Page 1

73022387

Revision g (2019-01)

From software version 1.12

Data Logger

DL230

Operating Instructions

Page 2

Exclusion of liability

The information contained in this document is the property of Honeywell. The

following information may only be used for its intended purpose. This document

or its contents must not be copied, published or made accessible to a third party in full or in part without the express consent of Elster GmbH.

All specifications and descriptions in these operating instructions have been

compiled following careful testing. In spite of this, errors cannot be completely

ruled out. Honeywell can therefore not provide any guarantee that the content

is complete or correct. The instructions must also not be seen as a warranty of

product features. Furthermore, features are also described here, which are only

available as an option.

Honeywell cannot accept liability in any case for direct, special or consequential

damage suffered by third parties. The information and specifications in this

document may be amended without notice.

In view of extended product liability, the listed data and material properties should only be regarded as reference values and must always be

checked for each individual case and corrected if necessary. This is especially the case when safety aspects are affected.

Further support is available from your local branch office or agent. The address

is available on the Internet or from Honeywell.

This manual or parts of it may only be disclosed or copied with written consent

from Honeywell.

If the product described here is improperly handled, repaired or changed by

unauthorized persons or if spare parts other than those supplied by Honeywell

are used, our warranty will be rendered void.

All rights reserved.

Copyright © 2019 Elster GmbH, D-55252 Mainz-Kastel. All rights reserved.

Mainz-Kastel, January 2019

Page 3

3

Contents

1 General ................................................................................................. 7

1.1 Information about this manual ....................................................... 7

1.2 Warranty provisions ....................................................................... 7

1.3 Customer service .......................................................................... 7

1.3.1 Customer service and repairs ..............................................................8

1.3.2 Electronic hotline ..................................................................................8

1.4 Meaning of symbols ...................................................................... 8

1.4.1 Safety instructions ................................................................................8

1.4.2 Tips and recommendations ..................................................................9

1.5 Limitation of liability ....................................................................... 9

1.6 Copyright protection .................................................................... 10

1.7 Scope of delivery ......................................................................... 10

1.8 Spare parts and accessories ....................................................... 11

1.9 Storage ........................................................................................ 12

2 Safety ................................................................................................. 13

2.1 General ........................................................................................ 13

2.2 Intended use ................................................................................ 14

2.3 Personnel .................................................................................... 15

2.4 Personal protective equipment .................................................... 16

2.5 Specific risks ............................................................................... 17

2.6 Environmental protection............................................................. 18

2.7 Operator's responsibility .............................................................. 18

3 Technical data ................................................................................... 19

3.1 General data ................................................................................ 19

3.2 Power supply for DL230 without integrated power supply unit ... 20

3.2.1 Battery power supply for the basic device .......................................... 20

3.2.2 Battery power supply for the integrated modem ................................. 20

3.2.3 Battery power supply for the modem module ..................................... 21

3.3 Power supply for the DL230 with integrated power supply unit .. 21

3.3.1 External power supply ........................................................................ 21

3.3.2 Battery power supply for the DL230 during power failure ................... 21

3.3.3 Buffer batteries for the integrated modem during power failure ......... 21

3.3.4 Buffer battery for the modem module during power failure ................ 22

3.4 Power supply for the DL230 with Power over Ethernet (PoE) .... 22

3.5 Digital inputs ................................................................................ 22

3.5.1 Pulse and signal inputs ...................................................................... 23

3.5.2 Encoder inputs ................................................................................... 24

3.6 Digital outputs .............................................................................. 24

3.6.1 Nominal data ...................................................................................... 24

3.7 Interfaces ..................................................................................... 25

3.7.1 Serial optical interface ........................................................................ 25

Page 4

4

3.7.2 Integrated modem .............................................................................. 25

3.7.3 Serial electrical interface (optional) .................................................... 25

3.7.4 GSM / GPRS modem module ............................................................ 26

3.7.5 Ethernet Module (optional) ................................................................. 27

3.8 Measurement conditions ............................................................. 27

3.8.1 Environment ....................................................................................... 27

3.9 Labelling ...................................................................................... 28

3.9.1 Designation Data Logger ................................................................... 28

3.9.2 ATEX marking .................................................................................... 29

3.9.3 Device software Identification ............................................................ 30

4 Construction and Function .............................................................. 31

4.1 External view ............................................................................... 31

4.2 Internal view ................................................................................ 32

4.3 Short description .......................................................................... 32

4.4 Connections ................................................................................. 33

5 Assembly, Connection and Putting into Operation ....................... 34

5.1 Assembly ..................................................................................... 34

5.1.1 Assembly on a pipeline ...................................................................... 35

5.1.2 Assembly on a wall ............................................................................ 36

5.2 Connection .................................................................................. 37

5.2.1 Connecting meters ............................................................................. 38

5.2.2 Sealing the input terminals ................................................................. 39

5.2.3 Connecting the power supply ............................................................. 39

5.2.4 Connect outputs of the DL230 ........................................................... 40

5.3 Putting into operation................................................................... 43

5.3.1 Configuration of measurement parameters ........................................ 43

5.3.2 Sealing ............................................................................................... 49

5.3.3 Closing the housing ........................................................................... 50

5.3.4 Verifying assembly and connection ................................................... 51

5.3.5 Data transfer ...................................................................................... 51

6 Operation ........................................................................................... 52

6.1 Safety........................................................................................... 52

6.1.1 Personal protective equipment .......................................................... 52

6.2 Operating personnel .................................................................... 52

6.2.1 Instructed personnel .......................................................................... 52

6.2.2 Qualified personnel ............................................................................ 52

6.2.3 Calibration officer ............................................................................... 53

6.3 Basic principles ............................................................................ 54

6.3.1 Display ............................................................................................... 55

6.3.2 Button functions ................................................................................. 56

6.3.3 Data recall, display navigation ........................................................... 57

6.3.4 Meaning of status symbols ................................................................ 58

6.3.5 Error messages when entering values ............................................... 59

6.3.6 Access rights ..................................................................................... 60

Page 5

5

6.4 Data register content ................................................................... 62

6.4.1 Access rights ...................................................................................... 62

6.4.2 "Main" register (main display)............................................................. 63

6.4.3 "Cust." Register (Customer) ............................................................... 64

6.4.4 "Admin" Register (Administrator)........................................................ 66

6.4.5 "Serv." register (Service) .................................................................... 67

6.4.6 "Ctrl." register (control) ....................................................................... 68

6.5 Use as high-flow display device .................................................. 70

6.6 Use as flow-recording device ..................................................... 71

6.6.1 Search function for checking archive entries ...................................... 72

7 Maintenance ...................................................................................... 73

7.1 Safety .......................................................................................... 73

7.1.1 Personnel ........................................................................................... 75

7.1.2 Personal protective equipment ........................................................... 75

7.1.3 Environmental protection ................................................................... 75

7.2 Testing and changing device batteries ........................................ 76

7.2.1 Changing and connecting device batteries ........................................ 76

7.2.2 Entering the battery capacity .............................................................. 79

7.2.3 Display remaining battery power ........................................................ 80

7.3 Changing and testing modem batteries ...................................... 80

7.3.1 Changing and connecting modem batteries ....................................... 80

7.3.2 Display modem battery voltage .......................................................... 84

7.4 Changing the fuse of the power supply unit ................................ 84

8 Faults .................................................................................................. 87

8.1 Safety .......................................................................................... 87

8.1.1 Personnel ........................................................................................... 88

8.1.2 Personal protective equipment ........................................................... 88

8.1.3 Improper elimination of faults ............................................................. 88

8.1.4 Behaviour in the event of faults .......................................................... 89

8.2 Fault and other status messages ................................................ 89

9 Appendix ............................................................................................ 93

9.1 List of spare parts and accessories ............................................. 93

9.1.1 Fastening elements ............................................................................ 93

9.1.2 Small parts and miscellaneous .......................................................... 93

9.1.3 Documentation ................................................................................... 94

9.2 Connection, Replacement and Retrofit of Components .............. 94

9.3 EC Declaration of Conformity ...................................................... 98

9.4 ATEX Type Examination Certificate ............................................ 99

9.4.1 Associated apparatus for Zone 0/1 .................................................... 99

Page 6

Page 7

General 7

The data and material properties indicated serve as reference values. These must be verified on a case-by-case basis and adjusted as necessary.

The application manual is available for you for the

commissioning of the various communication and device

applications.

1 General

1.1 Information about this manual

This manual allows for safe and efficient use of the device.

Compliance with all safety information and instructions for use contained in

this operating manual is a prerequisite for safe working processes and

proper use of the device. Furthermore, the valid guidelines, standards, local

accident prevention regulations, and general safety regulations must be

complied with for the respective area of application of the device.

This manual forms a constituent part of the product and must be stored

within the immediate vicinity of the device and be accessible to installation,

service, maintenance, and cleaning personnel at all times. The graphic illustrations used in this manual serve as a visual representation of the described processes and are therefore not necessarily to scale and may deviate from the actual design of the device.

1.2 Warranty provisions

The current warranty provisions can be found in the general terms and

conditions online under:

http://www.elster-instromet.com/en/general-terms-of-business

1.3 Customer service

Our customer service team is responsible for providing technical

information and repairs. Our employees are constantly striving to acquire

new information and gain experience and these are both valuable sources

for improving our products.

Page 8

8 General

1.3.1 Customer service and repairs

– Tel. +49 (0) 61 34 / 605-0

– Fax +49 (0) 61 34 / 605-390

– E-mail: Katinka.Fiedler@Honeywell.com

1.3.2 Electronic hotline

In the event of faults, you can also contact the electronic

hotline.

– Tel. +49 (0) 6134 / 605-123

– http://www.elster-instromet.com/en/support

– E-mail: ElsterSupport@Honeywell.com

1.4 Meaning of symbols

1.4.1 Safety instructions

In this manual, safety information is denoted by the use of symbols. The

safety information is introduced by signal words, which identify the level of

risk.

This safety information must be complied with and care should be taken to

prevent accidents, personal injury, and material damage.

DANGER!

