Page 1

e

n

e

r

g

www.energysavingtrust.org.uk

g

n

i

v

a

s

y

DU144

Automatic Bypass Valve

INSTALLATION INSTRUCTIONS

Building Regulations

An Automatic Bypass Valve (DU144) controls water flow in the Heating Circuit according to the water pressure

across it and is used to maintain a minimum flow rate through the boiler and to limit circulation pressure when other

water paths are closed.

A bypass circuit must be installed if the Boiler manufacturer requires one, or specifies that a minimum flow rate has

to be maintained whilst the Boiler is firing.

The use of Automatic Bypass Valves becomes particularly important when Heating Systems include large numbers

of Thermostatic Radiator Valves (TRVs) – whilst the TRVs are open the Automatic Bypass Valve remains closed,

however, as the TRVs start to close, the Automatic Bypass Valve starts to open maintaining the required water

flow through the boiler. Using an Automatic Bypass Valve is also likely to reduce noise in systems caused by

excess water velocities.

Because manual or fixed position valves do not regulate the flow and allow water to bypass even when it is not

necessary, Building Regulations require bypass circuits to use Automatic Bypass Valves and not fixed position

valves.

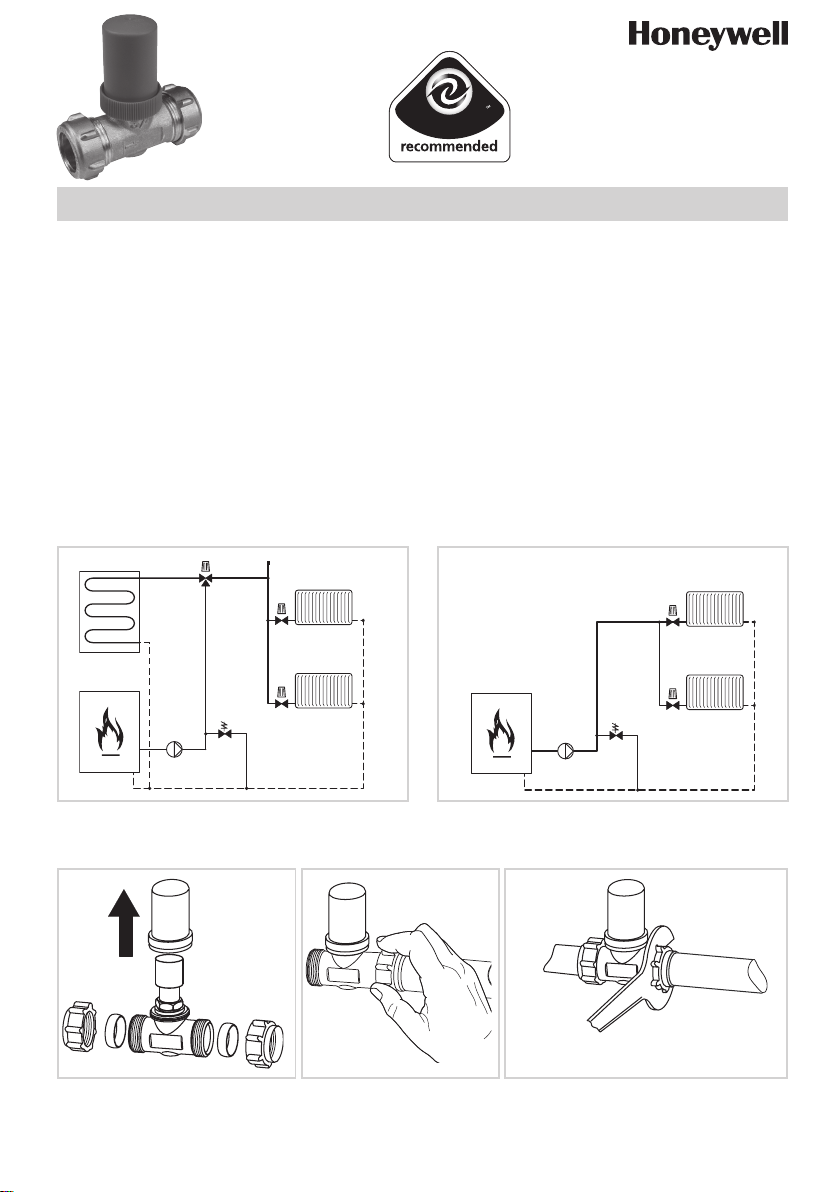

Location in System

Installation

Remove protective cap to set

04 100 25 001 000 EN2H-0286GE25 R0207

ABV

TRV

TRV

Install the DU144 with flow in

the direction of the Arrow on

the Body

TRV

TRV

ABV

System with combi boilerSystem with stored hot water

Use a correctly sized open ended

spanner to tighten.

Do not over tighten.

