Page 1

GasBook

Honeywell Gas Detection

Page 2

1

Introduction

The Gas Book is intended to offer

a simple guide to

anyone considering the

use of xed and portable

gas detection equipment.

The aim has been to provide a complete

and comprehensive introduction to the

subject– from detailing the principles of

detection that different devices employ to

providing information on certications

and application suitability.

A diverse variety of applications

and processes increasingly involve

the use and manufacture of highly

dangerous substances, particularly

ammable, toxic and Oxygen gases.

Inevitably, occasional escapes of

gas occur, which create a potential

hazard to the industrial plants, their

employees and people living nearby.

Worldwide incidents, involving

asphyxiation, explosions and loss of

life, are a constant reminder of this

problem.

2

www.honeywellanalytics.com / www.gasmonitors.com2 www.honeywellanalytics.com

www.honeywellanalytics.com / www.gasmonitors.com

n most industries, one of the key parts of any safety plan for reducing

risks to personnel and plant is the use of early warning devices such

as gas detectors. These can help to provide more time in which to take

I

remedial or protective action. They can also be used as part of a total,

integrated monitoring and safety system which may include various other

safety aspects including fire detection and emergency process shutdown.

Gas detection can be divided into two overriding categories; fixed gas

detection and portable gas detection. As the name might suggest, fixed gas

detection represents a static type of detection system for flammable, toxic

and Oxygen gas hazards and is designed to monitor processes, and protect

plant and assets as well as personnel on-site.

Portable gas detection is designed specifically to protect personnel from

the threat of flammable, toxic or Oxygen gas hazards and is typically a

small device worn by an operator to monitor the breathing zone. Many sites

incorporate a mix of both fixed and portable gas detection as part of their

safety philosophy, but the suitability of which type to use will depend on

several factors, including how often the area is accessed by personnel.

Page 3

Contents

Section Subject Page Section Subject Page

1 Introduction 2

2 Honeywell Gas Detection brands 4-5

3 What is gas? 6

4 Gas hazards 7

5 Flammable gas hazards 8

Flammable limit 9

Flammable gas properties 10-11

Flammable gases data 12-19

6 Toxic gas hazards 20

Workplace exposure limits 21

Toxic exposure limits 22-25

Toxic gases data 26-29

7 Asphyxiant (Oxygen deciency) hazard 30

8 Oxygen enrichment 31

9 Typical areas that require gas detection 32-35

10 Principles of detection 36

Combustible gas sensor 36

Catalytic sensor 36

Speed of response 37

Sensor output 37

Calibration 38

Infrared gas detector 39

Open path ammable infrared gas detector 40

Electrochemical cell sensors 41

Photo Ionised Detection (PID) 42

Chemcassette

Comparison of gas detection techniques 43

11 Selecting gas detection 44-45

12 Maximising time and efciency 46-47

13 Communications protocols 48-49

14 Fixed gas detection from Honeywell 50-51

15 Portable gas detectors 52

Why are portable gas detectors so important? 54

Breathing zone 55

Typical gases requiring portable detection 55

Portable gas detector types 56

Operational modes of a gas detector 56

Features and functionality 57

Accessories 58

Alarms and status indication 59

Typical applications for portable gas detectors 60

Conned spaces 60-61

Marine 62

Water treatment industry 63

Military 64-65

Hazardous Material (HAZMAT)

emergency response 66

Oil and gas (on and offshore) 67

PID Information 68

Measuring Solvent, Fuel and VOC Vapour

in the workplace environment 68-71

Maintaining portable gas detection 72

Reducing the cost of device testing 73

How to perform a manual bump test 73

Portable gas detectors from Honeywell 74-75

16 North American hazardous area standards

and approvals 76

North American Ex marking and

area classication 77

17 European hazardous area standards

and approvals 78-79

®

sensor 42

18 ATEX 80-81

19 Area classication 86-87

20 Apparatus design 88-89

21 Apparatus classication 90-91

22 Ingress protection of enclosures 92-93

23 Safety integrity levels (SIL) 94-95

24 Gas detection systems 96-97

Location of sensors 98-99

Typical sensor mounting options 100

Typical system congurations 100-101

25 Installation 102

26 Gas detection maintenance and ongoing care 106-109

27 Glossary 110-113

IEC Standards 82-83

Equipment markings 84-85

3

Page 4

2

Honeywell Gas

Detection brands

At Honeywell Analytics our key focus is our customers. We believe that the evolution

of gas detection should be driven by the people using our equipment, rather than

engineers deciding the needs of industry. With this in mind, we listen to what our

customers want, rene our solutions to meet changing demands and we grow as our

customers grow to ensure we are able to provide an added value service that meets

individual requirements.

Working with Industry…

since the birth of gas detection

ith 50 years experience in the industry, we have been

inuential in gas detection since the very beginning.

Many of our historic products set new benchmarks

W

use and innovation. Today, our product lines have evolved to meet

the requirements of diverse industries and applications, delivering

comprehensive solutions designed to drive down the cost of gas

detection, whilst providing enhanced safety.

for gas detection in terms of performance, ease of

Our Technical Support Centre and Product Application and Training

Specialists, eld engineers and in-house engineering support represent

some of the very best the industry has to offer, providing over 1,100

years cumulative expertise, allowing us to deliver local business

support on a corporate scale.

4 www.honeywellanalytics.com / www.gasmonitors.com

Page 5

GAS

FACT

The word gas was

coined in 1650–60 by

J. B. van Helmont

(1577–1644), a Flemish

chemist. It comes from

the Greek word

for chaos.

W Technologies by Honeywell is a World leader in the gas

detection industry with a strong commitment to providing

customers with high performance, dependable portable

B

service and ongoing support.

We design, manufacture and market innovative portable gas detection

solutions for a wide variety of applications and industries, with options

to suit all budgets and hazard monitoring requirements.

Our comprehensive range includes options from single gas units that

require no ongoing maintenance, to feature-rich multi-gas devices that

deliver additional value-added functionality.

As a leading expert in the eld of portable gas detection, we provide

customised on-site/eld based training to meet specic customer

needs and application support to assist customers with the selection

and integration of solutions that are entirely t for purpose.

When it comes to device care, we also offer cost-effective benchmark

support and maintenance through our comprehensive approved

partner network.

products that are backed up by exceptional customer

Delivering value added solutions at

affordable prices for 25 years

BW Technologies by Honeywell was originally established in 1987

in Calgary, Canada. Over the last 25 years, we have been bringing

innovative gas detection solutions to market that add value, enhance

safety and help to reduce the ongoing cost of portable gas detection.

With ofces all over the World, and a diverse and talented team of

industry experts on hand to provide support to customers, we offer a

large corporate infrastructure supported by locally focused teams that

have a unique understanding of industry and applications as well as

regional needs.

5

Page 6

3

What is

Gas?

The name gas comes from the word

chaos. Gas is a swarm of molecules

moving randomly and chaotically,

constantly colliding with each other

and anything else around them. Gases

ll any available volume and due to the

very high speed at which they move will

mix rapidly into any atmosphere

in which they are released.

Vehicle engines

combust fuel

and Oxygen and

produce exhaust

gases that

include Nitrogen

Oxides, Carbon

Monoxide and

Carbon Dioxide.

Different gases are all around

us in everyday life. The air we

breathe is made up of several

different gases including

Oxygen and Nitrogen.

Air Composition

The table

gives the

sea-level

composition

of air (in

percent by

volume at the

temperature of

15°C and the

pressure of

101325 Pa).

Name Symbol Percent by Volume

Nitrogen N2 78.084%

Oxygen O

Argon Ar 0.934%

Carbon Dioxide CO

Neon Ne 0.001818%

Methane CH

2 20.9476%

2 0.0314%

4 0.0002%

Helium He 0.000524%

Krypton Kr 0.000114%

Hydrogen H

Xenon Xe 0.0000087%

6 www.honeywellanalytics.com / www.gasmonitors.com

2 0.00005%

Page 7

4

Gas

Hazards

There are three main

types of gas hazard:

Gases can be lighter,

heavier or about the same

density as air. Gases

can have an odour or

be odourless. Gases

can have colour or be

colourless. If you can’t

see it, smell it or touch it,

it doesn’t mean that it is

not there.

Flammable

RISK OF FIRE

AND/OR EXPLOSION

e.g.

Methane,

Butane, Propane

Toxic

RISK OF

POISONING

e.g.

Carbon Monoxide,

Hydrogen, Chlorine

Natural Gas (Methane) is used

in many homes for heating

and cooking.

Asphyxiant

RISK OF

SUFFOCATION

e.g.

Oxygen deciency. Oxygen

can be consumed or

displaced by another gas

!

7

7

Page 8

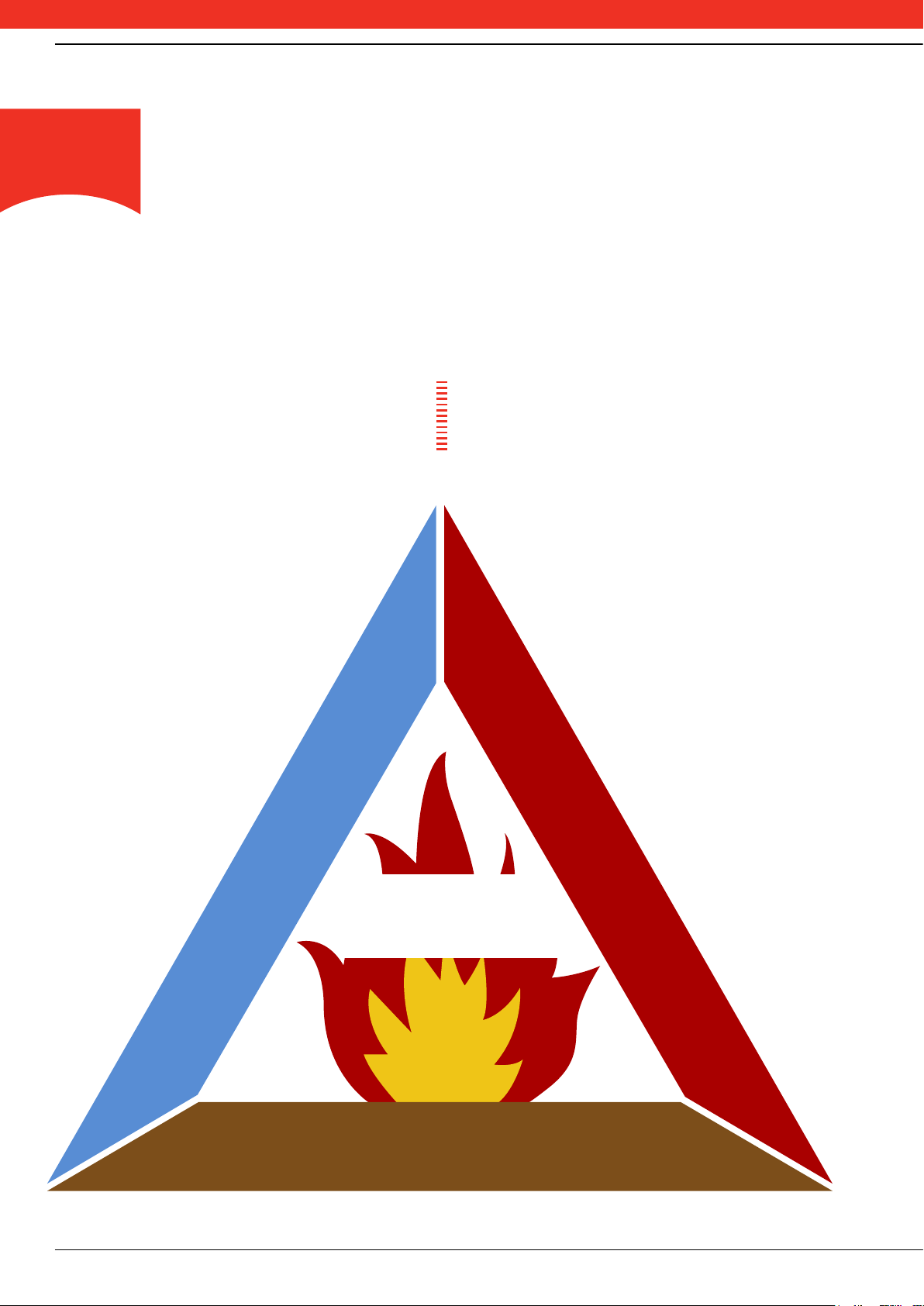

5

Flammable

Gas Hazards

Combustion is a fairly simple

chemical reaction in which

Oxygen is combined rapidly

with another substance

resulting in the release of

energy. This energy appears

mainly as heat – sometimes

in the form of ames.