... indicates an imminently dangerous situation which, if not

avoided, could lead to death or serious injury.

WARNING!

... indicates a potentially dangerous situation which, if not

avoided, could lead to death or serious injury.

CAUTION!

... indicates a potentially dangerous situation which, if not

avoided, may lead to minor or slight injuries.

… indicates dangers resulting from electrical current. A

non-compliance of the safety information poses a risk of serious or life-threatening injuries.

Page 9

General 9

CAUTION!

... indicates a potentially dangerous situation which, if not

avoided, could lead to material damage.

1.4.2 Tips and recommendations

… provides useful tips and recommendations as well as

information for ensuring efficient and smooth operations.

1.5 Limitation of liability

All of the information contained in this manual has been compiled under

consideration of valid standards and regulations, the latest technological

developments, and our many years of experience and expertise. The

manufacturer shall accept no liability for damages resulting from:

– Non-compliance of the manual

– Improper use

– Deployment of unqualified personnel

– Unauthorized modifications

– Technical changes

– Use of unauthorized spare parts

The actual scope of delivery may deviate from the information and graphics

presented herein due to special designs, the selection of additional ordering options, or the latest technological developments.

The obligations stipulated in the delivery contract, the general terms and

conditions and delivery conditions of the manufacturer, and the statutory

provisions valid at the time of signing the contract, shall apply.

This manual should be read carefully before commencing all

works on and with the device, particularly before putting the

device into operation! The manufacturer shall not assume

any liability for damage and errors caused by failing to

observe these instructions.

We reserve the right to make technical changes within the scope of improving usability and further development.

Page 10

10 General

1.6 Copyright protection

This manual is copyright-protected and is intended for internal use only. A

transfer of this manual to third parties, a reproduction of any kind, whether

partially or fully, and the use and/or disclosure of its content, are not

permitted without written consent from the manufacturer, except for internal

purposes. Contraventions to this provision shall result in damage

compensation. We reserve the right to assert further claims.

1.7 Scope of delivery

The scope of delivery for the DL230 includes:

– Data Logger DL230

– Dispatch list

– Design data sheet

– Manual

– Bag of accessories

Page 11

General 11

1.8 Spare parts and accessories

WARNING!

Incorrect use of spare parts and accessories may present a risk to safety!

False or incorrect use of spare parts and accessories may

impair safety and lead to damage, malfunctions, or total

failures.

Therefore:

– Only use original spare parts and accessories produced

by the manufacturer.

– The manufacturer should always be contacted in the

event of uncertainty.

A list of spare parts and accessories can be found in the appendix. Spare

parts and accessories can be ordered from an authorized retailer or from

our customer service team directly.

The free "enSuite" program also belongs to the accessories for the DL230

and is available under www.elster-instromet.com. This can be used to program the DL230 data logger via its data interfaces to perform advanced

applications.

The DL230 can be supplied as a calibrated and non-calibrated device and

is also available in different models.

Further details can be found under www.elster-instromet.com and in the

"Assembly, Connection and Putting into Operation" chapter.

Page 12

12 General

1.9 Storage

CAUTION!

Exceeding or falling below the valid temperature range

for the batteries may impair performance.

If the valid temperature range of the batteries during storage of the device is exceeded or fallen below, the performance of the batteries may be impaired.

Therefore:

– For long periods of storage, please ensure that the valid

temperature range for the fitted batteries does not fall

below -25 °C or exceed +55 °C.

CAUTION!

Material damage caused by the formation of

condensation.

Fluctuations in temperature during storage may cause condensation to form. This may lead to subsequent malfunctions of the device.

Therefore:

– After storage or transport in cold weather conditions or

after having been exposed to strong temperature

fluctuations, the device should slowly be adjusted to the

room temperature before being put into operation.

– If condensation has formed, wait at least 12 hours be-

fore putting the device into operation.

If the power supply to the device is cut off during storage

due to disconnecting the batteries then the date and time

must be reset.

The following rules apply for storage:

– The relative humidity should be a maximum of 93%.

– Do not store packages in the open air.

– The storage temperature should not fall below -25 °C and should not

exceed +60 °C.

– Avoid mechanical vibrations during storage of the device.

Page 13

Safety 13

2 Safety

This chapter gives an overview of all of the most important safety aspects

in order to best protect personnel and to ensure a safe and smooth

operation of the device. A non-compliance with the safety information and

instructions for use specified in this manual could result in serious damage.

2.1 General

The DL230 is an intrinsically safe device as per the ATEX Product Directive

94/9/EC and the ATEX Operating Directive 1999/92/EC EN, and is suitable

for operation within the following explosive gas atmospheres:

– DL230 with integrated power supply unit and integrated modem:

Associated apparatus for zones 0 and 1

– DL230 with integrated power supply unit and integrated modem:

Zone 2 for gases in temperature class T4

DANGER!

Using incorrect batteries presents a risk of explosion!

Only use batteries prescribed by Elster in accordance with

Chapter 9.1.2.

When connecting and operating the DL230 in explosive gas

atmospheres, the corresponding standards must be

observed:

DIN EN 60079-0

DIN EN 60079-14

The device may only be used as associated apparatus for

zone 0 and 1 or inside zone 2, if installation has been

carried out according to the separate requirements

stipulated under DIN EN 60079-14 and the operating

conditions (see "Technical Data" chapter) as well as the

connection conditions (see "Assembly, Connection and

Putting into Operation" chapter).

Page 14

14 Safety

The device may be dangerous if unqualified personnel use it incorrectly or

do not use it according to its intended purpose.

– All of those persons, who are charged performing works on or with the

device, must have read and understood the manual before commencing such works. This shall also apply if the person in question has already worked with the same or a similar device or has been trained by

the manufacturer.

– Being familiar with the content of the manual is a necessary condition

for protecting personnel against risks, preventing errors from occurring,

and therefore ensuring a safe and smooth operation of the device.

– In order to avoid risks and to ensure optimal performance of the device,

neither modifications nor changes should be carried out without express consent from the manufacturer.

– All operating instructions should be kept in a clearly legible condition on

the device. Damaged or illegible instructions should be replaced immediately.

– The setting values and value ranges specified in this manual should be

complied with.

2.2 Intended use

This device is solely designed and constructed for the intended use described below.

Data logger DL230 is provided as a compact device which can be calibrated for measuring and saving counter pulses, meter readings or level

changes for various types of energy.

Intended use also refers to compliance with all of the information contained

in this manual. Any use beyond the intended use and/or other types of use,

shall be considered as misuse and can result in dangerous situations. The

manufacturer shall not be held liable for any claims for damages resulting

from misuse of this device.

WARNING!

Danger resulting from misuse.

Misuse of the device may lead to dangerous situations.

Therefore:

– Only use the device according to its intended use.

– Do not use the device to regulate the gas flow or other

variables affecting the gas volume in the entire system.

Page 15

Safety 15

2.3 Personnel

WARNING!

Risk of injury to unqualified personnel.

Improper use of the device may lead to significant personal

injury or material damage.

Therefore:

– All works should solely be carried out by qualified per-

sonnel.

The following qualifications are used in the manual to denote different

areas of responsibility:

– Instructed personnel

will be informed of the tasks assigned to them and possible risks resulting from inappropriate behaviour, in a training session provided by the

operator.

– Qualified personnel

on the basis of their specialist training, knowledge and experience, as

well as their awareness of the relevant statutory provisions, are in a

position to perform their assigned tasks on the device and are able to

independently identify and prevent possible risks.

– Gas specialists

who, on the basis of their specialist training, knowledge and experience, as well as their awareness of the relevant standards and regulations, are in a position to perform works on gas-handling equipment

and to independently identify possible risks. The gas specialist will be

specially trained in the respective area and will be familiar with the relevant standards and regulations.

– Calibration officer

on the basis of their professional training, knowledge and experience

and awareness of applicable standards and regulations, are in a position to perform the works on gas systems. The calibration officer will be

trained on works on devices and installations subject to calibration regulations and will be familiar with the relevant standards and regulations.

– Electricians

who, on the basis of their specialist training, knowledge and experience, as well as their awareness of the relevant standards and regulations, are in a position to perform the works on electrical installations

and to independently identify and prevent possible risks. The electrician

will be specially trained in the respective area and will be familiar with

the relevant standards and regulations.

Page 16

16 Safety

WARNING!

Risk to unauthorized persons!

Unauthorized persons, who do not meet the

aforementioned criteria, will not be familiar with the risks in

the working area.

Therefore:

– Please keep unauthorized persons away from the work-

ing area.

– In cases of doubt, approach said person and direct them

out of the working area.

– Interrupt the works if unauthorized persons enter the

working area.

Only those persons who can be trusted to reliably execute their works shall

be authorized to work on or with the device. People whose reactivity is impaired, e.g. by drugs, alcohol or medication, shall not be authorized to perform such works.

– When selecting personnel, please observe the valid age and profes-

sional guidelines for all of the gas-handling equipment.

2.4 Personal protective equipment

When working on the device inside a gas-handling plant, personal protective equipment must be worn to minimize risks to health.

– During works on the device, the necessary personal protective equip-

ment must be worn inside the respective plant at all times

– The notices relating to personal protective equipment mounted in the

working area must be followed at all times.

Page 17

Safety 17

2.5 Specific risks

The residual risks arising from the risk assessment will be listed below.

Please observe the safety and warning information specified in the

following chapters to reduce risks to health and to prevent dangerous

situations from arising.

WARNING!

Misuse of batteries may present a risk of injury.

Special care must be taken when handling batteries.

Therefore:

– Do not throw batteries into the fire or expose these to

high temperatures. There is a risk of explosion.

– Do not charge batteries. There is a risk of explosion.

– Liquids, that are produced as a result of misuse may

lead to skin irritation. Avoid physical contact with such

liquid. In the event of contact, rinse with large quantities

of water. If the liquid enters the eyes, immediately rinse

with water for 10 minutes and seek medical attention.

WARNING!

Risk of fire from highly flammable substances!

Highly flammable substances, liquids or gases could catch

fire and lead to serious or fatal injuries.

