Page 1

CLIF-CBUSLC Interface

TABLE OF CONTENTS

Installation &

Commissioning

Instructions

TABLE OF CONTENTS ...........................................................1

Safety Information ..................................................................2

General Safety Information .................................................2

Information as per EN 60730 .............................................2

WEEE Directive ..................................................................2

Standards, Approvals, etc. .................................................2

Related Technical Literature .................................................2

Specifications .........................................................................3

System Overview ....................................................................3

Overview of Hardware ........................................................3

System Architecture ...........................................................4

Bus and Port Connections ..................................................5

Mounting/Dismounting ....................................................... 12

Before Installation ............................................................ 12

Dimensions ...................................................................... 12

Wiring and Set-Up ............................................................... 13

General Safety Considerations ....................................... 13

Wiring Terminals .............................................................. 13

Terminal Assignment ....................................................... 13

Power Supply ................................................................... 13

RIN-APU24 ...................................................................... 14

Lightning Protection ......................................................... 14

Engineering, Commissioning ............................................ 15

Required Preparations ..................................................... 15

Extra Parts ............................................................................ 16

LonWorks Communications ............................................... 17

General Information .......................................................... 17

Connecting to a LONWORKS Network ............................... 17

C-Bus Connection ................................................................ 18

C-Bus Topologies ............................................................. 18

C-Bus Cables ................................................................... 18

Connecting CLIF-CBUSLC via RS485-1 to C-Bus .......... 19

Effect of Poll Rate + Subscribed Points on CPU Load ..... 20

C-Bus-Related Size Recommendations .......................... 20

Troubleshooting ................................................................... 21

General ............................................................................. 21

Power LED (green) of CLIF-CBUSLC .............................. 21

Status LED (red) of CLIF-CBUSLC .................................. 21

L2 LED .............................................................................. 21

Tx and Rx LEDs ............................................................... 21

Appendix 1: Earth Grounding ............................................. 22

CLIF-CBUSLC and SELV ................................................ 22

CLIF-CBUSLC and Standard EN60204-1 ........................ 22

Earth Grounding of EN60204-1 Applicable Systems ....... 22

Index ...................................................................................... 24

Trademark Information

ONWORKS, and Neuron are trademarks of Echelon

LON, L

Corporation registered in the United States and other

countries.

® U.S. Registered Trademark

Copyright © 2017 Honeywell Inc. • All Rights Reserved EN1Z-1026GE51 R0417

Page 2

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

SAFETY INFORMATION

General Safety Information

► When performing any work, all instructions given by the

manufacturer and in particular the safety instructions

provided in these Installation and Commissioning

Instructions are to be observed. Make sure that the local

standards and regulations are observed at all times.

► The CLIF-CBUSLC Interface and C-Bus controllers may be

installed and mounted only by authorized and trained

personnel.

► If the device housing is damaged or missing, immediately

disconnect it from any power.

► If the device is broken or defective, do not attempt to repair

it yourself; rather, return it to the manufacturer.

► It is recommended that devices be kept at room tem-

perature for at least 24 hours before applying power. This

is to allow any condensation resulting from low shipping /

storage temperatures to evaporate.

► The CLIF-CBUSLC must be installed in such a manner

(e.g., in a lockable cabinet) as to ensure that uncertified

persons have no access to the terminals.

► In the case of vertical mounting on DIN rails, the CLIF-

CBUSLC Interface should be secured in place using a

commercially-available stopper.

► If the CLIF-CBUSLC is modified in any way, except by the

manufacturer, all warranties concerning operation and

safety are invalidated.

► Rules regarding electrostatic discharge should be followed.

► Use only accessory equipment which comes from or has

been approved by Honeywell.

Information as per EN 60730

Purpose

The purpose of the device is: OPERATING CONTROL. The

CLIF-CBUSLC is an interface device intended for HVAC in

home (residential, commercial, and light-industrial)

environments.

Construction

The CLIF-CBUSLC is an independently mounted electronic

control unit with fixed wiring.

Mounting Method

The CLIF-CBUSLC is suitable for mounting as follows:

► in cabinets;

► in fuse boxes conforming with standard DIN43880, and

having a slot height of max. 45 mm;

► on walls (using accessory MVC-80-AC1).

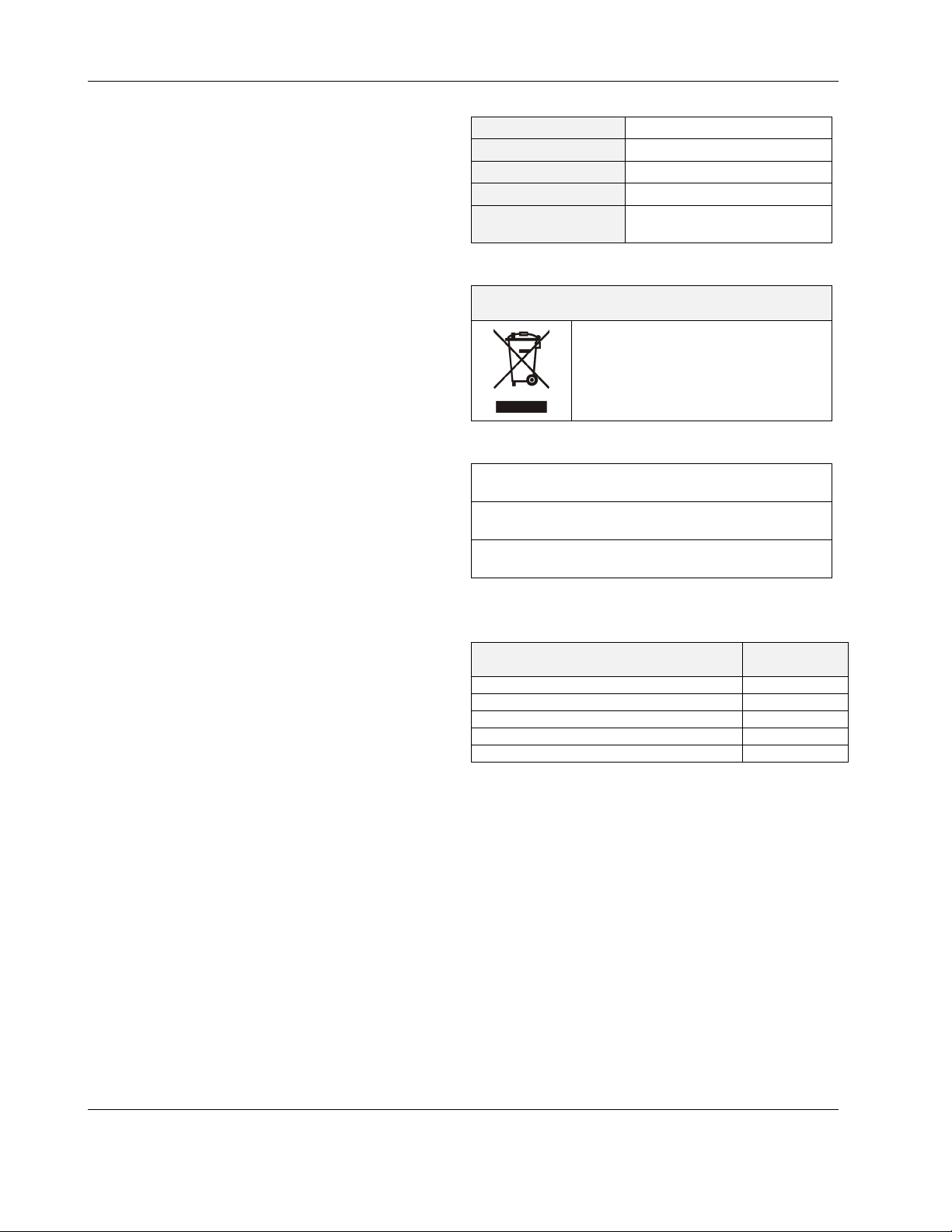

Table 1. Information as per EN 60730

Shock protection

Pollution degree

Installation

Software class

Ball-pressure test

temperature

Class II

2

Class 3

Class A

housing parts >75 °C

terminals >125 °C

WEEE Directive

WEEE: Waste Electrical and Electronic

Equipment Directive

At the end of the product life, dispose of

the packaging and product in an

appropriate recycling center.

Do not dispose of the device with the

usual domestic refuse.

Do not burn the device.

Standards, Approvals, etc.

Degree of Protection: IP20 (mounted on walls, with two

Refer to Code of Practice standards IEC 61000-5-1 and -2

for guidance.

The device complies with Ethernet Protocol versions IEEEC

802.3.

accessory MVC-80-AC1 covers)

RELATED TECHNICAL LITERATURE

Table 2. Related Technical Literature

Title

CLIF-CBUSLC – Product Data EN0Z-1026GE51

CLIF-CBUSLC – Mounting Instructions MU1Z-1026GE51

CentraLine NX C-Bus Driver – User Guide EN2Z-1021GE51

IF-LON2 – Product Data & Mounting Instr. MU1Z-0545GE51

General Security Best Practices EN0Z-1017GE51

Product

Literature no.

