Honeywell CENTRA LINE LION CLLIONLC01 Installation & Commissioning Instructions

Installation &

Commissioning

LION Controller

CONTENTS

Safety Information............................................................. 3

General Safety Information............................................ 3

Safety Information as per EN60730-1........................... 3

System Overview............................................................... 4

System Architecture....................................................... 4

I/O Modules ................................................................... 5

Interfaces and Bus Connections .................................... 9

Technical Data............................................................... 9

Instructions

LION

SYSTEM

INSTALLATION AND COMMISSIONING INSTRUCTIONS

Setting I/O Bus Switch ................................................. 29

Connecting Field Devices ............................................ 30

Commissioning I/O Modules ........................................ 31

Updating Software ....................................................... 31

Connecting to External Systems or Interfaces ............. 32

Connecting via LONWORKS Bus.................................... 32

Connecting via C-Bus .................................................. 33

Connecting HMIs or Laptops ....................................... 33

Connecting Modems .................................................... 33

Planning ........................................................................... 10

Overview...................................................................... 10

Transformer Selection ................................................. 10

Fusing Specifications................................................... 11

System Protective Earth Grounding............................. 11

Lightning Protection ..................................................... 11

Panel Bus Topologies.................................................. 11

LONWORKS Bus Topologies.......................................... 12

C-Bus Topologies ........................................................ 12

Accessories ................................................................. 12

Cable Specifications .................................................... 13

Dimensions .................................................................. 16

Mounting/Dismounting Modules.................................... 18

Mounting/Dismounting Controller/Sockets ................... 18

Mounting/Dismounting Electronic Modules .................. 20

Mounting/Dismounting Manual Disconnect Modules ... 21

Mounting/Dismounting Auxiliary Terminal Packages ... 22

Mounting/Dismounting Cross Connectors.................... 23

Mounting/Dismounting Swivel Label Holders............... 23

Wiring and Setting Up the System................................. 24

General Safety Considerations .................................... 24

Wiring Push-in Terminals............................................. 24

Connecting Power Supply............................................ 25

Connecting Single Bus Controller Systems ................. 26

Connecting Panel Bus and LONWORKS Bus Mixed

Controller Systems ...................................................... 27

Setting Address of Panel Bus I/O Modules .................. 29

Description of the CLLIONLC01 ..................................... 34

Overview...................................................................... 34

Features....................................................................... 35

Description of the I/O Modules....................................... 40

Common Features ....................................................... 40

Analog Input Modules .................................................. 40

Analog Output Modules ............................................... 45

Binary Input Modules ................................................... 50

Relay Output Modules ................................................. 53

Floating Output Module................................................ 58

Mixed Panel Bus I/O Module CLIOP830A ................... 62

Description of Extra Parts............................................... 65

Manual Disconnect Modules........................................ 65

XS814 Auxiliary Terminal Package.............................. 66

XS830 Auxiliary Terminal Package.............................. 66

XS831 Auxiliary Terminal Package.............................. 66

Cross Connectors ........................................................ 67

XAL10 Swivel Label Holders........................................ 67

XAL11 Swivel Label Holders........................................ 67

XS816 Bridge Connectors ........................................... 67

LON Software Interface Description .............................. 68

Overview...................................................................... 68

CLIOL821A Analog Input Module ................................ 68

CLIOL(R)822A Analog Output Module......................... 70

CLIOL823A Binary Input Module ................................. 72

CLIOL(R)824A Relay Output Module........................... 73

Copyright © 2009 Honeywell GmbH All Rights Reserved EN1Z-0921GE51 R0709

3.4

LION System

Troubleshooting............................................................... 74

Testing Wiring Connections.......................................... 74

Troubleshooting on the CLLIONLC01 Controller ..........74

I/O Modules Troubleshooting........................................78

Appendix 1: System Protective Earth Grounding .........82

LION Systems and SELV .............................................82

LION Systems and Standard EN60204-1 .....................82

Earth Grounding of EN60204-1 Applicable Systems ....82

Appendix 2: Remote Communications...........................84

Approved Modems .......................................................84

Modem or ISDN Terminal Adapter Connection ............84

Modem Requirements ..................................................84

Troubleshooting............................................................84

Appendix 3: Sensor Characteristics...............................85

BALCO 500 ..................................................................85

NTC 20 kΩ....................................................................86

PT 1000........................................................................87

NI1000TK5000 .............................................................89

NTC 10 kΩ....................................................................90

PT 3000........................................................................91

Trademark Information

Echelon, LON, L

trademarks of Echelon Corporation registered in the United

States and other countries.

ONMARK, LONTALK, LONWORKS, Neuron, are

EN1Z-0921GE51 R0709 2

LION System

Safety Information

General Safety Information

► When performing any work (installation, mounting, start-

up), all instructions given by the manufacturer and in

particular the safety instructions provided in these

Installation and Commissioning Instructions are to be

observed.

► The LION System (including the CLLIONLC01, I/O

modules, manual disconnect modules, and the auxiliary

terminal packages) may be installed and mounted only

by authorized and trained personnel.

► Rules regarding electrostatic discharge should be

followed.

► If the LION System is modified in any way, except by the

manufacturer, all warranties concerning operation and

safety are invalidated.

► Make sure that the local standards and regulations are

observed at all times. Examples of such regulations are

VDE 0800 and VDE 0100 or EN 60204-1 for earth

grounding.

► Use only accessory equipment which comes from or has

been approved by CentraLine.

► It is recommended that devices are to be kept at room

temperature for at least 24 hours before applying power.

This is to allow any condensation resulting from low

shipping/storage temperatures to evaporate.

► The LION System must be installed in such a manner

(e.g., in a lockable cabinet) as to ensure that uncertified

persons have no access to the terminals.

Safety Information as per

EN60730-1

Purpose

The LION System is an independently mounted electronic

control system with fixed wiring.

It is used for the purpose of building HVAC control and is

suitable for use only in non-safety controls for installation on

or in appliances.

Pollution degree Pollution Degree 2,

suitable for use in residential

controls, commercial controls,

in a clean environment.

Overvoltage

category

Rated impulse

voltage

Automatic action Type 1.C

Software class

Ball-pressure test

temperature

Category II

for mains-powered (16A) controls

Category I

for 24 V powered controls

2500 VAC

(micro-interruption for the relay

outputs)

Class A

75 °C for all housing and plastic

parts

125 °C in the case of devices

applied with voltage-carrying parts

and connectors

Electromagnetic

interference

System transformer Europe: safety isolating

Table 1 System data as per EN60730-1

3 EN1Z-0921GE51 R0709

Tested at 230 VAC,

with the modules in normal

condition.

transformers according to

IEC61558-2-6

U.S.A. and Canada: NEC Class-2

transformers

System Overview LION System

System Overview

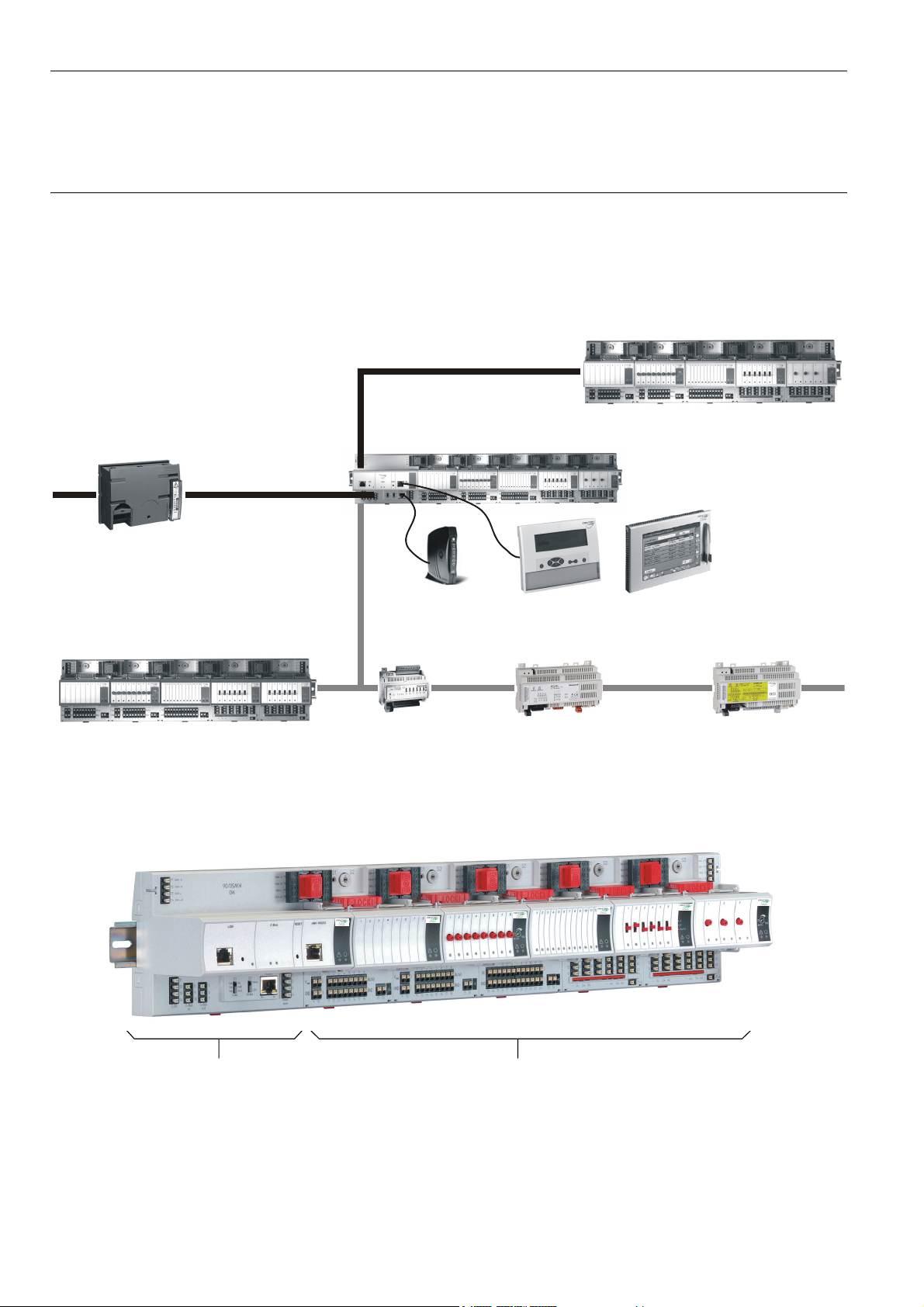

System Architecture

An LION System consists of the CLLIONLC01 Controller and various I/O modules.

The CLLIONLC01 Controller provides interface connections, which allow connection to external systems.

Auxiliary parts enable special features.

Panel I/O (CLIOPxx)

Panel Bus (<40 m)

existing XL500

controllers

C-Bus

CLLIONLC01 + CLIOxx

LonWorks Bus

LonWorks I/O (CLIOLxx)

Fig. 1 LION System architecture

CLMMI00N22 or CLMMI00N31MODEM

XFCLxxxXFCxxx SERVAL

Controller I/O Modules

Fig. 2 CLLIONLC01 Controller and I/O modules

EN1Z-0921GE51 R0709 4

LION System System Overview

X

X

X

X

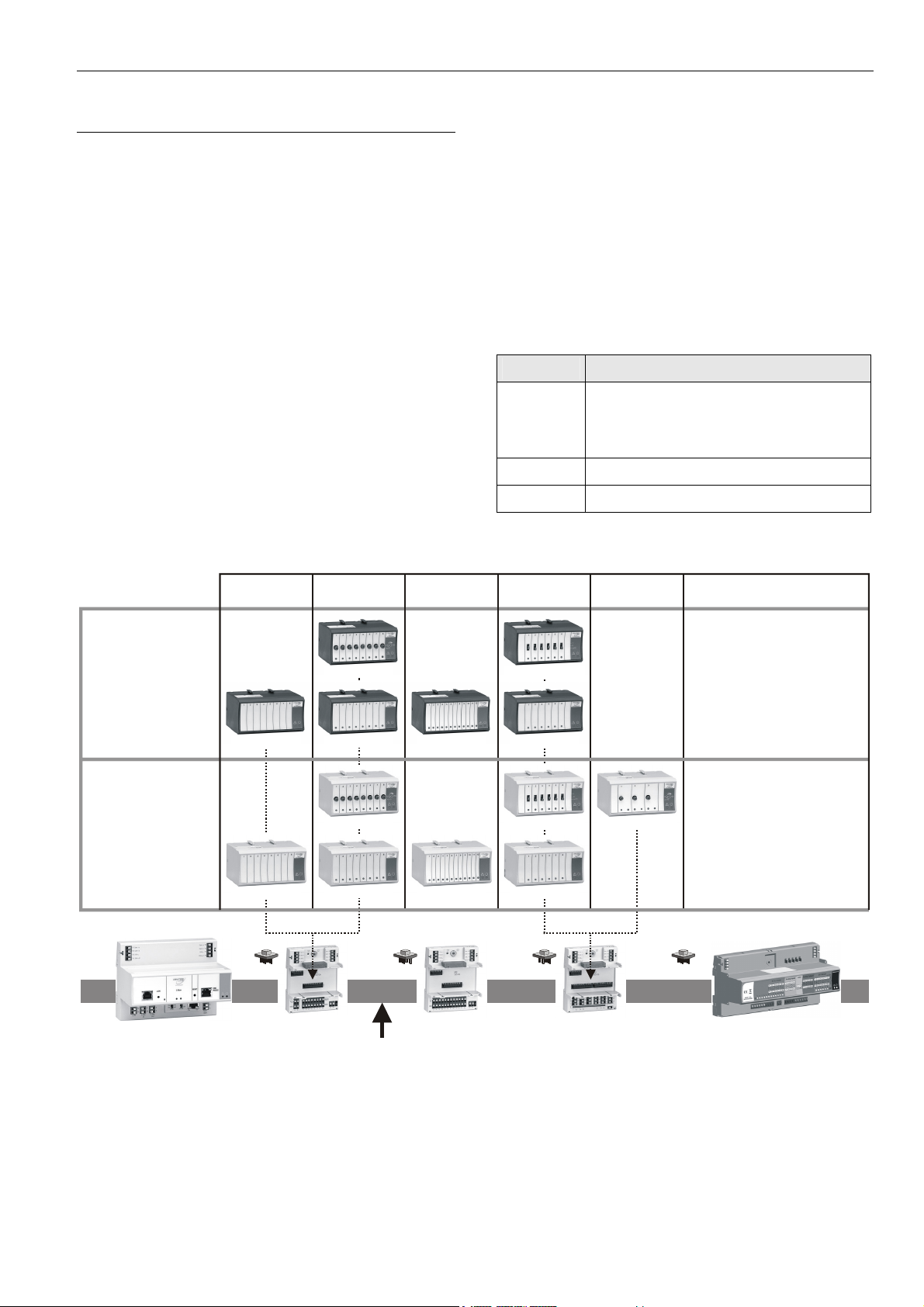

I/O Modules

Variants of Pluggable I/O Modules

There are 2 variants of pluggable I/O modules:

• Panel Bus I/O modules with communication via Panel

Bus (light gray housings)

Modules are automatically commissioned (with firmware

download) by the CLLIONLC01 Controller

• L

ONWORKS Bus I/O modules (dark gray housings) with

communication via L

compatible) for easy integration and use with 3

controllers

Mixed I/O Modules

Besides the pluggable Panel Bus I/O modules (consisting of

a terminal socket and a removable electronic module), there

are also mixed Panel Bus I/O modules. Specifically: the

CLIOP830A is a mixed Panel Bus I/O modules, featuring an

integrated terminal socket and a variety of inputs and

outputs.

Mixed Panel Bus I/O modules have a light-gray housing and

are likewise automatically commissioned (with firmware

download) by the CLLIONLC01 Controller.

