Page 1

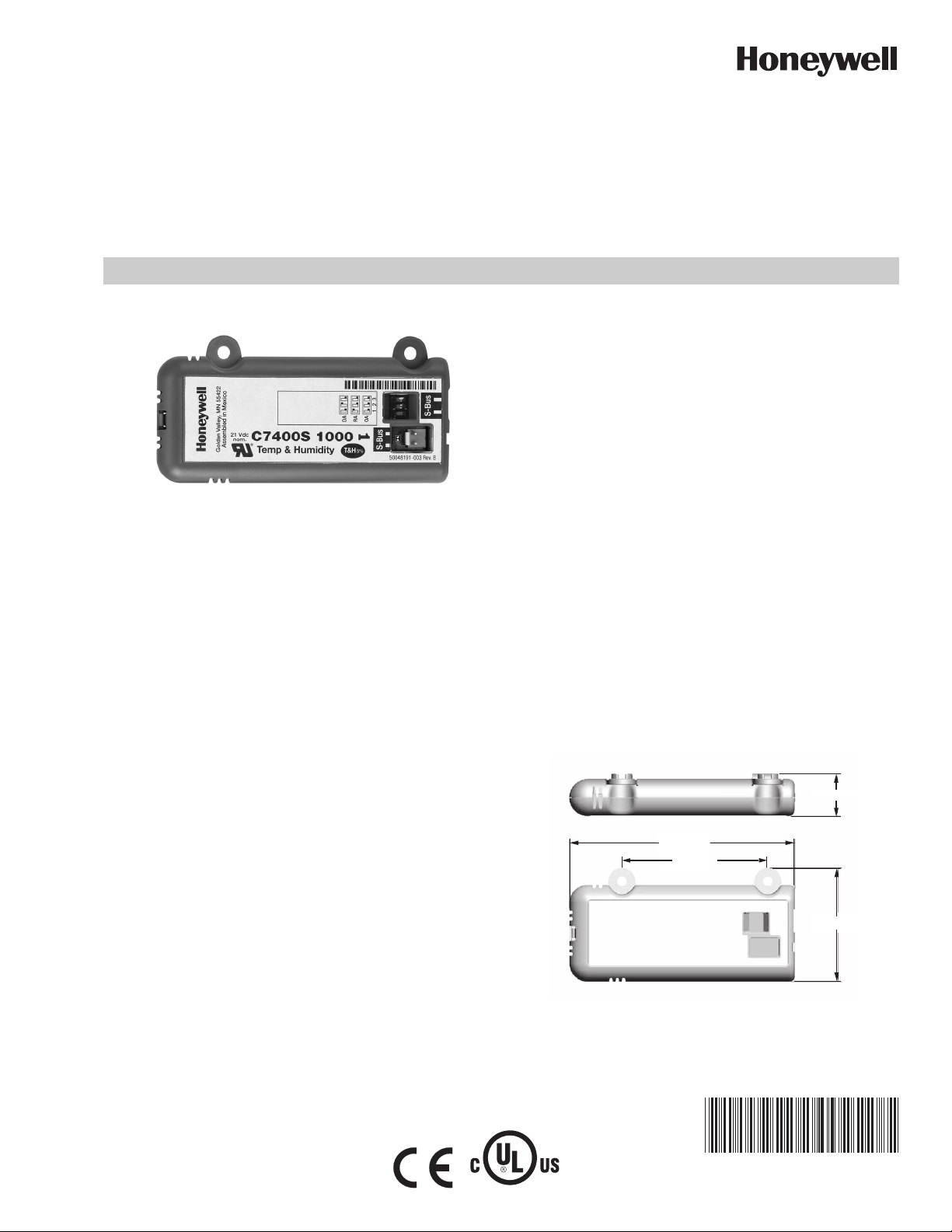

C7400S Enthalpy Sylk Bus Sensor

M32331

4-1/4 (108)

2-1/64 (55)

51/64 (21)

2-3/4 (70)

INSTALLATION INSTRUCTIONS

Environmental

Operating Temperature range: -40 to 150 °F (-40 to 65 °C)

Storage Temperature range: -40 to 150 °F (-40 to 65 °C)

Shipping Temperature range: -40 to 150 °F (-40 to 65 °C)

Operating Relative Humidity range: 5% to 95% RH non-

condensing

Temperature and Humidity, C7400S:

Temperature sensing range: -40 to 150 °F (-40 to 65 °C)

Humidity sensing range: 0 to 100% RH with 5% accuracy.

PRODUCT DESCRIPTION

The C7400S Sylk Bus sensor is a combination temperature

and humidity sensor, which is intended to be used in

commercial roof top units for sensing air. The sensor is

powered by and communicates on the Sylk Bus. The C7400S

communicates temperature and humidity separately digitally

on the Sylk Bus Communication Protocol.

A separate controller such as the JADE™ Economizer

System (Model W7220) provides power and communications

on the Sylk Bus for the C7400S Sylk Bus sensor.

