Page 1

AUTOMATIC BYPASS AND DIFFERENTIAL PRESSURE

VALVE WITH DIFFERENTIAL PRESSURE INDICATOR

Design

The bypass and differential pressure valve comprises:

• Body with internally threaded inlet and outlet

• Spring bonnet

• Display tube for differential pressure indication

• Adjustment facility

• Valve disc

• Spring

Materials

• Unpolished brass housing

• High-grade synthetic material spring bonnet

• High-temperature resistant synthetic material display tube

• High-quality synthetic material adjus ter knob

• Brass valve disc

• Stainless-steel spring

• EPDM seals

DU146

PRODUCT DATA

Application

The DU146 automatic bypass and differential pressure valve

is used to maintain constant differential pressure in a heating

system. It reduces flow noise in a system, particularly as

thermostatic radiator valves are closing. The boiler return

temperature is raised and this reduces the corrosion caused

by flue gas condensation. In addition, when radiator valves

are closed it also maintains flow over the temperature sensor

on the boiler to ensure proper operation of external temperature compensating controls. On gas fired water heaters it

guarantees a minimum flow circulation when thermostats or

radiator valves are closed.

Features

• Simple installation between the flow and return pipe-

work

• Minimises flow noise

• No external controls required

• Differential pressure finely adjustable

• Simple adjustment using the integral differential

pressure indicator

• Hinders boiler corrosion

• Setting value is in meters water column

• Tried and tested

Range of Applicati on

For pumped hot water heating systems

Specifications

Medium

Operating temperature

Operating pressure

Differential pressure

Connection size

Hot water

max. 110°C (230°F)

max. 3,0 bar (43,5 P.S.I.)

Adjustable between

0,05...0,5 bar (0,7...7,3 P.S.I.)

Set during manufacture at 0,2 bar

(2,9 P.S.I.)

3/4" and 1 1/4"

Copyright © 2002 Honeywell AG • All rights reserved EN0H-0181GE25 R0402

Page 2

DU146

Function

At equal pressure between the inlet and outlet side the valve

is closed. The valve disc is pushed by a spring against the

valve seat. If there is a pressure difference between the inlet

and outlet sides, then a force is exerted on the valve disc and

against the spring. If this force exceeds the force of the

spring, then the valve begins to open in proportion to the rise

in differential pressure and maintains a constant bypas s flow

as indicated on the flow diagram.

