Page 1

E528 Smart Digital Thermostat Product Guide

Table of Contents

E528 Product Guide

Table of Contents .............................................. Page 1

Overview and General Concept ......................... Page 2

Application ......................................................... Page 2

Wireless Communication ................................... Page 4

Installation Requirements .................................. Page 4

Mounting ............................................................ Page 5

Input/Output ....................................................... Page 6

E528.4G New Installation .................................. Page 8

Wiring ................................................................ Page 10

Load Specifications ........................................... Page 13

FCC Information ................................................ Page 13

Technical Specifications .................................... Page 14

Document Revision History ............................... Page 15

Rev 8.0 12/16/2016 1

Page 2

E528 Product Guide

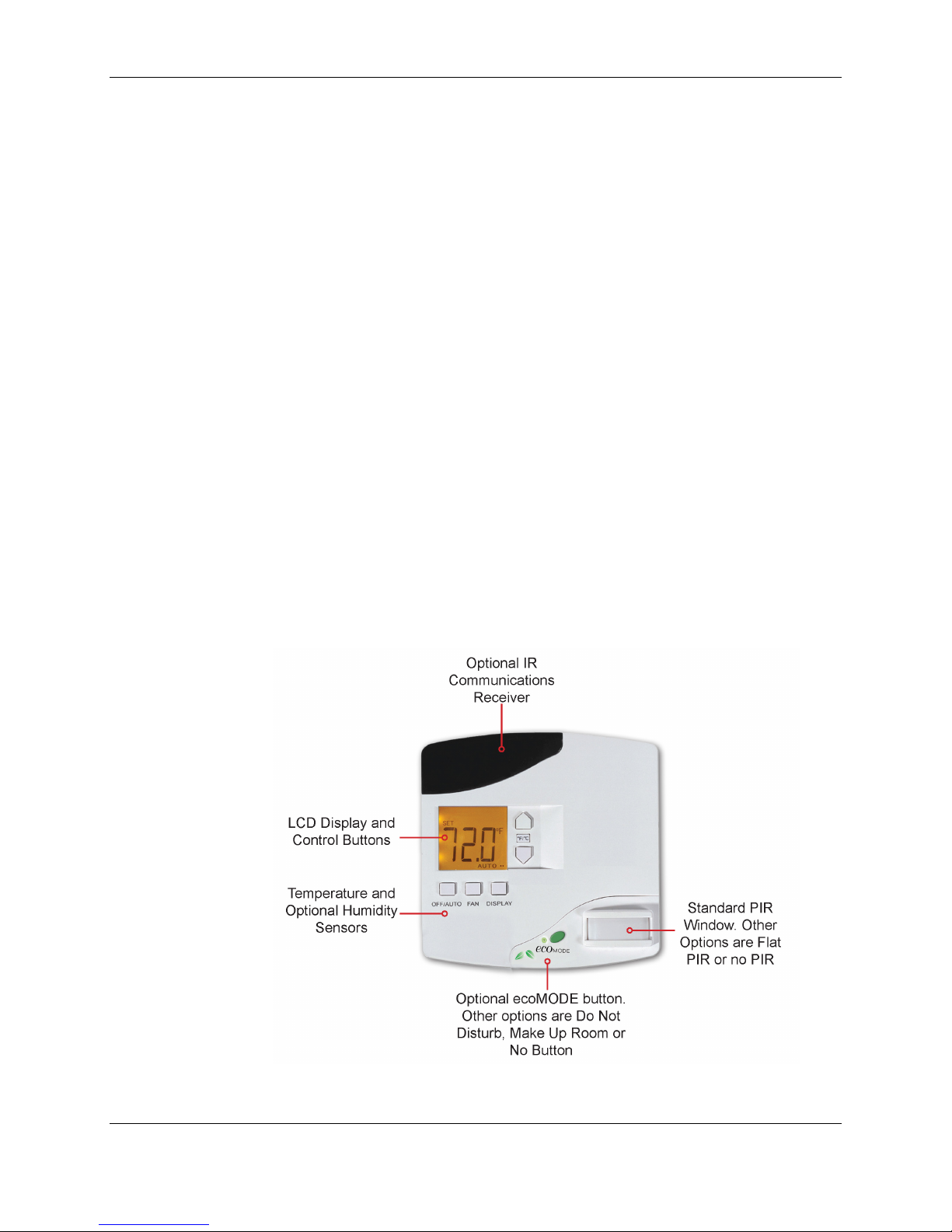

Figure 1. E528 Digital Thermostat

Overview and

General Concepts

INNCOM's e4 Smart Digital Thermostat is a powerful, multi-purpose Direct

Digital Control (DDC) device that can control virtually any HVAC system found

in hotel guestrooms.