EN1Z-1026GE51 R0417 2

Page 3

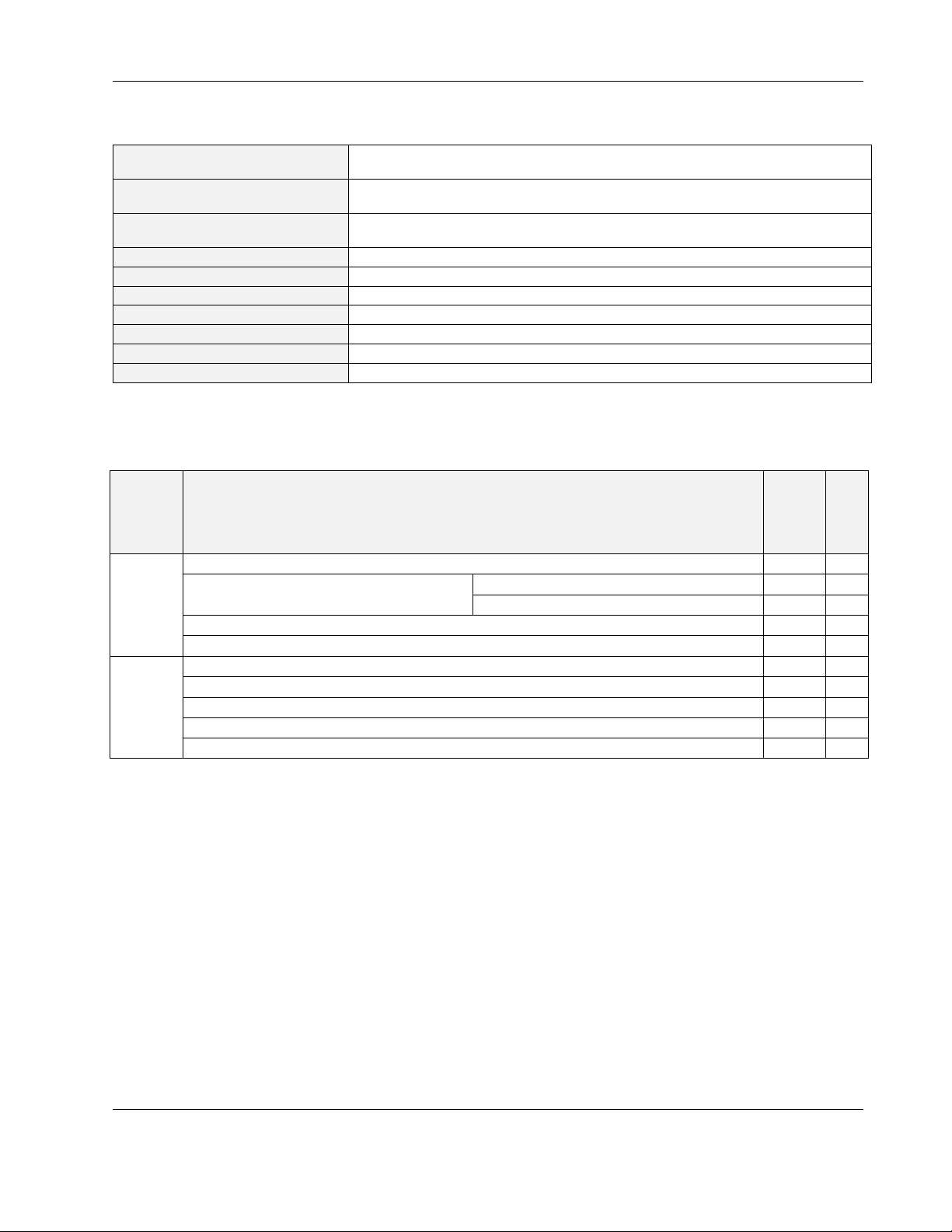

SPECIFICATIONS

Power supply

Power consumption

Current consumption

Ambient temperature

Storage temperature

Humidity

Dimensions

Degree of protection

Fire class

Weight

SYSTEM OVERVIEW

Overview of Hardware

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

Table 3. CLIF-CBUSLC specifications

19 … 29 VAC, 50/60 Hz or

20 … 30 VDC

typically dc: 5 W; max. 6 W

typically ac: 9 VA; max. 11 VA

typically dc: 210 mA; max. 240 mA

typically ac: 370 mA; max. 410 mA

0 … 40 °C (wall-mounting)

-20 … +70 °C

5 … 95% r.h. non-condensing

See Fig. 12 and Fig. 13.

IP20 (mounted on walls, with two accessory MVC-80-AC1 covers)

V0

0.6 kg (excl. packaging)

Table 4. Overview of hardware

feature description

RS485-1, isolated, C-Bus communication 1200 m 1

bus

interfaces

LEDs

Ethernet Interface

USB 2.0 Device Interface (as Network Interface) 3 m 1

USB 2.0 Host Interface (max. 500 mA) 3 m 1

power LED (green) -- 1

status LED (red, controllable by firmware) -- 1

LED L1 (yellow) unused -- 1

LED L2 (yellow) indicating that a SUSI client (ARENAAX, COACHAX or ARENA 3.0) is connected -- 1

bus status LEDs (for isolated RS485-1 interface) -- 2

max.

cable

length

e-mail communication, browser access 100 m 1

SUSI IP communication 100 m 1

no.

