Page 1

CIPer Model 30 Controller

INSTALLATION INSTRUCTIONS

Introduction

The Honeywell CIPer Model 30 is a compact, Internet

Protocol (IP) edge controller for VAV, Unitary and Plant

applications. With its native Niagara N4 on-board

programming platform; the CIPer controller provides

Internet connectivity, Web serving capability, integrated

control, data logging, alarming, trending, and scheduling

management. The controller can be used to aggregate

information (including real-time data, alarms, trends,

and history) and integrate this data to the Sentience

Cloud for value-added data analytics.

Tabl e 1 Parts and description

Model number Description

WEB-C3036EPUBNH

WEB-C3036EPVBNH

WEB-O3022H

WEB-O9056H

Honeywell CIPer - IP controller with 3 universal inputs, 6 Binary Outputs, 3 Universal I/O and

HOA switches

Honeywell CIPer - IP controller with 3 universal inputs, 6 Binary Outputs, 3 Universal I/O, VAV

airflow sensor and HOA switches

IO module with 3 universal inputs, 2 Binary Outputs, 2 Universal I/O and HOA switches

IO module with 9 universal inputs, 6 Binary Outputs, 5 Universal I/O and HOA switches

Specifications:

Power consumption: AC: Max 100VA

Rated input voltage: 20-30 VAC; 50/60Hz

Impulse voltage: 330V

Ambient temperature: -4 to 131F (-20 to 55C)

Storage temperature: -4 to 150F (-20 to 65C)

Humidity: 5% to 95% non-condensing

Differential pressure sensor range (VAV mo

WC (0 to 374 Pa) 32 to 122F (0 to 55C)

Universal Inputs / Analog Outputs (configurable)

UI

/ 3 configurable as AO

Flexible UI’s to connect external sensors like

20KNTC, PT1000 and other resistive sensors

Digital Output type / rating: Solid-State Relay, 1.5A

Continuous, 3.5A inrush for 100 mS.

Digital Output voltage rating: 20 to 30 VAC

Hz

Pulse Inputs: 100Hz max, minimum

ON / 5 mS OFF.

Purpose of Control: Operating Control,

Management Equipment

Action

Pollution degree: 2

ELV limits realized: 24V

: Type 1

duty cycle: 5 mS

del): 0-2”

@ 50/60

Open Energy

: 6

Before Installation

WARNING! Install all equipment in accordance with the

National Electric Code and in a manner acceptable to the local

authority having jurisdiction. Read these instructions and the

CIPer Model 30 controller Installation Instructions (31-00183-

01) carefully before installing equipment. Failure to follow all

instructions may result in equipment damage or a hazardous

condition.

Attention! Installez tout le matériel en conformité avec le

Code national de l'électricité et d'une manière acceptable pour

l'autorité localecompétente. Lisez ces instructions et le guide d'

installation et fonctionnement de l'ACM (LT-ACMIOG) avant

l'installation du matériel. Le non respect des instructions peut

entraîner desdes dommages matériels ou une situation

dangereuse.

WARNING! The CIPer 30 controller and its components may

be susceptible to electrostatic discharge (ESD). Use

appropriate ESD grounding techniques while handling the

product. When possible, always handle the product by its nonelectrical components.

© Honeywell Page 1 31-00183-02

Page 2

The CIPer 30 controller is available in two models (See table 1).

Review the power, input, and output specifications before installing the controller.

