Page 1

GB

F

NL

I

E

445501

D GB F NL I E

TR CZ PL RUS H

Operating instructions

Pressure switches for air DL..A, DL..K

© 2018 Elster GmbH · Edition 05.18

Cert. version 05.18

Translation from the German

Contents

Contents

Pressure switches for air DL..A, DL..K......1

Contents ..............................1

Safety.................................1

Checking the usage .....................

Type code .............................2

Part designations ........................ 2

Type label.............................. 2

Installation ............................

Positive pressure measurement .............3

Negative pressure measurement . . . . . . . . . . . . 4

Differential pressure measurement ...........4

Wiring ................................4

Adjustment ............................5

Function check.........................5

Accessories ...........................5

Z-angle bracket .........................5

U-angle bracket .........................6

Standard coupler plug ....................6

Motor flange adapter . . . . . . . . . . . . . . . . . . . . . 6

Tube set ...............................6

Pilot lamp set, red or blue .................6

LED set, red/green....................... 7

External adjustment ......................7

Technical data .........................7

Designed lifetime ........................ 7

Logistics ..............................8

Certification ...........................8

Declaration of conformity ..................8

Contact ...............................8

DK S N P GR

➔ www.docuthek.com

Safety

Safety

Please read and keep in a safe place

Please read through these instructions

carefully before installing or operating. Following the

installation, pass the instructions on to the operator. This unit must be installed and commissioned

in accordance with the regulations and standards

in force. These instructions can also be found at

www.docuthek.com.

Explanation of symbols

• , 1 , , ... = Action

▷ = Instruction

Liability

We will not be held liable for damage resulting from

non-observance of the instructions and non-compliant use.

Safety instructions

Information that is relevant for safety is indicated in

the instructions as follows:

DANGER

Indicates potentially fatal situations.

WARNING

Indicates possible danger to life and limb.

CAUTION

Indicates possible material damage.

All interventions may only be carried out by qualified

gas technicians. Electrical interventions may only be

carried out by qualified electricians.

Conversion, spare parts

All technical changes are prohibited. Only use OEM

spare parts.

Changes to edition 11.17

The following chapters have been changed:

– Checking the usage

– Installation

– Certification

GB-1

Page 2

GB

F

NL

I

E

Checking the usage

DL 1,5 – A, DL K, DL 5 – 150A, DL 5 – 150K

For monitoring positive, negative or differential air or

flue gas pressures.

This function is only guaranteed when used within

the specified limits– see page7 (Technical data).

Any other use is considered as non-compliant.

Type code

Code Description

DL Pressure switch for air

1,5 – 150 Max. setting in mbar

K

A

T T-product

-

-

-4

-5

-6

-9

K

T

T

N

A External adjustment

W Z-angle bracket

Part designations

1 Upper housing section with cover

Lower housing section

Hand wheel

4 M16 cable gland

Type label

Max. inlet pressure = withstand pressure, mains voltage, ambient temperature, enclosure: see type label.

With tube connection and hand wheel

Additionally with Rp¼connection

(optional: Rp

1

/8)

Electrical connection

via screw terminals, ½" NPT

via screw terminals

via screw terminals, IP 65

4-pin plug, without socket

4-pin plug, with socket

4-pin plug, with socket, IP 65

Red/green pilot LED for 24 V DC/AC

Blue pilot lamp for 230 V AC

Red/green pilot LED for 230 V AC

Blue pilot lamp for 120 V AC

22

3

4

1

D-49018 Osnabrück, Germany

DL

CE

2

3

1

Installation

CAUTION

Please observe the following to ensure that the DL

is not damaged during installation and operation:

– Dropping the device can cause permanent da-

mage. In this event, replace the entire device

and associated modules before use.

– Use approved sealing material only.

– Note the max. medium and ambient tempera-

tures, see page7 (Technical data).

– Condensation must not be allowed to get into

the housing (if possible, install pipework with an

ascending gradient). Otherwise, there is a risk of

icing of condensation at subzero temperatures,

the switching point shifting or corrosion in the

device which can lead to malfunctions.

