Page 1

C7962B

Visible Light Flame Detector

FEATURES

• Used with 7800 SERIES Flame Safeguard controls with

R7851B Flame Amplifier.

• Has an integral collar threaded (internal 1/2-14 NPSM)

for mounting on 1/2 inch sight pipe.

• Has 1/2-in. spud (1/2-14 internal thread) for electrical

conduit wiring.

• Conduit clamp provided for flexible conduit wiring.

APPLICATION

The C7962B Visible Light Flame Detector detects the visible

light emitted by fuel oil combustion flames. The C7962B

Detector is used with Honeywell 7800 SERIES Flame

Safeguard controls to provide fuel oil flame supervision in

commercial and industrial burners.

PRODUCT DATA

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Installation ........................................................................ 2

Ordering Information ........................................................ 2

Adjustments and Checkout .............................................. 6

Troubleshooting ................................................................ 6

Maintenance ..................................................................... 7

65-0277-03

Page 2

C7962B VISIBLE LIGHT FLAME DETECTOR

WARNING

SPECIFICATIONS

Model:

C7962B Visible Light Flame Detector.

Electrical Ratings:

Connections:

Two eight-foot (2.44 meters) color-coded NEC Class 1

leadwires.

Environmental Ratings:

Ambient Operating Temperature:

-40°F to +165°F (-40°C to +74°C)

Storage Temperature Rating:

-20°F to +120°F (-29°C to +49°C).

Humidity:

90% relative humidity, noncondensing.

Vibration:

0.5G.

Maximum Pressure Rating:

5 psi.

Mounting:

Collar with 1/2-14NPSM (internal thread) for mounting on a

1/2 inch sight pipe.

