Page 1

EN1I-6312

USER’S MANUAL

CD3200

THYRISTOR UNIT

Up To 110A

Rev. 12/2004

Page 2

Page 3

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

1 www.honeywell.com/imc

CD3200 Thyristor Unit up to 110A

Index:

1. Glossary 5

1.1 Terminology 5

1.2 Input signal 5

1.3 Power feed back 5

1.4 What is a thyristor unit 5

2. Technical specifications 6

2.1 General Features: 6

2.2 Input features 7

2.3 Output features 7

2.4 Derating curve 7

3. Ordering information 8

4. Installation and wiring information 9

4.1 Identification of the unit 9

4.2 Installation 9

4.3 Dimensions 10

4.4 Dimension CT (Heater Break HB) 10

4.5 Fixing holes 11

5. Wiring Instructions 12

5.2 Cabling detail 13

5.3 Wiring connection 15

5.4 LED Status Table 17

6. Start up 18

6.1 To remove the board 19

6.2 Auxiliary supply 20

6.3 Analog input 21

6.4 Heater Break Alarm 23

6.5 Current Limit Tuning 28

7. Thyristor firing mode 29

7.1 Phase Angle + Current Limit (PA) 29

7.2 Configurator 30

8. Fuse and fuseholder for UL certification units 32

8.1 Fuse and Fuse Code 32

8.2 FuseHolder size 33

9. Fuse and fuseholder for CE mark unit 34

9.1 Fuse and Fuse Code 34

9.2 FuseHolder size 35

Page 4

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 2

10. Modbus communication 36

10.1 Physical requirements 36

10.2 ModBus RTU protocol 36

10.3 Word parameters 41

10.4 Address Configuration 48

11. Maintenance 51

11.1 Trouble Shooting 51

11.2 Repairing procedure 52

11.3 Fans 52

11.4 Servicing 52

11.5 Warranty conditions 52

Page 5

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

3 www.honeywell.com/imc

CAUTION

Thyristor units are used in power industrial equipment. When the thyristor unit is working, there

are on the unit the following voltages

- Maximum main supply voltage on power terminals up to 600V.

- Auxiliary supply 230-460Vac.

- Fan voltage 230Vac 50/60Hz Power consumption 14W.

Don't remove the plastic cover which provides adequate protection against electric shock.

Don’t use this thyristor in aerospace and nuclear application.

Electric Shock Hazard

When thyristor unit has been connected to main supply voltage and is switched off, before to touch

it be secure that the unit is isolated and wait at least one minu te to permit to discharge internal

capacitors. Thus be secure that:

• access to thyristor unit is only permitted to specialized personnel;

• the authorised personnel must read this manual before to have access to the unit;

• the access to the units must be denied to unauthorized personnel.

Important warnings

• Local regulations regarding electrical installation should be rigidly observed.

• Safety regulations must be rigidly observed.

• Don't bend components to maintain insulation distances.

• Protect the units from high temperature, humidity and vibrations.

• Don't touch components to prevent elettrostatichal discharges on them.

• Verify that all ratings are in line with real needs.

• If authorized personnel must measure voltage, current etc. on units, take away rings and other

jewels from fingers and hands.

• Authorized personnel working on thyristor unit under power supply voltage must work on

insulated board. Be secure that board is not connected to earth.

This listing does not represent a complete enumeration of all necessary safety cautions.

Page 6

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 4

Protection

CD3000 thyristor family has a polymeric plastic cover in compliance to International specification

IP20. To understand if IP20 protection is sufficient should be evaluated the installation place where

the units are installed.

Open Type Equipment.

Maximum surrounding air temperature 40°C.

Earth

CD3000 family has isolated heatsink. For safety connect the heatsink to earth to avoid shocks in

case that circuit board or thyristors lost insulation. Earth impedance should be correspondent to

local earth regulation. Periodically the earth efficiency should be inspected.

Electronic Supply

CD3000 family electronic circuit should be supplied by dedicated voltage supply for all electronic

circuit but not in parallel with contactor's coil, solenoids and other inductive or capacitive loads. It's

recommended to use a shielded transformer.

Electromagnetic compatibility

Our thyristor unit has an excellent immunity to electromagnetic interferences if all suggestions

contained in this manual are respected. In respect to a good Engineering practise, all inductive

loads like solenoids contactor coils should have a filter in parallel.

Emissions

All thyristor switching at high speed generate some radiofrequency disturbance. CD3000 serie

complies with EMC rules for CE mark. In many installations near electronic devices has not been

noted problems. If radiofrequency device at low frequency are used near the thyristor unit, some

precautions should be taken like line filters and shielded cables for input signal an d for load cables.

CU

LISTED

S

U

L

®

NOTE

We reserves the right to apply modifications to the our products without any advice.

Page 7

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

5 www.honeywell.com/imc

1.Glossary

1.1 Terminology

V: voltage power supply.

I: the full circulating current in thyristor unit.

P: total load power.

1.2 Input signal

SSR: This input type is a square waveform generated by a temperature controller.

AN: Analog input.

IRS: Communication command.

1.3 Power feed back

Feedback: supply voltage fluctuation changes the power to the load. To overcome this effect the

voltage supplied to the load is measured and compared with power demand from controller, the

error signal is used to automatically hold the power at demanded level.

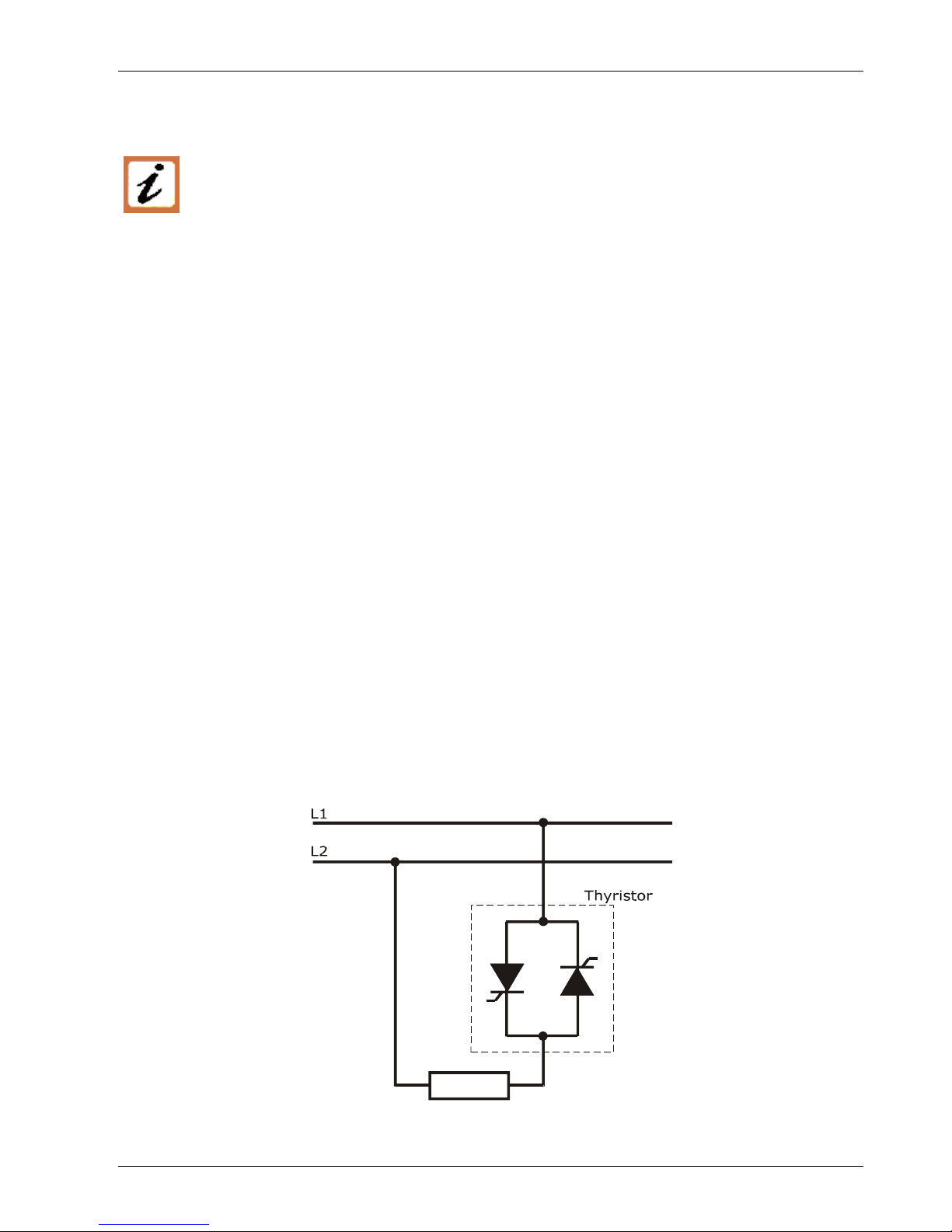

1.4 What is a thyristor unit

A thyristor unit is semiconductor device which acts as a switch formed by two thyristors in

antiparallel. To switch on the alternating current the input signal will be on and the thyristor will

switch off at first zero crossing voltage with no input signal. The benefits of thyristor units

compared with elettromechanical contactors are numerouses: no mooving parts, no maintenance

and capacity to switch very fast. Thyristors are the only solution to control transformers and

special loads that change resistance with temperature and with age.

LOAD

Page 8

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 6

2. Technical specifications

2.1 General Features:

Operating temperature

0÷40°C for higher temperature see derating curve

Voltage power supply 24V minimum, 480V max and 600V on request

Input signal SSR

4÷20mA

0÷10V

potentiometer (10k ohm)

customer configurable with automatic zero/span calibration

Firing mode One of these firing modes can be configured on line via serial port

Phase Angle + Current Limit (PA)

Soft Start + Phase Angle + Current Limit (S + PA)

Auxiliary voltage supply 230V ±15%; 10VA power consumption

440V ±15%; 10VA power consumption

Fan voltage supply 230V ±15%;

110V ±15%; on request

Heater break alarm

Discrimination better than 20%. Circuit microprocessor based to

diagnose partial or total load failure and short circuit on Thyristors.

Latching alarm plus reset. Relay output 0,5A at 125V

Feedback

Voltage feedbak (V)

Square Voltage feedbak (V²)

Power feedback (VxI) (option)

Serial communication RS485 Modbus protocol (option)

Mounting

Din rail mounting up to 45A

Bulk head over 45A

Protection IP20

Page 9

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

7 www.honeywell.com/imc

2.2 Input features

Input signal

Input

Impedance

Analog 0÷10V 8200 ohm

Analog 4÷20mA 100 ohm

Potentiometer

10Kohm

8200 ohm

2.3 Output features

NA=not Available

Current Voltage range Ripetitive peak

reverse voltage

Latching

current

Max peak

one cycle

Leakage

current

I2T value for

fusing

Frequency

range

Power

loss

Isolation

Voltage

(A) (V) (440V)

(500V) (mAeff)

(10msec.)