The igniting substance is

normally, but not always, a

Hydrocarbon compound and

can be solid, liquid, vapour

or gas. However, only gases

and vapours are considered

in this publication.

(N.B. The terms

‘ammable’, ‘explosive’,

and ‘combustible’

are, for the purpose

of this publication,

interchangeable).

The Fire

Triangle

The process of combustion can be

represented by the well known re triangle.

Three factors are always needed to cause

combustion:

A SOURCE OF

IGNITION

1

OXYGEN

2

FUEL IN THE FORM

3

OF A GAS

OR VAPOUR

In any re protection system,

therefore, the aim is to always

remove at least one of these three

potentially hazardous items.

AIR

FIRE

FUEL

HEAT

8 www.honeywellanalytics.com / www.gasmonitors.com

Page 9

Flammable Limit

There is only a limited band of gas/air concentration which

will produce a combustible mixture. This band is specic

for each gas and vapour and is bounded by an upper level,

known as the Upper Explosive Limit (or the UEL) and a

lower level, called the Lower Explosive Limit (LEL).

Limits of Flammability

TOO RICH

GAS

FACT

High levels of O2 increase

the ammability of materials

and gases – at levels such

as 24%, items such as

clothing can spontaneously

combust!

100% v/v gas

0% v/v air

t levels below the LEL, there is

insufcient gas to produce an

explosion i.e. the mixture is too

A

the mixture has insufcient Oxygen i.e. the

mixture is too ‘rich’. The ammable range

therefore falls between the limits of the LEL

and UEL for each individual gas or mixture of

gases. Outside these limits, the mixture is not

capable of combustion. The Flammable Gases

Data on page 12 indicates the limiting values

for some of the better-known combustible

gases and compounds. The data is given for

gases and vapours at normal conditions of

pressure and temperature.

‘lean’, whilst above the UEL,

FLAMMABLE

RANGE

TOO LEAN

An increase in pressure, temperature or

Oxygen content will generally broaden the

ammability range.

In the average industrial plant, there would

normally be no gases leaking into the

surrounding area or, at worst, only a low

background level of gas present. Therefore the

detecting and early warning system will only

be required to detect levels from 0% of

gas up to the lower explosive limit. By the

time this concentration is reached,

shut-down procedures or site clearance

should have been put into operation. In fact

this will typically take place at a concentration

UEL

(upper explosive limit)

LEL

(lower explosive limit)

0% v/v gas

100% v/v air

of less than 50% of the LEL value, so that an

adequate safety margin is provided.

However, it should always be remembered

that in enclosed or unventilated areas, a

concentration in excess of the UEL can

sometimes occur. At times of inspection,

special care needs to be taken when operating

hatches or doors, since the ingress of air from

outside can dilute the gases to a hazardous,

combustible mixture.

(N.B LEL/LFL and UEL/UFL are, for the purpose of this

publication, interchangeable).

9

Page 10

Flammable Gas

Properties

Ignition Temperature

Flammable gases also have a temperature where ignition

will take place, even without an external ignition source

such as a spark or ame. This temperature is called the

Ignition Temperature. Apparatus for use in a hazardous

area must not have a surface temperature that exceeds the

Ignition Temperature. Apparatus is therefore marked with a

maximum surface temperature or T rating.

FLASH POINT (F.P. °C)

The ash point of a ammable liquid is the lowest temperature at which the surface of the

liquid emits sufcient vapour to be ignited by a small ame. Do not confuse this with Ignition

Temperature as the two can be very different:

Gas / Vapour Flash Point °C Ignition Temp. °C

Methane <-188 595

Kerosene 38 210

Bitumen 270 310

To convert a Celsius temperature into Fahrenheit: Tf = ((9/5)*Tc)+32 E.g. to convert -20 Celsius into Fahrenheit, first multiply the Celsius

temperature reading by nine-fifths to get -36. Then add 32 to get -4°F.

VAPOUR DENSITY

Helps determine sensor placement

The density of a gas/vapour is compared with air

When air = 1.0:

Vapour density < 1.0 will rise

Vapour density > 1.0 will fall

Gas/Vapour Vapour Density

Methane 0.55

Carbon Monoxide 0.97

Hydrogen Sulphide 1.45

Petrol Vapour 3.0 approx

10 www.honeywellanalytics.com / www.gasmonitors.com

Page 11

GAS

FACT

It’s not just gas that holds

a potential threat - dust

can also be explosive!

Examples of explosive

dusts include polystyrene,

cornstarch and iron.

11

11

Page 12

Flammable Gases Data

Molecular

WeightFormulaCAS NumberCommon Name

Acetaldehyde 75-07-0 CH3CHO 44.05 20 1.52 –38 4.00 60.00 74 1,108 204

Acetic acid 64-19-7 CH3COOH 60.05 118 2.07 40 4.00 17.00 100 428 464

Acetic anhydride 108-24-7 (CH3CO)2O 102.09 140 3.52 49 2.00 10.30 85 428 334

Acetone 67-64-1 (CH3)2CO 58.08 56 2.00 <–20 2.50 13.00 80 316 535

Acetonitrile 75-05-8 CH3CN 41.05 82 1.42 2 3.00 16.00 51 275 523

Acetyl chloride 75-36-5 CH3COCl 78.5 51 2.70 –4 5.00 19.00 157 620 390

Acetylene 74-86-2 CH=CH 26 -84 0.90 gas 2.30 100.00 24 1,092 305

Acetyl fluoride 557-99-3 CH3COF 62.04 20 2.14 <–17 5.60 19.90 142 505 434

Acrylaldehyde 107-02-8 CH2=CHCHO 56.06 53 1.93 –18 2.80 31.80 65 728 217

Acrylic acid 79-10-7 CH2=CHCOOH 72.06 139 2.48 56 2.90 85 406

Acrylonitrile 107-13-1 CH2=CHCN 53.1 77 1.83 –5 2.80 28.00 64 620 480

Acryloyl chloride 814-68-6 CH2CHCOCl 90.51 72 3.12 –8 2.68 18.00 220 662 463

Allyl acetate 591-87-7 CH2=CHCH2OOCCH3 100.12 103 3.45 13 1.70 10.10 69 420 348

Allyl alcohol 107-18-6 CH2=CHCH2CH 58.08 96 2.00 21 2.50 18.00 61 438 378

Allyl chloride 107-05-1 CH2=CHCH2Cl 76.52 45 2.64 –32 2.90 11.20 92 357 390

Ammonia 7664-41-7 NH3 17 -33 0.59 gas 15.00 33.60 107 240 630

Aniline 62-53-3 C6H6NH2 93.1 184 3.22 75 1.20 11.00 47 425 630

Benzaldehyde 100-52-7 C6H5CHO 106.12 179 3.66 64 1.40 62 192

Benzene 71-43-2 C6H6 78.1 80 2.70 –11 1.20 8.60 39 280 560

1-Bromobutane 109-65-9 CH3(CH2)2CH2Br 137.02 102 4.72 13 2.50 6.60 143 380 265

Bromoethane 74-96-4 CH3CH2Br 108.97 38 3.75 <–20 6.70 11.30 306 517 511

1,3 Butadiene 106-99-0 CH2=CHCH=CH2 54.09 -4.5 1.87 gas 1.40 16.30 31 365 430

Butane 106-97-8 C4H10 58.1 -1 2.05 gas 1.40 9.30 33 225 372

Isobutane 75-28-5 (CH3)2CHCH3 58.12 -12 2.00 gas 1.30 9.80 31 236 460

Butan-1-ol 71-36-3 CH3(CH2)2CH2OH 74.12 116 2.55 29 1.40 12.00 52 372 359

Butanone 78-93-3 CH3CH2COCH3 72.1 80 2.48 –9 1.50 13.40 45 402 404

But-1-ene 106-98-9 CH2=CHCH2CH3 56.11 -6.3 1.95 gas 1.40 10.00 38 235 440

But-2-ene (isomer not stated) 107-01-7 CH3CH=CHCH3 56.11 1 1.94 gas 1.60 10.00 40 228 325

Butyl acetate 123-86-4 CH3COOCH2(CH2)2CH3 116.2 127 4.01 22 1.20 8.50 58 408 370

n-Butyl acrylate 141-32-2 CH2=CHCOOC4H9 128.17 145 4.41 38 1.20 9.90 63 425 268

Butylamine 109-73-9 CH3(CH2)3NH2 73.14 78 2.52 –12 1.70 9.80 49 286 312

Isobutylamine 78-81-9 (CH3)2CHCH2NH2 73.14 64 2.52 –20 1.47 10.80 44 330 374

Isobutylisobutyrate 97-85-8 (CH3)2CHCOOCH2CH(CH3)2 144.21 145 4.93 34 0.80 47 424

Butylmethacrylate 97-88-1 CH2=C(CH3)COO(CH2)3CH3 142.2 160 4.90 53 1.00 6.80 58 395 289

Tert-butyl methyl ether 1634-04-4 CH3OC(CH3)2 88.15 55 3.03 –27 1.50 8.40 54 310 385

n-Butylpropionate 590-01-2 C2H5COOC4H9 130.18 145 4.48 40 1.00 7.70 53 409 389

Butyraldehyde 123-72-8 CH3CH2CH2CHO 72.1 75 2.48 –16 1.80 12.50 54 378 191

Isobutyraldehyde 78-84-2 (CH3)2CHCHO 72.11 63 2.48 –22 1.60 11.00 47 320 176

Carbon disulphide 75-15-0 CS2 76.1 46 2.64 –30 0.60 60.00 19 1,900 95

Carbon monoxide 630-08-0 CO 28 -191 0.97 gas 10.90 74.00 126 870 805

Carbonyl sulphide 463-58-1 COS 60.08 -50 2.07 gas 6.50 28.50 100 700 209

Chlorobenzene 108-90-7 C6H5Cl 112.6 132 3.88 28 1.30 11.00 60 520 637

1-Chlorobutane 109-69-3 CH3(CH2)2CH2Cl 92.57 78 3.20 –12 1.80 10.00 69 386 250

2-Chlorobutane 78-86-4 CH3CHClC2H5 92.57 68 3.19 <–18 2.00 8.80 77 339 368

1-Chloro-2,3-epoxypropane 106-89-8 OCH2CHCH2Cl 92.52 115 3.30 28 2.30 34.40 86 1,325 385

Chloroethane 75-00-3 CH3CH2Cl 64.5 12 2.22 gas 3.60 15.40 95 413 510

2-Chloroethanol 107-07-3 CH2ClCH2OH 80.51 129 2.78 55 4.90 16.00 160 540 425

Chloroethylene 75-01-4 CH2=CHCl 62.3 -15 2.15 gas 3.60 33.00 94 610 415

Chloromethane 74-87-3 CH3Cl 50.5 -24 1.78 gas 7.60 19.00 160 410 625

1-Chloro-2-methylpropane 513-36-0 (CH3)2CHCH2Cl 92.57 68 3.19 <–14 2.00 8.80 75 340 416

3-Chloro-2-methylprop-1-ene 563-47-3 CH2=C(CH3)CH2Cl 90.55 71 3.12 –16 2.10 77 478

5-Chloropentan-2-one 5891-21-4 CH3CO(CH2)3Cl 120.58 71 4.16 61 2.00 98 440

1-Chloropropane 540-54-5 CH3CH2CH2Cl 78.54 37 2.70 –32 2.40 11.10 78 365 520

2-Chloropropane 75-29-6 (CH3)2CHCl 78.54 47 2.70 <–20 2.80 10.70 92 350 590

Chlorotrifluoroethyl-ene 79-38-9 CF2=CFCl 116.47 -28.4 4.01 gas 4.60 84.30 220 3,117 607

-Chlorotoluene 100-44-7 C6H5CH2Cl 126.58 4.36 60 1.10 55 585

Boiling

Point °C

Relative

Vapourisation Density

12 www.honeywellanalytics.com / www.gasmonitors.com

12

www.honeywellanalytics.com / www.gasmonitors.com

Page 13

References: BS EN 60079-20-1 (supersedes 61779) Electrical apparatus for the detection and

measurement of flammable gases-Part 1: General requirements and test methods. NIST Chemistry Web

Book June 2005 release. Aldrich Handbook of Fine Chemicals and Laboratory Equipment 2003-2004.

