum number of channels allowed for your system. For more

information about setting the maximum value, see the topic titled

"Adjusting sizing of non-licensed items" in the Supplementary

Installation Tasks Guide. Note that the maximum number of channels

that may be used in a system is defined in the Experion specification

for that Experion release, This number is likely to be less than the

maximum number that can be configured in the database as shown in

"Adjusting sizing of non-licensed items."

Port properties for a Honeywell FSC channel

The Port tab defines the communication-related properties for a

channel. The Port Type for FSC controllers can be:

n Serial. Only applicable to a directly-connected serial FSC

controller. A serial communications interface, such as RS-232. See

the section below titled "Serial port properties" for more

information.

n TerminalServer. Only applicable to a serial FSC controller that

communicates with the server via a terminal server. See the

section below titled "Terminal Server port properties" for more

information.

n LANVendor. Only applicable to an Ethernet FSC controller. See the

section below titled "LANVendor port properties" for more

information.

Serial port properties

ATTENTION: Only applicable to serial FSC controllers.

Property Description

Serial Port

Name

Baud rate The number of data bits per second.

The device name of the serial port.

The default is 9600.

22

Number of The number of data bits used for transmission.

Page 23

Chapter 2 - Honeywell FSC channel and controller reference

Property Description

Data Bits The default is 8.

Stop Bits The number of stop bits used for transmission

The default is 1.

Parity Defines parity verification of each character and must match

configuration on the end device.

The default is NONE.

Checksum The type of checksum error detection used for the port. Select the

value that matches the setting on the communication device:

l CRC16_0 or CRC16_1 (if Cyclic Redundancy Check (CRC) is set)

l ONESCOMP or TWOSCOMP (if Longitudinal Redundancy Check

(LRC) is set)

l XOR (If exclusive or is set)

XON/XOFF The type of XON/XOFF software flow control used to stop a receiver

from being overrun with messages from a sender. The types are:

l Input (use XON/XOFF to control the flow of data on the receive

line)

l None (default)

l Output (use XON/XOFF to control the flow of data on the

transmit line)

Handshaking

For RS-232

Options

l Enable RTS/CTS flow control. Stops a receiver from being overrun

with messages from a sender by using RTS/CTS flow control.

l Detect DCD. Select if the Data Carrier Detect communication

status line of the COM port requires monitoring (usually when

using modem or microwave linking). When selected, the

communications fails if the desired COM status line is not

high—for example, on a dial-up link connection for a modem.

l Detect DSR. Select if the Data Set Ready communication status

line of the COM port requires monitoring (usually when using

modem or microwave linking). When selected, the

23

Page 24

Chapter 2 - Honeywell FSC channel and controller reference

Property Description

communications fails if the desired COM status is not achieved.

Note: No options are available for RS-422.

For RS-485. The server does not support RS-485 for FSC controllers.

Terminal Server port properties

ATTENTION: Only applicable to serial FSC controllers.

Property Description

Terminal

Server TCP

The name and port number of terminal server to which the channel is

connected.

Host Name

You can specify either a TCP host name or an IP address, but it must

Terminal

Server TCP

match the TCP host name used when you installed and internally

configured the terminal server.

Port No

Idle Timeout The time, in seconds, the channel waits for a successful connection to

the server before closing the connection.

A value of 0 indicates that the connection is never closed.

Checksum The type of checksum error detection used for the port. Select the

value that matches the setting on the communication device:

l CRC16_0 or CRC16_1 (if Cyclic Redundancy Check (CRC) is set)

l ONESCOMP or TWOSCOMP (if Longitudinal Redundancy Check

(LRC) is set)

l XOR (If exclusive or is set)

24

LANVendor port properties

ATTENTION: Only applicable to serial FSC controllers.

Page 25

Chapter 2 - Honeywell FSC channel and controller reference

Property Description

Port Name Leave blank.

Redundant port properties

A communications link being used as a redundant link requires an

additional port definition for the redundant port. After you complete

the port definition, enter the same kind of port definition for the

redundant port.

Main properties for a Honeywell FSC controller

The Main tab defines the basic properties for a Honeywell FSC

controller.

For information about how to create a controller, see "Building

controllers and channels" in the Quick Builder User’s Guide.

Property Description

Name The unique name of the controller. A maximum of 10

alphanumeric characters (no spaces or double quotes). Note: In

Station displays, underscore characters ( _ ) appear as spaces.

Description (Optional) A description of the controller. A maximum of 132

alphanumeric characters, including spaces.