– Protect the connections against dirt or moisture

in the medium to be measured or the surround-

ing air. If necessary, install a filter.

– In case of highly fluctuating pressures, install a

damping nozzle/restrictor orifice.

– When installing outdoors, place the DL in a

roofed area and protect from direct sunlight

(even IP65 version). To avoid condensation,

the cover with pressure equalization element

can be used on some types.

– In the case of an uneven mounting surface, se-

cure the pressure switch to the mounting plate

or air duct with only two screws on the same

side in order to avoid subjecting the pressure

switch to mechanical stress.

– When using silicone tubes, only use silicone

tubes which have been sufficiently cured. Va-

pours containing silicone can adversely affect

the functioning of electrical contacts.

– In the case of high humidity or aggressive gas

components, we recommend using a pressure

switch with gold contact due to its higher resist-

ance to corrosion. Closed-circuit current moni-

toring is recommended under difficult operating

conditions.

▷

The DL must not be in contact with masonry.

Minimum clearance 20mm.

▷ Ensure that there is sufficient installation space.

▷ Ensure unobstructed view of the hand wheel.

▷

Installation in the vertical or horizontal position, or

upside down, preferably with vertical diaphragm.

If installed in a vertical position, the switching

pointpS will correspond to the scale valueSK.

GB-2

Page 3

GB

F

NL

I

E

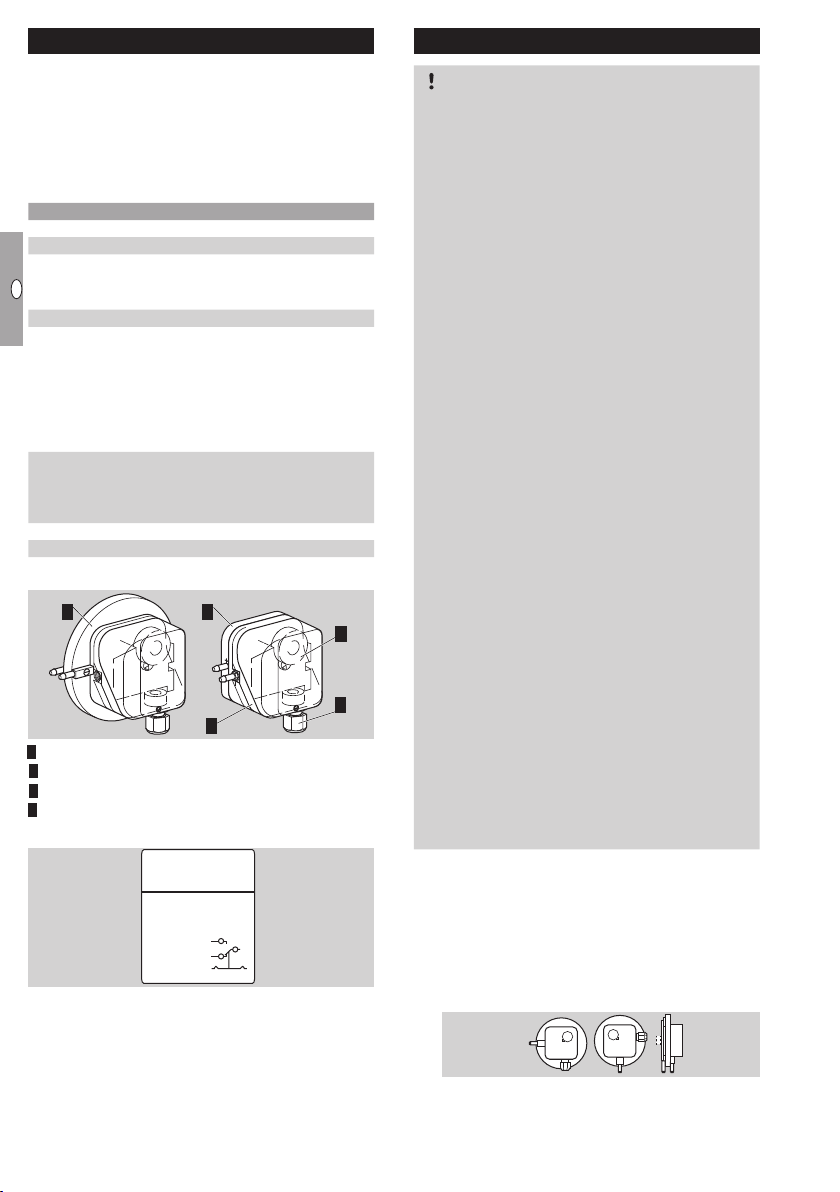

▷

50 (1.97")

30 (1.18")

20

(0.79")

25 (0.98")

45 (1.77")

5,2

(0.2")

11,3 (0.44")

7 (0.27")

7,5 (0.3")

10

(0.4")

40 (1.6")

