Page 1

Xenon™ 1900/1902

Preliminary Draft

Area-Imaging Scanner

User’s Guide

™

Page 2

Disclaimer

Preliminary Draft

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this document without prior notice,

and the reader should in all cases consult HII to determine whether any such

changes have been made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained

herein; nor for incidental or consequential damages resulting from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by copyright.

All rights are reserved. No part of this document may be photocopied, reproduced, or translated into another language without the prior written consent of

HII.

© 2010 Honeywell International Inc. All rights reserved.

Other product names or marks mentioned in this document may be trademarks

or registered trademarks of other companies and are the property of their

respective owners.

Web Address:

Microsoft® Windows®, Windows NT®, Windows 2000, Windows ME, Windows

XP, and the Windows logo are trademarks or registered trademarks of Microsoft

Corporation.

The Bluetooth® word mark and logos are owned by Bluetooth SIG, Inc.

Other product names or marks mentioned in this document may be trademarks

or registered trademarks of other companies and are the property of their

respective owners.

www.honeywellaidc.com

Page 3

Product Agency Compliance - Xenon 1900

Preliminary Draft

USA

FCC Part 15 Subpart B Class B

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class B digital device pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio or television technician for

help.

If necessary, the user should consult the dealer or an experienced radio/

television technician for additional suggestions. The user may find the following booklet helpful: “Something About Interference.” This is available at

FCC local regional offices. Honeywell is not responsible for any radio or

television interference caused by unauthorized modifications of this equipment or the substitution or attachment of connecting cables and equipment

other than those specified by Honeywell. The correction is the responsibility of the user.

Use only shielded data cables with this system.

Caution: Any changes or modifications made to this equipment not

expressly approved by Honeywell may void the FCC authorization to operate this equipment.

UL Statement

UL listed: UL60950-1.

Page 4

Canada

Preliminary Draft

Industry Canada ICES-003

This Class B digital apparatus complies with Canadian ICES-003. Operation is subject to the following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including

interference that may cause undesired operation.

Conformité à la règlementation canadienne

Cet appareil numérique de la Classe A est conforme à la norme NMB-003

du Canada. Son fonctionnement est assujetti aux conditions suivantes :

1. Cet appareil ne doit pas causer de brouillage préjudiciable.

2. Cet appareil doit pouvoir accepter tout brouillage reçu, y compris le

brouillage pouvant causer un fonctionnement indésirable.

cUL Statement

cUL listed: CSA C22.2 No.60950-1-03.

Europe

The CE marking indicates compliance to 2004/108/EC EMC Directive

with Standards EN55022 CLASS B, EN55024, EN61000-3-2,

EN61000-3-3. In addition, complies to 2006/95/EC Low Voltage Directive, when shipped with recommended power supply.

For further information please contact:

Honeywell International Inc. shall not be liable for use of our product with

equipment (i.e., power supplies, personal computers, etc.) that is not CE

marked and does not comply with the Low Voltage Directive.

Honeywell Imaging & Mobility Europe BV

Nijverheidsweg 9-13

5627 BT Eindhoven

The Netherlands

Waste Electrical and Electronic Equipment

Information

Honeywell complies with Directive 2002/96/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 27 January 2003 on waste electrical

and electronic equipment (WEEE).

This product has required the extraction and use of natural resources for its

production. It may contain hazardous substances that could impact health

and the environment, if not properly disposed.

Page 5

In order to avoid the dissemination of those substances in our environment

Preliminary Draft

and to diminish the pressure on the natural resources, we encourage you to

use the appropriate take-back systems for product disposal. Those systems will reuse or recycle most of the materials of the product you are disposing in a sound way.

The crossed out wheeled bin symbol informs you that the product

should not be disposed of along with municipal waste and invites you to

use the appropriate separate take-back systems for product disposal.

If you need more information on the collection, reuse, and recycling systems, please contact your local or regional waste administration.

You may also contact your supplier for more information on the environmental performances of this product.

Germany

If your product is marked with the GS symbol, then the product

has been issued a GS certificate showing compliance to IEC

60950-1.

Australia/NZ

C-Tick Statement

Conforms to AS/NZS 3548 EMC requirement

Mexico

Conforms to NOM-019.

Russia

Gost-R certificate

Page 6

South Korea

Preliminary Draft

International

Eye Safety Statement: LED

This device has been tested in accordance with IEC60825-1 LED safety,

and has been certified to be a Class 1 LED product.

CB Scheme

Certified to IEC60950-1 (2001) First Edition.

Patents

Please refer to the product packaging for patent information.

Solids and Water Protection

The Xenon 1900 has a rating of IP41, immunity of foreign particles and dripping

water.

Page 7

Product Agency Compliance - Xenon 1902 and

Preliminary Draft

CCB01-010BT Base

USA

FCC Part 15 Subpart C

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including

interference that may cause undesired operation.

Caution: Any changes or modifications made to this equipment

not expressly approved by Honeywell may void the

FCC authorization to operate this equipment.

UL Statement

UL listed: UL60950-1.

Canada

Industry Canada

This device complies with Canadian RSS-210. Operation is subject to the

following conditions:

1. This device may not cause interference.

2. This device must accept any interference, including interference that

may cause undesired operation.

Conformité à la règlementation canadienne

Cet appareil ISM est conforme à la norme CNR-210 du Canada. Son fonctionnement est assujetti aux conditions suivantes :

1. Cet appareil ne doit pas causer de brouillage préjudiciable.

2. Cet appareil doit pouvoir accepter tout brouillage reçu, y compris le

brouillage pouvant causer un fonctionnement indésirable.

Page 8

C-UL Statement

Preliminary Draft

C-UL listed: CSA C22.2 No.60950-1-03 for I.T.E product safety.

Europe

The CE marking on the product indicates that this device is in conformity with all essential requirements of the 1999/5/EC R&TTE Directive.

In addition, complies to 2006/95/EC Low Voltage Directive, when

shipped with recommended power supply. For further information, contact:

Honeywell Imaging & Mobility Europe BV

International Inc.

Nijverheidsweg 9-13

5627 BT Eindhoven

The Netherlands

Honeywell shall not be liable for use of our product with equipment (i.e.,

power supplies, personal computers, etc.) that is not CE marked and does

not comply with the Low Voltage Directive. This equipment is intended for

use throughout the European Community and has been assessed to the

following standards:

EN 300 328

EN 301 489-1

EN 301 489-17

EN60950-1

EN60825-1

Waste Electrical and Electronic Equipment

Information

Honeywell complies with Directive 2002/96/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL on waste electrical and electronic

equipment (WEEE).

This product has required the extraction and use of natural resources for its

production. It may contain hazardous substances that could impact health

and the environment, if not properly disposed.

In order to avoid the dissemination of those substances in our environment

and to diminish the pressure on the natural resources, we encourage you

to use the appropriate take-back systems for product disposal. Those systems will reuse or recycle most of the materials of the product you are disposing in a sound way.

The crossed out wheeled bin symbol informs you that the product

should not be disposed of along with municipal waste and invites you to

use the appropriate separate take-back systems for product disposal.

Page 9

If you need more information on the collection, reuse, and recycling sys-

!

Preliminary Draft

tems, contact your local or regional waste administration.

You may also contact your supplier for more information on the environ-

mental performances of this product.

Germany

If your product is marked with the GS symbol, then the product

has been issued a GS certificate showing compliance to IEC

60950-1.

Australia/NZ

C-Tick Statement

Conforms to AS/NZS 3548 EMC requirements.

Russia

International

Safety Precautions for Lithium Batteries

• Do not place batteries in fire or heat the batteries.

• Do not store batteries near fire or other high temperature locations.

• Do not store or carry batteries together with metal objects.

• Do not expose batteries to water or allow the batteries to get wet.

• Do not connect (short) the positive and negative terminals, of the

batteries, to each other with any metal object.

• Do not pierce, strike or step on batteries or subject batteries to strong

impacts or shocks.

• Do not disassemble or modify batteries.

Caution:

Danger of explosion if batteries are incorrectly replaced.

Replace only with the same or equivalent type recommended

by the manufacturer. Dispose of used batteries according to

the recycle program for batteries as directed by the governing

agency for the country where the batteries are to be discarded.

Page 10

Eye Safety Statement

Preliminary Draft

LED

This device has been tested in accordance with IEC60825-1:

1993+A1+A2 LED safety, and has been certified to be a Class 1 LED

device.

Radio Technology

Class II

CB Scheme

Certified to CB Scheme IEC 60950-1.

Solids and Water Protection

The Xenon 1902 has a rating of IP41, immunity of foreign particles and

dripping water.

Patents

Refer to product packaging for patent information.

Page 11

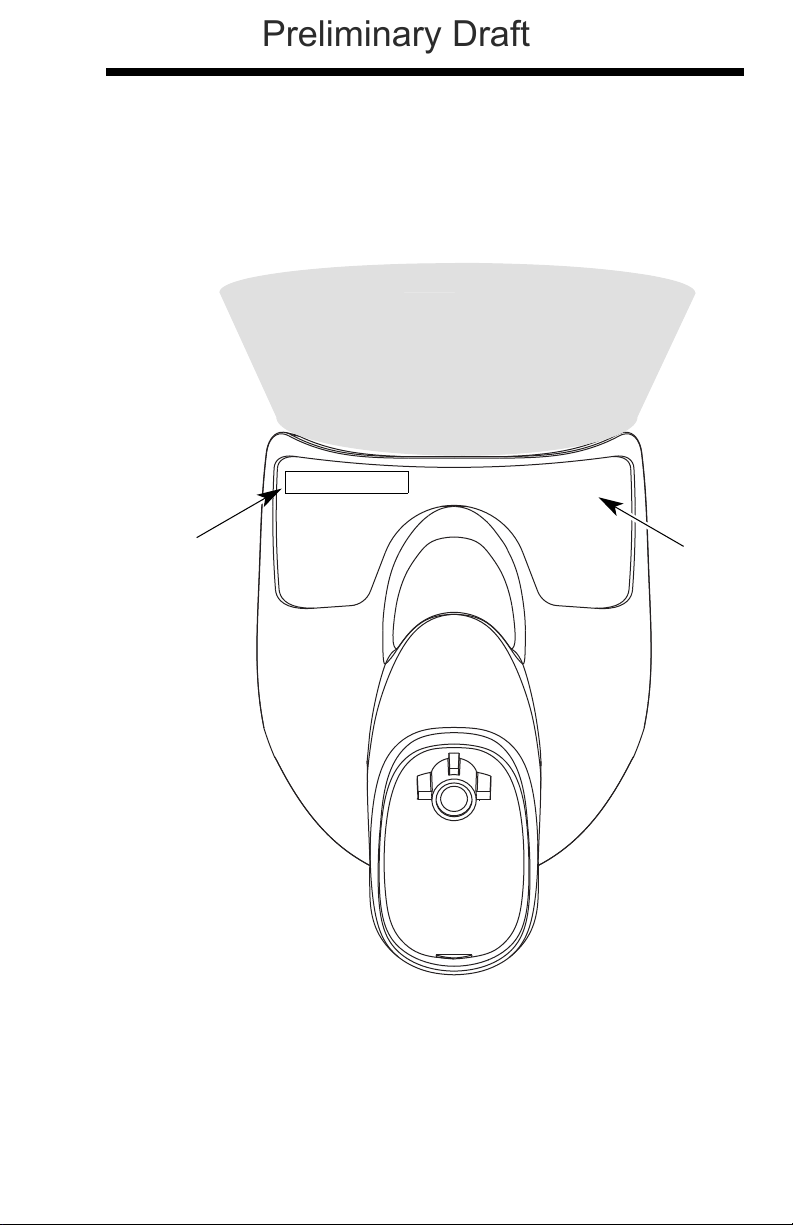

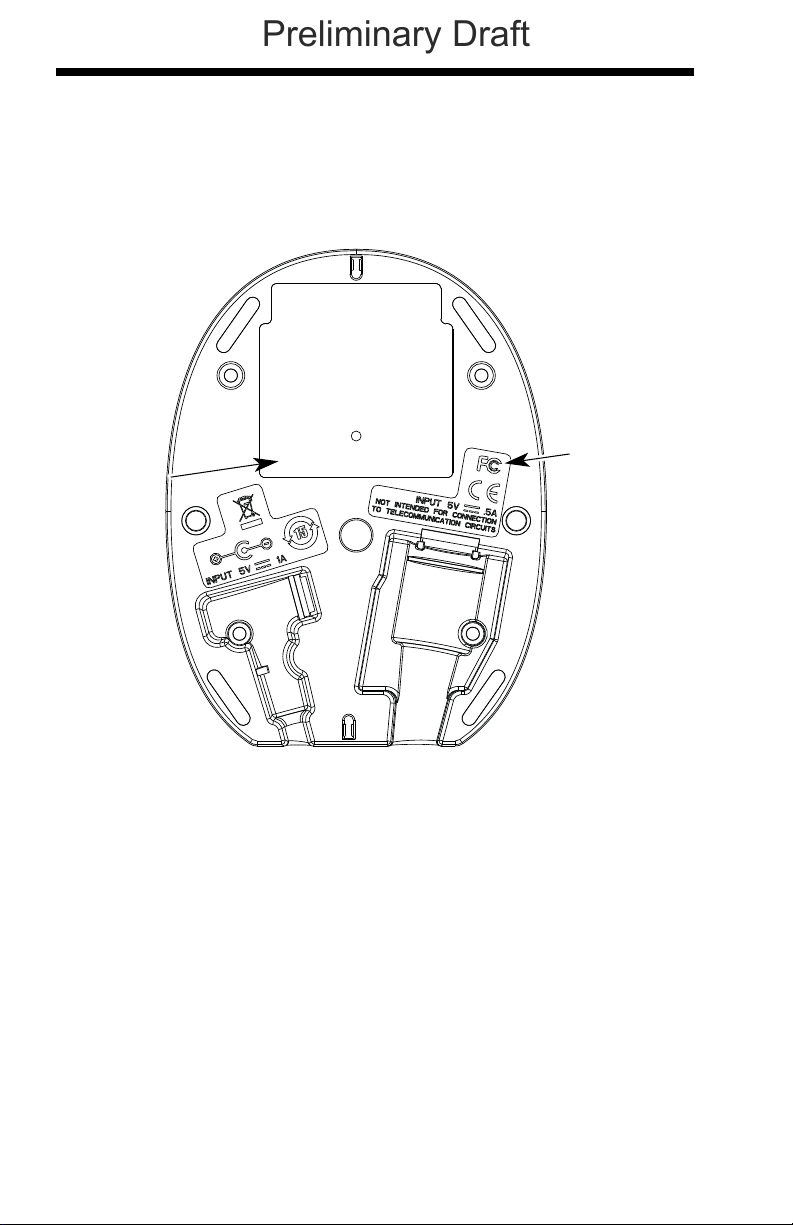

Required Safety Labels

Scanner

Compliance

Label

location

Item

Number, Serial

Number and

Revision

Information

location

Illumination output

Preliminary Draft

Page 12

CCB01-010BT Base

Item Number,

Serial

Number and

Revision

Information

location

Compliance

Label

location

Preliminary Draft

Page 13

Table of Contents

Preliminary Draft

Chapter 1 - Getting Started

About This Manual ......................................................1-1

Unpacking Your Device............................................... 1-1

Connecting the Device ................................................ 1-2

Connecting with USB ............................................ 1-2

Connecting with Keyboard Wedge........................ 1-3

Connecting with RS232 Serial Port....................... 1-5

Connecting with RS485......................................... 1-6

Reading Techniques ................................................... 1-8

Menu Bar Code Security Settings ............................... 1-8

Resetting the Factory Defaults.................................... 1-9

Setting Custom Defaults ............................................. 1-9

Resetting the Custom Defaults ................................. 1-10

Chapter 2 - Programming the Interface

Introduction ................................................................. 2-1