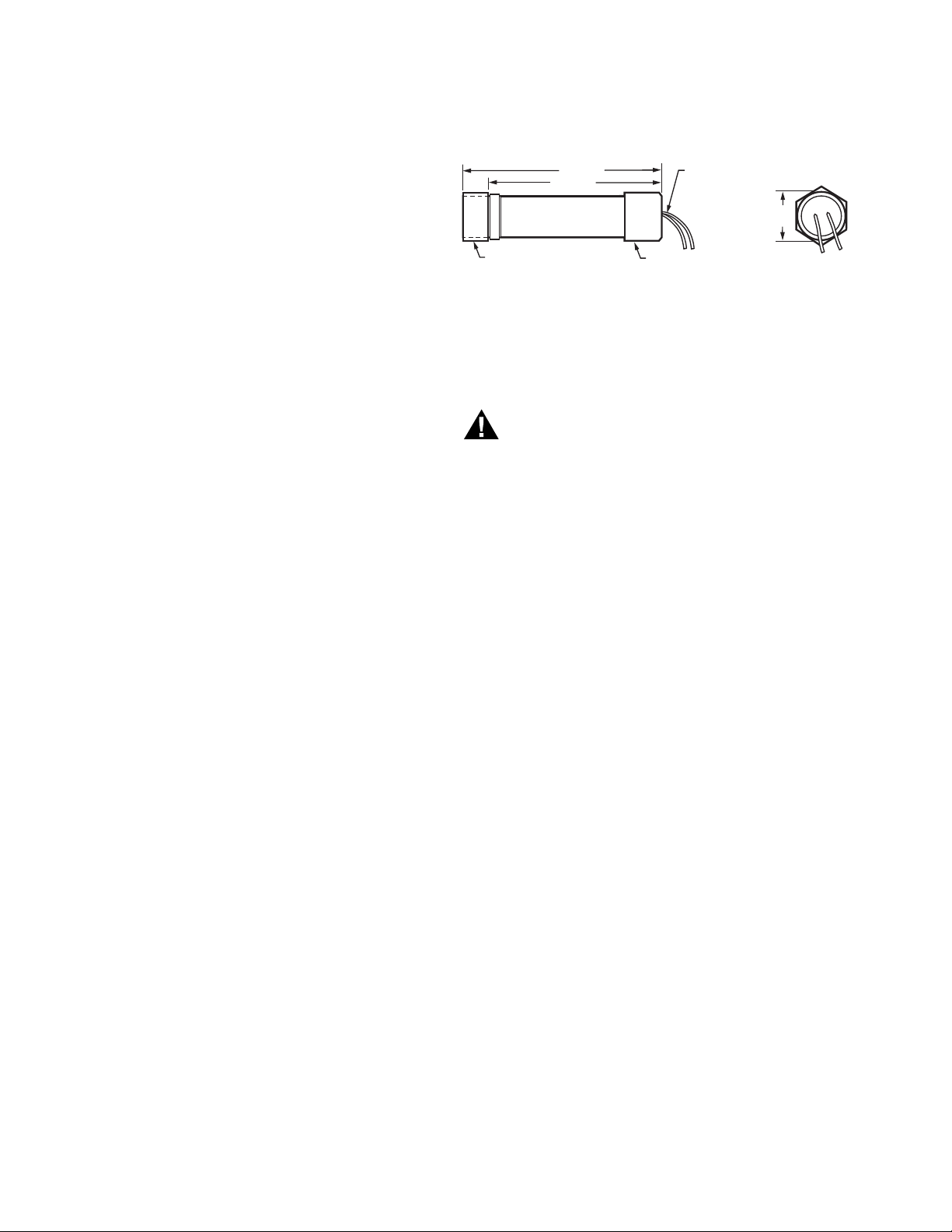

3-7/8 (98)

3-3/8 (86)

COLLAR WITH 1/2-14 NPSM

INTERNAL THREADS

C7962B

Fig. 1. C7962B Visible Light Flame Detector

dimensions in in. (mm).

INSTALLATION

Electrical Shock Hazard.

Can cause serious injury, death or property

damage.

Disconnect power supply before beginning installation.

More than one disconnect may be required.

8 FOOT

(2.44 METER)

LEADWIRES (2)

SPUD CONNECTOR

(1/2-14 NPSM

INTERNAL THREADS)

(25)

1

M29272

Dimensions:

See Fig. 1.

Accessory:

32007439-001 Mounting Bracket and screws. (Included with

C7962B1010)

118367A Swivel Mount.

130413 Conduit Clamp (included)

Approvals:

Underwriters Laboratories, Inc. listed: File No. MP268, Vol.

30, 31

Canadian Standards Association (CSA): 95329.

When Installing This Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced, flame

safeguard control technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Disconnect the power supply before beginning installation to

prevent electrical shock and equipment damage. All wiring

must comply with applicable electrical codes, ordinances and

regulations. Use NEC Class 1 (line voltage) wiring.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

65-0277—03 2

Page 3

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause serious injury, death or property

damage.

1. The C7962B Flame Detectors must be used with

Honeywell flame safeguard controls (primaries,

programmers, multiburner systems, and burner

management systems). Using with controls not

manufactured by Honeywell could result in unsafe

conditions.

2. Disconnect power supply before beginning

installation to prevent electrical shock or equipment

damage. More than one disconnect may be

involved.

3. Read the installation instructions before starting the

installation.

4. All wiring must be NEC Class 1 (line voltage).

Basic Requirements for Flame Detector Installation

It is necessary for the detector to actually see the flame.

Locate the detector as close to the flame as physical

arrangement and temperature restrictions permit.

Sighting requirements for different types of flame supervision

are:

C7962B VISIBLE LIGHT FLAME DETECTOR

If a C7962B is to be used for a blast tube installation, its

location should be determined by the burner manufacturer.

Contact the manufacturer before making any modifications to

the installation.