The three e4 models meet different application requirements. The e528 and

e527 are wired and are typically used for new installation. The e529 is batterypowered and is designed to meet the needs of existing properties where

rewiring is not practicable.

This document describes Model e528; information on the e529 and e527 can

be found in their respective product guides.

Application

In its most basic form, the e528 functions as a programmable DDC thermostat,

automatically adjusting fan speeds and valves to achieve set temperature

(Note: Guests can manually select heat or cool by pressing the OFF/AUTO

button and cycling through OFF, AUTO, HEAT and COOL). The e528 is also

an “intelligent” device capable of linking ancillary sensors and serving as an

information gateway. For example, coupled with a magnetic door switch (wired

or wireless), motion detectors, and other devices, the e528 becomes the brain

of a highly effective Energy Management System (EMS) application,

communicating EMS information requirements to central servers. It comes

standard with five relays and can be equipped with an on-board Infrared (IR) or

radio frequency (RF) transceiver and Passive Infrared (PIR) motion detector.

The e528 interfaces with all common HVAC unit voltage configurations (24 volt

to 277 volt). The e528 can be installed in a wired or wireless INNCOM

guestroom control system, which makes installation feasible and affordable in

either new construction or retrofit installations.

Through interfaces with other devices and sensors, the e528 supports the

following functions:

Rev 8.0 12/16/2016 2

Page 3

E528 Product Guide

Figure 2. E528 Graphic Interface

Remote HVAC control

• Guestroom HVAC diagnostics

• Remote room occupancy indication

• Automatic lighting control

• Remote mini-bar access reporting

• Remote smoke detector annunciation

• Central Electronic Lock control

• Humidity control

• Remote drape control

• Outside temperature display

• Peak demand load shedding

• Property/Building Management System (PMS/BMS) interface

A centrally controlled EMS package is created when the e528 is connected to

the property's Central Interface Network (CINET) with a pair of low voltage

wires or by the property’s high-speed TCP/IP network with the addition of a

TCT (an Ethernet gateway device). RF networking is possible with radio

equipped models.

The e528 features a guest-friendly graphic interface with intuitive controls

(Figure 2). A user guide for the e528, written primarily for installers and facility

management personnel, is available (see References below).