Therefore:

– Do not smoke within the danger zone or within close

proximity to this zone. No naked flames or ignition

sources are permitted within this zone.

– Have a fire extinguisher close to hand.

– Suspicious substances, liquids or gases should be re-

ported to the responsible member of staff immediately.

– Work should be stopped immediately in the event of a

fire. You should leave the danger zone until it is given

the all-clear.

Page 18

18 Safety

2.6 Environmental protection

CAUTION!

Environmentally hazardous substances!

If environmentally hazardous substances are handled incorrectly this may cause significant damage to the environment, particularly if they are improperly disposed of.

Therefore:

– The instructions below should be observed at all times.

– Appropriate measures should be taken immediately if

environmentally hazardous substances are accidentally

released into the environment. In cases of doubt, please

inform the responsible local authority about the

damages.

The following environmentally hazardous substances are used:

– Batteries

Batteries contain toxic heavy metals. These must be treated as special

hazardous waste and must be disposed of in municipal waste collection

points or by a waste specialist.

2.7 Operator's responsibility

The device will be used in the commercial sector. The operator of the

device will therefore be subject to legal obligations concerning occupational

safety.

i

Important information

To protect the device from unauthorized manual access,

make sure that only authorized persons have direct access to

the device after installation.

In addition to the safety information contained in these instructions, the

valid safety, accident prevention, and environmental protection regulations

for the area of application of the device, must be adhered to. In particular:

– The operator must ensure that the valid safety, accident prevention,

and environmental protection regulations for the entire plant in which

the device is being integrated, are complied with.

Page 19

Technical data 19

– The operator must be familiar with the valid occupational safety regula-

tions and must also be able to conduct a risk assessment to determine

risks arising from the specific working conditions in the respective area

of application of the device. The operator must then implement this in

the form of operating instructions for the operation of the device.

– Throughout the entire life cycle of the device, the operator must deter-

mine whether their prepared operating instructions are compatible with

current regulations and amend these if and when necessary.

– The operator must clearly regulate and define responsibilities for the

assembly, connection, putting into operation, and maintenance of the

device.

– The operator must ensure that all employees who use the device have

read and understood this manual. Furthermore, the operator must provide training to personnel at regular intervals and inform them of the

potential risks.

– The operator of the entire plant in which the device is to be integrated,

must provide personnel with the necessary protective equipment.

Furthermore, the operator is responsible for ensuring that the device

remains in a perfect functioning order at all times. The following therefore

apply:

– The operator must ensure that the installation and maintenance works

described in this manual are carried out correctly.

– The operator must regularly have all safety mechanisms checked for

their functionality and completeness.

3 Technical data

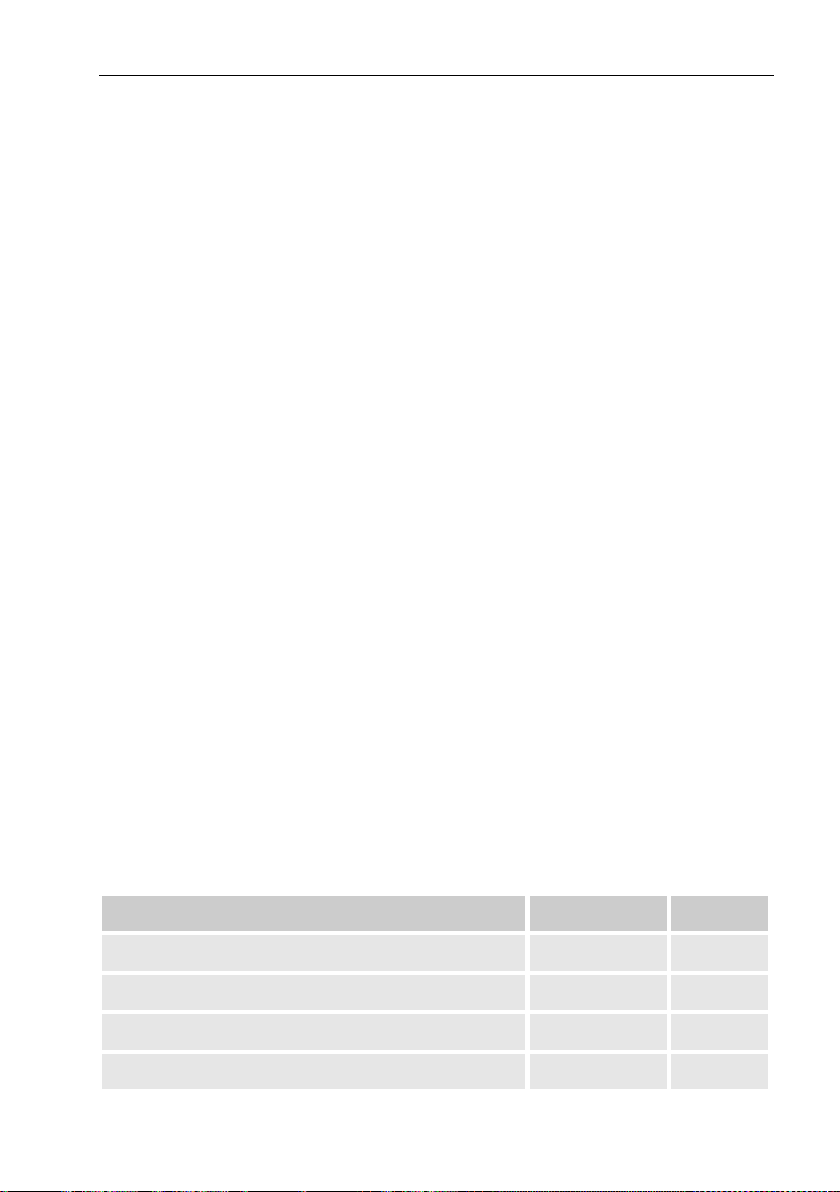

3.1 General data

Data

Value

Unit

Width (incl. antenna cover)

250

mm

Height (incl. cable glands)

175

mm

Depth

85

mm

Permissible ambient temperature range

-25 ... +60

°C

Page 20

20 Technical data

3.2 Power supply for DL230 without integrated power supply unit

3.2.1 Battery power supply for the basic device

Data

Value

Unit

Voltage

3.6

V

General nominal capacity

16.5

Ah

Usable capacity

13.0

Ah

Minimum number of batteries required

1

units

Minimum operating life (at standard

measurement conditions)

8

years

The standard measurement conditions are defined as follows:

Data

Value

Measurement cycle

10 seconds

Mode input 1 to 4

Pulse input

Display active

60 minutes per month

Interface or modem active

30 minutes per month

Ambient temperature

-10 ... +50°C

3.2.2 Battery power supply for the integrated modem

Data

Value

Unit

Voltage

3.6

V

General nominal capacity

13.0

Ah

Usable capacity

8.0

Ah

Minimum number of batteries required

1

units

Page 21

Technical data 21

3.2.3 Battery power supply for the modem module

If the DL230 has a plug-in modem module (not a soldered modem), the

modem battery is connected to the connection board in the housing base.

For this purpose, any of the two connectors can be used.

WARNING!

If you use two batteries, always connect only two new

and unused batteries !

Connecting two batteries with different charge states at the

same time may cause a battery to explode.

The information in chapter 3.2.2 applies to the battery.

Order number of the connection board for the modem battery for retrofitting: see chapter 9.1.2.

3.3 Power supply for the DL230 with integrated power supply unit

3.3.1 External power supply

Data

Value

Unit

Supply voltage

230

V AC

Power consumption, maximum

10

W

cable cross-section of solid wire

0,14 … 2,5

mm2

cable cross-section of stranded wire with

wire ferrules

0,25 … 2,5

mm2

3.3.2 Battery power supply for the DL230 during power failure

Connect the batteries to X5 or X6 of the CPU board for switching to battery

mode in the event of a power failure. See chapter 3.2.1 “Battery power

supply for the basic device"

3.3.3 Buffer batteries for the integrated modem during power

failure

The buffer batteries can optionally be connected to the X9 or X10 of the

CPU board to ensure that data continues to be transmitted, even in the

event of a power failure. For technical data of the battery, see chapter 3.2.2

“Battery power supply for the integrated modem”.

Page 22

22 Technical data

3.3.4 Buffer battery for the modem module during power failure

The buffer battery for the modem module can optionally be connected to

the ST1 of the power supply board to ensure that data continues to be

transmitted, even in the event of a power failure. For technical data of the

battery, see chapter 3.2.2 “Battery power supply for the integrated modem”.

3.4 Power supply for the DL230 with Power over Ethernet

(PoE)

If the DL230 is equipped with an Ethernet module and if the Ethernet network (or a switch) provides the Power over Ethernet function, the DL230

can be supplied with power from the Ethernet module. An integrated power

supply is not required.