ONWORKS (FTT10-A, link power

pluggable

ANALOG INPUT

pluggable

ANALOG OUTPUT

rd

-party

pluggable

BINARY INPUT

Terminal Sockets

Pluggable I/O modules are mounted on the appropriate

terminal sockets. Pluggable Panel Bus I/O modules and

pluggable L

ONWORKS Bus I/O modules use the same

terminal sockets. The terminal sockets are available with

push-in terminals (XS82…) or with screw-type terminals

(XSU82…).

Mixed I/O modules feature an integrated terminal socket.

Color Coding

To distinguish modules and components, the following color

coding is used:

Color Part

Red All of the user-accessible adjustable

mechanical parts (i.e., bridge connectors

and locking mechanism) and operating

controls (manual overrides, etc.)

Light-gray

Dark-gray

Panel Bus I/O modules

ONWORKS Bus I/O modules

L

Table 2 Color coding of LION Modules

pluggable

RELAY OUTPUT

pluggable

FLOATING

OUTPUT

MIXED I/Os

LonWorks

CLIOLR822A

BUS MODULES

CLIOL821A

PANEL

CLIOL822A

CLIOPR822A

CLIOL823A

BUS MODULES

CLIOP821A

CLLIONLC01

CLIOP822A

XS821-22

XSU821-22

CLIOP823A

LonWorks or Panel Bus

Fig. 3 Overview of I/O modules and terminal sockets

S823

SU823

CLIOLR824A

CLIOL824A

CLIOPR824A

CLIOP824A

CLIOPR825A

S824-25

SU824-25

CLIOP830A

PANEL BUS I/O MODULE

5 EN1Z-0921GE51 R0709

System Overview LION System

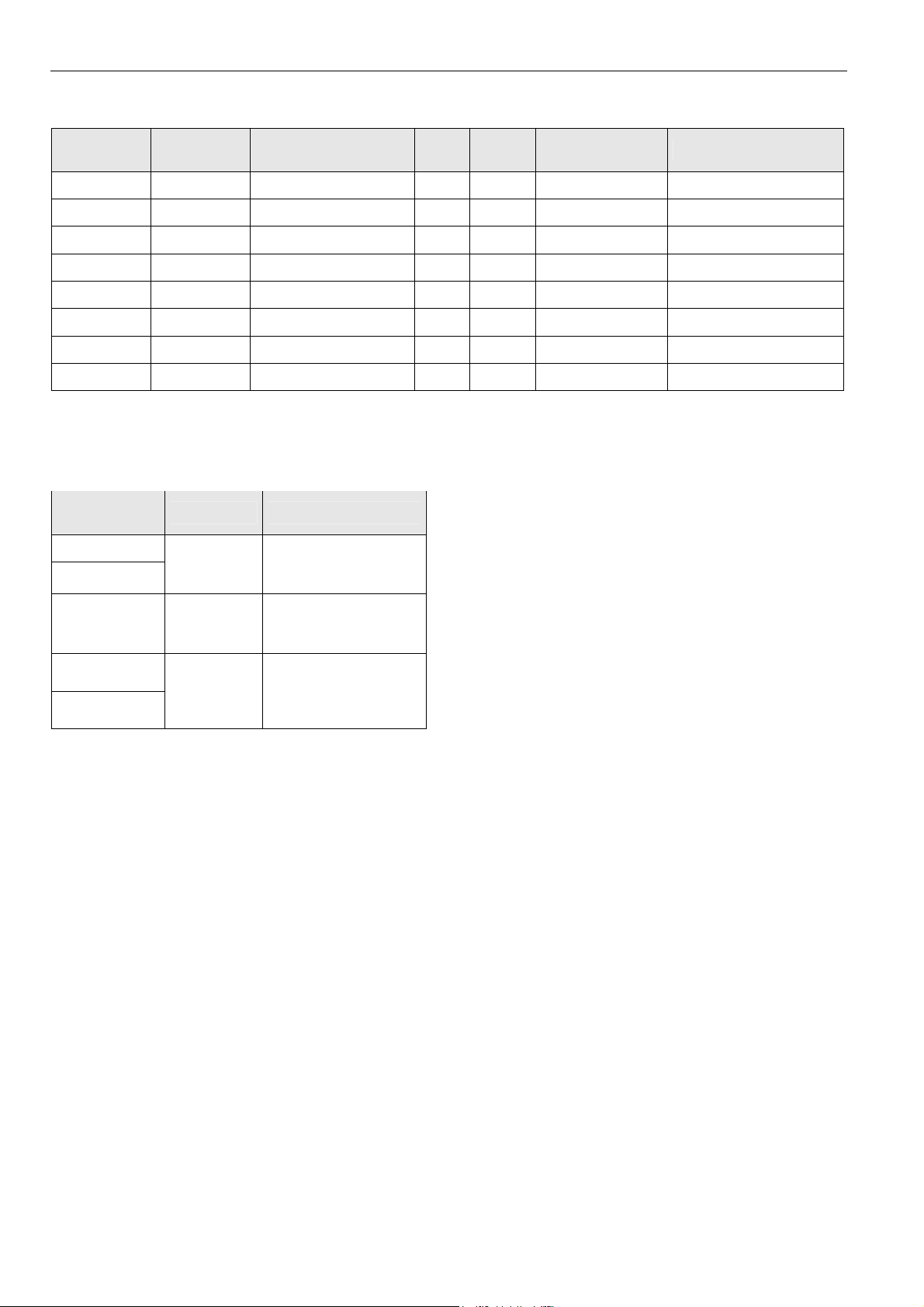

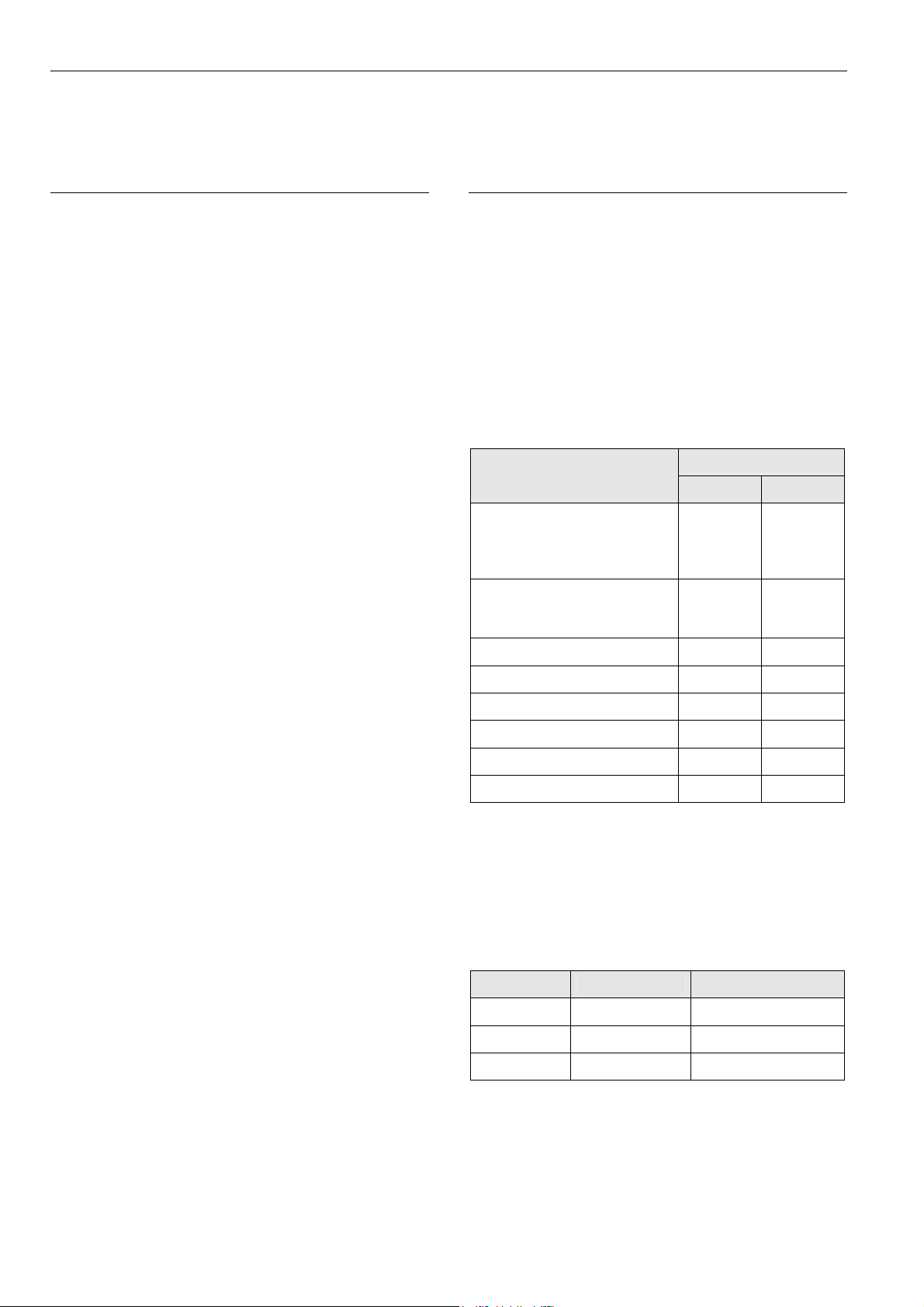

I/O Module Overview

Panel Bus

module

LONWORKS

Bus module

Description Inputs Outputs Manual controls LEDs 1)

CLIOP821A CLIOL821A Analog input module 8 – – –

CLIOP822A CLIOL822A Analog output module – 8 – 8 status LEDs

CLIOPR822A CLIOLR822A Analog output module – 8 8 Manual overrides 8 status LEDs

CLIOP823A CLIOL823A Binary input module 12 – – 12 status LEDs

CLIOP824A CLIOL824A Relay output module – 6 2) – 6 status LEDs

CLIOPR824A CLIOLR824A Relay output module – 6 2) 6 Manual overrides 6 status LEDs

CLIOPR825A – Floating output module – 3 3 Manual overrides 3 pairs of status LEDs

CLIOP830A -- Mixed I/O module 20 14 -- 18 status LEDs

1)

In addition to the power LED and service LED

2)

Changeover outputs

Table 3 Overview of I/O modules

Corresponding Terminal Sockets

I/O module

CLIOP/CLIOL…

…821

…822

…823

…824

…825

Socket Scope of delivery

XS821-22

XSU821-22

XS823

XSU823

1 terminal socket,

1 bridge connector

1 swivel label holder

1 terminal socket,

1 bridge connector

1 swivel label holder

1 terminal socket,

XS824-25

XSU824-25

1 bridge connector

1 swivel label holder

1 long cross connector

Table 4 Pluggable I/O modules and corresponding

terminal sockets

Note

In the following e.g., …822 is used to summarize all analog

output modules (Panel Bus/L

ONWORKS Bus, with/without

manual overrides)