Rev 8.0 12/16/2016 3

Page 4

E528 Product Guide

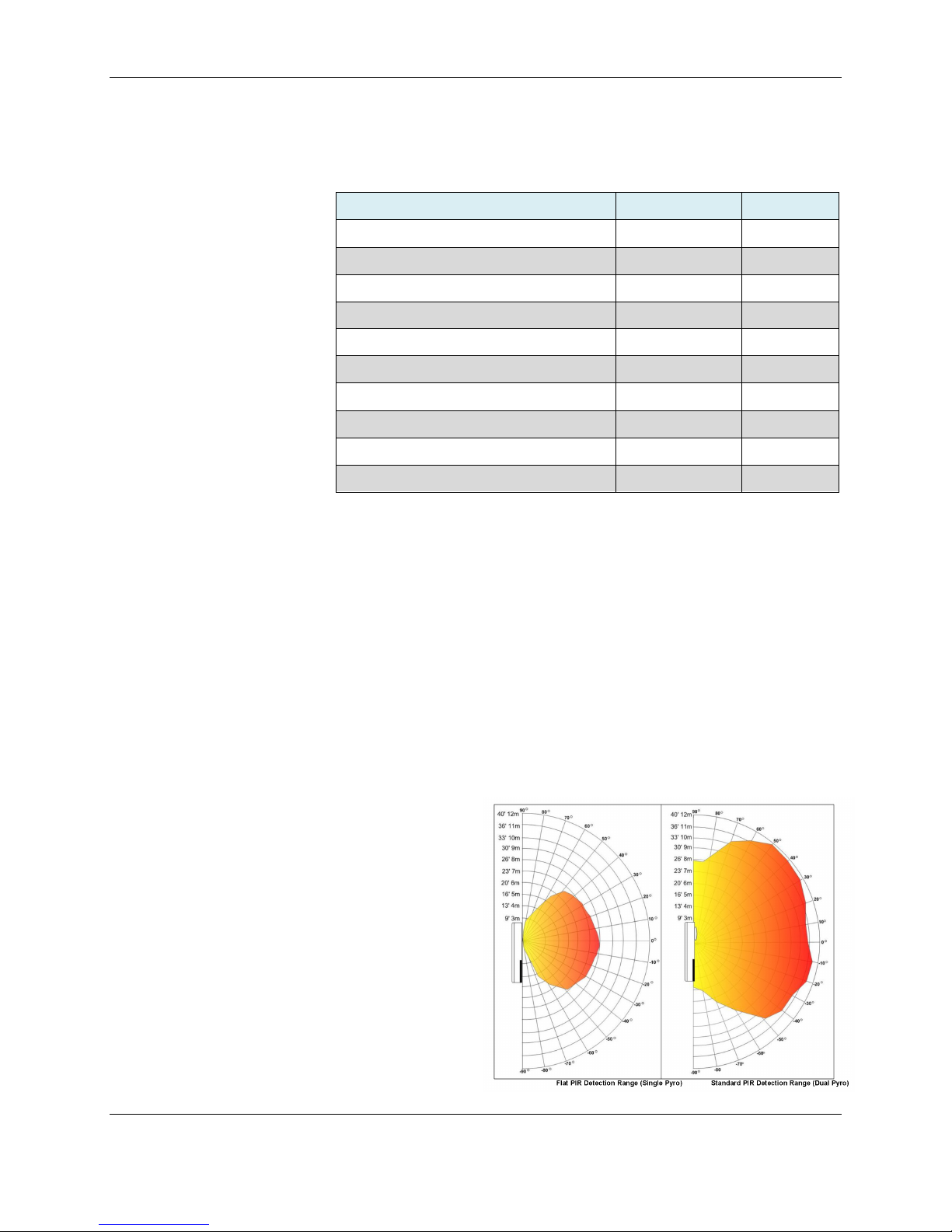

Figure 3. PIR

Wireless Communication

2.4HHz Wireless RF

Table 1 e528 RF Characteristics

Performance 0dB 20dB

RF Data Rate 250kbps 250kbps

Antenna Type SMT SMT

Indoor Range 70ft 100ft+

Outdoor/RF line-of-site range 540ft 1000ft+

Transmit Power 1mW 10mW

Receive Sensitivity -94.6dBm -94.6dBm

Frequency Band 2.4GHz 2.4GHz

Encryption AES-128 AES-128

Protocol 802.15.4 802.15.4

Frequency Channels 11-26 11-26

Installation Requirements

Location: The e528 must be located on a partitioning interior wall,

approximately 1.5 m (5 ft) above the floor, in a site of average

temperature. It is important to ensure that the thermostat is located away

from direct sunlight or radiant heat, air discharge grills, stairwells, outside

doors, steam or water pipes, warm air stacks, unheated/uncooled areas,

or sources of electrical or radio interference. The unit should not be

placed on an outside wall or behind a door. It is essential that the e4 is

mounted flush to the wall and mounted level in both the horizontal and

vertical planes; incorrect mounting can degrade IR, PIR, and

temperature measurement performance.

Installation Requirements for e4

equipped with PIR Motion Detection

The e4 thermostat can be equipped with a PIR

detector to augment the energy management

scheme by detecting motion in the guestroom.

Consider the PIR’s view angle, range

characteristics, and mounting position to ensure

proper coverage. Figure 3 below shows the ranges

of the flat and standard PIRs.