Data

Value

Unit

Supply voltage

36 V to 56 V

V DC

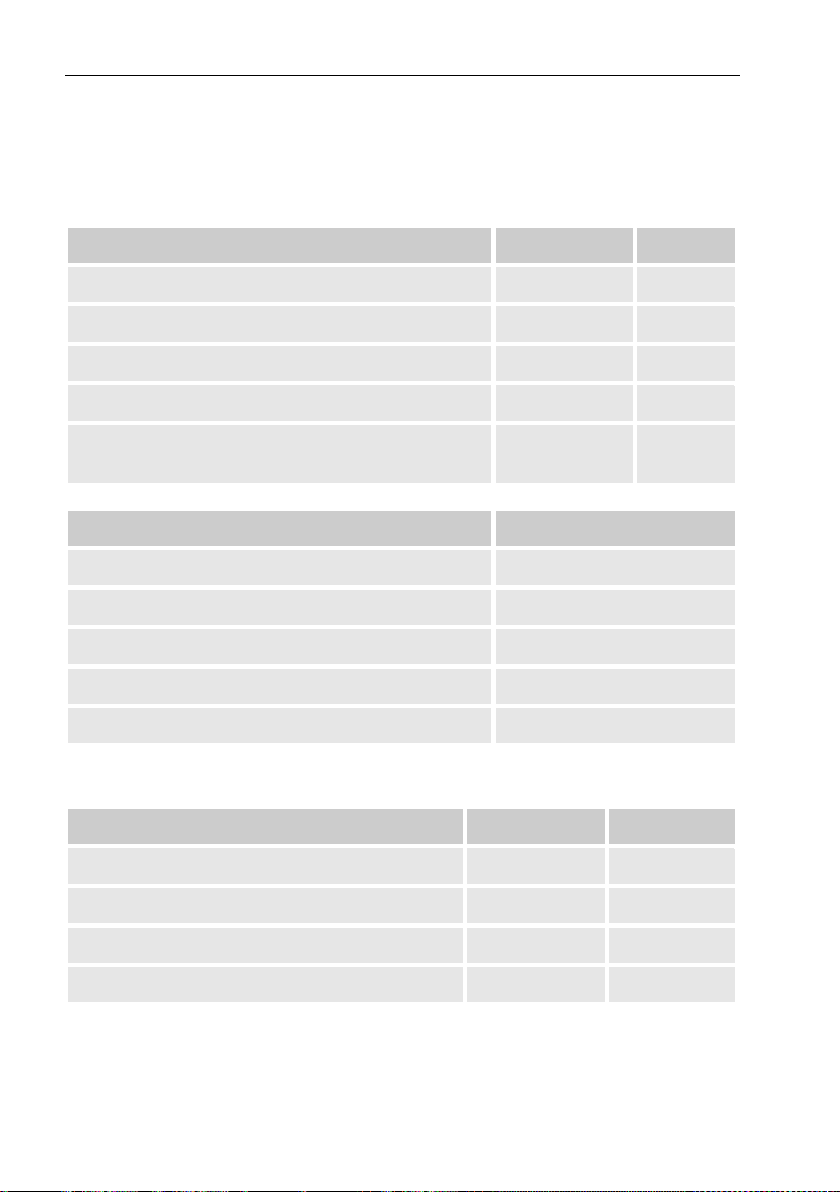

3.5 Digital inputs

Pulse transducer and Encoders, which are installed in a hazardous area

(Zone 0, 1 or 2) have to keep the following electrical parameters.

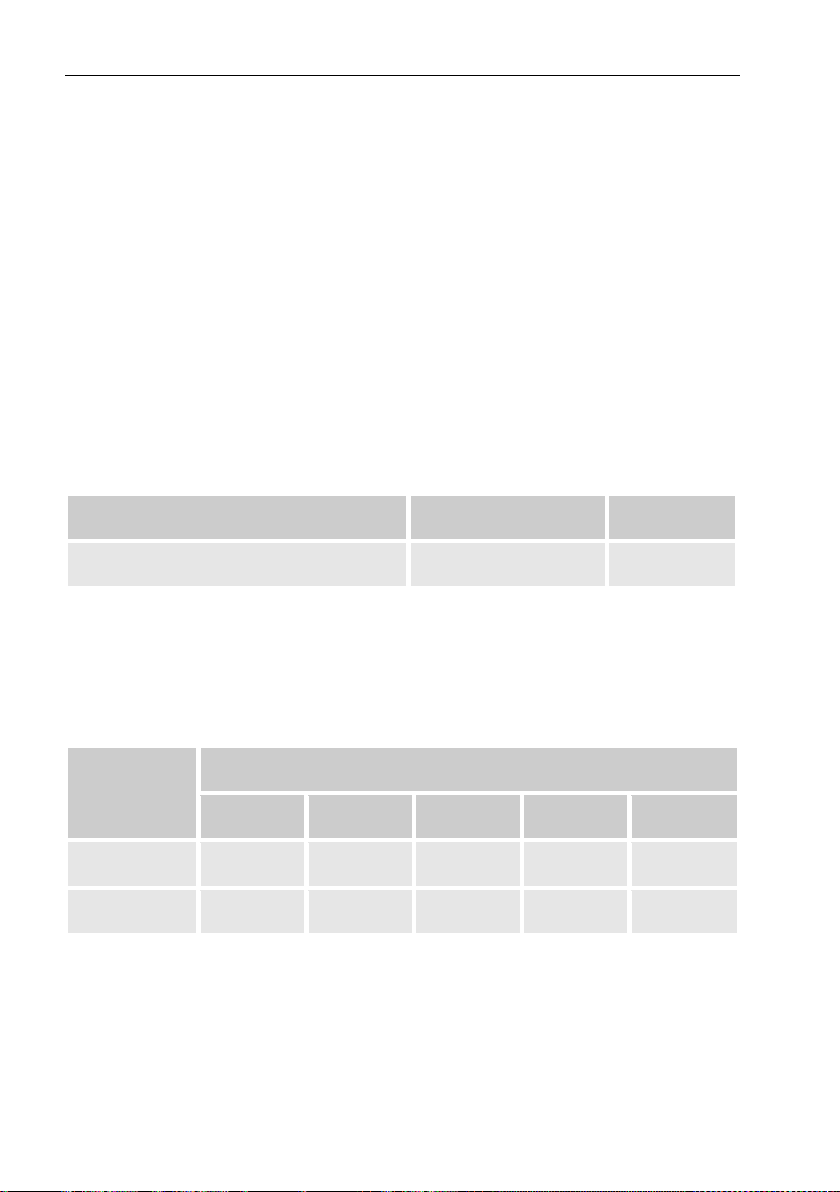

Connector

Electrical Parameters

Uo

Io

Po

Co

Lo

DE1, DE2

9,56V

19,6mA

46,9mW

3,6µF

92mH

DE3, DE4

9,56V

1,7mA

4,1mW

3,6µF

12,1H

Page 23

Technical data 23

3.5.1 Pulse and signal inputs

Data

Value

Unit

Open-circuit voltage U0 (at DE1 and DE2)

typ.

2.7

V

Open-circuit voltage U0 (at DE3 and DE4)

typ.

3.1

V

Internal resistance R

I

> 1

MΩ

Short circuit current I

K

max.

5

μA

Switch point "ON":

▪ Resistance Re

max.

100

kΩ

▪ Voltage Ue

max.

0.8

V

Switch point "OFF":

▪ Resistance Ra

min.

2

MΩ

▪ Voltage Ua

min.

3

V

Pulse duration te

min.

62.5

ms

Pause duration ta

min.

62.5

ms

Counting frequency f

max.

10

Hz

Cable length

max.

30

m

Cable cross-section

0,3 … 2,5

mm2

The maximum counting frequency of the digital inputs can be adjusted

using the "enSuite" software. The limit values specified for frequency and

duration shall only apply if the so-called "software debounce" has been

switched off.

The maximum counting frequency is parameterized to 2 Hz

as a default. Changing parameters to f

max

≤ 10 Hz is only

possible with skilled, qualified staff and when administrator

or calibration lock is open. Changes to the input frequency

must be documented by the operator of the device.

If the software debounce is parameterized to a frequency

higher than 2 Hz, then it may lead to counting errors

caused by electromagnetic interference under certain

circumstances.

Page 24

24 Technical data

3.5.2 Encoder inputs

An encoder can only be connected to inputs 1 and 2 (terminals DE1 and DE2).

Data

Value

Unit

Encoder protocol

Namur, SCR, SCR+

-

Cable length

max. 30

m

3.6 Digital outputs

Both DA1 and DA2 digital outputs can be configured as low frequency

pulse or signal outputs.

3.6.1 Nominal data

Data

Value

Unit

Maximum switching voltage

30

V DC

Maximum switching current

100

mA DC

Maximum voltage drop

1

V

Maximum residual current

0.001

mA

Pulse duration

min.

125

ms

Pause duration

min.

125

ms

Output frequency

max.

4

Hz

cable cross-section

0,3 … 2,5

mm2

Page 25

Technical data 25

3.7 Interfaces

3.7.1 Serial optical interface

Data

Value

Data transfer rate

9600 Baud

Format

1 start bit, 1 parity bit, 1 stop bit

The baud rate of the serial optical interface is adjustable to

19200 Bd. However, the function with this baud rate depends

among others also from the optical read out head and therefore cannot be guaranteed.

3.7.2 Integrated modem

Data

Value

Unit

Modem type

2G: GSM / GPRS

3G: GSM / GPRS / UMTS

Frequency bands

2G: 850 /900 /1800 /1900

3G: 850 /900 /1800 /1900 /2100

MHz

3.7.3 Serial electrical interface (optional)

The serial interface can be used if the DL230 is not equipped with an integrated modem and if it is only used in the safe area or in ATEX zone 2.