Associated

Asset

Channel Name The channel on which the controller communicates with the

Marginal Alarm

Limit

The Tag Name of the Asset to be associated with the alarm group.

server.

If you use both serial and Ethernet controllers, you must select a

serial/terminal server channel for a serial controller, and a

LANHoneywell channel for an Ethernet controller.

The communications alarm marginal limit at which the controller

is declared to be marginal. When this limit is reached, a high

priority alarm is generated. To change the priority of the alarm

system wide, see the topic titled "Configuring system alarm

priorities" in the Server and Client Configuration Guide. To change

the priority of the alarm for one controller, see the topic titled

25

Page 26

Chapter 2 - Honeywell FSC channel and controller reference

Property Description

"About configuring custom system alarm priorities for an

individual channel or controller" in the Server and Client

Configuration Guide.

A controller barometer monitors the total number of requests and

the number of times the controller did not respond or response

was incorrect. The barometer increments by two or more,

depending on the error, and decrements for each good call.

The default value is 25.

Fail Alarm Limit The communications alarm fail limit at which the controller is

declared to have failed. When this barometer limit is reached, an

urgent alarm is generated. To change the priority of the alarm

system wide, see the topic titled "Configuring system alarm

priorities" in the Server and Client Configuration Guide. To change

the priority of the alarm for one controller, see the topic titled

"About configuring custom system alarm priorities for an

individual channel or controller" in the Server and Client

Configuration Guide.

Dynamic

Scanning

Fastest Scan

Period

Communication

Address

Set this to double the value specified for the controller Marginal

Alarm Limit.

The default is 50.

Select the Dynamic Scanning check box to enable dynamic

scanning of all point parameters on this controller. The default

setting for this check box is selected.

Define the fastest possible scan period (in seconds) that dynamic

scanning will scan point parameters on this controller. The default

is 15 seconds.

The dynamic scanning period does not affect the static scanning

rate for a parameter. For example, if the scanning rate for a

parameter is 10 seconds, and the dynamic scanning rate for the

controller is 15 seconds, the parameter will still be scanned at a

period of 10 seconds.

Set this to four times the FSC System number. The FSCSystem

number is set using the FSC configuration utility, FSC Navigator.

See the section "Communication address" in the topic titled "Serial

connection settings for Honeywell FSC."

26

Page 27

Chapter 2 - Honeywell FSC channel and controller reference

Property Description

FSC Type Shows the controller type, which corresponds to the type of

channel (serial or Ethernet) selected in Channel Name.

Data Table The data table that this controller addresses.

l Serial controller, see the section "Modbus data tables and

function codes" in the topic titled "Serial connection settings

for Honeywell FSC"

l Ethernet controller, see the section "Ethernet data tables" in

the topic titled "Ethernet connection settings for Honeywell

FSC"

Diagnostic Applicable only to a serial controller. The value, in seconds,

between diagnostic polls. The default is 60 seconds.

To disable diagnostic polls, set the value to 0.

BaseSER Applicable only to a serial controller. The base address for this

controller. See the topic titled "Assigning SER numbers for

sequence of events" for more information.

IP Address 1

The controller's Ethernet addresses.

IP Address 2

SOE Enable

Select SOE Enable if you want SOE data. Specify the time, in

seconds, between polls for SOE data in SOERate.

SOE Rate

Only one logical controller per physical FSC controller can have

SOE Enabled. If an SOE only controller is built, this should be the

only logical controller with SOE enabled for that particular

physical FSC controller.

The SOE Rate must be a minimum of 5 seconds and defaults to 30

seconds.

See the topic titled "Assigning SER numbers for sequence of

events" for more information.

Sync Enable

Select Sync Enable if you want to synchronize the controller time

with the server time. Specify the time, in minutes, since midnight

Sync Time

before synchronizing in SyncTime.

The default is –1 (no synchronization).

27

Page 28

Chapter 2 - Honeywell FSC channel and controller reference

Property Description

See the topic titled "About time synchronization on Honeywell FSC

controllers" for more information.

Item Type The type of controller specified when this item was created.

Last Modified The date and time the controller properties were modified.

Last

Downloaded

Item Number The unique item number currently assigned to this controller, in

The date and time the controller was last downloaded to the

server.

the format RTUnnnnn.

You can change the Item Number if you need to match your

current server database configuration. The number must be

between 00001 and the maximum number of controllers allowed

for your system.