(A)

(mAeff) tp=10msec (Hz)

I=Inom

(W)

Vac

15A 24÷440 1200 NA 150 230 15 610 47÷70 18 2500

25A 24÷440 1200 NA 150 230 15 610 47÷70 30 2500

35A 24÷500 1200 1600 250 400 15 780 47÷70 42 2500

45A 24÷500 1200 1600 250 600 15 1800 47÷70 54 2500

60A 24÷500 1200 1600 450 1000 15 4750 47÷70 72 2500

90A 24÷500 1200 1600 450 2000 15 19200 47÷70 108 2500

110A 24÷500 1200 1600 450 1350 15 8830 47÷70 137 2500

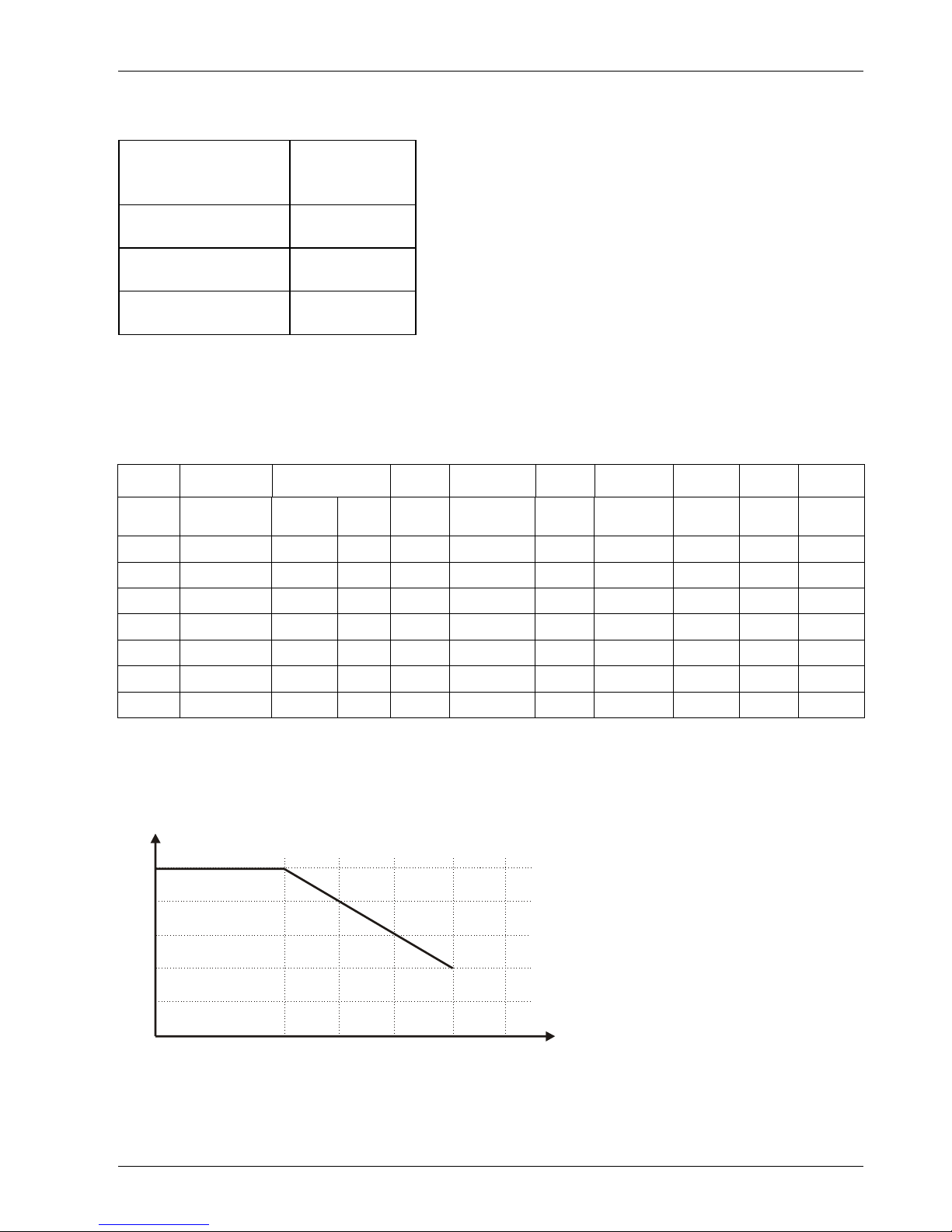

2.4 Derating curve

1

0.8

0.6

0.4

0.2

0

45 55 65 75 85

K

°C

I = I x K

NOMMAX

Page 10

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 8

3. Ordering information

Model CD3200

1 2 3 4 5 6 7 8

CD3200

Ex:CD3200 90A/ 400/ 480/ 460/ SSR/ ZC/ V2/ UL

1 Nominal current of CD3200M

15A 45A 110A

25A 60A

35A 90A

2 Operating Load Voltage (incoming voltage supply)

Specify the value of the line supply.

3 Max VOLTAGE of CD3200

480V

600V

The voltage on the identification label must be equal or more than

operating voltage. The minimum voltage supply to the load is 24V.

4 Auxiliary Voltage

230V 200÷230V ±15%; 10VA

460V 300÷460V ±15%; 10VA

600V 600V ±15%; 10VA (on request)

5 Input

SSR 4÷30VDC

0-10V 0÷10V analog input

4-20mA 4÷20mA analog input

10K pot Potentiometer

6 Firing

PA Phase Angle + Current Limit

S + PA Soft Start + Phase Angle + Current Limit

7 Feedback

V Voltage feedback (V)

V2 Square Voltage feedback (V²)

VxI Power feedback (VxI) (option)

8 Options

COMM MODBUS protocol in RS485 is standard

CD-KP External Keypad

HB Heater Break Alarm

FAN110

Fan voltage supply 110VAC ± 15% (std 230VAC ± 15%) 14W

50/60Hz

UL UL Certification

EF External fuse and fuseholder

NF No Fuse

Page 11

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

9 www.honeywell.com/imc

4.Installation and wiring information

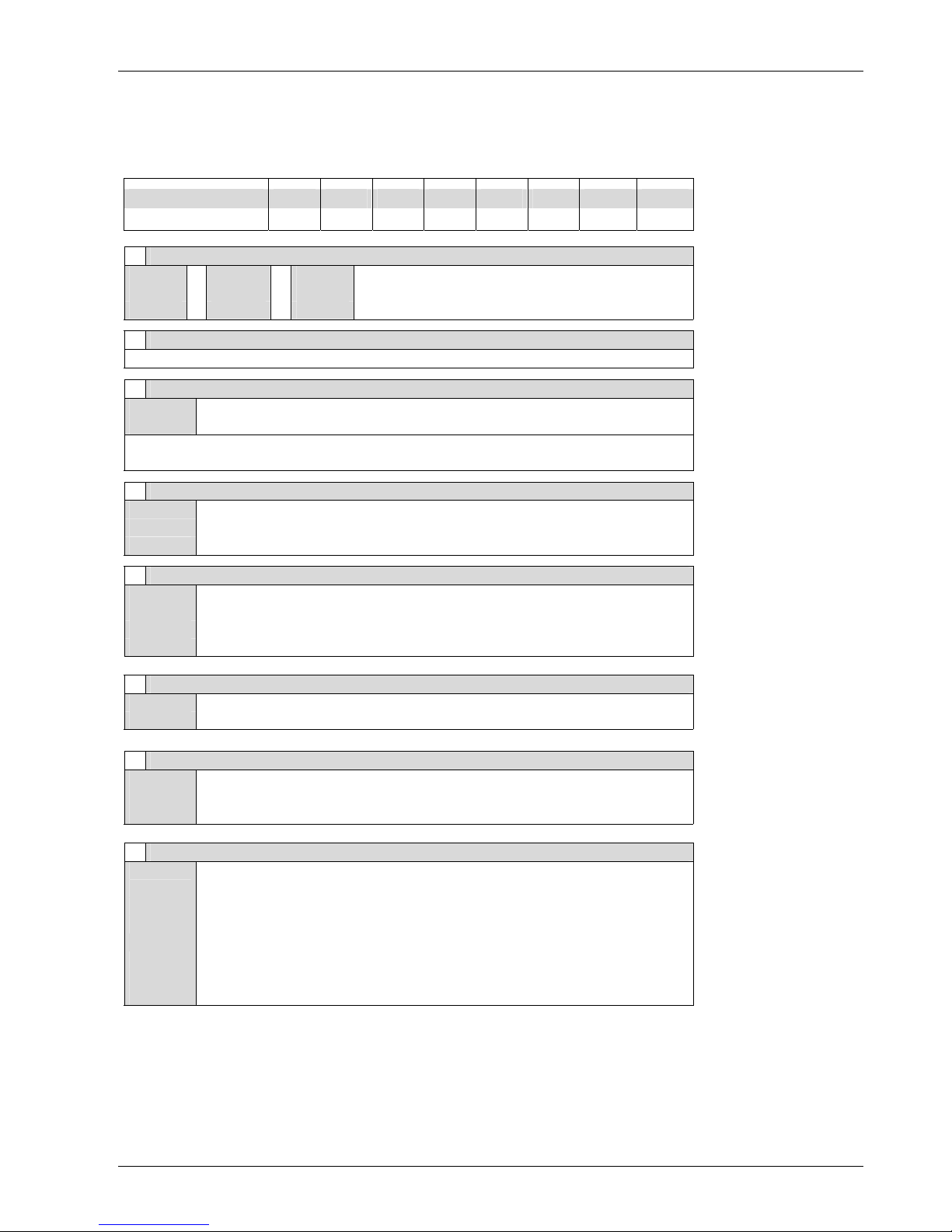

4.1 Identification of the unit

Before to install the CD3200 unit examine for damages or deficiencies. If any is found,

notify the carrier immediately. Check that the product features shown on CD3200

cover and identification label corresponds to that ordered.

INPUTAMPS AUX. FIRING OPT.

0-10V15 60

240V

____

4-20mA25 90

440V

SC DT

SSR35 110

POT45

___

____

PA

S.S

ZC

An identification label provides all the

informations regarding the factory

settings of the unit. This label is on the

board inside the unit, as represented

4.2 Installation

CD3200 unit should be always

mounted in vertical position to

improve air cooling on heatsink.

Maintain minimum distances in

vertical and in horizontal as below

represented. Don’t install in proximity of hot

elements and near units generating

electromagnetic interferences.

A

IR OUTPUT

A

IR INP UT

15cm

2 cm

When more units are mounted inside a cubicle

provide air circulation as below represented.

Sometimes it is necessary to provide a fan to

have a better air circulation.