Programming the Interface - Plug and Play ................ 2-1

Keyboard Wedge................................................... 2-1

Laptop Direct Connect........................................... 2-1

RS232 Serial Port.................................................. 2-2

RS485 ................................................................... 2-2

RS485 Packet Mode ............................................. 2-3

USB IBM SurePos................................................. 2-4

USB PC or Macintosh Keyboard........................... 2-4

USB HID................................................................ 2-5

USB Serial............................................................. 2-5

Verifone

Gilbarco

Honeywell Bioptic Aux Port Configuration............. 2-7

Datalogic™ Magellan

NCR Bioptic Aux Port Configuration...................... 2-8

Wincor Nixdorf Terminal Default Settings ............. 2-8

®

Ruby Terminal Default Settings ............ 2-6

®

Terminal Default Settings ..................... 2-7

©

Bioptic

Aux Port Configuration..................................... 2-7

i

Page 14

Wincor Nixdorf Beetle™ Terminal

Preliminary Draft

Default Settings................................................2-9

Keyboard Country Layout..........................................2-10

Keyboard Style ..........................................................2-17

Keyboard Conversion ................................................2-18

Control Character Output...........................................2-19

Keyboard Modifiers....................................................2-19

RS232 Baud Rate......................................................2-22

RS232 Word Length: Data Bits, Stop Bits,

and Parity ................................................................2-23

RS232 Receiver Time-Out.........................................2-24

RS232 Handshaking..................................................2-24

RS232 Timeout....................................................2-25

XON/XOFF ..........................................................2-25

ACK/NAK .............................................................2-25

Scanner to Bioptic Communication............................2-26

Scanner-Bioptic Packet Mode .............................2-26

Scanner-Bioptic ACK/NAK Mode......................... 2-27

Scanner-Bioptic ACK/NAK Timeout..................... 2-27

Chapter 3 - Cordless System Operation

How the Cordless Base Works....................................3-1

Linking the Scanner to the Base..................................3-1

Communication Between the Cordless System

and the Host..............................................................3-2

RF (Radio Frequency) Module Operation....................3-2

System Conditions.......................................................3-2

Linking Process .....................................................3-3

Scanner Is Out of Range .......................................3-3

Scanner Is Moved Back Into Range ......................3-3

Out of Range and Back into Range

with Batch Mode On.........................................3-3

Page Button.................................................................3-3

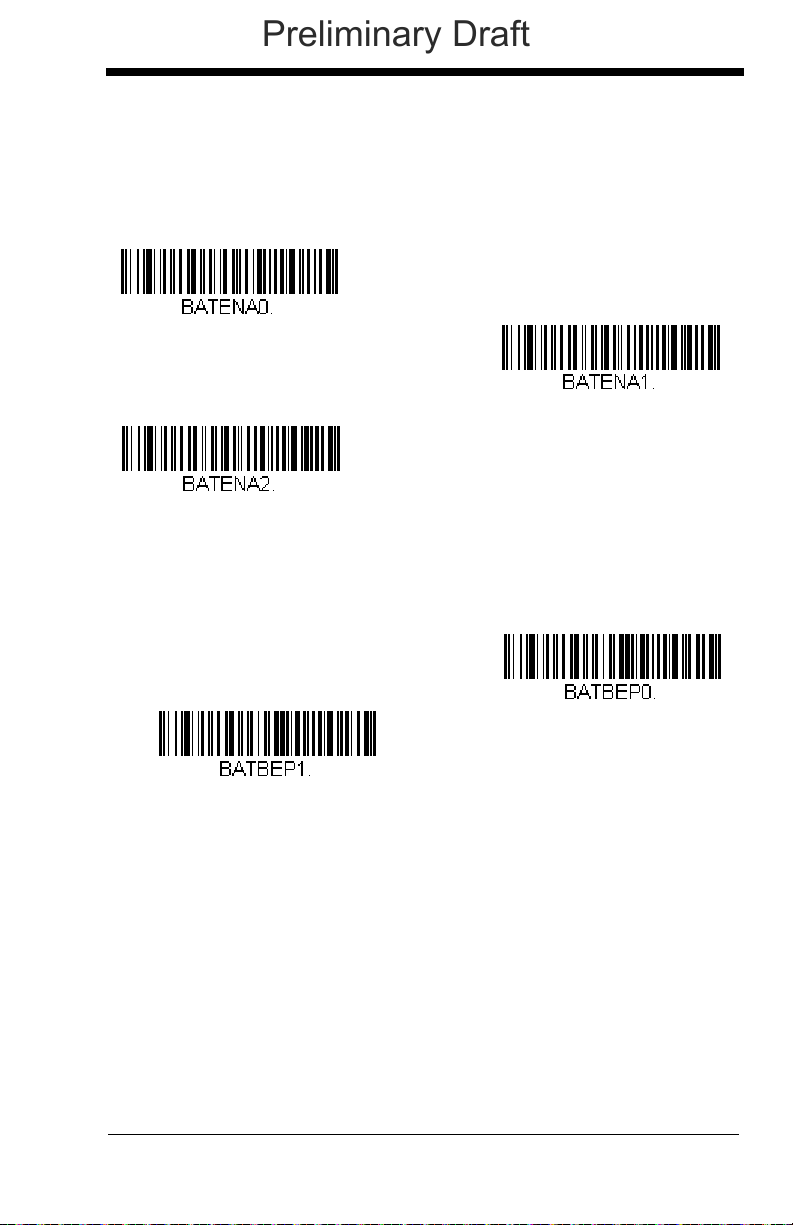

About the Battery.........................................................3-3

Charging Information .............................................3-4

Battery Recommendations ....................................3-4

ii

Page 15

Proper Disposal of the Battery .............................. 3-5

Preliminary Draft

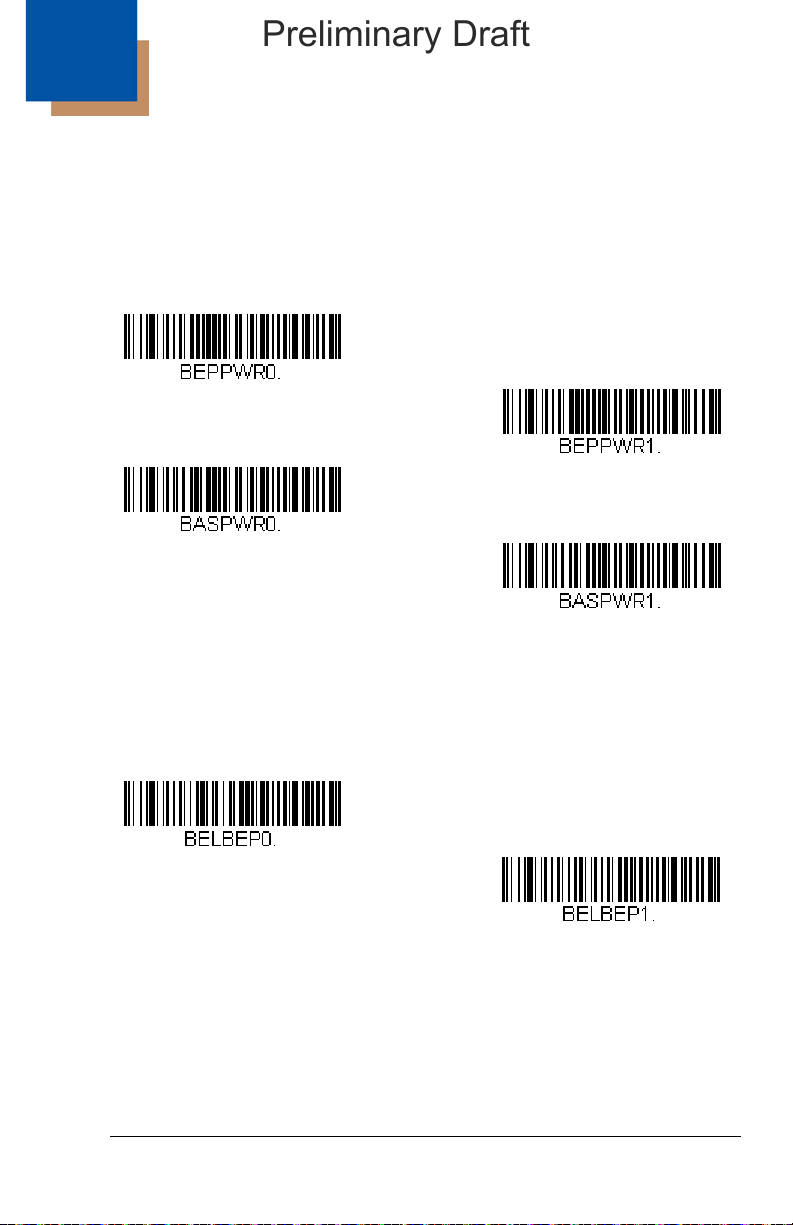

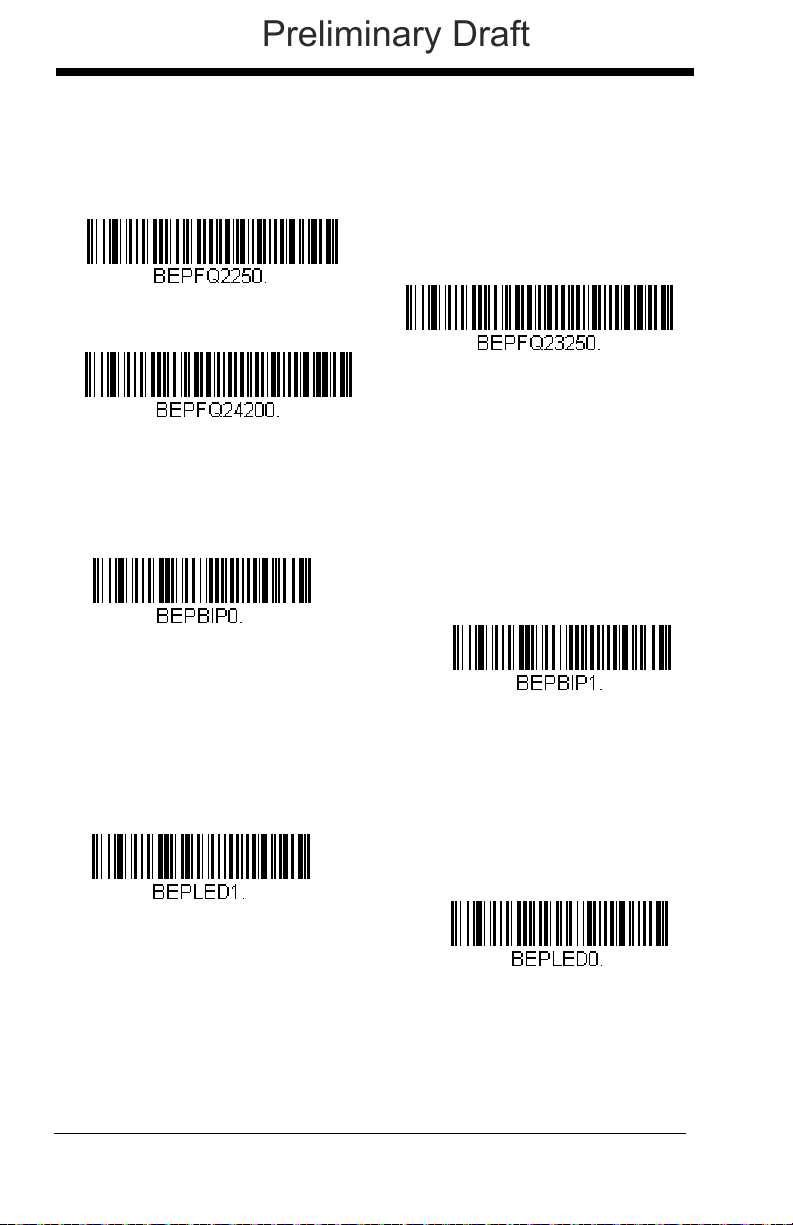

Beeper and LED Sequences and Meaning................. 3-5

Scanner LED Sequences and Meaning ................ 3-6

Base LED Sequences and Meaning ..................... 3-6

Base Power Communication Indicator .................. 3-7

Reset Scanner ............................................................ 3-7

Scanning while in Base Cradle ................................... 3-7

Paging ......................................................................... 3-8