Rev 8.0 12/16/2016 4

Detection Ranges

Page 5

E528 Product Guide

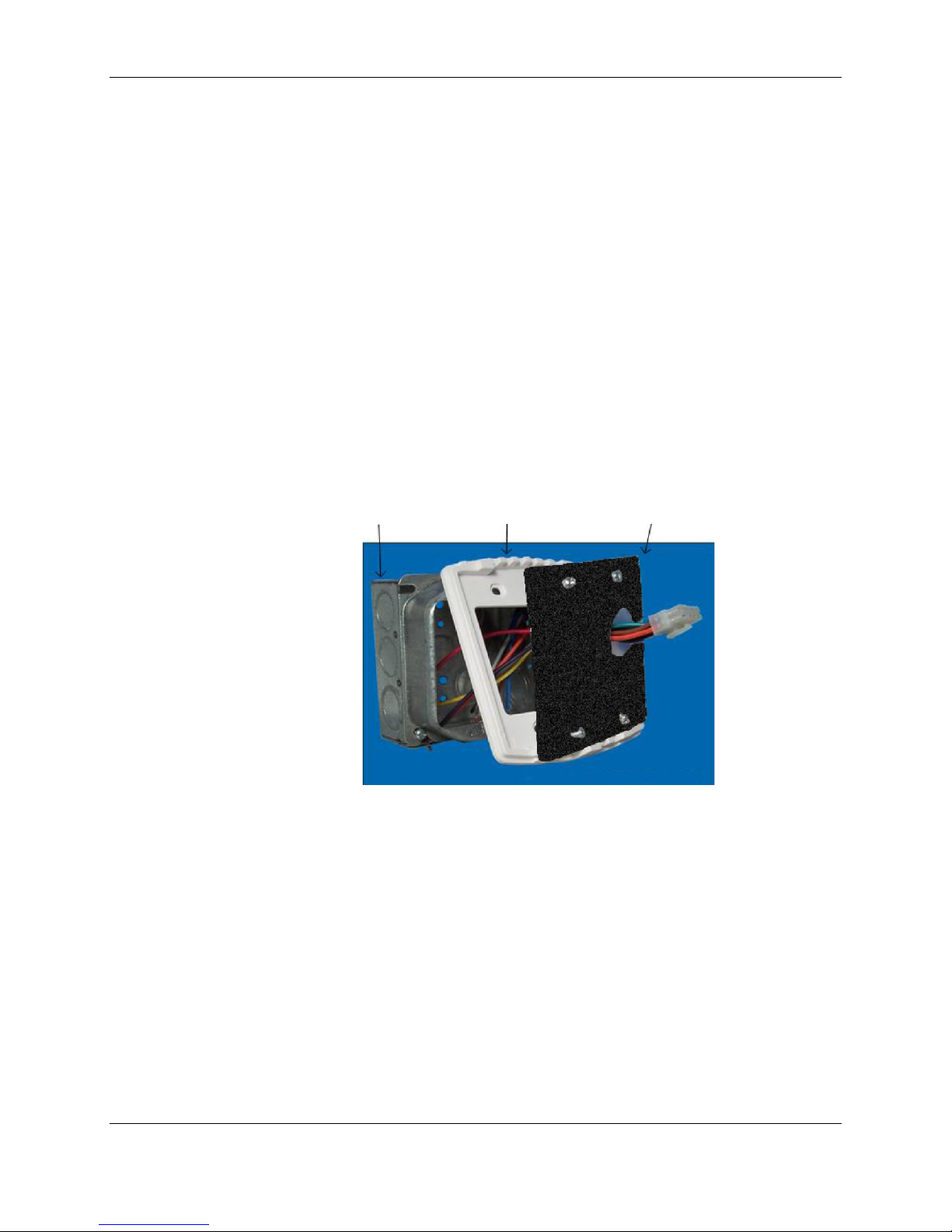

Figure 4 Mounting Assembly

Mounting Box Back Mounting Plate Back Plate Insulator

Mounting

The e528 is usually mounted on a standard double-gang (4 x 4) junction box. If

mounted on a single-gang box, the left side (display side) of the e528 overlaps

the wall area to the left of the junction box. A low-voltage mounting plate, mud

ring, or low-voltage caddy may be used for mounting 24 volt applications.

To mount the e528:

1. Remove the two small screws at the base of the e528.

2. Pull the bottom of the back-mounting plate slightly away from the front

housing and then pull the back-mounting plate down.

3. Position the back plate insulator within the mounting plate as shown i

F

igure 4.