Data

Value

Adjustable interface types

RS232 or RS485

Supply voltage at Usio

7.5 … 9 V

Page 26

26 Technical data

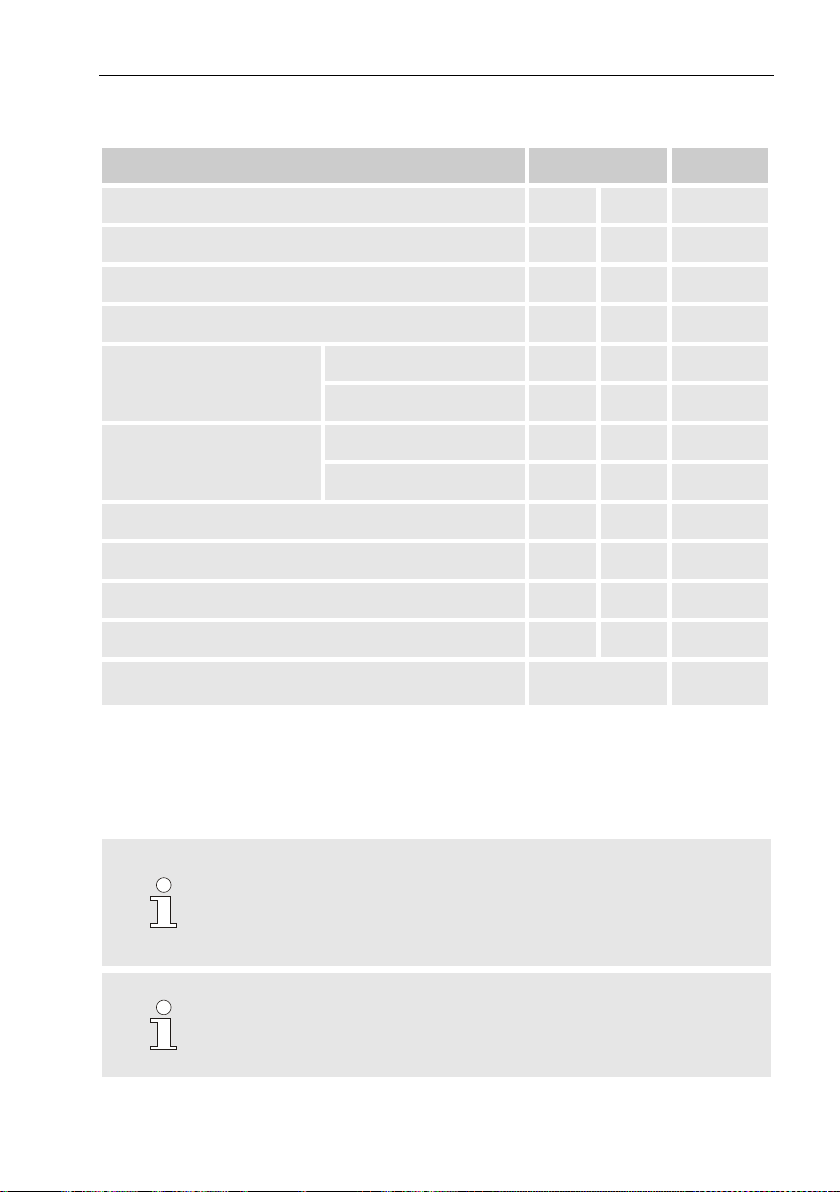

3.7.3.1 Intrinsic safety parameters of the serial interface of the DL230

Highest voltage which is permitted to be applied to the data lines, and current limitation on the data lines.

Connector

Voltage

Current

+Usio

U

max

= 12,5 V

RI, DCD, RXD

Ui ≤ 24 V

Ii ≤ 90 mA

3.7.3.2 Technical Data of the RS485-Interface of the DL230

Parameter

Value

Mode of operation

RS485 2-Draht (half duplex)

RS485 4-Draht (full duplex)

Termination

Do not use termination resistors at the remote

terminals.

Maximum data rate

19.200 Baud

Number of remote terminals

Driver output power: max. 16 Unit Loads1

Input power consumption2:

- 6 Unit Loads (RS485, not. insulated)

- 3 Unit Loads (RS485, electrical insulated)

3.7.4 GSM / GPRS modem module

The modem module can be used if the DL230 is not equipped with an integrated modem and if it is only used in the safe area or in ATEX zone 2.

Data

Value

Unit

Modem type

2G: GSM / GPRS

3G: GSM / GPRS / UMTS

Frequency bands

2G: 850 /900 /1800 /1900

3G: 850 /900 /1800 /1900 /2100

MHz

1

Unit Load: Standard RS-485 Receiver with input resistor = 12 kOhm

2

See application manual for details of RS-485 interface connection

Page 27

Technical data 27

3.7.5 Ethernet Module (optional)

The Ethernet Module can be used if the DL230 is not equipped with an integrated modem and if the DL230 is only used in the safe area or in ATEX

zone 2.

3.7.5.1 Intrinsic safety parameters of the Ethernet Module

The Power over Ethernet function (PoE) of the Ethernet module supports

power class 0. This results in the highest possible current that can be supplied from a PoE power supply.

Connector

Voltage

Current

Ethernet Module K1-1 to K1-6

Ui ≤ 57 V

Ii ≤ 270 mA

3.7.5.2 Technical Data of the Ethernet Module

Parameter

Value

Ethernet Type

10/100 Mbit/s auto sensing

Power supply

with integrated power supply unit

or Power over Ethernet (PoE)

Functions

TCP-IP Client/Server, FTP

3.8 Measurement conditions

3.8.1 Environment

Data

Value

Unit

Temperature range

-25…+60

°C

Relative humidity, max.

93

%

Page 28

28 Technical data

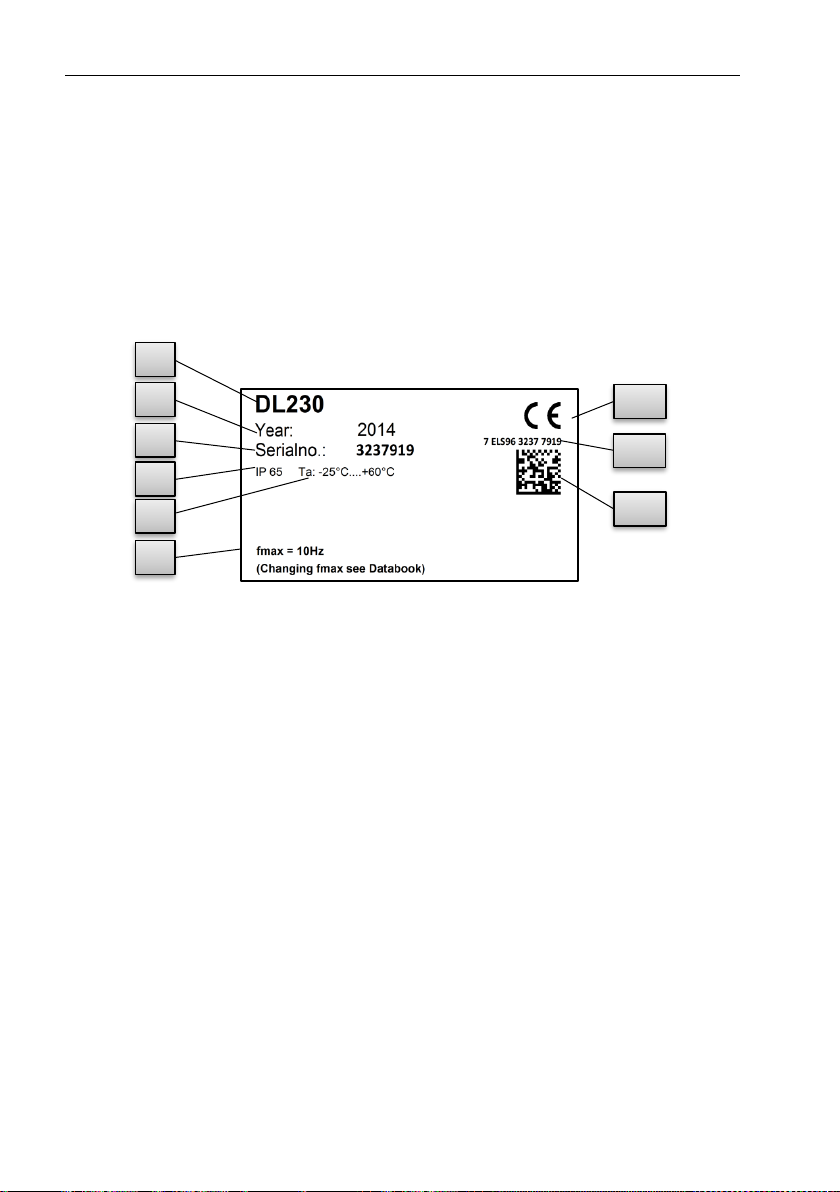

3.9 Labelling

The label is placed on the front panel of the device (see “Construction and

Function” chapter).

3.9.1 Designation Data Logger

The designation of the DL230 contains the following information:

III.: 1

1 Type designation

6 Maximum input frequency

2 Year of manufacture

7 CE marking

3 Serial number

8 Manufacturer independent

identification number

4 IP protection class data

5 Ambient temperature range

9 Datamatrix Code

1

2

3

4

5

6

9

7

8

Page 29

Technical data 29

3.9.2 ATEX marking

The plates for the "ATEX" marking of the DL230 are located on the top

panel of the device housing.

3.9.2.1 Associated apparatus for Zone 0 and 1

III.: 2

1 Manufacturer and address

4 ATEX-marking

2 Type designation of the device

5 Permissible ambient

temperature range

3 Identification number on the plate

3.9.2.2 Zone 2

III. 3

1 Manufacturer and address

4 ATEX-marking

2 Type designation of the device

5 Permissible ambient

temperature range

3 Identification number on the

plate

2 4 3

5

1

2

4

3

5

1

Page 30

30 Technical data

3.9.3 Device software Identification

◼ Move the cursor using the arrow keys to the "Serv." register and to the

values "Vers" (device software version) and "Chk" (checksum) via the

following path:

Serv. Identification Data Logger Vers or Chk

◼ The checksum "Chk" can be recalculated for verification purposes by

pressing the ENTER button.

Page 31

Construction and Function 31

4 Construction and Function

4.1 External view

III. 4

1 Display

6 Cable glands

2 Function key

7 Arrow keys

3 Optical interface

8 Enter button „ENTER“

4 Escape button „ESC“

9 Aerial

5 Hinge

10 Sealing eyelets

1

2

3

4

5

6

7

9

8

10

Page 32

32 Construction and Function

4.2 Internal view

III. 5

1 Connections for counting and

signal inputs DE1 to DE4

2 Connections for pulse and

signal outputs DA1 to DA2

3 Device battery connections

4 Connections for the power

supply unit

5 Modem battery connections

6 Modem with SIM card holder

7 Connector for interface

boards (optional use in place

of the modem)

4.3 Short description

The DL230 data logger is used to determine maximum load and to register

load profiles in gas plants for special-rate clients. Up to four meters or lowfrequency pulse outputs from volume correctors can be connected to the

data logger. This means that the device is suitable for plants with more

than one measurement.

Two of the input channels can also alternatively be connected to encoder

counters. Inputs which do not capture consumption information or original

meter readings can also be parameterized as status inputs.

1 2 3 4 5 6 7

Page 33

Construction and Function 33

Simple monitoring functions are possible with this. Events can be stored in

an archive, emitted as a status signal or transmitted to a central location via

SMS if required.

Two digital outputs can be used to transfer consumption information or to

signal warnings and alarms.

Energy supply is with lithium batteries. In addition, the device can also be

equipped with a 230VAC power supply unit.