EN1Z-0921GE51 R0709 6

LION System System Overview

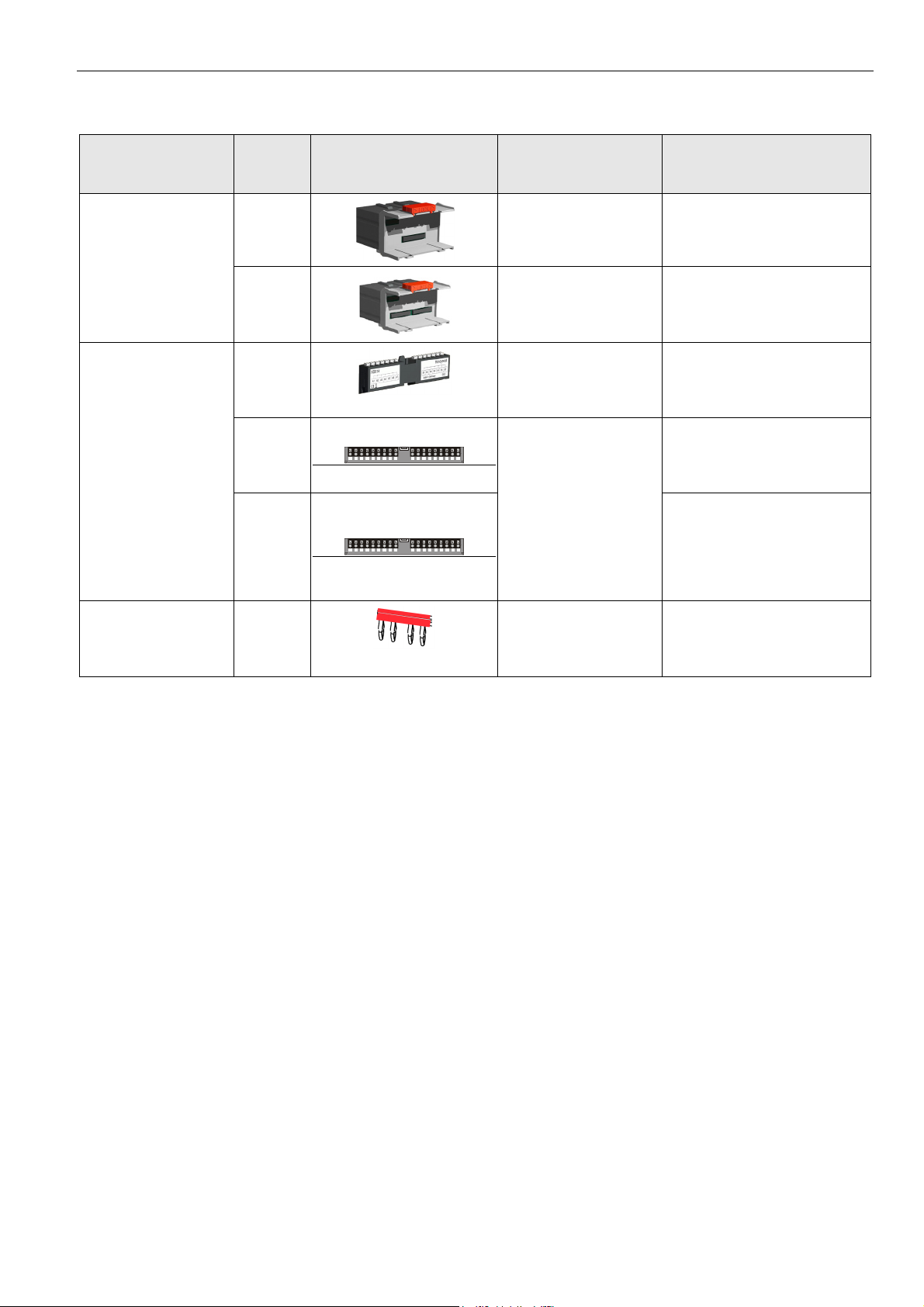

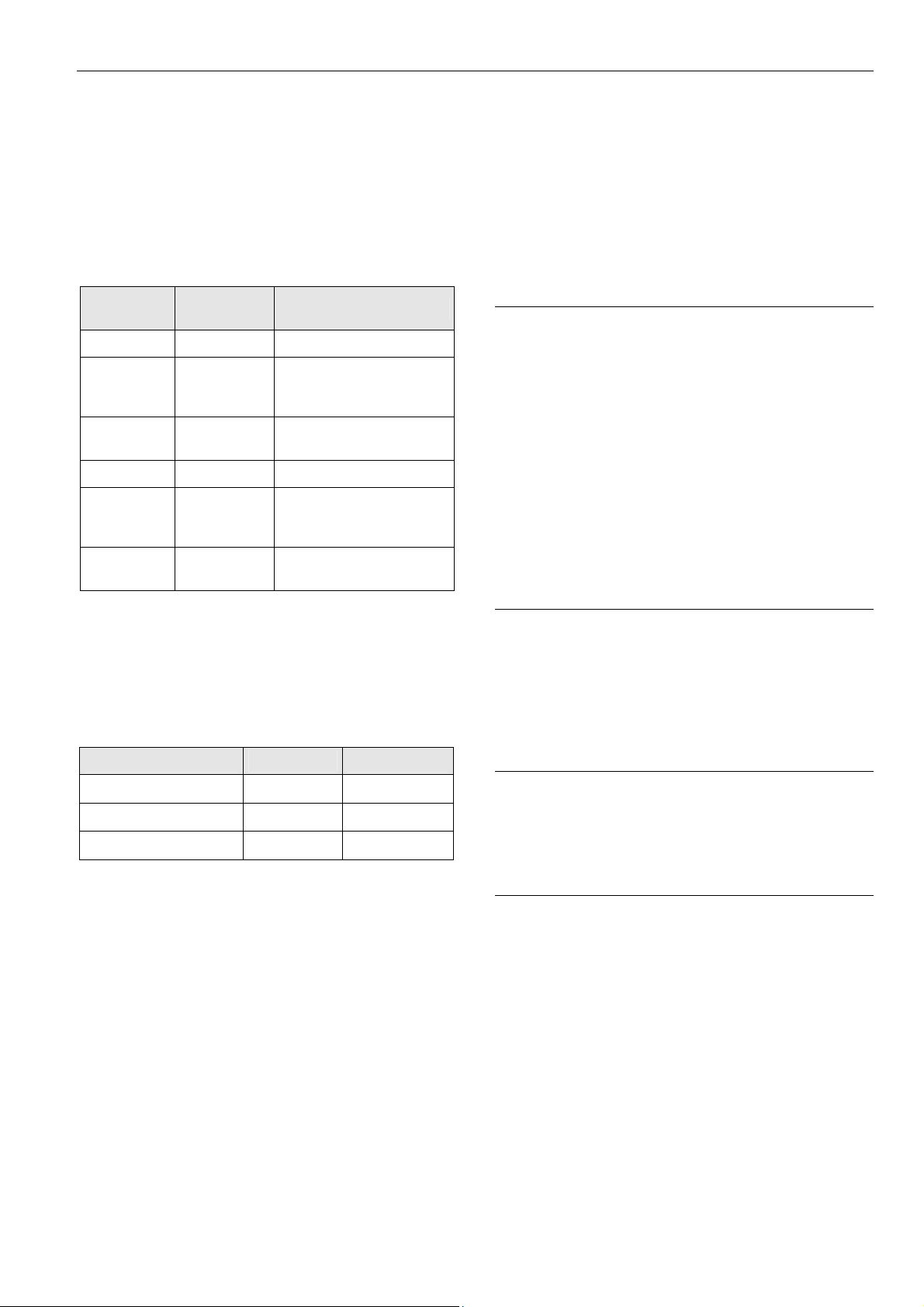

Auxiliary Parts

Corresponding

Module Type Figure

I/O modules

Information

CLIOP/CLIOL…

Manual disconnect

modules

Auxiliary terminal

package

Cross connectors,

short (yellow)

XS812

XS812RO

XS814

XS830

XS831

XS817

A1 A2A3A4

A1 B1 A2 B2

A5 A6A7A8 A9

A3 B3

B5 B6B7B8 B9

B1 B2B3B4

A5 B5 A6 B6

A4 B4 G1 G2

A8 B8

A7 B7

…821

…822

…823

…824

…825

Module allows disconnection of

individual I/O signals

Module allows disconnection of

individual I/O signals

For 24 V applications only

Two groups of 7 terminals

All pluggable LION I/O

modules

connected to each other for

redistributing voltage (see also

Fig. 94)

Two groups of nine internally-

connected push-in terminals, for

distributing signals/power (see

also Fig. 96).

CLIOP830A, only

Two groups of four pairs of

push-in terminals, for converting

0…20 mA signals into

0…10 Vdc signals, and one

push-in ground terminal per

group. (see also Fig. 98)

Connects 3 relay commons,

…824

…825

required in case of line voltage

and low voltage in the same I/O

module

Table 5 Auxiliary parts

Spare Parts

7 EN1Z-0921GE51 R0709

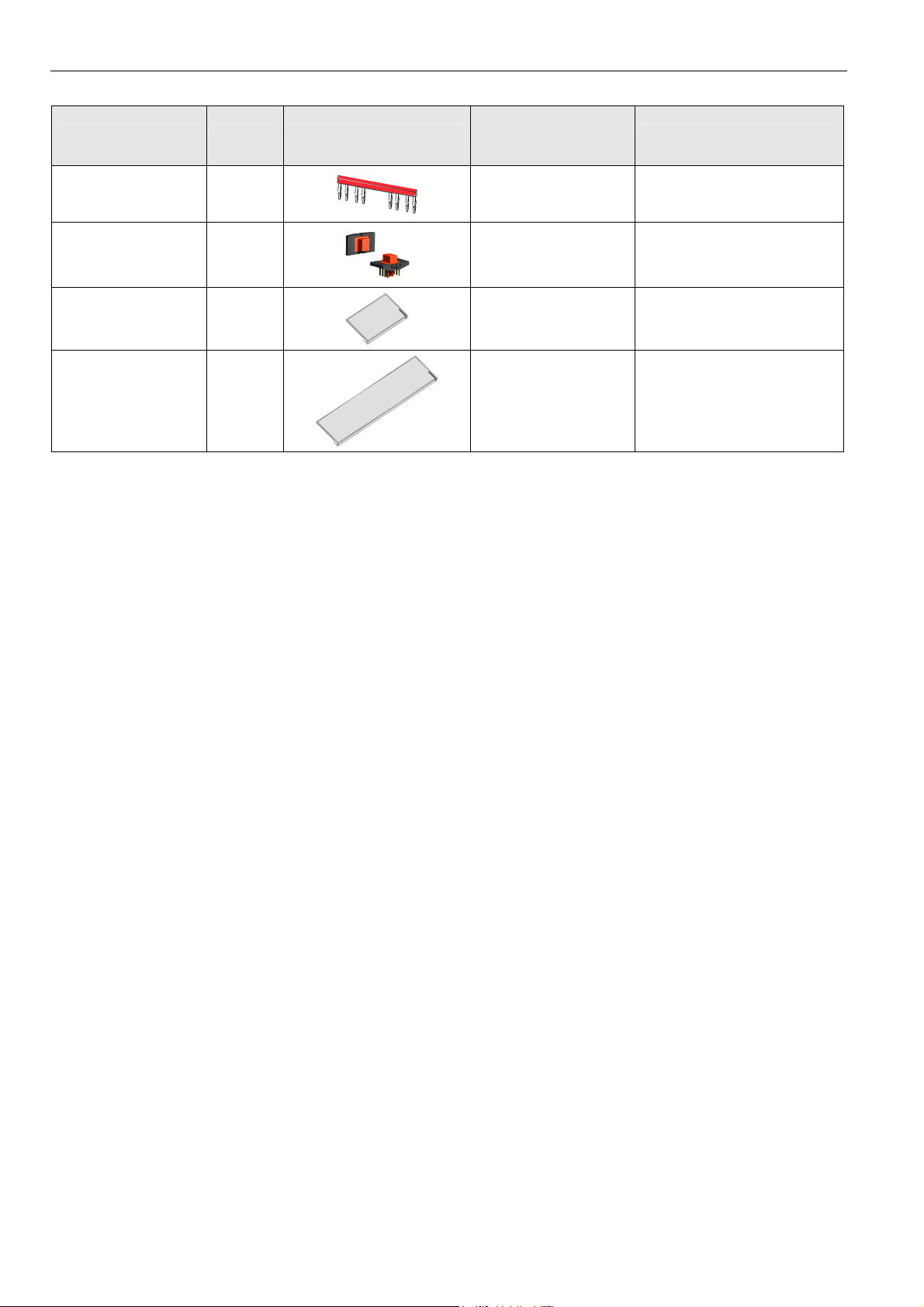

System Overview LION System

Corresponding

Module Type Figure

I/O modules

CLIOP/CLIOL…

Information

Cross connectors, long

(red)

Connector bridge XS816

Swivel label holder XAL10

Swivel label holder XAL11

Table 6 Spare parts

XS815

…824

…825

All LION I/O modules

All pluggable LION I/O

modules

CLIOP830A, only

Connects 6 relay commons

Connects CLLIONLC01 and I/O

modules

Can be plugged into socket, for

attaching label generated by

the engineering tool

Can be plugged into module,

for attaching label generated by

the engineering tool.

EN1Z-0921GE51 R0709 8

LION System System Overview

Interfaces and Bus Connections

The LION System can be connected to the following devices

and systems:

Panel Bus

• For communication with up to 16 Panel Bus I/O modules

• Polarity-insensitive

L

ONWORKS Bus

• For communication with other LONWORKS Bus devices

within the building

• FTT10, link power compatible

• Polarity-insensitive

C-Bus

• For communication with other controllers, e.g., existing

Excel 500 Controllers

HMI

• For connecting an operator interface (e.g., CLMMI00N22

or CLMMI00N31) or a laptop, e.g., for engineering

Modem

• For connecting a modem or an ISDN terminal adapter

Technical Data

System Data

Operating voltage 24 VAC, ± 20 %, 21 … 30 VDC

Max. number of C-Bus

participants

Power consumption

30

Max. 3.57 A

(1 CLLIONLC01 Controller

+ 16 I/O modules)

Standards

Protection class IP20

Product standard EMC EN 60730-2-9

Testing electrical

components

Certification CE

System transformer

Low-Voltage Device

Safety Assessment

Table 8 Standards

IEC68

The system transformer(s) must

be safety isolating transformers

according to IEC 61558-2-6.

In the U.S.A. and Canada, NEC

Class 2 transformers must be

used.

EN 60730-1

EN 60730-2-9

Operational Environment

Ambient operating

temperature

Ambient operating

humidity

Ambient storage

temperature

Ambient storage

humidity

Vibration under

operation

Dust, vibration According to EN60730-1

RFI, EMI Home environment

Table 9 Operational environment

0 … 50 °C (32 … 122 °F)

5 … 93 % rel. humidity

(non condensing)

–20 … 70 °C (–4 … +158 °F)

5 … 95 % rel. humidity

(non condensing)

0.024” double amplitude

(2 … 30 Hz),

0.6 g (30 … 300 Hz)

Push-in terminals 1.5 mm2

Screw-type terminals 1.5 mm2

Overvoltage protection

Calculated lifetime of

weakest component

under typical operating

conditions

Table 7 System data

9 EN1Z-0921GE51 R0709

All inputs and outputs are

protected against 24 VAC and

40 VDC overvoltage as well as

against short-circuiting.

MTBF

≥ 13.7 years

Planning LION System

Planning

Overview

Engineering with CARE

During CARE engineering, the type of I/O modules, terminal

assignment and module configuration are defined

depending on the application. The same applies to

engineering with COACH (which is possible starting with

COACH version 2.02).

Planning

In this step, the following has to be defined, if applicable:

• Power supply

• Fusing

• Earth grounding

• Lightning protection

• Panel Bus wiring

• Design of a L

• Design of a C-Bus network

• Useful accessories

• Cable selection

ONWORKS network

Transformer Selection

Note

In Europe the system transformer(s) must be safety isolating

transformers according to IEC61558-2-6.

In the U.S.A. and Canada, NEC Class-2 transformers must

be used.

Power Consumption

When selecting the appropriate transformer, take into

account the number of individual modules, accessories, and

field devices in determining the total power consumption.

Devices powered

CLLIONLC01 with

CLMMI00N22 (backlight ON)

and with watchdog load (max.

500 mA)

CLLIONLC01 with

CLMMI00N22 (backlight ON)

but without watchdog load

Power consumption

24 VAC 24 VDC

690 mA 640 mA

190 mA 140 mA

…821 130 mA 80mA

…822 160 mA 90 mA

…823 180 mA 130 mA

…824 140 mA 90 mA

…825 140 mA 90 mA

CLIOP830A 200 mA 95 mA

Table 10 Power consumption of LION System components

depending on power supply

Connectable Power Supplies

CentraLine CRT Series (Europe)

Transformer Primary side Secondary side

CRT 2 220/230 VAC 24 VAC, 50 VA, 2 A

CRT 6 220/230 VAC 24 VAC, 150 VA, 6 A

CRT 12 220/230 VAC 24 VAC, 300 VA, 12 A

Table 11 CentraLine CRT series transformers data

EN1Z-0921GE51 R0709

10

LION System Planning

CentraLine 1450 Series (North America)

• 50/60 Hz

• Insulated accessory outputs

• Built-in fuses

• Line transient /surge protection

• AC convenience outlet

• NEC Class-2

Part number

1450 7287

-001 120 VAC 24 VAC, 50 VA

-002 120 VAC

-003 120 VAC

-004 240/220 VAC 24 VAC, 50 VA

-005 240/220 VAC

-006 240/220 VAC

Table 12 CentraLine 1450 series transformers data

Standard Transformers (Europe, North America)

Standard commercially available transformers used to

supply power to LION Systems must fulfill the following

specifications:

Output voltage Impedance AC current

Primary side Secondary side

2 x 24 VAC, 40 VA,

and 100 VA from separate

transformer

24 VAC, 100 VA,

and 24 VDC; 600 mA

2 x 24 VAC, 40 VA,

and 100 VA from separate

transformer

24 VAC, 100 VA, and

24 VDC, 600 mA

Power Supply of Field Devices

Depending upon the power consumption of the field devices

used, it is possible to use either a single transformer to

power both the CLLIONLC01 and attached field devices, or

it may be necessary to employ an additional transformer.

See also section "Field Device Cables" on page 14 and

connection examples on page 30.

Fusing Specifications

For connection examples see description of the I/O modules

on page 40 and following.

F1 (Fusing for CLLIONLC01 and I/O Modules))

Rating: 4 A, time-lag fuse (slo-blo)

For example:

Manufacturer: Littlefuse

Type: 218004

F2 (Fusing for Active Field Devices)

Depends upon loads in use.

System Protective Earth Grounding

LION Systems comply with SELV (Safety Extra-Low

Voltage). Earth grounding is therefore not recommended.

However, if compliance with EN60204-1 is required, see

Appendix 1.

Lightning Protection

24.5 VAC to 25.5 VAC

24.5 VAC to 25.5 VAC

24.5 VAC to 25.5 VAC

Table 13 Requirements for standard transformers

RIN-APU24 Uninterruptable Power Supply

The RIN-APU24 Uninterruptable Power Supply can be wired

to power LION Systems.

See also RIN-APU24 Uninterruptable Power Supply –

Mounting Instructions (MU1B-0258GE51) for detailed wiring

diagrams.

11 EN1Z-0921GE51 R0709

≤ 1.15 Ω

≤ 0.40 Ω

≤ 0.17 Ω

max. 2 A

max. 6 A

max. 12 A

Please contact your local CentraLine representative for

information on lightning protection.

Panel Bus Topologies

• Up to 16 Panel Bus I/O modules can be controlled by a

single CLLIONLC01.

• Panel Bus I/O modules must be addressed using the

HEX switch on the terminal socket.

• Maximum distance between controller and Panel Bus

I/O module: 40 m.

• No bus termination

• Polarity-insensitive

Planning LION System

X

LONWORKS Bus Topologies

The LONWORKS Bus is a 78-kilobit serial link that uses

transformer isolation so that the bus wiring does not have a

polarity. I.e. it is not important which of the two LONWORKS

Bus terminals are connected to each wire of the twisted pair.

The L

ONWORKS Bus does not need to be shielded on the

controller module side.

The LONWORKS Bus can be wired in daisy chain, star, loop

or any combination thereof as long as the maximum wire

length requirements are met.

Configuration

The recommended configuration is a daisy chain with two

bus terminations. This layout allows for max. L

ONWORKS

Bus lengths, and its simple structure presents the least

number of possible problems, particularly when adding on to

an existing bus.

See also “L

ONWORKS Mechanisms”, Product Literature no.:

EN0B-0270GE51.

C-Bus Topologies

Accessories

Besides the auxiliary parts of Table 5 on page 7, the

following accessories are available.