4. Attach the mounting plate to the junction box, using the mounting screws

provided with the e528. Ensure that the plate is mounted with the rais

arrow pointing UP.

n

ed

To simplify installing and removing the e528, the headers and sockets

described below and shown in Figure 5 are located on the back of the

e528. These accept pre-made wiring harnesses provided by INNCOM.

(Note: Take care to note which e528 model is being used. Each model

has slightly changed headers and connectors as identified in the

drawings on the next page.)

Rev 8.0 12/16/2016 5

Page 6

E528 Product Guide

E528 3G headers

E528 4G headers

10-pin Molex

10-pin Molex

valve signals.

H1 – Microprocessor Programming

Socket Accepts

the 10 pin Molex

plug pre-wired

with 8” colorcoded leads.

Connect to the

HVAC unit’s

power, fan and

H1 – External Temperature Control Sensor

H2 – Power Input

H4 – IR Eye 5

H5 – Microprocessor Programming

H6 – PIR Sensor

H7 – Humidity Sensor

H8 – ES1 Key

H9 – Low Voltage Comm/Device Connection

H10 – RF Programming

Socket Accepts

the 10 pin Molex

plug pre-wired

with 8” colorcoded leads.

Connect to the

HVAC unit’s

power, fan and

valve signals.

H3 – External Temperature Control Sensor

H4 – Power Input

H5 – RS485 Network

H6 – ES1 Key

H7 – Low Voltage Comm/Device Connection

H8 – PIR

H9 – IR Eye 5

Input/Output

The I/O headers for the e528.3G* and 4G* thermostats are substantially

different (see Figure 5 above). The statements and table below detail only the

headers that differ in function.

Low Voltage comm / device connector: This header accepts the provided 6pin harness used to connect low voltage communication, door/window position

switch, and other room devices to the e528. Table 3 shows pinout and function

for the 3G and 4G. For specifics, refer to the as-built wiring diagrams.

* “3G,” and “4G” are internal INNCOM product designations used for convenience to differentiate

individual hardware configurations. No difference in device capability or effectiveness is implied.

Due to end-of-life for certain 3G components, the e528.4G is now the standard INNCOM install,

but 3G installations are still supported.

Rev 8.0 12/16/2016 6

Page 7

E528 Product Guide

Wire Color

Female

Male

Function

Comment

Red

2 2 12VDC Out/In

12VDC Supply

Yellow

4 4 IN 1

Door, Window, PIR, Other

Blue

6 6 CNET A

RS485 Twisted Pair

Table 3. E528 3G/4G Low Voltage Harness (P/N 62-1467) Pinout

Connector

Connector

Brown 1 1 Common GND

Orange 3 3 S5Bus Data Tx/RX or IN 2 Communication Bus

Green 5 5 CNET B RS485 Twisted Pair

External temperature control sensor: This header accepts the wiring

harness from an external temperature probe that can be used to supply the

e528 with remote temperature measurements. The e528 uses a 10K 1%

thermistor for external temperature measurement. This external temperature

sensor can be used to monitor room temperature at a different location from

where the e528 is mounted or to monitor pipe water temperature.

RS485 Networks: (refer to Figure 5)

E528.3G cannot act as the media gateway for in-room traffic towards the

RS485 network. The most common way to connect the e528.3G is to connect

a PC-485.S5 (P/N: 01-9905) on the S5bus.

E528.4G to 2G RS485 Networked Application: with or without door switch

input (See Figure 6)

• Using the adapter (P/N 203-251), connect the harness from the wall

box (P/N 62-1462) previously connected to the thermostat being

replaced to H1 of the adapter.

• Connect the harness H3 (rainbow) of 203-251 to the low voltage

comm/device connection of the e528.4G

• Connect the harness H2 (black) of 203-251 to the RS485 header of the

e528.4G

NOTE: Take care to not reverse the connections to the e528.4G!