Versions

A = Standard version

Special versions on request

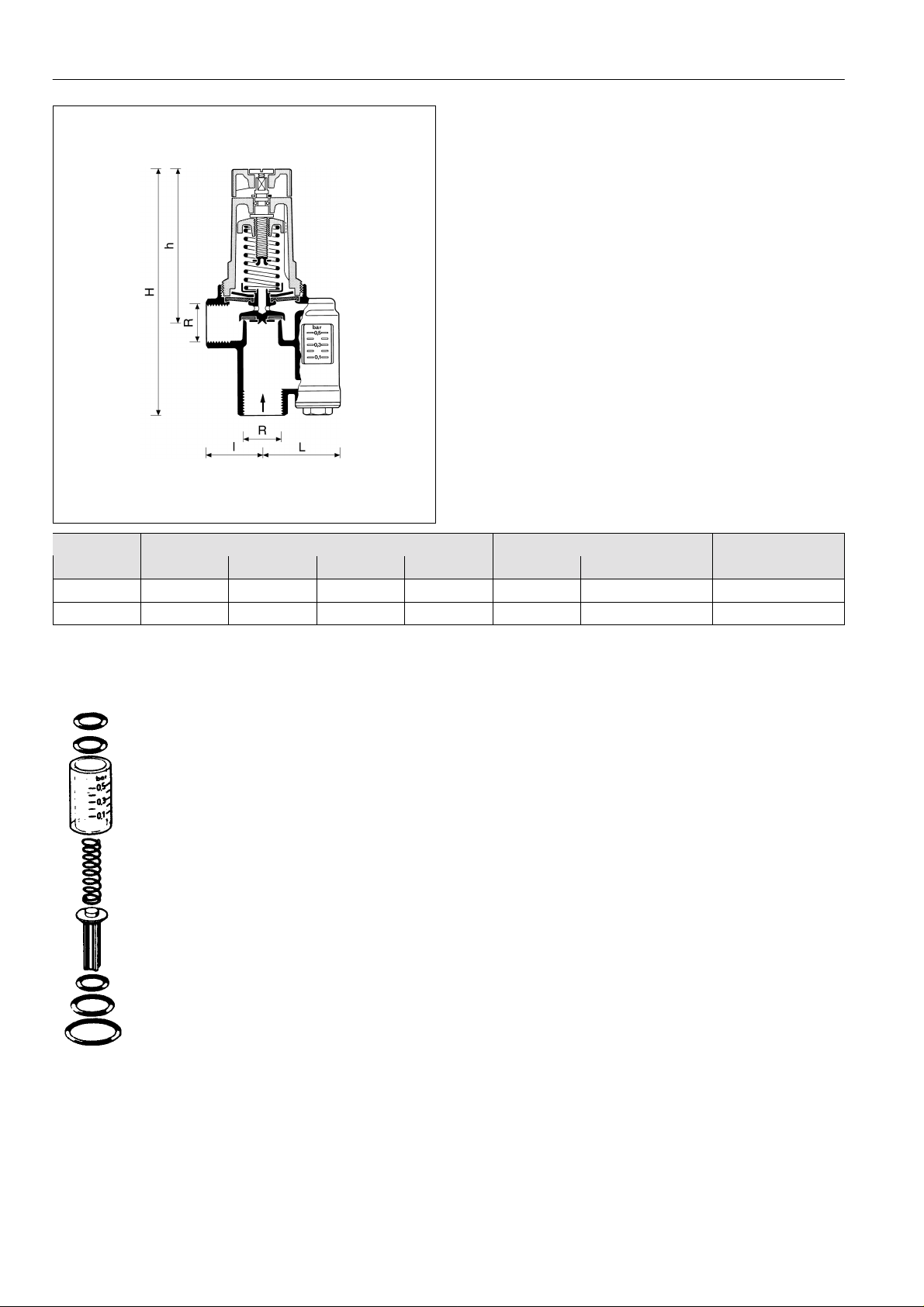

Dimensions for installations 90/70 up toType R

L I H h ca. kW approx. kcal/h

3/4" 36 50 160 100 70 60 000 DU146-3/4 A

1 1/4" 51 58 213 155 232 200 000 DU146-1 1/4 A

Ordering-No.

Accessories

Complete indicator tube

For DU146 differential

pressure and bypass

valve.

Comprising: Indicator

tube, spring, indicator

piston and 5 ‘O’ rings

DU146AH-A

EN0H-0181GE25 R0402 2 Honeywell AG • All rights reserved

Page 3

DU146

Installation Guidelines

• Simple installation between flow and return

• No external controls required

• Not suitable for district heating installations

• For maintenance purposes it is recommended that shutoff

valves be fitted on both sides of the bypass valve

Flow Diagrams

Typical Applications

Automatic bypass and differential pressure valves are installed in heating systems to maintain a constant differential

pressure and to minimise water flow noise.

DU 146 can be installed:

• On heating systems with three-way mixer valves

• On heating systems with four-way mixer valves

• On gas-fired hot water circulation heating systems

Turns

Honeywell AG • All rights reserved 3 EN0H-0181GE25 R0402

Page 4

DU146

Home and Buil ding Control

Honeywell AG Phone: (49) 2932 9880

Zu den Ruhrwiesen 3 Fax: (49) 2932 988239

D-59755 Arnsberg-Neheim mng@honeywell.com http://europe.hbc.honeywell.com

EN0H-0181GE25 R0402 4 Subject to change • All rights reserved

Loading...

Loading...