Page 1

DT900AM Series DUAL TEC® Motion Sensor for Commercial

and Light Industrial Applications—Installation Instructions

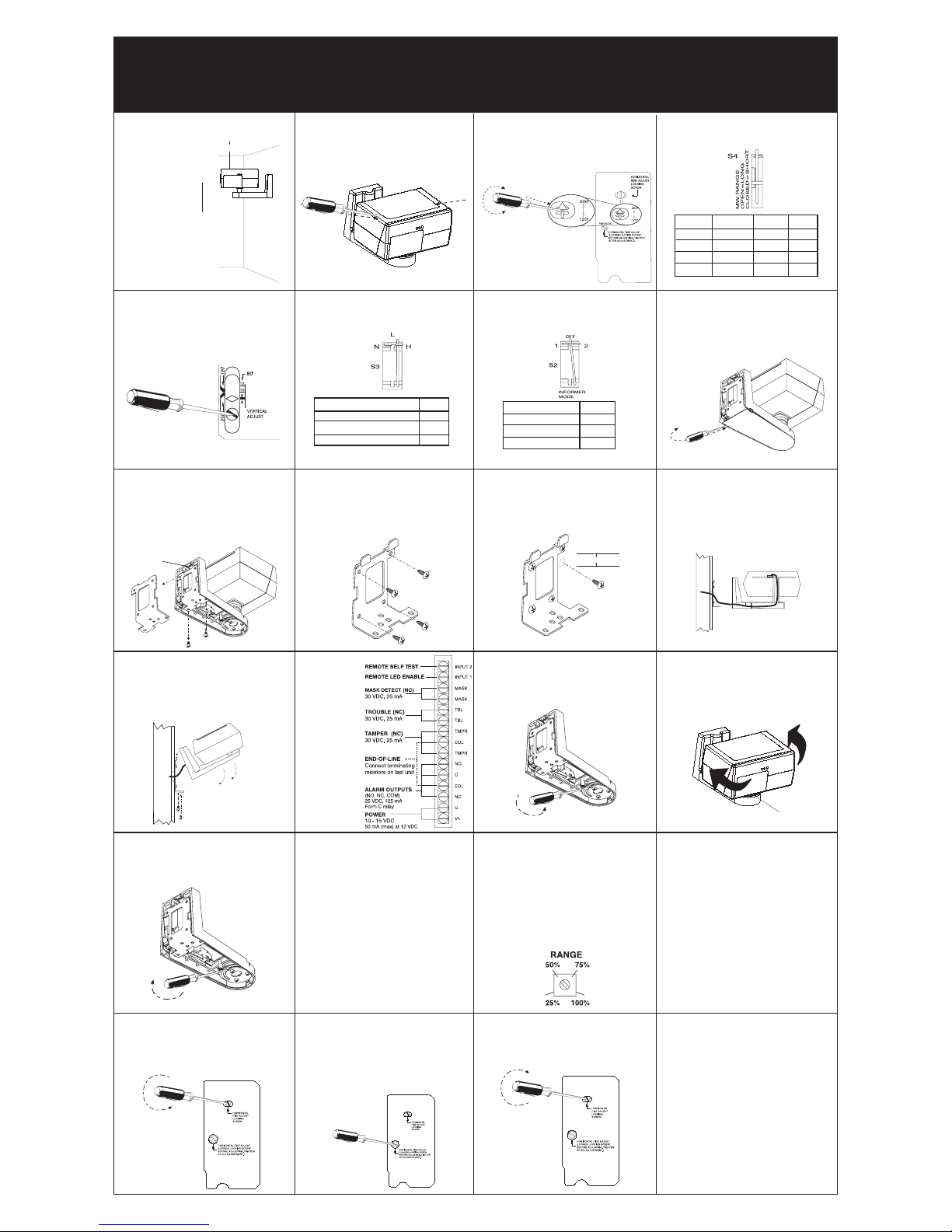

Step 1

Select mounting height.