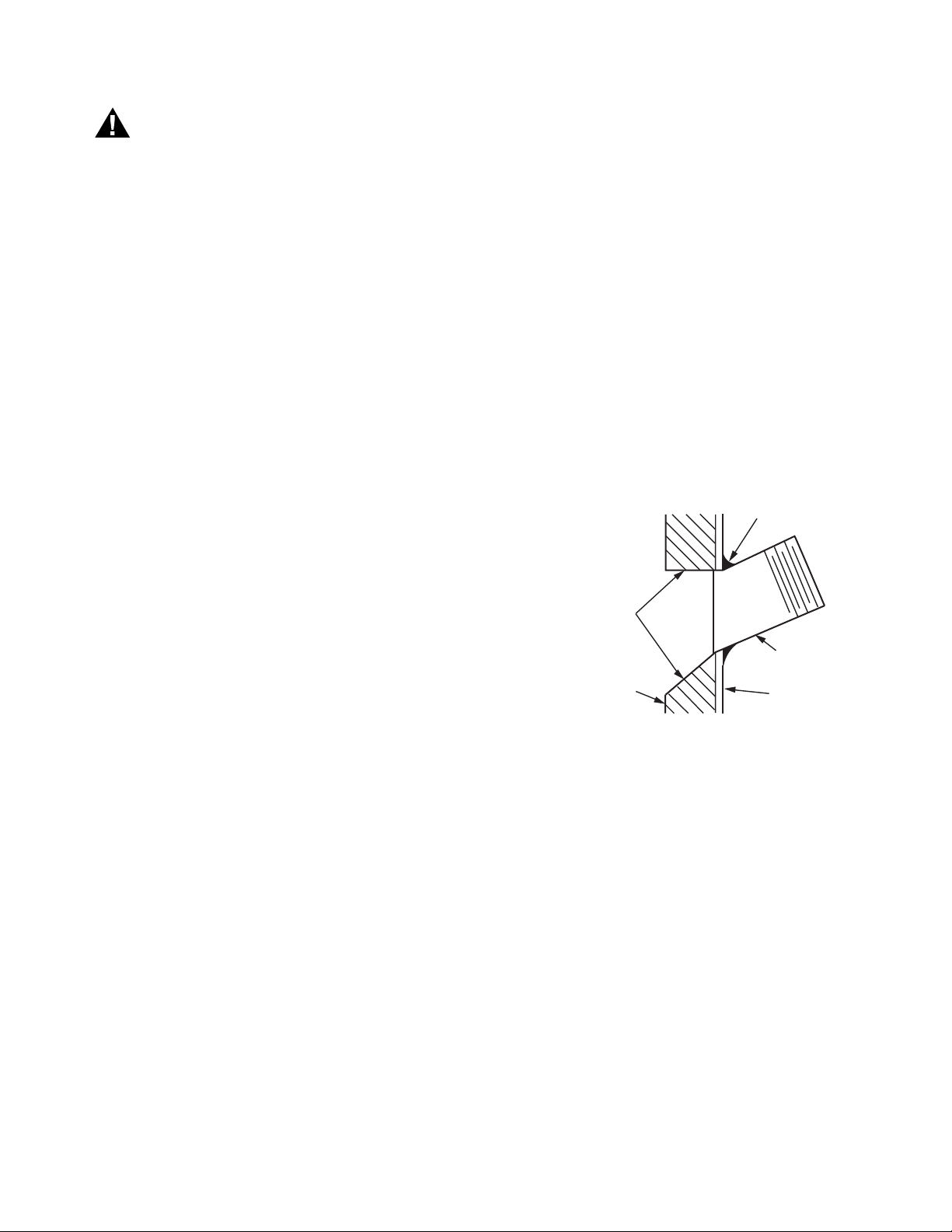

Prepare Hole in Wall of Combustion Chamber

Cut a hole of the proper diameter for the sight pipe in the wall

of the combustion chamber at the selected location. Flare the

hole to leave room for small adjustments of the sighting angle.

The taper of the hole should be about 1 inch for every 3 inches

(25 mm for every 76 mm) of wall thickness.

Mounting the Sight Pipe (Fig. 2)

Thread one end of the pipe to fit the mounting collar on the

detector. Cut the pipe to the desired length (as short as

practicable) and at an angle so it fits flush with the wall of the

combustion chamber. Tack-weld the pipe to the wall in a trial

position. Do not permanently weld the sight pipe in place until

after completing the Adjustments and Checkout section.

NOTE: If you use a swivel mount (part no. 118367A) and you

are positive about the location and sighting angle, you

can permanently weld the pipe.

TEMPORARY

TACK WELD

1. Pilot flame only—Sighting must be along the axis of the

pilot flame. The smallest pilot flame that can be sighted

must be capable of igniting the main burner (see Pilot

Turndown Test).

2. Main flame only—Sighting must be at the most stable

part of the flame for all firing rates.

3. Pilot and main flame—Sighting must be at the junction of

both flames.