Preconfigured Connection Cables

Type

XW882

XW582

+ XW586

XW884

XW885 Laptops

XW585

+ XW586

XW586 Modems

Connecting

CLLIONLC01 with

CLMMI00N22 Operator

Interface

CLMMI00N22 Operator

Interface

Adapter cable for Excel

500/600 Controllers

Laptops

Features

5 m, shielded,

RJ45 plug with clip

See XW582 and

XW586

0.2 m, shielded,

RJ45 – 9 pin sub-D

3 m, shielded,

RJ45 plug with clip

See XW582 and

XW586

1.8 m, RJ45 – 9 pin

sub-D

Via the C-Bus up to 30 C-Bus devices (e.g., controllers, etc.)

can communicate with one another and a PC central. The

C-Bus must be connected via the individual controllers

(open ring).

Note

Star connection is not allowed because uncontrollable line

reflections may occur.

Instead of LION Controllers, other C-Bus controllers (e.g.,

the Excel 500, Excel 100, PANTHER) can also be

connected.

LION

Excel 100 Excel 500

PANTHER

Fig. 4 C-Bus topology Excel 5000

Table 14 Preconfigured connection cables

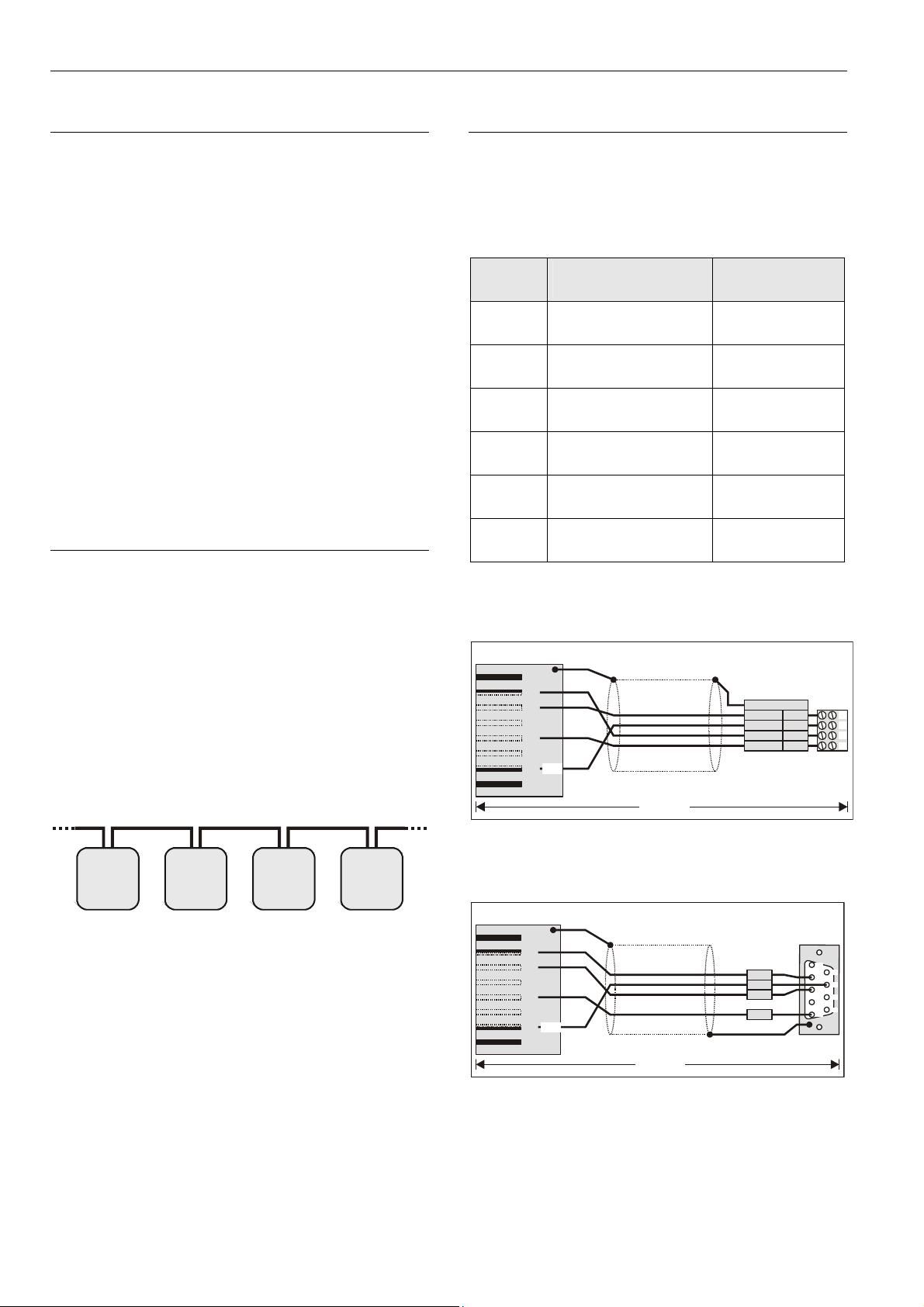

XW882 Cable Details

RJ45 plug with clip at front

12

SHIELD

3678

4

5

+5V

XW882

Fig. 5 CLLIONLC01/CLMMI00N22 cable details

XW884 Cable Details

RJ45 plug with clip at front

12

SHIELD

3678

4

5

+5V

LOOSE

ENDS

R

G

L

E

Y

R

B

G

R

W

H

sub-D female

R

x

R

T

T

x

G

N

CLMMI00N22

WIRING

TERMINALS

A

Y

n

(

d

e

)

s

u

t

o

W

O

L

T

D

x

W

O

E

V

+

5

N

R

N

E

E

D

x

N

E

T

G

I

D

RS232 plug

D

S

D

D

1

2

3

4

1

6

2

7

3

8

4

9

5

W884

Fig. 6 CLLIONLC01/Excel 500/600 cable details

EN1Z-0921GE51 R0709

12

LION System Planning

XW885 Cable Details

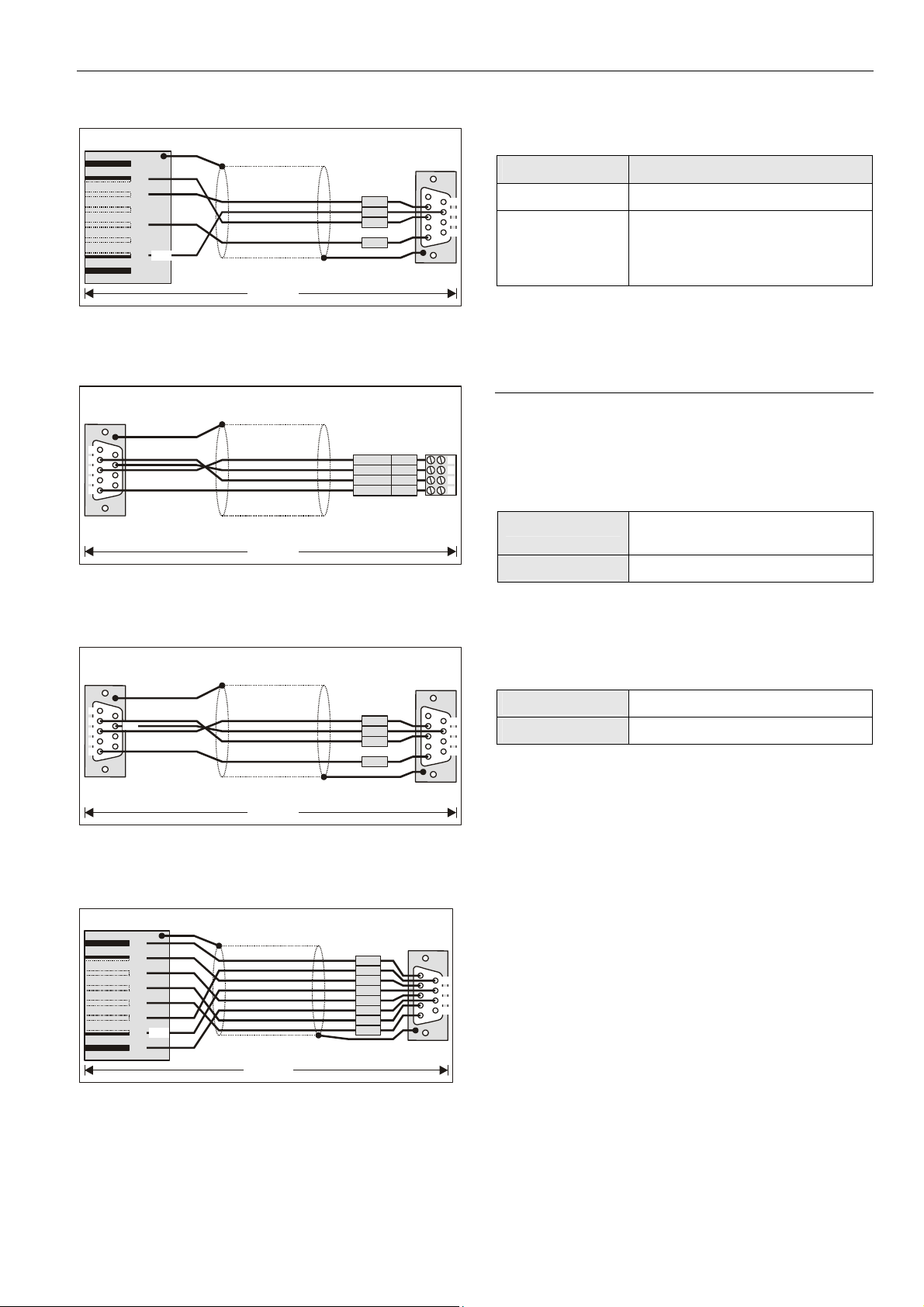

RJ45 plug with clip at front

12

SHIELD

3678

4

5

+5V

XW885

Fig. 7 CLLIONLC01/laptop cable details

XW582 Cable Details

LOOSE

to XC5010C

1

6

2

7

3

8

4

9

5

SHIELD

ENDS

XW582

Fig. 8 XW582 cable details

XW585 Cable Details

RS232 plug

sub-D female

1

6

2

7

+5V

3

8

4

9

5

SHIELD

RS232 plug

sub-D female

D

x

R

R

S

T

T

D

x

D

N

G

CLMMI00N22

WIRING

TERMINALS

W

O

L

L

E

T

Y

B

G

W

D

x

W

O

R

E

V

+

5

N

R

N

E

E

D

R

x

N

E

T

G

I

D

H

RS232 plug

sub-D female

R

D

x

R

S

T

T

D

x

D

N

G

LONWORKS Bus Termination Modules

Type Description

1

209541 LONWORKS Bus termination module

6

2

7

3

8

4

5

9

XAL-Term

L

ONWORKS connection and

termination module, which can be

mounted on DIN rails and in fuse

boxes

Table 15 LONWORKS Bus termination modules

Cable Specifications

Power Supply Cables

When checking the length of the power supply cable, the

1

2

3

4

1

2

3

4

5

connection cables to all I/O modules must be taken into

account.

Max. length 3 m (per side of the controller),

see Fig. 33 on page 26

Cross section

min. 0.75 mm

2

(AWG 18)

Table 16 Power supply cables specification

Panel Bus Cables

Max. length

6

7

Cable type

8

9

Table 17 Panel Bus cables specification

40 m

twisted pair, e.g., J-Y-Y 2 x 2 x 0.8

XW585

Fig. 9 XW585 cable details

XW586 Cable Details

RJ45 plug with clip at front

12

SHIELD

3678

4

5

+5V

XW586

RS232 plug

sub-D male

D

C

D

R

S

D

D

x

R

S

R

T

T

D

x

S

T

C

D

T

R

G

D

N

1

6

2

7

3

8

4

9

5

Fig. 10 XW586 cable details

13 EN1Z-0921GE51 R0709

Planning LION System

LONWORKS Bus Cables

Cable type Max. bus length

Belden 85102 (plenum) 2700 m (8900 ft)

Belden 8471 (non-plenum) 2700 m (8900 ft)

Level IV, 22 AWG 1400 m (4600 ft)

JY (St) Y 2 x 2 x 0.8 900 m (3000 ft)

TIA568A Cat. 5 24AWG, twisted pair 900 m (3000 ft)

Table 18 Doubly-terminated bus specifications

Notes

• The cable types listed above are as recommended by

Echelon in their FTT-10A User Guide.

• The cable recommended by CentraLine is the level IV,

22 AWG, solid core, non-shielded cable.

• Belden part numbers are 9H2201504 (plenum) and

9D220150 (non-plenum).

FTT Specification

The FTT specification includes two components that must

be met for proper system operation:

• The distance from each transceiver to all other

transceivers and to the termination must not exceed the

max. node-to-node distance.

• If multiple paths exist, the maximum total wire length is

the total amount of wire used.

Cable type

Max. node-tonode distance

Max. total wire

length

Note

In the event that the limit on the total wire length is

exceeded, the FTT physical layer repeaters (FTT 10A) can

be added to interconnect segments. This increases the

overall length by an amount equal to the original

specification for that cable type and bus type for each

repeater used.

For example, adding repeaters for a doubly-terminated bus

using JY (St) Y 2 x 2 x 0.8 cable increases the maximum

length 900 m (3000 ft) for each repeater.

Field Device Cables

Cross-sectional area

Type of signal

24 VAC power

0…10 V signals 0.081 – 2.08 mm2 (28 – 14 AWG)

Table 20 Cable sizing for connection of field devices

For wiring field devices see page 30.

≤ 100 m (300 ft)

(Fig. 40 on p. 30)

one transformer

1.5 mm2

(16 AWG)

≤ 400 m (1300 ft)

(Fig. 41 on p. 30)

separate

transformers

not allowed for

> 100 m (300 ft)

Belden 85102 500 m (1650 ft) 500 m (1650 ft)

Belden 8471 400 m (1300 ft) 500 m (1650 ft)

Level IV, 22AWG 400 m (1300 ft) 500 m (1650 ft)

JY (St) Y 2 x 2 x 0.8 320 m (1050 ft) 500 m (1650 ft)

TIA568A Cat. 5

24AWG, twisted pair

Table 19 Free topology (singly-terminated) specifications

250 m (825 ft) 450 m (1500 ft)

NOTICE

Unpredictable reflections on the bus due to step change

in line impedance characteristics!

► Do not use different wire types or gauges on the same

ONWORKS network segment.

L

EN1Z-0921GE51 R0709

14

LION System Planning

C-Bus Cables

Note

Observe national regulations for C-Bus cables!

• For Europe only shielded cable is permitted.

• For the U.S. shielded or unshielded cable can be used.

Cable type Description Recommended for

J-Y-(ST)Y

2 x 2 x 0.8

A-Y-(ST)Y

2 x 2 x 0.8

AK 3702

AK 3740A shielded

Belden 9842 twisted pair Europe, US also possible

Belden 9841 shielded US

AK 3702

AK 3740A shielded

Table 21 C-Bus cable types

Maximum Cable Length

The maximum C-Bus cable length is 1200 m (4000 ft).