Step 2

Carefully push screwdriver into slots

to disengage latches and open top

cover.

Step 3

DT906AM ONLY: Firmly insert

screwdriver into slot in arrow and

rotate PIR Mirror Selector to the

correct range.

Step 5

Locate correct sensor range scale

and rotate Vertical Adjustment Screw

until the diamond corresponds to the

sensor mounting height (coarse

adjust).

Step 6

Set switch S3 to establish the

sensitivity best suited to your application.

Step 7

Select INFORMER

®

mode with switch

S2, if desired. (See INFORMER Mode

section).

SENSITIVITY

HIGH (Pulse Count 1)

NORMAL (Pulse Count 2)

LOW (Pulse Count 3)

H*

N

L**

S3

*Factory default setting; recommended setting

for DT906AM. **Not connected.

Step 8

Carefully push screwdriver into slot

to disengage latch and remove

bottom cover.

Step 9

Unfasten screws and remove mounting plate from sensor. If required,

remove the knockout to allow wire

entry via electric metallic tubing or

surface wiring conduit.

Step 10

Attach mounting plate to wall at

desired height, using four screws

(not supplied).

Step 11

Install M5 (#10) screw (not supplied)

in wall 1.9 cm (3/4”) below mounting

screw, as shown, for tamper activation.

Step 12

Pull about 30 cm (12”) of wire from

wall through the opening in the

mounting plate and route wire to the

terminal strip.

Step 13

Hang the sensor on the mounting

plate hooks and fasten with the two

mounting plate screws.

Step 14

Wire the

unit as

shown.

Use

0.8 - 1.5 mm

(22-16 AWG).

NOTE: Secure

wires to

mounting plate

with tie wraps.

Step 15

Loosen horizontal locking screw in

sensor support base.

Step 16

Grasp housing and rotate it to the

desired position (coarse adjust). If

fine adjust is needed see Steps 21-

23.

NOTE: Reference marks = 5° change.

Step 18

Apply power to the sensor, and all

the LED’s will start flashing rapidly.

Wait 90 seconds for the power-up

self-test to finish, at which point, if

there is no motion in the detection

area, all the LED’s will be off, and the

sensor will be ready for walk testing.

If the three LED’s do not go off after

90 seconds, refer to the Troubleshooting section.

1.9 cm (3/4”)

Step 21

For fine horizontal adjustment, loosen

the PIR horizontal fine locking screw

on the PCB.

Step 23

Tighten the horizontal fine locking

screw on the PCB.

NOTE: Fine adjustment allows for small

changes (3 degrees right or left) between

coarse settings.

Step 22

Rotate the horizontal fine adjust knob

to the desired position.

30 cm (12”) minimum

*Factory default setting.

Step 4

Set switch S4 to establish microwave

range.

Step 17

Tighten horizontal locking screw in

sensor support base.

Step 24

Remove the jumper at J4 on the PCB

to disable the LEDs after walktesting, and complete installation by

closing the top cover and replacing

the bottom cover.

NOTE: Fine adjust may be needed during

walk-test. (See Troubleshooting section.)

2 m (6’)

4 m (12’)

Step 20

Walk-test the sensor to check for

adequate detection coverage and to

verify the sensor is fully functional.

Depending on the selected sensitivity level, the sensor will alarm after

taking between 2 and 4 steps in the

detection pattern.

NOTE: If an on-going trouble, mask or

INFORMER condition occurs, the LEDs will

display a pattern that identifies the trouble.

(See the Troubleshooting section).

Step 19

Turn the microwave potentiometer

counterclockwise to decrease the

microwave range to minimum.

During walk-test, gradually turn the

potentiometer clockwise increasing

microwave sensitivity until the

desired range is obtained.

Optimal

Mounting

Height

2.3m (7’6”)

Mounting Location Guidelines

• Avoid direct or reflected sunlight

• Aim sensor away from windows, heating/

cooling devices or large moving objects.