3 EN1Z-1026GE51 R0417

Page 4

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

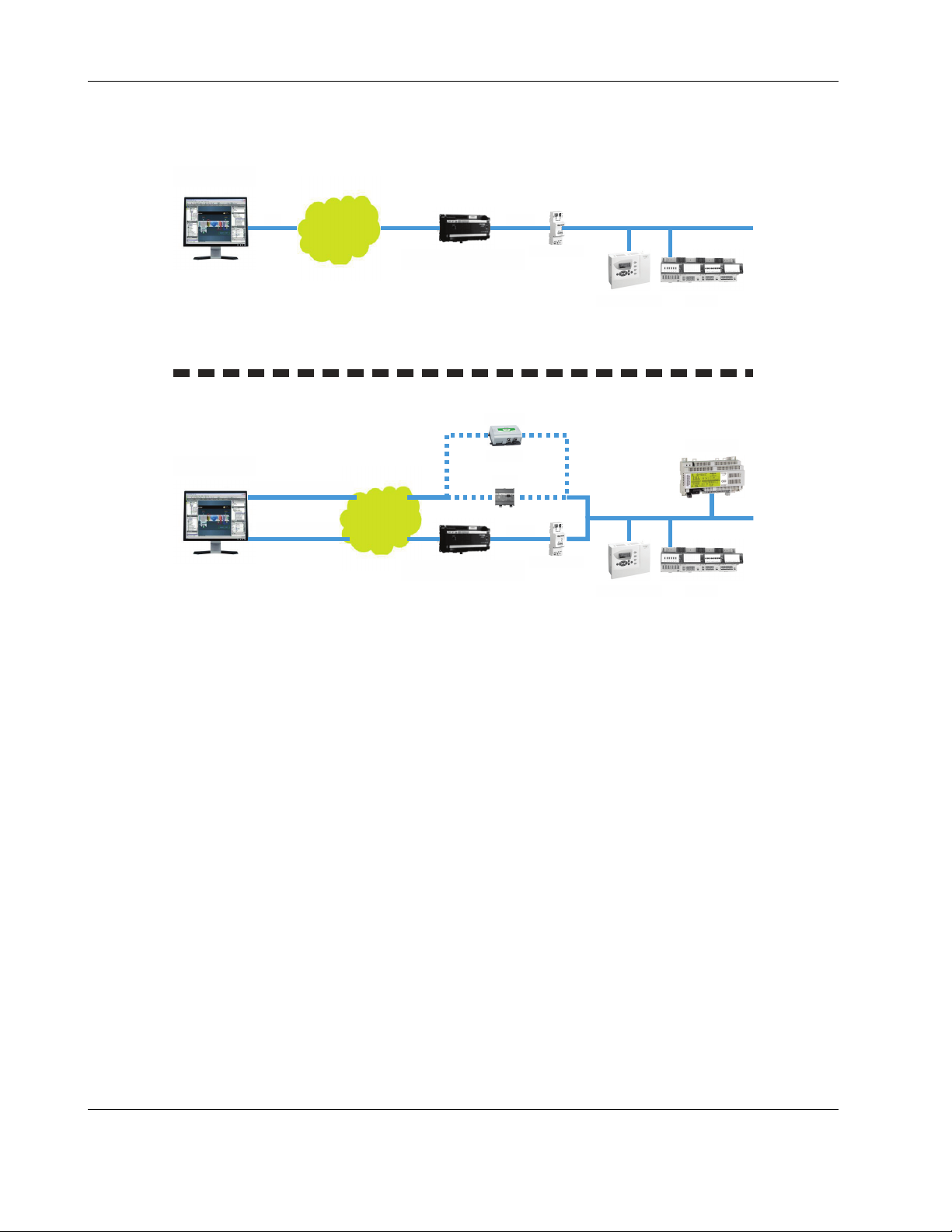

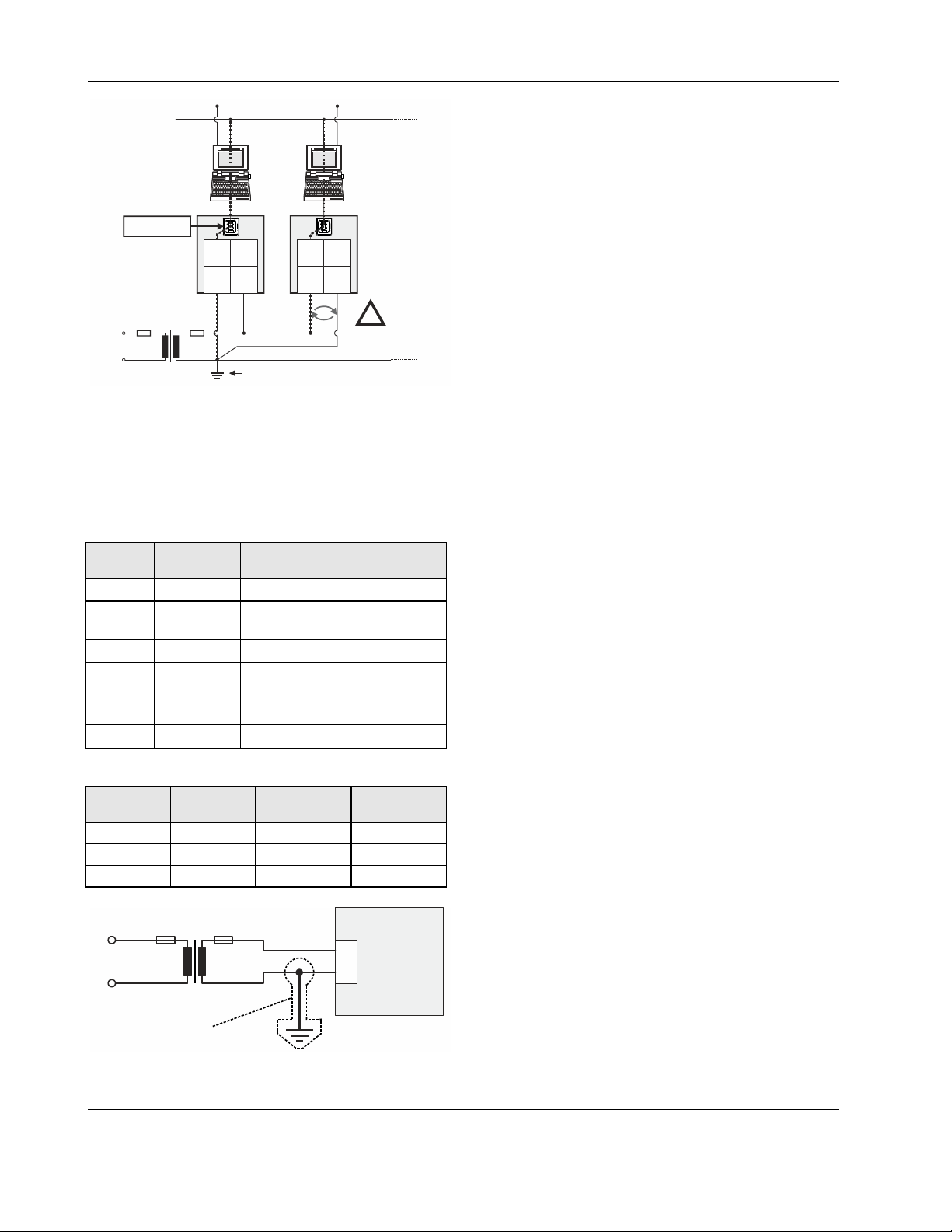

System Architecture

ARENA 3.xx

IP

IP

NETWORK

CLIF-CBUSLC

ARENA NX

LonWorks via IP

IP

C-BUS via IP

NETWORK

CLIF-CBUSLC

Fig. 1. CentraLine C-Bus System architecture

USB

HAWK

- OR -

L-IP

USB

IF-LON2

IF-LON2

PANTHER

PANTHER

LION

SERVAL

LION

EN1Z-1026GE51 R0417 4

Page 5

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

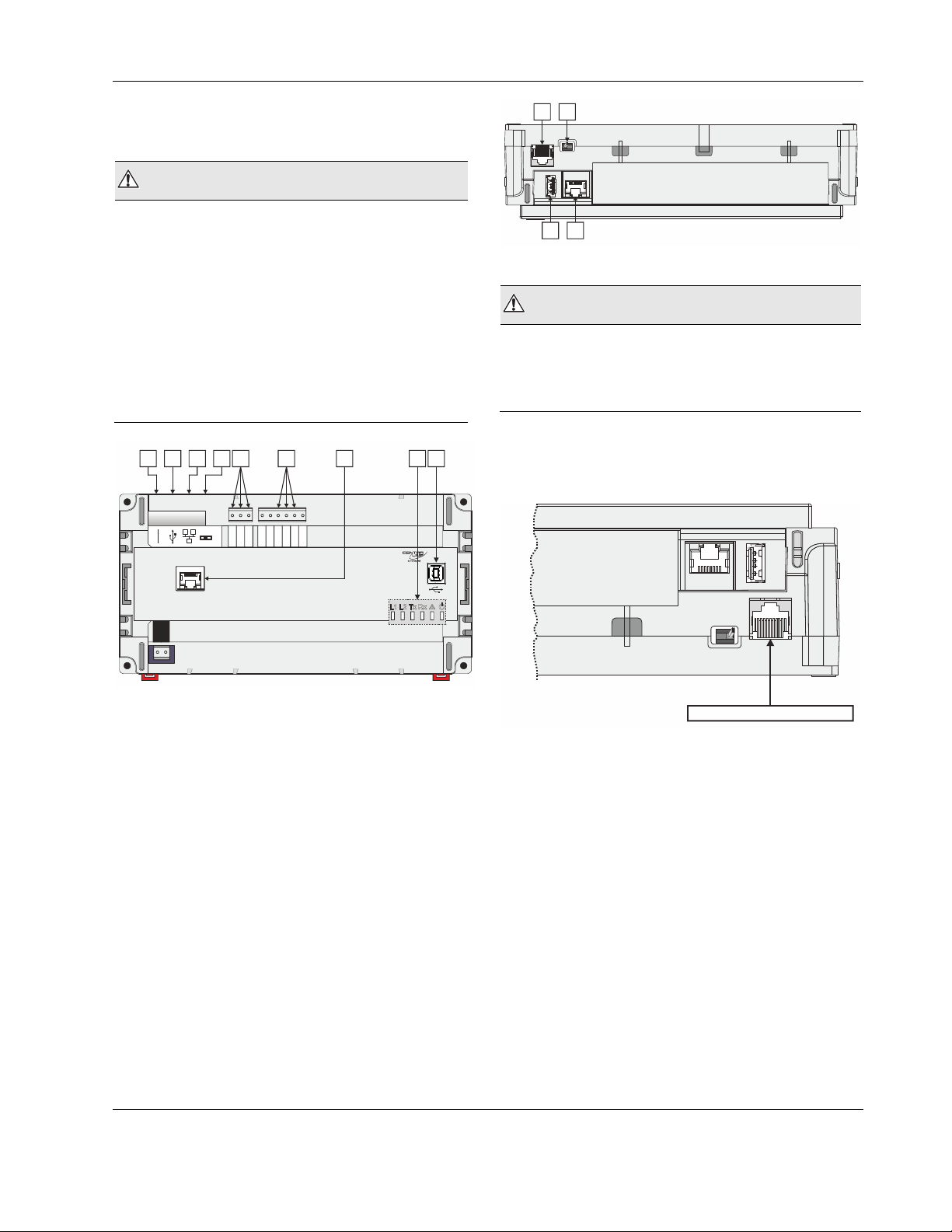

Bus and Port Connections

Overview

WARNING

Risk of electric shock or equipment damage!

► Do not touch any live parts in the cabinet!

► Disconnect the power supply before making connections

to or removing connections from terminals of the CLIFCBUSLC

► Do not reconnect the power supply until you have

completed installation.

► It is prohibited to power the CLIF-CBUSLC with the same

transformer used to power controllers or other devices

(e.g., the PW M-Bus Adapter).

► Observe the rules regarding electrostatic discharge.

5

485-1-

485-1+

6 7

n.a.

n.a.

485-2-

485-2+

9

n.a.

GND2

182

RS232

J1 J8

3

4

END

BIAS

MID

RS485-1

24 25 26 27 28 29 30 31 32

GND1

1 4

J1 J8

3

2

Fig. 3. Side view

WARNING

Risk of electric shock or equipment damage!

► It is prohibited to connect any of the RJ45 sockets of the

CLIF-CBUSLC Interface to a so-called PoE-enabled device

("Power over Ethernet").

RS232 / RJ45 Socket

Via its RS232 / RJ45 socket, the CLIF-CBUSLC can be

connected to a terminal for debugging purposes.

J1 J8

24V~

24V-0

1

2

Fig. 2. Top view

Legend

1 RS232 / RJ45 socket (for factory debugging)

2 USB 2.0 Host Interface (for connection of the IF-

LON2); max. 500 mA, high speed

3 Ethernet / RJ45 socket (for SUSI communication);

10/100 Mbit/s; 1 "link" LED and 1 "activity" LED

4 Three-position slide switch (for setting bias and ter-

mination resistance of RS485-1: MUST REMAIN IN

MIDDLE POSITION!)

5 RS485-1 (isolated; for C-Bus communication)

6 RS485-2 (non-isolated; DO NOT USE)

7 Future functionality

8 LEDs

9 USB 2.0 Device Interface (for connection to web

browser for setup)

RS232-RJ45 SOCKET

Fig. 4. RS232 / RJ45 socket

USB 2.0 Host Interface

Via its USB 2.0 Host interface, the CLIF-CBUSLC can be

connected to the IF-LON2 External Interface Adapter and thus

thus to L

also section "LonWorks Communications" on pg. 17.

ONWORKS networks. Max. 500 mA, high speed. See

5 EN1Z-1026GE51 R0417

Page 6

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

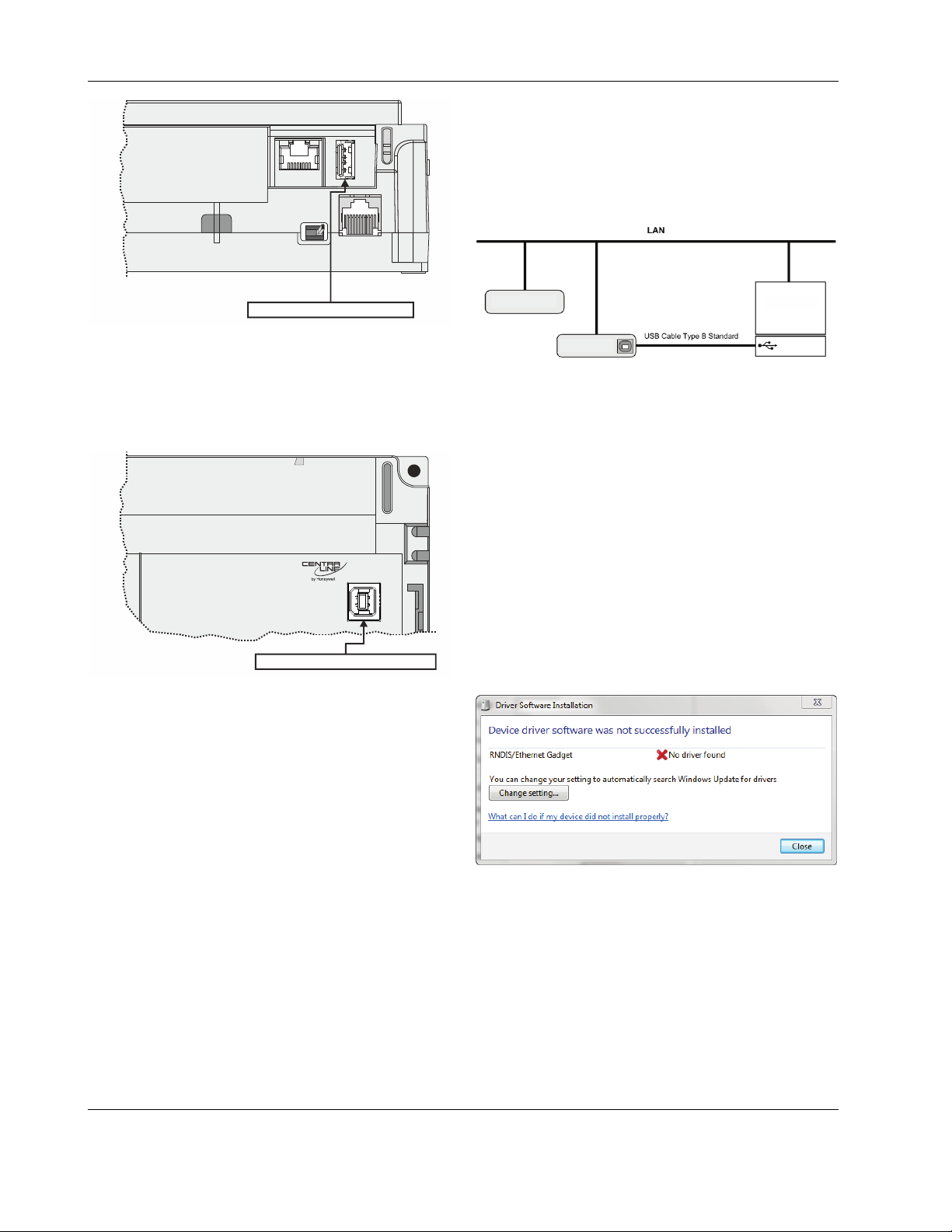

USB Driver Installation

Windows 7

J1 J8

In order to connect the CLIF-CBUS Interface to the Windows

7 PC, you will need an USB cable of type A-Male-to-type-BMale (Type B standard).

The CLIF-CBUS Interface will be connected to the Windows 7

PC as shown in the following figure.

USB 2.0 Host Interface

Fig. 5. USB 2.0 Host interface

USB 2.0 Device Interface

The CLIF-CBUSLC is equipped with a USB 2.0 Device Interface at the front. This interface is for connection to a web

browser for setting up the device.

USB 2.0 Device Interface

Fig. 6. USB 2.0 Device Interface

A standard USB type-B connector can be inserted into this

USB 2.0 Device Interface.

NOTE: Before attempting to connect a web browser to the

USB 2.0 Device Interface of the CLIF-CBUSLC,

you must first install the USB Driver on your PC.

See following section "USB Driver Installation".

CLIF-CBUSLC #2

WINDOWS 7 PC

CLIF-CBUSLC #1

Driver Variants

Depending on the firmware version, there are two different

ways to install the USB driver.

1. On most PCs, the update is done automatically with the

Windows update function.

2. In the case of firmware 4.00.00 or higher, you can use

the Microsoft driver from your Windows 7 installation

(procedure then starts with step 17 of the following

Procedure).

PROCEDURE

1. Insert the A Male connector of the USB cable into an

USB inferface jack of the PC and insert the B Male connector into the controller's USB device interface jack.

RESULT: The Found New Hardware Wizard is

enabled in the Windows Task Line.

2. In the Windows Task Line, double-click the icon.

RESULT: The Driver Software Installation message

box displays.

EN1Z-1026GE51 R0417 6

3. If no RNDIS/Ethernet Gadget driver was found as

indicated by the message "X No driver found", click the

Change setting… button.

RESULT: The Device Installation Settings dialog box

displays.