Page 12

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 10

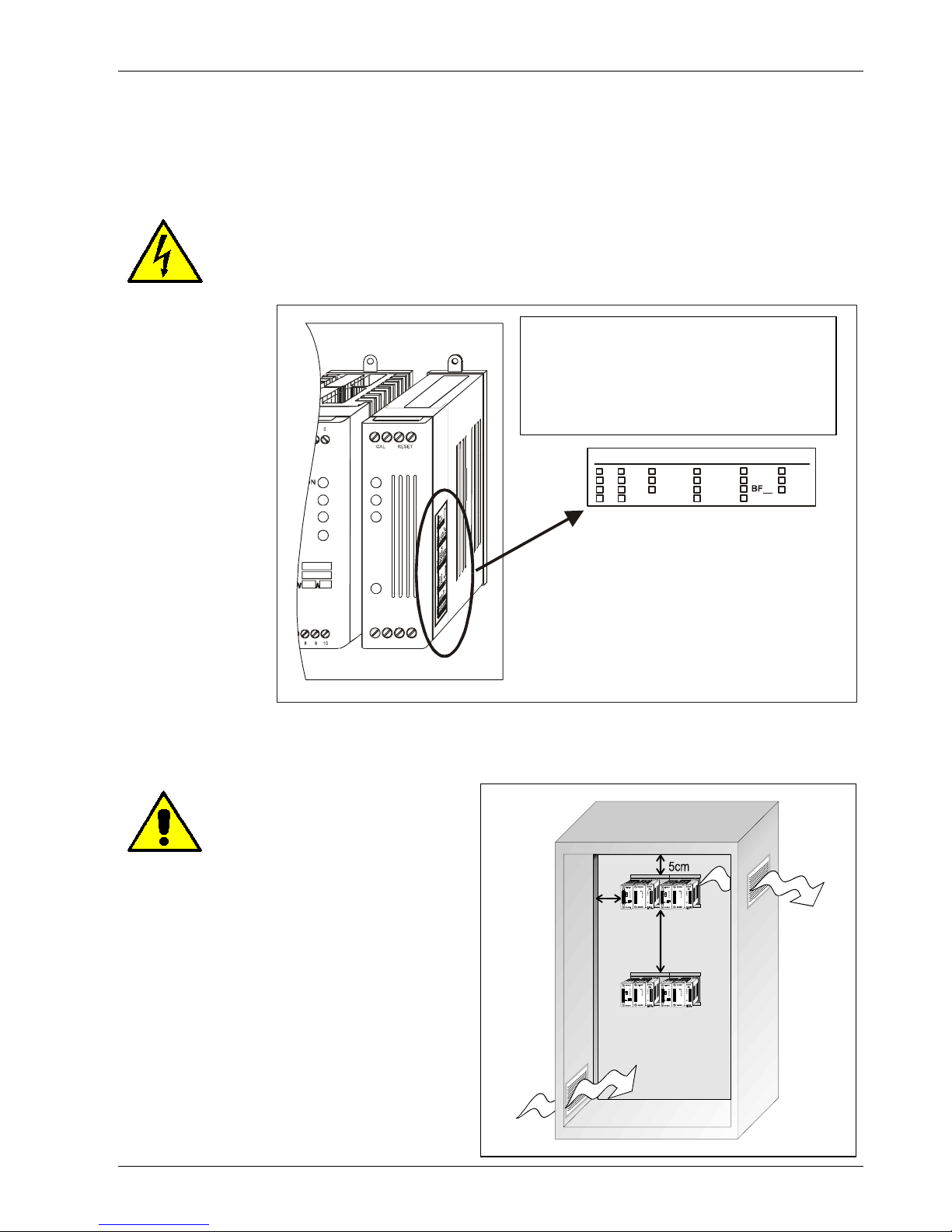

4.3 Dimensions

Size W(mm) H(mm) D(mm)

15A (S0C) 63 120 120

25A (S0C) 63 120 120

35A (S3C) 85 120 120

45A (S3C) 85 120 120

60A (S7C) 148 120 159

90A (S7C) 148 120 159

110A (S8C) 148 138 159

4.4 Dimension CT (Heater Break HB)

8

1

2

39

39 20

Page 13

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

11 www.honeywell.com/imc

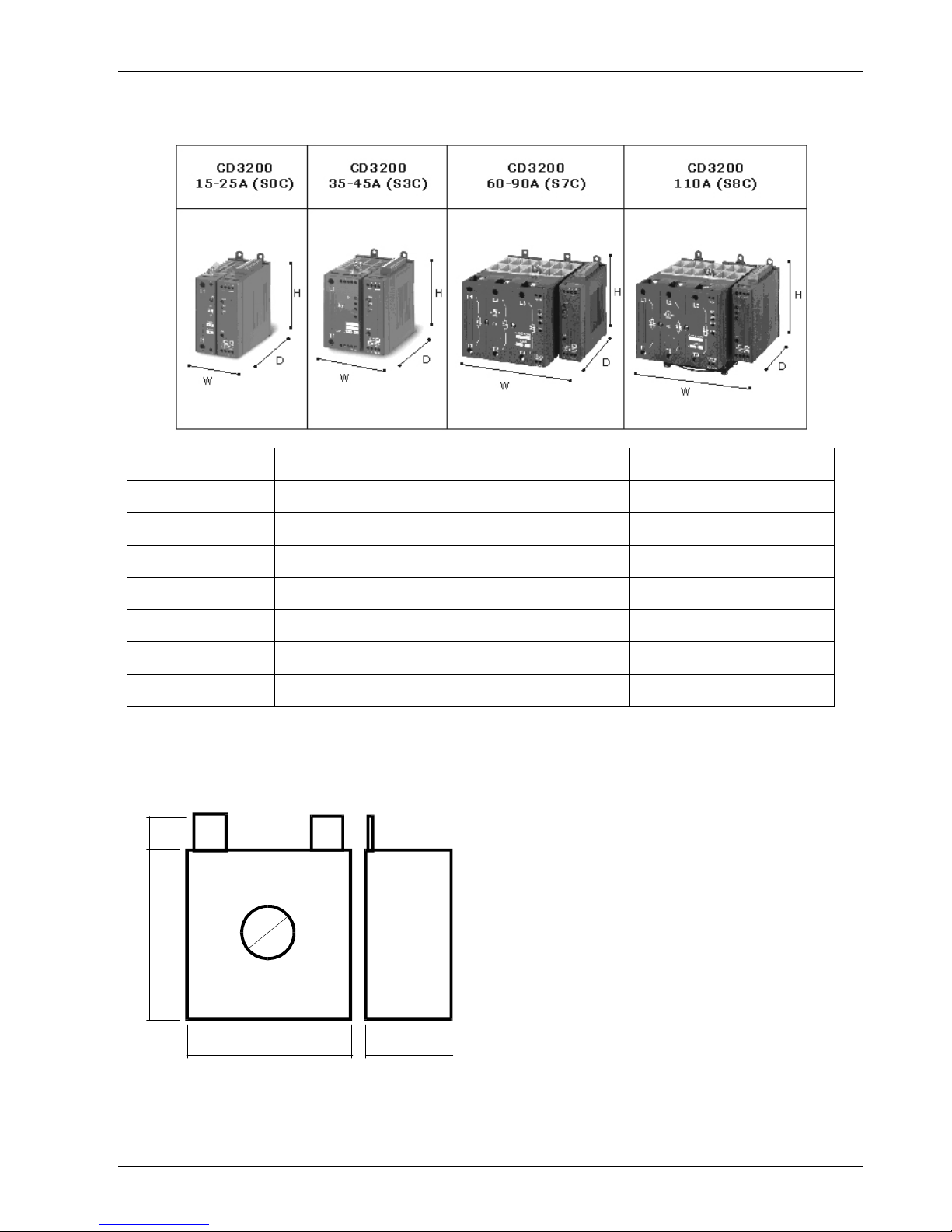

4.5 Fixing holes

A

B

C

D

Size A(mm) B(mm) C(mm) D(mm)

15A (S0C) 110 - - -

25A (S0C) 110 - - -

35A (S3C) - 110 - -

45A (S3C) - 110 - -

60A (S7C) - - 110 65

90A (S7C) - - 110 65

110A (S8C) - - 110 65

Page 14

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 12

5. Wiring Instructions

Warning: this procedure can be done just by specialized personnel.

CD3000M unit has isolated heatsink. For safety connect the heatsink to hearth using its terminal

with hearth symbol.

CD3000M can be susceptible to airborne interferences from near equipment or from interferences

on main supply, so a number of precautions must be taken.

• Contactors coils and chokes must have in parallel a RC filter and must be supplied with a

different voltage line.

• All input/output signal must use screened bifilar wires.

• Signal input and output must not routing in same cable try and must not be parallel.

• Local regulations regarding electrical installation should be rigidly observed.

3.3.2 Auxiliary terminals

Before connect or disconnect, make sure that the power, control cables and wires are

insulated from the voltage.

Terminal Description

1 - External Calibration command 24Vdc max

2 + External Calibration command 24Vdc max

3 Reset

4 Reset

5 + Output Command signal to CD3200 (Internal Connections)

6 - Output Command signal to CD3200 (Internal Connections)

A2+ + Input command signal 4÷20mA, 0÷10V

A1- - Input command signal 4÷20mA, 0÷10V

7 RS485 A

8 RS485 B

9 Output +8Vdc stabilized 1mA MAX potentiometer power supply

10 Common relay H.B. alarm

11 NC/NO H.B. relay alarm

12 External Current Profile

13 CT input with H.B. option

14 CT input with H.B. option

15 Nc not connected

16 Auxiliary supply voltage 240-440Vac

17 Ground

18 Auxiliary supply voltage 240-440Vac

5.1.1 Power Terminals

Before connect or disconnect, make sure that the power, control cables and wires are

insulated from the voltage

Terminal Description

L1 Line Input

T1 Load Output

Page 15

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

13 www.honeywell.com/imc

5.2Cabling detail

Use 75°C copper (CU) conductor only, provided with the terminal type indicated below.

(Utiliser conducteur de cuivre (CU) pour 75°C seulement , avec les terminal suivants )

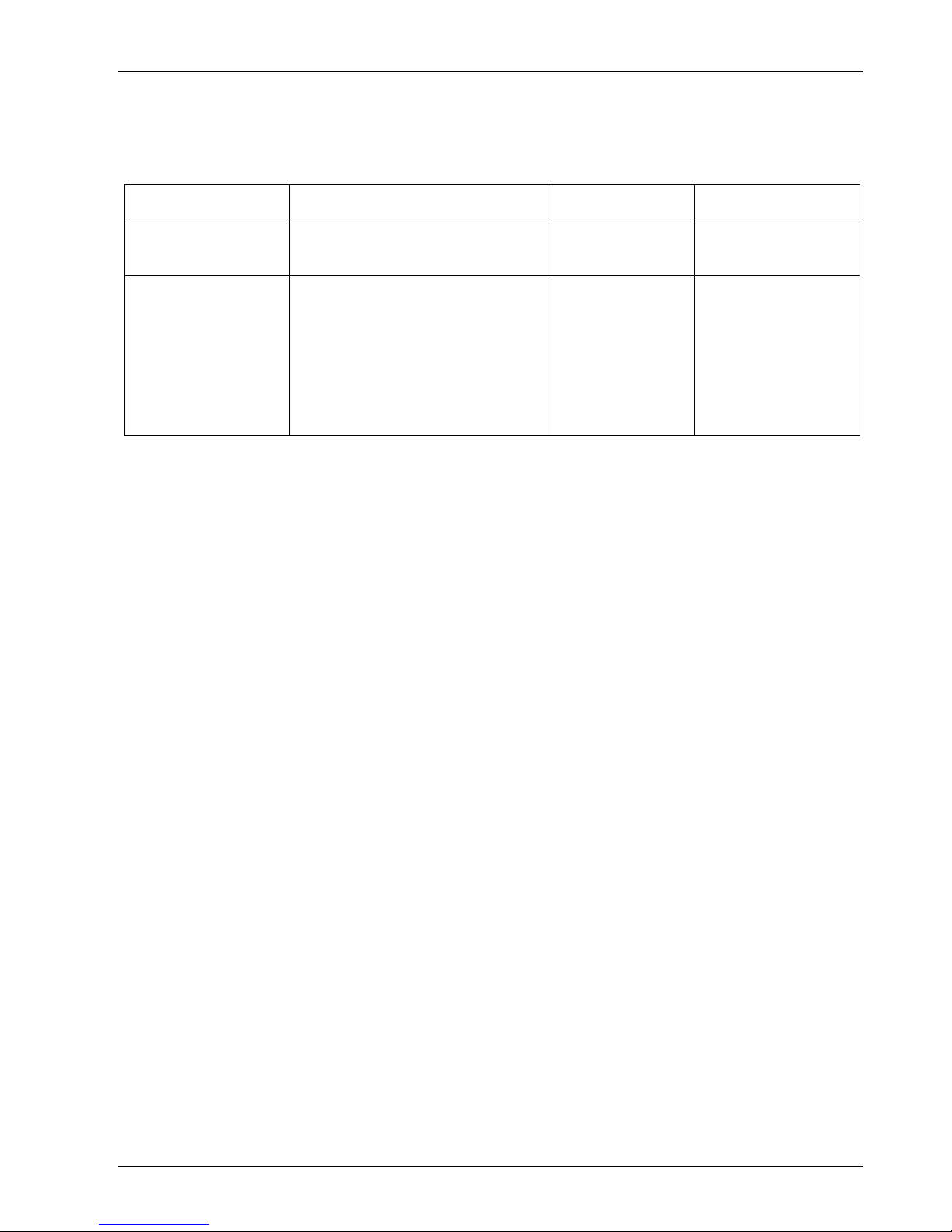

Current/courant

Torque/couple

Lb-in (N-m)

Wire/cable

Wire

terminal/terminal

15A, 25A, 35A, 45A 26.6 (3.0) 18-8

UL Listed (ZMVV)

Wire Pin Terminal

(terminal avec cosse)

60A, 90A, 110A 70.8 (8.0) 18-1

UL Listed (ZMVV)

- Fork/Spade

Terminal

(terminal avec

cosse a fourche)

- Copper Tube Cr.