Paging Mode ......................................................... 3-8

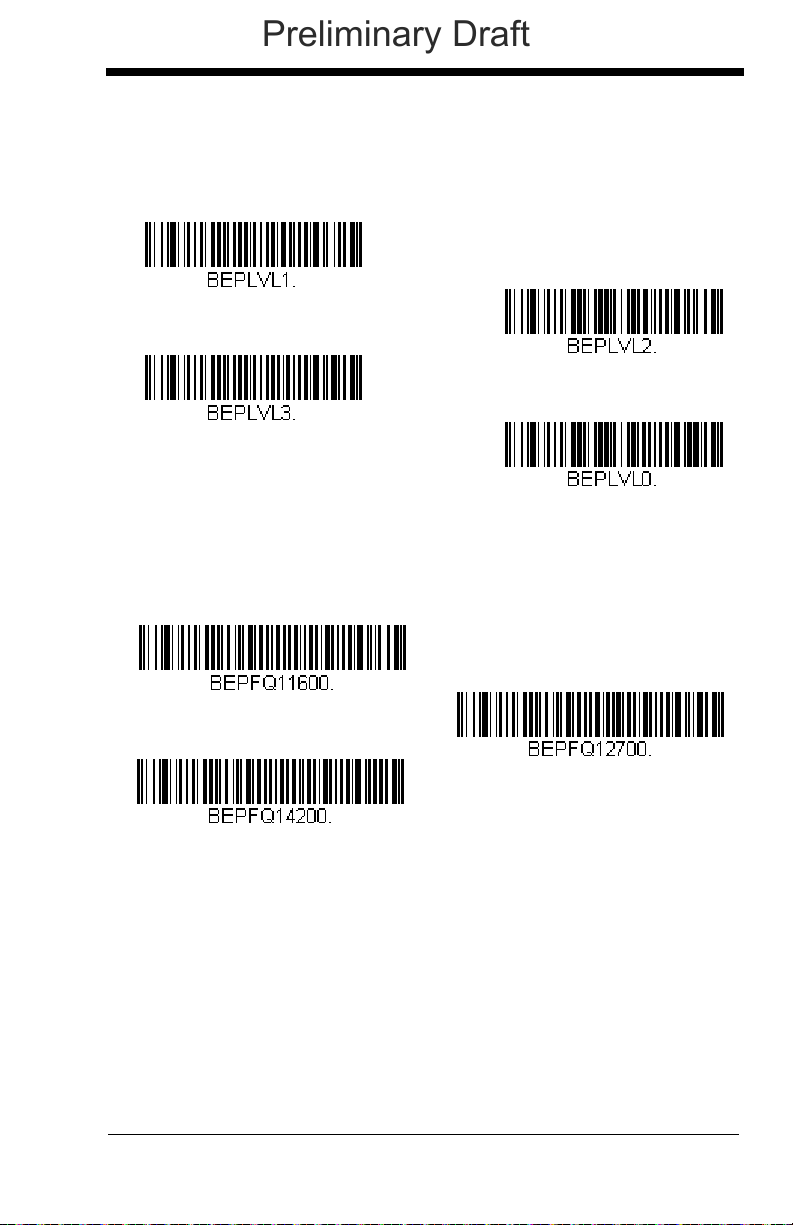

Paging Pitch ......................................................... 3-8

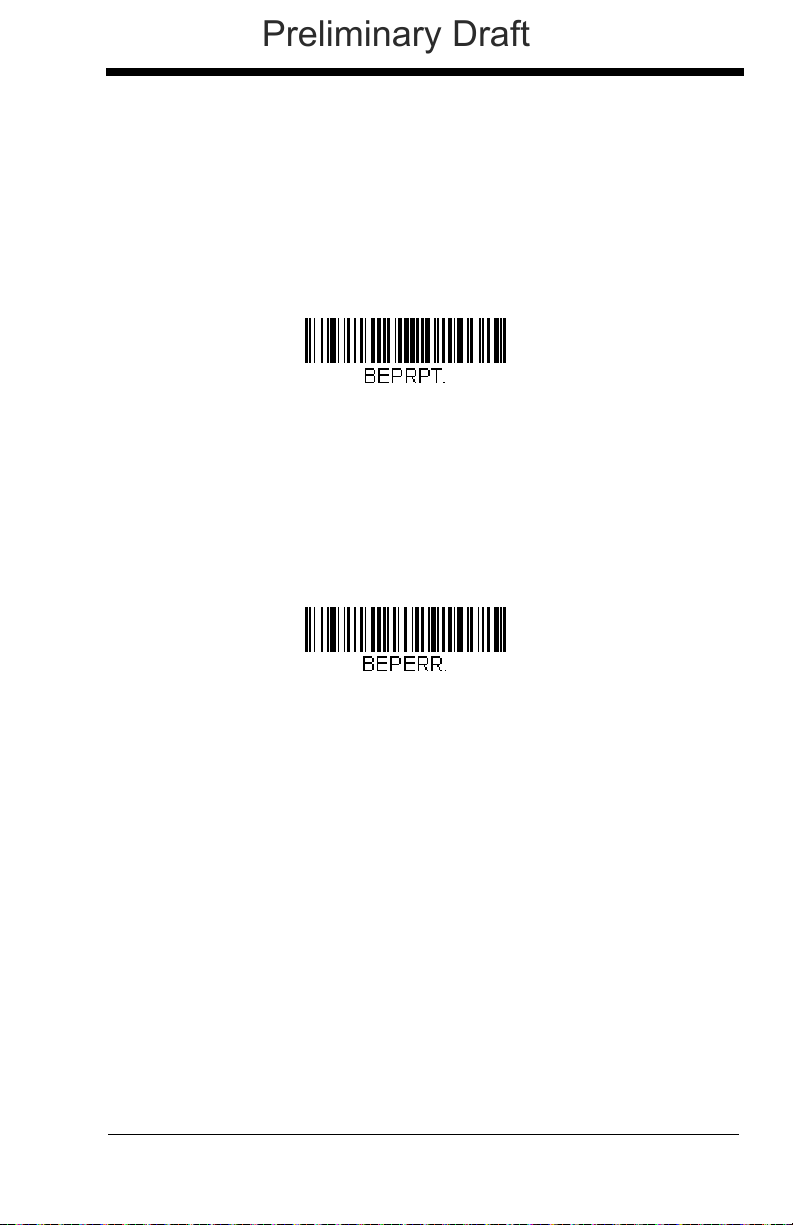

Error Indicators............................................................ 3-9

Beeper Pitch - Base Error ..................................... 3-9

Number of Beeps - Base Error.............................. 3-9

Scanner Report ........................................................... 3-9

Scanner Address....................................................... 3-10

Base Address............................................................ 3-10

Single Scanner Modes .............................................. 3-10

Charge Only Mode .............................................. 3-10

Linked Modes...................................................... 3-11

Unlinking the Scanner ............................................... 3-11

Override Locked Scanner.................................... 3-12

Out-of-Range Alarm .................................................. 3-12

Alarm Sound Type............................................... 3-12

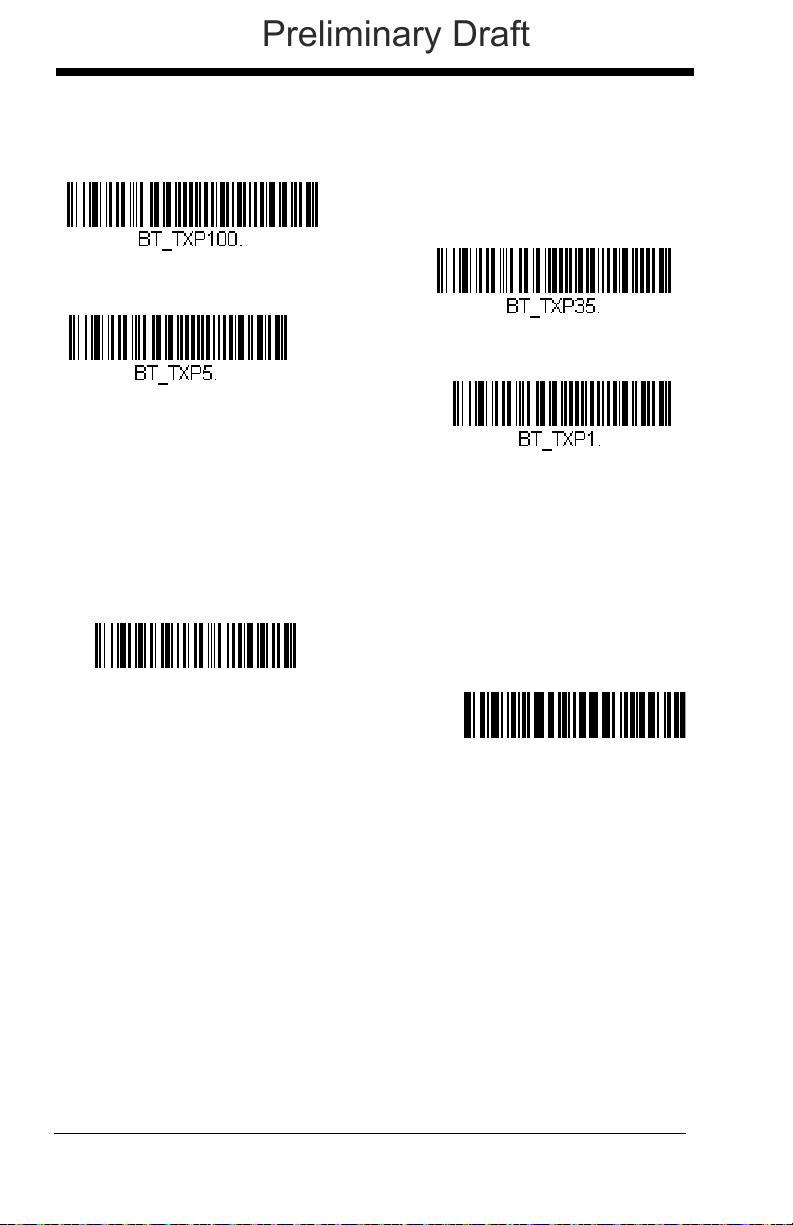

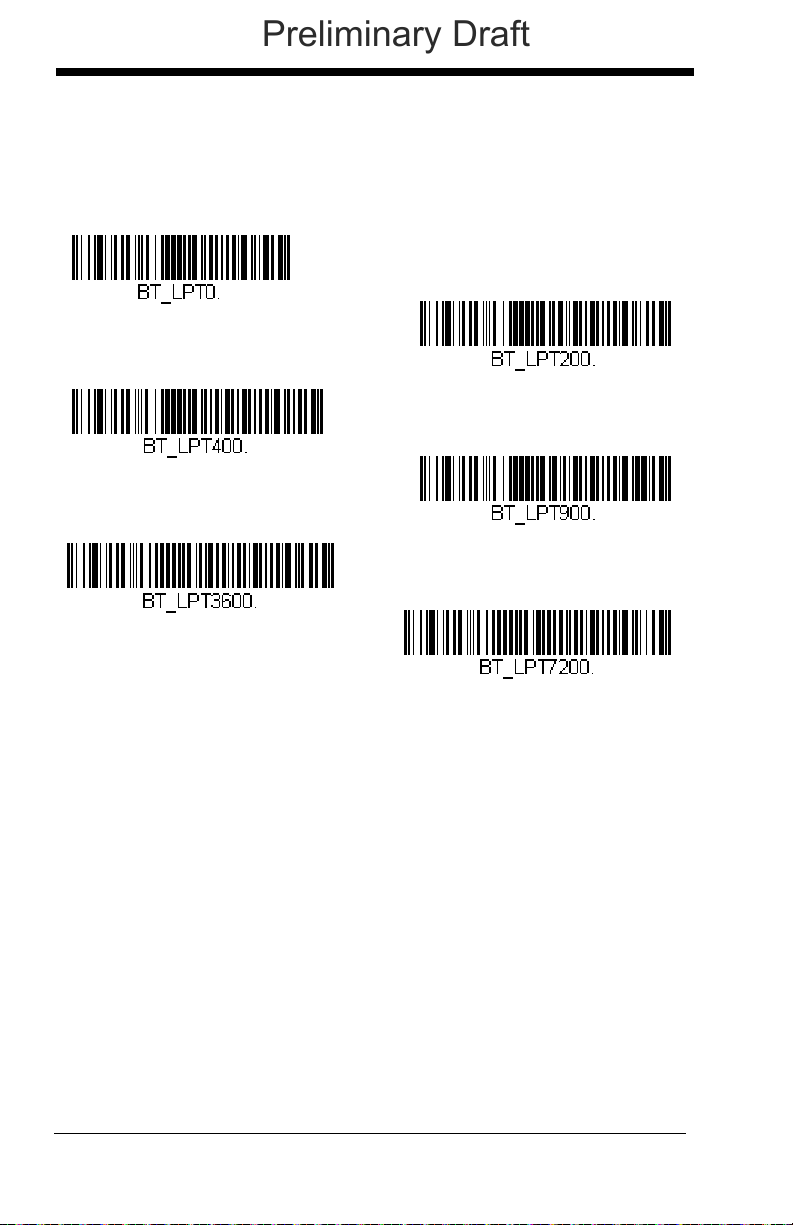

Flexible Power Management..................................... 3-13

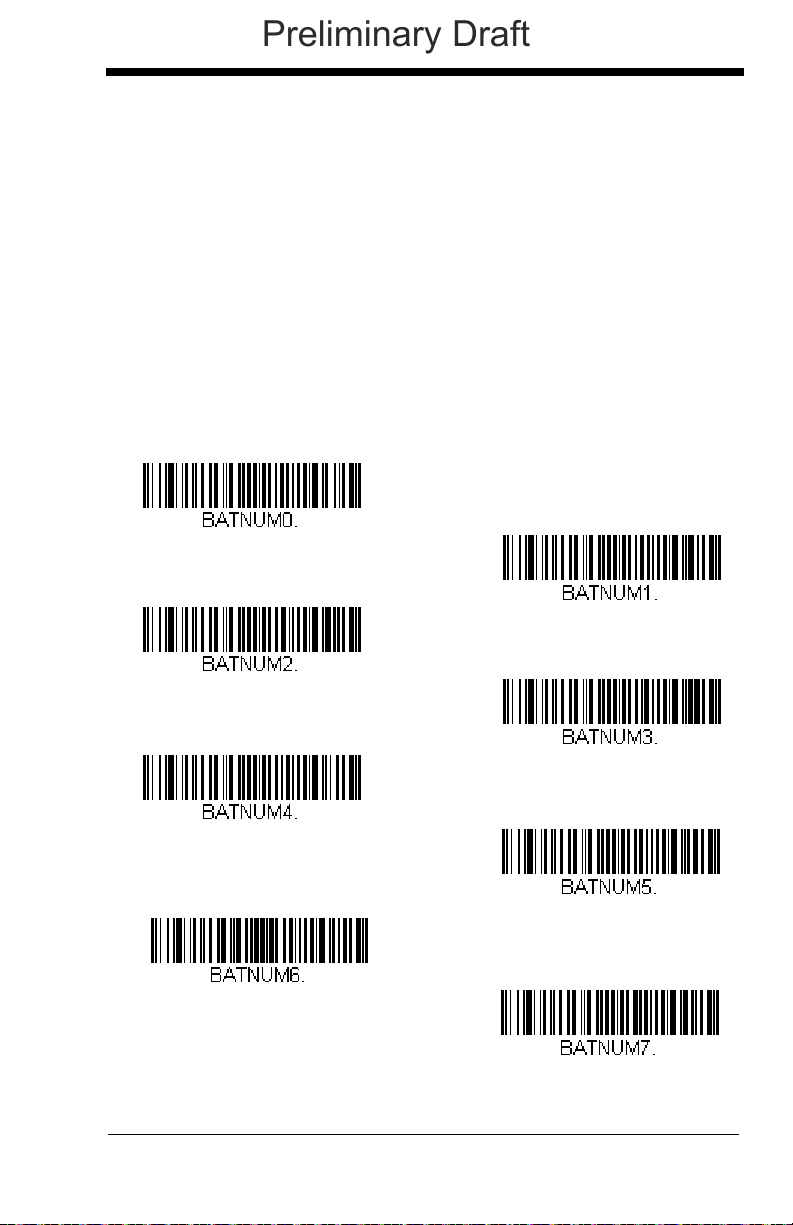

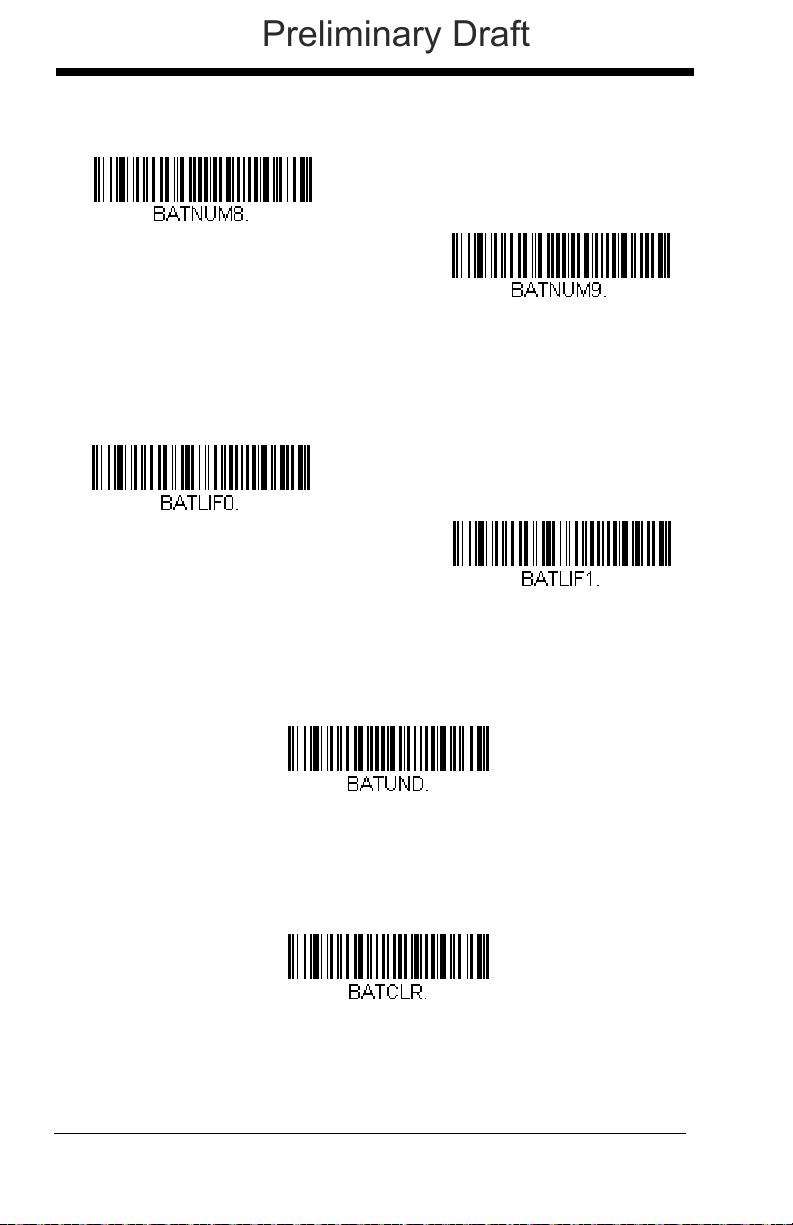

Batch Mode ............................................................... 3-14

Batch Mode Beep................................................ 3-15

Batch Mode Storage............................................ 3-15

Batch Mode Quantity........................................... 3-16

Batch Mode Output Order ................................... 3-18

Delete Last Code................................................. 3-18

Clear All Codes ................................................... 3-18

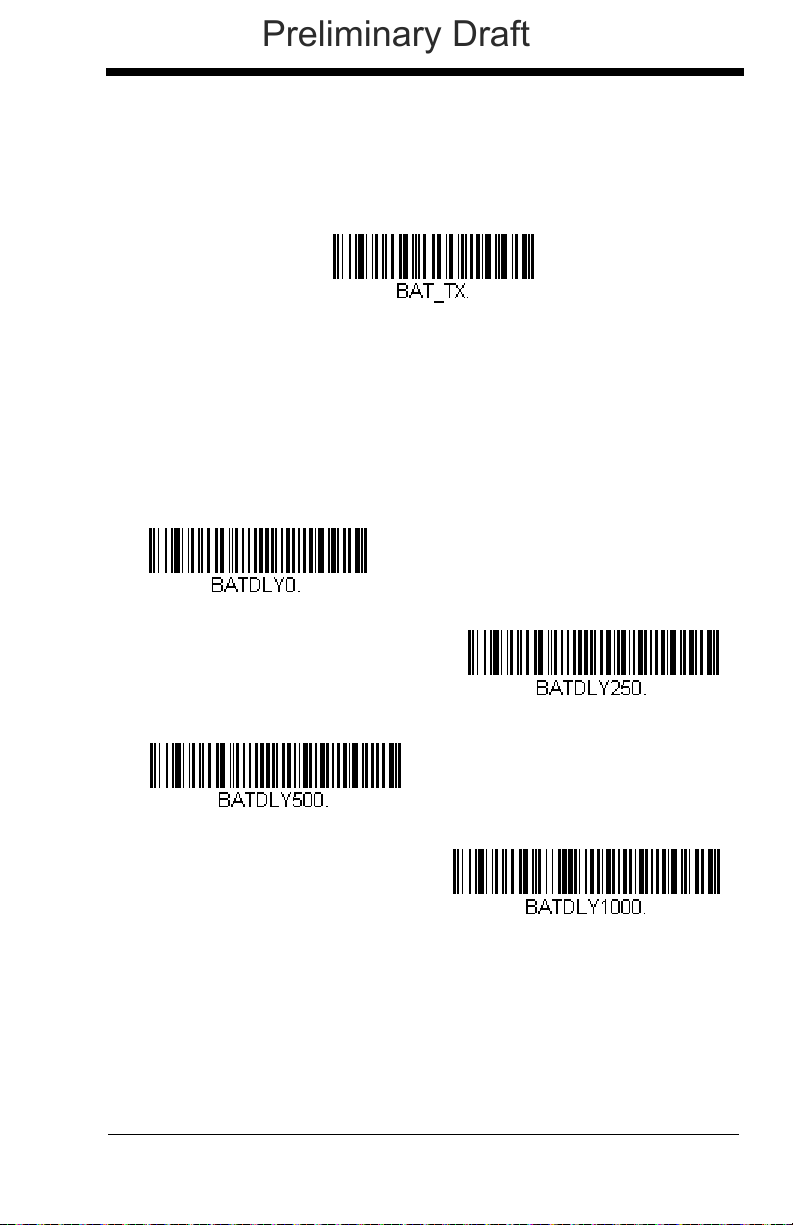

Transmit Records to Host.................................... 3-19

Batch Mode Transmit Delay................................ 3-19

Multiple Scanner Operation....................................... 3-19

Scanner Name .......................................................... 3-20

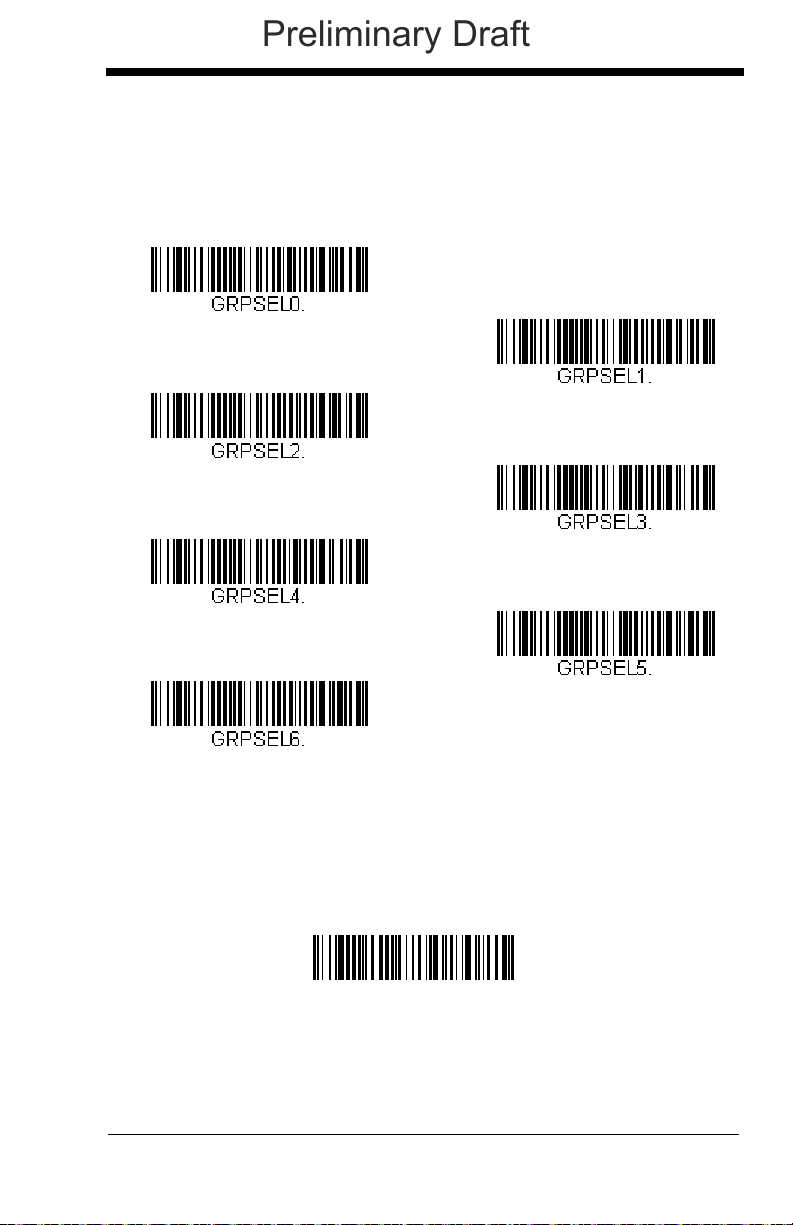

Application Work Groups .......................................... 3-22

Application Work Group Selection....................... 3-23

iii

Page 16

Resetting the Factory Defaults:

Preliminary Draft

All Application Work Groups....................................3-23

Resetting the Custom Defaults:

All Application Work Groups....................................3-24

Using the Scanner with Bluetooth Devices................3-24

PCs/Laptops ........................................................3-24

PDAs/Mobility Systems Devices.......................... 3-25

Changing the Scanner’s Bluetooth PIN Code...... 3-25

Minimizing Bluetooth/ISM Band Network Activity ......3-25

Auto Reconnect Mode .........................................3-26

Maximum Link Attempts ......................................3-27

Relink Time-Out...................................................3-27

Bluetooth/ISM Network Activity Examples........... 3-28

Host Command Acknowledgment .............................3-29

Chapter 4 - Input/Output Settings

Power Up Beeper ........................................................4-1

Beep on BEL Character...............................................4-1

Trigger Click.................................................................4-2

Good Read and Error Indicators..................................4-2

Beeper – Good Read............................................. 4-2

Beeper Volume – Good Read................................ 4-3

Beeper Pitch – Good Read.................................... 4-3

Beeper Pitch – Error ..............................................4-4

Beeper Duration – Good Read ..............................4-4

LED – Good Read .................................................4-4

Number of Beeps – Good Read ............................4-5

Number of Beeps – Error....................................... 4-5

Good Read Delay ..................................................4-6

User-Specified Good Read Delay.......................... 4-6

Manual/Serial Trigger Modes.......................................4-6

Manual Trigger....................................................... 4-6

Serial Trigger .........................................................4-7

In-Stand Sensor Mode.................................................4-8

Presentation Mode.......................................................4-9

Presentation LED Behavior after Decode.............. 4-9

iv

Page 17

Presentation Sensitivity....................................... 4-10

Preliminary Draft

Streaming Presentation™ Mode ............................... 4-10

Mobile Phone Read Mode......................................... 4-11

Image Snap and Ship................................................ 4-11

Hands Free Time-Out ............................................... 4-11

Reread Delay ............................................................ 4-12

User-Specified Reread Delay.................................... 4-12

Illumination Lights ..................................................... 4-13

Aimer Delay............................................................... 4-13

User-Specified Aimer Delay ................................ 4-13

Scanner Time-Out..................................................... 4-14

Aimer Mode............................................................... 4-14

Centering................................................................... 4-14

Preferred Symbology ................................................ 4-16

High Priority Symbology...................................... 4-17

Low Priority Symbology....................................... 4-17

Preferred Symbology Time-out ........................... 4-17

Preferred Symbology Default .............................. 4-18

Output Sequence Overview ......................................4-18

Require Output Sequence................................... 4-18

Output Sequence Editor...................................... 4-18

To Add an Output Sequence............................... 4-19

Other Programming Selections ........................... 4-19

Output Sequence Editor...................................... 4-21

Partial Sequence................................................. 4-21

Require Output Sequence................................... 4-22

Multiple Symbols ....................................................... 4-22

No Read .................................................................... 4-23

Video Reverse........................................................... 4-23

Chapter 5 - Data Editing

Prefix/Suffix Overview ................................................. 5-1

To Add a Prefix or Suffix: ...................................... 5-1

To Clear One or All Prefixes or Suffixes................ 5-2

To Add a Carriage Return Suffix

to All Symbologies ........................................... 5-3

v

Page 18

Prefix Selections..........................................................5-3

Preliminary Draft

Suffix Selections ..........................................................5-4

Function Code Transmit ..............................................5-4

Intercharacter, Interfunction,

and Intermessage Delays..........................................5-4

Intercharacter Delay ..............................................5-5

User Specified Intercharacter Delay ......................5-5

Interfunction Delay.................................................5-6

Intermessage Delay............................................... 5-6

Chapter 6 - Data Formatting

Data Format Editor Introduction...................................6-1

To Add a Data Format .................................................6-1

Other Programming Selections.............................. 6-3

Terminal ID Table ........................................................6-4

Data Format Editor Commands...................................6-4

Move Commands................................................... 6-5

Search Commands ................................................6-6

Miscellaneous Commands..................................... 6-7

Data Formatter.............................................................6-8

Data Format Non-Match Error Tone ......................6-9

Primary/Alternate Data Formats ................................6-10

Single Scan Data Format Change .......................6-10

Chapter 7 - Symbologies

All Symbologies ...........................................................7-2

Message Length Description .......................................7-2

Codabar.......................................................................7-3

Codabar Concatenation......................................... 7-4

Code 39 .......................................................................7-6

Code 32 Pharmaceutical (PARAF) ........................7-8

Full ASCII............................................................... 7-9

Code 39 Code Page ..............................................7-9

Interleaved 2 of 5.......................................................7-10

NEC 2 of 5 .................................................................7-12

Code 93 .....................................................................7-14

vi

Page 19

Code 93 Code Page............................................ 7-14

Preliminary Draft

Straight 2 of 5 Industrial (three-bar start/stop) .......... 7-15

Straight 2 of 5 IATA (two-bar start/stop).................... 7-16

Matrix 2 of 5 .............................................................. 7-17

Code 11..................................................................... 7-18

Code 128................................................................... 7-19

ISBT 128 Concatenation ..................................... 7-19

Code 128 Code Page.......................................... 7-20

GS1-128.................................................................... 7-21

Telepen ..................................................................... 7-22

UPC-A ....................................................................... 7-23

UPC-A/EAN-13

with Extended Coupon Code .................................. 7-25

UPC-E0 ..................................................................... 7-26

UPC-E1 ..................................................................... 7-29

EAN/JAN-13.............................................................. 7-29

ISBN Translate.................................................... 7-31

EAN/JAN-8................................................................ 7-32

MSI............................................................................ 7-34

GS1 DataBar Omnidirectional................................... 7-36

GS1 DataBar Limited ................................................ 7-36

GS1 DataBar Expanded............................................ 7-37

Trioptic Code............................................................. 7-38

Codablock A.............................................................. 7-38

Codablock F .............................................................. 7-40

PDF417 ..................................................................... 7-41

MicroPDF417 ............................................................ 7-42

GS1 Composite Codes ............................................. 7-43

UPC/EAN Version ............................................... 7-43

GS1 Emulation .......................................................... 7-44

TCIF Linked Code 39 (TLC39).................................. 7-45

QR Code ................................................................... 7-45

Data Matrix................................................................ 7-47

MaxiCode .................................................................. 7-48

Aztec Code................................................................ 7-49

Chinese Sensible (Han Xin) Code ............................ 7-50

Postal Codes - 2D ..................................................... 7-51

vii

Page 20

Single 2D Postal Codes:...................................... 7-51

Preliminary Draft

Combination 2D Postal Codes:............................ 7-52

Postal Codes - Linear ................................................7-54

China Post (Hong Kong 2 of 5)............................ 7-54

Korea Post ...........................................................7-56

Chapter 8 - Imaging Commands

Single-Use Basis .........................................................8-1

Command Syntax ........................................................8-1

Image Snap - IMGSNP................................................8-2

IMGSNP Modifiers .................................................8-2

Image Ship - IMGSHP .................................................8-5

IMGSHP Modifiers .................................................8-5

Intelligent Signature Capture - IMGBOX....................8-14

Signature Capture Optimize ................................8-14

IMGBOX Modifiers...............................................8-15

RF Default Imaging Device........................................8-19

Chapter 9 - Interface Keys

Keyboard Function Relationships................................9-1

Supported Interface Keys ............................................9-3

Chapter 10 - Utilities

To Add a Test Code I.D. Prefix to All Symbologies ...10-1

Show Decoder Revision ............................................10-1

Show Scan Driver Revision .......................................10-1

Show Software Revision............................................10-1

Show Data Format.....................................................10-2

Test Menu..................................................................10-2

TotalFreedom ............................................................10-2

Application Plug-Ins (Apps) .......................................10-3

EZConfig Introduction................................................10-3

Installing EZConfig from the Web ........................10-4

viii

Page 21

Chapter 11 - Serial Programming Commands

Preliminary Draft

Conventions .............................................................. 11-1

Menu Command Syntax............................................ 11-1

Query Commands ..................................................... 11-2

Responses .......................................................... 11-3

Trigger Commands ................................................... 11-4

Resetting the Standard Product Defaults.................. 11-4

Menu Commands...................................................... 11-5

Chapter 12 - Product Specifications

1900 Scanner Product Specifications ....................... 12-1

1902 Scanner Product Specifications ....................... 12-2

CCB01-010BT Charge Base Product Specifications 12-3

Standard Cable Pinouts ............................................ 12-4

Keyboard Wedge................................................. 12-4

Serial Output ...................................................... 12-5

RS485 Output ..................................................... 12-6

USB..................................................................... 12-7

Chapter 13 - Maintenance

Repairs...................................................................... 13-1

Maintenance.............................................................. 13-1

Cleaning the Device ............................................ 13-1

Inspecting Cords and Connectors....................... 13-1

Replacing Cables in Corded Scanners .....................13-1

Replacing an Interface Cable.............................. 13-2

Replacing Cables and Batteries

in Cordless Systems ............................................... 13-2

Replacing an Interface Cable in a Base.............. 13-2

Changing a scanner Battery................................ 13-3

Troubleshooting a Xenon Scanner............................ 13-3

Troubleshooting a Cordless System ......................... 13-4

Troubleshooting a Base ...................................... 13-4

Troubleshooting a Cordless Scanner.................. 13-5

ix

Page 22

Chapter 14 - Customer Support

Preliminary Draft

Appendix A - Reference Charts

Symbology Chart ........................................................ A-1

ASCII Conversion Chart (Code Page 1252)............... A-4

Code Page Mapping of Printed Barcodes .................. A-6

x

Page 23

1

Preliminary Draft

Getting Started

About This Manual

This User’s Guide provides installation and programming instructions for the

Xenon™ 1900 and 1902 area-imaging scanners. Product specifications,

dimensions, warranty, and customer support information are also included.

Honeywell bar code scanners are factory programmed for the most common

terminal and communications settings. If you need to change these settings,

programming is accomplished by scanning the bar codes in this guide.

An asterisk (*) next to an option indicates the default setting.

Unpacking Your Device

After you open the shipping carton containing the product, take the following

steps:

• Check for damage during shipment. Report damage immediately to the

carrier who delivered the carton.

• Make sure the items in the carton match your order.

• Save the shipping container for later storage or shipping.

1 - 1

Page 24

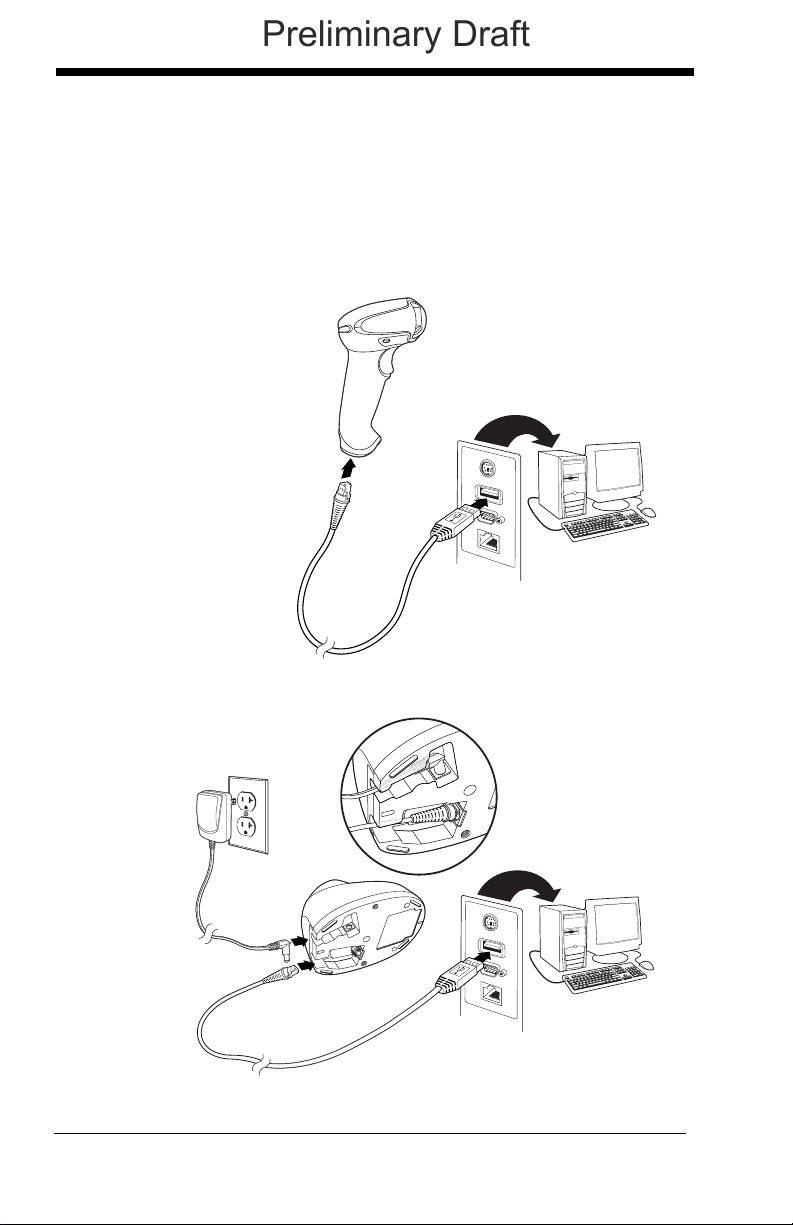

Connecting the Device

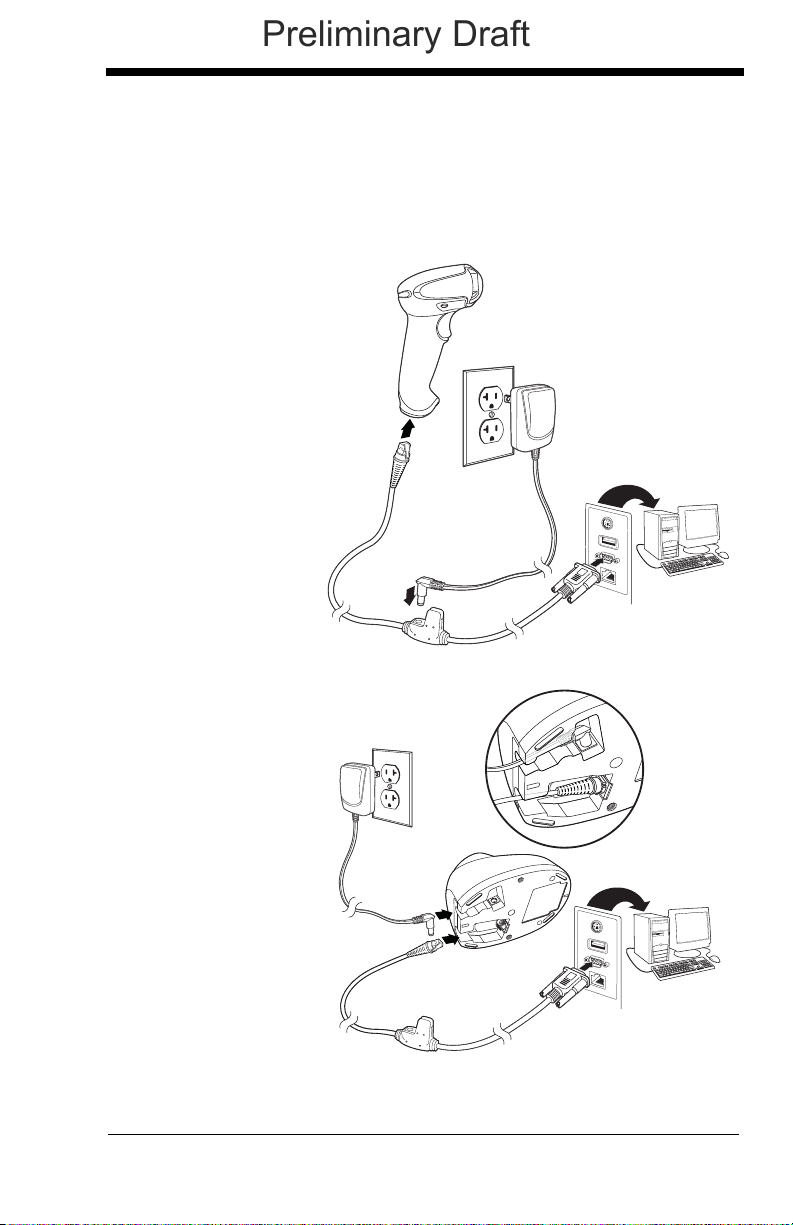

Corded Scanner USB

Connection:

Cordless Base USB

Connection:

Preliminary Draft

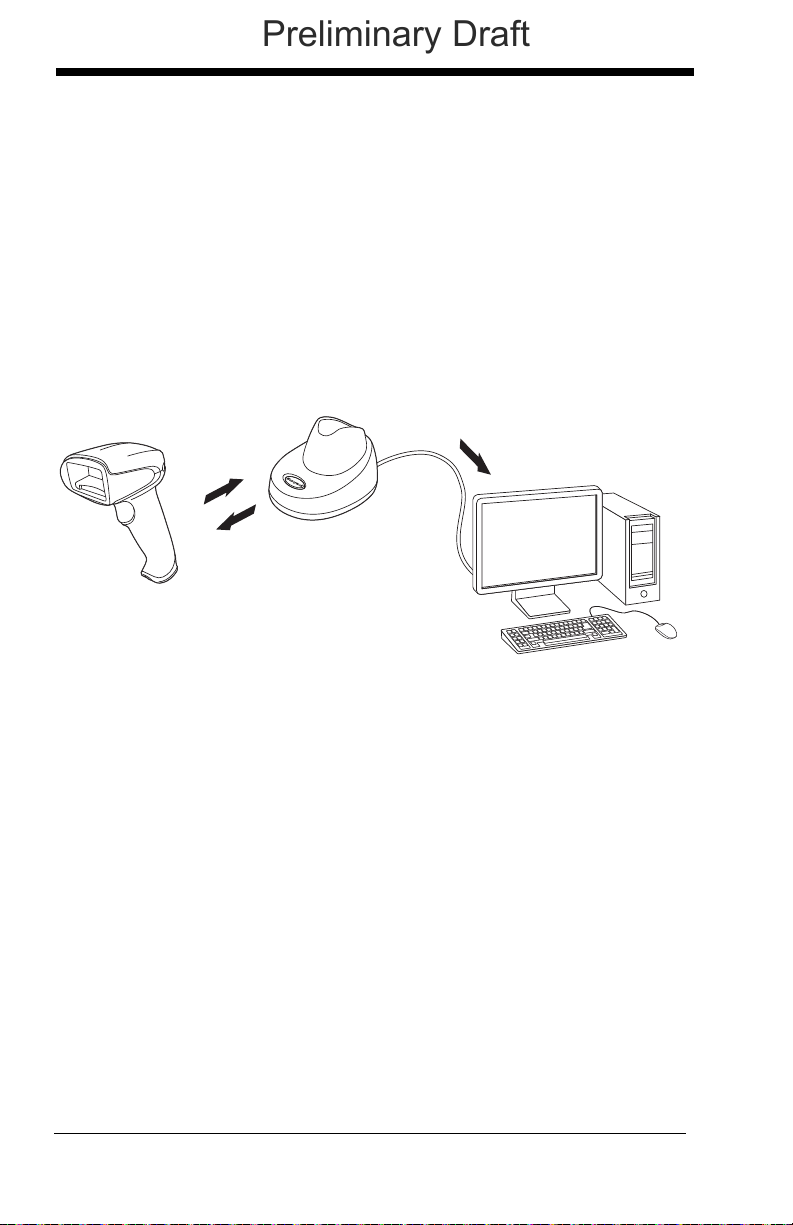

Connecting with USB

A scanner or a cordless base can be connected to the USB port of a computer.

1. Connect the appropriate interface cable to the device first, then to the

computer.

1 - 2

Page 25

2. Make sure the cables are secured in the wireways in the bottom of the

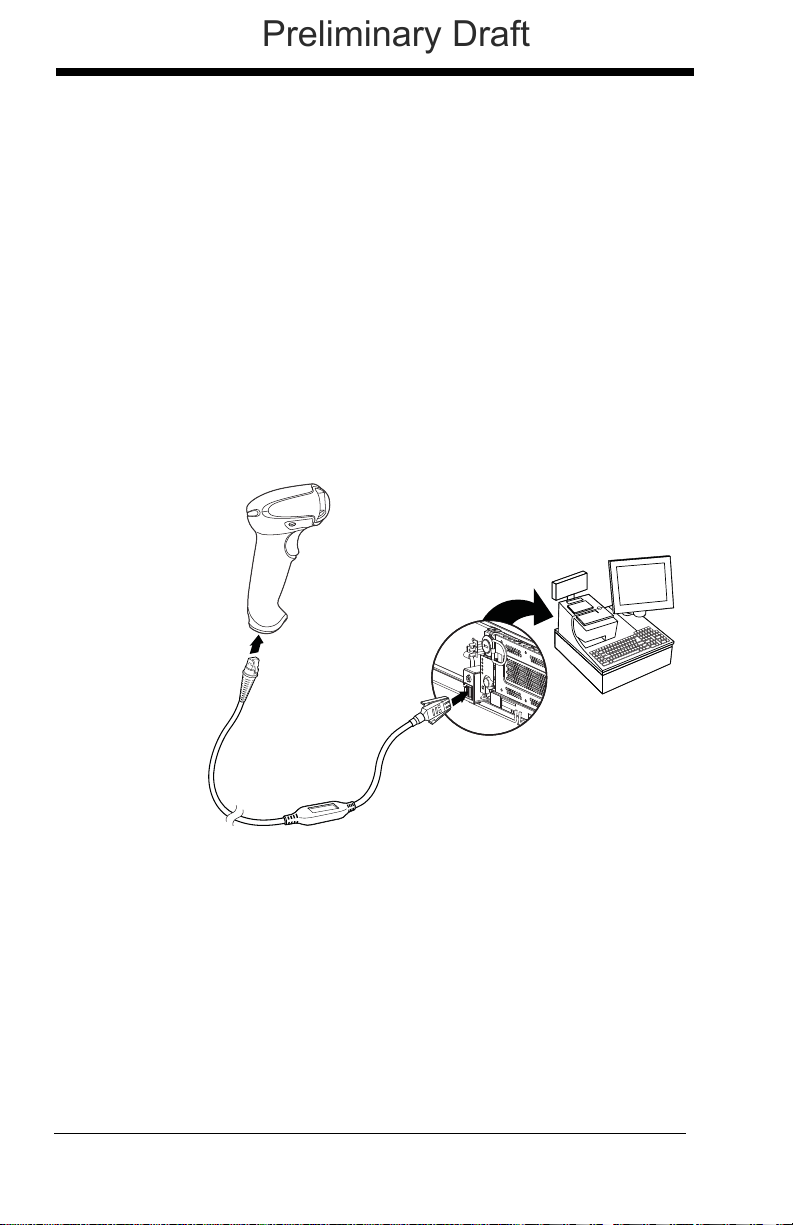

Corded Scanner

Keyboard Wedge

Connection:

Preliminary Draft

cordless base and that the base sits flat on a horizontal surface.

3. The scanner beeps.

4. Verify the scanner or cordless base operation by scanning a bar code

from the Sample Symbols in the back of this manual.

The unit defaults to a USB PC Keyboard. Refer to page 2-4 for other USB

terminal settings.

For additional USB programming and technical information, refer to “USB

Application Note,” available at www.honeywellaidc.com.

Connecting with Keyboard Wedge

A scanner or cordless base can be connected between the keyboard and

PC as a “keyboard wedge,” plugged into the serial port, or connected to a

portable data terminal in wand emulation or non decoded output mode.

The following is an example of a keyboard wedge connection:

1. Turn off power and disconnect the keyboard cable from the back of the

terminal/computer.

2. Connect the appropriate interface cable to the device and to the

terminal/computer.

1 - 3

Page 26

3. Make sure the cables are secured in the wireways in the bottom of the

Cordless Base

Keyboard Wedge

Connection:

Preliminary Draft

cordless base and that the base sits flat on a horizontal surface.

4. Turn the terminal/computer power back on. The scanner beeps.

5. Verify the scanner or cordless base operation by scanning a bar code

from the Sample Symbols in the back of this manual. The scanner

beeps once.

The unit defaults to an IBM PC AT and compatibles keyboard wedge interface with a USA keyboard. A carriage return (CR) suffix is added to bar

code data.

1 - 4

Page 27

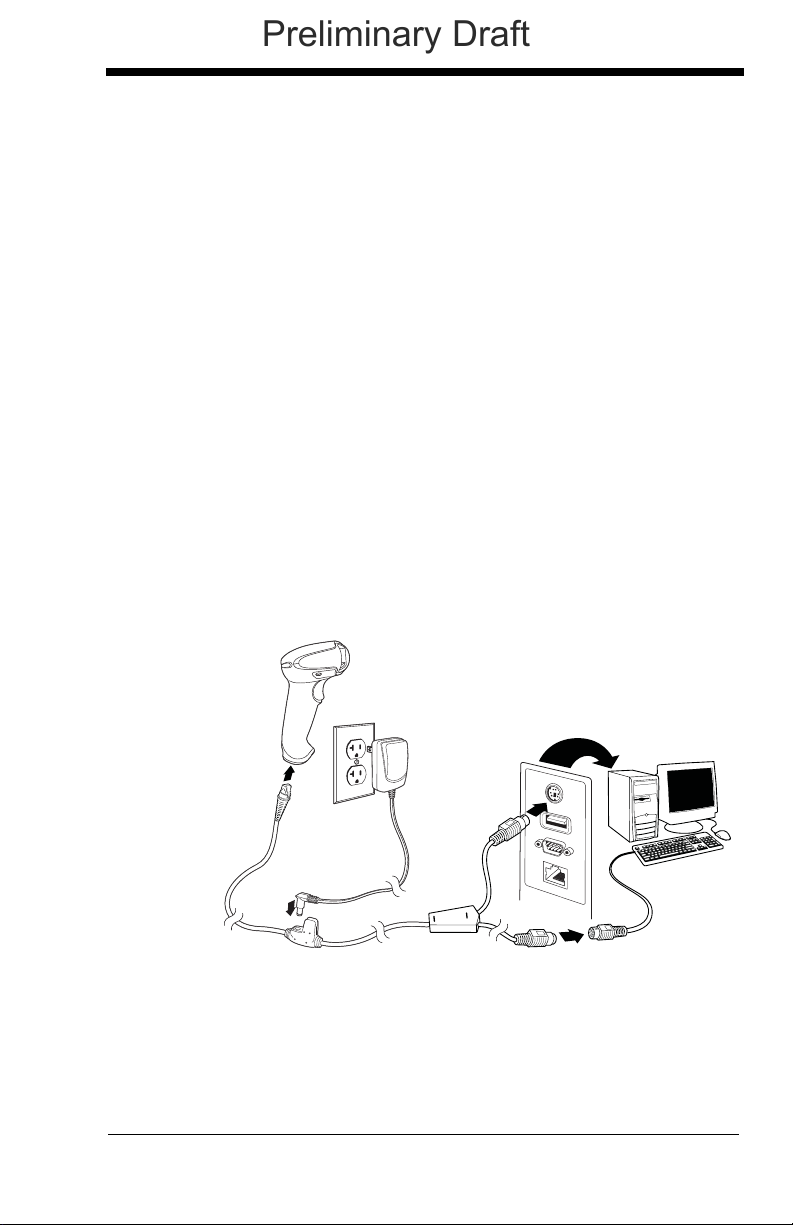

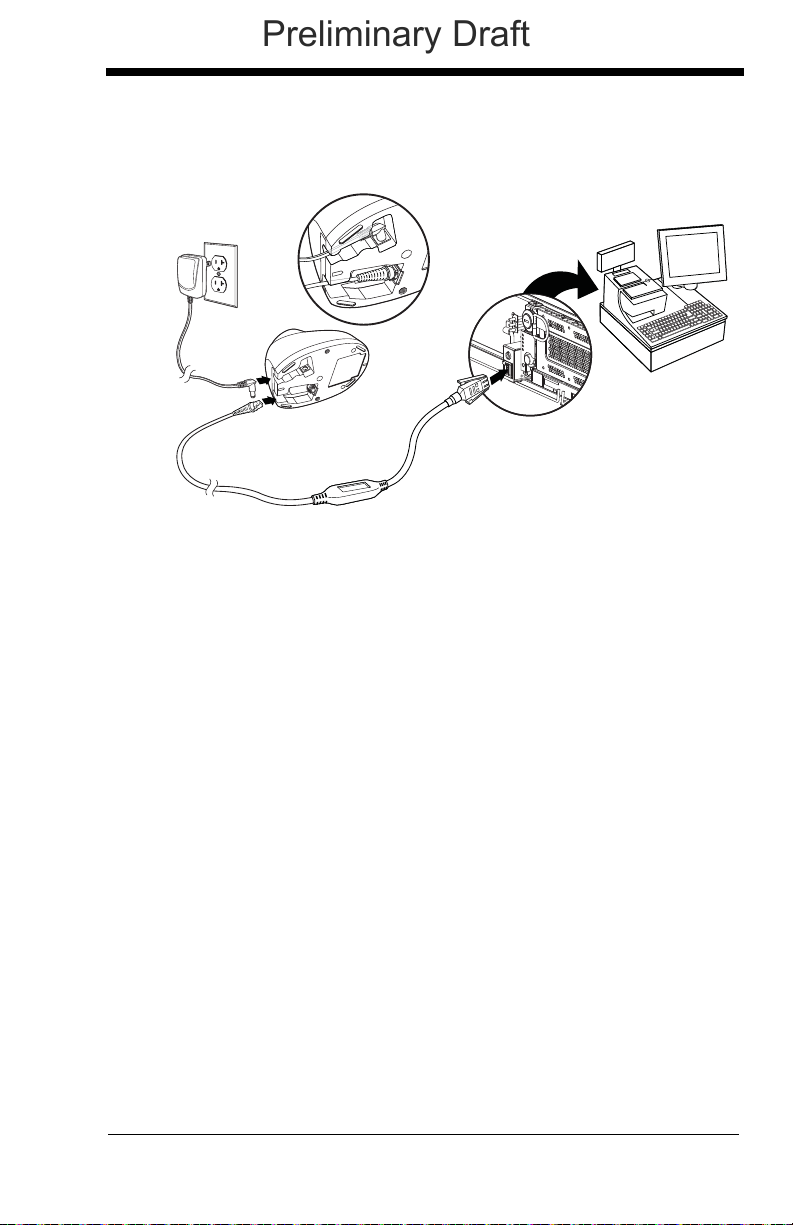

Connecting with RS232 Serial Port

Corded Scanner

RS232 Serial Port

Connection:

Cordless Base

RS232 Serial Port

Connection:

Preliminary Draft

1. Turn off power to the terminal/computer.

2. Connect the appropriate interface cable to the scanner.

Note: For the scanner or cordless base to work properly, you must have the

correct cable for your type of terminal/computer.

1 - 5

Page 28

3. Make sure the cables are secured in the wireways in the bottom of the

Corded Scanner

RS485

Connection:

Preliminary Draft

cordless base and that the base sits flat on a horizontal surface.

4. Plug the serial connector into the serial port on your computer.

Tighten the two screws to secure the connector to the port.

5. Once the scanner or cordless base has been fully connected, power

up the computer.

This interface programs 115,200 baud, 8 data bits, no parity, and 1 stop bit.

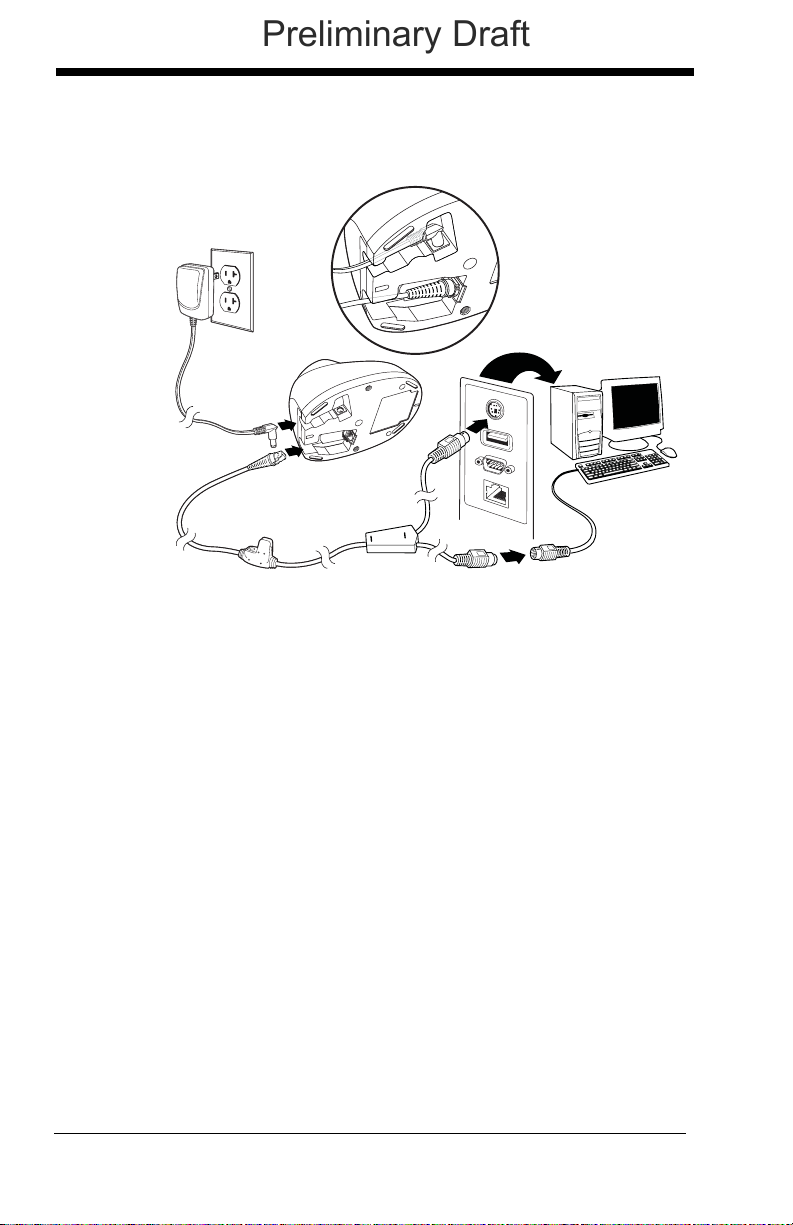

Connecting with RS485

A scanner or cordless base can be connected for an IBM POS terminal

interface

1. Connect the appropriate interface cable to the device, then to the computer.

1 - 6

Page 29

2. Make sure the cables are secured in the wireways in the bottom of the

Cordless Base

RS485

Connection:

Preliminary Draft

cordless base and that the base sits flat on a horizontal surface.