Mounting a C7962B Flame Detector

Locate the Sight Pipe

The location of the sight pipe is the most critical part of the

installation. A black iron pipe is recommended. Do not use a

stainless steel or galvanized pipe because the internal surface

blackens with use ad deposits from the combustion chamber

settle on it.

Under optimum conditions, the flame detector can detect most

oil combustion flames at a distance of six feet (1.8 meters).

The critical factors in determining the flame-detector distance

separation are the optimized flame signal (current or voltage)

and the flame detector temperature. Other factors may be

influential and are associated with the specific installation. For

minimum flame signals, see Table 1 and for ambient operating

temperatures, refer to Specifications, page 2.

Use 1/2 inch pipe for a C7962B. Since no two situations are

likely to be the same, length and sighting angle of the pipe

must be determined at the time and place of installation.

Generally, it is desirable to have the sight pipe tilting downward

to prevent soot or dirt buildup.

FLARED HOLE

BLACK IRON

SIGHT PIPE

REFRACTORY

M3019B

Fig. 2. Mounting sight pipe.

BOILER

PLATE

Sight Pipe Ventilation

It may be necessary to ventilate the sight pipe to cool the flame

detector or to clear the sight pipe of UV radiation absorbing

material such as smoke, excessive moisture or, in some

instances, unburned fuel.

For a negative pressure combustion chamber, drilling a few

holes in the section of the sight pipe outside of the combustion

chamber will allow air at atmospheric pressure to flow through

the sight pipe into the chamber. A perforated pipe nipple

between the sight pipe and the detector can also be used.

(See Fig. 3.)

For a positive pressure combustion chamber, connect a supply

of pressurized air from the burner blower through the sight pipe

into the chamber. The supply air pressure must be greater that

the chamber pressure.

Swivel Mount

To facilitate proper sighting of the flame, a swivel mount (part

number 118367A) is available. The swivel mount will require a

3/4 to 1/2 inch reducer and a 1/2 inch close nipple to mount a

C7962B. For mounting details, refer to form 50-0361 for the

118367A Swivel Mount.

3 65-0277—03

Page 4

C7962B VISIBLE LIGHT FLAME DETECTOR

A

1

[27]

1

16

4-5/8 (117)

1

[32]

1

4

5

8

9

16

[14]

[16]

5

8

1 [41]

C7962B DETECTOR

136733 HEAT BLOCK

1/2-INCH SIGHT PIPE

1/2-14 NPSM

INTERNAL

THREADS

1/2-14 NPSM

EXTERNAL

THREADS

1/2-14 NPSM

INTERNAL

THREADS

HIGH TEMPERATURES (ABOVE 215°F [102°C])

DO NOT USE FOR TEMPERATURES ABOVE 266°F [130°C]

M29281

Mount the Detector (Fig. 3)

Mount the detector onto the sight pipe, pipe tee, nipple, or

other fitting. Make sure the flange gasket is in place inside the

mounting collar on the detector, and then screw the collar onto

the sight pipe or fitting.

C7962B

FLANGE

GASKET

DD PIPE TEE,

PERFORATED

NIPPLE, OR OTHER

SUITABLE DEVICE

FOR VENTILATION,

IF REQUIRED.

BLACK IRON

SIGHT PIPE

COMBUSTION

CHAMBER

WALL

Using a Heat Block with a C7962B (Fig. 4)

If the temperature of the sight pipe will become high enough to

cause the C7962B to overheat (above 165°F [74°C]) up to

266°F (130°C), screw a 136733 Heat Block (order separately)

onto the sight pipe before mounting the detector.

M20913

Fig. 3. Mounting a C7962B on a combustion chamber

(viewed from above).

Fig. 4. Mounting dimensions of 136733 Heat Block in in. (mm).

REPLACING C7013 OR C7014

For locations shown in Fig. 5.

65-0277—03 4

Page 5

CAUTION

M29283

BLAST TUBE

“F” TERMINAL

C7013/C7014 PHOTOCELL

HOUSING AND HOLDER

M29284

BLAST TUBE

C7962

32007439 BRACKET

Fig. 5. Location of C7013/C7014 in a conventional

pressure atomizing oil burner.