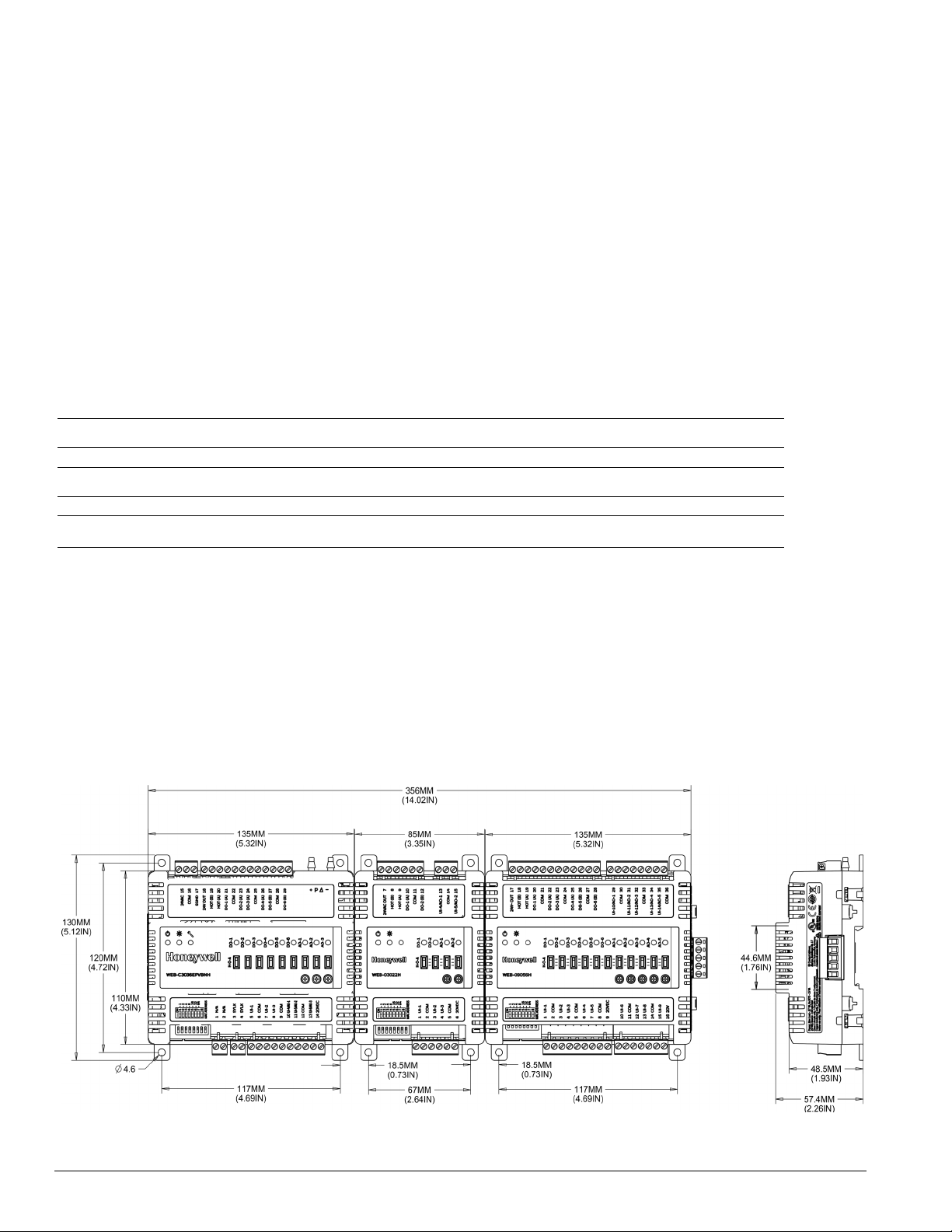

Installation

The CIPer Model 30 controller must be mounted in a position that allows clearance for wiring, servicing, removal,

connection of the terminal blocks and access to the MAC address DIP switches. It may be mounted in any

orientation.

Mounting

The CIPer controller mounts on a standard DIN rail in one of two ways:

vertically, with the connections on the right and left sides of the unit.

horizontally, with the connections on the top and bottom of the unit.

The controller also has a locking clip, as do both type of I/O expansion modules. Mounting on DIN rail ensures

accurate alignment of connectors between all modules. The controller can also be screw-mounted using the four

mounting tabs, accessible under the covers. These mounting tabs may be broken off if needed to save space when

DIN rail mounting.

As per the Construction of this controller, it can be mounted independently for Panel mounting.

Note: Mount the controller prior to mounting any necessary items (I/O modules).

WARNING! Be sure the CIPer controller does not have power connected while mounting.

Attention! Assurez-vous que l'appareil n'est pas connecté à l'alimentation lors du montage.

To mount the CIPer controller on a DIN rail:

1 Holding the controller with its top tilted in towards the DIN rail, hook the two top flex snaps on the back of

the controller onto the top of the DIN rail.

2 Push down and in to latch the two bottom latching tabs of the controller onto the DIN rail.

3 Properly ground the panel, then terminate grounded components of power, communications, and I/O

wiring.

To remove the CIPer controller from the DIN rail:

1 Push straight down from the top to release the bottom tabs.

2 Rotate the bottom of the controller out towards you and pull the controller up and away from the DIN rail to

release the bottom latching tabs.

Fig. 1 Panel mounting - controller dimensions in mm (inches)

© Honeywell Printed in USA 31-00183-02

Page 3

IMPORTANT! Avoid mounting in areas where acid fumes or other deteriorating vapors can attack the metal parts of the

controller, or in areas where escaping gas or other explosive vapors are present.

