Page 1

CS8800 Water Heater

Pilot Burner Assembly

APPLICATION

The CS8800 Pilot Burner Assemblies provides standing

pilot ignition of the main burner and power for the

WT8800 control module and VT8800 valve. The CS8800

is a primary aerated pilot burner.

On some models a temperature cut out switch (TCO) is

provided to sense a clogged flame arrestor or a

flammable vapor incident. When the TCO opens, the

power to the control is interrupted and pilot goes out.

There are separate LP and natural gas models.

The CS8800 Pilot Burner was designed for gas fired hot

water tank heating applications.

INSTALLATION

When Installing This Product…

1. Read these instructions carefully. Failure to follow

2. Check the ratings given in the instructions and on

3. Make sure the installer is a trained, experienced

4. After completing the installation, use these

INSTALLATION INSTRUCTIONS

the instructions can damage the product or cause

a hazardous condition.

the product to make sure the product is suitable for

your application.

service technician.

instructions to check out the product operation.

SPECIFICATIONS

Maximum Temperature Ratings:

Target (flame hood) 1575

Orifice 600

Bracket Assembly 1000

Appliance Operating Ambient Temperature Range:

°F to 140°F (0°C to 60°C)

32

Orifice Requirements:

CS8800A Natural Gas: 0.013 to 0.0143 in. (480 BTU/hr

to 580 BTU/hr at 4.5 in. WC)

CS8800B LP Gas: 0.007 to 0.0083 in. (340 BTU/hr to

480 BTU/hr at 10 in. WC)

CS8800C Natural Gas: 0.0155 to 0.0165 in. (685 BTU/hr

to 776 BTU/hr at 4.5 in. WC)

CS8800D LP Gas: 0.0115 to 0.0125 in. (910 BTU/hr to

1075 BTU/hr at 10 in. WC)

Models:

There are four models available:

CS8800A: “U” channel bracket for burner base

mounting.

CS8800B: Angle bracket for main burner tube

mounting.

CS8800C: Angle bracket similar to CS8800B except

designed to light burner from above.

CS8800D: Angle bracket same as CS8800B.

°F

°F (800°F for models using

stainless steel gas connections)

°F

WARNING

Oxygen Depletion Hazard.

Can cause injury or death due to asphyxiation.

1. Use this pilot burner on vented appliances only.

2. Replace pilot burner with same exact part

number. If equipped with a TCO switch, it must

be installed in the location provided on the pilot

burner. If the TCO switch is mounted on the

appliance, connect the thermopile leads to the

TCO switch. Follow the Instructions provided

with replacement pilot burner.

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

Follow these warnings exactly:

1. Avoid dangerous accumulation of fuel gas by

turning off gas supply at the appliance service

valve before starting the installation procedure.

2. Perform the Gas Leak Test (see page 2) after

the completion of the installation.

3. Do not bend pilot tubing at the gas control or

pilot burner after the compression nut is

tightened. Gas leakage at the connection can

result.

Follow the appliance manufacturer instructions if

available; otherwise, use the instructions provided below.

Location

1. Position the pilot burner for easy access and

observation. In replacement applications, replace

the pilot burner with an identical unit and position

the new pilot burner in the same location and

orientation as the original pilot burner. If the model

has a TCO, position and attach the TCO in the

exact location as the original TCO. If the model has

terminals to connect a TCO, connect the TCO.