Page 7

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

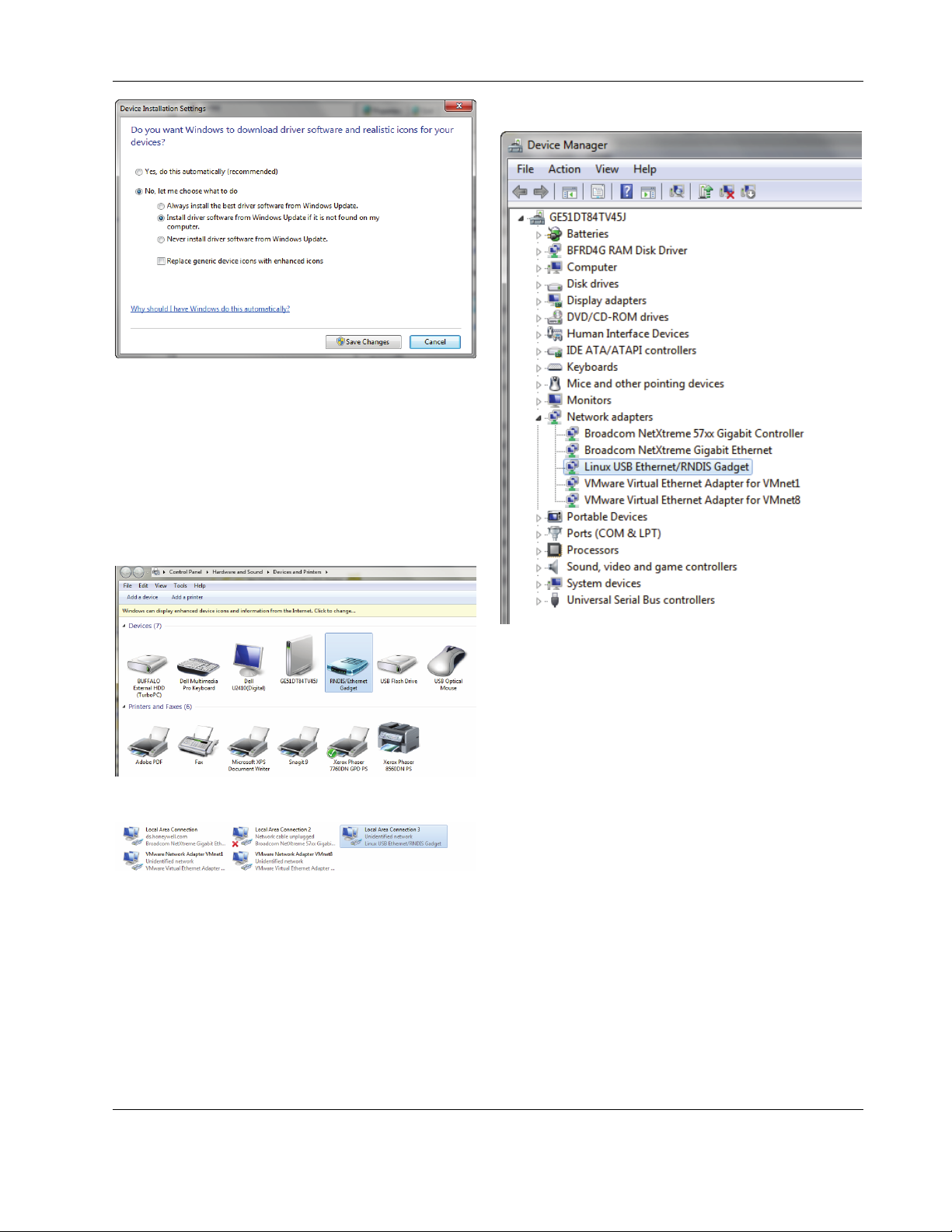

In Control Panel \ Device Manager \ Network Adapters

4. Select No, let me choose what to do, and then select

Install driver software from Windows Update if it is

not found on my computer.

5. Click the Save Changes button.

RESULT: Software tries to install the RNDIS / Ether-

net Gadget driver. If the driver is successfully installed, it can be seen in the following

locations within Windows (see figures

below):

In Control Panel \ Hardware and Sound \ Devices and Printers

In Control Panel \ Network and Internet \ Network Connections

6. If the driver has still not been successfully installed, do

the following:

7. Right-click on the driver in the Network adapters folder

in the Device Manager, and then click Update Driver

Software.

8. Click Browse my computer for driver software.

9. Click Let me Pick from a list of device drivers on my

computer.

10. Click Have Disk…

11. Click Browse… and navigate to the folder

<drive:>\CARE\drivers.

12. Depending on your Windows operating system type (32bit or 64-bit), select the RNDIS USB driver (32-bit) or the

RNDIS USB driver (64-bit) file, and then click Open.

13. Click OK.

14. Select Linux USB Ethernet/RNDIS Gadget, and then

click Next>.

15. If a warning message displays, click Continue Anyway.

RESULT: Windows will install the driver.

16. Click Close.

17. Check the successful installation of the driver as

described in step 5.

18. If this still does not work, use the driver shipped with

Windows.

19. Right-click on the driver in the Network adapters folder

in the Device Manager, and then click Update Driver

Software.

20. Click Browse my computer for driver software.

7 EN1Z-1026GE51 R0417

Page 8

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

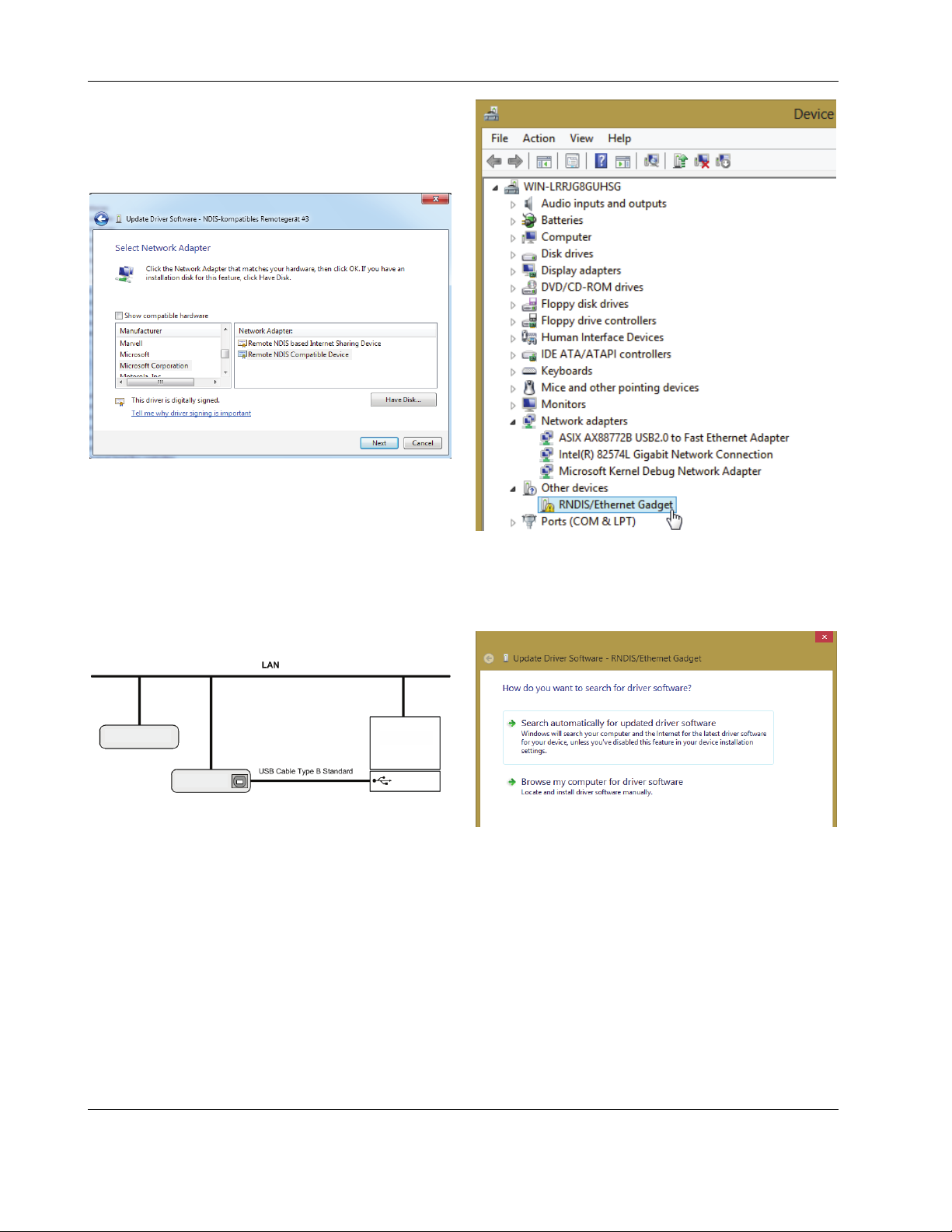

21. Click Let me Pick from a list of device drivers on my

computer.

22. Uncheck the Show compatible hardware box.

23. Select the Manufacturer Microsoft Corporation

24. Select Remote NDIS Compatible Device

25. Check the successful installation of the driver as

described in step 5.

26. If the device status is “This device cannot start. (Code

10)”, reboot your PC.

Windows 8

In order to connect the CLIF-CBUS Interface to the Windows

8 PC, you will need an USB cable of type A-Male-to-type-BMale (Type B standard).

The CLIF-CBUS Interface will be connected to the Windows 8

PC as shown in the following figure.

CLIF-CBUSLC #2

CLIF-CBUSLC #1

WINDOWS 8 PC

PROCEDURE

1. Insert the A Male connector of the USB cable into an

USB interface jack of the PC and insert the B Male

connector into the controller's USB device interface jack.

2. In Windows, start the device manager.

3. Click Other devices, then right-click RNDIS/Ethernet

Gadget and then select Update driver Software…

RESULT: The Update Driver Software – RNDIS /

Ethernet Gadget dialog displays.

4. Click Browse my computer for driver Software…

EN1Z-1026GE51 R0417 8

Page 9

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

5. Click Let me pick from a list of device drivers on my

computer.

6. Select Network adapters.

8. Select USB-RNDIS-Adapter, and then click Next button.

RESULT: The Update Driver Warning message box

9. Confirm the warning by clicking Yes button.

RESULT: The driver will be installed successfully as

displays.

indicated by the final message box.

10. Click the Close button.

7. Select Microsoft.

9 EN1Z-1026GE51 R0417

Windows 10

In the case of controllers with firmware 4.00.00 or higher, the

appropriate driver is automatically installed with a Windows

update. In the case of controllers with firmware 3.04.05 or

Page 10

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

lower, the automatic installation does not work: Please download the appropriate USB driver prior to the installation at:

http://catalog.update.microsoft.com/v7/site/ScopedViewRedire

ct.aspx?updateid=37e35bd4-d788-4b83-9416-f78e439f90a2

Please connect the controller to the PC as described in

section "Windows 8" and perform the general installation

procedures for drivers in Windows 10.

Ethernet / RJ45 Socket

The CLIF-CBUSLC is equipped with an Ethernet / RJ45

socket featuring one LED.

J1 J8

Ethernet / RJ45 socket

Fig. 7. Ethernet / RJ45 socket

This Ethernet / RJ45 socket is a 10/100-Mbaud Ethernet

interface permitting communication with a SUSI client like

AX

ARENA

(as per IEEEC 802.3)

NOTE: The Ethernet / RJ45 socket is usually earth-

, ARENANX, COACHAX, COACHNX, or ARENA 3.0

LINK/ACT.