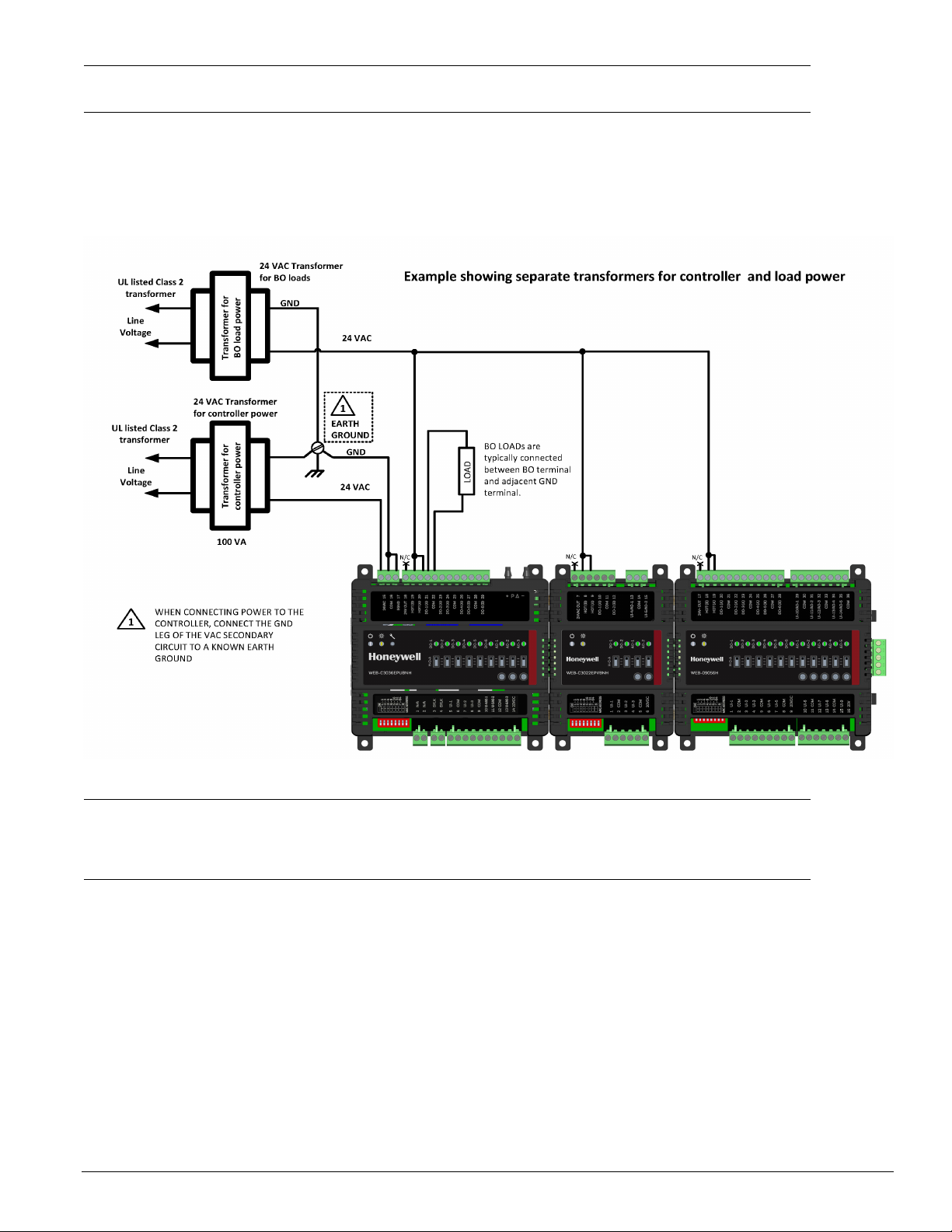

Power

The CIPer controller requires 20-30 VAC, 50/60Hz. Power consumption is based on the sum of the VA rating for

each controller and should not exceed 100VA. If additional modules are required then they must be powered from

a separate transformer. Refer VA rating for each module in the note below.

Fig. 2 Use separate transformers for controllers and load power

Note: Transformer VA load for module power only (no BO loads)

a) WEB-C3036EPVBNH = 50VA

b) WEB-O9056H = 35VA

c) WEB-O3022H = 15VA

Using Terminal blocks

The CIPer controller uses removable terminal blocks to simplify field wiring of power and cabling. If desired, you

can remove the terminal blocks from the unit, terminate cable, and reset the block when you finish.

To termina te cable:

1 Strip a wire jacket from the end of the cable.

2 Use a small screwdriver to turn the adjustment screw fully counter-clockwise. The clamps in the wire slot

separate as you turn the screw.

3 When the clamps in the wire slot are fully open, insert the stripped end of the cable (the insulation end

must be flush with the terminal block). Be sure to insert all cable strands into the wire slot.

4 Hold the cable in place and turn the adjustment screw clockwise to tighten it until the clamps in the wire

slot secure the cable. Tug gently on the cable to ensure that it’s securely terminated

© Honeywell Page 3 31-00183-02

Page 4

5 Both type of I/O modules WEB-O3022H and WEB-O9056H can be connected directly to the WEB-

C3036EPVBNH controller as shown in Fig. 3.