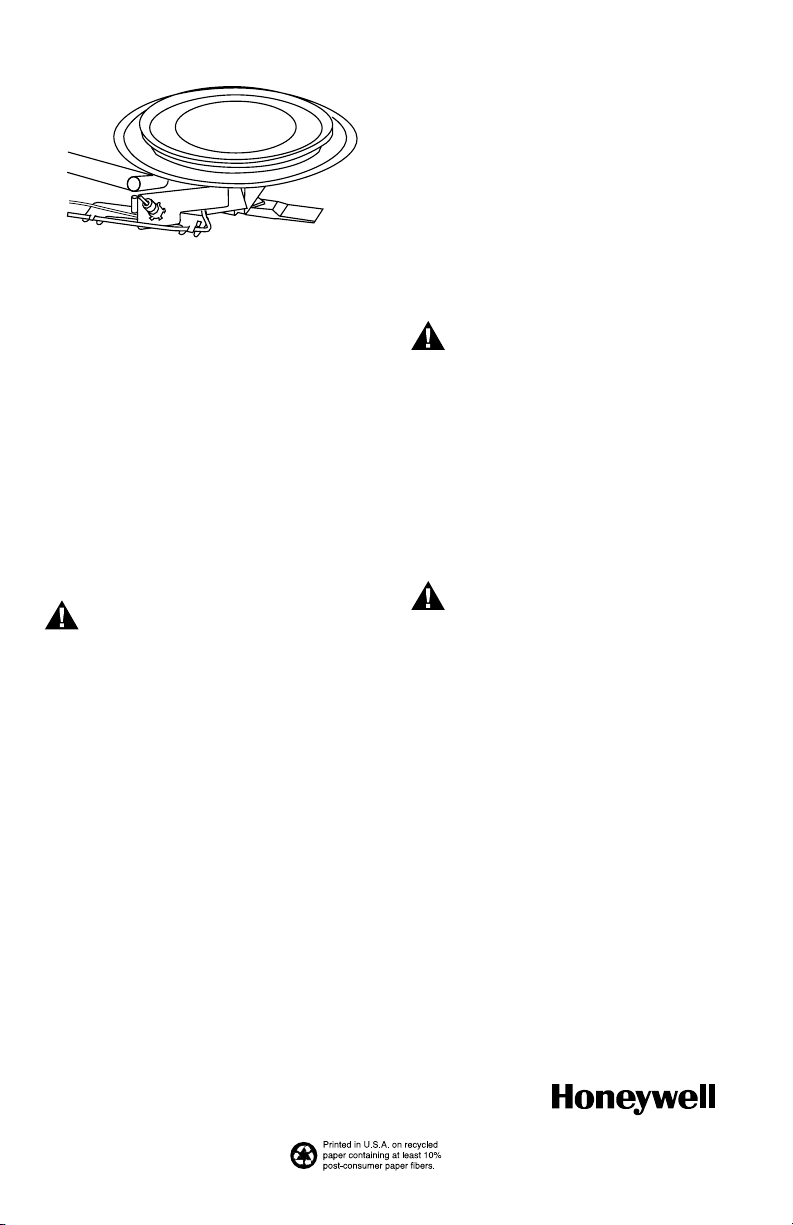

2. Mount the pilot burner on the main burner. See

Fig. 1. Mounting surfaces other than the main

burner can shift, bend, or warp as the water heater

tank expands and contracts during operation.

69-1863-03

Page 2

CS8800 WATER HEATER PILOT BURNER ASSEMBLY

Fig. 1. Mount pilot burner on main burner.

3. Mount the pilot burner so the ignition flame

remains properly positioned with respect to the

main burner flame.

4. Supply the pilot flame with ample air that is free

of combustion products.

5. Do not impinge the pilot flame on adjacent parts.

Do not impinge the main burner flame on the pilot

burner.

6. Do not expose the pilot flame to falling scale that

could impair ignition of the main burner.

7. Do not expose the pilot burner to the main burner

rollout while igniting or extinguishing.

8. Do not expose the pilot flame to drafts that push

or pull the pilot flame away from the thermopile.

M13697

STARTUP AND CHECKOUT

Perform Gas Leak Test

WARNING

Fire or Explosion Hazard.

Can cause property damage, serious injury

or death.

Check for gas leaks with soap and water solution

any time work is done on a gas system.

Gas Leak Test

1. Ensure that the gas supply is turned on at the

appliance service valve.

2. Paint the pipe connections upstream from the pilot

burner with a rich soap and water solution. Bubbles

indicate a gas leak.

3. If a leak is detected, tighten the pipe connections.

4. Stand clear of the main burner while lighting to

prevent injury from hidden leaks that could cause

flashback in the appliance vestibule. Light the main

burner.

5. With the main burner in operation, paint the pipe

joints (including the adapters) and gas control inlet

and outlet with a rich soap and water solution.

6. If another leak is detected, tighten the adapter

screws, joints and pipe connections.

7. Replace the part if the leak cannot be stopped.

Pilot Flame

The pilot flame should envelop 3/8 in. to 1/2 in.

(10 to 13 mm) of the thermopile tip.

Ignite Pilot Burner

1. Before lighting the pilot burner, turn the knob to its

lowest setting. Wait for unburned gas to vent.

WARNING

Explosion or Fire Hazard.

Can cause severe injury, death or property

damage.

LP gas is heavier than air and does not vent

upward. Smell for LP gas next to the floor. If you

smell gas, shut off the main valve in the gas

piping or “ON LP” at the tank. Perform the Gas

Leak Test to recheck the connections.

2. Light the pilot burner according to the appliance

manufacturer instructions.

SERVICE

WARNING

Fire or Explosion Hazard.

Can cause property damage, serious injury

or death.

Perform Gas Leak Test anytime work is done to

the system.

Thermopile Performance

Thermopiles require proper temperature differential

between the hot-junction (tip) and cold-junction (base) to

provide satisfactory operation of millivoltage gas controls.

Thermopiles perform less effectively when exposed to

excessive cold-junction or hot-junction temperatures.

Excessive cold-junction temperatures can be caused by

heat radiation from adjacent surfaces or high ambient air

temperatures. Excessive cold-junction temperatures can

be eliminated by shielding the pilot flame, or construct a

baffle to direct secondary air over the pilot burner base.

Excessive hot-junction temperatures can be eliminated

by proper flame adjustment.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2008 Honeywell International Inc.

69-1863—03 M.S. Rev. 07-08

Loading...

Loading...