59 (2.3")

ø 5,5 (0.22")

ø 6 (0.22")

ø 4,2 (0.17")

10 (0.39")

1 (0.04")

1 = Rp 1/4 (+),

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

(4 = Rp

1

/8 (-),

1

/8" NPT (-))

1

(4)

2

3

(1/4" NPT (+))

1 = Rp 1/4 (+),

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

(4 = Rp

1

/8 (-),

1

/8" NPT (-))

1 = Rp

1

/4 (+),

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

(4 = Rp

1

/8 (-),

1

/8" NPT (-))

1

(4)

2

3

1

Test

2

3(4)

(1/4" NPT (+))

(

1

/4" NPT (+))

1 = Rp 1/4 (+),

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

(4 = Rp

1

/8 (-),

1

/8" NPT (-))

1 = Rp

1

/4 (+),

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

(4 = Rp

1

/8 (-),

1

/8" NPT (-))

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

)

1

(4)

2

3

1

2

3

Test

2

3(4)

(1/4" NPT (+))

(

1

/4" NPT (+))

If installed in another position, the switching

pointpS will change and no longer correspond

to the set scale valueSK. Switching pointpS

must be checked.

SK + 0.18 mbar

[+ 0.071 "WC]

SK - 0.18 mbar

[- 0.071 "WC]

DL 1,5A

DL 3K,

DL 3A

DL 5 – 150A,

DL 5 – 150K

▷

For 1 mm thick mounting plates, use self-tapping

screws for plastic:

DL..A, DL 3K: Ø 3.5 x 8 mm or Ø 4 x 8 mm.

DL 5 – 150K: Ø3.5 x 16 mm.

1 Fit the DL.

DL 1,5A

DL 3A

DL 3K

e.g. SK = -0.5:

ps = -0.5 + 0.18

ps = -0.32 mbar

49,5 (1.9")

44,5 (1.7")

DL..A: Rp ¼

(DL..AT: ¼" NPT)

ø 6,1 (ø 0.24")

Connect the pressure line.

▷

DL..A: upon delivery, port 2 is closed off by a

rubber cap.

DL 1,5A, DL A

1 = Rp 1/4 (+),

2

3

1

(4)

(1/4" NPT (+))

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

1

(4 = Rp

/8 (-),

1

/8" NPT (-))