1. Remove C7013/C7014.

2. Attach bracket 32007439-001 (included with

C7962B1010) onto C7962 detector using screws and

nuts provided.

3. Attach the assembled detector and bracket onto the oil

pipe going to the nozzle with the remaining screw and

nut.

4. Adjust the assembly into a location to provide adequate

clearance and for a clear view of the flame. Tighten the

screw to secure into place. See Fig. 6.

Fig. 6. Mounting a C7962 in a conventional pressure

atomizing oil burner.

WIRING

Equipment Damage Hazard.

Can cause improper operation.

The blue leadwire must be connected to the F terminal

of the flame safeguard control subbase or terminal strip

and the white leadwire to the G terminal. Failure to

observe the circuit polarity by reversing the leadwires

(even momentarily) may cause the flame detector to

improperly supervise the combustion flame.

IMPORTANT

All wiring must comply with applicable local electrical

codes, ordinances and regulations. Use NEC Class 1

(line voltage) wiring.

C7962B VISIBLE LIGHT FLAME DETECTOR

The detector has color-coded and labeled, plastic-insulated,

no. 18 AWG leadwires, eight ft. (2.44 m) long, rated for 221°F

(105°C).

1. Keep the flame signal leadwires as short as possible

from the flame detector to the terminal strip or wiring

subbase. Capacitance increases with wire length, reducing the signal strength.

NOTE: The maximum permissible leadwire length depends

on the type of leadwire and the conduit type and

diameter. The ultimate limiting factor is flame signal

leadwire length is the signal current or voltage at the

flame safeguard device.

2. If needed, splice detector leadwires for longer leadwire

runs, observing the following considerations:

a. Make required splices in a junction box.

b. Use moisture-resistant no. 14 wire suitable for at

least 167°F (75°C).

c. For high temperature installation, use Honeywell

Specification no. 32004766-003 or equivalent for the

F leadwire. This wire is rated up to 400°F (250°C) for

continuous duty. It is tested for operation up to 20 kV

and for breakdown up to 35 kV. For the other

leadwires, use moisture-resistant no. 14 wire

selected for a temperature rating above the

maximum operating temperature.

d. F and G wires must be run in their own conduit

independent of other power carrying leadwires. More

than one scanner F and G wire can be run in the

same conduit.

e. A shielded twisted pair wire may be substituted for

using conduit for routing the F leadwire. Be advised

of the capacitance per foot of shielded wire

effectively reduces the flame signal at the flame

safeguard device. Be sure to ground the shield to the

G terminal at the flame safeguard wiring subbase.

f. The detector wires need to be run in their own

conduit as well, avoiding other electrical noise

carrying wiring.

g. The scanner wires should remain separated a

minimum of two in. (51 mm) from other line voltage

wires in the main control panel to the flame

safeguard device.

3. Avoid installation considerations that can influence

detector operation and maximum leadwire length, such

as:

a. Moisture.

b. Ignition interference.

c. High resistance connections—poor grounds.

d. Leadwire capacitance.

e. Voltage fluctuations.

f. Induced line transients.

g. Floating grounds—grounds at some voltage above

earth ground.

h. No G. wire—burner used as ground.

i. Detector output less than maximum attainable for the

installation (inadequate sighting).

IMPORTANT

Do not run the flame detector wiring in the same

conduit with high voltage ignition transformer wires.

5 65-0277—03

Page 6

C7962B VISIBLE LIGHT FLAME DETECTOR

WARNING

Earth Ground

The detector and the flame safeguard control must be

connected to earth ground. A convenient method of

accomplishing this is to connect the detector to the flame

safeguard control with a flexible conduit, or ensure a good

ground connection at the mounting bracket.

ADJUSTMENTS AND CHECKOUT

Before welding the C7962B sight pipe in its final location, or

before tightening the C7962B, complete both the adjustments

and checkout tests that follow and any required by the burner

manufacturer.

Adjust detector Sighting Position

With the flame detector installed and burners running, adjust

the position of the flame detector for optimum flame signal. The

flame signal will be read in voltage (Vdc).

The R7851B Amplifier used with the 7800 SERIES controls,

has a dc voltage flame signal output.

For the R7851B Amplifier, a volt-ohmmeter with a zero to 5 of

10 Vdc scale and a minimum sensitivity of 1 megohm/volt is

suggested. See Fig. 5.