3. Turn the terminal/computer power back on. The scanner beeps.

4. Verify the scanner or cordless base operation by scanning a bar code

from the Sample Symbols in the back of this manual. The scanner

beeps once.

For further RS485 settings, refer to RS485, page 2-2..

1 - 7

Page 30

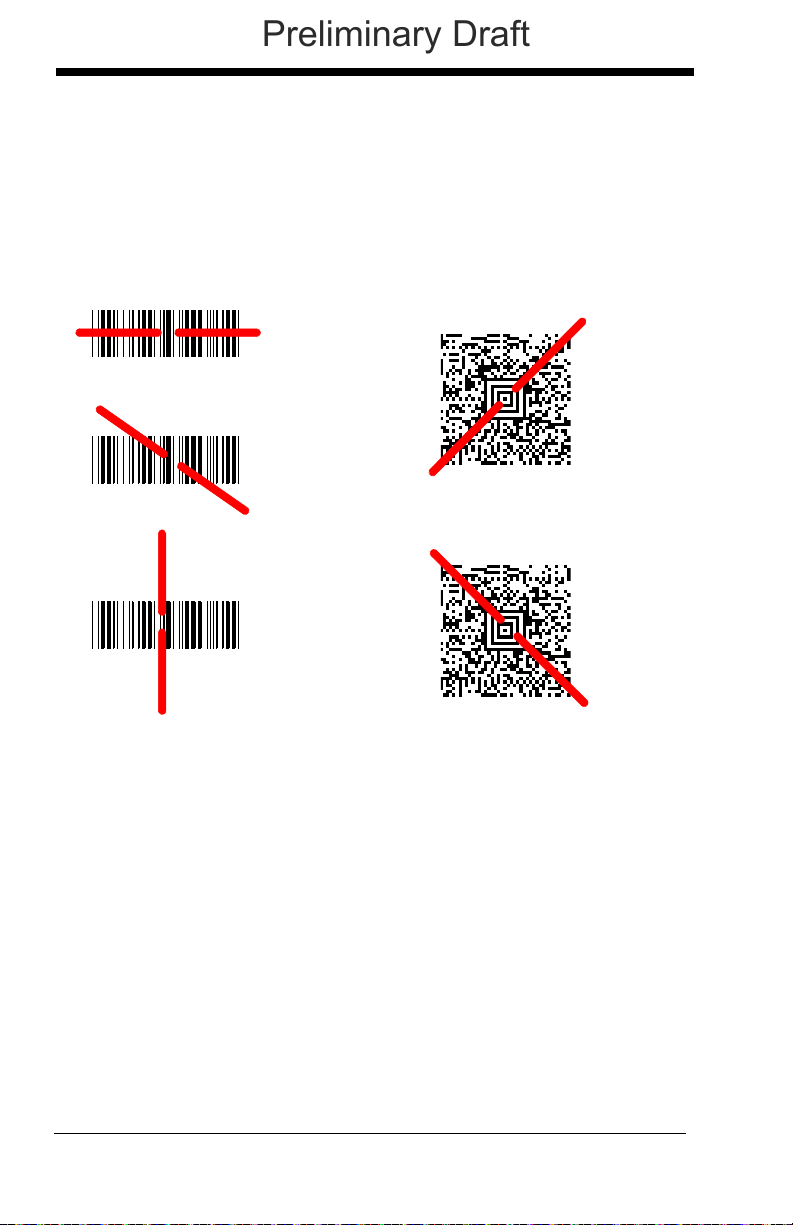

Reading Techniques

Linear bar code 2D Matrix symbol

Preliminary Draft

The scanner has a view finder that projects a bright red aiming beam that corresponds to the scanner’s horizontal field of view. The aiming beam should be

centered over the bar code, but it can be positioned in any direction for a good

read.

The aiming beam is smaller when the scanner is closer to the code and larger

when it is farther from the code. Symbologies with smaller bars or elements

(mil size) should be read closer to the unit. Symbologies with larger bars or elements (mil size) should be read farther from the unit. To read single or multiple

symbols (on a page or on an object), hold the scanner at an appropriate distance from the target, pull the trigger, and center the aiming beam on the symbol. If the code being scanned is highly reflective (e.g., laminated), it may be

necessary to tilt the code up 15° to 18° to prevent unwanted reflection.

Menu Bar Code Security Settings

Honeywell scanners are programmed by scanning menu bar codes or by sending serial commands to the scanner. If you want to restrict the ability to scan

menu codes, you can use the Menu Bar Code Security settings. Please contact

the nearest technical support office (see Technical Assistance on page 14-1)

for further information.

1 - 8

Page 31

Resetting the Factory Defaults

Restore Factory Defaults

Save Defaults

Preliminary Draft

If you aren’t sure what programming options are in your scanner, or you’ve

changed some options and want the factory default settings restored, first scan

the Restore Factory Defaults bar code, then scan Save Defaults. This resets

the scanner to the factory defaults.

Note: If using a cordless system, scanning the Save Defaults bar code also

causes both the scanner and the base to perform a reset and become

unlinked. The scanner must be placed in its base to re-establish the link

before any setup codes are entered. See Cordless System

Operation beginning on page 3-1 for additional information.

The Menu Commands, beginning on page 11-5 list the factory default settings

for each of the commands (indicated by an asterisk (*) on the programming

pages).

Setting Custom Defaults

You have the ability to create a set of menu commands as your own, custom

defaults. To do so, scan the Set Custom Defaults bar code below before each

menu command or sequence you want saved. If your command requires scanning numeric codes from the back cover, then a Save code, that entire

sequence will be saved to your custom defaults. Scan the Set Custom

Defaults code again before the next command you want saved to your custom

defaults.

1 - 9

Page 32

When you have entered all the commands you want to save for your custom

Save Custom Defaults

Set Custom Defaults

Custom Product Default Settings:

Current Application Group

Preliminary Draft

defaults, scan the Save Custom Defaults bar code.

Note: If using a cordless system, scanning the Save Defaults bar code also

causes both the scanner and the base to perform a reset and become

unlinked. The scanner must be placed in its base to re-establish the link

before any setup codes are entered. See Cordless System

Operation beginning on page 3-1 for additional information.

You may have a series of custom settings and want to correct a single setting.

To do so, just scan the new setting to overwrite the old one. For example, if you

had previously saved the setting for Beeper Volume at Low to your custom

defaults, and decide you want ithe beeper volume set to High, just scan the Set

Custom Defaults bar code, then scan the Beeper Volume High menu code,

and then Save Custom Defaults. The rest of the custom defaults will remain,

but the beeper volume settiing will be updated.

Resetting the Custom Defaults

If you want the custom default settings restored to your scanner, scan the Custom Product Default Settings bar code below. This resets the scanner to the

custom defaults. If there are no custom defaults, it will reset the scanner to the

factory defaults. Any settings that have not been specified through the custom

defaults will be defaulted to the factory default settings.

Note: If using a cordless system, scanning this bar code also causes both the

scanner and the base to perform a reset and become unlinked. The

scanner must be placed in its base to re-establish the link. See Cordless

System Operation beginning on page 3-1 for additional information.

1 - 10

Page 33

2

IBM PC AT and Compatibles with

CR suffix

Laptop Direct Connect

with CR suffix

Preliminary Draft

Programming the Interface

Introduction

This chapter describes how to program your system for the desired interface.

Programming the Interface - Plug and Play

Plug and Play bar codes provide instant scanner set up for commonly used

interfaces.

Note: After you scan one of the codes, power cycle the host terminal to have

the interface in effect.

Keyboard Wedge

If you want your system programmed for an IBM PC AT and compatibles

keyboard wedge interface with a USA keyboard, scan the bar code below.

Keyboard wedge is the default interface.

Note: The following bar code also programs a carriage return (CR) suffix.

Laptop Direct Connect

For most laptops, scanning the Laptop Direct Connect bar code allows

operation of the scanner in parallel with the integral keyboard. The following Laptop Direct Connect bar code also programs a carriage return (CR)

suffix and turns on Emulate External Keyboard (page 2-18).

2 - 1

Page 34

RS232 Serial Port

RS232 Interface

IBM Port 5B Interface

IBM Port 9B

HHBCR-1 Interface

IBM Port 17 Interface

IBM Port 9B

HHBCR-2 Interface

Preliminary Draft

The RS232 Interface bar code is used when connecting to the serial port

of a PC or terminal. The following RS232 Interface bar code also programs a carriage return (CR) and a line feed (LF) suffix, baud rate, and

data format as indicated below. It also changes the trigger mode to man-

ual.

Option Setting

Baud Rate 115,200 bps

Data Format 8 data bits, no parity bit, 1 stop bit

RS485

Scan one of the following “Plug and Play” codes to program the scanner for

an IBM POS terminal interface.

Note: After scanning one of these codes, you must power cycle the cash

register.

2 - 2

Page 35

Each bar code above also programs the following suffixes for each symbol-

Packet Mode On

* Packet Mode Off

Packet Length

Preliminary Draft

ogy:

Symbology Suffix Symbology Suffix

EAN 8 0C Code 39 00 0A 0B

EAN 13 16 Interleaved 2 of 5 00 0D 0B

UPC A 0D Code 128 * 00 0A 0B

UPC E 0A Code 128 ** 00 18 0B

* Suffixes programmed for Code 128 with IBM 4683 Port 5B, IBM 4683 Port 9B

HHBCR-1, and IBM 4683 Port 17 Interfaces

**Suffixes programmed for Code 128 with IBM 4683 Port 9 HHBCR-2 Interface

RS485 Packet Mode

The following selection allows you to break up large bar code data into

smaller packets on an IBM POS terminal. To break up large bar codes into

small packets, scan the Packet Mode On bar code below. Scan the Packet

Mode Off bar code if you want large bar code data to be sent to the host in

a single chunk.

Default = Packet Mode Off.

RS485 Packet Length

If you are using Packet mode, you can specify the size of the data

“packet” that is sent to the host. Scan the Packet Length bar code,

then then the packet size (from 20 - 256) from the Programming Chart

inside the back cover of this manual, then Save.

Default = 40

.

2 - 3

Page 36

USB IBM SurePos

USB IBM SurePos

(USB Handheld Scanner)

Interface

USB IBM SurePos

(USB Tabletop Scanner)

Interface

U

S

B

K

e

y

b

o

a

r

d

(

P

C

)

USB Keyboard (Mac)

USB Japanese Keyboard (PC)

Preliminary Draft

Scan one of the following “Plug and Play” codes to program the scanner for

an IBM SurePos (USB handheld scanner) or IBM SurePos (USB tabletop

scanner) interface.

Note: After scanning one of these codes, you must power cycle the cash

register.

Each bar code above also programs the following suffixes for each symbology:

Symbology Suffix Symbology Suffix

EAN 8 0C Code 39 00 0A 0B

EAN 13 16 Interleaved 2 of 5 00 0D 0B

UPC A 0D Code 128 00 18 0B

UPC E 0A Code 39 00 0A 0B

USB PC or Macintosh Keyboard

Scan one of the following codes to program the scanner for USB PC Keyboard or USB Macintosh Keyboard. Scanning these codes also adds a CR

and LF.

2 - 4

Page 37

USB HID

USB HID Bar Code Scanner

USB Serial

CTS/RTS Emulation On

* CTS/RTS Emulation Off

Preliminary Draft

Scan the following code to program the scanner for USB HID bar code

scanners.

USB Serial

Scan the following code to program the scanner to emulate a regular

RS232-based COM Port. If you are using a Microsoft® Windows® PC, you

will need to download a driver from the Honeywell website

(www.honeywellaidc.com). The driver will use the next available COM Port

number. Apple® Macintosh computers recognize the scanner as a USB

CDC class device and automatically uses a class driver.

Note: No extra configuration (e.g., baud rate) is necessary.

CTS/RTS Emulation

2 - 5

Page 38

ACK/NAK Mode

ACK/NAK Mode On

* ACK/NAK Mode Off

Verifone Ruby Settings

Preliminary Draft

Verifone® Ruby Terminal Default Settings

Scan the following Plug and Play code to program the scanner for a Verifone Ruby terminal. This bar code sets the baud rate to 1200 bps and the

data format to 8 data bits, no parity bit, 1 stop bit. It also also adds a line

feed (LF) suffix and programs the following prefixes for each symbology:

Symbology Prefix

UPC-A A

UPC-E A

EAN-8 FF

EAN-13 F

2 - 6

Page 39

Gilbarco® Terminal Default Settings

Gilbarco Settings

Honeywell Bioptic Settings

Datalogic Magellan Bioptic Settings

Preliminary Draft

Scan the following Plug and Play code to program the scanner for a Gilbarco terminal. This bar code sets the baud rate to 2400 bps and the data

format to 7 data bits, even parity, 2 stop bits. It also also adds a carriage

return (CR) suffix and programs the following prefixes for each symbology:

Symbology Prefix

UPC-A A

UPC-E E0

EAN-8 FF

EAN-13 F

Honeywell Bioptic Aux Port Configuration

Scan the following Plug and Play code to program the scanner for a Honeywell bioptic scanner auxiliary port configuration. This bar code sets the

baud rate to 38400 bps and the data format to 8 data bits, no parity, 1 stop

bit.

Datalogic™ Magellan© Bioptic Aux Port Configuration

Scan the following Plug and Play code to program the scanner for a Datalogic Magellan bioptic scanner auxiliary port configuration. This bar code

sets the baud rate to 9600 bps and the data format to 8 data bits, no parity,

1 stop bit.

2 - 7

Page 40

NCR Bioptic Aux Port Configuration

NCR Bioptic Settings

Wincor Nixdorf Terminal Settings

Preliminary Draft

Scan the following Plug and Play code to program the scanner for an NCR

bioptic scanner auxiliary port configuration. The following prefixes are programmed for each symbology:

Symbology Prefix Symbology Prefix

UPC-A A Code 39 B1

UPC-E E0 Interleaved 2 of 5 B2

EAN-8 FF All other bar

codes

EAN-13 F

B3

Wincor Nixdorf Terminal Default Settings

Scan the following Plug and Play code to program the scanner for a Wincor

Nixdorf terminal. This bar code sets the baud rate to 9600 bps and the

data format to 8 data bits, no parity, 1 stop bit.

2 - 8

Page 41

Wincor Nixdorf Beetle™ Terminal Default Settings

Wincor Nixdorf Beetle Settings

Preliminary Draft

Scan the following Plug and Play code to program the scanner for a Wincor

Nixdorf Beetle terminal. The following prefixes are programmed for each

symbology:

Symbology Prefix Symbology Prefix

Code 128 K EAN-13 A

Code 93 L GS1-128 P

Codabar N Interleaved 2 of 5 I

UPC-A A0 Plessey O

UPC-E C Straight 2 of 5 IATA H

EAN-8 B All other bar codes M

2 - 9

Page 42

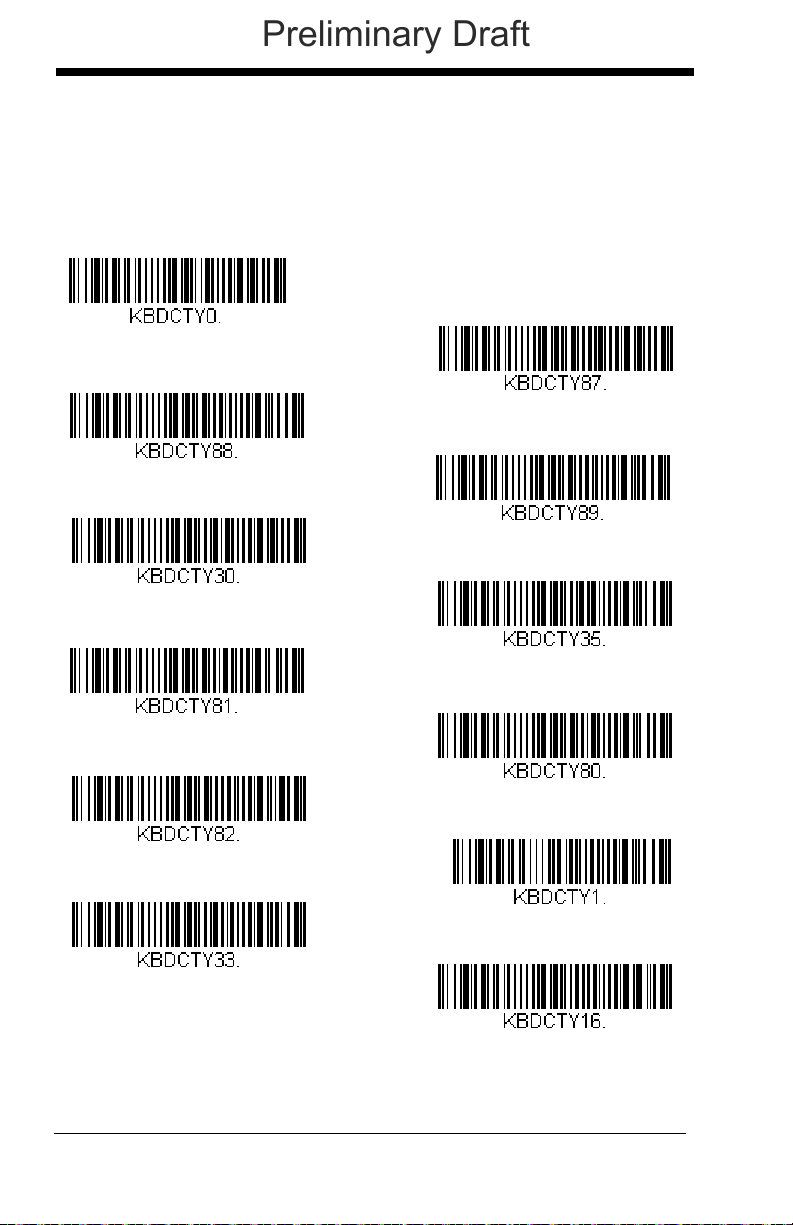

Keyboard Country Layout

* United States

United States (Dvorak left)