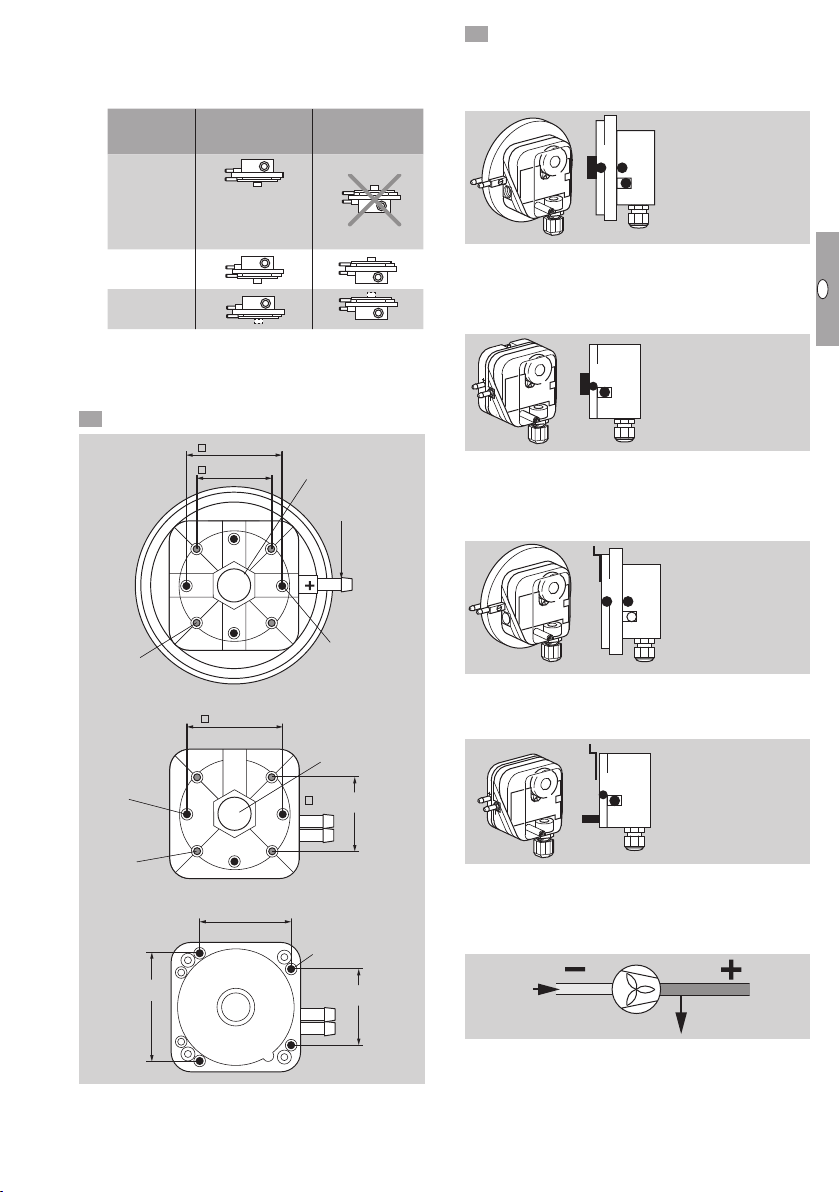

▷ Positive pressure: port 1 or 2

▷ Negative pressure: port 3

▷ Special version DL 3A – 3Z: port 4

DL 5 – 150A

Test

2

1

3(4)

1

/4 (+),

1 = Rp

1

/4" NPT (+))

(

2 = ø 4,75 x 1 mm (+)

3 = ø 4,75 x 1 mm (-)

1

(4 = Rp

/8 (-),

1

/8" NPT (-))

▷ Positive pressure: port 1 or 2

▷

Negative pressure: port 3; after unscrewing

port3 also port4

DL K

2

3,5 × 8

(0.14" × 0.3")

DL 5–150A

2,7 × 8

(0.11" × 0.3")

3,5 × 8

(0.14" × 0.3")

DL 5–150K

64 (2.5")

49,5 (1.9")

54,5 (2.1")

2,7 × 8

(0.11" × 0.3")

DL..A: Rp ¼

(DL..AT: ¼" NPT)

44,5 (1.7")

2,7 × 16

(0.11" × 0.6")

45 (1.8")

▷ Positive pressure: port 2

▷ Negative pressure: port 3

DL 5 – 150K

2

(5)

▷ Positive pressure: port 2

▷ Negative pressure: port 3

▷ Optional test point for positive pressure: port5

Positive pressure measurement

▷ 1 or 2 = positive pressure port(+).

▷ If port2 is used, close off port1.

3 or 4 = remains open to ventilate the upper

▷

diaphragm chamber.