Measure the flame signal for the pilot flame alone, the main

burner flame alone, and both together (unless monitoring pilot

only when using an intermittent pilot or supervising the main

flame only when using direct spark ignition). Also, measure the

flame signal at low and high firing rates and while modulating

(if applicable).

With the flame detector in its final position, all flame signals

must be steady with a voltage value as indicated for the device.

If the minimum signal cannot be obtained or is unstable, refer

to the Troubleshooting section.

Pilot Turndown Test

If the detector is used to prove a pilot flame before the main

fuel valve can be opened, perform a Pilot Turndown Test.

Follow the procedures in both the instructions for the

appropriate flame safeguard control and in the burner

manufacturer instructions.

Final Checkout

Before putting the burner into service, check out the installation

using the procedures in the Checkout section of the

instructions for the appropriate flame safeguard control. After

completing the checkout, run the burner through at least one

complete cycle to verify correct operation.

POSITIVE (+)

METER LEAD

NEGATIVE (-)

METER LEAD

Fig. 7. Measuring flame signal voltage of

7800 SERIES controls.

Measure the flame signal voltage as illustrated in Fig. 5. Be

careful to connect the positive meter lead to the positive (+)

amplifier jack and the negative meter lead to the negative (-)

amplifier jack for a 7800 SERIES control. If the 7800 SERIES

control has the optional Keyboard Display Module (KDM), a

zero to five Vdc reading will be displayed on the KDM.

Move the flame detector and sight pipe (if not permanently

attached to the burner/boiler) to view the flame from various

positions. Allow a few seconds for the meter reading to

stabilize. A maximum steady voltage reading is desirable. The

flame signal must be above the minimum acceptable level for

the flame safeguard control and associated amplifier.

ONE MEGOHM/VOLT

METER

M7382

TROUBLESHOOTING

Electrical Shock Hazard.

Can cause serious injury, death or property

damage.

Be extremely careful while troubleshooting the

detector; line voltage is present on some of the

terminals when power is on.

Open the master switch to disconnect power before

removing or installing the detector.

Inadequate Flame Signal

If a satisfactory flame signal cannot be obtained while adjusting

the sighting position of the detector, perform the procedures

indicated in steps 1 through 7, below. If other difficulties are

encountered in the system, refer to Troubleshooting in the

instructions for the appropriate Honeywell flame safeguard

control.

1. Check for proper line voltage. Make sure the master

switch is closed, connections are correct, and power

supply is the correct voltage and frequency.

2. Check the detector wiring for defects, including:

a. incorrect connections.

b. wiring type or size of wire.

c. deteriorated wire.

d. open circuits.

e. short circuits.

f. leakage paths caused by moisture, soot, or dirt.

3. With the burner running, check the temperature at the

detector. When it exceeds 165°F (74°C):

a. use a heat block (part number 136733).

b. add the additional insulation between the wall of the

combustion chamber and the detector.

65-0277—03 6

Page 7

C7962B VISIBLE LIGHT FLAME DETECTOR

c. add a shield or screen to reflect radiated heat away

from the detector, or

d. add cooling (refer to Sight Pipe Ventilation).

4. Remove the detector and clean the viewing window with

a soft, clean cloth.

5. Clean the inside of the sight pipe (if one is used) before

reinstalling the detector.

6. If the flame signal continues to be too low, replace the

plug-in amplifier (if the control has one).

7. If you still cannot obtain a proper flame signal, replace

the C7962B Flame Detector.

IMPORTANT

At the completion of troubleshooting, be sure to perform the Adjustments and Checkouts.

MAINTENANCE

Periodic Maintenance

1. Clean the viewing window and sight pipe (if used) when

necessary. Remove the detector and use a soft, clean

cloth to remove accumulated contaminants from the cell

surface.

2. Replace the C7962B if it is damaged in any way.

3. Keep the flame detection system adjusted for the

smoothest, most reliable operation as recommended by

the burner manufacturer.

7 65-0277—03

Page 8

C7962B VISIBLE LIGHT FLAME DETECTOR

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2009 Honeywell International Inc.

65-0277—03 M.S. Rev. 05-09

Loading...

Loading...