United States (International)

Albania

Azeri (Cyrillic)

Azeri (Latin)

Belarus

Belgium

United States (Dvorak)

United States (Dvorak right)

Bosnia

Brazil

Preliminary Draft

Scan the appropriate country code below to program the keyboard layout for

your country or language. As a general rule, the following characters are supported, but need special care for countries other than the United States:

@ | $ # { } [ ] = / ‘ \ < > ~

2 - 10

Page 43

Keyboard Country (continued)

Bulgaria (Latin)

Canada (French)

Canada (Multilingual)

Croatia

Czech

Czech (Programmers)

Czech (QWERTY)

Czech (QWERTZ)

Bulgaria (Cyrillic)

Canada (French legacy)

Brazil (MS)

Denmark

Dutch (Netherlands)

Preliminary Draft

2 - 11

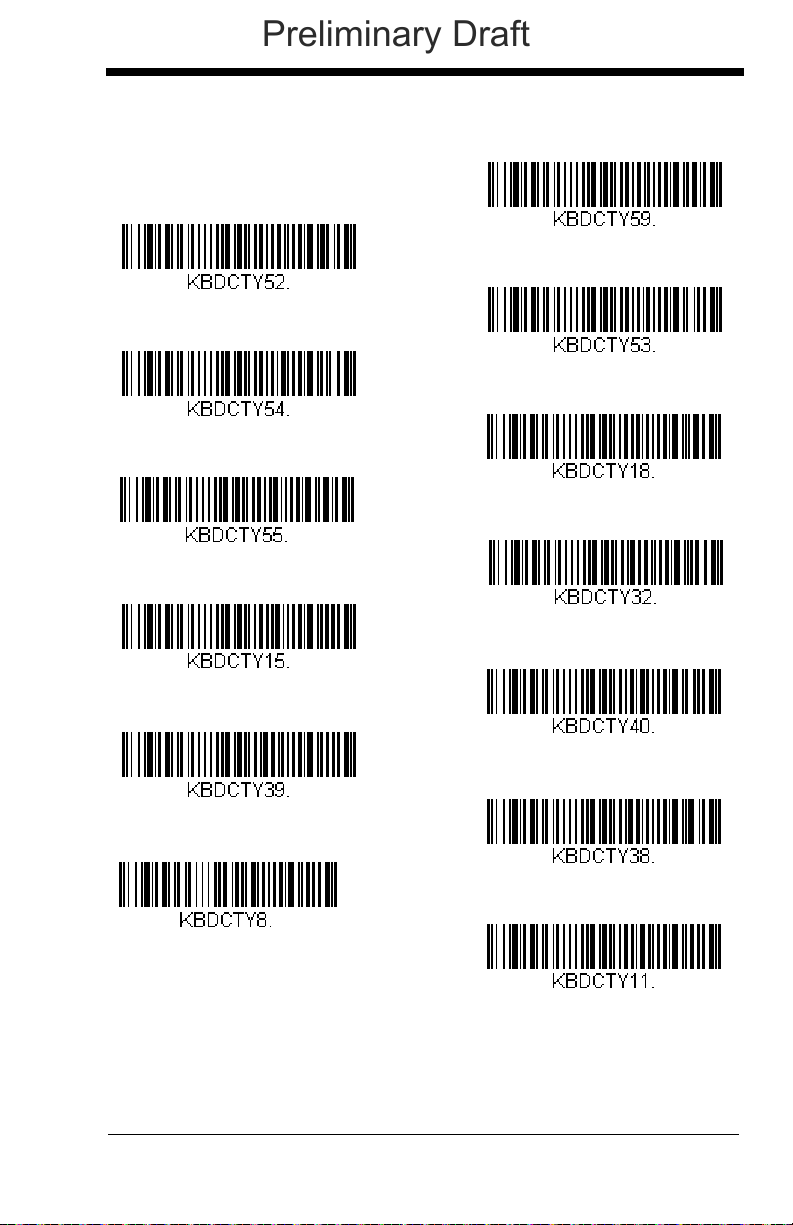

Page 44

Keyboard Country (continued)

Finland

Gaelic

Germany

Greek

Greek (220 Latin)

Greek (220)

Greek (319 Latin)

Greek (319)

Faeroese

France

Estonia

Greek (Latin)

Greek (MS)

Preliminary Draft

2 - 12

Page 45

Keyboard Country (continued)

Italian (142)

Hungarian (101 key)

Iceland

Irish

Italy

Japan ASCII

Kazakh

Kyrgyz (Cyrillic)

Hebrew

Hungary

Greek (Polytonic)

Latin America

Latvia

Preliminary Draft

2 - 13

Page 46

Keyboard Country (continued)

Lithuania (IBM)

Malta

Mongolian (Cyrillic)

Norway

Poland

Polish (214)

Polish (Programmers)

Portugal

Lithuania

Macedonia

Latvia (QWERTY)

Romania

Russia

Preliminary Draft

2 - 14

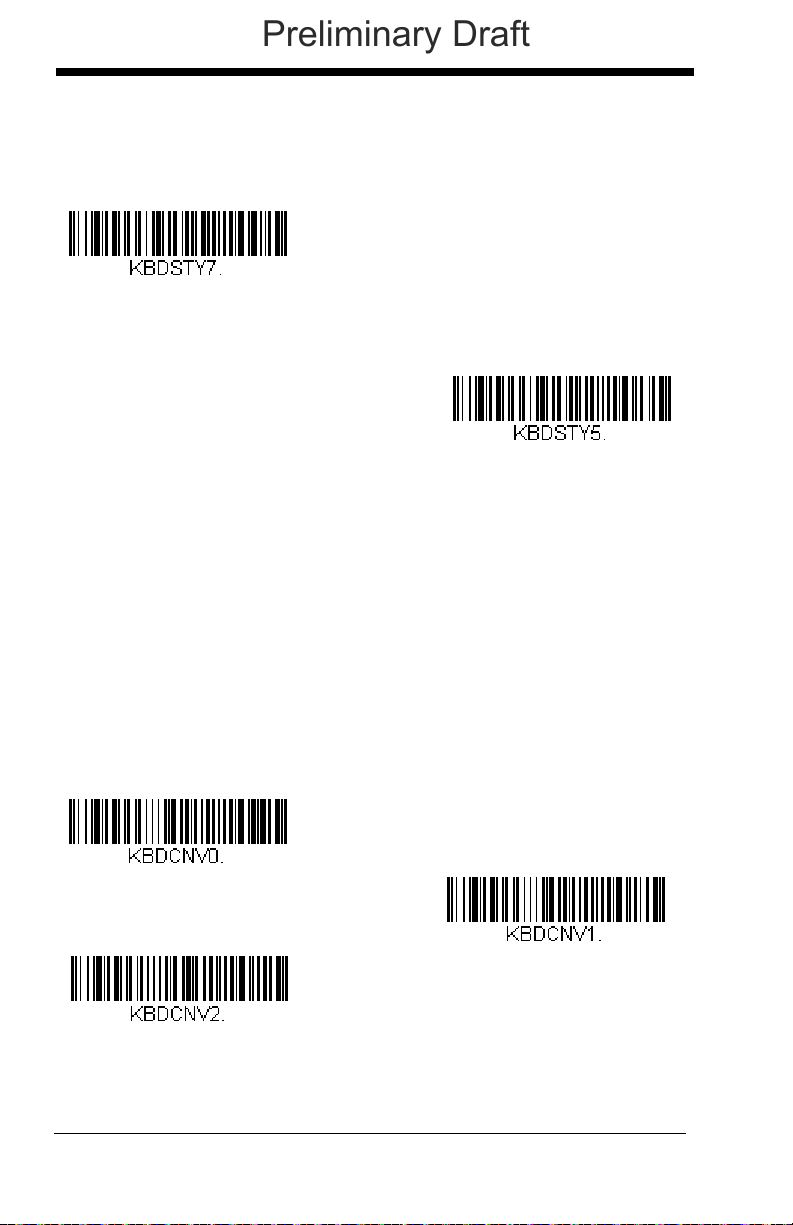

Page 47

Keyboard Country (continued)

SCS

Serbia (Latin)

Slovakia

Slovakia (QWERTY)

Slovakia (QWERTZ)

Slovenia

Spain

Spanish variation

Russian (Typewriter)

Serbia (Cyrillic)

Russian (MS)

Sweden

Switzerland (French)

Preliminary Draft

2 - 15

Page 48

Keyboard Country (continued)

Turkey F

Ukrainian

United Kingdom

United Stated (Dvorak right)

United States (Dvorak left)

United States (Dvorak)

United States (International)

Uzbek (Cyrillic)

Tatar

Turkey Q

Switzerland (German)

Preliminary Draft

Refer to the Honeywell website (www.honeywell.com/aidc) for complete keyboard country support information and applicable interfaces. If you need to program a keyboard for a country other than one listed above, scan the Program

Keyboard Country bar code below, then scan the numeric bar code(s) for the

2 - 16

Page 49

appropriate country from the inside back cover, then the Save bar code.

Program Keyboard Country

* Regular

Caps Lock

Shift Lock

Automatic Caps Lock

Preliminary Draft

Keyboard Style

This programs keyboard styles, such as Caps Lock and Shift Lock. If you have

used Keyboard Conversion settings, they will override any of the following Keyboard Style settings.

Regular is used when you normally have the Caps Lock key off.

Caps Lock

Shift Lock

to U.S. keyboards).

is used when you normally have the Caps Lock key on.

is used when you normally have the Shift Lock key on (not common

Default = Regular.

Automatic Caps Lock is used if you change the Caps Lock key on and off.

The software tracks and reflects if you have Caps Lock on or off . This selection

can only be used with systems that have an LED that notes the Caps Lock status (AT keyboards).

2 - 17

Page 50

Autocaps via NumLock bar code should be scanned in countries (e.g., Ger-

Autocaps via NumLock

Emulate External Keyboard

* Keyboard Conversion Off

Convert All Characters

to Upper Case

Convert All Characters

to Lower Case

Preliminary Draft

many, France) where the Caps Lock key cannot be used to toggle Caps Lock.

The NumLock option works similarly to the regular Autocaps, but uses the NumLock key to retrieve the current state of the Caps Lock.

Emulate External Keyboard should be scanned if you do not have an external

keyboard (IBM AT or equivalent).

Note: After scanning the Emulate External Keyboard bar code, you must power

cycle your computer.

Keyboard Conversion

Alphabetic keyboard characters can be forced to be all upper case or all lowercase. So if you have the following bar code: “abc569GK,” you can make the

output “ABC569GK” by scanning Convert All Characters to Upper Case, or to

“abc569gk” by scanning Convert All Characters to Lower Case.

These settings override Keyboard Style selections.

Note: If your interface is a keyboard wedge, first scan the menu code for

Automatic Caps Lock (page 2-17). Otherwise, your ouput may not be as

expected.

Default = Keyboard Conversion Off

2 - 18

.

Page 51

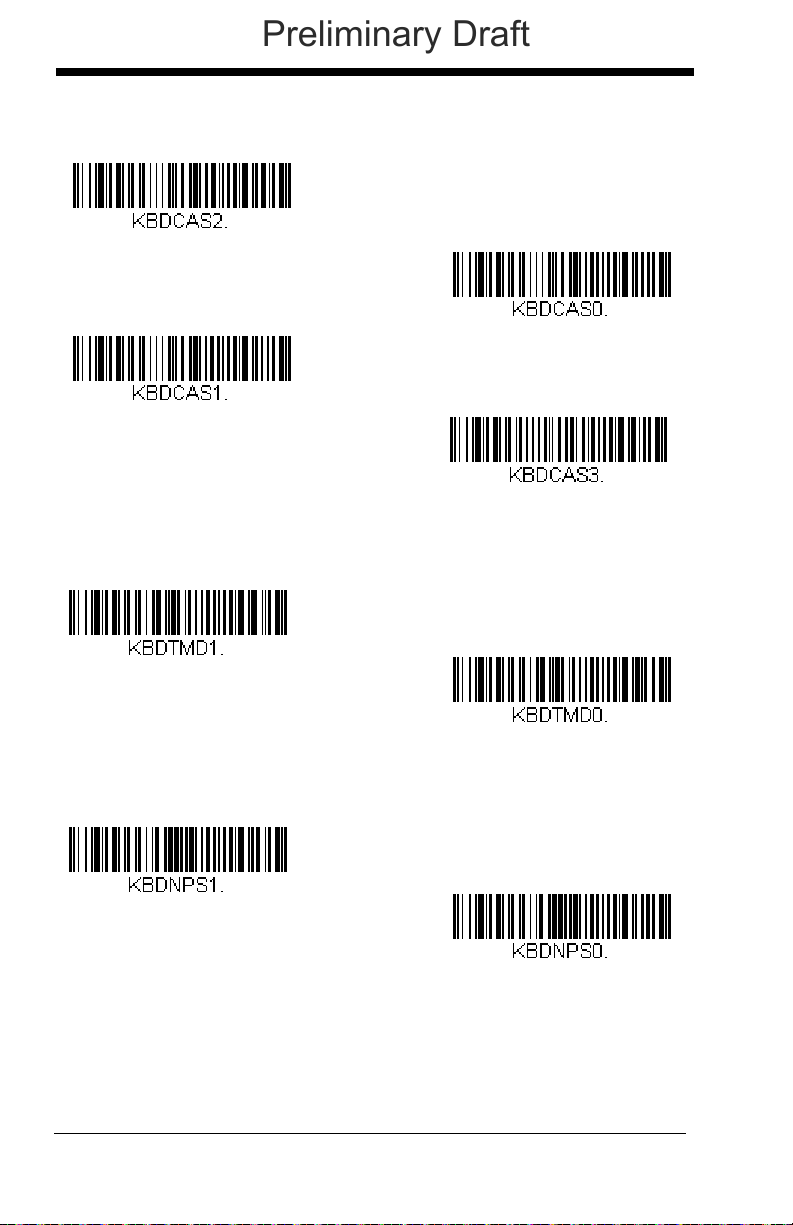

Control Character Output

Control Character Output On

* Control Character Output Off

Preliminary Draft

This selection sends a text string instead of a control character. For example,

when the control character for a carriage return is expected, the output would

display [CR] instead of the ASCII code of 0D. Refer to ASCII Conversion Chart

(Code Page 1252) on page A-4. Only codes 00 through 1F are converted (the

first column of the chart).

Note: Control + ASCII Mode overrides this mode.

Default = Off.

Keyboard Modifiers

This modifies special keyboard features, such as CTRL+ ASCII codes and

Turbo Mode.

Control + ASCII Mode On: The scanner sends key combinations for ASCII

control characters for values 00-1F. Windows is the preferred mode. All keyboard country codes are supported. DOS mode is a legacy mode, and it does

not support all keyboard country codes. New users should use the Windows

mode. Refer to Keyboard Function Relationships, page 9-1 for CTRL+ ASCII

Val ues.

Windows Mode Prefix/Suffix Off: The scanner sends key combinations for

ASCII control characters for values 00-1F, but it does not transmit any prefix or

suffix information.

2 - 19

Page 52

Default = Control + ASCII Mode Off.

Windows Mode Control + ASCII

Mode On

* Control + ASCII Mode Off

DOS Mode Control + ASCII Mode

On

Windows Mode Prefix/Suffix Off

Turbo Mode On

* Turbo Mode Off

Numeric Keypad Mode On

* Numeric Keypad Mode Off

Preliminary Draft

Turbo Mode: The scanner sends characters to a terminal faster. If the terminal drops characters, do not use Turbo Mode.

Default = Off

Numeric Keypad Mode: Sends numeric characters as if entered from a

numeric keypad.

2 - 20

Default = Off

Page 53

Automatic Direct Connect Mode: This selection can be used if you have an

Automatic Direct Connect Mode

On

* Automatic Direct Connect

Mode Off

Preliminary Draft

IBM AT style terminal and the system is dropping characters.

Default = Off

2 - 21

Page 54

RS232 Baud Rate

300

2400

600

1200

4800

38400

* 9600

19200

115,200

57,600

Preliminary Draft

Baud Rate sends the data from the scanner to the terminal at the specified rate.

The host terminal must be set for the same baud rate as the scanner.

9600.

Default =

2 - 22

Page 55

RS232 Word Length: Data Bits, Stop Bits,

7 Data, 1 Stop, Parity Even

7 Data, 1 Stop, Parity None

7 Data, 1 Stop, Parity Odd

7 Data, 2 Stop, Parity Even

7 Data, 2 Stop Parity None

* 8 Data, 1 Stop, Parity None

8 Data, 1 Stop, Parity Even

7 Data, 2 Stop, Parity Odd

8 Data, 1 Stop, Parity Odd

Preliminary Draft

and Parity

Data Bits sets the word length at 7 or 8 bits of data per character. If an applica-

tion requires only ASCII Hex characters 0 through 7F decimal (text, digits, and

punctuation), select 7 data bits. For applications that require use of the full

ASCII set, select 8 data bits per character.

Stop Bits sets the stop bits at 1 or 2.

Parity provides a means of checking character bit patterns for validity.

Default = None.

Default = 8.

Default = 1.