For more information about setting the maximum value, see the

topic titled "Adjusting sizing of non-licensed items" in the

Supplementary Installation Tasks Guide.

Note that the maximum number of controllers that may be used in

a system is defined in the Experion specification for that Experion

release, This number is likely to be less than the maximum number

that can be configured in the database as shown in "Adjusting

sizing of non-licensed items."

About time synchronization on Honeywell FSC controllers

28

You can synchronize the time of FSC controllers with the server.

The Sync Time parameter is specified in minutes since midnight.

When the assigned time is reached, the server sends a

synchronization command with the current time to the controller.

If you define several 'logical' controllers for a particular controller, you

can specify a different synchronization time for each logical

controller, in order to synchronize the physical controller at different

intervals in the day.

Page 29

Chapter 2 - Honeywell FSC channel and controller reference

Optimizing Honeywell FSC scanning performance

The maximum amount of data that can be acquired from an FSC

controller is influenced by the rate of sending scan packets to the

controller. An understanding of FSC scan packets will help you

configure points so that optimal data acquisition performance is

achieved, by maximizing the amount of data acquired with each scan

packet.

The scan packets that have been built can be listed by using the list

scan utility, lisscn. Listing scan packets helps verify the scanning

strategy. See the Server and Client Configuration Guide for usage of

lisscn.

29

Page 30

Chapter 2 - Honeywell FSC channel and controller reference

30

Page 31

CHAPTER

3

HONEYWELL FSC POINTS REFERENCE

This section describes how to configure points for a Honeywell FSC

controller using Quick Builder.

In this section:

Defining a Honeywell FSC address for a point parameter 32

31

Page 32

Chapter 3 - Honeywell FSC points reference

Defining a Honeywell FSC address for a point parameter

The format for an FSC data table address is:

ControllerName Address

Part Description

ControllerName The name of the FSC controller.

Address The address in the controller where the value is recorded.

The address syntax can be either:

l Address syntax for coils and registers

l Address syntax for SOE only points

See the relevant sections below for more information.

If you would like help with the address, you can use the Address

Builder. To display the Address Builder, click next to Address.

Address syntax for coils and registers

Address [Format|BitNumber] [SER SerNumber]

Part Description

Address

The server addressable memory address within the controller's data

table.

l Serial controller, see the section "Modbus data tables and function

codes" in the topic titled "Serial connection settings for Honeywell

FSC"

l Ethernet controller, see the section "Ethernet data tables" in the

topic titled "Ethernet connection settings for Honeywell FSC"

32

Format

(Optional) Select an appropriate format to read raw values.

To scale See the section below titled "Scaling with data formats."

Page 33

Part Description

To read without scaling Select a format of C16, or enter a 0, to read all 16

bits in the register without scaling. To read less than 16 bits without

scaling, enter the starting bit number (1 to 15). If you are not using

scaling, the point range is still used for PV indicator bar height only (the

PV indicator bar is on the Point Detail display on Station).

To read floating point values The supported floating point formats are

specific to the controller type:

l Serial, see the section below titled "IEEEFP formats for serial

controllers"

l Ethernet, see the section below titled "Data formats supported for

Ethernet controllers"

Select format IEEEFP to read two consecutive registers as a single

precision floating point number.

Chapter 3 - Honeywell FSC points reference

BitNumber

SerNumber

(Optional) For Input register and Holding register data tables, a starting

bit number can be specified. The valid range is 0 (default) to 15 where 0

is the right most bit in the 16-bit register.

Analog and accumulator point parameters can read up to 16 bits.

Status point parameters read 1, 2, or 3 consecutive bits.

The SER number. See the topic titled "Assigning SER numbers for

sequence of events" for more information.

ATTENTION: For a status point with an OP configured with four

output states (that is, across two consecutive coils), control of the

OP is carried out by executing separate writes to each of the two

coils. Therefore, a value is written to the first coil then another

immediately to the second coil. FSC controller logic should be

programmed to make allowance for these two separate writes

operations.

Note that enabling Reverse for a status point will not reverse the

value recorded for any SOEs generated for that point.