Page 2

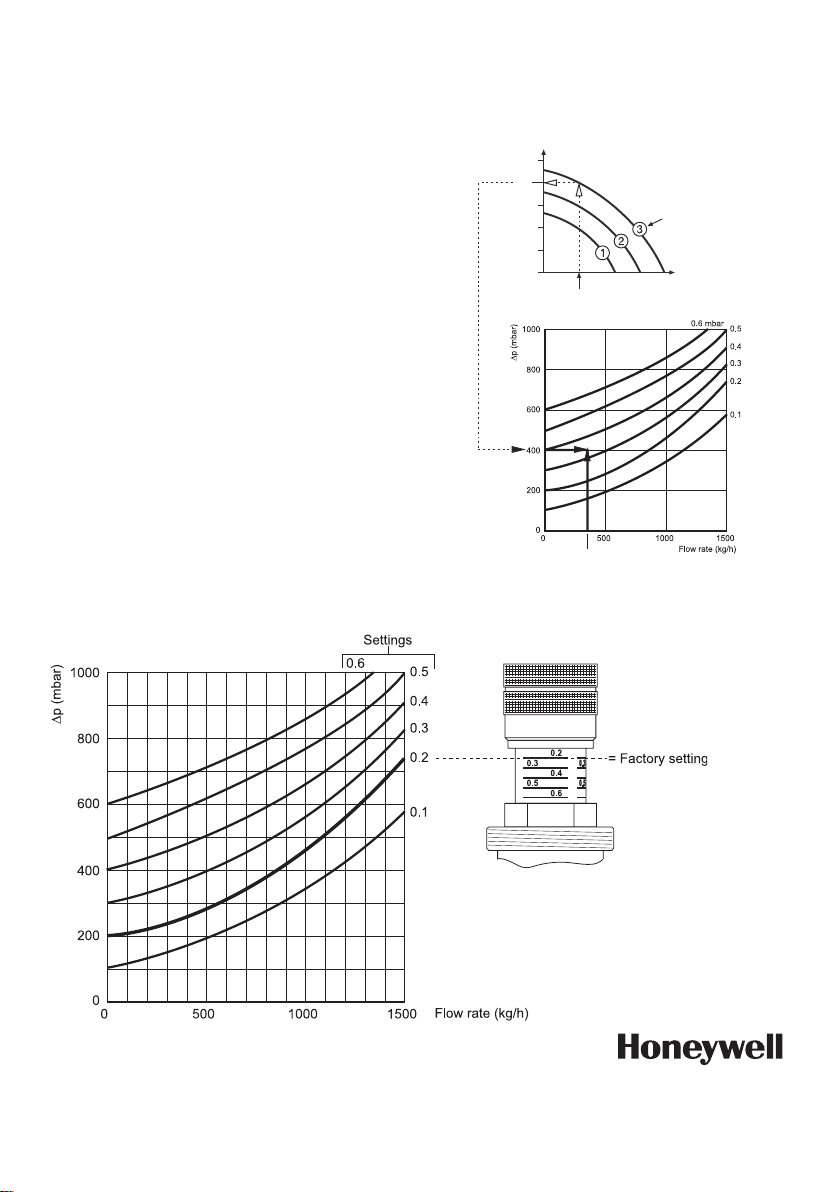

Setting Procedure

1) Commission and balance the Heating System –

take note of the selected pump speed.

2) Using the Boiler manufacturer’s instructions, find

the minimum flow requirement for the Boiler.

3) Using the Pump manufacturer‘s Pump curves

determine the available Pump head when

operating at the required minimum flow and the

selected Pump speed.

4) Using the DU144 Setting chart, the calculated

Pump Head and the minimum Boiler Flow to find

the optimum setting for the DU144

Note: To set the DU144, remove the protective cap

and turn the setting handle until the bottom of

the handle crosses the corresponding line on the

DU144 stem.

Note: The cap is internally fixed with sealing wax

during assembly. Turn firmly to break the seal.

Should persistent water velocity noise occur in the

Heating System, gradually turn the DU144 to a lower

setting until the noise is eliminated.

Important: replace protective cap after setting the

DU144 to avoid tampering

Example:

Minimum flow 300 l/h - Pump speed 3.

Pump chart indicates 4 m head (Use Pump

Manufactures chart).

Pump Head

3) Available head

(example 4m)

5) Available head

(example 4m)

5m

4m

3m

2m

1m

2) 300 l/h Boiler min. flow

4) Minimum flow

(example 300 l/h)

Pump Speed

Flow l/h

Using DU144 Setting Chart:

4m Head / Minimum Flow 300 l/h

Result = Set DU144 to setting 0.35

Note: For pre-setting use

line below the

number

Honeywell Control Systems Ltd.

Honeywell House

Arlington Business Park

Bracknell, Berkshire RG12 1EB

Phone: 01344 656000

Fax: 01344 656240

Manufactured for and on behalf of the Environment and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

Subject to change • All rights reserved

EN2H-0286GE25 R0207

© 2007 Honeywell International Inc.

Loading...

Loading...