For data communication purposes an integrated modem is available, which

supports the GSM, GPRS and UMTS (2G and 3G) radio standards. Alternatively, communication modules can be used for Ethernet communication

or for communication via RS232/RS485 interface.

Use of the DL230 is via 7 keys and an alphanumeric display on the front

panel.

4.4 Connections

The DL230 memory can be connected to:

– a maximum of three batteries (2x device batteries and 1x modem bat-

tery or 1x device battery and 2x modem batteries)

– Optional 230V connection to an internal power supply unit

The following can be used to monitor and record data and to transmit data

and program functions:

– 4 counting and signal inputs DE1, DE2, DE3, DE4

– 2 pulse and signal outputs DA1, DA2

– Integrated GSM/GPRS modem

– Optical data interface

Further details on the connection possibilities for the DL230

and the available equipment versions can be found in the

"Technical Data" chapter and in chapter "Assembly, Connection and Putting into Operation".

Page 34

34 Assembly, Connection and Putting into Operation

5 Assembly, Connection and Putting into Oper-

ation

5.1 Assembly

The DL230 can be operated as associated apparatus for ATEX zone 0

or 1 and inside ATEX zone 2. Notice the yellow ATEX marking on each

device.

When using in zone 2, the following warning applies:

DANGER!

The DL230 must not be used in Zone 0 or Zone 1!

WARNING!

When using in Zone 2 may present a risk of explosion!

– Do not open when an explosive atmosphere may be

present!

– Potential electrostatic charging hazard: Do not rub

against the display-window!

– Notice the intrinsic safety parameters of chapter 3.7.3.1

when connecting the serial interface.

The DL230 can either be mounted on a wall or a pipeline.

Should problems arise during assembly, e.g. with regard to

the selection of suitable assembly tools, please contact our

customer service team (see "General" chapter).

Page 35

Assembly, Connection and Putting into Operation 35

5.1.1 Assembly on a pipeline

Mount the DL230 to a pipeline using an A2 universal bracket with a pipe clamp (see Appendix) as well as corresponding cylinder screws.

III. 6

1. Screw into place with the aid of two self-tapping screws for plastic 4x13

mm (III. 6: 1 ) cylinder screws, insert the A2 universal bracket in the

boreholes provided (III. 6: 3 ) on the DL230 (III. 6: 2 ).

2. Tighten the screws so that the bracket is sitting in a fixed position.

3. The A2 universal bracket (III. 6: 3 ) and the device (III. 6: 2 ) should be

fastened to the pipeline (III. 6: 5 ) using the pipe clamp (III. 6: 4 )

4. The device should be mounted on the pipeline in such a way that it is in

a fixed position and cannot fall down or twisted.

WARNING!

When using longer self-tapping screws then there is a risk

of leaks in the housing

2

3

1

4

5

Page 36

36 Assembly, Connection and Putting into Operation

5.1.2 Assembly on a wall

The DL230 can be mounted on the wall without opening the

housing. The holes are accessible by pressing the grey covering strips on both the right and left-hand side of the cover

out-wards at the small groove.

III. 7

1. Bore four holes in the positions marked on the wall (see dimensions

in III. 7).

2. Select wall plugs, which correspond to the size of the screws and

insert these in the boreholes in the wall.

3. Use four universal screws 50mm x 5mm for attaching the DL230 to

a wall.

Page 37

Assembly, Connection and Putting into Operation 37

5.2 Connection

The DL230 is available as officially calibrated or a factory calibrated device. Information regarding additional equipment

versions of the DL230 can be found under www.elsterinstromet.com.

DANGER!

The connection of non-intrinsically-safe or nonassociated apparatus presents a risk of explosion!

The operation of the DL230 as associated apparatus for zone

0 or 1 and the connection of non-intrinsically-safe equipment

which exceeds those conditions and limit values specified in

the declaration of conformity, presents a risk of explosion.

Therefore:

– When the DL230 is used as associated apparatus only

devices with intrinsically-safe circuits and electrical data

that corresponds to those requirements stipulated in the

declaration of conformity for the DL230 (see Appendix),

should be connected.

– When connecting the DL230 and putting it into operation, the guide-

lines of the corresponding EN 60079-0 and EN 60079-14 standards

should be observed.

– The wiring of the connections should be professionally carried out by a

gas specialist or a calibration officer.

– Active outputs cannot be switched.

– Connect unused cable glands as per EN 60079-14 with the help of a

plug or a suitable screw cap.

To program the device and carry out further applications the optical interface of the DL230 (see the "Construction and Function" chapter) can be

used. Further details can be found under www.elster-instromet.com.

The connections described below should only be sealed by

a calibration officer. If the DL230 is used for operations,

which are not subject to calibration regulations, the seals on

the respective connections can be omitted.

Page 38

38 Assembly, Connection and Putting into Operation

5.2.1 Connecting meters

For the purpose of measuring consumption the pulse transducers from up

to four meters can be connected to the DE1 to DE4 digital inputs of the

DL230. Alternatively, encoders can be connected to inputs DE1 and DE2.

III. 8

Further details and special features

regarding the use of the pulse

transducer and encoder are

described in the following subchapters.

The wire cross-section for the connection to the DL230

inputs is 0.3 … 2.5 mm

2

.

When using stranded wire, use appropriate wire ferrules.

Use only cables, which fit to the cable glands in order to

keep IP protection class also after the installation.

Minimum cable diameter:

Cable gland M12 ≥ 5 mm

Cable gland M16 ≥ 5,5 mm.

5.2.1.1 Connection to a pulse transducer

1. Connect the meter's pulse transducers to the DE1 to DE4 terminals (III.

8) of the DL230. The polarity can be freely selected (the symbols "+"

and "-" on the terminals are used for the connection of other pulse

transducers or encoders).

2. Adjust the measurement parameters, e.g. the cp value (pulse constant),

as described in chapter 5.3.1.2.

5.2.1.2 Connection to an encoder

1. Connect the meter's encoder(s) to the DE1 and DE2 terminals (III. 8) of

the DL230.

The polarity should be taken into consideration, i.e. connect the "+" of

the encoder to the "DE1 +" terminal and "-" to the "DE1 -" terminal

respectively.

2. Adjust the measurement parameters, e.g. the encoder type, as described in chapter 5.3.1.3.

Page 39

Assembly, Connection and Putting into Operation 39

5.2.2 Sealing the input terminals

After connecting to the meter as per chapter 5.2.1 the respective DE1 to

DE4 input terminal must be sealed for official calibration measurements.

For this purpose, terminal covers are provided in the bag of accessories. If

required, these should be screwed over the connected terminals and an

adhesive seal should then be bonded to the fastening screw (see chapter

5.3.2).

5.2.3 Connecting the power supply

5.2.3.1 Power supply for the DL230 with integrated power supply unit

DANGER!

Danger to life from electrical current!

Touching live parts poses an imminent danger to life.

Therefore:

– Works on the electrical components of the device, i.e.

the connection of the power supply unit, should solely be

carried out by qualified electricians.

– When performing all works to the electrical system,

switch off the power, secure it against an accidental

restart and check to ensure that the voltage has been

cut.

– Keep moisture from live parts away. This could lead to

short-circuit.

The power supply unit to connect the 230 V~ power supply, is

in-built into the base of the DL230.

III. 9

1. Switch off the supply voltage and secure

it against an accidental restart!

2. Connect the 230V~ supply voltage to the

terminal block ( 1 ) of the power supply.

Terminal "PE" is the connection for the

protective conductor (protective

earthing).

1

Page 40

40 Assembly, Connection and Putting into Operation

The wire cross-section for the connection to the integrated

power supply unit is 0.3 … 2.5 mm

2

.

When using stranded wire, use appropriate wire ferrules.

Use only cables, which fit to the cable glands in order to keep

IP protection class also after the installation.

Minimum cable diameter:

Cable gland M12 ≥ 5 mm

Cable gland M16 ≥ 5,5 mm.

DANGER!

Danger to life from electrical current!

Connect the protective earthing of the mains power supply

to the J2 screw terminal, connection "E"!

5.2.4 Connect outputs of the DL230

DANGER!

The connection of non-intrinsically-safe or nonassociated apparatus presents a risk of explosion!

The operation of the DL230 as associated apparatus for zone

0 or 1 and the connection of non-intrinsically-safe equipment

which exceeds those conditions and limit values specified in

the declaration of conformity, presents a risk of explosion.

Therefore:

– When the DL230 is used as associated apparatus only

devices with intrinsically-safe circuits and electrical data

that corresponds to those requirements stipulated in the

ATEX declaration for the DL230 (see Appendix), should

be connected. Notice also the limitations of chapter 3.6.1.

– Screw the terminal covers over the connected output

terminals again.

The wire cross-section for the connection to the DL230 out-

puts is 0.3 … 2.5 mm

2

.

When using stranded wire, use appropriate wire ferrules.

Page 41

Assembly, Connection and Putting into Operation 41

Use only cables, which fit to the cable glands in order to

keep IP protection class also after the installation.

Minimum cable diameter:

Cable gland M12 ≥ 5 mm

Cable gland M16 ≥ 5,5 mm.

Different downstream devices can be connected to the

digital outputs of the DL230. The outputs are preconfigured

for this purpose (see chapter 5.3.1.5).

Ill.: 10

1. Remove the terminal cover for the digital

outputs (terminals DA1 and / or DA2) (Ill.: 10).

2. Connect the downstream device to the

corresponding digital outputs (terminals DA1

to DA2) of the DL230 (Ill.: 10).

3. Screw the terminal covers over the connected

terminals after connecting the cables. If

required, a seal should then be bonded to the

fastening screw (see chapter 5.3.2).

4. If necessary, adjust the cp value (pulse

contact) for the pulse outputs as described in

chapter 5.3.1.5.

5.2.4.1 Electrical insulation of the outputs

In standard cases, all negative poles of the outputs are electrically connected to the motherboard.

For special applications, i.e. switching a positive pole, each output can be

electrically separated from the motherboard and from the other outputs.

CAUTION!