• Sensor must have a clear line-of-sight to

protected area

INFORMER MODE

OFF

MODE 1

MODE 2

S2

OFF*

1

2

*Factory default setting (not connected).

Knockout

MODEL RANGE

Switch S4

MIRROR

Selector

DT906AM 61 m (200’) OPEN* 200’ *

DT906AM

37 m (120’) CLOSED 120’

DT900AM 24.4 m (80’) OPEN* N/A

DT900AM 15 m (50’) CLOSED N/A

Page 2

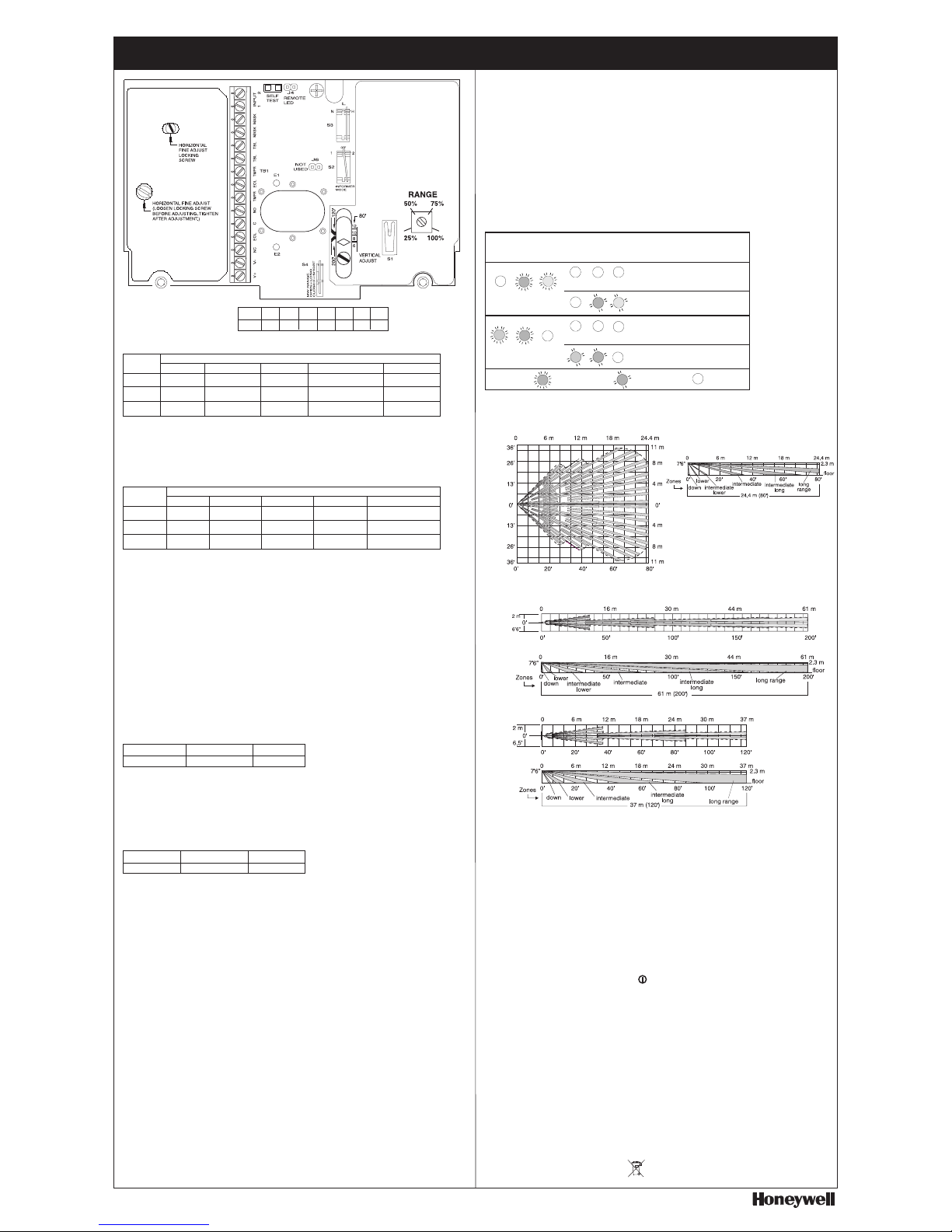

DT900AM Series DUAL TEC® Motion Sensor Product Information

6 8 10 12 80 120 200

1.8 2.4 3 3.7 24.4 37 61

Feet

Meters

Red

Yellow

Green

Normal

ON

Alarm

ON

Microwave

ON

PIR

Power Up/Trouble

1

Rapid Flash

Rapid Flash

Rapid Flash

Mask

Rapid Flash

OFF

Rapid Flash

Microwave INFORMER

1,2

Rapid Flash

Rapid Flash

OFF

OPERATION MODE

Figure 1

DT900AM

Printed Circuit Board (PCB)

LED INDICATORS

LED

PIR INFORMER

1,2

Rapid Flash

OFF

Rapid Flash

1

If a Trouble or INFORMER condition LED pattern disappears before being noted, initiate a self test (see Self Test section),

and the sensor will show the last LED pattern stored in the sensor’s memory. To clear this display, initiate another self test.

2

The noted LED patterns will only occur when no motion is present in the detection pattern. For additional microwave

and PIR INFORMER mode LED information, see the Troubleshooting section.

NOTE: LED’s operate as listed only when the LED’s are enabled (see LED Enable section).

Alarm Relay

Trouble Relay

Mask Relay

Normal

Closed

Closed

Closed

Intrusion

Open

Closed

Closed

Trouble

1

Closed

Open

Closed

Mask

1

Closed

Closed

Open

OPERATION MODE

RELAY OPERATION

Relay

PIR/MW INFORMER

2

Closed

Open

Closed

1

In a Trouble or Mask condition, the Trouble relay or Mask relay (respectively) will latch open until the condition has been

cleared. For more information, see the Troubleshooting section.

2

For information on INFORMER conditions, see the INFORMER Troubleshooting Matrix in the Troubleshooting section.