Fig. 8. Ethernet / RJ45 socket

grounded. For additional information on earth

grounding, see also "Appendix 1: Earth Grounding"

on pg. 22.

LEDs

The CLIF-CBUSLC features the following LEDs:

Fig. 9. CLIF-CBUSLC LEDs

Table 5. CLIF-CBUSLC LEDs

symbol

See also section "Troubleshooting" on page 21 for a detailed

description of the behaviors of the LEDs and their meanings.

RS485 Interface

General

The CLIF-CBUSLC has one C-Bus interface:

RS485-1 (consisting of push-in terminals 24 [GND-1], 25,

RS485-1 Bias and Termination Resistors

RS485-1 is equipped with a three-position slide switch which

can be used to switch its bias resistors OFF (position "MID" –

this is the default and the only allowed setting), ON (position

"BIAS"), and ON with an additional 150Ω termination resistor

(position "END").

color function, description

L1 yellow unused

L2 yellow

LED indicating that a SUSI client

(ARENA

AX

, COACHAX or ARENA 3.0) is

connected

Tx yellow

Rx yellow

!

red status LED indicating hardware problems

RS485-1 status LED indicating transmission of C-Bus signals

RS485-1 status LED indicating reception

of C-Bus signals.

green power LED

and 26) is isolated.

J1 J8

MID

BIAS

END

EN1Z-1026GE51 R0417 10

RS485-1

3-POSITION SLIDE SWITCH

Fig. 10. RS485-1 three-position slide switch

The slide switch setting must remain in the leftmost position

for "MID".

Page 11

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

Table 6. Required slide switch settings

setting remarks

END DO NOT USE!

BIAS DO NOT USE!

MID

For C-Bus communication, the switch must be in the

leftmost position.

+5V

MID

(MANDATORY!)

RS485-1 (+)

47 kOHM

ISO

25

MID

BIAS

RS485-1 (-)

END

47 kOHM

26

GND-1

Fig. 11. RS485-1 three-position slide switch setting MID

RS485 Standard

According to the RS485 standard (TIA/EIA-485: "Electrical

Characteristics of Generators and Receivers for Use in

Balanced Digital Multipoint Systems"), only one driver communicating via an RS485 interface may transmit data at a

time. Further, according to U.L. requirements, the RS485

interface may be loaded with a max. of 32 unit loads. A max.

of 29 C-Bus devices may be connected.

IMPORTANT

The cable length affects the baud rate. See Table 7.

Table 7. Baud rate vs. max. cable length for RS485

Baud rate Max. cable length (L)

9.6 - 76.8 kbps 1200 m

For information on wire gauge, max. permissible cable length,

possible shielding and grounding requirements, and the max.

number of devices which can be connected to a bus, refer to

standard EIA-485.

11 EN1Z-1026GE51 R0417

Page 12

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

MOUNTING/DISMOUNTING

Before Installation

IMPORTANT

To allow the evaporation of any condensation resulting from low shipping / storage temperatures, keep the device at room

temperature for at least 24 h before applying power.

US requirement, only: This device must be installed in a UL-listed enclosure offering adequate space to maintain the

segregation of line voltage field wiring and Class 2 field wiring.

In the case of vertical mounting on DIN rails, the CLIF-CBUSLC should be secured in place using a commercially-available

stopper. See also the CLIF-CBUSLC – Mounting Instructions (MU1Z-1006GE51).

Dimensions

215.5

25 262728 29 30 31 32

24

END

BIAS

RS232

RS485-1

MID

GND1

n.a.

n.a.

485-1-

485-1+

n.a.

485-2-

485-2+

GND2

57.5

49.5

J1 J8

24V~

24V-0

1

2

5245

110

Fig. 12. CLIF-CBUSLC (shown: model with onboard I/Os), dimensions (in mm)

215.5

J1 J8

57.5

52

147

Fig. 13. CLIF-CBUSLC with covers, dimensions (in mm)

NOTE: Use of the covers (MVC-80-AC1) obstructs access to the Ethernet and USB 2.0 Host Interfaces and RS232 socket.

EN1Z-1026GE51 R0417 12

Page 13

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

WIRING AND SET-UP

General Safety Considerations

All wiring must comply with applicable electrical codes and

ordinances, including VDE, National Electric Code (NEC)

or equivalent, and any local regulations must be observed.

Refer to job or manufacturer’s drawings for details. Local

wiring guidelines (e.g., IEC 364-6-61 or VDE 0100) may

take precedence over recommendations provided here.

Electrical work should be carried out by a qualified

electrician.

Electrical connections must be made at terminal blocks.

For Europe only: To comply with CE requirements, devices

with a voltage in the range of 50 ... 1000 VAC or 75 ...

1500 VDC which are not provided with a supply cord and

plug or with other means for disconnection from the supply

having a contact separation of at least 3 mm in all poles

must have the means for disconnection incorporated in the

fixed wiring.

WARNING

Risk of electric shock or equipment damage!

► Observe precautions for handling electrostatic sensitive

devices.

► Do not touch any live parts in the cabinet.

► Do not open the device housing.

► Disconnect the power supply before making connections to

or removing connections from terminals of the CLIFCBUSLC and devices wired to it.

► Do not use spare terminals as wiring support points.

► To prevent risk of injury due to electrical shock and/or

damage to the device due to short-circuiting, low-voltage

and high-voltage lines must be kept separate from one

another.

► All terminals are protected (up to 24 Vac) against short-

circuiting and incorrect wiring. Higher voltages may

damage the device.

► Do not reconnect the power supply until you have

completed the installation.

Fusing Specifications

System Fusing

We recommend that the system be equipped with an external

fuse.

Fusing of Active Field Devices

F2 (depends upon given load).

Wiring Terminals

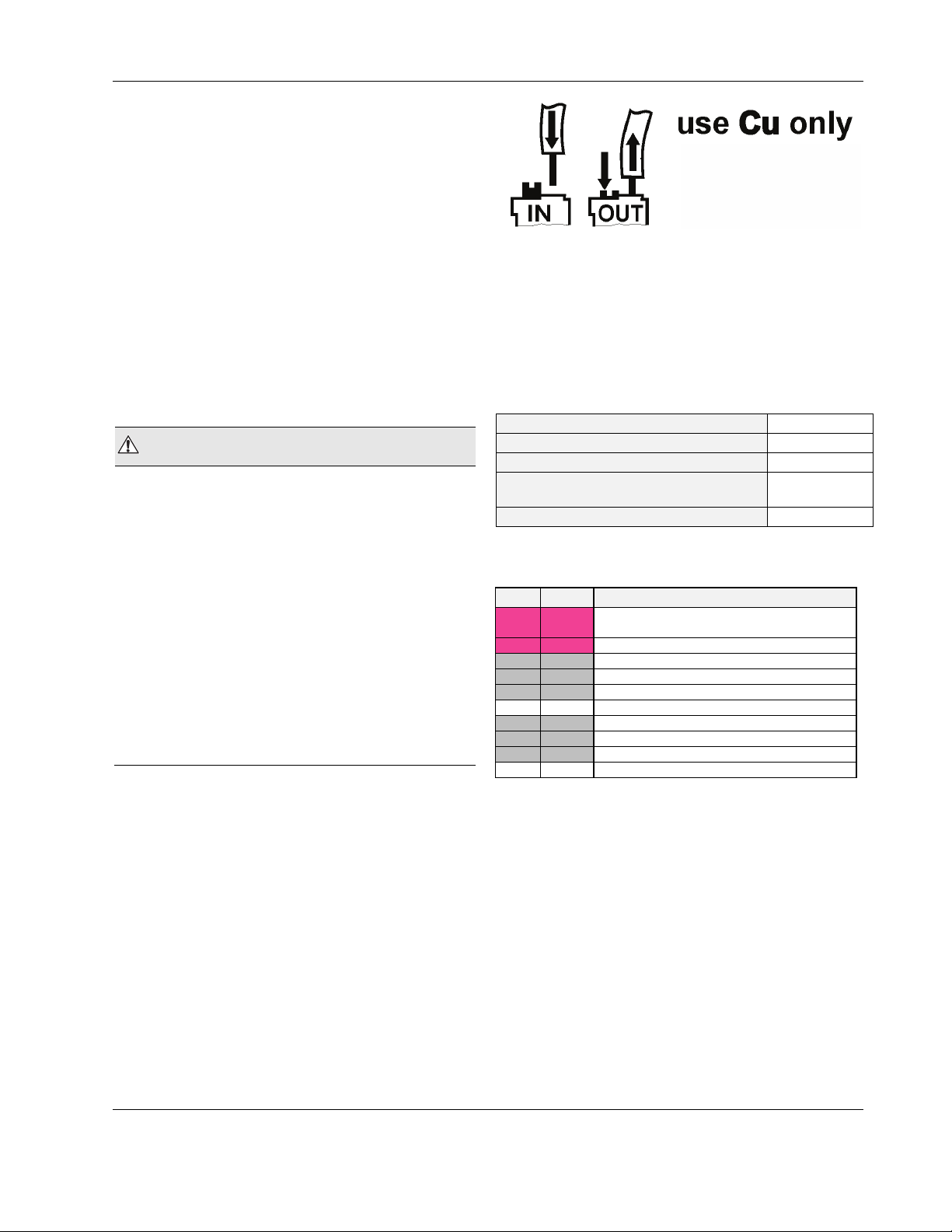

The CLIF-CBUSLC is equipped with push-in terminal plugs.

Fig. 14. Inserting/removing wires from push-in terminals

NOTE: With solid conductors, ferrules are prohibited.

NOTE: Use only one conductor per push-in terminal.

NOTE: If, nevertheless, two stranded wires are to be

plug gauge

solid conductor H05(07) V-K

stranded conductor H05(07) V-K

stranded conductor with wire end ferrules

(w/o plastic collar)

stripping length

connected to a single push-in terminal, twin wire

end ferrules must be used.

Table 8. CLIF-CBUSLC push-in terminal wiring

specifications

0.2 … 1.50 mm

0.2 … 1.50 mm

0.2 … 1.50 mm

0.2 … 1.50 mm

10.0 +1.0 mm

Terminal Assignment

Table 9. Terminal assignment

term. signal description

1 24V-0

2 24V~ supply voltage (24V)

24 GND-1 reference GND of RS485-1 (isolated)

25 485-1+ "+" signal for RS485-1 (isolated)

26 485-1- "-" signal for RS485-1 (isolated)

27,28 not used

29 485-2+ not used

30 485-2- not used

31 GND-2 not used

32 - not used

supply voltage (GND), internally connected

with terminal 31

Power Supply

Powering CLIF-CBUSLC

Power is supplied via a removable terminal plug (attached to

terminals 1 and 2).

The power supply of the CLIF-CBUSLC must conform to

Safety Class II. To reduce overall current consumption, the

CLIF-CBUSLC can be powered by a switch power supply

(rather than by a transformer). See also Table 3 on pg. 3.

NOTE: Danger of short-circuiting when another controller

besides the CLIF-CBUSLC is supplied by the same

transformer if proper polarity is not ensured. See

Fig. 15.

2

2

2

2

13 EN1Z-1026GE51 R0417

Page 14

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

EARTH GROUND

N, L

SHORT-CIRCUITING!