SPECIFICATIONS

Electrical

Supply Voltage: 7 to 21 Vdc

Power Consumption: 5 mA

Output Rating: 75 ohm load switched at 9600 Baud

Wiring: Sylk Bus: 2-wire (18 to 22 AWG)

Dimensions (See Fig. 1):

Height: 0.8 inches (20.5 mm)

Width: 2.17 inches (55 mm)

Length: 4.25 inches (108 mm)

Weight: 0.58 lb. (0.265 kg)

Listing Agency Approvals:

EN61000-6-3,EN61000-3-2;EN61000-3-3;EN61000-6-1;

EN60730-1 Annex H.23 (emissions)

Annex H.26 (immunity)

CE Mark FOR EU

Fig. 1. Dimensions in inches and (mm) showing mounting

holes.

62-0332-03

E4436

Page 2

C7400S ENTHALPY SYLK BUS SENSOR

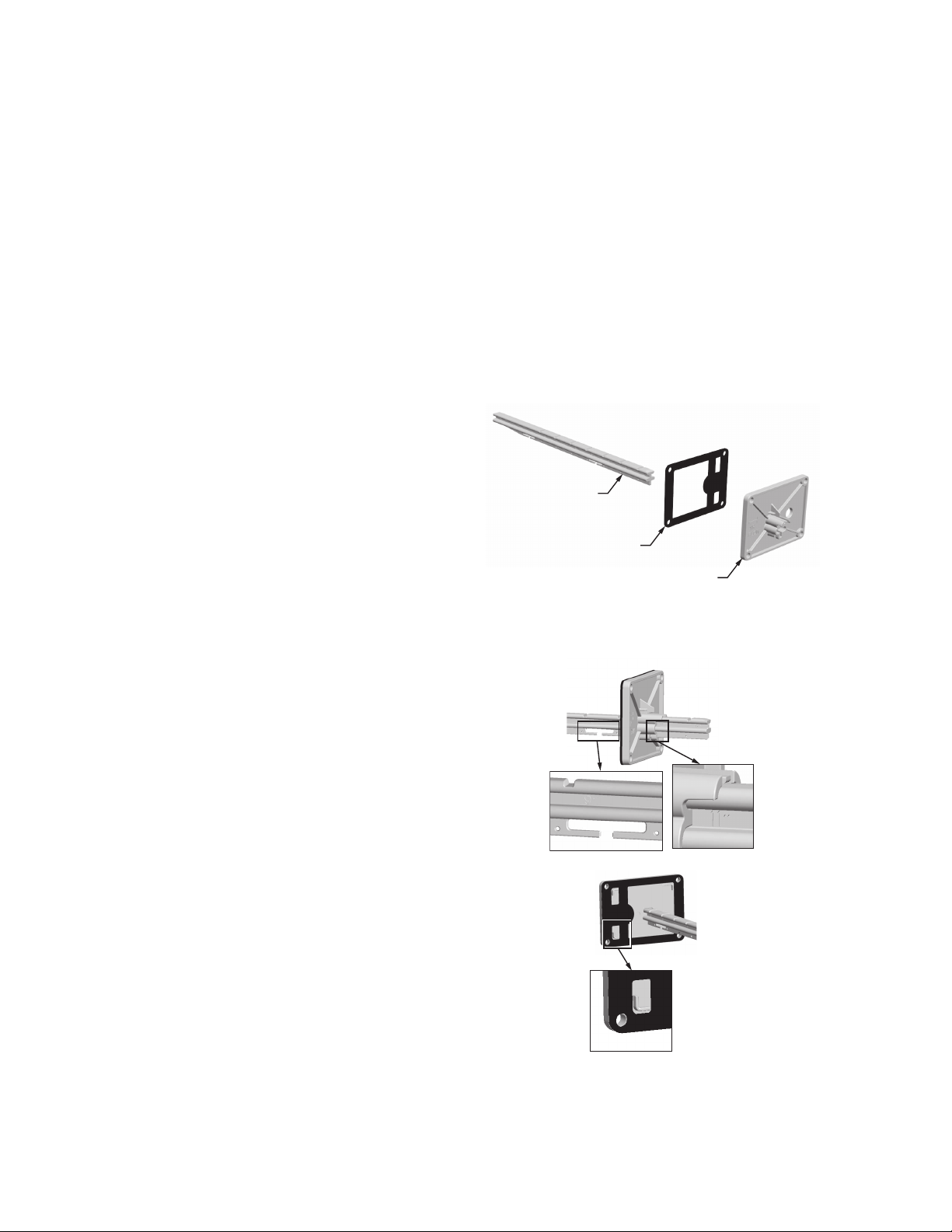

ROD - 1 PIECE

FLANGE - 1 PIECE

GASKET - 1 PIECE

M32281

BEFORE INSTALLATION

Review the “Specifications” on page 1 before installing the

sensor.