See section "C-Bus Topologies" on page 12.

shielded,

twisted pair

shielded,

twisted pair

unshielded,

twisted pair

unshielded,

twisted pair

Europe, inside cabinet

Europe, outside cabinet

US

not approved for Europe

US (low-cost)

not approved for Europe

US

not approved for Europe

US (low-cost)

not approved for Europe

15 EN1Z-0921GE51 R0709

Planning LION System

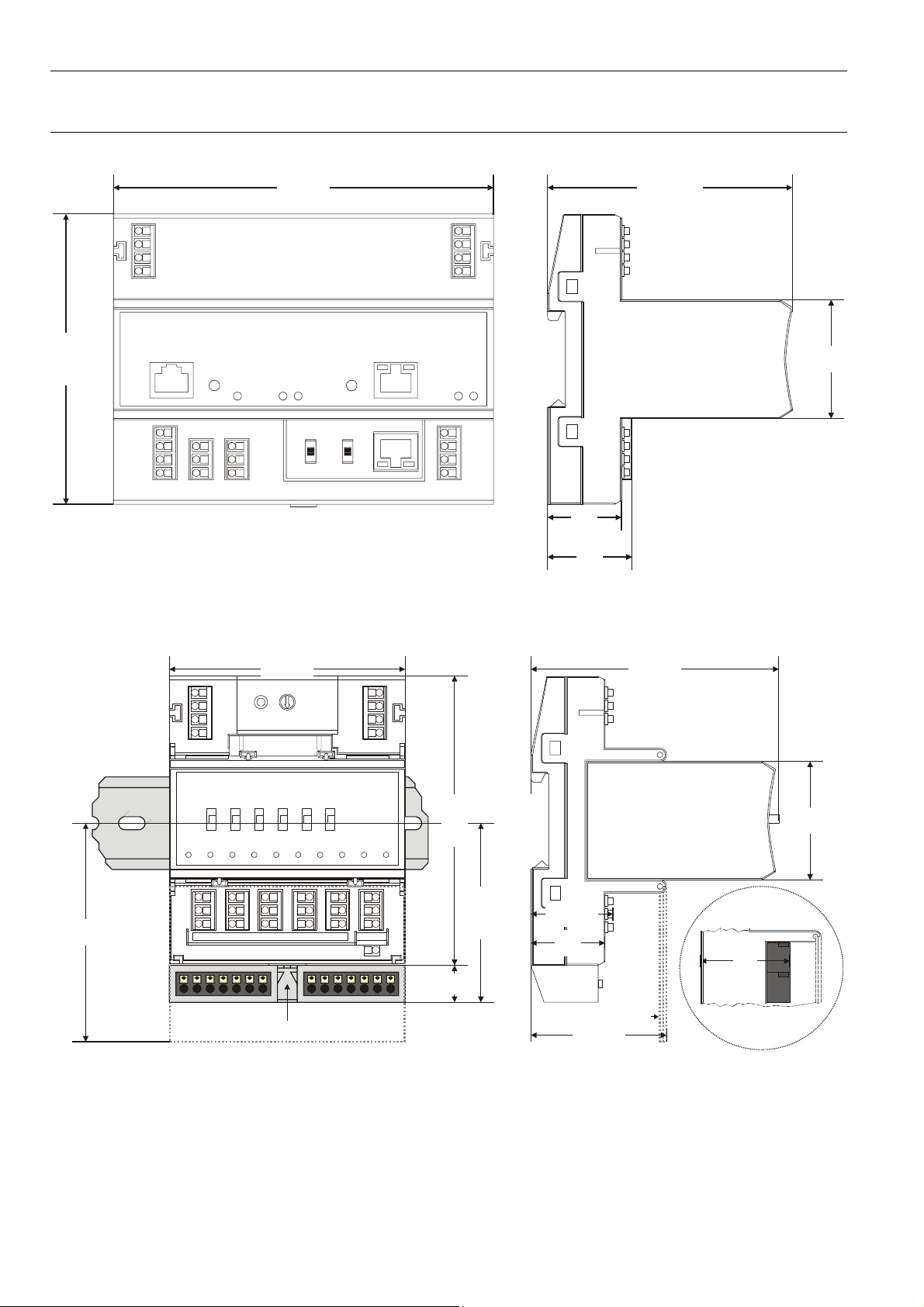

Dimensions

Controller Module

144

110

Fig. 11 Controller module, outside dimensions (in mm)

28

32

92.75

45

Pluggable I/O Modules

89.5 94.1

LOCK

45

83

110

67.5

30.6

28

SCREW-TYPE

TERMINALS

38

14

XS814 Aux. Terminal Package (optional)

SWIVEL LABEL HOLDER

51.5

Fig. 12 Pluggable I/O modules (shown with manual overrides), including XS814 Aux. Terminal Package, dimensions (in mm)

EN1Z-0921GE51 R0709

16

LION System Planning

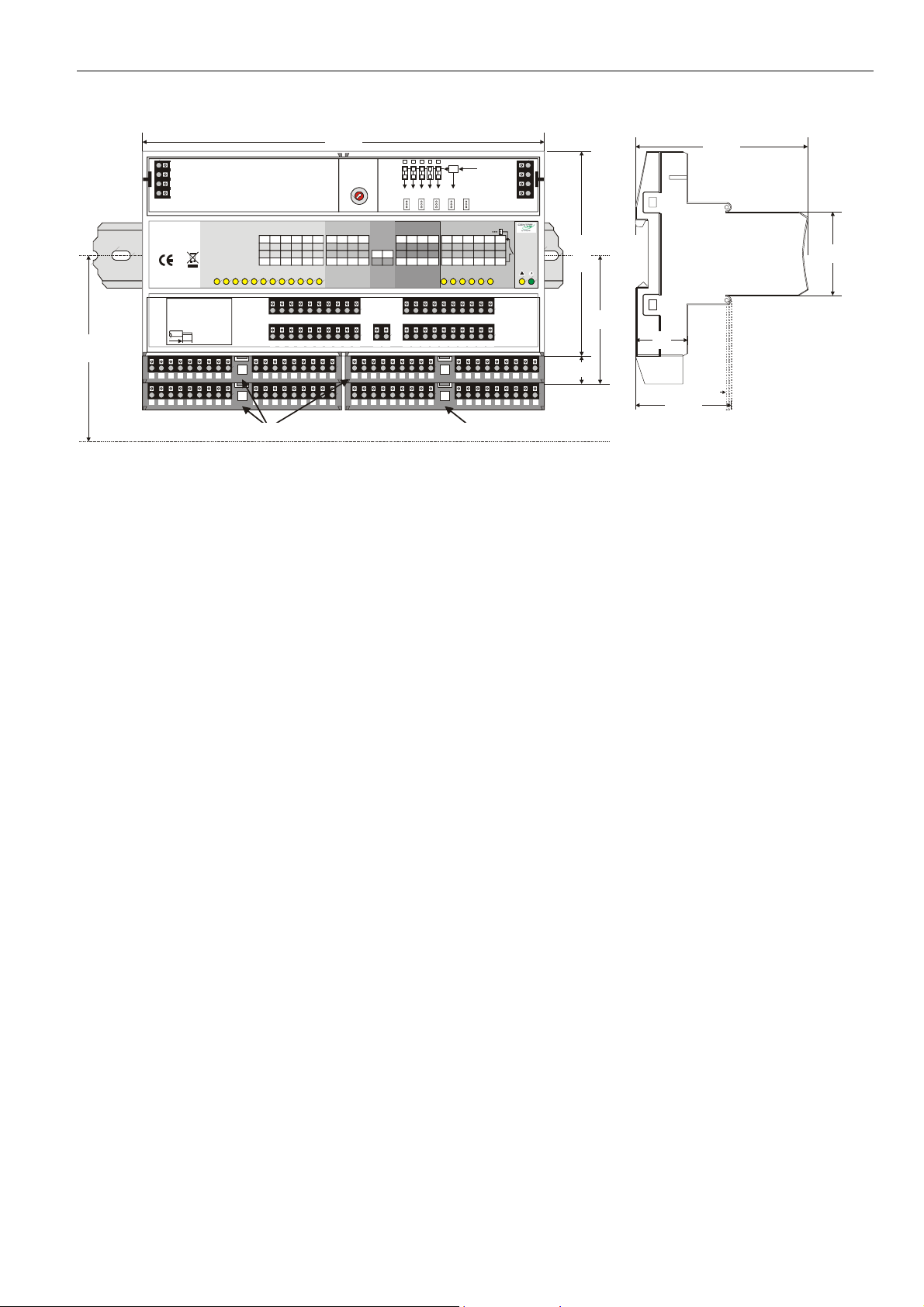

Mixed I/O Module

216

75

71

COM a

COM b

72

24V~

100

73

24V~0

74

1 12 23 34 45 56 67

Install. Instr.

DI

EN1B-0375GE51

CLIOP830A

12 BI / 8 AI / 8 AO / 6 RO

24V, 15VA, T50

0706AX0001-XFU830A

8

Made in Germany

0532

A5 A6 A7 A8 A9

A1 A2A3A4

CLEARANCE

A1 A2 A3 A4 A5 A6 A7 A8 A9 B1 B2 B3 B4 B5 B6 B7 B8 B9

A

C

Binary Inputs

B8 B9 B10

B7

B11B12

7

8 9 10

11 12

1 2 3 4 5 6

B5 B6

B1 B2B3B4

8 9310411512

7 8 9

10 11 12 17 18 19 20

1 21 222324

2

B5 B6 B7 B8 B9

B1 B2B3B4

4

5

3

6

2

7

24V for relay 1...5

1

8

0

9

S2

F

A

E

B

C

D

J1 J2 J3 J4 J5

Analog Inputs Analog Outputs 24V Relays

AI6

AI7

18 19 20

AI3

GND

AI8

AO5

AO6 AO7 AO8

25

262728 35

G1 G2

21 22 23 24

AI4 41

42

AO1 AO2 AO 3 AO4 NO1 NO2 NO3 NO4 NO5 NO6

AI5

17

13 14 15 16

AI1 AI2

25 26 27 28 35 36 37 38 39 40

6 131415 16

41 42

A5 A6 A7 A8 A9

A1 A2A3A4

A1 B1 A2 B2 A3 B3 A4 B4 G1 G2A5 B5 A6 B6 A7 B7 A8 B8

D = XS831 Aux. Terminal Package (optional)A, B, and C = XS830 Aux. Terminal Packages (optional)

Fig. 13 Mixed I/O Module CLIOP830A (shown with four auxiliary terminal packages), dimensions (in mm)

External

COM a

40

24V

COM b

IN3

IN1 IN2

IN4

36 37 38 39 40

29 30 31 32 33 34

29 30 31 32 33 34

B

B1 B2B3B4

D

24V~

24V~0

IN5 IN6

DO

B5 B6 B7 B8 B9

76

77

78

!

110

69

28

15

SWIVEL LABEL HOLDER

92.5

45

51.5

17 EN1Z-0921GE51 R0709

Mounting/Dismounting Modules LION System

A

Mounting/Dismounting Modules

WARNING

Risk of electric shock or equipment damage!

► Do not touch any live parts in the cabinet.

► Disconnect the power supply before you start to install

the LION System.

More than one disconnect switch may be required to deenergize the system.

► Do not reconnect the power supply until you have

completed the installation.

Note

The terminal socket of each pluggable I/O module can be

mounted and wired before inserting and locking the

corresponding electronic module.

1 2

1:ABCDFERTAQWESDERT1

2:ABCDFERTAQWESDERT2

3:ABCDFERTAQWESDERT3

4:ABCDFERTAQWESDERT4

5:ABCDFERTAQWESDERT5

71 COM a

72 COM b

73 24V

~

74 24V 0

~

C-BUS RESET

LON

8765 4 32 1 8765 4 32 1

11 1

S1 S2

9.6k all

12 285

76k

13 396

76k

14 410 7

C-Bus

C-Bus

C-Bus

LON

out

in

4

71 COM a

72 COM b

73 24V

74 24V 0

1

AAA

21

11

22

12

23

13

14 4424 5434 64 25

PRESS

COM a

6:ABCDFERTAQWESDERT6

COM b

7:ABCDFERTAQWESDERT7

8:ABCDFERTAQWESDERT8

24V

~

24V 0

~

PRESS

PC/HMI

!

Modem

Panel

8765 4 32 1

mid

LON

end

I/O Bus

Rx Tx

Power/

Alarm

5678

1234

21

22 12345678

AUX

GND GND

9

10 11 12 13 14 15 16 17 18 25 26

5

PRESS

S1 S2

5

4

3

6

2

7

1

8

0

9

F

A

E

B

D

C

~

~

3

2

31

41

51

32

42

52

33

43

53

PRESS

1234

0

100

AUTO

AAAAAAAA

!

21

22 12345678

616261

62

AUX

6363

GND GND

9

10 11 12 13 14 15 16 17 18 25 26

S1 S2

5

4

3

6

2

1

0

F

E

B

D

C

5678

7

8

9

A

Fig. 14 CLLIONLC01 and I/O modules mounted on

multiple DIN rails

!

AI/AOV

PRESS

0

UTO

!

AI/AOV

1:ABCDFERTAQWESDERT1

2:ABCDFERTAQWESDERT2

3:ABCDFERTAQWESDERT3

4:ABCDFERTAQWESDERT4

5:ABCDFERTAQWESDERT5

6:ABCDFERTAQWESDERT6

7:ABCDFERTAQWESDERT7

8:ABCDFERTAQWESDERT8

5 6 7 8 9 10

1 234

123456789101112

BI

GND

13 14 15 16 17 18 19 20 21 22 23 24 25 26

S1 S2

PRESS

1234

100

21

31

11

22

32

12

23

33

13

14 4424 5434 64 25

6

11 12

!

5

4

3

6

2

7

1

8

0

9

F

A

E

B

D

C

56

--1

--0

--AUTO

!