PC 1 PC 2

USB 2.0

Device Interface

CPU #1 CPU #2

L

LINE

N

24 V~

24 V~0

24V~ 24V~24V~0 24V~0

2 21 1

NOISE-FREE EARTH GROUND

(ONLY ONE PER SYSTEM)

CPU 2

REVERSED

!

POLARITY!

Fig. 15. Incorrect polarity → SHORT-CIRCUITING!

Transformer Data

In Europe, if the CLIF-CBUSLC is powered by transformers,

then such transformers must be safety isolating transformers

conforming to IEC61558-2-6. In the U.S. and Canada, if the

CLIF-CBUSLC is powered by transformers, then such transformers must be NEC Class-2 transformers.

Table 10. 1450 series transformers data

part #

1450 7287

-001 120 Vac 24 Vac, 50 VA

-002 120 Vac

-003 120 Vac 24 Vac, 100 VA, 24 Vdc, 600 mA

-004 240/220 Vac 24 Vac, 50 VA

-005 240/220 Vac

-006 240/220 Vac 24 Vac, 100 VA, 24 Vdc, 600 mA

transformer primary side

CRT 2 230 Vac 2 A 500 mA

CRT 6 230 Vac 6 A 1300 mA

CRT 12 230 Vac 12 A 2500 mA

primary side secondary side

2 x 24 Vac, 40 VA, 100 VA from

separate transformer

2 x 24 Vac, 40 VA, 100 VA from

separate transformer

Table 11. Overview of CRT Series AC/DC current

max. AC

current

PRIMARY SIDE

max. DC

current

CLIF-CBUSLC

RIN-APU24

The RIN-APU24 Uninterruptable Power Supply can be directly

wired to a CLIF-CBUSLC.

See RIN-APU24 Uninterruptable Power Supply – Mounting

Instructions (Product Literature no.: EN0B-0382GE51) for a

detailed wiring diagram.

Lightning Protection

Please contact your local Honeywell representative for

information on lightning protection.

230 VAC

120 VAC

24 VAC

24 V0

2

1

NOT

RECOMMENDED

Fig. 16. Connection of CLIF-CBUSLC

EN1Z-1026GE51 R0417 14

Page 15

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

ENGINEERING, COMMISSIONING

Please refer also to ARENAAX / COACHAX – User Guide

(Product Literature No.: EN2Z-0996GE51) for detailed

information.

Required Preparations

In order to access (with a laptop or PC) the CLIF-CBUSLC via

Ethernet/IP for the first time, a password must be defined. For

setup, you must connect a PC with a web browser to the USB

2.0 Device interface as described below.

USB 2.0 Device Interface

This USB 2.0 Device interface is the interface for setting up

the communication settings and downloading new firmware.

An "A-Male to B-Male" USB cable is required.

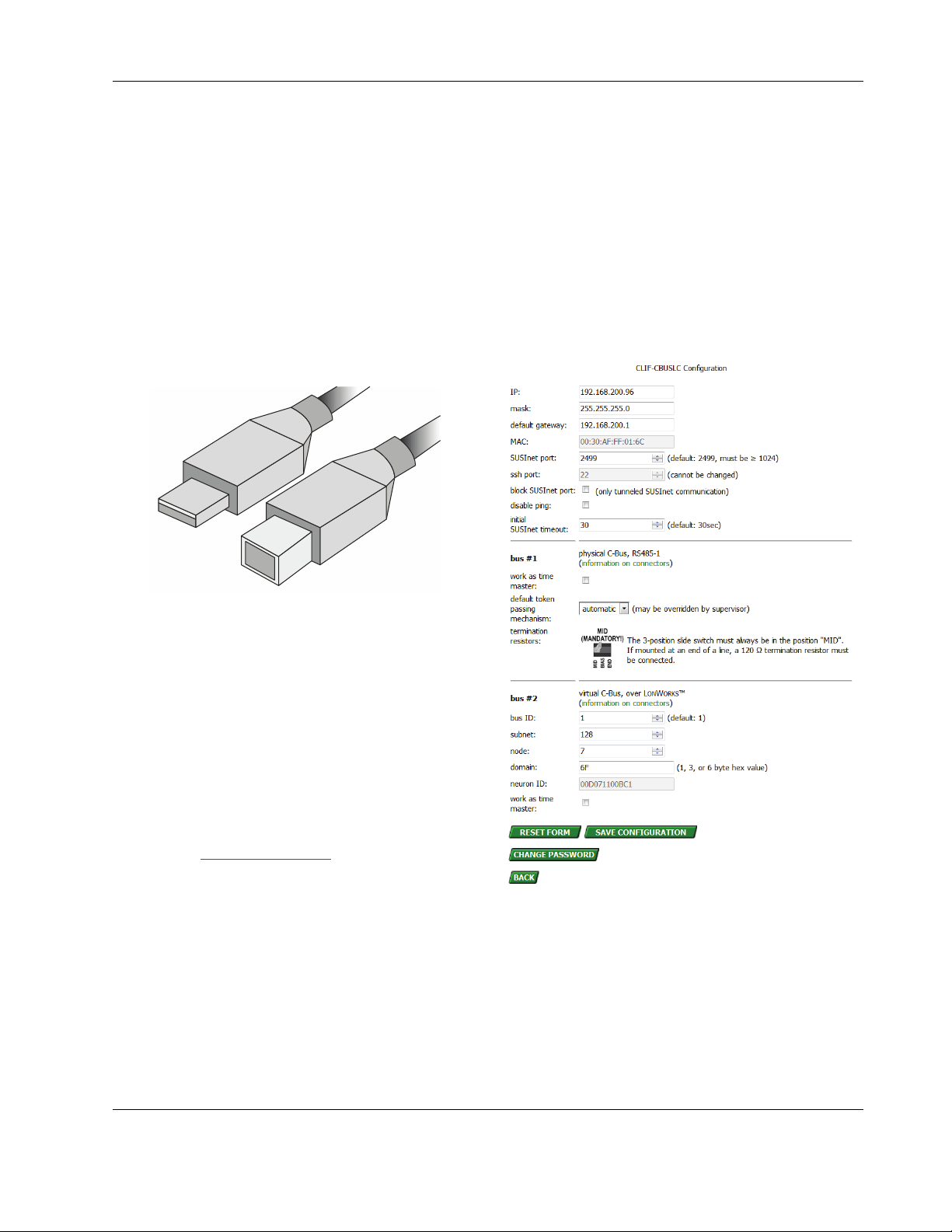

6. The configuration mask (see Fig. 18) will then appear.

Enter the IP address, subnet mask, and default gateway

address.

Do not select "block SUSInet port" (this is needed only if

you want to tunnel SUSInet communication over ssh)

7. In case you are using the virtual C-Bus over L

option, enter the L

(subnet, node, domain). You can retreive this information

from the engineering tool. Use the same subnet and

domain and a node address which is not used by another

device).

8. If you want your interface to hourly synchronize the time of

your bus devices, select "work as time master".

9. Press "SAVE CONFIGURATION". When you are done,

you may log out or go back to the status display.

ONWORKS communication parameters

ONWORKS

Fig. 17. A-male to B-male USB cable

For access via USB, the CLIF-CBUSLC has a permanent

default IP address 192.168.255.241.

Set-Up

After removing the CLIF-CBUSLC from its shipping box,

attach power and wait approx. 1 minute while it powers up.

During power-up, the red warning LED (see Fig. 9 on pg. 10)

will be lit. As soon as this warning LED goes dark, you may

commence with the set-up, as follows:

1. Connect one end of the A-male to B-male USB cable (see

Fig. 17) to your PC and the other end to the USB 2.0

Device Interface (see Fig. 6 on pg. 6) located on the front

of your CLIF-CBUSLC.

2. Enter URL http://192.168.255.241 in your web browser. An

initial mask will then appear on the screen of your PC.

3. When setting up your CLIF-CBUSLC for the first time, you

will have to enter an administrator password. This

administrator password must contain:

▪ 8 or more (but not more than 31) characters

▪ uppercase letters

▪ lowercase letters

▪ numerals

▪ no whitespace characters

4. A login mask will appear. You may now login using the

administrator password.

5. Press the CONFIGURATION button.

Fig. 18. Configuration mask

NOTE: Regarding time master functionality, the CLIF-

CBUSLC does not observe daylight saving time.

If your controllers do automatic daylight saving

time, we recommend not to use the time master

functionality. If there is a local workstation permanently on the bus, we recommend that this

workstation should be responsible to synchronize

date and time.

15 EN1Z-1026GE51 R0417

Page 16

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

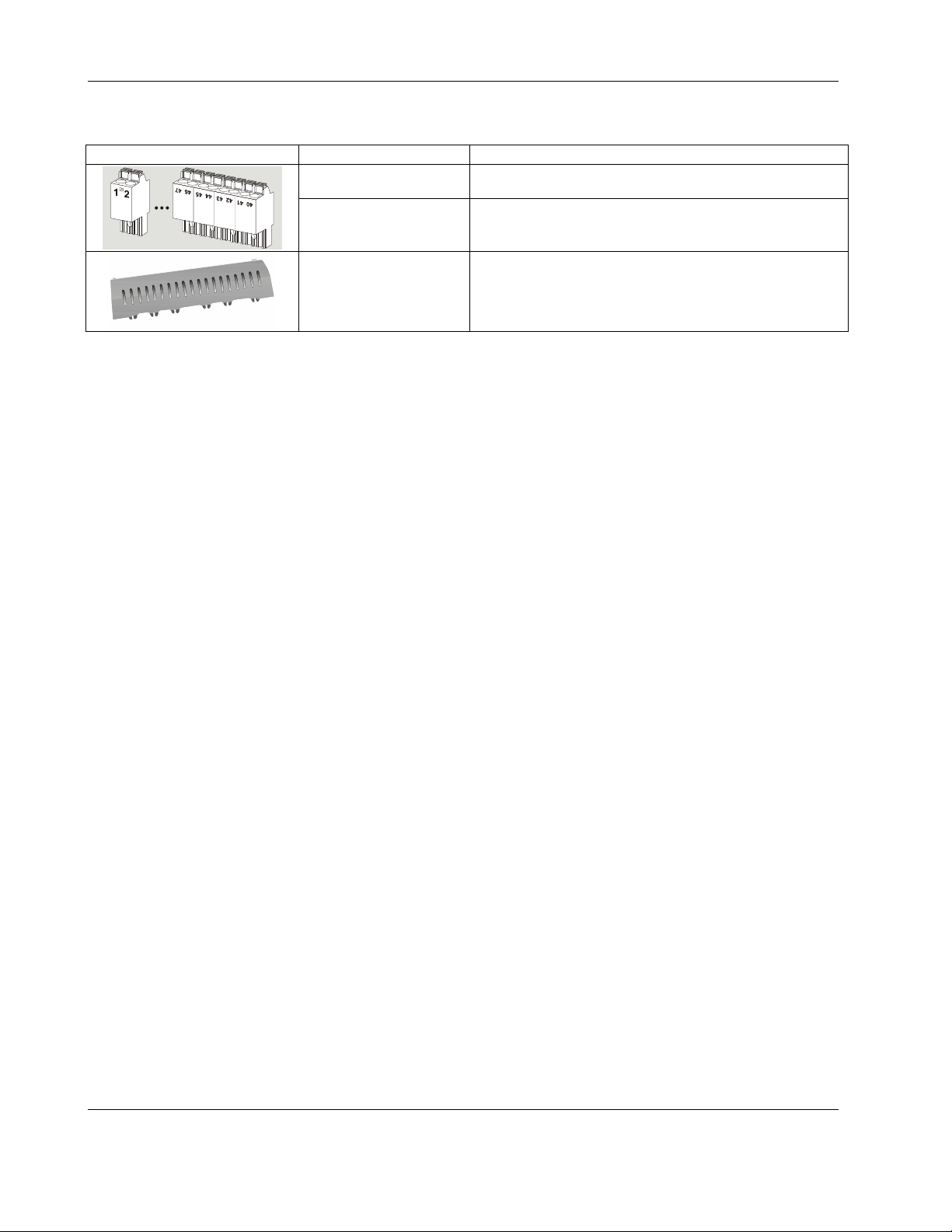

EXTRA PARTS

Table 12. Extra parts

TPU-11-01

TPU-45-01

order no. description

Removable terminal plugs, push-in type; complete set of 3

plugs (for terminals 1 - 47); for the CLAXEH00ND100A.