Reduced battery life

Activation of electrical isolation of outputs reduces battery life

when operating the battery.

It is then impossible to give a reliable prediction of the remaining battery life.

Page 42

42 Assembly, Connection and Putting into Operation

An electrically-insulated output only requires electricity if the

output is active (switched-on). You can therefore minimize the

negative influence of an electrically-insulated output on the

battery life by setting the pulse duration to the lowest possible

value when using it as a pulse output.

The configuration software "enSuite" is suitable for this purpose.

The electrical insulation of the outputs is not an approved

electrical isolation in accordance with ATEX. An approved Exisolator is required when using the device as associated

apparatus in Ex zone 0 or 1.

In order to activate the electrical insulation of an output, move the switch

lever behind the corresponding output terminal away from the terminal:

Ill.: 11

Switch for electrical isolation

Output DA2 is electrically isolated

(the slider on the switch is up)

Output DA1 is not electrically isolated

(the slider on the switch is down)

Page 43

Assembly, Connection and Putting into Operation 43

5.3 Putting into operation

5.3.1 Configuration of measurement parameters

If the DL230 is subject to calibration regulations, the works

described below should only be performed by legally

authorized individuals.

The necessary operating parameters can be adjusted using the free

configuration program "enSuite", which is available under www.elsterinstromet.com.

If the program is not available, the configuration can also be carried out

using the keyboard as described below (see chapter 5.3.1.2).

Before adjusting the measurement parameters via the

keyboard, please read chapter 6 to learn how the device is

operated.

5.3.1.1 Opening the calibration lock

The calibration lock is located at the back of the housing cover in the form

of a button, and this can be secured by means of an adhesive label. This

button must be pressed in order to adjust the values and parameters protected by configuration regulations.

Ill.: 12

Position of the

push-button to

open the calibration lock.

Page 44

44 Assembly, Connection and Putting into Operation

5.3.1.2 Adjusting the parameters for the pulse transducer of the meter

If a pulse transducer is connected as per 0 then adjust the input mode and

the cp value as follows:

1. Setting the input mode:

– Move the cursor to the "Serv." tab and via the path below to the input

mode "Md.E1":

Serv. Input 1 Settings Md.E1

– Press the ENTER button The set value flashes.

– Repeatedly press one of the or arrow keys until the text "Pulse

Input" flashes.

– Press the ENTER key to confirm the value setting. The input value can

be deleted by using the ESC key.

2. Setting the cp (pulse constant) value:

– Move the cursor to cp value "cp.E1" in the same path

– Press the ENTER button. One of the value's digits flashes.

– Move the cursor to the digits using the or arrow keys and update

them using the or arrow keys.

– Press the ENTER key to confirm the value setting. The input value can

be deleted by using the ESC key.

The same process can also be used for the other inputs, inputs 2 to 4.

5.3.1.3 Activating encoder mode

If an encoder is connected as per 5.2.1.2, the encoder mode is activated as

follows:

Start the "Encoder Recognition" function using the DL230 keypad as

follows:

– Move the cursor to the "Serv." register and to the value "Md.I1" (input

mode) via the following path:

Serv. Input 1 Parameter settings Md.I1

– Press the ENTER button the set value flashes.

– Repeatedly press one of the or arrow keys until the value "Auto-

Encoder" flashes.

– Press the ENTER key to confirm the value setting. Input can be can-

celled using the ESC key.

– Wait until "Auto-Encoder" is replaced by another value. This can take

up to a minute as the DL230 activates and test all known encoder protocols consecutively.

Page 45

Assembly, Connection and Putting into Operation 45

– On successful detection the DL230 displays the label "Vo1" on the me-

ter reading of the meter:

Serv. Input 1 Vo1

Unlike the "Auto Detect" function, you can also select the connected

encoder type directly under "Md.I1".

Serv. Input 1 Parameter settings Md.I1

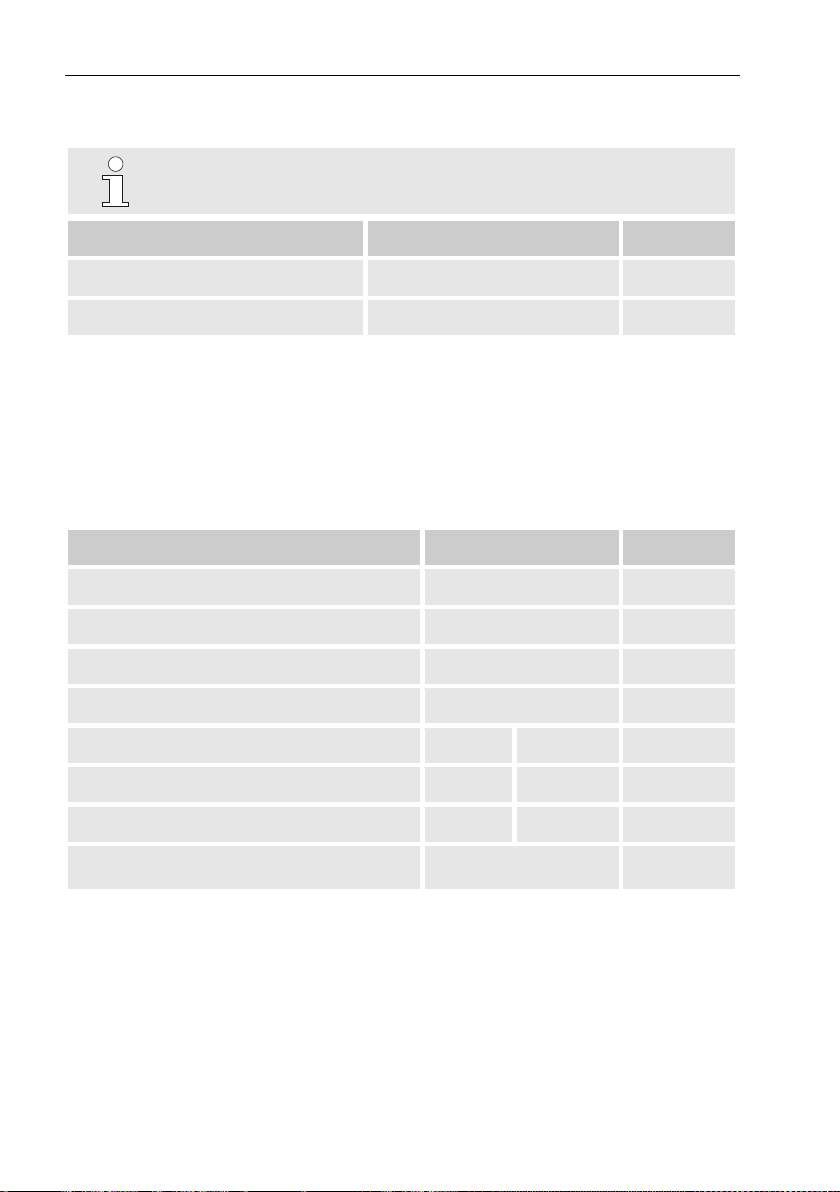

The following encoder types can be selected:

Md.E1

Description

Enc.Namur a

Encoder with Namur a protocol

Enc.SCR EDIS

Encoder SCR with EDIS95 protocol

Enc.SCR OBIS

Encoder SCR with OBIS05 protocol

Enc.SCR+EDIS

Encoder SCR+ with EDIS95 protocol

Enc.SCR+OBIS

Encoder SCR+ with OBIS05 protocol

Enc.Nam. a-b

Encoder with Namur a and b protocols

The same process can be used for input 2.

With the parameter "EZyk" you can set for both encoder inputs at what in-

tervals the encoder is read out. Default is 900 seconds (15 minutes).

Changing this parameter has a significant impact on battery life !

"EZyk" can be found in the display under the path:

Serv. Device settings Measurement

5.3.1.4 Adjusting meter readings

To control the measuring of volumes, the meters (V1 to V4) of the DL230

can be adjusted to the same respective value as the meters connected

when the calibration or administrator lock is open (with an entry in the PTB

log).

– Open the calibration lock or the administration lock

– Move the cursor to the "Serv." register and to the value "V1", "V2", "V3"

or "V4":

Serv. Input 1 V1

Serv. Input 2 V2

Serv. Input 3 V3

Serv. Input 4 V4

– Press the ENTER button. One of the value's digits flashes.

– Move the cursor to the digits using the or arrow keys and update

them using the or arrow keys.

Page 46

46 Assembly, Connection and Putting into Operation

– Once you have changed all of the digits, press the ENTER key in order

to confirm your entry. The input value can be deleted by using the ESC

key.