Data may change by country

and date, always refer to local

up-to-date regulations.

Please note: Where “gas” is stated under Flash Point (F.P. C°), the compound is always in a gaseous state

and therefore does not have a FP.

Flammable Limits

F.P. °C LFL % v/v UFL % v/v LFL mg/L UFL mg/L I.T. °C

13

13

Page 14

Flammable Gases Data (continued)

Molecular

WeightFormulaCAS NumberCommon Name

Cresols (mixed isomers) 1319-77-3 CH3C5H4OH 108.14 191 3.73 81 1.10 50 555

Crotonaldehyde 123-73-9 CH3CH=CHCHO 70.09 102 2.41 13 2.10 16.00 82 470 280

Cumene 98-82-8 C6H5CH(CH3)2 120.19 152 4.13 31 0.80 6.50 40 328 424

Cyclobutane 287-23-0 CH2(CH2)2CH2 56.1 13 1.93 gas 1.80 42

Cycloheptane 291-64-5 CH2(CH2)5CH2 98.19 118.5 3.39 <10 1.10 6.70 44 275

Cyclohexane 110-82-7 CH2(CH2)4CH2 84.2 81 2.90 –18 1.00 8.00 35 290 259

Cyclohexanol 108-93-0 CH2(CH2)4CHOH 100.16 161 3.45 61 1.20 11.10 50 460 300

Cyclohexanone 108-94-1 CH2(CH2)4CO 98.1 156 3.38 43 1.30 8.40 53 386 419

Cyclohexene 110-83-8 CH2(CH2)3CH=CH 82.14 83 2.83 –17 1.10 8.30 37 244

Cyclohexylamine 108-91-8 CH2(CH2)4CHNH2 99.17 134 3.42 32 1.10 9.40 47 372 293

Cyclopentane 287-92-3 CH2(CH2)3CH2 70.13 50 2.40 –37 1.40 41 320

Cyclopentene 142-29-0 CH=CHCH2CH2CH 68.12 44 2.30 <–22 1.48 41 309

Cyclopropane 75-19-4 CH2CH2CH2 42.1 -33 1.45 gas 2.40 10.40 42 183 498

Cyclopropyl methyl ketone 765-43-5 CH3COCHCH2CH2 84.12 114 2.90 15 1.70 58 452

p-Cymene 99-87-6 CH3CH6H4CH(CH3)2 134.22 176 4.62 47 0.70 5.60 39 366 436

Decahydro-naphthalene trans 493-02-7 CH2(CH2)3CHCH(CH2)3CH2 138.25 185 4.76 54 0.70 4.90 40 284 288

Decane (mixed isomers) 124-18-5 C10H22 142.28 173 4.90 46 0.70 5.60 41 332 201

Dibutyl ether 142-96-1 (CH3(CH2)3)2O 130.2 141 4.48 25 0.90 8.50 48 460 198

Dichlorobenzenes (isomer not stated)

Dichlorodiethyl-silane 1719-53-5 (C2H5)SiCl2 157.11 128 24 3.40 223

1,1-Dichloroethane 75-34-3 CH3CHCl2 99 57 3.42 –10 5.60 16.00 230 660 440

1,2-Dichloroethane 107-06-2 CH2ClCH2Cl 99 84 3.42 13 6.20 16.00 255 654 438

Dichloroethylene 540-59-0 ClCH=CHCl 96.94 37 3.55 –10 9.70 12.80 391 516 440

1,2-Dichloro-propane 78-87-5 CH3CHClCH2Cl 113 96 3.90 15 3.40 14.50 160 682 557

Dicyclopentadiene 77-73-6 C10H12 132.2 170 4.55 36 0.80 43 455

Diethylamine 109-89-7 (C2H5)2NH 73.14 55 2.53 –23 1.70 10.00 50 306 312

Diethylcarbonate 105-58-8 (CH3CH2O)2CO 118.13 126 4.07 24 1.40 11.70 69 570 450

Diethyl ether 60-29-7 (CH3CH5)2O 74.1 34 2.55 –45 1.70 36.00 60 1,118 160

1,1-Difluoro-ethylene 75-38-7 CH2=CF2 64.03 -83 2.21 gas 3.90 25.10 102 665 380

Diisobutylamine 110-96-3 ((CH3)2CHCH2)2NH 129.24 137 4.45 26 0.80 3.60 42 190 256

Diisobutyl carbinol 108-82-7 ((CH3)2CHCH2)2CHOH 144.25 178 4.97 75 0.70 6.10 42 370 290

Diisopentyl ether 544-01-4 (CH3)2CH(CH2)2O(CH2)2CH(CH3)2 158.28 170 5.45 44 1.27 104 185

Diisopropylamine 108-18-9 ((CH3)2CH)2NH 101.19 84 3.48 –20 1.20 8.50 49 358 285

Diisopropyl ether 108-20-3 ((CH3)2CH)2O 102.17 69 3.52 –28 1.00 21.00 45 900 405

Dimethylamine 124-40-3 (CH3)2NH 45.08 7 1.55 gas 2.80 14.40 53 272 400

Dimethoxymethane 109-87-5 CH2(OCH)3)2 76.09 41 2.60 –21 2.20 19.90 71 630 247

3-(Dimethylamino)propiononitrile 1738-25-6 (CH3)2NHCH2CH2CN 98.15 171 3.38 50 1.57 62 317

Dimethyl ether 115-10-6 (CH3)2O 46.1 -25 1.59 gas 2.70 32.00 51 610 240

N,N-Dimethylformamide 68-12-2 HCON(CH3)2 73.1 152 2.51 58 1.80 16.00 55 500 440

3,4-Dimethyl hexane 583-48-2 CH3CH2CH(CH3)CH(CH3)CH2CH3 114.23 119 3.87 2 0.80 6.50 38 310 305

N,N-Dimethyl hydrazine 57-14-7 (CH3)2NNH2 60.1 62 2.07 –18 2.40 20 60 490 240

1,4-Dioxane 123-91-1 OCH2CH2OCH2CH2 88.1 101 3.03 11 1.40 22.50 51 813 379

1,3-Dioxolane 646-06-0 OCH2CH2OCH2 74.08 74 2.55 –5 2.30 30.50 70 935 245

Dipropylamine 142-84-7 (CH3CH2CH2)2NH 101.19 105 3.48 4 1.20 9.10 50 376 280

Ethane 74-84-0 CH3CH3 30.1 -87 1.04 gas 2.50 15.50 31 194 515

Ethanethiol 75-08-1 CH3CH2SH 62.1 35 2.11 <–20 2.80 18.00 73 466 295

Ethanol 64-17-5 CH3CH2OH 46.1 78 1.59 12 3.10 19.00 59 359 363

2-Ethoxyethanol 110-80-5 CH3CH2OCH2CH2OH 90.12 135 3.10 40 1.70 15.70 68 593 235

2-Ethoxyethyl acetate 111-15-9 CH3COOCH2CH2OCH2CH3 132.16 156 4.72 47 1.20 12.70 65 642 380

Ethyl acetate 141-78-6 CH3COOCH2CH3 88.1 77 3.04 –4 2.00 2.80 73 470 460

Ethyl acetoacetate 141-97-9 CH3COCH2COOCH2CH3 130.14 181 4.50 65 1.00 9.50 54 519 350

Ethyl acrylate 140-88-5 CH2=CHCOOCH2CH3 100.1 100 3.45 9 1.40 14.00 59 588 350

Ethylamine 75-04-7 C2H5NH2 45.08 16.6 1.50 <–20 3.50 14.00 49 260 425

Ethylbenzene 100-41-4 CH2CH3C6H5 106.2 135 3.66 23 0.80 7.80 44 340 431

Ethyl butyrate 105-54-4 CH3CH2CH2COOC2H5 116.16 120 4.00 21 1.40 66 435

Ethylcyclobutane 4806-61-5 CH3CH2CHCH2CH2CH2 84.16 2.90 <–16 1.20 7.70 42 272 212

Ethylcyclohexane 1678-91-7 CH3CH2CH(CH2)4CH2 112.2 131 3.87 <24 0.80 6.60 42 310 238

Ethylcyclopentane 1640-89-7 CH3CH2CH(CH2)3CH2 98.2 103 3.40 <5 1.05 6.80 42 280 262

Ethylene 74-85-1 CH2=CH2 28.1 -104 0.97 2.30 36.00 26 423 425

106-46-7 C6H4Cl2 147 179 5.07 86 2.20 9.20 134 564 648

Boiling

Point °C

Relative

Vapourisation Density

14 www.honeywellanalytics.com / www.gasmonitors.com

14

www.honeywellanalytics.com / www.gasmonitors.com

Page 15

Flammable Limits

F.P. °C LFL % v/v UFL % v/v LFL mg/L UFL mg/L I.T. °C

15

15

Page 16

Flammable Gases Data (continued)

Molecular

WeightFormulaCAS NumberCommon Name

Ethylenediamine 107-15-3 NH2CH2CH2NH2 60.1 118 2.07 34 2.50 18.00 64 396 403

Ethylene oxide 75-21-8 CH2CH2O 44 11 1.52 <–18 2.60 100.00 47 1,848 435

Ethyl formate 109-94-4 HCOOCH2CH3 74.08 52 2.65 –20 2.70 16.50 87 497 440

Ethyl isobutyrate 97-62-1 (CH3)2CHCOOC2H5 116.16 112 4.00 10 1.60 75 438

Ethyl methacrylate 97-63-2 CH2=CCH3COOCH2CH3 114.14 118 3.90 20 1.50 70

Ethyl methyl ether 540-67-0 CH3OCH2CH3 60.1 8 2.10 gas 2.00 10.10 50 255 190

Ethyl nitrite 109-95-5 CH3CH2ONO 75.07 2.60 –35 3.00 50.00 94 1,555 95

Formaldehyde 50-00-0 HCHO 30 -19 1.03 60 7.00 73.00 88 920 424

Formic acid 64-18-6 HCOOH 46.03 101 1.60 42 18.00 57.00 190 1,049 520

2-Furaldehyde 98-01-1 OCH=CHCH=CHCHO 96.08 162 3.30 60 2.10 19.30 85 768 316

Furan 110-00-9 CH=CHCH=CHO 68.07 32 2.30 <–20 2.30 14.30 66 408 390

Furfuryl alcohol 98-00-0 OC(CH2OH)CHCHCH 98.1 170 3.38 61 1.80 16.30 70 670 370

1,2,3-Trimethyl-benzene 526-73-8 CHCHCHC(CH3)C(CH3)C(CH3) 120.19 175 4.15 51 0.80 7.00 470

Heptane (mixed isomers) 142-82-5 C7H16 100.2 98 3.46 –4 0.85 6.70 35 281 215

Hexane (mixed isomers) 110-54-3 CH3(CH2)4CH3 86.2 69 2.97 –21 1.00 8.90 35 319 233

1-Hexanol 111-27-3 C6H13OH 102.17 156 3.50 63 1.10 47 293

Hexan-2-one 591-78-6 CH3CO(CH2)3CH3 100.16 127 3.46 23 1.20 9.40 50 392 533

Hydrogen 1333-74-0 H2 2 -253 0.07 gas 4.00 77.00 3.4 63 560

Hydrogen cyanide 74-90-8 HCN 27 26 0.90 <–20 5.40 46.00 60 520 538

Hydrogen sulphide 7783-06-4 H2S 34.1 -60 1.19 gas 4.00 45.50 57 650 270

4-Hydroxy-4-methyl-penta-2-one 123-42-2 CH3COCH2C(CH3)2OH 116.16 166 4.00 58 1.80 6.90 88 336 680