GB-3

3 = ø 4,75 x 1 mm (-)

3

2 = ø 4,75 x 1 mm (+)

3

3 = ø 4,75 x 1 mm (-)

(5 = ø 4,75 x 1 mm (+)

2 = ø 4,75 x 1 mm (+)

Page 4

GB

F

NL

I

E

Negative pressure measurement

▷ 3 or 4 = negative pressure port(-).

▷

1 or 2 = remains open to ventilate the upper

diaphragm chamber.

Differential pressure measurement

▷ 1 or 2 = port for the higher positive pressure or

lower negative pressure(+).

▷ 3 or 4 = port for the lower positive pressure or

higher negative pressure(-).

Seal the ports that are not in use.

1 Disconnect the system from the electrical power

supply.

3 42

6 75

M16 x 1,5:

ø 4–10 mm

▷

Contacts and close when subject to increasing pressure. Contacts 1 and close when subject to falling pressure. With the NO contact, the

NC contact is omitted.

NO

L1

3

COM

2

NC

1

NO

1

2

NC

3

COM

Wiring

▷

If the DL..G (DL..TG) has switched a voltage

>24V (>30V) and a current >0.1A at cosφ=1

or >0.05A at cosφ=0.6 once, the gold plating

on the contacts will have been burnt through. It

can then only be operated at this power rating

or higher power rating.

CAUTION

To ensure that the DL is not damaged during opera-

tion, note the switching capacity, see page 7

(Technical data).

▷ In the case of low switching capacities, such as

24V, 8mA, for example, we recommend using

an RCmodule (22 Ω, 1μF) in air containing

silicone or oil.

C = 1 µF R = 22 Ω

NO

2

NC

1

COM

3

DL 1,5A

▷

The connection depends on the positive or nega-

tive adjusting range.

-

0

,

5

-

0

r

,

a

2

b

5

m

5

,

1

0

–

,

0

5

,

0

-

DL 1,5A

▷

Negative adjusting range 0 to -0.5 mbar: con-

0

,

2

5

0

,

5

5

,

1

1

m

b

a

r

5

=

2

,

1

0

1

0

P

a

0

,

1

5

7

,

0

tacts 3 and 1 close when subject to increasing

negative pressure. Contacts 2 and 3 close when

subject to falling negative pressure.

NO

NC

2

1

µ

COM

3

GB-4

Page 5

GB

F

NL

I

E

Adjustment

NO

2

NC

1

COM

3

COM

3

NC

1

NO

2

▷

The switching point is adjustable via hand wheel.

1 Disconnect the system from the electrical power

supply.

Detach the housing cover, see page7 (Tech-

nical data).

Connect an ohmmeter.

NO

1

2

NC

3

COM

NO

COM

2

NC

3

1

4 Set the switching point using the hand wheel.

5 Connect a pressure gauge.

0

▷

Deviation from the switching point during testing

pursuant to EN1854:

Air pressure switches:

DL 5 – 150A,

DL 5 – 150K

DL 1,5A

DL 3A, DL 3K

▷

If the DL does not trip at the desired switch-

Deviation

± 15%

± 15% or ± 6 Pa

± 15% or ± 6 Pa

ing point, correct the adjusting range using the

hand wheel. Relieve the pressure and repeat

the process.

Function check

▷ We recommend a function check once a year.

▷ Press the test key during operation– the pres-

sure switch switches.

1 cm = 1 mbar

TEST

+

6 Apply pressure. In doing so, monitor the switch-

ing point on the ohmmeter and the pressure

gauge.

▷ Max. inlet pressure = withstand pressure

Max.

inlet

pressure

mbar

Switching

differential**

mbar

Type

Adjusting

range*

mbar

min. max. min. max.

DL 1,5A -0.5 1.5 50 0.1 0.16

▷ In case of differential pressure, press both keys

simultaneously.