33

Page 34

Chapter 3 - Honeywell FSC points reference

Example

Analog point

PV source 161 U4095 SER 1000

SP destination 162 U4095

Mode destination 25 1

Status point

PV source 26

Accumulator point

PV source 171 C16

IEEEFP formats for serial controllers

Format Description

IEEEFPB Bytes are big endian format (this is the same as IEEEFP)

IEEEFPBB Bytes are byte-swapped big endian format

IEEEFPL Bytes are little endian format

IEEEFPLB Bytes are byte-swapped little endian format

ATTENTION:

l IEEEFP numbers use two data addresses to hold the number,

address and address -1. Do not specify address -1 (the lower

address) as the point parameter address.

l When configuring PLC data tables, do not assign overlapping

data addresses if floating point values are used and do not set

an IEEEFP address to 1.

34

Data formats supported for Ethernet controllers

FSC types: BI, BO

Page 35

Chapter 3 - Honeywell FSC points reference

Format Description

S8B Short signed integer

S16B Signed word

S32B Signed long integer

IEEEFP IEEE Floating point

FSC types: AI, AO

Format Description

FSC020MA 0 - 20 mA

FSC420MA 4 - 20 mA

FSC05V 0 - 5 V

FSC15V 1 - 5 V

FSC010V 0 - 10 V

FSC210V 2 - 10 V

Scaling with data formats

Parameter values with addresses in the Input register and Holding

register data tables can be scaled with a data format. Select the

format that corresponds to the counts that have been set in the PLC

register.

ATTENTION: If auxiliary parameters have a data format type that

requires scaling (U4095, U999, and so on), they will take the

same range as the PV.

The data format tells the server how to interpret the register value.

Raw values in the PLC register tables can be scaled by the 0% and

100% point range values in order to convert them into engineering

units (EU).

To select a format for scaling, you select the format that corresponds

to the counts that have been set in the register where the point

parameter value is sourced.

35

Page 36

Chapter 3 - Honeywell FSC points reference

Figure 3-1: Scaling raw data

Address syntax for SOE only points

POS: Index SER SerNumber

Part Description

Index

SerNumber

The server's internal position allocated to this point. It must be unique.

Range = 1–8192

The SER number. See the topic titled "Assigning SER numbers for

sequence of events."

36

Page 37

CHAPTER

TROUBLESHOOTING HONEYWELL FSC

4

ISSUES

This section describes troubleshooting tasks for Honeywell FSC that

you can perform either on the server or from any Station.

In this section:

Accessing diagnostics for an Ethernet controller 38

Testing Honeywell FSC communications with the server 38

Troubleshooting Honeywell FSC communication errors for a serial

controller 41

Troubleshooting Honeywell FSC communication errors for an

Ethernet controller 41

37

Page 38

Chapter 4 - Troubleshooting Honeywell FSC issues

Accessing diagnostics for an Ethernet controller

System information and extended diagnostic data are accessible from

Station for FSC Ethernet controllers.

System information

To access FSC System Information, double-click the PV of an FSC

Ethernet controller point. Alternatively, click Details in the Controller

Status, which shows the Ext Diagnostics tab, then click the System Info

tab for the required link.

The system information and extended diagnostic information is

updated automatically every 50 seconds. You can manually refresh

the information by clicking the Refresh button.

If the diagnostic data cannot be retrieved from the FSC Ethernet

controller, the most recent diagnostic data from the controller will

continue to be displayed until the new data is obtained. If successive

attempts to obtain diagnostic data from the controller fail, then an

alarm message will be generated in the Alarm Summary.

Extended diagnostics

To access FSC Extended Diagnostics, click the Details button in the

Controller Status. This shows up to 18 extended diagnostics messages

for each FSC Ethernet controller link. Each message represents a

hardware or software fault associated with that particular controller.

If an extended diagnostic message is present for a controller, an

alarm with a value of Message(s) Available will be present in the Alarm

Summary. To see the Extended Diagnostic information for an alarm

from the Alarm Summary, double-click the alarm to call up the

Controller Status, then click the Details button.

Testing Honeywell FSC communications with the server

Two diagnostic utilities, fsctst (for serial controllers) and fscetst (for

Ethernet controllers), are included as part of the server software.

These utilities test communications between the server and an FSC

controller. Channels and controllers must be downloaded from Quick

Builder before testing.

38

Page 39

Chapter 4 - Troubleshooting Honeywell FSC issues

n The server need not be running while using the utility as long as

the database service is running. If making a connection through a

terminal server, the server daemon service should also be running.

n The server is not communicating with your controllers. The test

utilities might interfere with communications.

To stop the server, enter the command at a Command Prompt:

hscserver /load

Answer 'y' to every prompt. This unloads the server, but leaves the

database in memory.