Kerosene 8008-20-6 150 38 0.70 5.00 210

1,3,5-Trimethylbenzene 108-67-8 CHC(CH3)CHC(CH3)CHC(CH3) 120.19 163 4.15 44 0.80 7.30 40 365 499

Methacryloyl chloride 920-46-7 CH2CCH3COCl 104.53 95 3.60 17 2.50 106 510

Methane (firedamp) 74-82-8 CH4 16 -161 0.55 <–188 4.40 17.00 29 113 537

Methanol 67-56-1 CH3OH 32 65 1.11 11 6.00 36.00 73 665 386

Methanethiol 74-93-1 CH3SH 48.11 6 1.60 4.10 4.10 21.00 80 420

2-Methoxyethanol 109-86-4 CH3OCH2CH2OH 76.1 124 2.63 39 1.80 20.60 76 650 285

Methyl acetate 79-20-9 CH3COOCH3 74.1 57 2.56 –10 3.10 16.00 95 475 502

Methyl acetoacetate 105-45-3 CH3COOCH2COCH3 116.12 169 4.00 62 1.30 14.20 62 685 280

Methyl acrylate 96-33-3 CH2=CHCOOCH3 86.1 80 3.00 –3 1.95 16.30 71 581 415

Methylamine 74-89-5 CH3NH2 31.1 -6 1.00 gas 4.20 20.70 55 270 430

2-Methylbutane 78-78-4 (CH3)2CHCH2CH3 72.15 30 2.50 –56 1.30 8.30 38 242 420

2-Methylbutan-2-ol 75-85-4 CH3CH2C(OH)(CH3)2 88.15 102 3.03 16 1.40 10.20 50 374 392

3-Methylbutan-1-ol 123-51-3 (CH3)2CH(CH2)2OH 88.15 130 3.03 42 1.30 10.50 47 385 339

2-Methylbut-2-ene 513-35-9 (CH3)2C=CHCH3 70.13 35 2.40 –53 1.30 6.60 37 189 290

Methyl chloro-formate 79-22-1 CH3OOCC 94.5 70 3.30 10 7.50 26 293 1,020 475

Methylcyclohexane 108-87-2 CH3CH(CH2)4CH2 98.2 101 3.38 –4 1.00 6.70 41 275 258

Methylcyclo-pentadienes

Methylcyclopentane 96-37-7 CH3CH(CH2)3CH2 84.16 72 2.90 <–10 1.00 8.40 35 296 258

Methylenecyclo-butane 1120-56-5 C(=CH2)CH2CH2CH2 68.12 2.35 <0 1.25 8.60 35 239 352

2-Methyl-1-buten-3-yne 78-80-8 HC=CC(CH3)CH2 66.1 32 2.28 –54 1.40 38 272

Methyl formate 107-31-3 HCOOCH3 60.05 32 2.07 –20 5.00 23.00 125 580 450

2-Methylfuran 534-22-5 OC(CH3)CHCHCH 82.1 63 2.83 <–16 1.40 9.70 47 325 318

Methylisocyanate 624-83-9 CH3NCO 57.05 37 1.98 –7 5.30 26.00 123 605 517

Methyl methacrylate 80-62-6 CH3=CCH3COOCH3 100.12 100 3.45 10 1.70 12.50 71 520 430

4-Methylpentan-2-ol 108-11-2 (CH3)2CHCH2CHOHCH3 102.17 132 3.50 37 1.14 5.50 47 235 334

4-Methylpentan-2-one 108-10-1 (CH3)2CHCH2COCH3 100.16 117 3.45 16 1.20 8.00 50 336 475

2-Methylpent-2-enal 623-36-9 CH3CH2CHC(CH3)COH 98.14 137 3.78 30 1.46 58 206

4-Methylpent-3-en-2-one 141-79-7 (CH3)2(CCHCOCH)3 98.14 129 3.78 24 1.60 7.20 64 289 306

2-Methyl-1-propanol 78-83-1 (CH3)2CHCH2OH 74.12 108 2.55 28 1.40 11.00 43 340 408

2-Methylprop-1-ene 115-11-7 (CH3)2C=CH2 56.11 -6.9 1.93 gas 1.60 10 37 235 483

2-Methylpyridine 109-06-8 NCH(CH3)CHCHCHCH 93.13 128 3.21 27 1.20 45 533

3-Methylpyridine 108-99-6 NCHCH(CH3)CHCHCH 93.13 144 3.21 43 1.40 8.10 53 308 537

4-Methylpyridine 108-89-4 NCHCHCH(CH3)CHCH 93.13 145 3.21 43 1.10 7.80 42 296 534

-Methyl styrene 98-83-9 C6H5C(CH3)=CH2 118.18 165 4.08 40 0.80 11.00 44 330 445

Methyl tert-pentyl ether 994-05-8 (CH3)2C(OCH3)CH2CH3 102.17 85 3.50 <–14 1.50 62 345

2-Methylthiophene 554-14-3 SC(CH3)CHCHCH 98.17 113 3.40 –1 1.30 6.50 52 261 433

Morpholine 110-91-8 OCH2CH2NHCH2CH2 87.12 129 3.00 31 1.40 15.20 65 550 230

(isomer not stated)

26519-91-5 C6H6 80.13 2.76 <–18 1.30 7.60 43 249 432

Boiling

Point °C

Relative

Vapourisation Density

16 www.honeywellanalytics.com / www.gasmonitors.com

16

www.honeywellanalytics.com / www.gasmonitors.com

Page 17

Flammable Limits

F.P. °C LFL % v/v UFL % v/v LFL mg/L UFL mg/L I.T. °C

17

17

Page 18

Flammable Gases Data (continued)

Molecular

WeightFormulaCAS NumberCommon Name

Naphtha 35 2.50 <–18 0.90 6.00 290

Naphthalene 91-20-3 C10H8 128.17 218 4.42 77 0.60 5.90 29 317 528

Nitrobenzene 98-95-3 CH3CH2NO2 123.1 211 4.25 88 1.40 40.00 72 2,067 480

Nitroethane 79-24-3 C2H5NO2 75.07 114 2.58 27 3.40 107 410

Nitromethane 75-52-5 CH3NO2 61.04 102.2 2.11 36 7.30 63.00 187 1,613 415

1-Nitropropane 108-03-2 CH3CH2CH2NO2 89.09 131 3.10 36 2.20 82 420

Nonane 111-84-2 CH3(CH2)7CH2 128.3 151 4.43 30 0.70 5.60 37 301 205

Octane 111-65-9 CH3(CH2)3CH3 114.2 126 3.93 13 0.80 6.50 38 311 206

1-Octanol 111-87-5 CH3(CH2)6CH2OH 130.23 196 4.50 81 0.90 7.00 49 385 270

Penta-1,3-diene 504-60-9 CH2=CH-CH=CH-CH3 68.12 42 2.34 <–31 1.20 9.40 35 261 361

Pentanes (mixed isomers) 109-66-0 C5H12 72.2 36 2.48 –40 1.40 7.80 42 261 258

Pentane-2,4-dione 123-54-6 CH3COCH2COCH3 100.1 140 3.50 34 1.70 71 340

Pentan-1-ol 71-41-0 CH3(CH2)3CH2OH 88.15 136 3.03 38 1.06 10.50 36 385 298

Pentan-3-one 96-22-0 (CH3CH2)2CO 86.13 101.5 3.00 12 1.60 58 445

Pentyl acetate 628-63-7 CH3COO-(CH2)4-CH3 130.18 147 4.48 25 1.00 7.10 55 387 360

Petroleum 2.80 <–20 1.20 8.00 560

Phenol 108-95-2 C6H5OH 94.11 182 3.24 75 1.30 9.50 50 370 595

Propane 74-98-6 CH3CH2CH3 44.1 -42 1.56 gas 1.70 10.90 31 200 470

Propan-1-ol 71-23-8 CH3CH2CH2OH 60.1 97 2.07 22 2.10 17.50 52 353 405

Propan-2-ol 67-63-0 (CH3)2CHOH 60.1 83 2.07 12 2.00 12.70 50 320 425

Propene 115-07-1 CH2=CHCH3 42.1 -48 gas 2.00 11.10 35 194 455

Propionic acid 79-09-4 CH3CH2COOH 74.08 141 2.55 52 2.10 12.00 64 370 435

Propionic aldehyde 123-38-6 C2H5CHO 58.08 46 2.00 <–26 2.00 47 188

Propyl acetate 109-60-4 CH3COOCH2CH2CH3 102.13 102 3.60 10 1.70 8.00 70 343 430

Isopropyl acetate 108-21-4 CH3COOCH(CH3)2 102.13 85 3.51 4 1.70 8.10 75 340 467

Propylamine 107-10-8 CH3(CH2)2NH2 59.11 48 2.04 –37 2.00 10.40 49 258 318

Isopropylamine 75-31-0 (CH3)2CHNH2 59.11 33 2.03 <–24 2.30 8.60 55 208 340

Isopropyl Chloroacetate 105-48-6 ClCH2COOCH(CH3)2 136.58 149 4.71 42 1.60 89 426

2-Isopropyl-5-methylhex-2-enal 35158-25-9 (CH3)2CH-C(CHO)CHCH2CH(CH3)2 154.25 189 5.31 41 3.05 192 188

Isopropyl nitrate 1712-64-7 (CH3)2CHONO2 105.09 101 11 2.00 100.00 75 3,738 175

Propyne 74-99-7 CH3C=CH 40.06 -23.2 1.38 gas 1.70 16.8 28 280 340

Prop-2-yn-1-ol 107-19-7 HC=CCH2OH 56.06 114 1.89 33 2.40 55 346

Pyridine 110-86-1 C5H5N 79.1 115 2.73 17 1.70 12.40 56 398 550

Styrene 100-42-5 C6H5CH=CH2 104.2 145 3.60 30 1.00 8.00 42 350 490

Tetrafluoroethylene 116-14-3 CF2=CF2 100.02 3.40 gas 10.00 59.00 420 2,245 255

2,2,3,3-Tetrafluoropropyl acrylate 7383-71-3 CH2=CHCOOCH2CF2CF2H 186.1 132 6.41 45 2.40 182 357

2,2,3,3

-Tetrafluoropropyl methacrylate

Tetrahydrofuran 109-99-9 CH2(CH2)2CH2O 72.1 64 2.49 –20 1.50 12.40 46 370 224

Tetrahydrofurfuryl alcohol 97-99-4 OCH2CH2CH2CHCH2OH 102.13 178 3.52 70 1.50 9.70 64 416 280

Tetrahydrothiophene 110-01-0 CH2(CH2)2CH2S 88.17 119 3.04 13 1.00 12.30 42 450 200

N,N,N’, N’-Tetramethyldiaminomethane

Thiophene 110-02-1 CH=CHCH=CHS 84.14 84 2.90 –9 1.50 12.50 50 420 395

Toluene 108-88-3 C6H5CH3 92.1 111 3.20 4 1.10 7.80 39 300 535

Triethylamine 121-44-8 (CH3CH2)3N 101.2 89 3.50 –7 1.20 8.00 51 339

1,1,1-Trifluoroethane 420-46-2 CF3CH3 84.04 2.90 6.80 17.60 234 605 714

2,2,2-Trifluoroethanol 75-89-8 CF3CH2OH 100.04 77 3.45 30 8.40 28.80 350 1,195 463

Trifluoroethylene 359-11-5 CF2=CFH 82.02 2.83 27.00 502 904 319

3,3,3-Trifluoro-prop-1-ene 677-21-4 CF3CH=CH2 96.05 -16 3.31 4.70 184 490

Trimethylamine 75-50-3 (CH3)3N 59.1 3 2.04 gas 2.00 12.00 50 297 190

2,2,4-Trimethylpentane 540-84-1 (CH3)2CHCH2C(CH3)3 114.23 98 3.90 –12 0.70 6.00 34 284 411

2,4,6-Trimethyl-1,3,5-trioxane 123-63-7 OCH(CH3)OCH(CH3)OCH(CH3) 132.16 123 4.56 27 1.30 72 235