Lug

(cosse tubulaire a

plage étroite)

Page 16

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 14

Power terminals wire details:

Current Supply Load

Cable Clable

mm

2

AWG

Screw

M

mm

2

AWG

Screw

M

15A 4 12 M5 4 12 M5

25A 6 10 M5 6 10 M5

35A 10 8 M5 10 8 M5

45A 10 8 M5 10 8 M5

60A 16 6 M6 16 6 M6

90A 35 3 M6 35 3 M6

110A 35 2 M6 35 2 M6

Auxiliary connectors and earth:

Current Auxiliary Supply Earth

Cable Clable

mm

2

AWG

mm

2

AWG

Screw

M

15A 0,50 18 4 12 M4

25A 0,50 18 4 12 M4

35A 0,50 18 6 10 M5

45A 0,50 18 6 10 M5

60A 0,50 18 6 10 M5

90A 0,50 18 10 8 M5

110A 0,50 18 16 6 M5

Page 17

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

15 www.honeywell.com/imc

5.3 Wiring connection

5.3.1 CD3200 15-25A

POWER UNIT

Input

CT

Reset

-

+

RS485-B

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A2+3A1-

4

RS485-A

COM

NO/NC

H.B.

Contact

8V

External

Calibration

+-

L1

L2

CT

**

* The user installation must be protect by

electromagnetic circuit breaker or by fuse

isolator

** If the Auxiliary Voltage (written on the

identification label) is different from Supply

Voltage (to the load ), use an external

transformer as designated above.

NOTE:

IMPORTANT

To work, terminals 3-4 must be linked.

The auxiliary voltage supply of CD3200 unit must be connected as above, and must be

syncronized with load voltage power supply (L1, L2).

5.3.2 CD3200 35-45A

POWER UNIT

Input

CT

Reset

-

+

RS485-A

162738495

10

RS485-B

COM

NO/NC

H.B.

Contact

8V

External

Calibration

+-

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A

2+

3

A

1-

4

CT

L1

L2

**

* The user installation must be protect by

electromagnetic circuit breaker or by fuse

isolator

** If the Auxiliary Voltage (written on the

identification label) is different from Supply

Voltage (to the load ), use an external

transformer as designated above.

NOTE: IMPORTANT

To work, terminals 3-4 must be linked.

The auxiliary voltage supply of CD3200 unit must be connected as above, and must be

syncronized with load voltage power supply (L1, L2).

Page 18

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 16

5.3.3 CD3200 60-90A

Input

CT

Reset

-

+

RS485-A

RS485-B

COM

NO/NC

H.B.

Contact

8V

External

Calibration

+-

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A

2+

3

A

1-

4

CT

L1

L2

**

L1

T1

* The user installation must be

protect by electromagnetic circuit

breaker or by fuse isolator

** If the Auxiliary Voltage (written

on the identification label) is

different from Supply Voltage (to

the load ), use an external

transformer as designated above.

NOTE:

IMPORTANT

To work, terminals 3-4 must be linked.

The auxiliary voltage supply of CD3200 unit must be connected as above, and must be

syncronized with load voltage power supply (L1, L2).

5.3.4 CD3200 110A

Input

CT

Reset

-

+

RS485-A

RS485-B

COM

NO/NC

H.B.

Contact

8V

External

Calibration

+-

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A

2+

3

A

1-

4

CT

L1

L2

**

L1

T1

FAN

220 Vac

* The user installation must be

protect by electromagnetic circuit

breaker or by fuse isolator

** If the Auxiliary Voltage (written

on the identification label) is

different from Supply Voltage (to

the load ), use an external

transformer as designated above.

NOTE:

IMPORTANT

To work, terminals 3-4 must be linked.

The auxiliary voltage supply of CD3200 unit must be connected as above, and must be

syncronized with load voltage power supply (L1, L2).

Fan voltage supply standard 230VAC ±15% 14W 50/60Hz or optional110VAC ±15%

14W 50/60Hz

Page 19

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

17 www.honeywell.com/imc

5.4 LED Status Table

LED STATUS DESCRIPTION

PW

Auxiliary supply is not connect

Auxiliary supply is connect

SC

SCR OK

SCR short circuit

HB

Laod OK

Load Fault

ON

OFF Condition(Load IS NOT Powered)

ON Condition(Load IS Powered)

= OFF

= ON

Page 20

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 18

6. Start up

Before to supply the thyristor unit:

• verify that load current equal or less than nominal;

For resistive load For indu ctive load

I

=

V

P

Tot

I

=

V

cos

φ

P

Tot

• verify that there is no short circuit on load;

• verify that main voltage equal or less than nominal;

• verify that all auxiliary connections are right and syncronized to main voltage!!!;

• Fan voltage equal than nominal (230V std, 120V optional)

After which supply thyristor unit giving the maximum input signal and verify that load current is

equal or less than thyristor unit nominal current.

Warning: this procedure can be done just by specialized personnel.

The thyristor unit is delivered configured and tuned in line with customer

requirements. If it’s necessary to change on site the configuration, procede as below

specified.

Page 21

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

19 www.honeywell.com/imc

6.1To remove the board

1 Remove plastic Cover 2 Pull the PCB

Page 22

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 20

6.2 Auxiliary supply

Warning: this procedure can be done just by specialized personnel.

To change auxiliary supply voltage sold the correct link-jumper on main PCB

230V Auxiliary supply

Main PCB

460V Auxiliary supply

J9

J10

J11

J9

J11

J10

J9

J10

J11

• If the Auxiliary Voltage (written on the identification label) is different from Supply Voltage

(to the load ), use an external transformer.

• If load voltage is not included in range of 230V ±15% or 460V +15% provide an external

transformer with primary equal to load voltage and secondary 230V if your unit is setted to

230V.

Page 23

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

21 www.honeywell.com/imc

6.3 Analog input

Warning: this procedure can be done just by specialized personnel.

6.3.1 Setting Analog input

To change input type remove plastic cover and configure jumpers as represented below:

Jumpers Configuration

FRONT PCB

Input

J7 J16 J17

SSR

ABC

ABC

ABC

0÷10V

ABC

ABC

ABC

4÷20MA

ABC

ABC

ABC

Front PCB

Page 24

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 22

6.3.2 Tuning Analog input

Warning: this procedure can be done just by specialized personnel.

UNIT OFF

ST AR T TUNE

END

TUNE

Mantain Kay CAL pushed

and Switch ON

SSR input (3-30V)

is tuned

Analog input

is tuned

Wait for more than 10 sec.

from start flashing

yellow and red leds

Within 10 sec. from start

flashing yellow and red leds

push again moment ary

CAL Key

Yellow led only is

flashing, apply

0 input Signal

I.E.: 0V for 0-10V

4mA for 4-20mA

Red led only is

flashing, apply

10V for 0-10V input

or

20mA for 4-20mA input

Now press CAL Key again

Now press CAL Key again

The leds will

stop flashing

Release key

when red and yellow

led are ON

Y ello and red leds

are flashing

SSR

ANALOG

INPUT TYPE

ON

ON

ON

2sec.

S/C

S/C

S/C

H.B.

H.B.

H.B.

ON

S/C

H.B

ON

S/C

H.B

0 Signal

Max Signal

Page 25

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

23 www.honeywell.com/imc

6.4 Heater Break Alarm

Heater Break Alarm is a microprocessor based circuit to diagnose partial or total load failure and

short circuit on SCR and fuses failure.

• discrimination better than 20%;

• latching alarm plus reset;

• relay output 0.5A at 125VAC.

Minimum current 3A. If load current is below this value make two turns or more

around current transformer. H.B. circuit also diagnose fuse failure.

H.B. circuit reads load current via a current transformer 25-50/0.05 or 100/0.05 depending on

thyristor size.

6.4.1 Heater Break Alarm indication

LED STATUS DESCRIPTION

SC

SCR OK

SCR short circuit

HB

Laod OK

Load Fault

: LED off

: LED on

The thyristor unit is supplied with a normally closed (N/C) contact.

In alarm condition and without auxiliary voltage the contact is closed (relay coil not

energized). In normal condition (no alarm) the contact is open (relay coil energized).

6.4.2 Reset

To reset Heater Break Alarm open RESET contact on terminal 3-4.

Page 26

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 24

6.4.3HB alarm contact

Warning: this procedure can be done just by specialized personnel.

The contact of the H.B. Relay is available on auxiliary termin als.

Terminal Descriprion

10 Common relay HB alarm

11 NO/NC HB relay alarm

To change relay status remove plastic cover and configure jumpers as represented below:

STATUS RELE STATUS

MAIN PCB

J19

IN Alarm Close

Circuit not

powered

Close

CB

A

(std)

OK Open

IN Alarm Open

Circuit not

powered

Open

CB

A

OK Close

Page 27

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

25 www.honeywell.com/imc

Main PCB

Page 28

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 26

6.4.4 Calibration

This procedure it’s necessary to give set point to Heater Break. CD3000M reads the load current

many times and when the value is the same for three times takes it as set point.

Calibration procedure:

• verify that connections are correct;

• supply the thyristor unit;

• push “CAL” button on front of CD3200 unit,

or supply with 24Vdc terminals 1-2 or send command via RS485;

• the thyristor unit goes in conduction state to measure load current;

• all LEDS are ON, this means that calibration procedure is active;

• after one minute LEDS for H.B. and S/C switch off (calibration procedure is done);

• the thyristor unit is ready to work.

Page 29

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

27 www.honeywell.com/imc

6.4.5 Digital input Command

POWER UNIT

Reset

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A2+3A1-

4

COM

NO/NC

H.B.

Contact

POWER UNIT

Reset

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A2+3A1-

4

COM

NO/NC

H.B.

Contact

6.4.6 RS485 Command

POWER UNIT

Reset

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A2+3A1-

4

COM

NO/NC

H.B.

Contact

POWER UNIT

Reset

1

65

7

8

9

10

11

12

13

14

15

16

17

18

2

A2+3A1-

4

COM

NO/NC

H.B.