When Installing This Product

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check ratings given in instructions and on the product to

ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

INSTALLATION AND SETUP

The following installation procedures should be performed in

the order listed:

1. Mounting — see “Mounting” on this page.

2. Wiring — see “Wiring” on page 3.

3. Checkout — see “Checkout” on page 3.

MOUNTING

Once installed, a sensor can be changed to a different

application by simply changing the DIP switch setting.

Sensor Mounting

The sensor can be mounted directly on to the sheet metal of

the unit or can be mounted in the air stream using the duct

mounting kit.

The duct mounting kit contains a rod to hold the sensor in the

duct, a flange to secure the sensor rod to the duct wall and to

fill the hole, and a gasket to prevent air from leaking through

the duct wall. See Fig. 2.

The rod has slots for threading the wire to prevent loose or

hanging wire in the duct and can be adjusted for 6 or 12 inch

length. The flange has extended relief for ease of mounting.

See Fig. 3.

IMPORTANT

Avoid mounting in areas where acid fumes or other

deteriorating vapors can attack the metal parts of the

sensor, or in areas where escaping gas or other

explosive vapors are present.

IMPORTANT

The sensor must be mounted in a position that

allows clearance for wiring, servicing, and removal.

The sensor is mounted directly to the sheet metal using self

tapping sheet metal screws or in the air stream using the duct

mounting kit. Use #6 or #8 screws (screws are not provided

and must be obtained separately). Use the dimensions in

Fig. 1 on page 1 as a guide.

The sensor must be mounted to allow air flow through the

sensor housing vent slots on the end or side.

The Sylk Bus sensor communicates with a controller (such as

the JADE™ Economizer Model W7220) on the two-wire

communication bus and can either be wired using a two pin

header or using a side connector. The unit pack Sylk Bus

sensor includes a two pin Euro connector with the packaging.

The SKU number of the Sylk Bus sensor is C7400S. All OAT

(Outdoor Air Temperature), RAT (Return Air Temperature) and

DAT (Discharge Air Temperature) sensors are the same SKU

number. The sensor is set for the appropriate type of sensing

using the three position DIP switch located on the sensor.

OAT position is OFF, OFF, OFF; RAT is ON, OFF, OFF and

DAT is OFF, ON, OFF. During installation the sensors are set

for the the appropriate usage. See “Sylk Bus Sensor Wiring”

on page 3 for DIP switch details.

Fig. 2. Duct Mounting Kit (Part # 50053060-001).

WIRE HO LDER

EXTENDE D RELI EF

(FOR CORRECT MOUNTING)

LENGTH ADJUSTS

TO 6 OR 12 INCHES

M32282

Fig. 3. Duct Mounting Adjustments.

62-0332—03 2

Page 3

C7400S ENTHALPY SYLK BUS SENSOR

WARNING

CAUTION

DIP

SWITCH

LABEL

M32271

SYLK BUS

TERMINALS

(1 AND 2)

DIP

SWITCHES

(3)

SYLK BUS

2 PIN “EURO”

CONNECTOR

WIRING

All wiring must comply with applicable electrical codes and

ordinances, or as specified on installation wiring diagrams.

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring, or

making wiring connections, to prevent electrical shock

or equipment damage.

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before

handling the sensor.

Prepare wiring as follows:

1. Strip 1/2 in. (13 mm) insulation from the conductor.

2. Cut a single wire to 3/16 in. (5 mm). Insert the wire in

the required terminal location and tighten the screw.

3. Pull on each wire in all terminals to check for good

mechanical connection.

Table 1. SYLK Bus Sensor Wiring Terminationsa.

Terminal

Type DescriptionNbr Label

1 S-BUS SYLK Bus Sylk Bus Communications

(Sensor Bus)

2 S-BUS SYLK Bus Sylk Bus Communications

(Sensor Bus)

a

Terminals are polarity insensitive.

Table 2. SYLK Bus Sensor DIP Switch Settings.

DIP Switch Positions for Switches 1, 2, & 3

Use

a

DA

b

RA

c

OA

a

DA = Discharge Air

b

RA = Return Air

c

OA = Outside Air

123

OFF ON OFF

ON OFF OFF

OFF OFF OFF

Sylk Bus Sensor Wiring

Use Fig. 4 and Table 1 to locate the wiring terminals for each

Sylk Bus sensor.

Use Fig. 4 and Table 2 to set the DIP switches for the desired

use of the sensor.

Fig. 4. Sylk Bus sensor DIP switches.

CHECKOUT

Refer to the JADE™ Economizer Module (Model W7220)

Installation Instructions (Honeywell form 62-0331).

TROUBLESHOOTING

Refer to the JADE™ Economizer Module (Model W7220)

Installation Instructions (Honeywell form 62-0331).

3 62-0332—03

Page 4

C7400S ENTHALPY SYLK BUS SENSOR

JADE™ is a trademark of Honeywell, Inc.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

62-0332—03 M.S. Rev. 05-11

Printed in U.S.A.

Loading...

Loading...