41

51

616261

42

52

62

43

53

6363

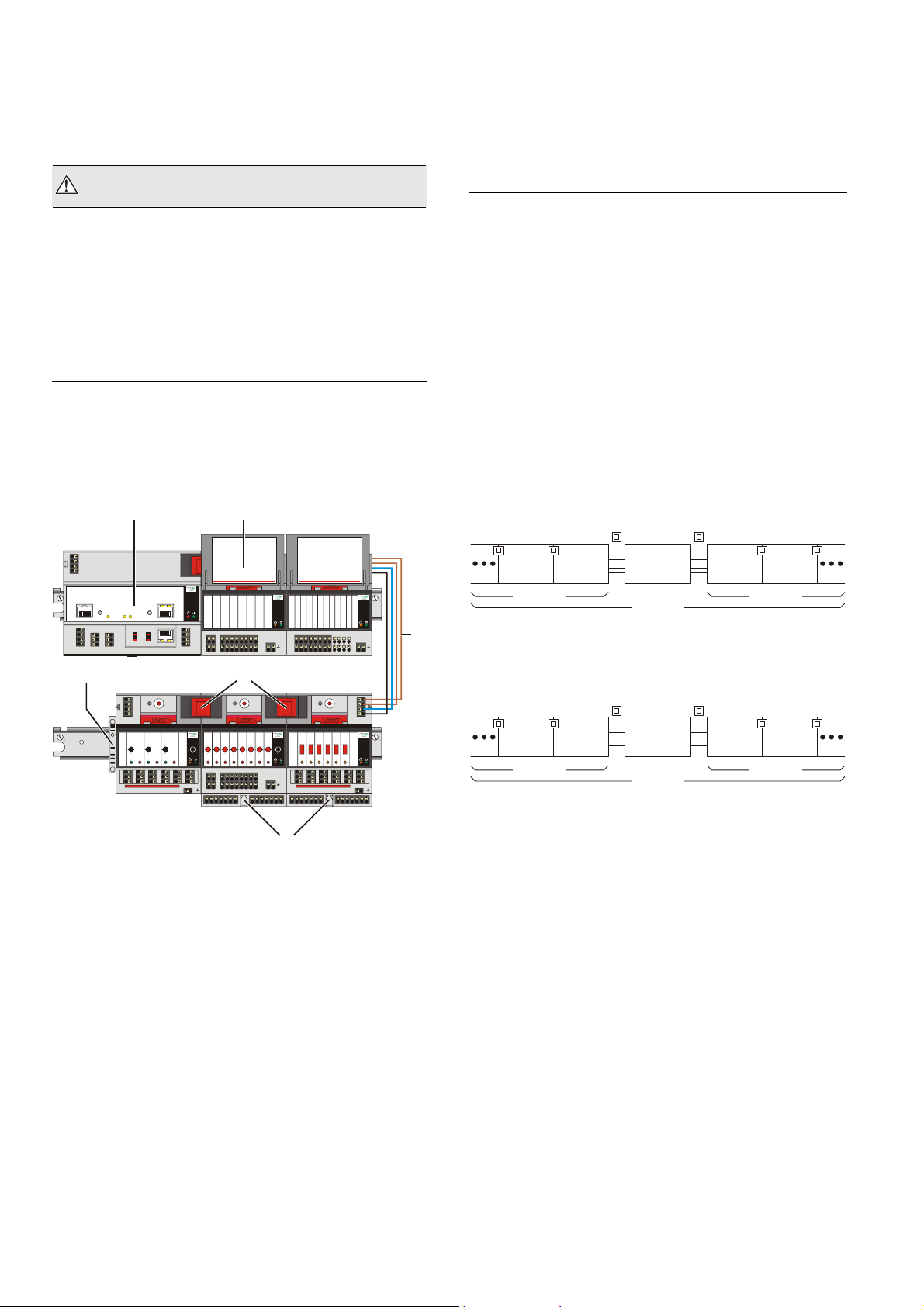

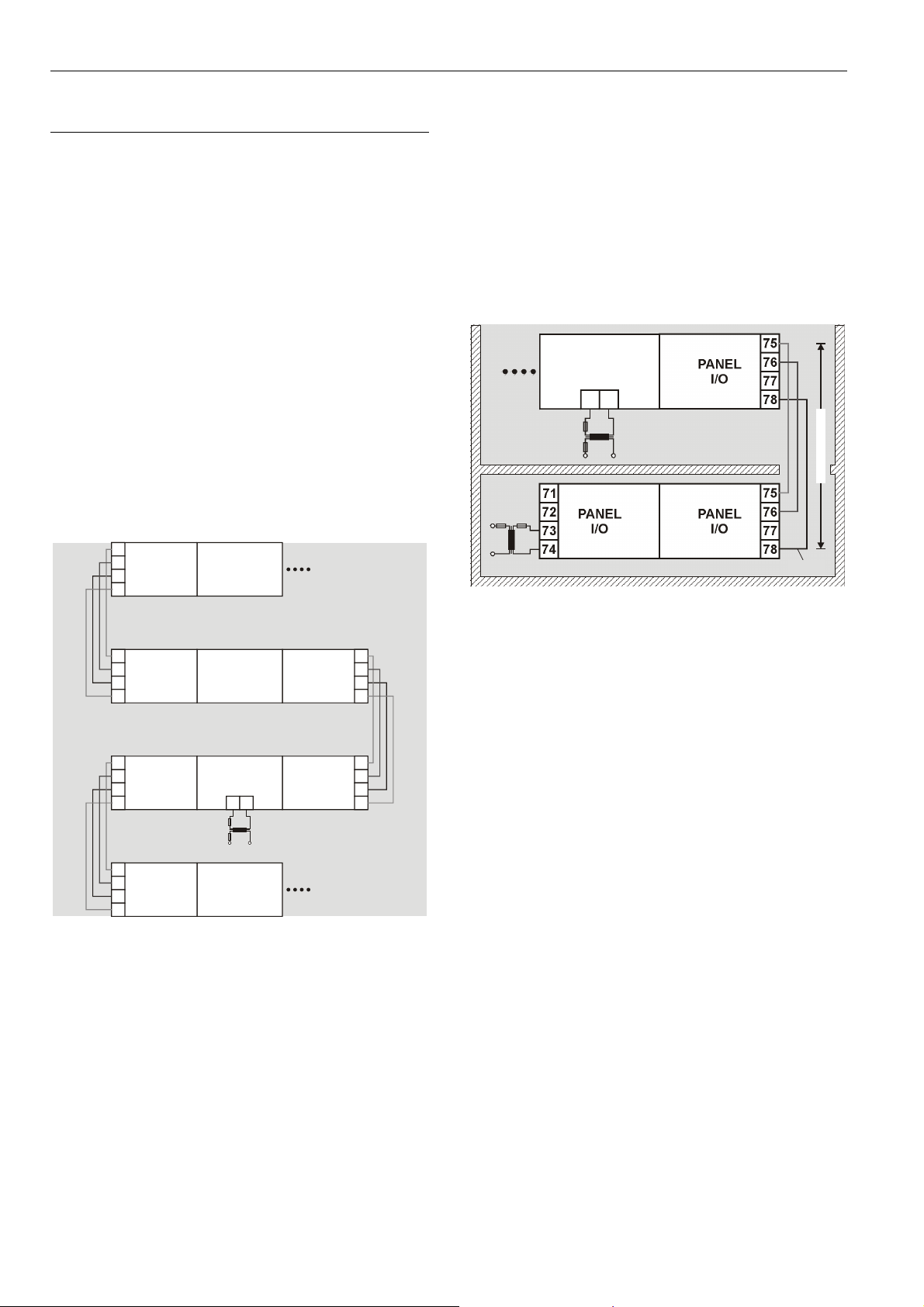

Mounting/Dismounting Controller/Sockets

Mounting Sockets

Notes

• When using both Panel Bus and LONWORKS Bus I/O

modules in a LION System, group both Panel Bus

modules (light gray) and LONWORKS Bus I/O modules

(dark gray), e.g., on different rails.

• Up to 10 Panel Bus I/O modules can be mounted to one

side of the controller. In total, up to 16 Panel Bus

I/O modules can be mounted to one controller.

• The CLLIONLC01 and the mixed Panel Bus I/O module

are mounted on the DIN rail in the same way as a

terminal socket.

PAN EL

BUS

3

Fig. 15 Max. number of Panel Bus I/O modules

I/O

max. 10

PANEL

BUS

I/O

CLLIONLC01

max. 16

LonWorks

BUS I/O

Fig. 16 Max. number of L

max. 10

LonWorks

BUS I/O

CLLIONLC01

max. 20

ONWORKS Bus I/O modules with

power supply via CLLIONLC01

PAN EL

BUS

I/O

LonWorks

BUS I/O

PAN EL

BUS

I/O

max. 10

LonWorks

LonWorks

BUS

BUS I/O

I/O

max. 10

Legend

1 CLLIONLC01

2 Swivel label holder

3 Cable connection

4 Stopper (from 3

rd

-party supplier)

5 Bridge connectors

6 Auxiliary terminal package

EN1Z-0921GE51 R0709

18

LION System Mounting/Dismounting Modules

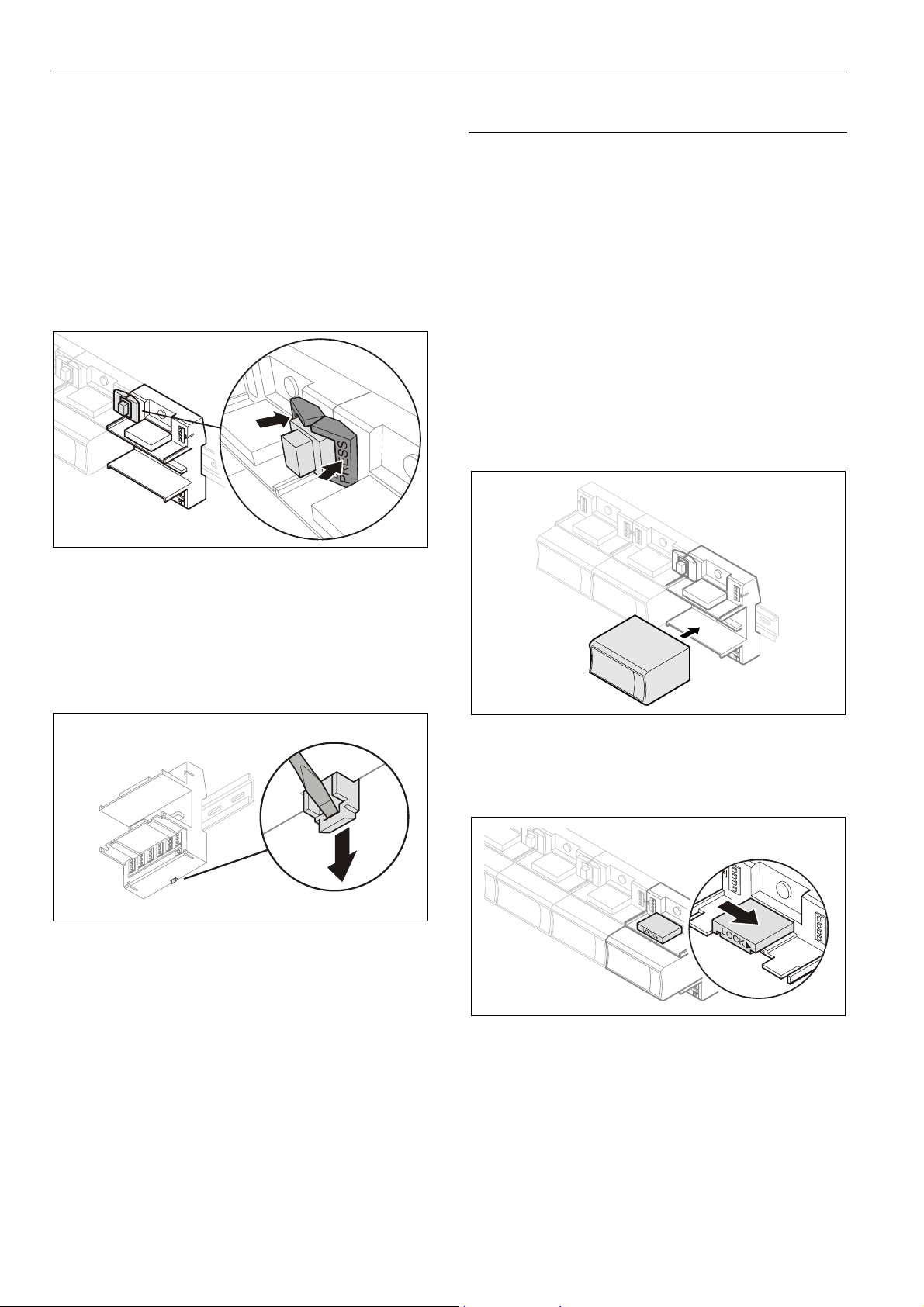

► Angle the terminal socket at the upper edge of the DIN

rail until it snaps in.

► Swing the terminal socket down and apply gentle force

until it snaps into position with an audible "click".

► Position controller module and terminal sockets flush with

one another along the rail.

► If desired, mount stoppers at the ends of the rail to

prevent sliding.

Connecting Sockets

Controller, terminal sockets, and mixed I/O modules on the

same DIN rail can be connected mechanically and

electrically with bridge connectors.

Controller and terminal sockets on different DIN rails must

be connected using cables, see Fig. 14 and page 25.

NOTICE

Risk of malfunction!

► Wire Panel Bus I/O modules and LONWORKS Bus

I/O modules separately.

► When using both Panel Bus and LONWORKS Bus

I/O modules in a LION System, L

I/O modules must be connected to the controller via

LON terminals 11 … 14.

Position the bridge connector on terminals 71 … 74 of the

right hand terminal socket or mixed I/O module or controller

and on terminals 75 … 78 of the left hand terminal socket or

mixed I/O module or controller. Then press the bridge

connector down.

ONWORKS Bus

Fig. 17 Mounting terminal sockets

Note

Take care to not bend the Omega clamp, which serves to

establish the electrical contact with the DIN rail and which

located on the back of the terminal socket.

Fig. 18 Connecting terminal sockets with bridge

connector

Notes

• Bridge connectors transmit both communication signals

and power supply between modules.

• Removing bridge connectors will interrupt the trans-

mission of both communication signals and power supply

between the modules.

19 EN1Z-0921GE51 R0709

Mounting/Dismounting Modules LION System

Dismounting Sockets

Disconnecting Sockets

Release all bridge connectors before removing the controller

module and/or the terminal sockets and/or mixed I/O

modules from the DIN rail.

► Press down at the same time both the gray side wings

next to the red button and then pull the bridge connector

out of the module.