MASK FUNCTION

Normal Anti-Mask Operation

The DT900AM series features an anti-mask function that detects attempts to mask the sensor. The sensor

sends active Infra-Red beams out into the sensor’s field-of-view, and monitors for reflections from materials

that will block or cover the sensor. If the sensor registers a mask condition, it will open the mask relay and

rapidly flash the red and green LEDs. To avoid false mask alarms, follow the mounting guidelines shown in

Step 1.

Clearing an Anti-Mask Condition

Visually inspect the sensor, and remove any materials blocking the sensor’s view, and the sensor will

normally reset automatically. If the sensor remains in a Mask condition, walk test the sensor to ensure a

maximum detection range, and then cycle the sensor’s power to reset it.

LED ENABLE (Note: TS50131-2-4 Compliant)

The LED’s will only be enabled either by installing Jumper J4 or by connecting the Remote LED Enable

terminal as per the table below (see also INPUT 1 & 2 in the Product Specifications section).

High/Not Connected Low

LED’s Disabled LED’s Enabled

Remote LED Enable

NOTE: Do not fit jumper J4 at the same time as the

Remote LED Enable terminal is low, or the LED’s will

not illuminate.

SELF TEST

The sensor will perform a series of self-tests in the following instances:

• On power up

• Automatically every hour during normal operation

• On installer initiation. Self tests can be installer initiated either by momentarily short circuiting the two self

test pads on the PCB (see Figure 1), or by connecting the Remote Self Test terminal, as per the table

below. (See INPUT 1 & 2 in the Product Specifications section.)

Remote Self Test

NOTE: When a self test error occurs, the Trouble

relay will latch open and all three LED’s will flash

rapidly. If the problem persists, refer to the Troubleshooting section.