Contact

If load current decreases for partial or total load failure (sensitivity 20% standard adjustable v ia

RS485) the yellow LED becomes ON and alarm relay changes status.

If CD3200 is still in conduction with no input signal (LED green OFF) it means that there is a short

circuit on thyristors and red LED (SC) becomes ON.

The diagnostic is active only when the switching period is longer than 60ms (3 main

voltage cycles).

If the load has been changed calibration procedure must be done again.

Page 30

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 28

6.5 Current Limit Tuning

Warning: this procedure can be done just by specialized personnel.

To adjust the current limit, remove the cover of the CD3200 module and tune the trimmer R13 as

below represented.

Completely anti-clockwise: current limit = 0%.

Completely clockwise: current limit = 100% of the maximum value of the used current

transformer.

Front PCB

Current Limit Pot.

Page 31

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

29 www.honeywell.com/imc

7. Thyristor firing mode

7.1 Phase Angle + Current Limit (PA)

With Phase Angle is possible to control the power to the load allowing to Thyristor to be in

conduction for a variable part of the voltage supply halt cycle. The load power can be adjusted

from 0 to 100% as a function of analog input signal, normally delivered by temperature controller

or by potentiometer. Normal it's used with inductive loads. The only disadvantage with phase

angle is the generation of interferences that can be reduced with filters.

LINE VOLT AGE

T

V

LOA D SUPPLY

T

Page 32

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 30

7.2 Configurator

To configure CD3200 unit, you can download the free software and the Configurator Manual from

our web site www.honeywell.com/imc.

To configure the unit you can use the standard communication on terminals 7-8 or use a

programming cable.

Page 33

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

31 www.honeywell.com/imc

To connect the programming cable to the thyristor unit, remove cover as in picture

PROG.

CONN.

Once removed the cover, put a side of cable in prog connector(K10) and the other side in the PC

RS232(9PIN) serial port.

Page 34

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 32

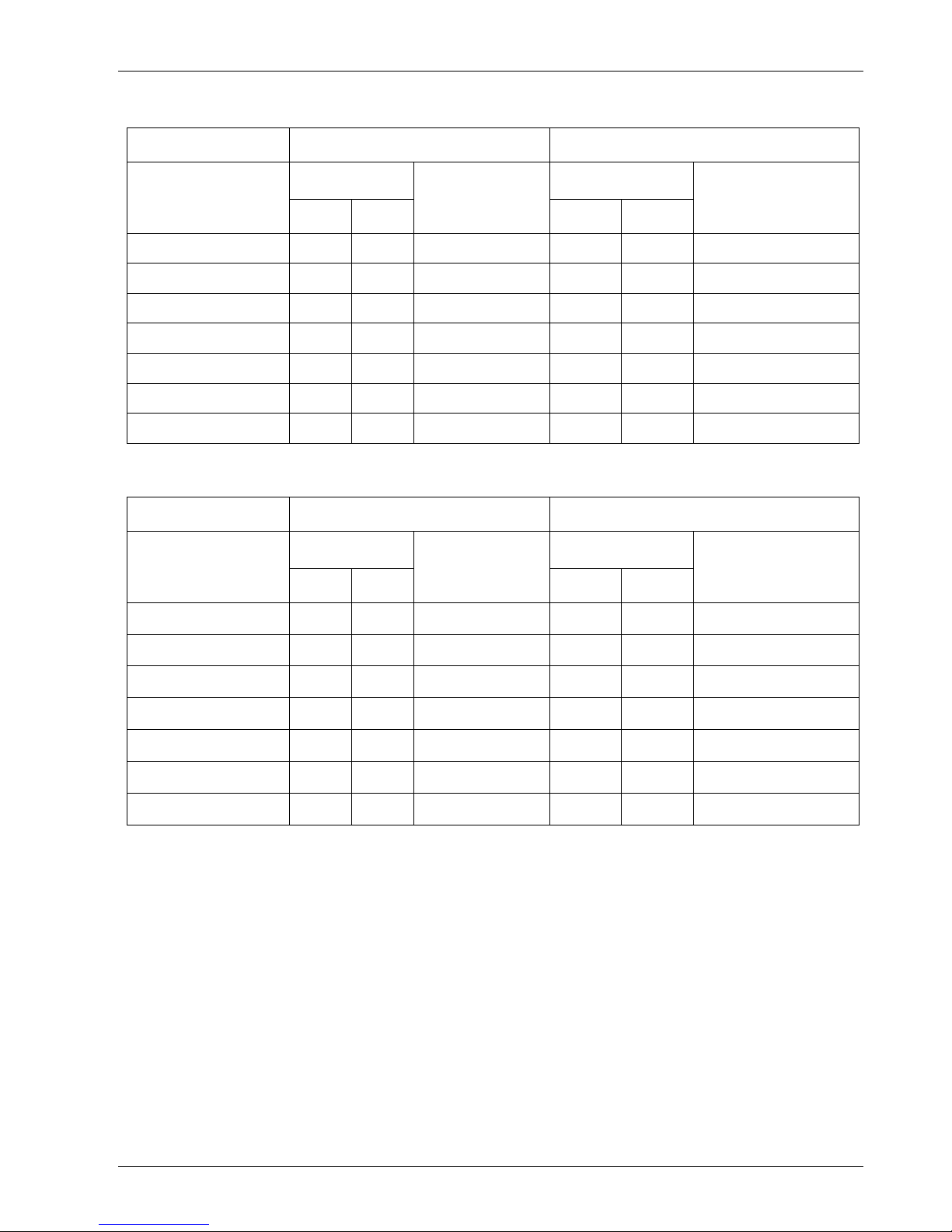

8.Fuse and fuseholder for UL certification units

8.1 Fuse and Fuse Code

CD3200 unit must be protected by fuses against short circuit selecting the proper I²t that must be

lower than thyristor one. The same caution must be taken if Circuit Breaker is used. Remember

that is very difficult to protect the thyristor if this choise is done.

WARNING!! USE SEMICONDUCTOR FUSES ONLY WITH proper I

2

t

Bussmann Div - Cooper (UK) Ltd

(200 kA

RMS

Symmetrical A.I.C.)

Ferraz Shawmut SA

(200 kA

RMS

Symmetrical A.I.C.)

Sizes

Fuse Mod. No.

/modéle fusible

Current

(A

RMS

)

I²t

(A2sec)

V ac Fuse Mod. No.

/modéle fusible

Current

(A

RMS

)

I²t

(A2sec)

Vac

15A FWC 16A10F 16 150 600 660 Grb 10-16 16 145 660

25A FWC 32A10F 32 600 600 660 Grb 10-32 32 740 660

35A FWP 40A14F 40 980 700 CP URC 14x51/40 40 700 660

45A FWP 50A14F 50 1800 700 CP URC 14x51/50 50 1500 660

60A FWP 80A22F 80 5100 700 CP URD 22x58/80 80 3800 660

90A N.A. - - - - - -

CP URQ

27x60/125

125 6970 660

110A N.A. - - - - - -

CP URQ

27x60/160

160 15000 660

High speed fuses are only used for the thyristor protection and can not be used to

protect the installation.

The user installation must be protect by electromagnetic circuit breaker or by fuse

isolator.

The warranty of thyristor is null if no proper fuses are used. See tab above.

Page 35

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

33 www.honeywell.com/imc

8.2 FuseHolder size

15-25A 35-45A

60 mm

80 mm

17mm

110 mm

77 mm

26mm

60A 90-110A

150 mm

107 mm

37mm

70 mm

9 mm

9 mm

6mm

19 mm

35mm

77 mm

125 mm

Page 36

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 34

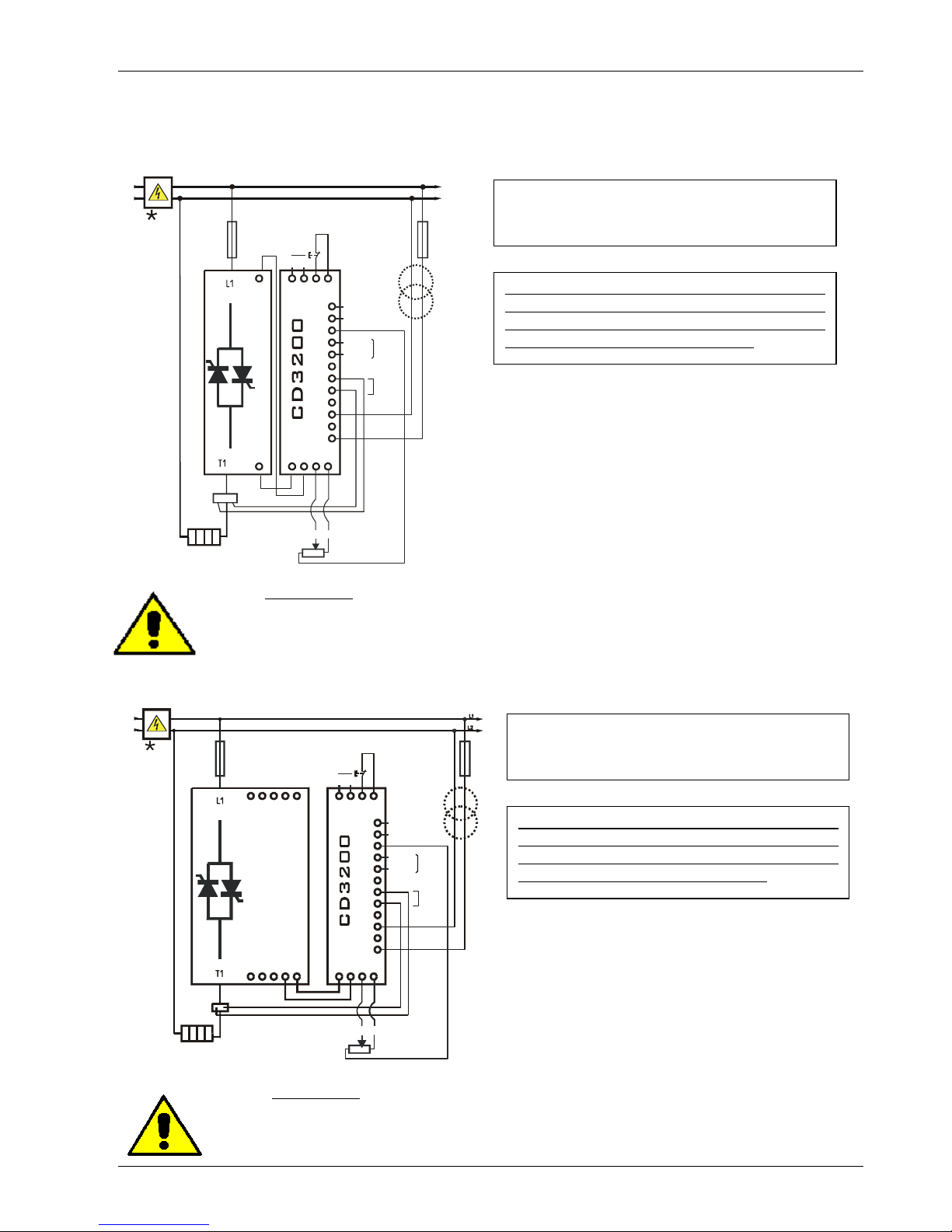

9. Fuse and fuseholder for CE mark unit

9.1 Fuse and Fuse Code

The thyristor unit must be protected by fuses against short circuit selecting the proper I²t that

must be lower than thyristor one. The same caution must be taken if Circuit Breaker is used.