TEST

TEST

+

–

DL 3A, ..3K 0.2 3 50 0.1 0.16

DL 3AT, ..3KT 0.3 3 150 0.1 0.16

DL 5A, ..5K 0.4 6 300 0.2 0.3

DL 5AT, ..5KT 0.5 5 300 0.2 0.3

DL 10A, ..10K,

..10AT, ..10KT

1 10 300 0.25 0.4

DL 30A, ..30K 2.5 30 300 0.35 0.9

DL 50A, ..50K,

..50AT, ..50KT

DL 150A,

..150K

Type

2.5 50 300 0.8 1.5

30 150 300 3 5

Adjusting

range*

"WC

min. max. min. max.

Max.

inlet

pressure

"WC

Switching

differential**

"WC

DL 3AT, ..3KT 0.12 1.2 58.5 0.04 0.06

DL 5AT, ..5KT 0.2 2 117 0.08 0.12

DL 10AT,

..10KT

DL 50AT,

..50KT

* Adjusting tolerance ±15% of the scale value, but

min. ±4Pa

0.4 4 117 0.1 0.16

1 20 117 0.3 0.6

Accessories

Z-angle bracket

DL 5 – 150K: Order No.: 74916158

DL 3 – 150A, DL 3K: Order No.: 74913661

7,5 (0.3")

1 (0.04")

10 (0.39")

40 (1.6")

59 (2.3")

ø 4,2 (0.17")

ø 5,5 (0.22")

ø 6 (0.22")

7 (0.27")

11,3 (0.44")

** Mean switching differential at min. and max. setting

GB-5

Page 6

GB

F

NL

I

E

U-angle bracket

47,5 (1.87"

2 31

DL 1,5 – 150A, DL 3 – 150K: Order No.: 74916185

Tube set

To be used with air only.

75 (2.95")

20

(0.79")

M4 x 12

50 (1.97")

30 (1.18")

20

(0.79")

45 (1.77")

25 (0.98")

6 (0.24")

16

24 (0.94")

43

(1.69")

-0,3

64 (2.52")

Standard coupler plug

(0.63")

)

40 (1.57")

M4 x 10

5,2

(0.2")

+0,1

(0.17")

4,20

10

(0.4")

39 (1.53")

Order No.: 74912952

Order No.: 74919272

Pilot lamp set, red or blue

DL..T, DL..N

Pilot lamp, red:

110/120 V AC, I = 1.2 mA, Order No.: 74920430;

220/250 V AC, I = 0.6 mA, Order No.: 74920429.

Pilot lamp, blue:

110/120 V AC, I = 1.2 mA, Order No.: 74916121;

220/250 V AC, I = 0.6 mA, Order No.: 74916122.

4

N

3

COM

NO

L1

2

NC

1

NO

2

NC

NO

1

3

COM

N

Order No.: 74916159

Motor flange adapter

Set including retaining screws

DL..A, DL 3 – 5K: Order No.: 74916157,

DL 5 – 150K: Order No.: 74916156.

GB-6

NO

NC

L1

3

COM

2

1

NC

N

NO

1

2

NC

3

COM

N

Page 7

GB

F

NL

I

E

LED set, red/green

DL..K2, DL..T2

24 V DC, I = 16 mA; 24 V AC, I = 8 mA,

Order No.: 74921089;

230 V AC, I = 0.6 mA, Order No.: 74923275.

2 31

4

NO

2

+

3 COM

1 NC

1

2

NC

NO

–

3

COM

N

External adjustment

In order to set the switching pressure from the outside, the cover for external adjustment (6mm Allen

key) for DL..A, DL5 – 150K can be retrofitted.

Order No.: 74916155

2 31

Technical data

Gas type: air or flue gas, no flammable gases, no

aggressive gases.

Max. inlet pressure = withstand pressure: see type

label or page 5 (Adjustment).

Micro switch to EN 61058-1.

Switching capacity:

DL..: 24 V (min. 0.05 A) to 250 V AC

(max. 5 A, at cos φ 0.6 = 1 A),

max. 6 A, temporarily (<1 s) 20A.