39

Page 40

Chapter 4 - Troubleshooting Honeywell FSC issues

To run the fsctst utility

1. Open a Command Prompt window.

2. Type fsctst and then press Enter.

3. Follow the directions as prompted.

You can read and write data to all registers that can be addressed

by the server.

For help using the utility, type ?.

4.

To check if your controllers are present, use the find a,b

command. This command locates all FSC controllers on the

channel with IDs between a and b.

For example:

C:\>fsctst

Enter LRN or device name of channel

chn0001

Enter command:

find 1,4

FIND device with id 1 to 4, at 28-May-98

14:06:52

Device 1 ?

Device 2 ?

Device 3 ? ...responding

Device 4 ?

Enter command:

q

To the left of the channel name is the channel number. The name

of the channel will be the letters 'chn' followed by the channel

number. For example, your Honeywell FSC channel 'COM3' might

be channel number 1. Its device name will be 'chn0001.'

40

Page 41

Chapter 4 - Troubleshooting Honeywell FSC issues

To run the fscetst utility

1. Open a Command Prompt window.

2. Type fscetst and then press Enter.

3. Follow the directions as prompted.

You can read and write data to all registers that can be addressed

by the server.

For help using the utility, type ?.

Troubleshooting Honeywell FSC communication errors for a serial controller

If any errors are encountered, review the previous sections.

Error Description

0106 (Device Timeout) No response was received from the controller.

8102 (MODBUS error 2 - illegal

data address)

After you have verified that the server is communicating with the

controller, you can build points to reference controller addresses.

ATTENTION: Remember to enable the channel from the SCADA

Controllers display.

You either specified an illegal address or an illegal

number of addresses.

Troubleshooting Honeywell FSC communication errors for an Ethernet controller

Ensure scan packets are optimized. See the topic titled "Optimizing

Honeywell FSC scanning performance" for more information.

If there are several logical controllers on a channel, make sure that

there is no more than one that has SOE enabled.

41

Page 42

Chapter 4 - Troubleshooting Honeywell FSC issues

42

Page 43

NOTICES

Notices

Trademarks

Experion®, PlantScape®, SafeBrowse®, TotalPlant®, and TDC 3000® are

registered trademarks of Honeywell International, Inc.

ControlEdge™ is a trademark of Honeywell International, Inc.

OneWireless™ is a trademark of Honeywell International, Inc.

Matrikon® and MatrikonOPC™ are trademarks of Matrikon

International. Matrikon International is a business unit of Honeywell

International, Inc.

Movilizer® is a registered trademark of Movilizer GmbH. Movilizer

GmbH is a business unit of Honeywell International, Inc.

Other trademarks

Microsoft and SQL Server are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or

other countries.

Trademarks that appear in this document are used only to the benefit

of the trademark owner, with no intention of trademark infringement.

Third-party licenses

This product may contain or be derived from materials, including

software, of third parties. The third party materials may be subject to

licenses, notices, restrictions and obligations imposed by the licensor.

The licenses, notices, restrictions and obligations, if any, may be found

in the materials accompanying the product, in the documents or files

accompanying such third party materials, in a file named third_party_

licenses on the media containing the product, or at

https://www.honeywell.com/en-us/privacy-statement..

Documentation feedback

You can find the most up-to-date documents on the Honeywell

Process Solutions Support website at:

http://www.honeywellprocess.com/support

43

Page 44

Notices

If you have comments about Honeywell Process Solutions

documentation, send your feedback to: hpsdocs@honeywell.com

Use this email address to provide feedback, or to report errors and

omissions in the documentation. For immediate help with a technical

problem, contact HPS Technical Support through your local

Customer Contact Center, or by raising a support request on the

Honeywell Process Solutions Support website.

How to report a security vulnerability

For the purpose of submission, a security vulnerability is defined as a

software defect or weakness that can be exploited to reduce the

operational or security capabilities of the software.

Honeywell investigates all reports of security vulnerabilities affecting

Honeywell products and services.

To report a potential security vulnerability against any Honeywell

product, please follow the instructions at:

https://www.honeywell.com/en-us/product-security.

Support

For support, contact your local Honeywell Process Solutions

Customer Contact Center (CCC). To find your local CCC visit the

website, https://www.honeywellprocess.com/en-US/contact-

us/customer-support-contacts/Pages/default.aspx.

Training classes

Honeywell holds technical training classes that are taught by process

control systems experts. For more information about these classes,

contact your Honeywell representative, or see

http://www.automationcollege.com.

44

Loading...

Loading...