Remember that is very difficult to protect the thyristor if this choise is done.

WARNING!! USE SEMICONDUCTOR FUSES ONLY WITH proper I

2

t

Sizes I²T (max)

(A² sec.)

Size and current Fuse and

Fuseholder

Code

Fuse

Code

15 600 10,3X38 / 16A FFH1038/16A FU1038/16A

25 600 10,3X38 / 32A FFH1038/32A FU1038/32A

35 780 14X15 / 40A FFH1451/40A FU1451/40A

45 1500 14X15 / 50A FFH1451/50A FU1451/50A

60 3800 22X58 / 80A FFH2258/80A FU2258/80A

90 6970 22X58 / 125A FFH2258/125A FU2258/125A

110 11000 27x60 / 160A FFHPSI27/160A FFHPSI27/160A

High speed fuses are only used for the thyristor protection and can not be used to

protect the installation.

The user installation must be protect by electromagnetic circuit breaker or by fuse

isolator.

The warranty of thyristor is null if no proper fuses are used. See tab above.

Page 37

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

35 www.honeywell.com/imc

9.2 FuseHolder size

15-25A 35-45A

60 mm

80 mm

17mm

110 mm

77 mm

26mm

60-90A 110A

150 mm

107 mm

37mm

70 mm

9 mm

9 mm

6mm

19 mm

35mm

77 mm

125 mm

Page 38

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 36

10.Modbus communication

The CD3200 is equipped with two-wire RS485-compatible serial communications, by

which means communication may occur between the Controller and a master device

(e.g. a computer or terminal).

10.1 Physical requirements

10.1.1 Character Transmission

Data format is fixed to be one start bit, eight data bits, one stop bit, baud rate 9600 and the parity

none.

10.2 ModBus RTU protocol

The standard RS485 Communications uses the industry standard MODBUS RTU protocol.

The following restrictions are imposed:

• Baud rates is fixed to 9600 Baud only.

• Support for multi-parameter Write operations is limited to support of the Multi-

Word Write Function (Number 16) but it permits the writing of only one

parameter per message.

The following MODBUS functions are supported:

Function Function Number

Read Holding Registers (Read n Word) 03

Preset Multiple Registers (Write n Word) 16

The Controller will identify itself in response to a Read Holding Registers message which enquires

the values of word parameters 121 and 122 (see Table 4-2).

MODBUS Function 17 (Report Slave ID) is not supported.

10.2.1 Message Formats

The first character of every message is the Controller address, in the range 1 - 255 and 0 for

broadcast messages.

The second character is always the Function Number.

The contents of the remainder of the message depends upon this Function Number.

In most cases the Controller is required to reply to the message by echoing the address and

Function Number.

Broadcast messages are supported at address 0 (to which the CD3000M responds by

taking some action without sending back any reply).

Data is transmitted as eight-bit binary bytes with one start bit, one stop bit and parity checking set

to none. A message is terminated simply by a delay of more than three character lengths at the

Baud rate used(in this case 9600 baud); any character received after such a delay is considered to

be the potential address at the start of a new message.

Page 39

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

37 www.honeywell.com/imc

Since only the RTU form of the protocol is supported, each message is followed by a two-byte

CRC 16 (a 16-bit cyclic redundancy checksum).

This checksum is calculated in accordance with a formula which involves recursive division of the

data by a polynomial, with the input to each division being the remainder of the results of the

previous division.

The dividing polynomial is

2

16

+ 215 + 22 + 1(Hex 18005)

but this is modified in two ways:

• because the bit order is reversed, the binary pattern is also reversed, making the most

significant bit (MSB) the right-most bit;

• because only the remainder is of interest, the right-most (most significant) bit can be

discarded.

Thus, the polynomial has the value Hex A001.

10.2.2 Bit’s order

Normal bit order

Most significant bit Least significant bit

Most significant byte Least significant Byte

Reversed bit order

Least significant bit Most significant bit

Least significant Byte Most significant byte

N.B.: Reversed order apples, so CRC16 return Reversed bit order

Page 40

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 38

START

Setting FFFF (Hex) To CR

CR= CRC error check data (1 wo rd)

I = Digits of calculation characters

in command message

J = Check on the number of times

of CR calculation

Settin g 1 to I

Settin g 1 to J

CR is shifted by

1 bit to right

Added 1t o J

Added 1 to I

END

After shifting CR by 1 bit to righ t, A001(Hex) and exclusive logical sum

(XOR) are executed for setting the result in CR

Bit at right and of CR is 1?

NO

NO

NO

YES

YES

YES

Eight times of calculation

is completed?

J>8

Calculation of all charactersis completed?

I>All charac ters numbers

Exclusive lo gic a l Sum (XO R ) is e x ecu ted on one charac ter (1 byte) at I

charactor of CR and de signat ed messa ge , an d results are set t o CR.

Page 41

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

39 www.honeywell.com/imc

10.2.3 C Language CRC 16 Example

static short CRC16 (unsigned char *p_first,unsigned char *p_last)

{

unsigned int crc=0xffff;

short j;

for (;p_first<=p_last;p_first++)

{

crc ^= *p_first;

for(j=8;j>0;j--)

{

if(crc & 0x0001)

{

crc = crc >> 1;

crc ^= 0xA001;

}

else

{

crc = crc >> 1;

}

}

}

return (crc);

}

10.2.4 Read Holding Registers (Read n Words) – Function 03

The message sent to the Controller to obtain the value of one or more registers comprises the

following eight bytes:

Addr. unit Func. Address

1° word

N° of Word CRC 16

3

3Hex

HI LO HI LO HI LO

The normal reply will echo the first two characters of the message received follow ed by a singlebyte data byte count (which will not includ e itself or the CRC).

For this message, the count value equals the number of parameter v a lues read multiplied by two.

Following the byte count, the specified number of parameter values are transmitted, followed by

the CRC16 bytes:

Addr. unit Func. Cont. 1° Value Last Value CRC 16

3

3Hex

HI LO HI LO HI LO

Page 42

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 40

10.2.5 Preset Multiple Registers (Write n Words) - Function 16

This is an eleven-byte message. only one parameter may be written for each received message.

The usual pre-amble is followed by the address of the parameter to be written, a two-byte word

count (always set to 1), a single-byte byte count (always set to 2), the value to be written and

the CRC16 bytes:

Addr. unit Func. Addr of

1° Word

N° of Word Cont. Valore CRC 16

16

10Hex

HI LO 0 1 2 HI LO HI LO

The Controller normally responds with the following eight-bit reply:

Addr. unit Func. N° of Word N° Word CRC 16

16

10Hex

HI LO 0 1 HI LO

10.2.6 Error and Exception Responses

If a received message contains a corrupted character (parity check failure, framing error etc.) or if

the CRC16 check fails, or if the received message is otherwise syntact ically flawed (e.g. byte count

or word count is incorrect), the thyristor will ignore that message.

If the received message is syntactically correct but nonetheless contains an illegal value, the

thyristor will send a five-byte exception response as follows :

Addr. unit Func. N.Exception CRC 16

HI LO

The Function Number byte contains the function number contained in the message which caused

the error, with its top bit set (i.e. Function 3 becomes 0x83) and the Exception Number is on of

the following codes:

Code Name Cause

1 ILLEGAL FUNCTION Function number out of range

2 ILLEGAL DATA ADDRES Parameter ID out of range or not supported

3 ILLEGAL DATA VALUE Attempt to write invalid data/required action not

executed

NOTE: Writing a parameter value equal to its current value is a valid transaction; this will

not cause an error response.

Page 43

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

41 www.honeywell.com/imc

10.3 Word parameters

Parametr N. Note

Actual Current 1H Read only

Actual Voltage 1L Read only

Set Current 2H Read /write

Set Voltage 2L Read /write

Status Table (shown in Tab 2.1.2) 3 Read only

Comand Table (shown in Tab 2.1.3) 4 Read /write

Output Power (0 – FFH) 5L

Read - (Write if BIT1i n Command table i = 1)

(0->0% - FF->100%)

Output Power Ramping (0 – FFH) 5L Read only

Power Scaling (0 – FFH) 6

Read - (Write if BIT1 in Command table i = 1)

(0->0% - FF->100%)*

Current Limit (0 – FFH) 7

Read - (Write if BIT4 in Command table i = 1)

(0->0% - FF->100%)

Manufact ID 121 Read only

Equipment ID 122 Read only

10.3.1 Actual Current Parameter 1H

Operations: Read

10.3.2 Actual Voltage Parameter 1L

Operations: Read

10.3.3 Set Current Parameter 2H

Operations: Read

10.3.4 Set Voltage Parameter 2L

Operations: Read

10.3.5 Status Table Parameter 3

Operations: Read

Meaning:

It’s a tab in bit that represents the “Status” of thyristor unit.

10.3.6 Comand Table Parameter 4

Operations: Read/Write

Meaning:

It’s a tab in bit for remote commands via RS485 (see tab).

Page 44

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 42

10.3.7 Output Power Parameter 5L

Command from controller

Operations: Read

Meaning:

It rapresents a value in points (0-255, 0-FF Hex) and it’s the power demand in % of controller.

Example:

0% = 0 0 (Hex)

50% = 128 80 (Hex)

100% = 255 FF (Hex)

Command via RS485

Operations: Read/Write

Meaning:

It’s a value in points (0-255, 0-FF Hex).

It’s power set point setted in thirst buffer.

Example:

0% = 0 0 (Hex)

50% = 128 80 (Hex)

100% = 255 FF (Hex)

10.3.8 Output Power Ramping (0 – FFH)

Operations: Read

10.3.9 Power adjust Parameter 6

Operations: Read/Write

Meaning:

It’s a value in points (0-255, 0-FF Hex).

It’s a scaling factor of power demand.

Example 1:

0% = 0

50% = 128

100% = 255

Example 2:

• Output Power: 100

Power Limit: 100%

-> Real power: 100

• Output Power: 100

Power Limit: 50%

-> Real power: 50

• Output Power: 80

Power Limit: 50%

-> Real power : 40

100

Power Adjust = 100%

Power Adjust = 80%

Power Adjust = 40%

80

60

40

20

0

4020 60 10080

Input %

OUT

%

Page 45

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

43 www.honeywell.com/imc

10.3.10 Current Limit Parameter 7

Command from current limit pot.

Operations: Read

Meaning:

It represents a value in points (0-255, 0-FF Hex) and it’s the power demand in % of controller.

Example:

0% = 0 0 (Hex)

50% = 128 80 (Hex)

100% = 255 FF (Hex)

Command via RS485

Operations: Read/Write

Meaning:

It’s a value in points (0-255, 0-FF Hex)

It’s the power set point setted in thirst buffer

Example:

0% = 0 0 (Hex)

50% = 128 80 (Hex)

100% = 255 FF (Hex)

10.3.11 Status Table

Bit Meaning Notes

0 Short circuit on SCR Read only

1 Load Failure Read only

2 On-Off Read only

3 HB Calibration in progress Read only 0=Normal - 1=Calibration

4 Current Limit Flag Read only 0=Normal - 1= Working in C.L.

5 Termal Read only

10.3.12Short circuit on SCR Bit 0

Operations: Read

Meaning:

It’s a bit indicating when the thyristor is in short circuit.

0 = OK

1 = Short circuit

10.3.13 Load Failure Bit 1

Operations: Read

Meaning:

It’s a bit indicating the partial or total load failure.

0 = OK

1 = Load failure

Page 46

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 44

10.3.14 On-Off Bit 2

Operations: Read

Meaning:

It’s a bit indicating when input signal is ON.

