Page 1

63-2615-07

C7632A,B

C7632A

C7632B

Sensor and Controller

CARBON DIOXIDE SENSOR

SPECIFICATIONS

Models: C7632 Sensor and Controller. A stand-alone car-

bon dioxide (CO

put.

C7632A: Wall mount model.

C7632B: Duct mount model.

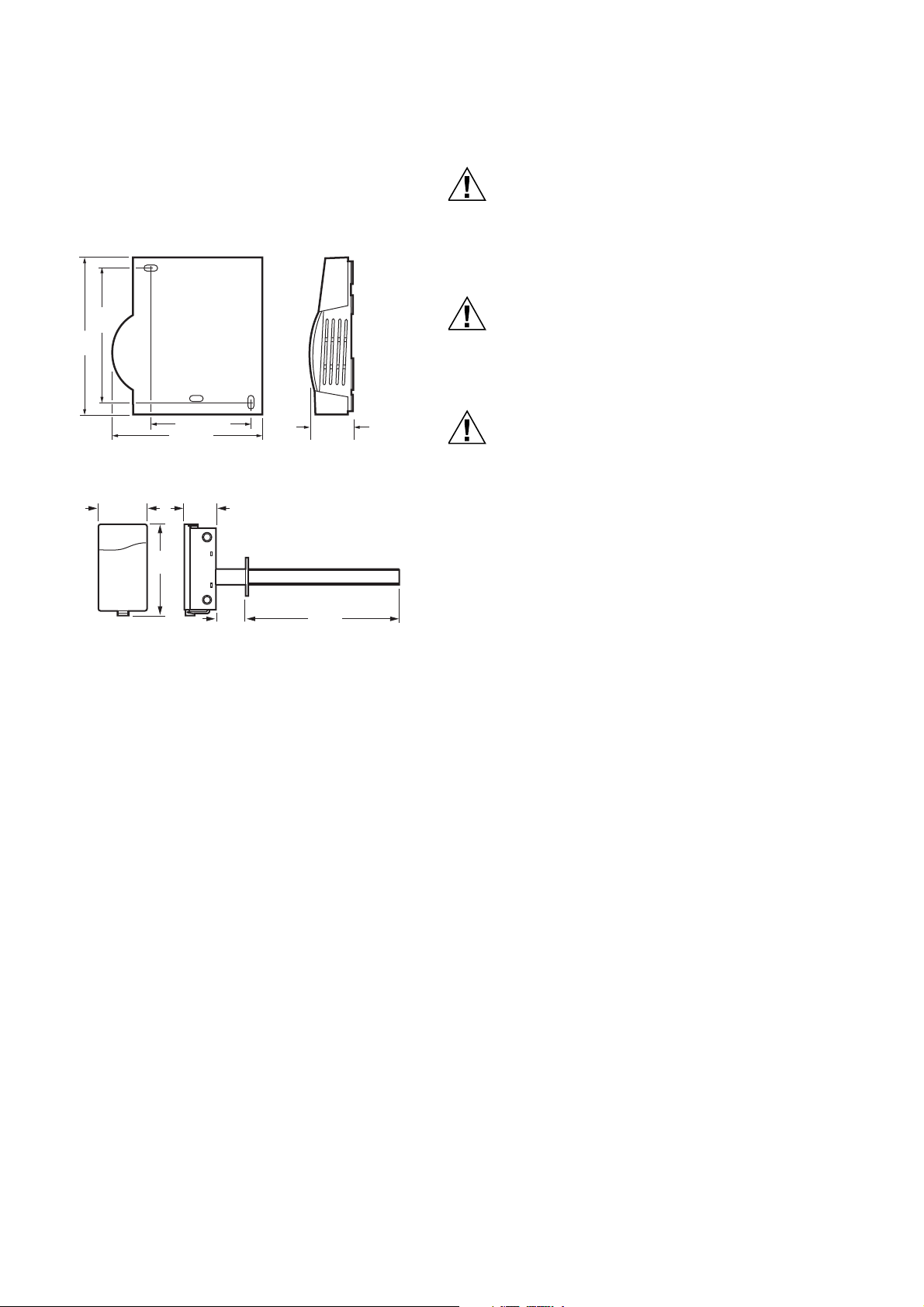

Dimensions:

C7632A: See Fig. 1.

C7632B: See Fig. 2.

Ambient Ratings:

Temperature:

Operating: +32°F to +122°F (0°C to +50°C).

Storage: -4°F to +158°F (-20°C to +70°C).