1,3,5-Trioxane 110-88-3 OCH2OCH2OCH2 90.1 115 3.11 45 3.20 29.00 121 1,096 410

Turpentine C10H16 149 35 0.80 254

Isovaleraldehyde 590-86-3 (CH3)2CHCH2CHO 86.13 90 2.97 –12 1.30 13.00 60 207

Vinyl acetate 108-05-4 CH3COOCH=CH2 86.09 72 3.00 –8 2.60 13.40 93 478 425

Vinylcyclohexenes (isomer not stated)

Vinylidene chloride 75-35-4 CH2=CCl2 96.94 30 3.40 –18 6.50 16.00 260 645 440

2-Vinylpyridine 100-69-6 NC(CH2=CH)CHCHCHCH 105.14 79 3.62 35 1.20 51 482

4-Vinylpyridine 100-43-6 NCHCHC(CH2=CH)CHCH 105.14 62 3.62 43 1.10 47 501

Xylenes 1330-20-7 C6H4(CH3)2 106.2 144 3.66 30 1.00 7.60 44 335 464

45102-52-1 CH2=C(CH2)COOCH2CF2CF2H 200.13 124 6.90 46 1.90 155 389

51-80-9 (CH3)2NCH2N(CH3)2 102.18 85 3.50 <–13 1.61 67 180

100-40-3 CH2CHC6H9 108.18 126 3.72 15 0.80 35 257

Boiling

Point °C

Relative

Vapourisation Density

18 www.honeywellanalytics.com / www.gasmonitors.com

18

www.honeywellanalytics.com / www.gasmonitors.com

Page 19

Flammable Limits

F.P. °C LFL % v/v UFL % v/v LFL mg/L UFL mg/L I.T. °C

19

19

Page 20

6

Toxic Gas

Hazards

Some gases are poisonous and can be dangerous to life at very low

concentrations. Some toxic gases have strong smells like the distinctive

‘rotten eggs’ smell of Hydrogen Sulphide (H

often used for the concentration of toxic gases are parts per million (ppm)

and parts per billion (ppb). For example 1ppm would be equivalent to a

room lled with a total of 1 million balls and 1 of those balls being red.

The red ball would represent 1ppm.

S). The measurements most

2

1 MILLION

BALLS

ore people die from toxic gas

exposure than from explosions

caused by the ignition of

M

noted that there is a large group of gases

which are both combustible and toxic, so

that even detectors of toxic gases

sometimes have to carry hazardous

area approval). The main reason for

ammable gas. (It should be

treating ammable and toxic gases separately

is that the hazards and regulations involved

and the types of sensor required are different.

With toxic substances, apart from the obvious

environmental problems, the main concern

is the effect on workers of

exposure to even very low

concentrations, which could be

inhaled, ingested, or absorbed

through the skin. Since adverse

effects can often result from

additive, long-term exposure,

it is important not only to

measure the concentration of

gas, but also the total time of

exposure. There are even some

known cases of synergism,

where substances

can interact and produce

a far worse effect when

combined than the separate

effect of each on its own.

Concern about concentrations of toxic

substances in the workplace focus on both

organic and inorganic compounds, including

the effects they could have on the health

and safety of employees, the possible

contamination of a manufactured end-product

(or equipment used in its manufacture) and

also the subsequent disruption of normal

working activities.

www.honeywellanalytics.com / www.gasmonitors.com20

www.honeywellanalytics.com / www.gasmonitors.com

Page 21

Workplace

Exposure

Limits

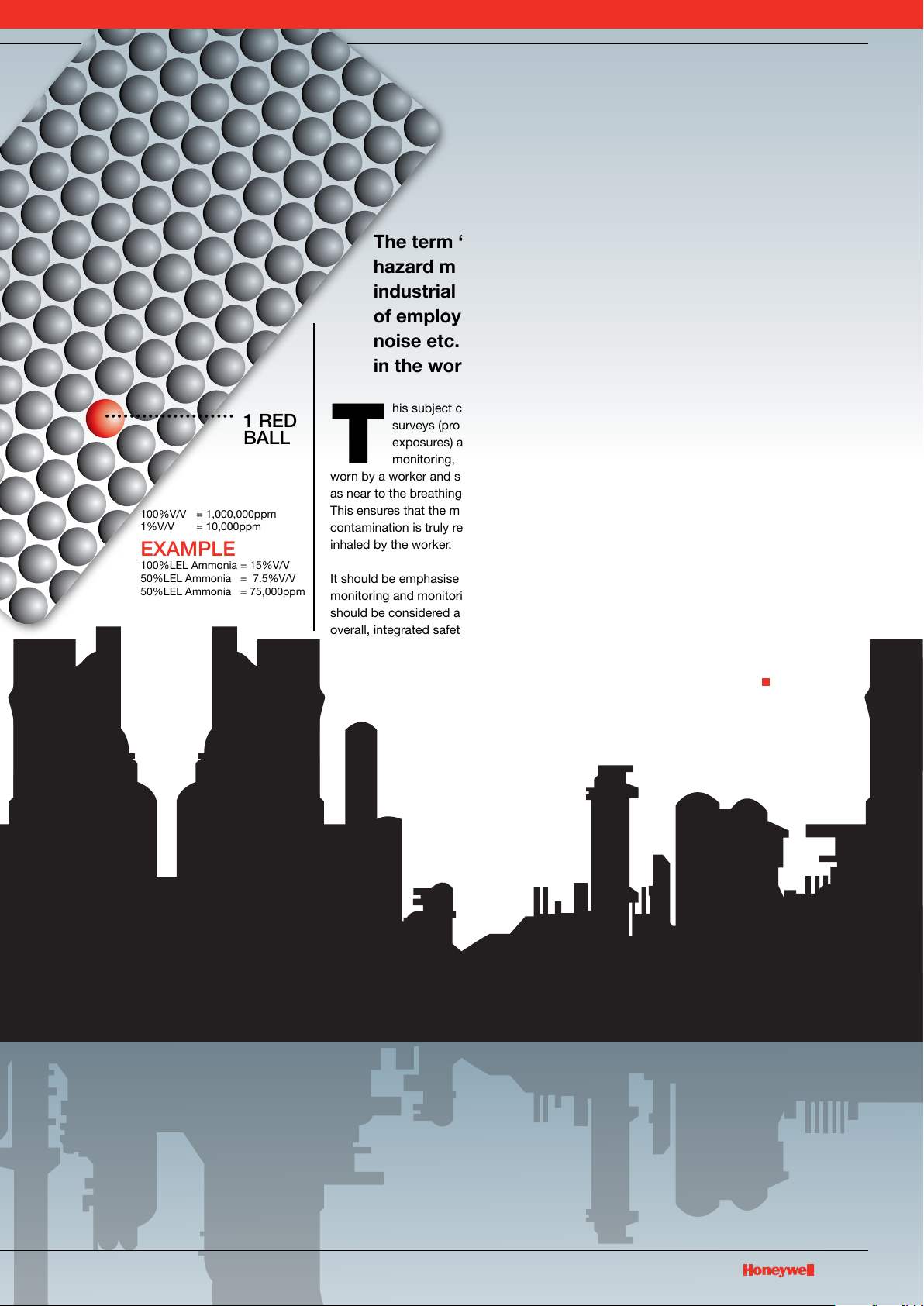

The term ‘workplace exposure limits’ or ‘occupational

hazard monitoring’ is generally used to cover the area of

industrial health monitoring associated with the exposure

of employees to hazardous conditions of gases, dust,

noise etc. In other words, the aim is to ensure that levels

in the workplace are below the statutory limits.

1 RED

BALL

100%V/V = 1,000,000ppm

1%V/V = 10,000ppm

EXAMPLE

100%LEL Ammonia = 15%V/V

50%LEL Ammonia = 7.5%V/V

50%LEL Ammonia = 75,000ppm

his subject covers both area

surveys (proling of potential

exposures) and personal

T

worn by a worker and sampling is carried out

as near to the breathing zone as possible.

This ensures that the measured level of

contamination is truly representative of that

inhaled by the worker.

It should be emphasised that both personal

monitoring and monitoring of the workplace

should be considered as important parts of an

overall, integrated safety plan. They are only

intended to provide the necessary information

about conditions as they exist in the

atmosphere. This then allows the necessary

monitoring, where instruments are

action to be taken to comply with

the relevant industrial regulations

and safety requirements.

Whatever method is decided upon, it is

important to take into account the nature of

the toxicity of any of the gases involved.

For instance, any instrument which

measures only a time-weighted average,

or an instrument which draws a sample for

subsequent laboratory analysis, would not

protect a worker against a short exposure to

a lethal dose of a highly toxic substance. On

the other hand, it may be quite normal to briey

exceed the average, Long-Term Exposure Limit

(LTEL) levels in some areas of a plant, and it

need not be indicated as an alarm situation.

Therefore, the optimum instrument system

should be capable of monitoring both short

and long-term exposure levels as well as

instantaneous alarm levels.

21

Page 22

Toxic Exposure Limits

European Occupational

Exposure Limits

Occupational Exposure Limit values (OELs) are set by competent

national authorities or other relevant national institutions as limits for

concentrations of hazardous compounds in workplace air. OELs for

hazardous substances represent an important tool for risk assessment

and management and valuable information for occupational safety and

health activities concerning hazardous substances.

ccupational Exposure Limits can

apply both to marketed products

and to waste and by-products

O

The limits protect workers against health

effects, but do not address safety issues

such as explosive risk. As limits frequently

change and can vary by country, you should

consult your relevant national authorities to

ensure that you have the latest information.

Occupational Exposure Limits in the UK

function under the Control of Substances

Hazardous to Health Regulations (COSHH).

The COSHH regulations require the employer

to ensure that the employee’s exposure to

substances hazardous to health is either

prevented or if not practically possible,

adequately controlled.

from production processes.

concentration varies from substance to

substance according to its toxicity. The

exposure times are averaged for eight hours

(8-hour Time-Weighted Average TWA) and

15 minutes (Short-Term Exposure Limit STEL).

For some substances, a brief exposure is

considered so critical that they are set only

a STEL, which should not be exceeded even

for a shorter time. The potency to penetrate

through skin is annotated in the WEL list by

remark “Skin”. Carcinogenicity, reproduction

toxicity, irritation and sensitisation potential

are considered when preparing a proposal

for an OEL according to the present

scientic knowledge.

GAS

FACT

Hydrogen is the

lightest, most

abundant and

explosive gas on

Earth.

As of 6 April 2005, the regulations introduced

a new, simpler Occupational Exposure Limit

system. The existing requirements to follow

good practice were brought together by

the introduction of eight principles in the

Control of Substances Hazardous to Health

(Amendment) Regulations 2004.

Maximum Exposure Limits (MELs) and

Occupational Exposure Standards (OESs)

were replaced with a single type of limit -

the Workplace Exposure Limit (WEL). All

the MELs, and most of the OESs, are being

transferred into the new system as WELs and

will retain their previous numerical values.

The OESs for approximately 100 substances

were deleted as the substances are now

banned, scarcely used or there is evidence

to suggest adverse health effects close to

the old limit value. The list of exposure limits

is known as EH40 and is available from the

UK Health and Safety Executive. All legally

enforceable WELs in the UK are air limit

values. The maximum admissible or accepted

www.honeywellanalytics.com / www.gasmonitors.com22

Page 23

2500

2000

1500

Effects of exposure to Carbon Monoxide

1000

500

Carbon Monoxide in parts per million (ppm)

5 10 20 40 80 160

Period of exposure in minutes

= Noticeable symtoms

/ start to feel unwell

= Feeling ill

= Death

23

Page 24

US Occupational

Exposure Limits

he Occupational Safety systems

in the United States vary from

state to state. Here, information is

T

Occupational Exposure Limits in the USA ACGIH, OSHA, and NIOSH.

The American Conference of Governmental

Industrial Hygienists (ACGIH) publishes

Maximum Allowable Concentrations (MAC),

which were later renamed to “Threshold Limit

Values” (TLVs).