0 = Input signal OFF

1 = Input signal ON

10.3.15 Calibration in progress Bit 3

Operations: Read

Meaning:

It’s a bit representing the “calibration in progress” status.

0 = No calibration

1 = Calibration in progress

10.3.16 Current Limit Bit 4

Operations: Read

Meaning:

This bit indicates when the unit is working in current limit.

0 = Normal

1 = Working in current limit

10.3.17 Command Table

Bit Meaning Notes

0 Calibration

Read /write 0=Off - 1=ACTVATE Calibration

( normal mode set to 0)

1 Firing command Read /write 0=from terminal - 1=from RS485

2 On-Off Read /write 0=Off - 1=On

3 RESET HB

Read /write 0=Off - 1=RESET

( normal mode set to 0)

4 Current Limit control Read /write 0=from C.L. pot. - 1=from RS485

N.B.: When the unit is switched off all command parameters are setted to 0.

10.3.18 Calibration Bit 0

Operations: Read / Write

Meaning:

It’s a bit that starts the calibration procedure

When this bit is zero the calibration procedure starts and automatically resets itself at the end.

Page 47

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

45 www.honeywell.com/imc

10.3.19 Firing command Bit 1

Operations: Read / Write

Meaning:

It’s a command bit used to switch from analog external command to command via RS485

0 = Command from analog input

1 = Command from RS485 input

10.3.20 On-Off Bit 2

Operations: Read / Write

Meaning:

It’s used to switch ON-OFF the power.

0 = Power disabled

1 = Power enabled

10.3.21 HB RESET Bit 3

Operations: Read / Write

Meaning:

It’s a command bit to reset HB alarm.

This parameter has to be at 0 to have the alarm working properly.

0 = Reset disabled

1 = Reset enabled

10.3.22 Current Limit control Bit 4

Operations: Read / Write

Meaning:

It’s a command bit used to switch from analog C.L. potentiometer to command via RS485.

0 = Command from Current Limit pot.

1 = Command from RS485 input

10.3.23 Configuration

Parameter N. Note

Password 123 Write

Actual Power 124 Read /write

Feed-Back Selection 125L Read /write

Soft Start 125H Read /write

HB Delay 126L Read /write

HB sensibility % 126H Read /write

Power Set 127 Read /write

Integral 128L Read /write

Prop. 128H Read /write

Page 48

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 46

10.3.24 Password Parameter 123

Operations: Write

Meaning:

If properly setted, gives the access to configuration.

10.3.25 Actual power Parameter 124

Operations: Read

10.3.26 Feed-Back Parameter 125L

Operations: Read

10.3.27 Soft start time Parameter 125H

Operations: Read/Write

Meaning:

Time

Soft Start Time

Par 125H x 5msec

OUT

It’s corresponds to the value in points (0 – 255, 0 – FF Hex).

Each step is 5msec .

The unit starts in phase angle mode with a ramp starting from

zero up to full voltage in a presetted and Adjustable time.

The time is setted by this parameter.

10.3.28 Delay time HB Parameter 126L

Operations: Read/Write

Meaning:

It’s a value in point (0 – 255, 0 – FF Hex).

Each step is 50msec.

It represents a delay time before to have HB alarm active.

When is used with soft start, this time must be longer than soft start time.

Par126H x 50msec > Par125H x 5msec

10.3.29 % HB Parameter 126H

Operations: Read/Write

Meaning:

It corresponds to a value in point (0-255, 0-FF Hex)

The maximum load current (100%) minus this parameter (x%) is the value establishing the HB

current set point.

Example:

Load current = 10A

Parameter 124H = 20% 51 Dec 33 Hex

Parameter 2 will be setted at 8A.

Page 49

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

47 www.honeywell.com/imc

10.3.29.1 Set power Parameter 127

Operations: Read/Write

10.3.29.2 Integral Parameter 128L

Operations: Read/Write

10.3.29.3 Prop Parameter 128H

Operations: Read/Write

Page 50

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 48

10.4 Address Configuration

Up to 255 CD3200 units, each with a unique address, may be

connected to a master device.

To configure communication address open cover and set the

dip-switch as specified

10.4.1ADDRESS TABLE

ID 8 7 6

1

ON OFF

2

3

4

5

6

7

8

5 4 3 2 1 ID 8 7 6 5 4 3 2 1

1 - - - - - - - X 26 - - - X X - X 2 - - - - - - X - 27 - - - X X - X X

3 - - - - - - X X 28 - - - X X X - 4 - - - - - X - - 29 - - - X X X - X

5 - - - - - X - X 30 - - - X X X X 6 - - - - - X X - 31 - - - X X X X X

7 - - - - - X X X 32 - - X - - - - 8 - - - - X - - - 33 - - X - - - - X

9 - - - - X - - X 34 - - X - - - X 10 - - - - X - X - 35 - - X - - - X X

11 - - - - X - X X 36 - - X - - X - 12 - - - - X X - - 37 - - X - - X - X

13 - - - - X X - X 38 - - X - - X X 14 - - - - X X X - 39 - - X - - X X X

15 - - - - X X X X 40 - - X - X - - 16 - - - X - - - - 41 - - X - X - - X

17 - - - X - - - X 42 - - X - X - X 18 - - - X - - X - 43 - - X - X - X X

19 - - - X - - X X 44 - - X - X X - 20 - - - X - X - - 45 - - X - X X - X

21 - - - X - X - X 46 - - X - X X X 22 - - - X - X X - 47 - - X - X X X X

23 - - - X - X X X 48 - - X X - - - 24 - - - X X - - - 49 - - X X - - - X

25 - - - X X - - X 50 - - X X - - X -

Page 51

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

49 www.honeywell.com/imc

ID 8 7 6 5 4 3 2 1 ID 8 7 6 5 4 3 2 1

51 - - X X - - X X 101 - X X - - X - X

52 - - X X - X - - 102 - X X - - X X 53 - - X X - X - X 103 - X X - - X X X

54 - - X X - X X - 104 - X X - X - - 55 - - X X - X X X 105 - X X - X - - X

56 - - X X X - - - 106 - X X - X - X 57 - - X X X - - X 107 - X X - X - X X

58 - - X X X - X - 108 - X X - X X - 59 - - X X X - X X 109 - X X - X X - X

60 - - X X X X - - 110 - X X - X X X 61 - - X X X X - X 111 - X X - X X X X

62 - - X X X X X - 112 - X X X - - - 63 - - X X X X X X 113 - X X X - - - X

64 - X - - - - - - 114 - X X X - - X 65 - X - - - - - X 115 - X X X - - X X

66 - X - - - - X - 116 - X X X - X - 67 - X - - - - X X 117 - X X X - X - X

68 - X - - - X - - 118 - X X X - X X 69 - X - - - X - X 119 - X X X - X X X

70 - X - - - X X - 120 - X X X X - - 71 - X - - - X X X 121 - X X X X - - X

72 - X - - X - - - 122 - X X X X - X 73 - X - - X - - X 123 - X X X X - X X

74 - X - - X - X - 124 - X X X X X - 75 - X - - X - X X 125 - X X X X X - X

76 - X - - X X - - 126 - X X X X X X 77 - X - - X X - X 127 - X X X X X X X

78 - X - - X X X - 128 X - - - - - - 79 - X - - X X X X 129 X - - - - - - X

80 - X - X - - - - 130 X - - - - - X 81 - X - X - - - X 131 X - - - - - X X

82 - X - X - - X - 132 X - - - - X - 83 - X - X - - X X 133 X - - - - X - X

84 - X - X - X - - 134 X - - - - X X 85 - X - X - X - X 135 X - - - - X X X

86 - X - X - X X - 136 X - - - X - - 87 - X - X - X X X 137 X - - - X - - X

88 - X - X X - - - 138 X - - - X - X 89 - X - X X - - X 139 X - - - X - X X

90 - X - X X - X - 140 X - - - X X - 91 - X - X X - X X 141 X - - - X X - X

92 - X - X X X - - 142 X - - - X X X 93 - X - X X X - X 143 X - - - X X X X

94 - X - X X X X - 144 X - - X - - - 95 - X - X X X X X 145 X - - X - - - X

96 - X X - - - - - 146 X - - X - - X 97 - X X - - - - X 147 X - - X - - X X

98 - X X - - - X - 148 X - - X - X - 99 - X X - - - X X 149 X - - X - X - X

100 - X X - - X - - 150 X - - X - X X -

Page 52

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 50

ID 8 7 6 5 4 3 2 1 ID 8 7 6 5 4 3 2 1

151 X - - X - X X X 201 X X - - X - - X

152 X - - X X - - - 202 X X - - X - X 153 X - - X X - - X 203 X X - - X - X X

154 X - - X X - X - 204 X X - - X X - 155 X - - X X - X X 205 X X - - X X - X

156 X - - X X X - - 206 X X - - X X X 157 X - - X X X - X 207 X X - - X X X X

158 X - - X X X X - 208 X X - X - - - 159 X - - X X X X X 209 X X - X - - - X

160 X - X - - - - - 210 X X - X - - X 161 X - X - - - - X 211 X X - X - - X X

162 X - X - - - X - 212 X X - X - X - 163 X - X - - - X X 213 X X - X - X - X

164 X - X - - X - - 214 X X - X - X X 165 X - X - - X - X 215 X X - X - X X X

166 X - X - - X X - 216 X X - X X - - 167 X - X - - X X X 217 X X - X X - - X

168 X - X - X - - - 218 X X - X X - X 169 X - X - X - - X 219 X X - X X - X X

170 X - X - X - X - 220 X X - X X X - 171 X - X - X - X X 221 X X - X X X - X

172 X - X - X X - - 222 X X - X X X X 173 X - X - X X - X 223 X X - X X X X X

174 X - X - X X X - 224 X X X - - - - 175 X - X - X X X X 225 X X X - - - - X

176 X - X X - - - - 226 X X X - - - X 177 X - X X - - - X 227 X X X - - - X X

178 X - X X - - X - 228 X X X - - X - 179 X - X X - - X X 229 X X X - - X - X

180 X - X X - X - - 230 X X X - - X X 181 X - X X - X - X 231 X X X - - X X X

182 X - X X - X X - 232 X X X - X - - 183 X - X X - X X X 233 X X X - X - - X

184 X - X X X - - - 234 X X X - X - X 185 X - X X X - - X 235 X X X - X - X X

186 X - X X X - X - 236 X X X - X X - 187 X - X X X - X X 237 X X X - X X - X

188 X - X X X X - - 238 X X X - X X X 189 X - X X X X - X 239 X X X - X X X X

190 X - X X X X X - 240 X X X X - - - 191 X - X X X X X X 241 X X X X - - - X

192 X X - - - - - - 242 X X X X - - X 193 X X - - - - - X 243 X X X X - - X X

194 X X - - - - X - 244 X X X X - X - 195 X X - - - - X X 245 X X X X - X - X

196 X X - - - X - - 246 X X X X - X X 197 X X - - - X - X 247 X X X X - X X X

198 X X - - - X X - 248 X X X X X - - 199 X X - - - X X X 249 X X X X X - - X

200 X X - - X - - - 250 X X X X X - X 251 X X X X X - X X

X = ON 252 X X X X X X

- = OFF 253 X X X X X X X

254 X X X X X X X

255 X X X X X X X X

Page 53

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

51 www.honeywell.com/imc

11. Maintenance

11.1 Trouble Shooting

Small problems sometimes can be solved locally with the help of the below tab of t rouble shootin g.