Rev 8.0 12/16/2016 7

Page 8

E528 Product Guide

Figure 6. 4G to 2G RS485 Networked Application

Figure 7. E527 4G New RS485

Networked Application

E528.4G New Installation

Stand alone application with/without door switch input

• Using the harness (P/N 62-1467), make the appropriate wire

RS485 Networked Application with/without door switch input

(See Figure 7)

• Using the harness (P/N 62-1467), make the appropriate wire

• Using the adapter (P/N 203-250) and P/N 62-1532-B.12 cables,

• RS485 In header and the RS485 B pair going to the next thermostat to

• Connect the harness of 203-250 to the RS485 network header of the

connections, then plug the harness into the low voltage comm/device

connection of the e528.4G

connections, then plug the harness into the low voltage comm/device

connection of the e528.4G.

connect the RS485 A pair to the two pin

RS485 Out header on the 203-250.

e528.4G.

Rev 8.0 12/16/2016 8

Page 9

E528 Product Guide

Figure 8 E528.4G to 2G standalone application

The e528.4G can be used to retrofit an application where a legacy e528 was used. Follow the procedure

below:

4G to 2G Standalone application: with/without door switch input (no backhaul network)

• Using the adapter (P/N 203-013) connect the harness from

the wall box (P/N 62-1462) previously connected to the

thermostat being replaced to H1 of the adapter

(see Figure 8).

• Connect the harness of 203-013 to the low voltage

comm/device connection of the e528.4G.

Molex 10-position female socket: This female socket

accepts the provided 10-pin Molex connector pre-wired with 8inch, color-coded wiring leads. These leads should be

connected to the 24VAC or 100–277VAC power, valve/fan

control wiring from the FCU, or other HVAC device with wire

nuts inside in the wall junction box in accordance with the

wiring diagram provided by INNCOM.

Note: For installations in which all leads are not required,

the extraneous leads should be cut off at the Molex

connector.

Figure 8 shows the pinout for the 10-position Molex male connector supplied with all relay output models

of the thermostat. The end view of the male connector from the wire insertion side with the pin numbers is

indicated. This is the same as looking at the female connector point on the back of the e528.

Typical functions for each wire are listed in Tables 4 and 5. For specifics, refer to the as-built wiring

diagrams.

Rev 8.0 12/16/2016 9

Page 10

E528 Product Guide

3

Black

Common

5

Brown

Medium Fan or Second Stage Heat

1

Green

Ground

3

White

Neutral

7

Brown

Hot Water Valve (FCU) or Reversing Valve

9

Violet

Fan Power

Table 4. 24VAC Harness Color Code, Pinout, and Typical Functions

24VAC Harness

Table 5. 100-277VAC Harness Color Code, Pinout,

Pin Color Typical Function

1 Green Ground

2 Red 24VAC

4 Blue High Fan

6 Yellow Cold Water Valve (FCU) or Compressor Signal

(Heat Pump)

7 White Hot Water Valve (FCU) or Reversing Valve

(Heat Pump)

8 Grey Valve Power

9 Violet Fan Power

10 Orange Low Fan

Wiring

and Typical Functions

100-277VAC Harness

Pin Color Typical Function

2 Black Line

4 Yellow High Fan

5 Orange Medium Fan or Second Stage Heat

6 Red Cold Water Valve (FCU) or Compressor Signal

(Heat Pump)

(Heat Pump)

8 Grey Valve Power

10 Blue Low Fan

The steps below provide an overview of the wiring process. Refer to the asbuilt wiring diagrams provided for exact details.

1. If applicable, use wire nuts to connect the 6-pin low-voltage harness wires

to the applicable low-voltage communication (if e528 is part of a wired

Rev 8.0 12/16/2016 10

Page 11

E528 Product Guide

RS485 centrally controlled system), door/window switch, or external PIR

wiring within the electrical box (Figure 8). Plug the 6-pin low voltage

harness onto the e528 low voltage comm. / device connection header.

2. Use wire nuts to connect the 10-pin Molex wiring harness to the power and

valve/fan control signal wires within the electrical box.

3. Plug the pre-wired 10-pin connector into the female receptacle at the back

of the e528.

4. Hook the tabs at the top rear of the e528 housing into the matching

depressions at the top of the mounting plate and rotate the bottom of the

housing toward the wall until it snaps into place on the mounting plate.

5. Secure the housing to the mounting plate with the two small screws

removed in Step 1 of the Mounting section.

6. Apply power to the e528 by closing the applicable supply breaker. Verify

that the e528 powers up. Several values should begin appearing on the

LCD display.