High/Not Connected Low

Normal Operation Self Test

INFORMER MODE

The INFORMER mode is a useful diagnostic tool for identifying environmental conditions that are liable to

cause installation problems.

The INFORMER circuit counts the number of events registered by both the microwave and PIR technologies,

and uses the resulting ratio to determine if either technology is working properly or is misapplied. Establish

the INFORMER mode using switch S2 (see Step 7).

Mode 1: Set S2 to position 1. In Mode 1, 32 PIR events without a microwave event will cause the unit to go

into PIR INFORMER. 128 microwave events without a PIR event will cause the unit to go into microwave

INFORMER.

Mode 2: Set S2 to position 2. In Mode 2, 16 PIR events without a microwave event will cause the unit to go

into PIR INFORMER. 16 microwave events without a PIR event will cause the unit to go into microwave

INFORMER.

NOTE: The Mode 2 setting is not recommended. Use only if INFORMER indication is required quickly.

Disabled: To disable INFORMER function, set S2 to the open (OFF) position (factory default setting).

When an INFORMER condition occurs, the trouble relay opens, and the LEDs display an INFORMER trouble

code (see the INFORMER Troubleshooting Matrix in the Troubleshooting section).

NOTE: One LED indication does not relate to one PIR or Microwave event.

TROUBLESHOOTING (Continued)

Problem: The sensor’s PIR range is too long or short.

Explanation: Various mounting locations may require fine vertical adjustment (e.g., due to uneven walls

or floors, etc.).

Solution: During the walk-test, if the PIR is short-ranged, turn the Vertical Adjust Screw counterclockwise. If

the PIR is over-ranged, turn the Vertical Adjust Screw clockwise. (See Step 5.)

Problem: A combination of the sensor’s LED’s are flashing slowly when there is no motion in the detection area.

Explanation: INFORMER mode is selected on the sensor, and there is a potential false alarm source in the

local environment.

Solution: The table below describes two trouble alerts which are reported by the INFORMER circuit. To

use this troubleshooting matrix:

1) Find the trouble alert that describes the condition of the walk-test LEDs (with no motion in the area).

2) Walk-test the sensor, carefully watching the reaction of the diagnostic LEDs.

3) Refer to the Possible Causes column of the matrix for an explanation of the way in which the

diagnostic LEDs reacted to the walk-test.

4) If no environmental sources can be found, initiate a self test. If the sensor fails the self test,

replace the sensor. If not, relocate the sensor and re-test.

NOTE: If on entering the

detection pattern the LEDs

go off, the INFORMER LED

pattern can be retrieved by

initiating a self test. (See

Note 1 in the LED Indicators section.)

INFORMER

Troubleshooting

Matrix

MW environmental problem

MW unstable

MW range too long

PIR was blocked

(Pattern disappears)

Reaction of LEDs

to Walk-Test

Condition of LEDs

with No Motion

MW

(Yellow)

ALARM

(Red)

PIR

(Green)

PIR

(Green)MW(Yellow)

ALARM

(Red)

RATIO

IMBALANCE

RATIO

IMBALANCE

Type of

Problem

RATIO

IMBALANCE

RATIO

IMBALANCE

PIR environmental problem

PIR unstable

MW range too short

Possible

Causes

PIR range too short

PIR aimed wrong

PIR not reporting

MW range too short

MW not reporting

LED Legend:

(Pattern disappears)

(Microwave INFORMER)

(PIR INFORMER)

PRODUCT SPECIFICATIONS

Range:

DT906AM

200’ Mirror - 61 m x 3 m (200' x 10')

120’ Mirror - 37 m x 3 m (120' x 10')

DT900AM

24.4 m x 21 m (80' x 69')

Power requirements:

10 - 15 VDC

50 mA (max) at 12 VDC

AC Ripple: 3V peak-to-peak

at nominal 12 VDC

Alarm relay:

Energized Form C

25 VDC, 125 mA

22 ohm series protection resistor

Trouble relay:

De-energized Form B

(Normally closed)

30 VDC, 25mA

Mask relay:

De-energized Form B

(Normally closed)

30 VDC, 25mA

Tamper Switches:

Wall, top & bottom covers

30 VDC, 25 mA (NC)

INPUT 1 (Remote LED Enable) &

INPUT 2 (Remote Self Test):

Active low (0 to 1.5V)

Inactive high (5 to V+ / Unconnected)

Microwave frequency:

X-Band; 10.687 GHz

PIR white light immunity:

6500 Lux typical

RFI immunity:

30 V/m, 10 MHz - 1000 MHz

Operating temperature:

-10

o

to 55o C / 14o to 131o F

(Indoor use environment)

Relative humidity:

5% to 95% relative humidity

(non-condensing)

PIR fields of view:

61 m (200’) Range 37 m (120’) Range 24.4 m (80’) Range

2 long 6 long 22 long

6 intermediate long 4 intermediate long 18 intermediate long

4 intermediate 4 intermediate 16 intermediate

4 intermediate lower 8 lower 12 intermediate lower

8 lower 2 down 8 lower

2 down 2 down

Sensitivity:

2 - 4 steps within field-of-view

Dimensions:

20 cm x 16.5 cm x 15.2 cm

8” x 6 1/2” x 6”

Weight:

1.36 kg

Packaged Product Approx.: 1.60 kg

Approvals/listings:

CE

PD6662:2004, prEN 50131-1:2004 and TS50131-2-4:2004

Security Grade 3, Environmental Class II.

Suitable for connection to an EN 60950 Class II Limited Power

Source in European installations.

Note: In TS50131-2-4 compliant installations, mount the

sensor at 2.3 m, select the high sensitivity setting and set

switch S4 to OPEN.

To obtain applicable EU compliance Declaration of Conformities

for this product, please refer to our Website,

http://www.security.honeywell.com/hsce/international/index.html.

For any additional information regarding the compliance of this

product to any EU specific requirements, please contact:

Quality Assurance Department,

Honeywell Security & Custom Electronics,

Newhouse Industrial Estate

Motherwell,

Lanarkshire ML1 5SB,

Scotland,

United Kingdom.

Tel: +44(0)1698 738200

Email: UK64Sales@Honeywell.com

TROUBLESHOOTING

Problem: All three LED’s are flashing rapidly (LED’s are enabled), and the Trouble relay is activated.

Explanation: The sensor is in one of the following three conditions:

Power Up: The sensor is still warming up.

Low Voltage: The sensor’s supply voltage is too low.

Self Test Failure: The sensor has failed one of its internal tests.

Solution: Wait for at least 90 seconds for the sensor to power up, and then ensure that the power supply is

greater than 8 VDC. If the three LED’s are still flashing rapidly, the sensor is faulty and should be replaced.

Problem: The sensor’s LED’s are not illuminating.

Explanation: The sensor is not set up correctly.

Solution: Check that either the Jumper J4 is fitted or that the Remote LED Enable terminal is connected to

0V, but NOT both at the same time. If only one of these options is selected, and the LED’s still do not

illuminate, the sensor is faulty and should be replaced.

DETECTION PATTERNS

Honeywell, IntelliSense, DUAL TEC and INFORMER are registered trademarks

of Honeywell International Inc. All right reserved. Made in China

Copyright 2006 Honeywell International Inc.

5-051-367-00 Rev A

Please contact your local authorised Honeywell

representative for product warranty information.

37 m (120’) Range

Patterns for: DT906AM

61 m (200’) Range

TOP

VIEW

SIDE

VIEW

TOP

VIEW

Patterns for: DT900AM

24.4 m (80’) Range

SIDE

VIEW

TOP

VIEW

SIDE VIEW

INPUT 1

INPUT 2

=LED is OFF

= LED is Flashing

Rapidly

= LED is Flashing

Slowly

Loading...

Loading...