Fig. 19 Releasing bridge connectors

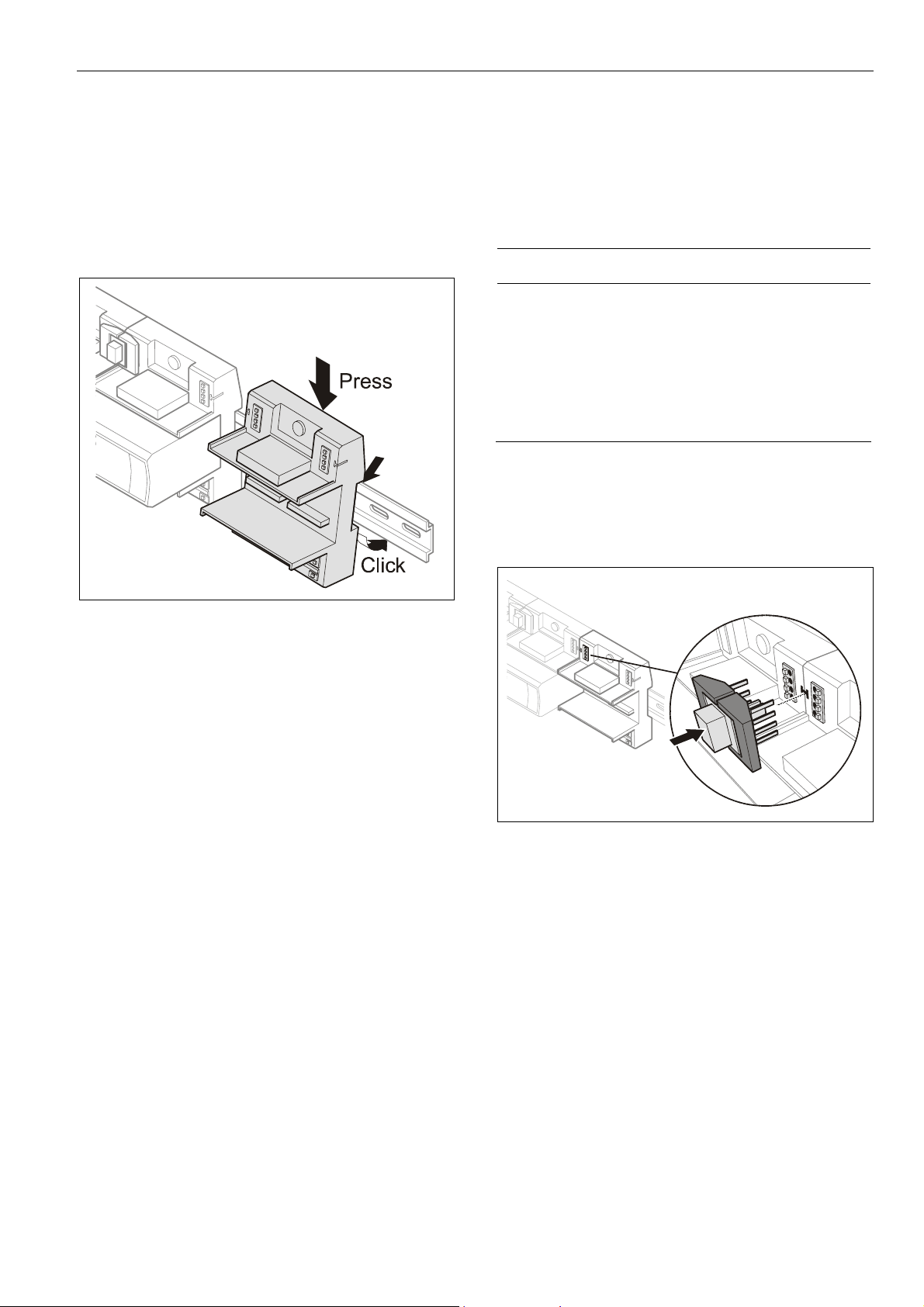

Mounting/Dismounting Electronic Modules

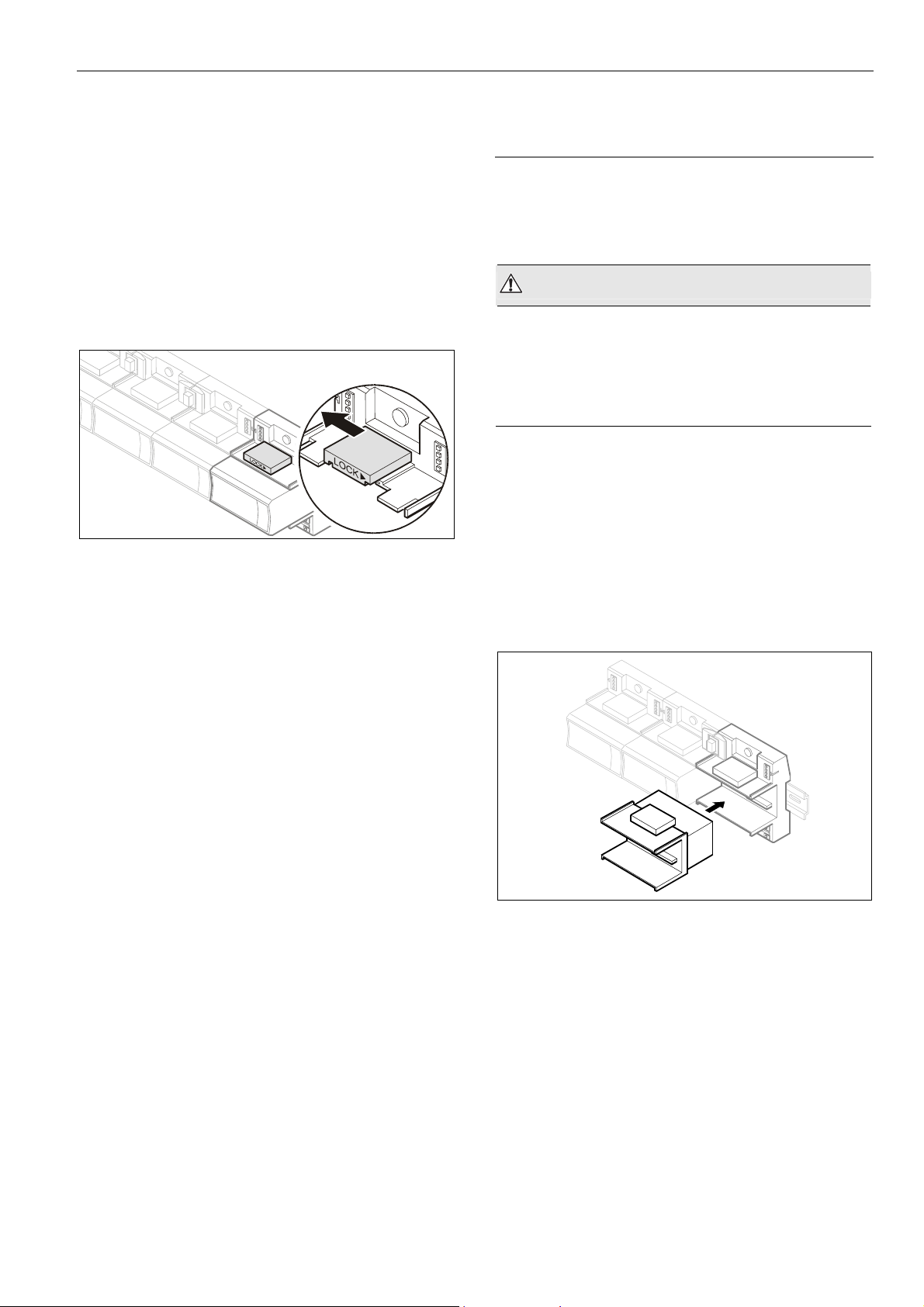

Mounting Electronic Modules

Note

Electronic modules can be removed from the socket or

inserted into the sockets without switching off the power

supply. The behavior of connected field devices must be

taken into consideration.

► Make sure that terminal socket und electronic I/O module

match; see Table 4 on page 6.

► Make sure that the red locking mechanism is in the open,

i.e., left, position.

► Gently push the electronic module onto the terminal

socket until snug.

Dismounting Controller / Terminal Sockets / Mixed I/O

Modules

► Insert a screwdriver into the latch on the underside of the

module and lever the red latch 2–3 mm downwards. The

module can then be swung away from the rail.

Fig. 20 Releasing latch

Fig. 21 Inserting the electronic module

► Lock the red locking mechanism by sliding it to the right.

Fig. 22 Locking the electronic module

Note

The red locking mechanism will not close if the electronic

module is not properly mounted.

EN1Z-0921GE51 R0709

20

LION System Mounting/Dismounting Modules

Dismounting Electronic Modules

Note

Electronic modules can be removed from the socket or

inserted into the sockets without switching off the power

supply. The behavior of connected field devices must be

taken into consideration.

► Open the red locking mechanism by sliding it to the left

and then gently pull the electronic module out of the

terminal socket.

Fig. 23 Dismounting the electronic module

Mounting/Dismounting Manual Disconnect

Modules

XS812 and XS812RO Manual Disconnect Modules are

mounted on the terminal socket appropriate for the

electronic module, see Table 4 on page 6. The electronic

module is mounted onto the manual disconnect module.

WARNING

Risk of electric shock or equipment damage!

The XS812RO Manual Disconnect Module is designed

for 24 V applications only!

► Never use the XS812RO Manual Disconnect Module with

line voltage.

Mounting Manual Disconnect Modules

► Make sure that manual disconnect module, electronic

module and terminal socket match, see Table 4 on

page 6.

► Make sure that the red locking mechanism is in the open,

i.e., left, position.

► Gently push the manual disconnect module onto the

terminal socket until snug.

► Lock the red locking mechanism by sliding it to the right.

Fig. 24 Mounting the manual disconnect modules

21 EN1Z-0921GE51 R0709

Mounting/Dismounting Modules LION System

Operating the Individual Switches

► Use a screwdriver to open/close the appropriate

disconnector switches of the manual disconnect

modules.

Fig. 25 Operating the disconnector switches

Dismounting Manual Disconnect Modules

► Open the red lock mechanism by sliding it to the left and

then gently pull the electronic module out of the terminal

socket.

Mounting/Dismounting Auxiliary Terminal

Packages

The XS814 Auxiliary Terminal Package can be mounted on

any pluggable I/O module.

The XS830 and XS831 Auxiliary Terminal Packages are

suitable for mixed I/O modules, only. Specifically, they can

be mounted on the top and/or bottom of the CLIOP830A.

For reasons of mechanical stability, a maximum of two rows

of Auxiliary Terminal Packages may be mounted together

on any given I/O module.

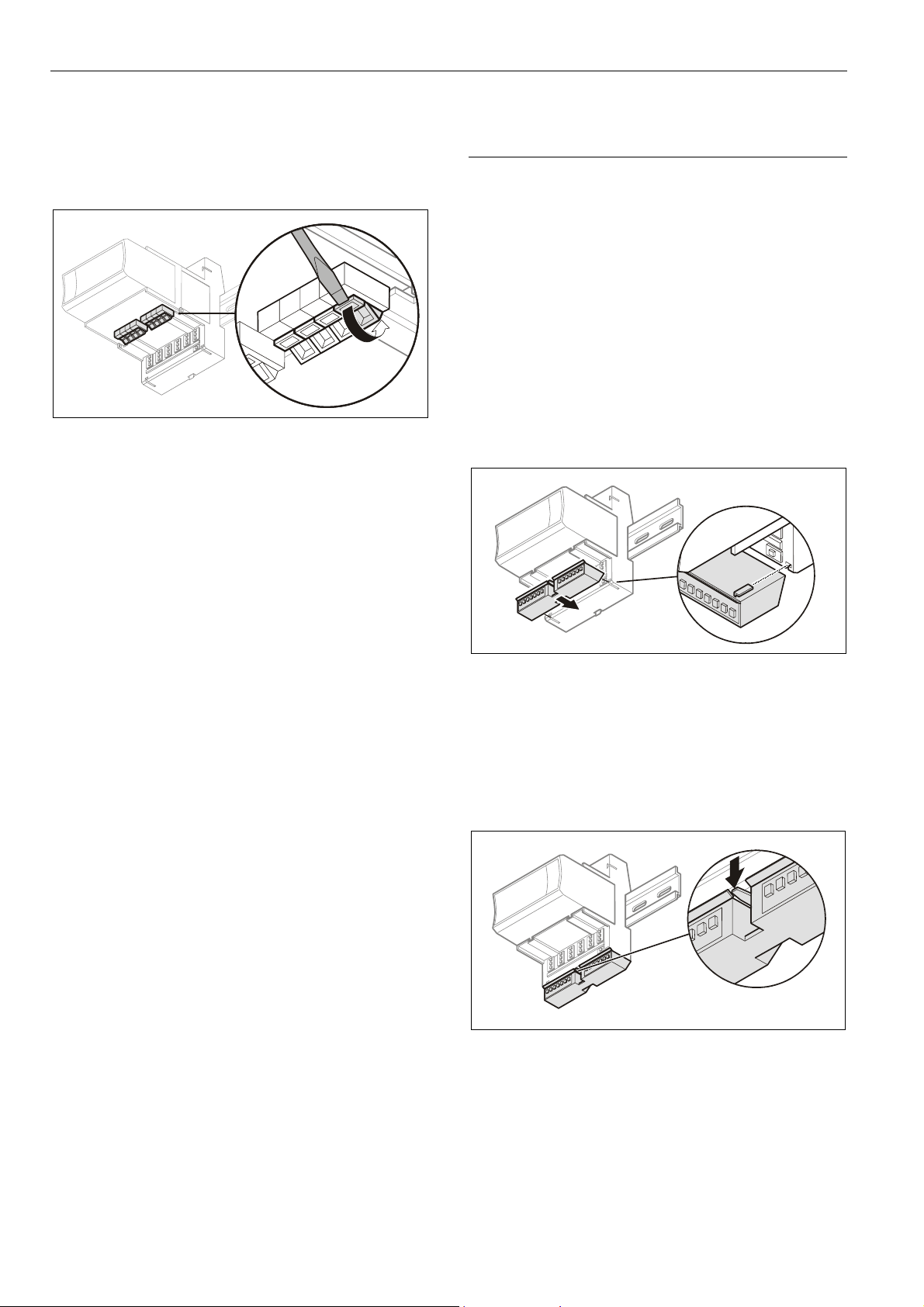

Mounting Auxiliary Terminal Packages

► Push the auxiliary terminal package onto the grooves of

the corresponding terminal socket / the mixed I/O

module.

Fig. 26 Mounting the auxiliary terminal package onto the

terminal socket / mixed I/O module

Dismounting Auxiliary Terminal Packages

► Push down the catch of the auxiliary terminal package

and pull it out of the grooves of the terminal socket / the

mixed I/O module.

Fig. 27 Dismounting the auxiliary terminal package from

the terminal socket / the mixed I/O module

EN1Z-0921GE51 R0709

22

LION System Mounting/Dismounting Modules

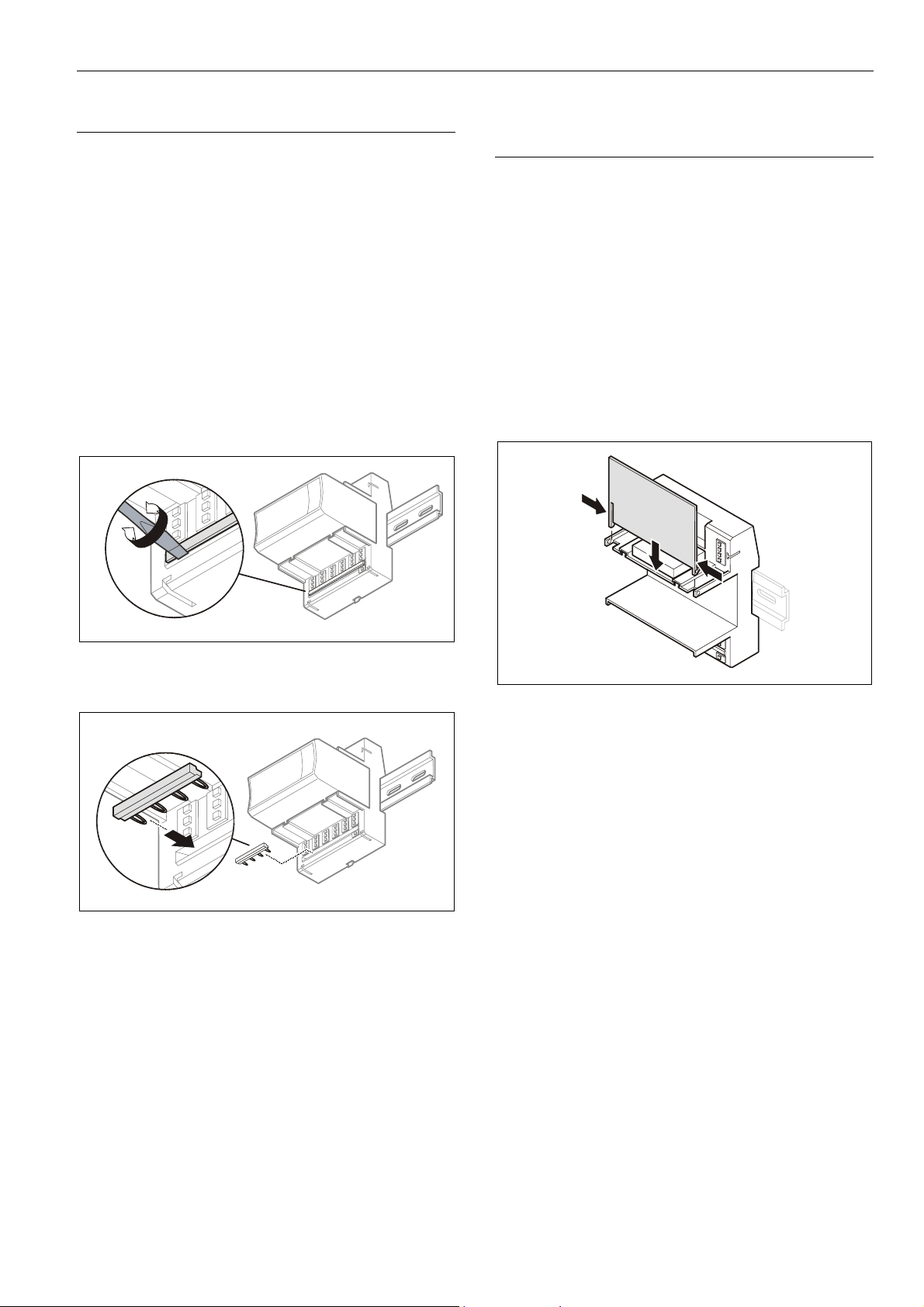

Mounting/Dismounting Cross Connectors

Note

The long cross connector (incl. in the scope of the delivery)

can be mounted to the XS824-25 or XSU824-25, as

required (Fig. 29). It can be dismounted (see Fig. 28) and, if

desired, replaced with one or two short connectors (optional

accessory, see Table 5 on page 7). It is not permitted to

replace these cross connectors with wire.

► Insert a screwdriver on one end of the cross connector

and swivel it to the right and to the left.

► Insert a screwdriver on the other end of the cross

connecter and swivel it to the right and to left until the

cross connector is released.

► If desired, insert another cross connector.

Mounting/Dismounting Swivel Label

Holders

Note

A swivel label holder is included in the scope of delivery of

each module.

Use only the (short / long) swivel label holders appropriate

for the given type (pluggable or mixed, respectively) of I/O

module.

Mounting Swivel Label Holders

► Snap the swivel label holder onto the hinges of the

terminal socket / mixed I/O module.

► Apply self-adhesive labels to the holders.