2 - 23

Page 56

RS232 Receiver Time-Out

RS232 Receiver Time-Out

Flow Control, No Timeout

* RTS/CTS Off

Two-Direction Flow Control

Flow Control with Timeout

Preliminary Draft

The unit stays awake to receive data until the RS232 Receiver Time-Out

expires. A manual or serial trigger resets the time-out. When an RS232

receiver is sleeping, a character may be sent to wake up the receiver and reset

the time-out. A transaction on the CTS line will also wake up the receiver. The

receiver takes 300 milliseconds to completely come up. Change the RS232

receiver time-out by scanning the bar code below, then scanning digits from the

inside back cover of this manual, then scanning Save. The range is 0 to 300

seconds.

Default = 0 seconds (no time-out - always on).

RS232 Handshaking

RS232 Handshaking allows control of data transmission from the scanner using

software commands from the host device. When RTS/CTS is turned Off, no

data flow control is used.

Flow Control, No Timeout: The scanner asserts RTS when it has data to

send, and will wait indefinitely for CTS to be asserted by the host.

Two-Direction Flow Control: The scanner asserts RTS when it is OK for the

host to transmit. The host asserts CTS when it is OK for the device to transmit.

Flow Control with Timeout: The scanner asserts RTS when it has data to

send and waits for a delay (see RS232 Timeout on page 2-25) for CTS to be

asserted by the host. If the delay time expires and CTS is not asserted, the

device transmit buffer is cleared and scanning may resume.

Default = RTS/CTS Off.

2 - 24

Page 57

RS232 Timeout

RS232 Timeout

* XON/XOFF Off

XON/XOFF On

Preliminary Draft

When using Flow Control with Timeout, you must program the length of the

delay you want to wait for CTS from the host. Set the length (in milliseconds) for a timeout by scanning the bar code below, then setting the timeout (from 1-5100 milliseconds) by scanning digits from the inside back

cover, then scanning Save.

XON/XOFF

Standard ASCII control characters can be used to tell the scanner to start

sending data (XON/XOFF On) or to stop sending data (XON/XOFF Off).

When the host sends the XOFF character (DC3, hex 13) to the scanner,

data transmission stops. To resume transmission, the host sends the XON

character (DC1, hex 11). Data transmission continues where it left off

when XOFF was sent.

Default = XON/XOFF Off

.

ACK/NAK

After transmitting data, the scanner waits for an ACK character (hex 06) or

a NAK character (hex 15) response from the host. If ACK is received, the

communications cycle is completed and the scanner looks for more bar

codes. If NAK is received, the last set of bar code data is retransmitted and

2 - 25

Page 58

the scanner waits for ACK/NAK again. Turn on the ACK/NAK protocol by

ACK/NAK On

* ACK/NAK Off

* Packet Mode Off

Packet Mode On

Preliminary Draft

scanning the ACK/NAK On bar code below. To turn off the protocol, scan

ACK/NAK Off.

Default = ACK/NAK Off

.

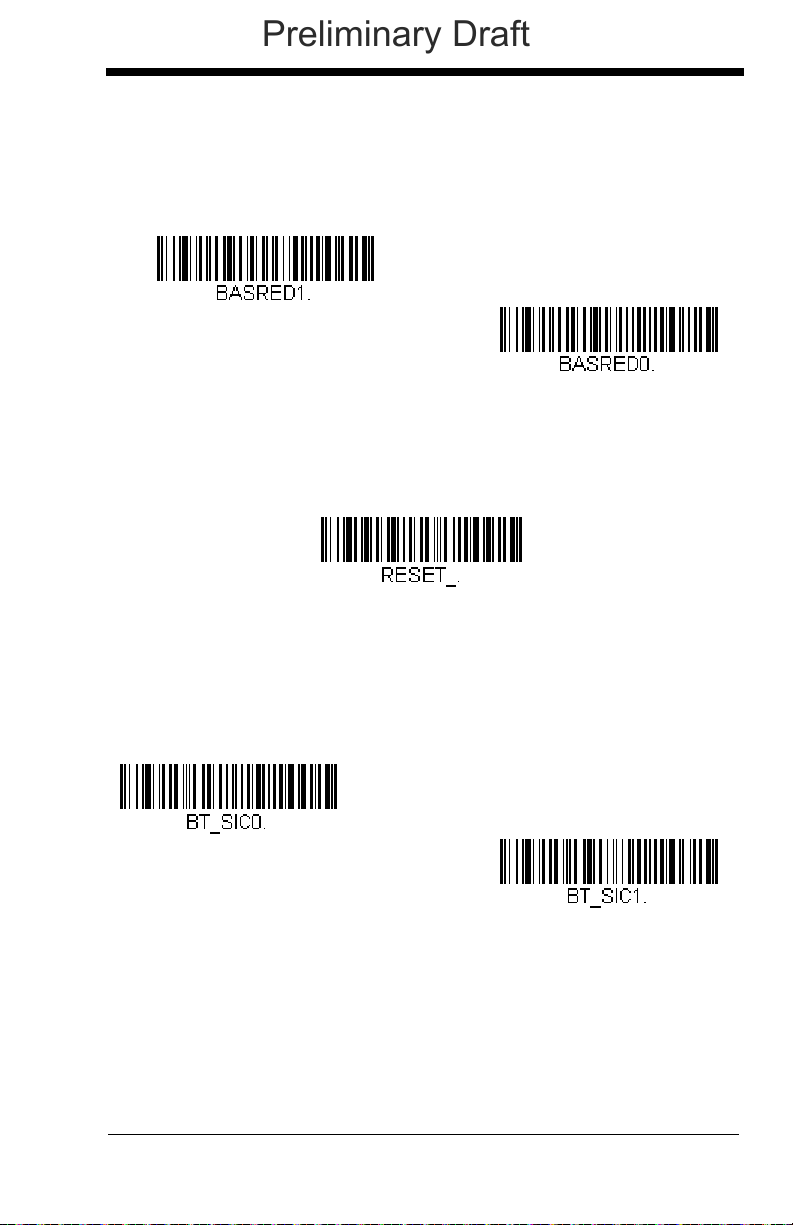

Scanner to Bioptic Communication

The following settings are used to set up communication between Honeywell

scanners and bioptic scanners.

Note: The scanner’s baud rate must be set to 38400 and the RS232 timeout

must be set to 3000 in order to communicate with a bioptic scanner. See

RS232 Baud Rate on page 2-22, and RS232 Timeout on page 2-25 for

further information.

Scanner-Bioptic Packet Mode

Packet Mode On must be scanned to set the scanner’s format so it is com-

patible with a bioptic scanner.

Default = Packet Mode Off.

2 - 26

Page 59

Scanner-Bioptic ACK/NAK Mode

* Bioptic ACK/NAK Off

Bioptic ACK/NAK On

ACK/NAK Timeout

Preliminary Draft

Bioptic ACK/Nak On must be scanned so the scanner will wait for an ACK

or NAK from a bioptic scanner after each packet is sent. The ScannerBioptic ACK/NAK Timeout (below) controls how long the scanner will wait

for a response.

Default = Bioptic ACK/NAK Off.

Scanner-Bioptic ACK/NAK Timeout

This allows you to set the length (in milliseconds) for a timeout for a bioptic

scanner’s ACK/NAK response. Scan the bar code below, then set the timeout (from 1-30,000 milliseconds) by scanning digits from the inside back

cover, then scanning Save.

Default = 5100.

2 - 27

Page 60

2 - 28

Preliminary Draft

Page 61

3

Scanner

CCB01-010BT

Charge Base

Page Button and

Base LEDs

Preliminary Draft

Cordless System Operation

Note: This chapter applies only to cordless scanning systems. It does not apply

to corded scanners.

How the Cordless Base Works

The cordless base provides the link between the cordless scanner and the host

system. The base contains an interface assembly and an RF communication

module. The RF communication module performs the data exchange between

the cordless scanner and the interface assembly. The control assembly coordinates the central interface activities including: transmitting/receiving commands

and data to/from the host system, performing software activities (parameter

menuing, visual indicator support, power-on diagnostics), and data translation

required for the host system.

The base also is the scanner’s battery charger. Refer to Beeper and LED

Sequences and Meaning, page 3-5, for additional information.

Linking the Scanner to the Base

Turn off power before connecting the base, then power up the computer once

the base is fully connected. When the base is connected and powered up, put

the scanner in the base to establish a link. The green LED on the base flashes

to indicate the scanner’s battery is charging.

If the scanner and base have previously been linked, you do not receive any

feedback. If this is the first time that the scanner and base are linked, both

devices emit a short chirp when their radios link. At this point, that one scanner

is linked to one base.

To determine if your cordless system is set up correctly, scan one of the sample

bar codes in the back of this manual. If the scanner provides a single good read

beep and the green LED lights, the scanner has successfully linked to the base.

If you receive an error tone and the red LED lights, the scanner has not linked to

the base. Refer to page 13-5 for troubleshooting information.

3 - 1

Page 62

Communication Between the Cordless System

3) Base sends data to host

1

)

Go

o

d

Re

a

d

2

)

ACK

f

r

o

m

b

a

s

e

Preliminary Draft

and the Host

The cordless scanner provides immediate feedback in the form of a “good read”

indication (a green LED on the scanner and an audible beep) after a bar code is

scanned correctly and the base has acknowledged receiving the data. This is

possible since the cordless system provides two-way communication between

the scanner and the base.

When data is scanned, the data is sent to the host system via the base unit.

The cordless scanner recognizes data acknowledgement (ACK) from the base

unit. If it cannot be determined that the data has been properly sent to the

base, the scanner issues an error indication. You must then check to see if the

scanned data was received by the host system.

RF (Radio Frequency) Module Operation

The cordless system uses a two-way Bluetooth® radio to transmit and receive

data between the scanner and the base. Designed for point-to-point and multipoint-to-single point applications, the radio operates using a license free ISM

band, which sends relatively small data packets at a fast data rate over a radio

signal with randomly changing frequencies, makes the cordless system highly

responsive to a wide variety of data collection applications and resistant to

noisy RF environments. Bluetooth Class 2 power level provides a communication range of 33 feet (10m) between the scanner and base/Bluetooth adapter,

depending on the environment.

System Conditions

The components of the cordless system interact in specific ways as you associate a scanner to a base, as you move a scanner out of range, bring a scanner

back in range, or swap scanners between two cordless systems. The following

information explains the cordless system operating conditions.

3 - 2

Page 63

Linking Process

!

Preliminary Draft

Once a scanner is placed into the base, the scanner’s battery charge status

is checked, and software automatically detects the scanner and links it to

the base depending on the selected link mode.

Scanner Is Out of Range

The cordless scanner is in communication with its base, even when it is not

transmitting bar code data. Whenever the scanner can’t communicate with

the base for a few seconds, it is out of range. If the scanner is out of range

and you scan a bar code, the scanner issues an error tone indicating no

communication with the base. In addition, your scanner and base can

sound an alarm if programmed to emit an alarm. Refer to Out-of-Range

Alarm, page 3-12.

Scanner Is Moved Back Into Range

The scanner re-links if the scanner or the base have been reset or the

scanner comes back into range. If the scanner re-links, you will hear a single chirp when the re-linking process (uploading of the parameter table) is

complete.

OutofRangeandBackintoRange with Batch Mode On

The scanner may store a number of symbols (approximately 500 U.P.C.

symbols; others may vary) when out of range and then send them to the

base when back in range (see Batch Mode on page 3-14).

You will not hear a communication error tone in this mode, but you will hear

a short buzz when you pull the trigger if the radio communication is not

working. Once the radio connection is made, the scanner produces a

series of beeps while the data is being transferred to the base.

Page Button

When you press the Page button on the base, the scanners associated with

that base will begin beeping (3 short and 1 long beep). If you pull the trigger on a scanner that is beeping in response, that scanner will stop beeping. If you press the Page button on the base a second time, all associated

scanners will stop beeping. See Paging on page 3-8 for further information

about Page Button settings.

About the Battery

There is a danger of explosion if the batteries are incorrectly replaced.

Replace the batteries with only the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to

the recycle program for batteries as directed by the governing agency

for the country where the batteries are to be discarded.

3 - 3

Page 64

Power is supplied to the cordless scanner by a rechargeable battery that is inte-

Preliminary Draft

grated in the scanner handle. Batteries are shipped approximately 30% to 60%

charged and should be fully charged for maximum charge capacity.

Charging Information

The battery is designed to charge while the scanner is positioned in the

cordless base unit. Refer to Base LED Sequences and Meaning, page 36, for an interpretation of the Charge Status indicators.

Place the scanner in the base that is connected to an appropriate power

supply.

Note: If you are powering the base through the interface cable (for

example, a USB cable) and not using an external power supply

plugged into the aux port, the current available for charging is

reduced and charge times are increased.

Battery Recommendations

• The battery is a lithium ion cell and can be used without a full charge, and

can also be charged without fully discharging, without impacting the

battery life. There is no need to perform any charge/discharge

conditioning on this type of battery.

• Keep the base connected to power when the host is not in use.

• Replace a defective battery immediately since it could damage the

scanner.

• Although your battery can be recharged many times, it will eventually be

depleted. Replace it after the battery is unable to hold an adequate

charge.

• If you are not sure if the battery or charger is working properly, send it to

Honeywell International Inc. or an authorized service center for

inspection. Refer to Customer Support on page 14-1 for additional

information.

Safety Precautions for Lithium Batteries

• Do not place batteries in fire or heat the batteries.

• Do not store batteries near fire or other high temperature locations.

• Do not store or carry batteries together with metal objects.

• Do not expose batteries to water or allow the batteries to get wet.

• Do not connect (short) the positive and negative terminals, of the

batteries, to each other with any metal object.

• Do not pierce, strike, or step on batteries or subject batteries to strong

impacts or shocks.

• Do not disassemble or modify batteries.

3 - 4

Page 65

Proper Disposal of the Battery

Preliminary Draft

When the battery has reached the end of its useful life,

the battery should be disposed of by a qualified recycler

or hazardous materials handler. Do not incinerate the

battery or dispose of the battery with general waste

materials. You may send the scanner’s battery to us.

(postage paid). The shipper is responsible for complying

with all federal, state, and local laws and regulations

ping of spent batteries. Contact the Product Service Department (page 14-

1) for recycling or disposal information. Since you may find that your cost

of returning the batteries significant, it may be more cost effective to locate

a local recycle/disposal company.

related to the packing, labeling, manifesting, and ship-

Beeper and LED Sequences and Meaning

The scanner contains LEDs on the top of the unit to indicate its power up, communication, and battery status. Simply stated, red LED = error; green

LED = success of any type. The unit’s audible indicators have meaning as well:

1 razz or error tone = error; 2 beeps = menu change; 1 beep = all other successes.

The table below lists the indication and cause of the LED illumination and beeps

for the scanner.

3 - 5

Page 66

Scanner LED Sequences and Meaning

Preliminary Draft

LED Indication Beeper Indication Cause

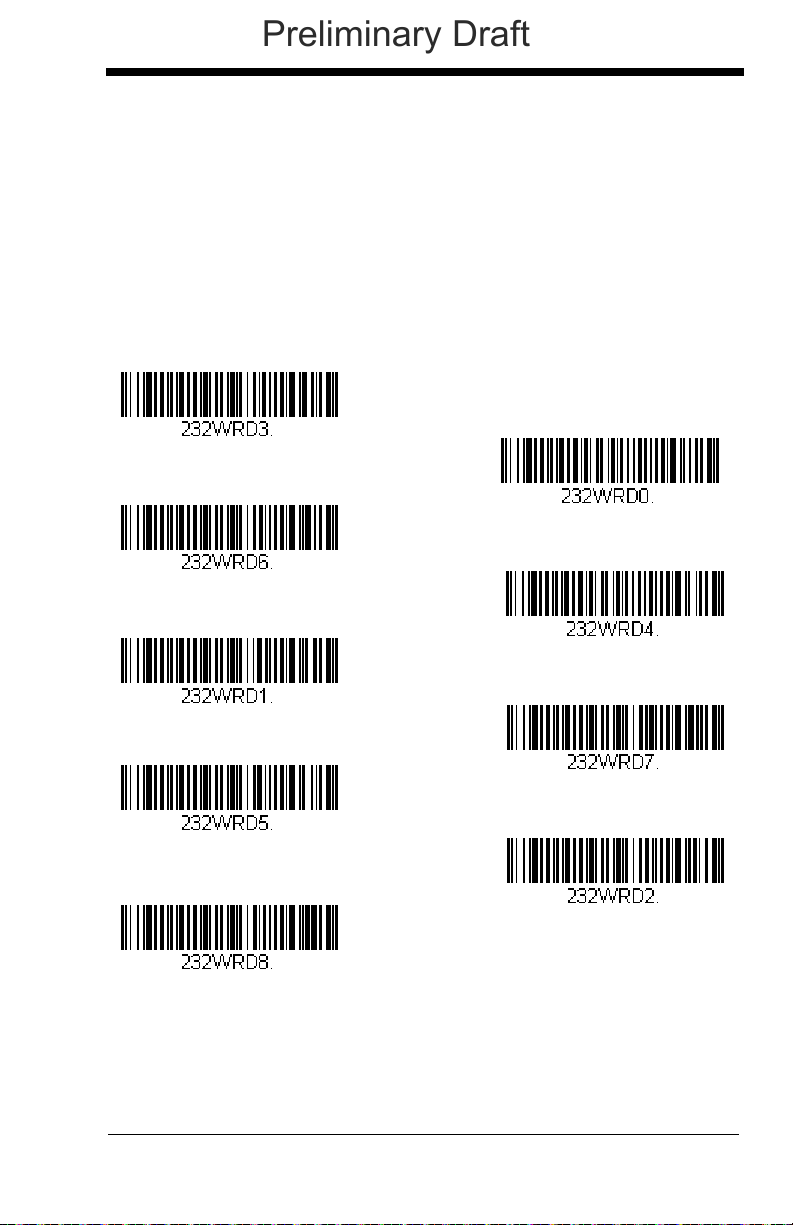

Normal Operation