Fig. 3 Stacked Controller and IO modules

Fig. 4 Remotely mounted expansion module

© Honeywell Printed in USA 31-00183-02

Page 5

Table 2

Terminal Description

Terminal Descriptio

n for WEB-C3036EP controller

1,2 Not used

3, 4 2 wire SYLK bus to connect SYLK modules

5, 7, 8 Universal inputs UI-1 to 3. Software

controlled input type selection supports 10k

Thermistor (type II), Dry Contact, 0-10Vdc,

0-20mA, and Pulse (In-1, -2, -3)

6 COM terminal for UI-1 & UI-2

9 COM terminal for UI-3 & UI-4/AO-1

10, 11, 13Universal Inputs/Outputs as UI-4 to 6

Analog Outputs: selectable 0-10vDC or 0-

20mA

12 COM terminal for UI-5/AO-2 or UI-6/AO-3

14 Supplies 20V DC

15 Controller input supply voltage 24VAC

16 Supply voltage GND

17 Electrical grounding / Earth

18 24VAC output from controller's power

(terminal 15) for DO devices

19 HOT B. Supplies power to common side of

controller's DO (For DO 5,6)

20 HOT A. supplies power to common side of

controller's DO (DO 1, 2, 3, 4)

22, 25, 28GND terminal for DO-1&2, DO-3&4, DO-5&6

respectively

21, 23,

DO-1 to DO-4

24, 26

27, 29 DO-5, DO-6

Ether

net Connections

Table 3 Ethernet Connections

Ethernet

RJ-45 jack

An RJ-45 jack for connection to Ethernet is

on top of the CIPer controller. Pin

designations for the RJ-45 jack are shown.

+‒ ‒ ‒ ‒+++

Pin Assignment

1 Bi-directional pair

A+

12345678

2 Bi-directional pair

A-

3 Bi-directional pair

B+

4 Bi-directional pair

C+

5 Bi-directional pair

C-

6 Bi-directional pair

B-

7 Bi-directional pair

D+

8 Bi-directional pair

D-

Cable type

and

length

Use an approved Category 5e or better

Ethernet drop cable with RJ-45 plugs. Use

professionally manufactured cables of no

more than 328 feet (100 meters).

Disposal

The product should not be disposed of with other

household waste. Check for the nearest authorized

collection centers or authorized recyclers. The correct

disposal of end-of-life equipment will help prevent

potential negative consequences for the environment

and human health. Do not burn this device.

Conformance statement

Fig. 5 Ethernet Connections

CIPer controller has a built-in four-port 1Gig Ethernet

switch that supports 10BASE-T (10 Mbps), 100BASETX (100 Mbps), and 1000BASE-T (1000 Mbps)

Ethernet connections. It automatically operates at

1000 Mbps if other devices and cabling support it.

© Honeywell Page 5 31-00183-02

This Class B digital apparatus complies with Canadian

ICES-003.

This device complies with Industry Canada

licenseexempt RSS standard(s). Operation is subject to

the following two conditions: (1) this device may not

cause interference, and (2) this device must accept

any interference, including interference that may

cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie

Canada applicables aux appareils radio exempts de

licence. L'exploitation est autorisée aux deux

conditions

suivantes: (1) l'appareil ne doit pas produire de

brouillage, et (2) l'utilisateur de l'appareil doit accepter

tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le

Page 6

fonctionnement.

This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference in a residential installation. This

equipment

generates uses and can radiate radio frequency energy

and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation. If

this equipment does cause harmful interference to

radio

or television reception, which can be determined by

turning the equipment off and on, the user is

encouraged

to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment

and receiver.

Connect the equipment into an outlet on a circuit

different from that to which the receiver is

connected.

Cet équipement a été testé et jugé conforme aux

limites de Classe B pour un appareil numérique, en

vertu de l’article 15 de la réglementation de la FCC. Ces

limites ont été instaurées pour fournir une protection

raisonnable contre toute interférence nuisible dans

une installation résidentielle. Cet équipement génère,

utilise et peut émettre de l’énergie radiofréquence. S’il

n’est pas installé et utilisé conformément aux

instructions, il peut provoquer des interférences sur les

communications radio. Cependant, il n’est pas garanti

que des interférences ne se produiront pas dans

certaines installations. Si cet équipement cause des

interférences à la réception radio ou télévisée (ce qui

peut être vérifié en éteignant l’appareil puis en le

remettant sous tension), l’utilisateur peut tenter de les

résoudre en suivant une ou plusieurs des mesures ciaprès:

Réorienter ou déplacer l’antenne réceptrice.

Augmenter l’espace entre l’appareil et le récepteur.

Brancher l’appareil à une prise de courant

différente de celle sur laquelle le récepteur est

branché.

Pour obtenir de l’aide, contacter le vendeur ou un

technicien radio/télévision expérimenté.

Notice

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

© Honeywell Printed in USA 31-00183-02

Page 7

Honeywell Building Technologies

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2019Honeywell International Inc.

31-00183-02

Loading...

Loading...