Threshold Limit Values are dened as an

exposure limit “to which it is believed nearly

all workers can be exposed day after day

for a working lifetime without ill effect”. The

ACGIH is a professional organisation of

occupational hygienists from universities

or governmental institutions. Occupational

hygienists from private industry can join as

associate members. Once a year, the different

committees propose new threshold limits

or best working practice guides. The list

of TLVs includes more than 700 chemical

substances and physical agents, as well as

dozens of Biological Exposure Indices for

selected chemicals.

given on 3 major providers of the

The ACGIH denes different TLV-Types as:

Threshold Limit Value – Time-Weighted

Average (TLV-TWA): the Time-Weighted

Average concentration for a conventional

8-hour workday and a 40-hour workweek,

to which it is believed that nearly all workers

may be repeatedly exposed, day after day,

without adverse effect.

Threshold Limit Value – Short-Term

Exposure Limit (TLV-STEL): the

concentration to which it is believed that

workers can be exposed continuously for

a short period of time without suffering

from irritation, chronic or irreversible tissue

damage, or narcosis. STEL is dened as a

15-minute TWA exposure, which should not

be exceeded at any time during a workday.

Threshold Limit Value – Ceiling (TLV-C):

the concentration that should not be

exceeded during any part of the working

exposure.

There is a general excursion limit

recommendation that applies to those

TLV-TWAs that do not have STELs.

Excursions in worker exposure levels may

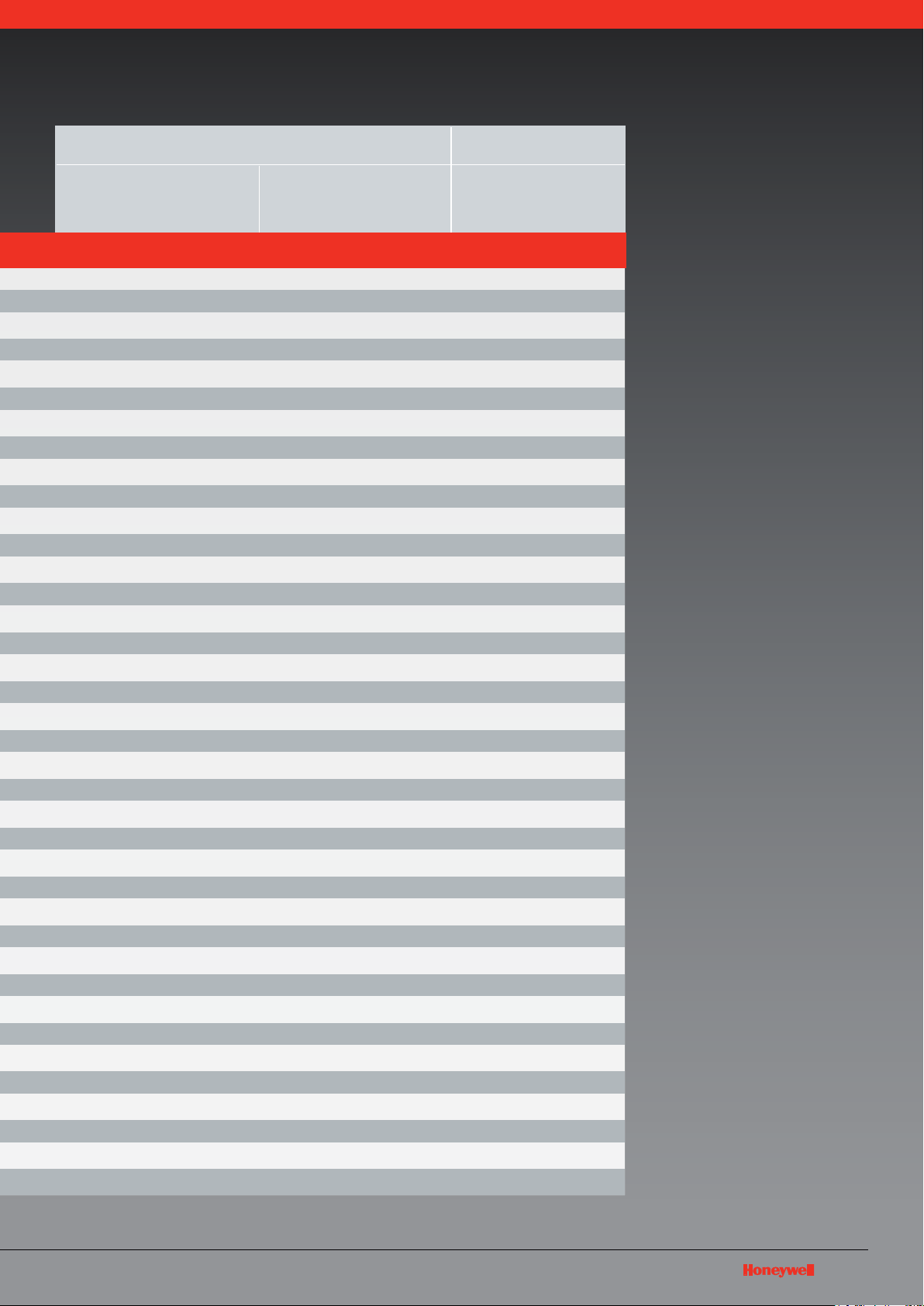

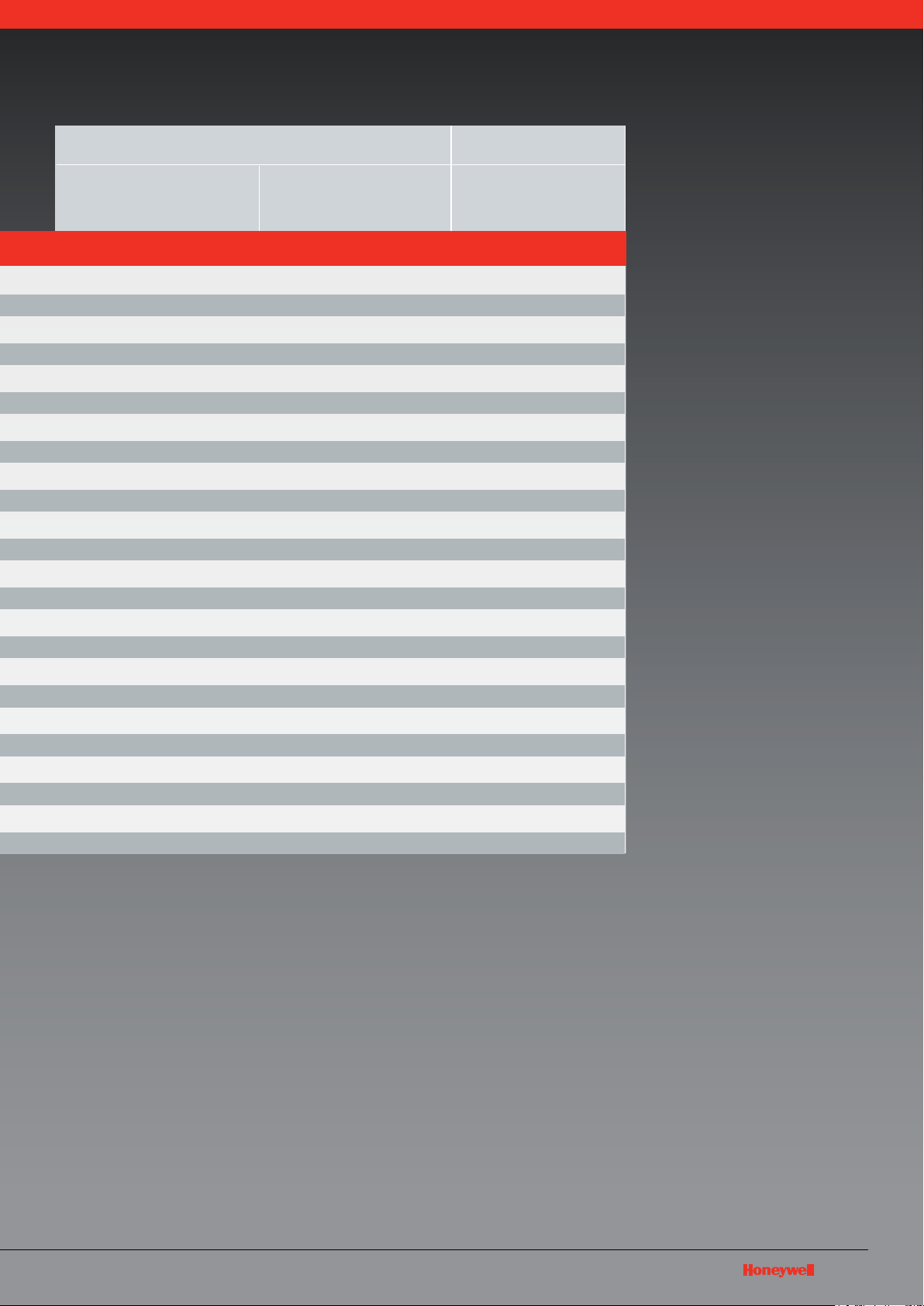

Occupational Exposure Limits Comparison Table

ACGIM OSHA NIOSH EH40 Meaning

Threshold Limit

Values (TLVs)

Permissible Exposure

Limits (PELs)

TLV-TWA TWA TWA TWA Long-term Exposure Limit

TLV-STEL STEL STEL STEL Short-Term Exposure Limit

TLV-C Ceiling Ceiling - The concentration that should

Excursion Limit Excursion Limit - - Limit if no STEL stated

- BEIs BEIs - Biological Exposure Indicies

24 www.honeywellanalytics.com / www.gasmonitors.com

Recommended

Exposure Levels (RELs)

Workplace Exposure

Limits (WELs)

Limit definition

(8hr-TWA reference period)

(15-minute exposure period)

not be exceeded during any

part of the working exposure

Page 25

exceed 3 times the TLV-TWA for no more than

a total of 30 minutes during a workday and

under no circumstances should they exceed 5

times the TLV-TWA, provided that the

TLV-TWA is not exceeded.

ACGIH-TLVs do not have a legal force in the

USA, they are only recommendations. OSHA

denes regulatory limits. However,

ACGIH-TLVs and the criteria documents are a

very common base for setting TLVs in the USA

and in many other countries. ACGIH exposure

limits are in many cases more protective than

OSHA’s. Many US companies use the current

ACGIH levels or other internal and more

protective limits.

The Occupational Safety and Health

Administration (OSHA) of the US Department

of Labor publishes Permissible Exposure

Limits (PEL). PELs are regulatory limits on

the amount or concentration of a substance

in the air and they are enforceable. The initial

set of limits from 1971 was based on the

ACGIH TLVs. OSHA currently has around

500 PELs for various forms of approximately

300 chemical substances, many of which are

widely used in industrial settings. Existing

PELs are contained in a document called

“29 CFR 1910.1000”, the air contaminants

standard. OSHA uses in a similar way as

the ACGIH the following types of OELs:

TWAs, Action Levels, Ceiling Limits, STELs,

Excursion Limits and in some cases Biological

Exposure Indices (BEIs).

The National Institute for Occupational

Safety and Health (NIOSH) has the statutory

responsibility for recommending exposure

levels that are protective to workers.

NIOSH has identied Recommended

Exposure Levels (RELs) for around 700

hazardous substances. These limits have

no legal force. NIOSH recommends their

limits via criteria documents to OSHA and

other OEL setting institutions. Types of

RELs are TWA, STEL, Ceiling and BEIs.

The recommendations and the criteria are

published in several different document types,

such as Current Intelligent Bulletins (CIB), Alerts,

Special Hazard Reviews, Occupational Hazard

Assessments and Technical Guidelines.

25

Page 26

Toxic Gases Data

The toxic gases listed below can be detected using equipment supplied by Honeywell Gas Detection. Gas data is supplied where known.

As product development is ongoing, contact Honeywell Analytics if the gas you require is not listed.

Data may change by country and date, always refer to local up-to-date regulations.