DL..G: 5 V (min. 0.01 A) to 250 V AC

(max. 5 A, at cos φ 0.6 = 1 A),

5 V (min. 0.01 A) to 48 V DC (max.1A),

DL..T: 30 – 240 V AC, 50/60 Hz,

5 A resistive or

0.5 A inductive (cos φ= 0.6),

DL..TG: < 30 V AC/DC,

0.1 A resistive or

0.05 A inductive (cos φ= 0.6).

Contact gap < 3 mm (μ).

Safety class II to VDE 0106-1.

Max. medium and ambient temperatures:

DL: -20 to +80°C (-4 to +176°F),

DL..T: -40 to +60°C (-40 to +140°F).

Long-term use in the upper ambient temperature

range accelerates the ageing of the elastomer materials and reduces the service life (please contact

manufacturer).

Storage temperature:

-20 to +40°C (-4 to +104°F).

Diaphragm pressure switch, NBR, silicone-free.

Housing: glass fibre reinforced PBT plastic with

low gas release.

Enclosure to IEC 60529: IP54, IP65.

Line entrance: M16 x 1.5 (1/2" NPT conduit),

clamping range: diameters of 4 to 10mm.

Type of connection: screw terminals.

Max. tightening torque, see Technical Information

bulletin DL (D, GB, F) – www.docuthek.com.

Weight: DL..A: 190g (6.7oz), DL..K: 220 g

(7.8oz).

Designed lifetime

This information on the designed lifetime is based on

using the product in accordance with these operating

instructions. Once the designed lifetime has been

reached, safety-relevant products must be replaced.

Designed lifetime (based on date of manufacture) in

accordance with EN13611, EN1854 for pressure

switches: 10 years.

You can find further explanations in the applicable

rules and regulations and on the afecor website

(www.afecor.org).

This procedure applies to heating systems. For

thermoprocessing equipment, observe local regulations.

GB-7

Page 8

GB

F

NL

I

E

Logistics

AGA

Transport

Protect the unit from external forces (blows, shocks,

vibration). On receipt of the product, check that the

delivery is complete, see page2 (Part designations). Report any transport damage immediately.

Storage

Store the product in a dry and clean place.

Storage temperature: see page7 (Technical data).

Storage time: 6months before using for the first

time. If stored for longer than this, the overall service

life will be reduced by the corresponding amount of

extra storage time.

Packaging

The packaging material is to be disposed of in ac-

cordance with local regulations.

Disposal

Components are to be disposed of separately in

accordance with local regulations.

The production is subject to the surveillance proce-

dure pursuant to Regulation (EU) 2016/426 AnnexIII

paragraph 3.

Elster GmbH

Scan of the Declaration of conformity (D, GB) – see

www.docuthek.com

FM approval

Factory Mutual Research Class: 3510 Flow and pressure safety switches.

Designed for applications pursuant to NFPA 85 and

NFPA 86.

UL approval

Certification

Declaration of conformity

We, the manufacturer, hereby declare that the product DL with product ID No. CE-0085AP0466 complies with the requirements of the listed Directives

and Standards.

Directives:

– 2014/30/EU – EMC

– 2014/35/EU – LVD

Regulation:

– (EU) 2016/426 – GAR

Standards:

– EN 13611:2015+AC:2016

– EN 1854:2010

The relevant product corresponds to the tested type

sample.

Contact

Contact

UL 353 Limit control

AGA approval

Australian Gas Association, Approval No.: 5484

Eurasian Customs Union

The product DL meets the technical specifications

of the Eurasian Customs Union.

RoHS compliant

Directive on the restriction of the use of

hazardous substances (RoHS) in China

Scan of the Disclosure Table China RoHS2 – see

certificates at www.docuthek.com

If you have any technical questions, please contact

your local branch office/agent. The addresses are

available on the Internet or from ElsterGmbH.

We reserve the right to make technical modifications

in the interests of progress.

Strotheweg 1, D-49504 Lotte (Büren)

Elster GmbH

Tel. +49 541 1214-0

Fax +49 541 1214-370

hts.lotte@honeywell.com, www.kromschroeder.com

GB-8

Loading...

Loading...