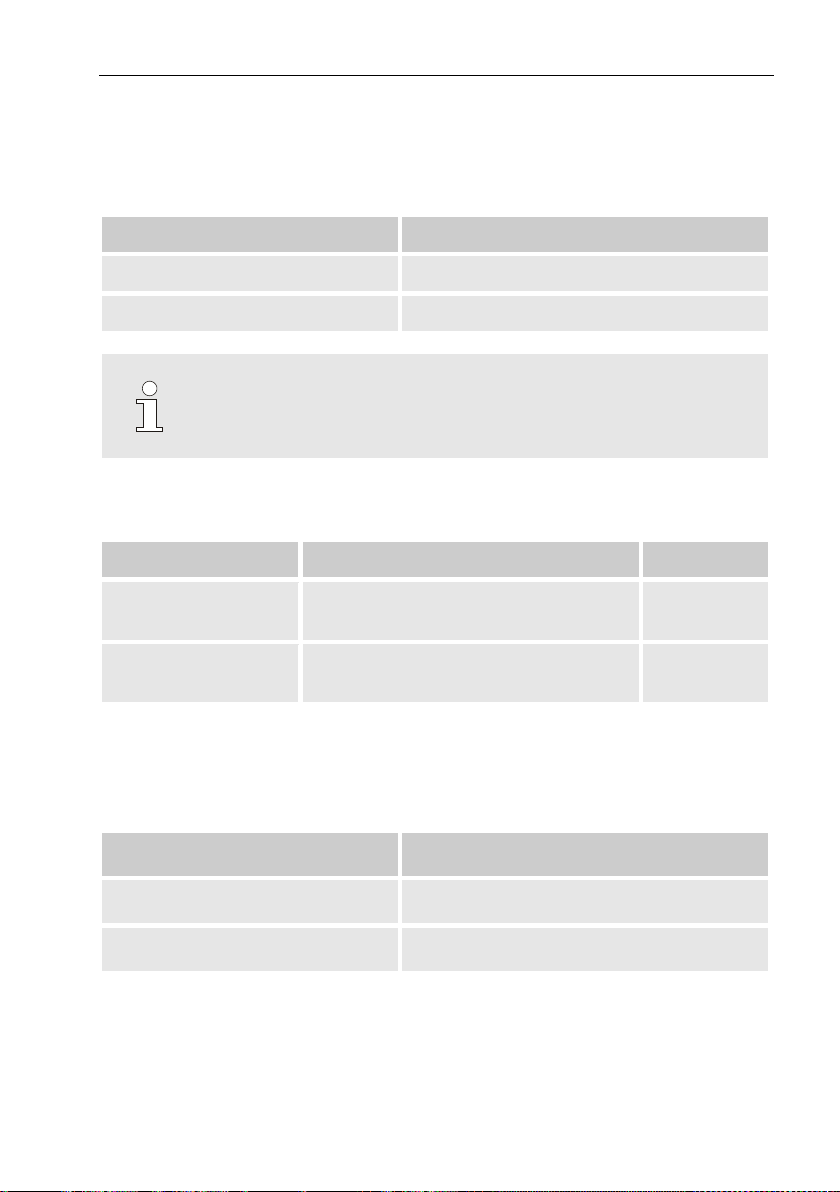

5.3.1.5 Configuration of the outputs

The cp values (pulse constants) for the outputs can also be

configured using the enSuite software.

The following functions are preset ex-factory for the outputs:

Output

Function

DA1

Pulse output for volume "V1" (cp.A1= 0.1)

DA2

Pulse output for volume "V2" (cp.A2= 0.1)

The cp value of an output indicates how many pulses are emitted per cubic

meter. A cp value of 0.1/m3 (0.1 pulses per m3) means that e.g. a pulse is

emitted per 10m3.

To change the cp values for output 1 or output 2, move the cursor to the

"Serv." register and go to "cp.A1" (for output 1) or "cp.A2" (for output 2) via

the following path:

Serv. Outputs Output 1 cp.O1

or Serv. Outputs Output 2 cp.O2

◼ Press the

ENTER

button a digit of the cp value will flash.

◼ Move the cursor to the digits using the or arrow keys and update

them using the or arrow keys.

◼ Press

ENTER

, so that the value setting is confirmed. The input value can

be deleted by using the ESC key.

Aside from the settings described here, a range of other functions can be configured for the outputs, e.g. status information

or time-synchronous pulses.

A complete description can be found in the DL230 Application

Manual that can be downloaded under www.elsterinstromet.com.

5.3.1.6 Setting the daylight-saving time

◼ Move the cursor to the "Serv." register and to the "MdTim" value (day-

light saving mode) via the following path:

Serv. Date and time MdTim

◼ Press the ENTER button the set value flashes.

◼ Change the value using the arrow keys or :

Page 47

Assembly, Connection and Putting into Operation 47

MdTim

Description

CEST off

No switchover to daylight saving time

(CEST = Central European Summer Time)

CEST auto

Automatic conversion to summertime in accordance

with EU regulations

CEST man.

The start and end of daylight saving time is configured

by the control centre every year.

◼ Press the ENTER button to confirm the set value. The input value can

be deleted by using the ESC key.

5.3.1.7 Deleting the measurement archive

Deleting the archive is not absolutely necessary when putting

the device into operation.

◼ Move the cursor to the "Serv." register and to the "Clr.A" value (delete

measurement archive) via the following path:

Serv. Edit and delete Clr.A

All measurement archives (no logs) will be deleted.

In order to ensure that the archive is not accidentally deleted,

the serial number of the DL230 must be entered whilst the

calibration lock is open (this number is located on the

identification plate of the device).

◼ Press the ENTER button. One of the value's digits flashes.

◼ Move the cursor using the arrow keys or to the digits and enter the

serial number of the device using the arrow keys

or .

◼ After you have entered the serial number of the device, press the

ENTER button to confirm the input. The input value can be deleted by

using the ESC key.

5.3.1.8 Deleting the Certification Data Log

The log can only be deleted if the calibration lock is open.

◼ Move the cursor to the "Serv." register and to the value "ClCDL" (delete

certification data log) via the following path:

Page 48

48 Assembly, Connection and Putting into Operation

Serv. Edit and delete ClCDL

◼ Press the ENTER key "0" flashes.

◼ Change the value using the arrow buttons or to "1".

◼ After you have entered the value, press the ENTER button to confirm

the input. The display shows as "busy" temporarily.

The certification data log is then deleted. The input value can be deleted

by using the ESC key.

5.3.1.9 Closing and securing the calibration lock

After all settings subject to calibration regulations have been adjusted,

close the calibration lock in the same way that it was opened: Press the

buttons described in chapter 5.3.1.1 once again.

The calibration switch is secured with an adhesive label as described in

chapter 5.3.2.2.

5.3.1.10 Use of the "HT/LT switch-over"

The DL230 also offers an option to carry out the switch over from the high

tariff meter (HT) to the low tariff (LT) meter.

Whether such a switch over has been parameterized can be found under:

Serv. Input 1 Parameter settings HTLT1

or Serv. Input 2 Parameter settings HTLT2

or Serv. Input 3 Parameter settings HTLT3

or Serv. Input 4 Parameter settings HTLT4

If the displayed value is "-.-.-", then no switch over took place. If the value is

not equal to "-.-.-", then a switch over to the set event is taking place.

In principle two settings are possible:

a) Meter 1 counts, meter 2 does not

b) Meter 1 counts at high tariff (HT) and meter 2 at low tariff (LT)

In case b) the switch over between HT and LT should be parameterized via

a settings file. Switch over either takes place in a "time-dependent" manner

or "controlled by an input". With the inactive meter, the short description will

be shown flashing.

Adjustment is simple to carry out via enSuite configuration

software.

Parameterization of the device is described in the DL230

application manual.

,

Page 49

Assembly, Connection and Putting into Operation 49

5.3.2 Sealing

5.3.2.1 External view

Ill.: 13

1 Possible sealing point to secure the identification plate via adhesive seal.

2 Optional user lock: Sealing the cover by means of wire seals through the

sealing eyelet at the top and the hinge at the bottom.

5.3.2.2 Internal view

Ill.: 14

1 Sealing point to secure the calibration switch.

2 Sealing points to secure the circuit board cover.

3 Sealing points to secure the terminal covers of the inputs and outputs

used.

1

2

2

1

2

3

Page 50

50 Assembly, Connection and Putting into Operation

These sealing points Ill.: 14/3 to secure the pulse inputs and

pulse outputs are subject to national regulations

(cf. WELMEC 11.1, chapter 2.7.1).

Depending on the legal situation in the respective country of

use, seals produced by legally authorized manufacturers or the

meter operators, should be used.

5.3.3 Closing the housing

CAUTION!

Damage to property caused by improper device closure!

If the device is not properly closed cables can get pinched

and cause damage.

Therefore:

– Please ensure that the cable ducts are positioned cor-

rectly when closing the device.

Ill.: 15

1. The grey covering strips on both the right and left-hand side of the cover are pressed outwards at the small groove ( 2 ). This means that the

screws on the cover become visible.

2. Close the housing using the four screws provided ( 1 ).

3. Press the grey covering strips back onto the cover until they snap into

place.

1

2

2

Page 51

Assembly, Connection and Putting into Operation 51

5.3.4 Verifying assembly and connection

WARNING!

Risk as a result of incorrect assembly and connection

Incorrect assembly and connection of the DL230 may lead

to life-threatening situations.

Therefore:

– Assemble and connect the DL230 correctly.

– Sealing should solely be carried out by a calibration

officer.

– Follow the guidelines of DIN EN 60079-14,

DIN EN 60079-0, the ATEX Product Directive 94/9/EC

as well as the ATEX Operating Directive 1999/92/EC

EN.

5.3.5 Data transfer

For the various options available regarding data transmission to a control

centre via the integrated modem then please follow the corresponding

instructions in the DL230 applications manual which can be downloaded

from von http://www.dl230.de/ (DOWNLOADS → Dokumente).

The data transfer settings can be configured without opening the calibration

lock.

Page 52

52 Operation

6 Operation

The "enSuite" software and data interfaces of the DL230 can

be used to perform further applications other than those

described below. Instructions can be found under

www.elster-instromet.com.

6.1 Safety

6.1.1 Personal protective equipment

When working on the device inside a gas-handling plant, personal protective equipment must be worn to minimize risks to health.

– During works on the device, the necessary personal protective equip-

ment must be worn inside the respective plant at all times

– The notices relating to personal protective equipment mounted in the

working area must be followed at all times.

6.2 Operating personnel

The following groups of people are authorized to perform different functions

when operating the DL230.

6.2.1 Instructed personnel

A person instructed on how to operate the DL230, who,

– will be informed of the tasks assigned to them and possible risks result-

ing from inappropriate behaviour, in a training session provided by the

operator.

– is authorized to read and take note of values and parameters using the

control elements of the DL230.

6.2.2 Qualified personnel

A person qualified to operate the DL230, who,

– on the basis of their specialist training, knowledge and experience, as

well as their awareness of the relevant statutory provisions, are in a

position to perform their assigned tasks on the device and are able to

independently identify and prevent possible risks.

Page 53

Operation 53

– is authorized to read and take note of values and parameters using the

control elements of the DL230, and to perform changes which are not

subject to calibration regulations.

6.2.3 Calibration officer

A calibration officer, who,

– on the basis of their professional training, knowledge and experience

and awareness of applicable standards and regulations, is in a position

to perform the works on gas systems. The calibration officer will be

trained on works on devices and installations subject to calibration regulations and will be familiar with the relevant standards and regulations.