Ammonia 7664-41-7 NH3 25 18 35 25 50 35

Arsine 7784-42-1 AsH3 0.05 0.16 0.05 0.2

Boron Trichloride 10294-34-5 BCl3

Boron Trifluoride 7637-07-2 BF3 1 (ceiling) 3 (ceiling)

Bromine 7726-95-6 Br2 0.1 0.66 0.2 1.3 0.1 0.7

Carbon Monoxide 630-08-0 CO 30 35 200 232 50 55

Chlorine 7782-50-5 Cl2 0.5 1.5 1 (ceiling) 3 (ceiling)

Chlorine Dioxide 10049-04-4 ClO2 0.1 0.28 0.3 0.84 0.1 0.3

1,4 Cyclohexane diisocyanate CHDI

Diborane 19287-45-7 B

Dichlorosilane (DCS) 4109-96-0 H2Cl2Si

Dimethyl Amine (DMA) 124-40-3 C2H7N 2 3.8 6 11 10 18

Dimethyl Hydrazine (UDMH) 57-14-7 C2H8N2

Disilane 1590-87-0 Si2H6

Ethylene Oxide 75-21-8 C2H4O 5 9.2 1.5

Fluorine 7782-41-4 F2 1 1.6 1 1.6 0.1 0.2

Germane 7782-65-2 GeH4 0.2 0.64 0.6 1.9

Hexamethylene Diisocyanate (HDI) 822-06-0 C8H12N2O2

Hydrazine 302-01-2 N2H4 0.02 0.03 0.1 0.13 1 1.3

Hydrogen 1333-74-0 H2

Hydrogen Bromide 10035-10-6 HBr 3 10 3 10

Hydrogen Chloride 7647-01-0 HCl 1 2 5 8 5 (ceiling) 7 (ceiling)

Hydrogen Cyanide 74-90-8 HCN 10 11 10 11

Hydrogen Fluoride 7664-39-3 HF 1.8 1.5 3 2.5 2

Hydrogen Iodide 10034-85-2 HI

Hydrogen Peroxide 7722-84-1 H2O2 1 1.4 2 2.8 1 1.4

Hydrogen Selenide 7783-07-5 H2Se 0.05 0.2

Hydrogen Sulphide 7783-06-4 H2S 5 7 10 14 2 10

Hydrogenated Methylene Bisphenyl Isocyanate (HMDI)

Isocyanatoethyl Methacrylate (IEM) C

Isophorone Diisocyanate (IPDI) C12H18N2O2

Methyl Fluoride (R41) 593-53-3 CH3F

Methylene Bisphenyl Isocyanate (MDI) 101-68-8 C15H10N2O2

Methylene Bisphenyl Isocyanate -2 (MDI-2) 101-68-8 C15H10N2O2

Methylenedianiline (MDA) 101-77-9 C13H14N2 0.01 0.08

Monomethyl Hydrazine (MMH) 60-34-4 CH6N2

Naphthalene Diisocyanate (NDI) 3173-72-6 C12H6N2O2

Nitric Acid 7697-37-2 HNO3 1 2.6 2 5

CAS Number FormulaCommon Name

2H6 0.1 0.1

7H9NO3

26 www.honeywellanalytics.com / www.gasmonitors.com

26

www.honeywellanalytics.com / www.gasmonitors.com

Page 27

Ref: EH40/2005 Workplace Exposure Limits, OSHA Standard 29 CFR 1910.1000 tables Z-1 and Z-2 and ACGIH Threshold Limit Valves and

Biological Exposure Indices Book 2005.

EH40 Workplace Exposure Limit (WEL)

Long-Term Exposure Limit

(8-hour TWA reference period)

ppm mg/m

OSHA Permissible

Exposure Limits (PEL)

Short-Term Exposure Limit

(15-minute reference period)

3

ppm mg/m

3

Long-term Exposure Limit

(8-hour TWA reference period)

ppm mg/m

3

27

27

Page 28

Toxic Gases Data (continued)

Nitric Oxide 10102-43-9 NO 25 30

Nitrogen Dioxide 10102-44-0 NO2 5 (ceiling) 9 (ceiling)

Nitrogen Trifluoride 7783-54-2 NF3 10 29

n-Butyl Amine (N-BA) 109-73-9 C4H11N 5 (ceiling) 15 (ceiling)

Ozone 10028-15-6 O3 0.2 0.4 0.1 0.2

Phosgene 75-44-5 COCl2 0.02 0.08 0.06 0.25 0.1 0.4

Phosphine 7803-51-2 PH3 0.1 0.14 0.2 0.28 0.3 0.4

Propylene Oxide 75-56-9 C3H6O 5 12 100 240

p-Phenylene Diamine (PPD) 106-50-3 C6H8N2 0.1 0.1

p-Phenylene Diisocyanate (PPDI) 104-49-4 C8H4N2O2

Silane 7803-62-5 SiH4 0.5 0.67 1 1.3

Stibine 7803-52-3 SbH3 0.1 0.5

Sulphur Dioxide 7446-09-5 SO2 5 13

Sulphuric Acid 7664-93-9 H2SO4 1

Tertiary Butyl Arsine (TBA)

Tertiary Butyl Phosphine (TBP) 2501-94-2 C

Tetraethyl Orthosilicate (TEOS) 78-10-4 C8H20O4Si

Tetrakis (Dimethylamino) Titanium (TDMAT) 3275-24-9 C8H24N4Ti

Tetramethyl Xylene Diisocyanate (TMXDI) C14H16N2O2

Toluene Diamine (TDA) 95-80-7 C7H10N2 50 191 150 574

Toluene Diisocyanate (TDI) 584-84-9 C9H6N2O2 0.02 (ceiling) 0.14 (ceiling)

Triethyl Amine (TEA) 121-44-8 C6H15N 2 8 4 17 2.5 100

Trimethylhexamethylene Diisocyanate (TMDI) C11H18N2O2

Unsymmetrical Dimethylhydrazine (UDMH) 57-14-7 C2H8N2

CAS Number FormulaCommon Name

4H11P

28 www.honeywellanalytics.com / www.gasmonitors.com

28

www.honeywellanalytics.com / www.gasmonitors.com

Page 29

EH40 Workplace Exposure Limit (WEL)

Long-Term Exposure Limit

(8-hour TWA reference period)

Short-Term Exposure Limit

(15-minute reference period)

OSHA Permissible

Exposure Limits (PEL)

Long-term Exposure Limit

(8-hour TWA reference period)

ppm mg/m

3

ppm mg/m

3

ppm mg/m

3

29

29

Page 30

7

Asphyxiant

Hazard

(Oxygen Deciency)

We all need to breathe the Oxygen (O2) in air to live.

Air is made up of several different gases including

Oxygen. Normal ambient air contains an Oxygen

concentration of 20.9% v/v. When the Oxygen level

falls below 19.5% v/v, the air is considered

Oxygen-decient. Oxygen concentrations below

16% v/v are considered unsafe for humans.

100%

OXYGEN DEPLETION

CAN BE CAUSED BY:

• Displacement

• Combustion

• Oxidation

• Chemical reaction

• Bacterial action

20.9%

v/v normal

v/v O

2

16%

v/v depletion

0%

v/v O

www.honeywellanalytics.com / www.gasmonitors.com30

2

6%

v/v fatal

Page 31

8

Oxygen

GAS

Enrichment

FACT

The atomic weight of

Radon is 222 atomic mass

units making it the heaviest

known gas. It is 220 times

heavier than the lightest

gas, Hydrogen.

It is often forgotten that Oxygen enrichment can also

cause a risk. At increased O

of materials and gases increases. At levels of 24%

items such as clothing can spontaneously combust.

Oxyacetylene welding equipment combines

Oxygen and Acetylene gas to produce an extremely

high temperature. Other areas where hazards may

arise from Oxygen enriched atmospheres include

manufacturing areas for storing rocket propulsion

systems, products used for bleaching in the pulp and

paper industry and clean water treatment facilities.

Sensors have to be specially certied for use in

O

enriched atmospheres.

2

levels the ammability

2

31

Page 32

9

Typical Areas

that Require

Gas Detection

There are many different applications for xed and portable gas detection. Industrial

processes increasingly involve the use and manufacture of highly dangerous substances,

particularly toxic and combustible gases. Inevitably, occasional escapes of gas occur,

which create a potential hazard to the plant, its employees and people living nearby.

Worldwide incidents involving asphyxiation, explosions and loss of life, are a constant

reminder of this problem.

Oil and gas (drilling

and production)

The oil and gas industry covers

a large number of upstream

activities from the on and

offshore exploration and

production of oil and gas to its

transportation and storage.

The Hydrocarbon gases involved

are a serious explosive risk

and toxic gases such as

Hydrogen Sulphide are often

present.

Typical Applications:

• Exploration drilling rigs

• Production platforms

• Onshore oil and gas terminals

• Facility turnarounds/shutdowns

• LPG storage areas

• Offshore and onshore drilling

and service rigs

• Offshore production platforms

• Personal Protective Equipment

(PPE)

Typical Gases:

Flammable: Various

Hydrocarbon gases including

Methane

Toxic: Hydrogen Sulphide,

Carbon Monoxide

Oxygen: Depletion

Refineries and

petrochemical

facilities

Reneries take crude oil mixes

and convert them into various

blends of Hydrocarbons for use

in a wide variety of subsequent

products.

Typical Applications:

• Flanges and pump seals for

Hydrocarbon detection

• Catalytic cracking process

monitoring

• Bulk storage areas

• Water drains, run-off gullies

and trenches

• Conned space entry

• Loading areas

• Ventilation systems

• Perimeter/fence-line

monitoring

• Planned maintenance and

shutdown/plant modication

Typical Gases:

Flammable: Various

Hydrocarbon gases including

Ethylene, Kerosene, Propane

and Methane

Toxic: Hydrogen Sulphide and

Sulphur Dioxide

Oxygen: Depletion

Chemical plants

Chemical plants manufacture

a myriad of products and

feedstocks. The nature and

diversity of chemicals used

and produced on site provide

considerable danger to assets

and personnel. These plants

often use a wide range of both

ammable and toxic gases in

their manufacturing processes.

Typical Applications:

• Raw material storage

• Process areas

• Laboratories

• Pump rows

• Compressor stations

• Loading/unloading areas

Typical Gases:

Flammable: Various

Hydrocarbons including

Petroleum and resins

Toxic: Various including

Hydrogen Sulphide,

Hydrogen Fluoride and Ammonia

Power generation

(traditional and

renewable)

Traditionally fossil fuels like coal,

oil and Natural Gas have been

used to generate electricity.

Today renewable energy is

becoming a key aspect of power

generation with wind power and

biogas becoming more prevalent

forms of power generation.

Typical Applications:

• Around boiler pipework and

burners

• In and around turbine

packages

• Working near landll gas

pipework

• Surface emissions monitoring

in landlls

• Blade production and welding

of steel parts (wind energy

manufacture)

• Conned spaces (in the tower

and nacelle)

• Working near landll leachate

pools and perimeter boreholes

Typical Gases:

Flammable: Natural Gas,

Hydrogen

Toxic: Carbon Monoxide,

Sulphur Oxide, Nitrogen Oxide,

Hydrogen Sulphide, VOCs

Oxygen: Depletion

www.honeywellanalytics.com / www.gasmonitors.com32

Page 33

We have produced various technical documents

regarding applications for gas detection. If you would

like to access this information, please visit

www.honeywellanalytics.com for xed gas detection

applications and www.gasmonitors.com for portable

gas detection applications.

Water treatment

Water treatment is a large industry

comprising of many processes

and aspects from the production

and distribution of clean water

to the collection, treatment

and disposal of waste such as

sewage.

Typical Applications:

• Purication plant monitoring

• Sewage digesters

• Plant sumps

• Plant intakes and penstocks

• Plant power generation

monitoring

• Hydrogen Sulphide scrubbers

Typical Gases:

Flammable: Various

Hydrocarbons including Methane

Toxic: Hydrogen Sulphide,

Carbon Dioxide, Chlorine,

Sulphur Dioxide and Ozone

Oxygen: Depletion

Marine

Marine gas hazards are

numerous. Liquid gas, fuel,

chemicals and other fossil fuels

harbour a risk of explosion.

There is a danger of suffocation

from Oxygen displacement when

using Nitrogen or other gases

for inerting. Toxic gases like

Hydrogen Sulphide also pose

considerable risks.