Relative Humidity (non-condensing): 0 to 95 percent.

PRODUCT DATA

) sensor with one 0-10 Vdc analog out-

2

APPLICATION

The C7632 Sensor and Controller is a stand-alone carbon

dioxide (CO

necessity with heating ventilation and air conditioning

(HVAC) controllers. The C7632 measures the CO

concentration in the ventilated space or duct. The C7632 is

used in HVAC systems to control the amount of fresh

outdoor air supplied to maintain acceptable levels of CO

the space.

) sensor for use in determining ventilation

2

2

in

2

FEATURES

• Non-Dispersion-Infrared (NDIR) technology used to

measure carbon dioxide gas.

• Special plated sensor provides long-term calibration

stability.

• Device provides voltage output based on CO

• Used for CO

• Automatic Background Calibration (ABC) algorithm

based on long-term evaluation reduces required

typical zero-drift check maintenance.

• Fixed 0 to 10 Vdc from 0 to 2000 ppm. No

adjustments are necessary.

• Compatible with Honeywell Excel 10, 15, 5000, and

any controller requiring 0-10 Vdc input.

based ventilation control.

2

levels.

2

Automatic Background Calibration (ABC) default: On.

Electrical Ratings:

Power Supply: 24 Vac ±20%, 50/60 Hz (Class 2).

Maximum Power Consumption:

Average: 1W.

Peak: 2W.

Peak Current (at 20 ms): 300 mA.

Linear Analog Output: 0-10 Vdc.

Mounting:

C7632A: Vertical surface with standard single-gang junction

box.

C7632B: Sheet metal duct with a sampling tube.

CO

Pressure Dependence: 1.6% change in reading per

2

1 kPa deviation from 100 kPa.

Output: Analog: 0-10 Vdc, 0-2000 ppm (fixed).

Sensor Performance Ratings:

Response Time: 1 min.

Carbon Dioxide Sensor:

Operation: Non-dispersive infrared (NDIR).

Sampling: Diffusion.

Range: 0 to 2000 ppm (fixed).

Annual Drift: ±10 ppm (nominal).

Accuracy: ±(30 ppm+2%) at normal temperature/pres-

sure.

Calibrated at the factory.

Uses automatic background calibration. No calibration

required for the life of the product.

Meets CEC Title 24 requirement of ±75ppm accuracy at

600ppm and 1000ppm ambient levels.

For proper CO2 operation, install only in spaces that see

at least 4 hours of continuous unoccupied time per

week.

Page 2

C7632A,B SENSOR AND CONTROLLER

CAUTION

CAUTION

CAUTION

2-11/16 (68)

1-1/16

(27)3-7/8 (99)

M19794

3-3/8

(86)

4-1/8

(104)

3-5/16 (84)

1-13/16

(46)

1-5/8

(41)

5-5/8

(142)

8 (203)

M19795

Wiring Connections:

C7632A: Terminal block.

C7632B: 20-gauge cable with three 6 in. leadwires.

Approvals:

CE.

C7632B: Flammability Rating, UL94-5V.

C7632A: NEMA1.

C7632B: NEMA3.

Fig. 1. C7632A dimensions in in. (mm).

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

Health Hazard.

Improper use can create dangerous situations.

Use in application for sensing carbon dioxide only.

For life-safety applications, this device can function

only as a secondary or lesser device.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before

handling the unit.

C7632A Cover Removal/ Replacement

The cover of the C7632A is fixed by a latch on the underside

of the unit.

C7632A Cover Removal (see Fig. 3)

Fig. 2. C7632B dimensions in in. (mm).

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

1. Unless the device is mounted, hold the base using the

wiring hole and/or the perforated vent.

2. Depress the tab on the underside of the device.

3. Swing the cover away from the base.

4. Lift cover from base.

C7632A Cover Replacement

1. Place top cover tab over the ridge along the base top.

2. Swing the cover down.

3. Press the lower edge of the case to latch.

Location and Mounting

C7632 Sensors mount directly on the wall, sheet metal duct,

or a panel. When planning the installation, allow enough

clearance for maintenance and service. Mount the sensor in

a well-ventilated area.

NOTES: Do not install the sensor where it can be affected

by: — drafts or dead spots behind doors and in

corners.

— air from ducts.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further

information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone direc-

2. Honeywell Customer Care

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

63-2615—07 2

tory).

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

Page 3

CAUTION

CAUTION

M19796

M19797

M19798

FLOW

Fig. 3. C7632A cover removal.