If you don’t succeed, contact us or your nearest distributor.

Symptom Indication on

front unit

Possible reasons of

the symptom

Actions

Green LED is

always light off.

- No voltage auxiliary

power supply to

terminals 1-3 (see

wiring diagram).

- Give auxiliary voltage supply

to terminals 1-3.

Green LED (PW)

light on and

green LED (ON)

in light off

condition.

- No input signal.

- Reversed polarities of

input signal.

- Reset contact in open

condition (see wiring

diagram).

- Provide to give input signal.

- Reverse the input signal

polarity.

- Make link on reset terminals.

Thyristor unit

doesn’t go in

conduction with

input signal.

Green LED (PW)

in light on

condition and

green LED (ON)

in light on

condition.

- Fuse failure.

- Load failure.

- Load connection

interruption.

- Thyristor faulty and

always in open

circuit.

- With HB option the

yellow led (HB) in

light on condition.

- Substitute the fuse.

- Repair the load.

- Provide to repair the wiring.

- Substitute the faulty thyristor.

- Check the load.

Load current

flows also with

no input signal.

Green LED (ON)

always in light

off condition.

- Short circuit on

thyristor. If there is

HB circuit the red

LED (SC) is light on.

- Substitute the thyristor. Check

that load is not in short

circuit.

Current flows at

nominal value

but yellow LED

(HB) in light on

condition.

Yellow HB in light

on condition.

- HB circuit not tuned.

- Current transformers

not properly wired (if

are external to

CD3200).

- Push CAL button in front unit

to start HB calibration

procedure.

- Control current transformers

wiring and Push CAL button in

front unit to start HB

calibration procedure.

RED LED (SC)

IS LIGHTED ALSO

IF CURRENT IS AT

NOMINAL VALUE

.

Red LED in light

on condition.

- HB circuit not

properly tuned.

- Push CAL button in front unit

to start HB calibration

procedure.

Thyristor unit

doesn’t work

properly.

- Wrong input signal

selection.

- Wrong input signal

calibration (out of

range).

- Auxiliary voltage

supply out of limits.

- Control input signal setting.

- Repeat input calibration

procedure.

- Verify the auxiliary voltage

supply.

Page 54

Honeywell CD3200 up to110A User’s Manual ver. 2.0

www.honeywell.com/imc 52

11.2 Repairing procedure

• Phone to us.

• Explain to Service Engineer the problem because sometimes it can be solved with a phone call.

• If this is not possible ship the unit to us or to your distributor.

• Write a fault description and give the name of your personnel to which refer.

• Use a rugged packaging to ship the unit.

11.3 Fans

The thyristor unit with forced ventilation uses fans that rotate permanently when the unit is

supplied. In case of accidental fan failure, there is an over heating temperature on heatsink. In this

case to give protection to thyristor there is a thermal switch properly setted. The function of this

switch is to open the input signal until the h eatsink temperature falls below the setted value. This

means that also with input signal in ON condition the unit is switched OFF and the system can not

work at full power. For these reason is important to control periodically the fan status checking

that is rotating.

11.4 Servicing

In order to have correct cooling, the user must clean the heatsink and the protective grill of fan.

The frequence of this servicing depends on environmenta l pollution.

Check periodically also if the screw for the power cables and safety earth are tightened correctly

11.5 Warranty conditions

We gives a 12 months warranty to its products. The warranty is limited to repairing and parts

substitution in our factory and does exclude products not properly used and fuses.

Warranty does not includes products with serial numbers deleted. The faulty product should be

shipped to us at your cost and our Service will evaluate if product is un d er warranty terms.

Substituted parts remains our property.

Page 55

User’s Manual ver. 2.0 CD3200 up to110A Honeywell

53 www.honeywell.com/imc

Sales and Service

For application assistance, current specifications, pricing, or name of the nearest Authorized Distributor, contact one of

the offices below.

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty work-manship. Contact your

local sales office of warranty information. If warranted goods are returned to Honeywell during the period of coverage,

Honeywell will repair of replace without charge those items it finds defective. The foregoing is Buyer’s sole remedy

and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for

a particular purpose. Specifications may change without notice. The information we supply is believed to be accurate

and reliable as of printing. However, we assume no responsibility for its use. While we provide application assistance

personally, through our literature and the Honeywell website, it is up to the customer to determine the suitability of the

product in the application.

ASIA PACIFIC

Control Products

Asia Pacific Headquarters

Phone: +(65) 6355-2828

Fax: +(65) 6445-3033

Australia

Honeywell Limited

Phone: +(61) 2-9370-4500

FAX: +(61) 2-9370-4525

Toll Free 1300-36-39-36

Toll Free Fax: 1300-36-04-70

China – PRC - Beijing

Honeywell China Inc.

Phone: +(86-10) 8458-3280

Fax: +(86-10) 8458-3102

China – PRC - Shanghai

Honeywell China Inc.

Phone: (86-21) 6237-0237

Fax: (86-21) 6237-1237

China - Hong Kong S.A.R.

Honeywell Ltd.

Phone: +(852) 2953-6412

Fax: +(852) 2953-6767

China – PRC - Chengdu

Honeywell China Inc.

Phone: +(86-28) 6786-348

Fax: +(86-28) 6787-061

China – PRC - Guangzhou

Honeywell China Inc.

Phone: +(86-20) 3879-1169

Fax: +(86-20) 3879-1269

China – PRC - Shenzhen

Honeywell China Inc.

Phone: +(86) 755-518-1226

Fax: +(86) 755-518-1221

Indonesia

Honeywell Indonesia Pte Ltd.

Phone: +(62) 21-535-8833

FAX: +(62) 21-5367 1008

India

TATA Honeywell Ltd.

Phone: +(91) 20 687

0445/0446

Fax: +(91) 20 681 2243/ 687

5992

Japan

Honeywell Inc

Phone: +(81) 3 5440 1425

Fax: +(81) 3 5440 1368

South Korea

Honeywell Korea Co Ltd

Phone: +(822) 799-6167

Fax: +(822) 792-9013

Malaysia

Honeywell Engineering

Sdn Bhd

Phone: +(60-3) 79584988

Fax: +(60-3) 7958-8922

New Zealand

Honeywell Limited

Phone: +(64-9) 623-5050

Fax: +(64-9) 623-5060

Toll Free (0800) 202-088

Philippines

Honeywell Systems

(Philippines) Inc.

Phone: +(63-2) 636-1661

/1662

Fax: +(63-2) 638-4013

Singapore

Honeywell South East

Asia

Phone: +(65) 6355-2828

Fax: +(65) 6445-3033

Thailand

Honeywell Systems

(Thailand) Ltd.

Phone: +(662) 693-3099

FAX: +(662) 693-3085

Taiwan R.O.C.

Honeywell Taiwan Ltd.

Phone: +(886-2) 22451000

FAX: +(886-2) 22453242

EUROPE

Austria

Honeywell Austria GmbH

Phone: +43 (316)400123

FAX: +43 (316)40017

Belgium

Honeywell SA/NV

Phone:

+31(0)205656999

FAX: +31(0)165330746

Bulgaria

Honeywell EOOD

Phone: +(359) 2 79 40

27

FAX: +(359) 2 79 40 90

Czech Republic

Honeywell spol. s.r.o.

Phone: +420-543245014

FAX: +420-54324-5011

Denmark

Honeywell A/S

Phone: +(45) 39 55 55 55

FAX: +(45) 39 55 55 58

Finland

Honeywell OY

Phone: +358 (3) 2727625

FAX: +358 (3) 2728600

France

Honeywell SA

Phone: +33 (0)1 60198075

FAX: +33 (0)1 60198201

Germany

Honeywell AG

Phone: +49 (69)8064336

FAX: +49 (69)806497336

Hungary

Honeywell Kft.

Phone: +36-1-451 4335

FAX: +36-1-451 4343

Italy

Honeywell S.p.A.

Phone: +39 02 9214 6503

FAX: +39 0292146377

The Netherlands

Honeywell B.V.

Phone: +31(0)205656999

FAX: +31(0)165330746

Norway

Honeywell A/S

Phone: (45) 39 55 55 55

Poland

Honeywell Sp. zo.o

Phone: +48-22-6060900

FAX: +48-22-6060901

Portugal

Honeywell Portugal Lda

Phone: +351 21 424 5000

FAX: +351 21 424 50 99

Romania

Honeywell Bucharest

Phone: 40212110076

FAX: +40 (40212103375)

Commonwealth of

Independent States (CIS)

Z.A.O. Honeywell

Phone: +(7 095) 796 98 36

FAX: +(7 095) 796 98 93

Slovak Republic

Honeywell s.r.o.

Phone: +421-2-58247 410

FAX: +421-2-58247 415

Spain

Honeywell S.A.

Phone: +34 (0)91313 61 00

FAX: +34 (0)91313 61 30

Sweden

Honeywell AB

Phone: +(46) 8 775 55 00

FAX: +(46) 8 775 56 00

Switzerland

Honeywell AG

Phone: +41 18552448

FAX: +(41) 1 855 24 45

Turkey

Honeywell Turkey A.S.

Phone: +90 216 575 6600

FAX: +90 216 575 6637

United Kingdom

Honeywell Control Systems

Ltd

Phone: +(44) 1698 481730

FAX: +(44) 1698 481276

MIDDLE EAST

Abu Dhabi U A E

Middle East Headquarters

Honeywell Middle East Ltd

Phone: +971 2 4041220

FAX: +971 2 4432536

Sultanate of Oman

Honeywell & Co Oman LLC

Phone: +968 701397

FAX +968 787351

Egypt

Honeywell Egypt Ltd

Phone: +202 4514460 /1/

2/ 3/ 4/ 5/ 6

FAX : +2024514467

Saudia Arabia

Honeywell Turki Arabia

Limited

Phone: +966-3-341-0140

Fax: +966-3-341-0216

Kuwait

Honeywell Kuwait KSC

Phone: +965 2421327

AFRICA

Mediterranean & African

Distributors

Honeywell SpA

Phone: +39 (02) 250 10

604

FAX: +39 (02) 250 10 659

South Africa (Republic of)

Honeywell Southern Africa

Honeywell S.A. Pty. Ltd

Phone: +27 11 6958000

FAX +27 118051504

NORTH AMERICA

Canada

Honeywell LTD

Phone: 1-800-737-3360

FAX: 1-800-565-4130

USA

Honeywell

Control Products,

International Headquarters

Phone: 1-800-537-6945

1-815-235-6847

FAX: 1-815-235-6545

E-mail:

info.sc@honeywell.com

LATIN AMERICA

Argentina

Honeywell S.A.I.C.

Phone: +(54-11) 4383-3637

FAX: +(54-11) 4325-6470

Brazil

Honeywell do Brasil & Cia

Phone: +(55-11) 7266-1900

FAX: +(55-11) 7266-1905

Chile

Honeywell Chile, S.A.

Phone: +(56-2) 233-0688

FAX: +(56-2) 231-6679

Mexico

Honeywell S.A. de C.V.

Phone: +(52) 55 5259-1966

FAX: +(52) 55 5570-2985

Puerto Rico

Honeywell Inc.

Phone: +(809) 792-7075

FAX: +(809) 792-0053

Trinidad

Honeywell Inc

Phone: +(868) 624-3964

FAX: +(868) 624-3969

Venezuela

Honeywell CA

Phone: +(58-2) 238-0211

FAX: +(58-2) 238-3391

Loading...

Loading...