7. Once installed and connected to power, the e528 Digital Thermostat

typically requires some configuration, specifically:

• If installing the e528 as part of a networked, centrally controlled EMS,

a unique network address must be assigned to the e528. This is done

by entering Service Parameter mode on the e528 and changing the

values of Parameters 10, 11, and 12, which hold the 5-digit network

address of the e528. This 5-digit number is typically the room number

in most applications. A “Room List” document is typically available that

lists all rooms and the associated values to set into Parameters 10, 11,

and 12. Refer to Reference A, Section 5.1, for complete instructions for

setting the e528 network address.

• If the particular HVAC equipment installed was not known when the

e528 was shipped, the fan and heat/cool control outputs of the e528

must be configured to correctly operate the installed HVAC equipment.

Setting the appropriate HVAC control parameters of the e528 to the

required values and resetting the device reconfigures the e528 to

properly control most HVAC units. Refer to Reference A, Section 5.2,

for instructions on changing the e528 HVAC related parameters.

NOTE: If installing 01-9560 64K memory e528 Digital Thermostats, be aware

that these devices support the INNCOM ES-1 Flash Memory Module. The ES1 provides the ability to copy HVAC related parameter settings from a “golden”

e528 that has previously been installed in a room and had its HVAC related

parameters set correctly and verified operationally with the HVAC equipment.

Once these settings are copied to the ES-1 module, plugging the ES-1 into a

new thermostat automatically uploads the settings.

Rev 8.0 12/16/2016 11

Page 12

E528 Product Guide

Figure 10 Electrical Box Connections Line and Low Voltage

Low-voltage

24VAC or 100-277

To E528 H9 header

To E528 10-pin Molex Socket

Wiring

regulations

E528 Framing Plate

Physical Separator

Figure 11. Electrical Box Connections 24VAC

24-volt and ground wires must

size wire nuts

24-volt transmitter

Low-voltage

external PIR wiring

24 VAC or 100-277

24-volt and ground

To E528 low voltage comm header

To the E528 10-pin Molex Socket

communication

door/window switch,

external PIR wiring

connections

should follow

the National

Electric Code

and adhere to

all local

power, valve/fan

control from HVAC

equipment

be routed to the low voltage side

of the box, passing over the top

of the physical separator. They

should be connected on the low-

voltage side with appropriate

communication

door/window switch,

VAC power

valve/fan control

wiring from HVAC

equipment

wires (shown in plum

for emphasis) MUST

PASS OVER the

physical separator to

the low voltage side

Rev 8.0 12/16/2016 12

Page 13

E528 Product Guide

Heat Relay

3 amps

3 amps

24 VA PD

24 VA PD

24 VA PD

3 amps

3 amps

3 amps

3 amps

High Fan

3 amps

3 amps

2.2 LLA

2.2 LLA

2.2 LLA

2.2 LLA

3 amps

3 amps

Low Fan

3 amps

3 amps

2.2 LLA

2.2 LLA

2.2 LLA

2.2 LLA

Table 6. Load Specifications

Load Specifications

The following load specification table (Table 6) describes the submitted load

characteristics for testing and UL certification of UL 873. The device complies

with the requirements of CAN/CSA C22.2 No. 24-93.

Model e528-A2L2-

I0P0-00WH

Voltage 24VAC 24VAC 24VAC 100-240VAC 220-277VAC 100-277VAC

K4-5

Cool Relay

K4-5

Relay K1

Medium

Fan Relay

K2-3

Relay K2-3

125-277VAC

General purpose

125-277VAC

General purpose

125-277VAC

General purpose

125-277VAC

General purpose

125-277VAC

General purpose

e528-A3L2-

I0P0-00WH

125-277VAC

General purpose

125-277VAC

General purpose

125-277VAC

General purpose

125-277VAC

General purpose

125-277VAC

General purpose

e528-A1L2-

I0P0-00WH

24 VA PD 24 VA PD 24 VA PD

13.2 LRA

2.2 LLA

13.2 LRA

13.2 LRA

e528-B0L2-

I0P0-00WH

13.2 LRA

2.2 LLA

13.2 LRA

13.2 LRA

e528-C0L2-

I0P0-00WH

13.2 LRA

2.2 LLA

13.2 LRA

13.2 LRA

e528-B1L2-I0P0-

00WH

125-277VAC

General purpose

125-277VAC

General purpose

13.2 LRA

2.2 LLA

13.2 LRA

13.2 LRA

MFCC ID: GTC202150TXR, or GTC202152TXR

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one of the

following measures:

Rev 8.0 12/16/2016 13

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Page 14

E528 Product Guide

Any changes or modifications not expressly approved by the party responsible

for compliance could void the user's authority to operate this equipment.