Wall Mounting (C7232A)

Mount the C7232A to the wall as follows:

1. Remove the C7632 cover.

2. Mount the device in a vertical position.

3. Mount the subbase directly on a wall using the type of

screws (not supplied) appropriate for the wall material.

4. Replace the cover.

C7632A,B SENSOR AND CONTROLLER

Fig. 4. Junction box mounting (C7632A).

Junction Box Mounting (Fig. 4)

Mount the C7232A to a junction box as follows:

1. Attach the wallplate using only the top screw.

2. Remove the C7632 cover.

3. Place the subbase on the wallplate hook.

4. Mount the subbase and wallplate to the junction box

using the lower screw.

5. Replace the cover.

Duct Mounting (see Fig. 5)

1. Place gasket on aspiration tube.

IMPORTANT

Ensure largest tab at tube control end is at the top.

2. Insert tube into duct; attach using screws and washers.

IMPORTANT

Leakage into the duct or the C7632 box cover from

the room will skew the sensor readings. Ensure the

box cover and duct seal completely.

3. Place o-ring on tube end; mount the control to the

tube.

Fig. 5. Duct mounting (C7632B).

WIRING (FIG. 6)

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Equipment Damage Hazard.

Electrostatic Discharge Can Short Equipment

Circuitry.

Ensure that you are properly grounded before

handling the unit.

IMPORTANT

1. All low voltage connections to this device must be

24 Vac Class 2.

2. All wiring must comply with applicable local codes,

ordinances and regulations.

3 63-2615—07

Page 4

C7632A,B SENSOR AND CONTROLLER

L1

(HOT)

L2

M19799

1

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

C7632

0-10 Vdc

G0 CO

2

G+

Table 1. C7632 Wiring Connections (see Fig. 6).

Designation C7632B Wire Color Function

G+ Red 24 Vac

G0 Black Common

CO

2

Brown Analog Output Signal

Fig. 6. Wiring the C7632.

Output (Table 2)

Table 2. 0-10 Vdc Output Signal.

CO2

0 200 400 600 800 10001200140016001800200

Level

(ppm)

Voltage

Output

012345678910

(Vdc)

4. Check the output signal. (See Checkout section.)

5. Reinstall the device.

Background Calibration

1. Remove the sensor cover and set it aside.

2. Ventilate the area and reduce occupancy to lower the

CO2 levels.

3. Maintain a reasonable proximity from the sensor to

avoid breathing on it, thus skewing calibration accuracy.

4. Keep the sensor in this environment for three to four

minutes.

5. Execute calibration by shorting the proper two soldering pads (see Fig. 7).

NOTE: The device should now provide accurate

6. Check the output signal. (See Checkout section.)

7. Reinstall the device.

0

output.

ZERO

CALIBRATION

BACKGROUND

CALIBRATION

M19856

CALIBRATION

Fig. 7. C7632 calibration pads.

Typically, calibration is unnecessary. No calibration kits are

available. However, if CO

desirable level, the sensor can be reset using either zero or

background calibration:

IMPORTANT

• With zero calibration, all CO

calibration skews the sensor zero level.

• Using background calibration, practical operation

(with a higher than zero level set) can be obtained.

Zero Calibration

1. Remove the sensor cover and set it aside.

2.

Apply a steady flow of CO2-free gas at 0.1 to 0.5 liter

per minute into the gas inlet tube located on the gold

sensor.

3. Execute calibration by shorting the proper two soldering pads (see Fig. 7).

NOTE: The device should now provide accurate out-

put.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability,

cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

levels can be brought to a

2

present during

2

CHECKOUT

Perform a quick test of the unit with the unit powered:

1. After calibration:

a. Check output signal immediately following proper

calibration (with minimum environmental change):

(1) Proper zero calibration: 0 Vdc.

(2) Typical background calibration: 2 Vdc. Depend-

ing on ambient CO

2.5 Vdc.

b. If the output is incorrect, repeat calibration

procedure.

c. Otherwise, continue with checkout.

2. Stand close to the unit and breathe air into the sensor.

NOTE: When connected to a damper in a ventilation

system, breathing on the sensor typically

signals an increase in air flow.

3. Check the output to ensure a strong rise in CO

level, range: 1.75 to

2

level.

2

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell GmbH

Böblinger Straße 17

D-71101 Schönaich

customer.honeywell.com

® U.S. Registered Trademark

© 2016 Honeywell International Inc.

63-2615—07 M.S. Rev. 02-16

Printed in U.S.A.

Loading...

Loading...