Removable terminal plugs, push-in type; complete set of 9

plugs (for terminals 1 - 47); for the CLAXEH14ND100A and

CLAXEH26ND100A.

MVC-80-AC1

Terminal cover (color: RAL9011); package of ten.

EN1Z-1026GE51 R0417 16

Page 17

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

LONWORKS COMMUNICATIONS

General Information

The CLIF-CBUSLC can be connected to LONWORKS networks.

networks. This requires the use of an IF-LON2 (see section

"IF-LON2" below), which is then plugged into to the CLIFCBUSLC's USB 2.0 Host Interface (see also section "USB 2.0

Host Interface" on pg. 5).

This permits individual CLIF-CBUSLC Interfaces to be

connected / disconnected from the L

without disturbing the operation of other devices.

The L

ONWORKS network is insensitive to polarity, eliminating

the possibility of installation errors due to miswiring.

Different network configurations (daisy-chain, loop, and star

configurations, or any combination thereof) are possible. See

also Excel 50/500 L

ONWORKS Mechanisms Interface

Description (Product Literature no.: EN0B-0270GE51).

Connecting to a LONWORKS Network

IMPORTANT

Do not bundle wires carrying field device signals or

ONWORKS communications together with high-voltage

L

power supply or relay cables. Specifically, maintain a

min. separation of 3 inches (76 mm) between such

cables. Local wiring codes may take precedence over

this recommendation.

IMPORTANT

Try to avoid installing in areas of high electromagnetic

noise (EMI).

Cable Types

The unit must be wired to the LONWORKS network using either

level IV 22 AWG (Belden part number 9D220150)

or

plenum-rated level IV 22 AWG (Belden part number

9H2201504) non-shielded, twisted-pair, solid-conductor

wire.

When possible, use Honeywell AK3781, AK3782, AK3791, or

AK3792 cable (US part numbers). See Excel 50/5000

L

ONWORKS Mechanisms (Product Literature no.: EN0B-

0270GE51), for details, including maximum lengths.

Use wire with a minimum size of 20 AWG (0.5 mm

maximum size of 14 AWG (2.5 mm

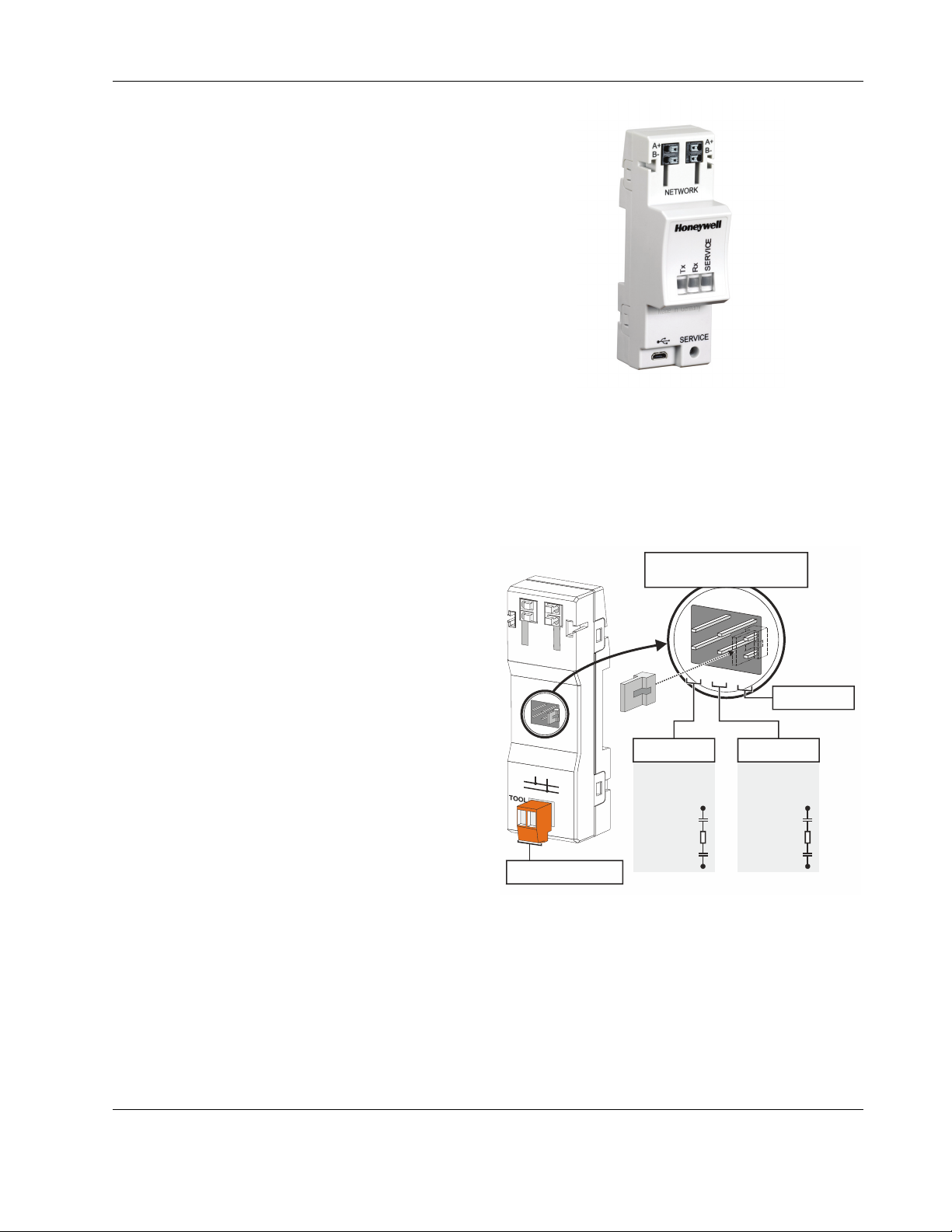

IF-LON2

Optionally, communication with physical I/O modules, with

room and zone controllers, and with CentraLine PANTHER,

TIGER, and LION controllers can utilize LonTalk.

The IF-LON2 is equipped with a free-topology transceiver

(FTT10A) for communication (at a data transmission rate of

78 Kbaud) on L

protocol).

The L

ONWORKS network is insensitive to polarity, eliminating

the possibility of installation errors due to miswiring. Different

network configurations (daisy-chain, loop, and star configurations, or any combination thereof) are possible. See

Excel 50/5000 L

no.: EN0B-0270GE51) for details.

ONWORKS® networks (using the LonTalk

ONWORKS Mechanisms (Product Literature

ONWORKS network

2

).

2

) and a

Fig. 19. IF-LON2

See also IF-LON2 – Mounting Instructions (Product Literature

no.: MU1B-0545GE51).

Depending upon the chosen network configuration, one or two

terminations may be required.

The following L

L

ONWORKS connection / termination module

ONWORKS termination module is available:

(mountable on DIN rails and in fuse boxes),

order no.: XAL-Term2

LONWORKS TERMINATION

PLUG-IN JUMPER

1

REMOVABLE SCREW-TYPE

2-POLE TERMINAL BLOCK

Fig. 20. L

5

2

6

PAR K P OS ITIO N

(NO TERMINATION)

FTT/LPT BUS FTT/LPT FREE

3

4

1

5

2

6

3

4

ONWORKS connection and termination module

FTT/LPT

BUS TOPOLOGY:

105 OHM

100 μ

105 Ohm

100 μ

1

2

FTT/LPT

FREE TOPOLOGY:

52.3 OHM

100 μ

52.3 Ohm

100 μ

1

2

17 EN1Z-1026GE51 R0417

Page 18

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

C-BUS CONNECTION

The CLIF-CBUSLC features an RS485 interfaces to which C-Bus devices can be connected: RS485-1 (consisting of push-in

terminals 24 [GND-1], 25, and 26).

C-Bus Topologies

Via the C-Bus, up to 30 C-Bus devices (e.g., controllers, etc.) can communicate with one another and a PC central. The C-Bus

must be connected via the individual controllers (open ring).

NOTE: Star connection is not allowed, as this might cause uncontrollable line reflections.

Instead of CLIF-CBUSLC Interfaces, C-Bus controllers (e.g., the Excel 500, Excel 100, LION, PANTHER) can also be

connected.

CLIF-

CBUSLC

Excel 100 Excel 500

Fig. 21. C-Bus topology Excel 5000

PANTHER

C-Bus Cables

NOTE: Observe national regulations for C-Bus cables!

Cable type Description Recommended for

J-Y-(ST)Y 2 x 2 x 0.8 shielded, twisted pair Europe, inside cabinet

A-Y-(ST)Y 2 x 2 x 0.8 shielded, twisted pair Europe, outside cabinet

AK 3702 unshielded, twisted pair US not approved for Europe

AK 3740A shielded US (low-cost) not approved for Europe

Belden 9842 twisted pair Europe, US also possible

Belden 9841 shielded US

AK 3702 unshielded, twisted pair US not approved for Europe

AK 3740A shielded US (low-cost) not approved for Europe

For Europe; only shielded cable is permitted.

For the U.S., shielded or unshielded cable can be used.

Table 13. C-Bus cable types

EN1Z-1026GE51 R0417 18

Page 19

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

Connecting CLIF-CBUSLC via RS485-1 to C-Bus

NOTE: Always power each CLIF-CBUSLC and the connected C-Bus devices via separate transformers.

NOTE: The max. C-Bus cable length is 1200 m (4000 ft).

NOTE: If any devices are not electrically isolated, signal ground connection is recommended. See section "RS485 Standard"

NOTE: If the CLIF-CBUSLC is connected at either of the line's two ends, an additional termination resistor (RT = 120 Ohm) is

NOTE: Regardless of the position of the CLIF-CBUSLC along the C-Bus, the 3-position switch must be set to MID.

Example: CLIF-CBUSLC and Connected C-Bus Devices

on pg. 11.

necessary.

NOTE!

R

T

120 OHM

24 25 26

GND-1

ISO

+5V

47 kOHM 47 kOHM

RS485-1 (+) RS485-1 (-)

CLIF-CBUSLC

= C-BUS DEVICE #1

24V~

24~0

1 2

F1

24 V

230 V

L

RS485-1

MID

GND-1

RS485 -

RS485 +

C-BUS

DEVICE #2

GND

RS485 +

C-BUS

DEVICE #3

RS485 -

GND

GND

RS485 -

RS485 +

C-BUS

DEVICE #N-1

NOTE!