IC ID: 1609A-202150TXR, or 1609A-202152TXR

This device complies with Industry Canada license-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d’industrie Canada applicables aux

appareils radio exempts de licence. L’exploitation est autorisée aux deux

conditions suivantes: (1) l’appareil ne doit pas produire de brouillage, et (2)

l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d’en compromettre le fonctionnement.

Technical Specifications

Table 7. Technical Specifications

Power Requirements 24 VAC at 50/60 Hz, 24 VDC nominal, 2.4 VA (e528-3xx/7xx and e528-4xx)

100 to 277 VAC at 50/60 Hz, 2.4 VA (e528-8xx)

Relay Contact Rating See Table 4.

Triac Relay Contact Rating 50 m at minimum, 250 m at maximum (e528-4xx)

Recommended Wire Size 18 gauge

Thermostat Measurement Range 33 to 99 degrees F (1 to 37 degrees C)

Outdoor Air Temperature 0 to 99 degrees F (-18 to 37 degrees C)

Display Resolution Whole degree F, 0.5 degree C (0.1 degree F in test mode)

Degrees C/Degrees F Display Toggle Button located on front display

Standard Deadband 2 degrees F (1 degree C) between heating and cooling

Ambient Operating 41 to 149 degrees F (5 to 65 degrees C), 0-95% RH noncondensing

Ambient Storage 33 to 149 degrees F (1 to 65 degrees C)

Dimensions (H x W x D) 4.7 x 4.7 x 1.2 in. (120 x 120 x 30 mm)

Shipping Weight 0.6 lb (0.27 kg)

Approvals L listed #873, CAN/CSA C22.2 No. 24-93 File #E202540/Part 15 of the FCC Rules

RF Specifications See TXT RF Product Guide

Rev 8.0 12/16/2016 14

Page 15

E528 Product Guide

REVISION

DATE ISSUED

REASON FOR CHANGE

v5

30-Jun-2008

Error in Figure 4 corrected; font discrepancies corrected.

v6.2

28-Oct-2010

Added 3G pinout note

Document Revision History

First issue 26-Apr-2006

v1 30-Jul-2007

v2 Not issued Product photos updated. Part number corrected. Figure 3 redrawn.

v3 27-Jun-2008

v4 30-Jun-2008 Switched to new document format.

v6 18-Feb-2010 Reformatted to new template, RF data updated

v6.1 22-Apr-2010 OP/N rewritten to include old scheme; photos updated.

v7.0 05-Apr-2012 Added 4G information

v7.1 18-Dec-2012 Revised FCC/IC statements

v7.2 12-Feb-2013 Removed ordering information

V7.3 10-Feb-2014 Updated connector photos

V8 15-Dec-2016 Reformat to HON branding. Remove G2 Legacy info

The material in this document is for information purposes only. The content and the product it describes are subject to change without notice.

Honeywell makes no representations or warranties with respect to this document. In no event shall Honeywell be liable for technical or editorial

omissions or mistakes in this document, nor shall it be liable for any damages, direct or incidental, arising out of or related to the use of this document.

No part of this document may be reproduced in any form or by any means without prior written permission from Honeywell.

Copyright © 2016 by Honeywell International, Inc. All Rights Reserved.

Honeywell I 277 W est Main Street I Niantic, CT 06357 I Phone: 1.860-739-4468 I www.INNCOM.com

Rev 8.0 12/16/2016 15

Reformatted for consistency with other product guides. Information about the

other e4 models added to the Overview section. Information on all ordering

options and new features added to the Ordering section.

New Figure 2 added (PIR range figures) and figure numbers changed to

accommodate the added figure.

Loading...

Loading...