Typical Applications:

• Clearance measurements of

tanks and cargo bays

• Ship hold inspections

• Vessel entry/below deck entry

• Conned spaces, e.g. electric

motor room, hold spaces and

inter-barrier spaces

• Inerting and purging

• Leak detection

• Airlocks

• Burner platform vent hoods

• Engine room gas supply

pipelines

Typical Gases:

Flammable: Various

Hydrocarbons including

Liquid Natural Gas and Methane

Toxic: Hydrogen Sulphide and

Carbon Monoxide

Oxygen: Depletion

Military and

national security

The World’s militaries require

gas detection monitoring and

due to their mobility, portable

gas detection forms a key part

of protection against dangerous

gases.

Typical Applications:

• Fuel storage tanks

(including inspection)

• Transportation

(particularly of fuel)

• Vehicle refuelling

• Aircraft tank inspections

• Submarine septic tanks and

Hydrogen build-up

• Naval vessels engine room

monitoring and septic tanks

• Equipment and vehicle

maintenance

Typical Gases:

Flammable: Various blends of

Aviation Kerosene, Diesel and

Gasoline

Toxic: Carbon Monoxide,

Carbon Dioxide,

Hydrogen Sulphide and

Volatile Organic Compounds (VOCs)

Oxygen: Depletion

Pulp and paper

production

This vast industry includes both

mechanical and chemical pulping

methods that turn wood into a

variety of paper based products.

Toxic gas threats are present from

bleaching agents, whilst fuels

used to drive mechanical pulping

create ammable gas risks.

Typical Applications:

• Digesters (in chemical pulping)

• Chlorine during bleaching

• Fuel monitoring in mechanical

pulping

Typical Gases:

Flammable: Methane

Toxic: Chlorine, Chlorine Dioxide

and Ozone

Oxygen: Depletion

33

Page 34

Typical Areas that Require Gas Detection (continued)

Printing

Depending on the materials

being printed, processes within

the printing industry use various

solvents, inks and dangerous

chemicals, which are often dried

in very hot ovens, creating the

need for robust gas detection to

ensure process safety.

Typical Applications:

• Bulk storage of inks and

varnishes

• Dryers and ovens

• Exhaust monitoring

Typical Gases:

Flammable: Various

Hydrocarbons including solvents

and Methane

Tunnels and

car parks

Exhaust fumes can build-up in

car parks and tunnels, creating

toxic gas hazards. Gas detection

is used to monitor the build up

of gases like Carbon Monoxide

and Methane and also control the

ventilation systems.

Typical Applications:

• Car tunnels

• Underground and

enclosed car parks

• Ventilation control

• Access tunnels

Typical Gases:

Flammable: Methane,

Liquid Petroleum Gas and

Petrol vapour

Toxic: Carbon Monoxide and

Nitrogen Dioxide

Semiconductor

Manufacturing semiconductor

materials involves the use of toxic

and ammable gas. Phosphine,

Arsenic, Boron Trichloride and

Gallium are commonly used as

doping agents. Hydrogen is

used both as a reactant and a

reducing atmosphere carrier

gas. Etching and cleaning gases

include Ammonia and other

peruoro compounds.

Typical Applications:

• Wafer reactor

• Wafer dryers

• Gas cabinets

• Chemical Vapour Deposition

Typical Gases:

Flammable: Hydrogen, Propane,

Silane and Methane

Toxic: Hydrogen Chloride, Arsine,

Boron Trichloride, Phosphine,

Carbon Monoxide,

Hydrogen Fluoride,

Ozone, Dichlorosilane,

Tetraethyl Orthosilicate,

Hexauorobutadiene 1,3,

Octauorocyclopentene,

Germane, Ammonia and

Nitrogen Dioxide

Oxygen: Depletion

Photovoltaics

With more focus on renewable

energy, the photovoltaic (PV)

industry is experiencing

considerable growth. PV

applications use semiconductors

that exhibit the photovoltaic effect

in order to convert solar radiation

into direct current electricity, and

therefore use a semiconductor

manufacturing process.

Typical Applications:

• Wafer reactor

• Wafer dryers

• Gas cabinets

• Chemical Vapour Deposition

Typical Gases:

Flammable: Hydrogen, Propane,

Silane and Methane

Toxic: Hydrogen Chloride, Arsine,

Boron Trichloride, Phosphine,

Carbon Monoxide,

Hydrogen Fluoride,

Ozone, Dichlorosilane,

Tetraethyl Orthosilicate,

Hexauorobutadiene 1,3,

Octauorocyclopentene,

Germane, Ammonia and

Nitrogen Dioxide

Oxygen: Depletion

Confined spaces

These locations provide one of the

key application uses for portable

gas detectors, owing to their ability

for dangerous gases to build up

(see Conned spaces on page 60

for detailed information).

Typical Applications:

• Shafts

• Trenches

• Sewers and manholes

• Pits

• Boilers

• Tunnels

• Tanks

• Vessels (including marine

vessel tanks)

• Pipelines

• Containers

Typical Gases:

Flammable: Methane

Toxic: Carbon Monoxide and

Hydrogen Sulphide

Oxygen: Depletion

Building and

construction

Various dangerous chemicals

are used during construction

work and due to the mobility of

operatives in these applications,

portable gas detection forms an

integral part of on-site Personal

Protective Equipment (PPE)

Typical Applications:

• Trenching and shoring

Typical Gases:

Flammable: Methane

Toxic: Carbon Monoxide and

Hydrogen Sulphide

Oxygen: Depletion

34 www.honeywellanalytics.com / www.gasmonitors.com

34

Page 35

Typical Areas that Require Gas Detection (continued)

Ammonia

Refrigeration

Many industries use refrigeration

as part of their processes – from

food and beverage manufacture,

gas liquefaction and chemical

manufacture to cryogenics and

Liquid Natural Gas shipping.

It is essential to ensure that

Ammonia does not build-up,

causing potentially explosive

atmospheres.

Typical Applications:

• Ammonia storage areas

• Plant room valves, joints

and seals

• Chiller and refrigerator

monitoring

• Air conditioning systems

Typical Gases:

Flammable: Ammonia

Toxic: Ammonia

Laboratory and

medical

Laboratories and medical

facilities like hospitals may use

many different ammable and

toxic substances. Very large

installations may also feature

their own on-site utility supplies

and back-up power stations.

Typical Applications:

• Laboratories

• Cryogenics and refrigeration

• Boiler rooms

Typical Gases:

Flammable: Methane and

Hydrogen

Toxic: Carbon Monoxide,

Chlorine, Ammonia and

Ethylene Oxide

Oxygen: Depletion/enrichment

Steel Mills

Due to the large number of

furnaces and processes that

subject metals to extreme heat,

Carbon Monoxide detection is

essential throughout the plant.

Typical Applications:

• Furnace monitoring

• Oven monitoring

Typical Gases:

Toxic: Carbon Monoxide

Landfill monitoring and

Biogas generation

Landlls are designed to promote

and accelerate the decomposition

of organic material and may also

contain sorting and storage areas

for inorganic material. Landll gas

(known as Biogas), is often collected

at these sites so care should be

taken when personnel are working

close to potential sources.

Typical Applications:

• When working near leachate

pools

• When working near perimeter

boreholes

• When working near landll gas

pipework

• When monitoring surface

emissions

• When working near

weighbridges

• When handling waste

Typical Gases:

Flammable: Methane

Toxic: Carbon Dioxide,

Hydrogen Sulphide, Benzene

and Toulene

Oxygen: Depletion

Agriculture and live

stock

When it comes to keeping

livestock, Methane and Ammonia

can build-up to dangerous levels

in cattle sheds. Agricultural stores

where fertilisers and pesticide

stocks are held can also pose

additional explosive dangers.

Typical Applications:

• Cattle shed monitoring

• Agricultural fertiliser and

chemical stores

Mining

There is an abundance of mineral

and fossil fuel reserves being

mined globally, leaving personnel

at risk from dangerous gas

build-ups in the enclosed spaces

of mine shafts. This makes portable

gas detection an essential

component of mining safety.

Typical Applications:

• Excavation

• Continuous monitoring whilst

working in shafts

Typical Gases:

Flammable: Methane

Toxic: Carbon Monoxide

Oxygen: Depletion

Commercial

buildings and public

facilities

Commercial and public facilities

like swimming pools, shopping

centres and schools use

integrated safety systems, which

can include gas detection.

Large visitor numbers can increase

the risk of Carbon Dioxide

build-up and heating systems

may also need to be monitored

for flammable gas leaks.

Typical Applications:

• Mechanical rooms

• Swimming pools

• Schools

• Heating pipework monitoring

• Indoor air quality monitoring

Typical Gases:

Flammable: Methane

Toxic: Carbon Dioxide,

Carbon Monoxide, Chlorine

Oxygen: Depletion

Turnarounds, plant

shutdowns and

planned equipment

modifications

No matter what the industry and

application, planned shutdowns

and maintenance schedules

create additional risks on site

because they represent deviations

from standard processes.

Gas detection in the form of

portable monitoring solutions

should always be used to limit

these risks when modifying

aspects or processes of the plant.

35

Page 36

10

Principles of

Detection

Combustible Gas

Sensors

Many people have probably seen a ame safety

lamp at some time and know something about its

use as an early form of ‘redamp’ (the gases found

in coal mines. Also known as “minedamp”) gas

detector in underground coal mines and sewers.

Although originally intended as a source of light, the

device could also be used to estimate the level of

combustible gases - to an accuracy of about 25-50%,

depending on the user’s experience, training, age,

colour perception etc.

Modern combustible gas detectors have to be much

more accurate, reliable and repeatable than this and

although various attempts were made to overcome

the safety lamp’s subjectiveness of measurement

(by using a ame temperature sensor for instance),

it has now been almost entirely superseded by more

modern, electronic devices.

Nevertheless, today’s most commonly used device,

the catalytic detector, is in some respects a modern

development of the early ame safety lamp, since it

also relies for its operation on the combustion of a gas

and its conversion to Carbon Dioxide and water.

Controller

Signal

Detector

Signal

Sensitive

bead

Catalytic

sensor

Nearly all modern, low-cost, combustible

gas detection sensors are of the

electro-catalytic type. They consist of a very

small sensing element sometimes called

a ‘bead’, a ‘Pellistor’, or a ‘Siegistor’- the

last two being registered trade names for

commercial devices. They are made of an

electrically heated Platinum wire coil, covered

rst with a ceramic base such as Alumina and

then with a nal outer coating of Palladium or

Rhodium catalyst dispersed in a substrate

of Thoria.

Non-sensitive

bead

3 Wire mV Bridge Circuit

www.honeywellanalytics.com / www.gasmonitors.com36

This type of sensor operates on the principle

that when a combustible gas/air mixture

passes over the hot catalyst surface,

combustion occurs and the heat evolved

increases the temperature of the ‘bead’.

This in turn alters the resistance of the

Platinum coil and can be measured by using

the coil as a temperature thermometer in a

standard electrical bridge circuit.

The resistance change is then directly related

to the gas concentration in the surrounding

atmosphere and can be displayed on a meter

or some similar indicating device.

Page 37

Speed of

response

To achieve the necessary requirements of

design safety, the catalytic type of sensor

has to be mounted in a strong metal housing

behind a ame arrestor. This allows the

gas/air mixture to diffuse into the housing

and on to the hot sensor element, but will

prevent the propagation of any ame to

the outside atmosphere. The ame arrestor

slightly reduces the speed of response of

the sensor but, in most cases the electrical

output will give a reading in a matter of

seconds after gas has been detected.

However, because the response curve is

considerably attened as it approaches

the nal reading, the response time is often

specied in terms of the time to reach 90

percent of its nal reading and is therefore

known as the T90 value. T90 values for

catalytic sensors are typically between 20

and 30 seconds.

(N.B. In the USA and some other countries,

this value is often quoted as the lower T60

reading and care should therefore be taken

when comparing the performance of

different sensors).

100

50

% Response (Indicated)

0

T60 T90

(TIME)

Sensor

output

To ensure temperature stability under

varying ambient conditions, the

best catalytic sensors use thermally

matched beads. They are located in

opposing arms of a Wheatstone bridge

electrical circuit, where the ‘sensitive’

sensor (usually known as the ‘s’ sensor)

will react to any combustible gases

present, whilst a balancing, ‘inactive’

or ‘non-sensitive’ (n-s) sensor will not.