END

MID

BIAS

Fig. 22. Connection of a CLIF-CBUSLC via its RS485-1 interface to a C-Bus

RS485 -

RS485 +

C-BUS

DEVICE #N

GND

19 EN1Z-1026GE51 R0417

Page 20

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

EFFECT OF POLL RATE + SUBSCRIBED POINTS ON CPU LOAD

The poll rate set for the CLIF-CBUSLC and the chosen number of subscribed datapoints both make a demand on the CPU load.

The following recommendations are therefore applicable.

C-Bus-Related Size Recommendations

Table 14. Recommended application sizes per controller and per project

No. of controllers

No. of datapoints

No. of datapoints per

project

No. of I/O modules per

LION controller

No. of time programs per

controller

Table 15. Recommended limits for CLIF-CBUSLC and C-Bus communication

Virtual C-Bus (i.e.,

C-Bus via LONWORKS)

Physical C-Bus systems

* This corresponds mainly to the no. of datapoints in trend if these datapoints do not update faster than once per minute. In the

case of physical C-Bus systems, the update rate of each datapoint can be influenced by the user (i.e., by changing the attribute

"trend hysteresis").

Operating System: WIN xx 32-bit Operating System: WIN xx 64-bit

9…13 LION controllers 15…17 LION controllers

15…17 PANTHER / TIGER controllers 15…17 PANTHER / TIGER controllers

Max. 381 per LION controller Max. 381 per LION controller

Max. 381 per PANTHER / TIGER controller Max. 381 per PANTHER / TIGER controller

4953 5715

Max. 16 (We recommend using only Panel Bus

I/O modules since they do not count as

ONWORKS devices.)

L

As many 25 I/O modules (combination of Panel

Bus I/O modules and L

are possible, but with some risk.

up to ≤ 64

local sys.

remote sys.

9,600 bps

76,800 bps

ONWORKS I/O modules)

No. of C-Bus devices

engineered with…

COACH CARE

15 29 10,000 10,000 500

15 29 10,000 10,000 250

15 29 10,000 -- 500

15 29 10,000 -- 1,000

Max. 16 (We recommend using only Panel Bus

I/O modules since they do not count as

L

ONWORKS devices.)

As many 25 I/O modules (combination of Panel

Bus I/O modules and L

are possible, but with some risk.

Max. 64

As many as 100 time programs per controller are

possible, but with some risk.

No. of data-

points

ONWORKS I/O modules)

No. of NVs

Update rate (data-

points per min.)*

EN1Z-1026GE51 R0417 20

Page 21

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

TROUBLESHOOTING

General

The following LEDs of the CLIF-CBUSLC can be used for troubleshooting purposes:

Power LED (green)

Status LED (red)

L2 LED (yellow)

Tx (sending data on RS485-1) and Rx (receiving data on RS485-1) LED

Power LED (green) of CLIF-CBUSLC

Table 16. CLIF-CBUSLC power LED

case power LED meaning remedy

ON Normal operation No action necessary.

1

OFF

2

Status LED (red) of CLIF-CBUSLC

case status LED meaning remedy

OFF after

1

power-up

ON con-

2

tinuously after

power-up

L2 LED

case bus LEDs meaning remedy

1

ON

continuously

after power-up

2

Dark

Tx and Rx LEDs

case bus LEDs meaning remedy

1

Both Tx and Rx

are flashing

2

Both Tx and Rx

are OFF

3

Rx is flashing

and Tx is OFF

4

Tx is flashing

and Rx is OFF

Power supply not OK.

Table 17. CLIF-CBUSLC status LED

Normal operation. No action necessary.

– No or invalid firmware

Table 18. CLIF-CBUSLC L2 LED

AX

A SUSI client (ARENA

ARENA 3.0) is connected

No client is connected

Normal operation; RS485-1 is functioning

properly.

No communication on RS485-1.

Communication on RS485-1 has been

switched OFF, but the CLIF-CBUSLC is

receiving data from controllers.

The CLIF-CBUSLC is attempting to establish

communication on RS485-1, but there is no

answer.

, COACHAX or

Table 19. CLIF-CBUSLC Tx and Rx LEDs

► Check power supply voltage.

► Check wiring.

► If problem persists, replace hardware.

► Try powering down and then powering up the CLIF-

CBUSLC.

► If problem persists, replace hardware.

No action necessary.

► If you are unable to establish communication, check

IP address, SUSI port number, …

No action necessary

► Switch ON communication on RS485-1. Further

handling like case 4 (below).

► Use client to establish a connection with correct

device ID and baud rate

► The communication rate (Kbaud) on RS485-1 has

not been correctly set; controllers on the C-Bus may

have been setup incorrectly; wiring problem or

hardware defect.

21 EN1Z-1026GE51 R0417

Page 22

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

APPENDIX 1: EARTH GROUNDING

CLIF-CBUSLC and SELV

In order to avoid distribution of noise or earth ground potential

differences over networks or other connections, the CLIFCBUSLC is designed to be in compliance with SELV (Safety

Extra-Low Voltage).

Furthermore, SELV offers the greatest possible safety against

electrical impact.

To support SELV, all Honeywell external (CRT series) or

internal transformers comply with standard EN60742.

Earth grounding is therefore not recommended.

CLIF-CBUSLC and Standard EN60204-1

However, if compliance with EN60204-1 is required, note the

following:

General Information about EN60204-1

EN60204-1 defines electrical safety for a complete application

/ machine including controllers, sensors, actuators and any

connected/controlled electrical device.

EN60204-1 requires controllers to be powered by PELV

(Protective Extra-Low Voltage) and earth grounding of the

secondary side of the used transformers or earth grounding of

the system ground.

Earth grounding is prescribed to prevent unexpected start-up

of connected rotating/moving machines due to an insulation

fault and double earth grounding somewhere in the plant.

In order to fulfill PELV (if earth grounding is prohibited), the

use of an earth leakage monitor is also possible.

When is EN60204-1 Applicable to CLIF-CBUSLC

Systems?

Safety against electrical impact

– EN60204-1 is not mandatory; this is because electrical

safety is provided by the use of SELV and transformers

according to standard EN60742.

Safety against unexpected start-up of rotating/moving

machines

– If the application/plant does not contain machines that

can be harmful to the operator due to an unexpected

start-up, the standard EN60204-1 is not applicable.

If such machines are encountered, then EN60204-1 must be

followed. Grounding is required.

Earth Grounding of EN60204-1 Applicable

Systems

NOTE: Our recommendation is that each CPU be supplied

► If system protective earth grounding is planned, use a

► For connection details, refer to the following examples.

Example 1

The following explains how to connect and earth multiple

CPUs (e.g., multiple CLIF-CBUSLCs, PANTHERs, TIGERs,

LIONs, etc. or any combination thereof) earth-grounded as

per EN60204-1.

NOTE: Use a noise-free earth ground inside the cabinet.

NOTE: If a field device that prohibits earth grounding is

► Connect earth ground to the respective terminal of the

L

LINE

N

L

LINE

N

(RECOMMENDED USE OF SEPARATE TRANSFORMERS)

with electricity from its own dedicated transformer.

cable as short as possible for grounding:

min. 1.5 mm² (16 AWG).

connected to the system ground, an isolation

monitoring device must be used instead of earth

grounding.

CPU, see Fig. 24.

CPU 1

RS485-2 + RS485-2 -

24V~24V~0

29 30

21

24 V~

24 V~0

NOISE-FREE EARTH GROUND

(ONLY ONE PER SYSTEM)

CPU 2

RS485-2 + RS485-2 -

24V~24V~0

29 30

21

24 V~

24 V~0

NOISE-FREE EARTH GROUND

(ONLY ONE PER SYSTEM)

Fig. 23. Connecting and earthing multiple CPUs

I/O MODULE I/O MODULE

COM

COM

24V~ 24V~24V~0 24V~0

B

A

74 7472 7273 7371 71

COM

COM

B

A

RECOMMENDED

24 V~

Y

GND

FIELD DEVICE

EN1Z-1026GE51 R0417 22

Page 23

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

Example 2

When connecting multiple CPUs to a single transformer, it is

imperative that the polarity of the power supply terminals of

the CPUs and the polarity of the transformer always correspond (namely: 24V-0 of the transformer must always be

connected to 24V-0 of the CPU, and 24V~ of the transformer

must always be connected with 24V~ of the CPU).

Depending upon the individual CPU, the numbering of the

corresponding two terminals may possibly deviate from the

norm (which is usually "terminal 1 = 24V-0" and "terminal 2 =

24V~"). In the following example, CPU 3 has a deviating

numbering and must be connected accordingly.

NOTE: When using a single transformer for several CPUs,

NOTE: If the field device transformer is physically far away

NOTE: Use one star-point to split power for multiple CPUs

► Connect earth ground to the proper terminal of the CPU.

each CPU ground must wired separately to the

star-point.

from the CPUs, earth grounding must still be

performed for the controller.

and field devices.

DEVIATING

CPU 1 CPU 2 CPU 3 CPU N

24V~ 24V~ 24V~ 24V~24V~0 24V~0 24V ~0 24V~ 0

2 2 2 21 1 1 1

NUMBERING!

LINE

24 V~

24 V~0

NOISE-FREE EARTH GROUND

(ONLY ONE PER SYSTEM)

L

N

Fig. 24. Connecting and earthing multiple CPUs

24 V~

Y

GND

FIELD DEVICE

23 EN1Z-1026GE51 R0417

Page 24

CLIF-CBUSLC INTERFACE – INSTALLATION & COMMISSIONING INSTRUCTIONS

INDEX

C-Bus

C-Bus via Ethernet Interface, 3

C-Bus via RS485-1, 5

LED, 10

C-Bus architecture, 4

C-Bus via RS485-1, 3, 10

disposal

WEEE Directive 2002/96/EC, 2

Ethernet / RJ45 socket

details, 10

protocol version, 2

Ethernet Interface

RJ45 socket, 5

External HMI

power consumption, 3

RJ45 socket, 12

extra parts

TPU-11-01 removable push-in terminal plugs, 13

TPU-45-01 removable push-in terminal plugs, 13

fusing, 13

LEDs, 5

L2, 3, 10, 21

power LED, 3, 10, 21

Rx, 3, 10, 21

status LED, 3, 10, 21

Tx, 3, 10, 21

power supply

failure indication, 21

power supply (field devices)

via Panel Bus I/O module, 14

RS232 / RJ45 socket, 5

RS232 Interface

RJ45 socket, 5

safety

electrical safety as per EN60204-1, 22

general safety information, 2, 13

PELV, 22

SELV, 22

USB

USB 2.0 Device Interface, 3, 5

details, 6

initially accessing CLIF-CBUSLC via Ethernet/IP, 15

USB 2.0 Host Interface, 3, 5

details, 5

Manufactured for and on behalf of the Environmental & Energy Solutions Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

CentraLine

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone +49 (0) 7031 637 845

Fax +49 (0) 7031 637 740

info@centraline.com

www.centraline.com

Subject to change without notice

EN1Z-1026GE51 R0417

Loading...

Loading...