Fig. 28 Dismounting the cross connectors (long cross

connector shown here)

Fig. 29 Mounting the cross connectors (short cross

connector shown here)

Fig. 30 Mounting the swivel label holder

Dismounting Swivel Label Holders

► Press the hinges together and remove the swivel label

holder.

23 EN1Z-0921GE51 R0709

Wiring and Setting Up the System LION System

Wiring and Setting Up the System

General Safety Considerations

• When connecting the CLLIONLC01 or LION I/O modules,

both VDE, National Electric Code (NEC) or equivalent,

and any local regulations concerning grounding and zero

voltage must be observed.

• Electrical work should be carried out by a qualified

electrician.

• The electrical connections must be made at the terminal

blocks. The corresponding connection diagrams are

located on the individual controller module and

I/O modules.

• For Europe only: To comply with CE requirements,

devices with a voltage in the range of 50 ... 1000 VAC or

75 ... 1500 VDC, which are not provided with a supply

cord and plug or with other means for disconnection from

the supply having a contact separation of at least 3 mm

in all poles, must have the means for disconnection

incorporated in the fixed wiring.

WARNING

Risk of electric shock or equipment damage!

► Do not touch any live parts in the cabinet.

► Disconnect the power supply before making connections

to or removing connections from terminals of controller or

I/O modules.

► Do not use spare terminals as wiring support points.

► Do not reconnect the power supply until you have

completed the installation.

► Observe precautions for handling electrostatic sensitive

devices.

Wiring Push-in Terminals

The terminal sockets of the pluggable I/O modules are

available in versions (…82…) featuring convenient push-in

terminals for easy wiring. The CLIOP830A likewise features

push-in terminals.

For correct wiring, cables must fulfill the following

specifications according to IEC664-1 / VDE 0110 (4.97):

Max. plug gauge

Solid conductor H05/07) V-U

Stranded conductor H05(07) V-K

Stranded conductor with wire end

ferrules (without plastic collar)

Stripping length

Table 22 Push-in terminals wiring specifications

0.14 … 1.50 mm

0.25 … 1.50 mm

0.25 … 1.50 mm

0.25 ... 1.50 mm

8.0 +1.0 mm

Wiring Screw-Type Terminals

The terminal sockets of the pluggable I/O modules are also

available with screw-type terminals.

For correct wiring, cables must fulfill the following

specifications according to IEC664-1 / VDE 0110 (4.97):

Max. plug gauge

Solid conductor H05/07) V-U

Stranded conductor H05(07) V-K

Stranded conductor with wire end

ferrules (without plastic collar)

0.14 … 1.50 mm

0.25 … 1.50 mm

0.25 … 1.50 mm

0.25 ... 1.50 mm

2

2

2

2

2

2

2

2

Stripping length

Table 23 Screw-type terminals wiring specifications

EN1Z-0921GE51 R0709

24

11.0 +1.0 mm

LION System Wiring and Setting Up the System

Connecting Power Supply

The LION System can be powered by one or more external

transformers.

Note

The maximum length for the power supply cable from a

transformer is 3 m. This also includes the length of the

modules and the connection cables between the rails.

Referring to Fig. 31 the following conditions must be fulfilled:

A + B ≤ 3 m and A + C ≤ 3 m

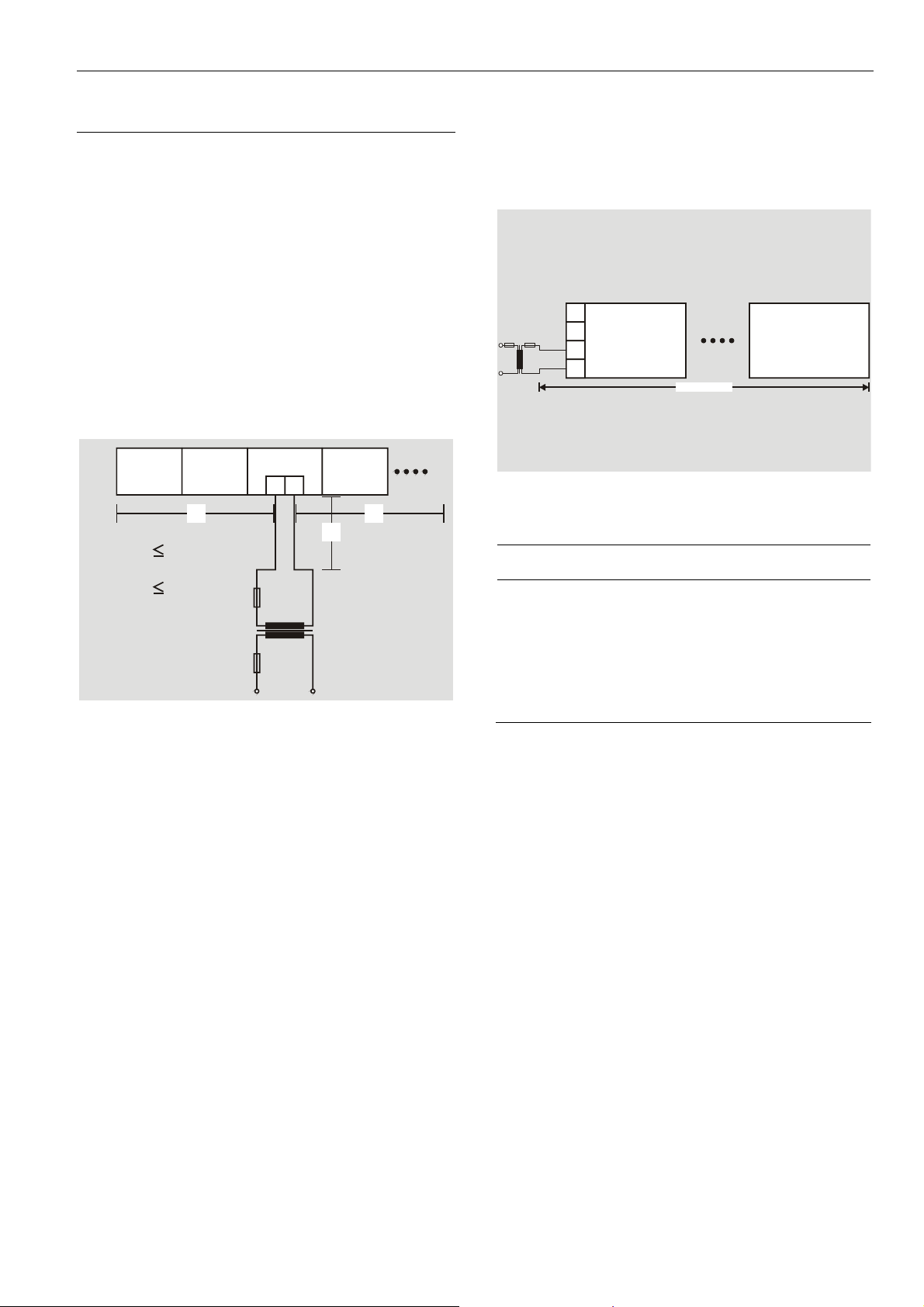

Single or the First Transformer

► Connect the transformer to terminals 1 and 2 of the

CLLIONLC01 Controller.

I/O I/O I/O

B C

A + B 3 m

AND

A + C 3 m

Fig. 31 Wiring power supply from the (first) transformer to

the controller module

CPU

21

A

Additional Transformer

► Connect the additional transformer in a second room or

cabinet to terminals 73 and 74 or 77 and 78 of an

I/O module.

TRANS-

FORMER 2

Fig. 32 Wiring the power supply from a second

71

72

73

74

MAX. 3 m

transformer

NOTICE

Equipment damage!

► Do not use bridge connectors to connect modules

powered by different transformers.

► When connecting modules powered by different

transformers using cables, be sure to not connect

terminals 73 and 77.

I/OI/O

25 EN1Z-0921GE51 R0709

Wiring and Setting Up the System LION System

Connecting Single Bus Controller Systems

This section describes how to connect a controller system

which uses Panel Bus I/O modules only or L

Bus I/O modules only.

Controller and I/O Modules on a Single Rail

► Connect controller and I/O modules using the bridge

connectors.

This provides power supply and communication connection.

No further wiring is necessary.

Controller and I/O Modules on Several Rails in a

Single Cabinet

The rails of a controller system are connected in series.

► Connect the rail ends as follows:

– Power supply

via power supply terminals 73, 74 or 77, 78

– Communication

via communication terminals 71, 72 or 75, 76

71

72

I/O

73

74

I/O

ONWORKS

Panel Bus I/O Modules in Separate Rooms

In this scenario, communication and reference voltage

(24 V0) must be connected between the rooms.

► Connect the last module of room 1 to the first module of

room 2:

– Reference voltage

via power supply terminals 74 or 78

terminals 73 and 77 must not be connected

– Communication

via communication terminals 71, 72 or 75, 76

75

CPU

PANE L

I/O

1 2

71

PANEL

I/O

PANE L

I/O

74

Fig. 34 Wiring the Panel Bus I/O modules in separate

rooms

76

77

78

75

7672

7773

78

24 V0

MAX. 40 m

I/OI/O

I/O

75

76

77

78

75

76

77

78

71

72

I/O

73

74

71

72

I/O

73

74

71

72

I/O

73

74

CPU

1 2

I/O

Fig. 33 Wiring the power supply and the communication

lines to the I/O modules

Maximum Power Cable Length

The maximum length for power supply cable per side is 3 m.

This also includes the connection cables between the rails,

the lengths of the modules, and the cable from the

transformer.

Maximum Cable Length

The maximum cable length for connecting room 1 and

room 2 is 40 m.

EN1Z-0921GE51 R0709

26

LION System Wiring and Setting Up the System

LonWorks Bus I/O Modules in Separate Rooms

In this scenario, only communication lines must be

connected between the rooms.

► Connect the last module of room 1 to the first module of

room 2:

– via communication terminals 71, 72 or 75, 76

75

CPU

1 2

71

LonWorks

I/O

74

Fig. 35 Wiring the LONWORKS Bus I/O modules in

separate rooms

Maximum Cable Length

For maximum cable lengths and cable specifications of the

communication lines, see Table 18 and Table 19 on

page 14.

LonWorks

I/O

LonWorks

I/O

76

77

78

75

7672

7773

78

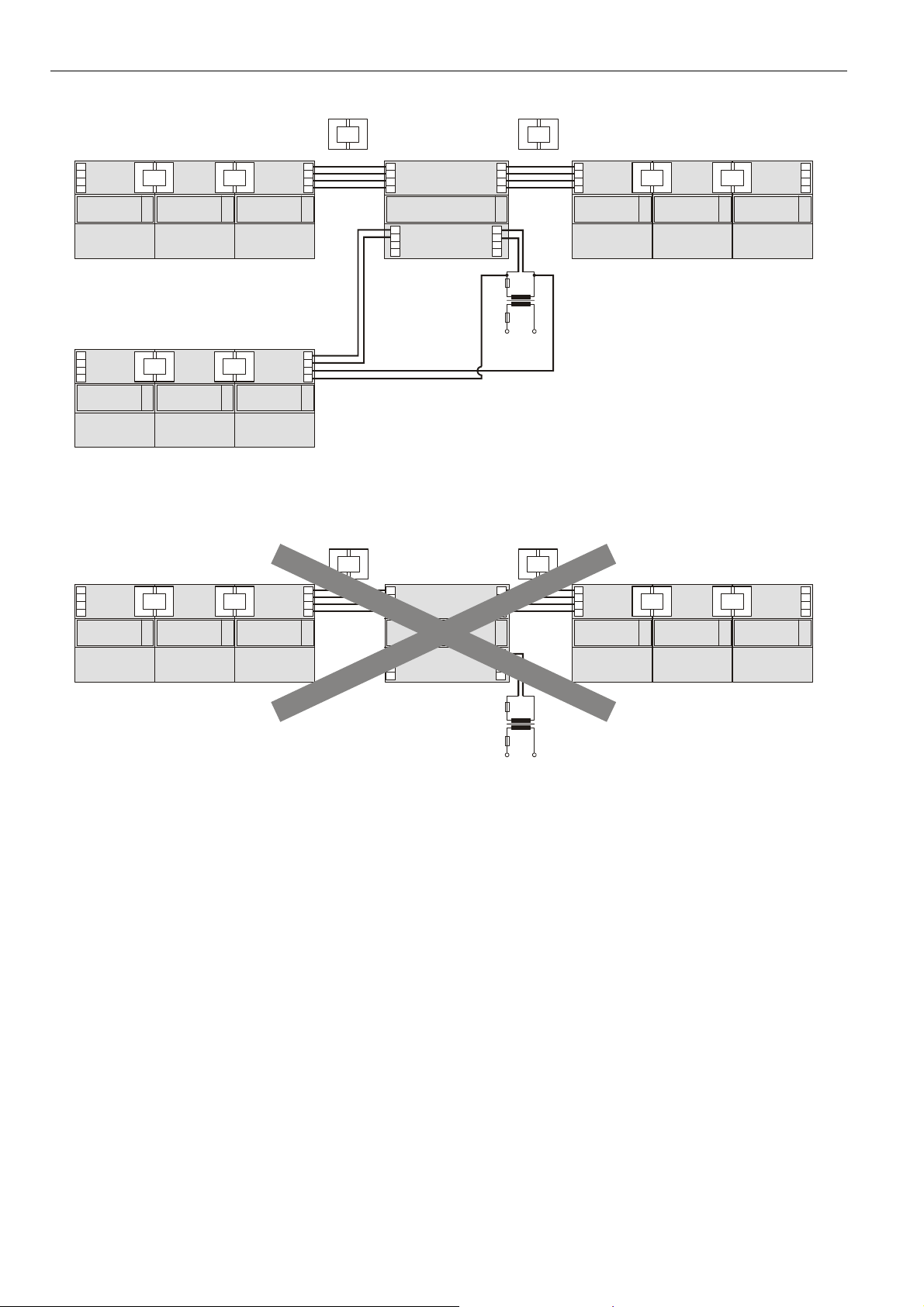

Connecting Panel Bus and LONWORKS Bus

Mixed Controller Systems

Connecting I/O Modules with Each Other

For connecting the I/O modules with each other, proceed as

described for single bus controller systems on page 25.

Connecting I/O Modules to the Controller

Panel Bus I/O Modules

► Connect communication terminals 71 …74 or 75… 78 of

Panel Bus I/O modules to communication terminals

71 …74 or 75… 78 of the controller module using either

– Bridge connectors

for flush mounting on a single DIN rail or

– Cables

for separate mounting,

e.g., on multiple rails, separate cabinets, etc.

L

ONWORKS Bus I/O Modules

► Connect communication terminals 71 … 74 or 75 … 78 of

L

ONWORKS Bus I/O modules to LONWORKS terminals

11 … 14 of the controller module using cables.

27 EN1Z-0921GE51 R0709

Wiring and Setting Up the System LION System

Panel Bus I/O modules Panel Bus I/O modules

71

72

73

74

71

75

72

76

73

77

74

78

71

75

72

76

73

77

74

78

75

76

77

78

XF...

LonWorks Bus I/O modules

71

72

73

74

71

75

72

76

73

77

74

78

71

75

72

76

73

77

74

78

75

76

77

78

Fig. 36 Mixed bus system – correct wiring

Panel Bus I/O modules LonWorks Bus modules

71

72

73

74

71

75

72

76

73

77

74

78

71

75

72

76

73

77

74

78

75

76

77

78

71

72

73

74

CLLIONLC01

11

12

13

14

71

72

CLLIONLC01

73

74

75

76

77

78

1

2

3

4

71

72

73

74

71

75

72

76

73

77

74

78

71

75

72

76

73

77

74

78

75

76

77

78

75

76

77

78

71

72

73

74

71

75

72

76

73

77

74

78

71

75

72

76

73

77

74

78

75

76

77

78

Fig. 37 Mixed bus system – incorrect wiring

11

12

13

14

1

2

3

4

EN1Z-0921GE51 R0709

28

Loading...

Loading...