Page 1

®

C7232A

C7232B

C7232A,B

Sensor and Controller

CARBON DIOXIDE SENSOR

PRODUCT DATA

FEATURES

• Models available with LCD that provides sensor

readings and status information.

• Non-Dispersion-Infrared (NDIR) technology used to

measure carbon dioxide gas.

• Gold-plated sensor provides long-term calibration

stability.

• Device provides voltage output based on CO

• Models available with SPST relay output.

• Used for CO

• Automatic Background Calibration (ABC) algorithm

based on long-term evaluation reduces required

typical zero-drift check maintenance.

based ventilation control.

2

levels.

2

APPLICATION

The C7232 Sensor and Controller is a stand-alone carbon

dioxide (CO

necessity with HVAC controllers. The C7232 measures the

concentration in the ventilated space or duct. The C7232

CO

2

is used in ventilation and air conditioning systems to control

the amount of fresh outdoor air supplied to maintain

acceptable levels of CO

) sensor for use in determining ventilation

2

in the space.

2

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 3

Wiring ............................................................................... 4

Calibration ........................................................................ 6

Checkout .......................................................................... 6

Appendix .......................................................................... 7

® U.S. Registered Trademark

Copyright © 2003 Honeywell International Inc.

All Rights Reserved

63-2571-4

Page 2

C7232A,B SENSOR AND CONTROLLER

5

SPECIFICATIONS

Models: C7232 Sensor and Controller. A stand-alone carbon

dioxide (CO

(one analog and one spst relay).

) sensor with two jumper-adjustable outputs

2

C7232A: Wall mount model.

C7232B: Duct mount model.

NOTE: Models are available with or without a 4-digit LCD

that indicates the current CO

concentration.

2

Dimensions:

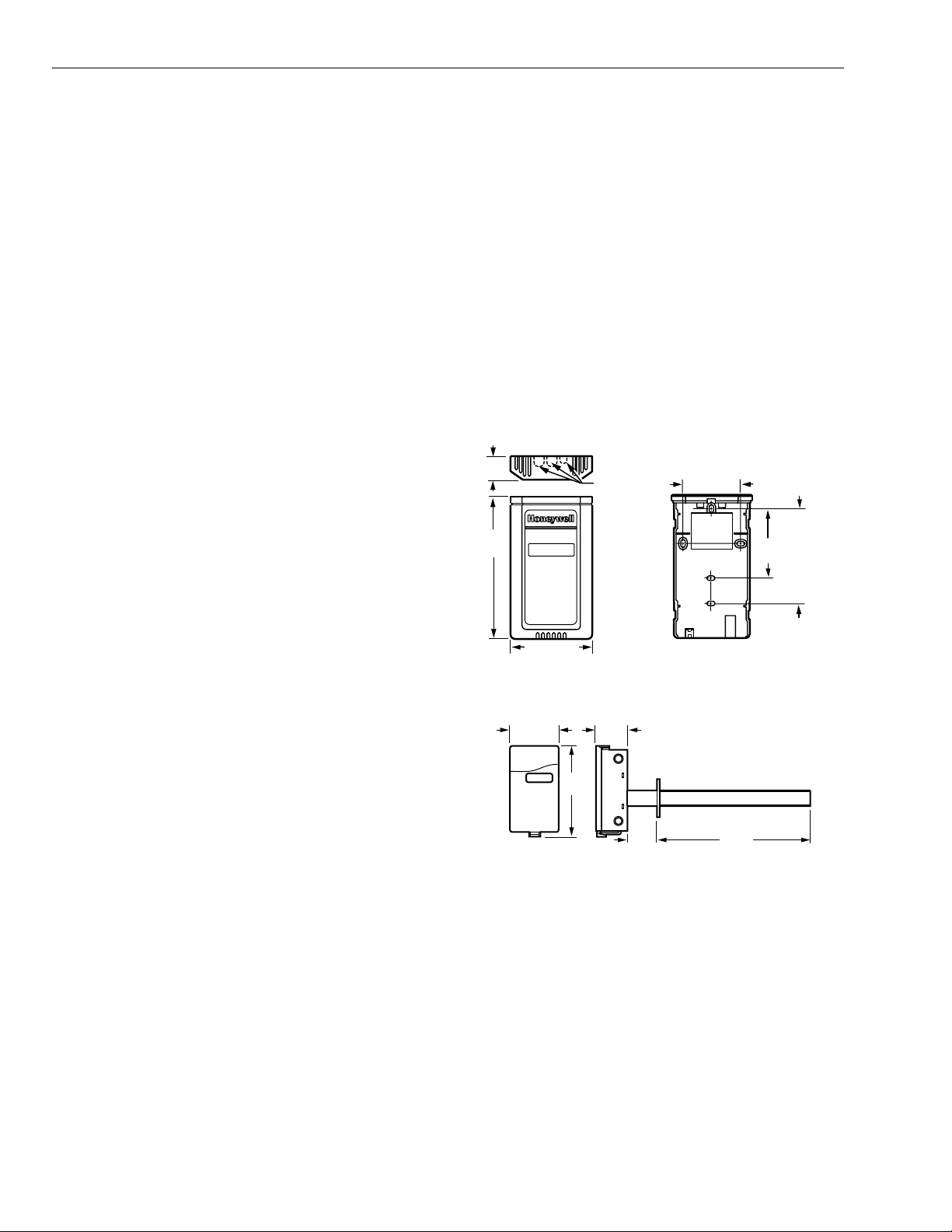

C7232A: See Fig. 1.

C7232B: See Fig. 2.

Sensor Performance Ratings:

Response Time: 2 min.

Carbon Dioxide Sensor:

Operation: Non-dispersive infrared (NDIR).

Sampling: Diffusion.

Range: 0 to 2000 ppm ±5% and ±50 ppm.

Annual Drift: 20 ppm (nominal).

Electrical Ratings:

Power Supply: 24 Vac ±20%, 50/60 Hz (Class 2).

Maximum Power Consumption: 3W.

Peak Current (at 20 ms): 600 mA.

Relay:

Configuration: Shipped N.O. (reconfigure with software.)

Contact Rating: 1A at 50 Vac/24 Vdc.

Minimum Permissible Load: 1 mA at 5 Vdc.

Linear Analog Output:

Voltage: 0/2-10 Vdc (resistive load greater than

5000 ohms).

Current: 0/4-20 mA (resistive load less than 500 ohms).

Connections:

Wiring:

C7232A: 20-gauge cable with six 8 in. leadwires.

C7232B: 20-gauge cable with six 6 in. leadwires.

Mounting:

C7232A: Vertical surface with standard single-gang junction

box.

C7232B: Sheet metal duct with a sampling tube.

Automatic Background Calibration (ABC) default: On.

Approvals:

Underwriters Laboratories Inc. Component Recognition:

UL94-5V, File No. E191465.

CE.

C7232A: NEMA1.

C7232B: NEMA3.

1

(25)

-1/16

(128)

3-5/32 (80)

KNOCKOUTS

FOR

EUROPEAN

APPLICATIONS

2-3/8 (60)

STANDARD

2-3/8

(60)

UTILITY

CONDUIT

BOX

(2X4)

MOUNTING

HOLES

M17540

Outputs (Jumper Adjustable, see Table 2):

Fig. 1. C7232A dimensions in in. (mm).

Analog: 0-10 Vdc (Default: 2-10 Vdc, 500 to 1500 ppm).

Relay: Normally Open Spst (Default: Close at 800 ppm).

3-5/16 (84)

Ambient Ratings:

1-13/16

(46)

Temperature:

Operating: +32°F to +122°F (0°C to +50°C).

Storage: -4°F to +158°F (-20°C to +70°C).

5-5/8

(142)

Relative Humidity (non-condensing): 0 to 95 percent.

CO

Pressure Dependence: 1.4% change in reading per

2

1 kPa deviation from 100 kPa.

M17592

1-5/8

(41)

8 (203)

Fig. 2. C7232B dimensions in in. (mm).

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2571—4 2

Page 3

INSTALLATION

B

S

S

L

C7232A,B SENSOR AND CONTROLLER

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

CAUTION

Health Hazard.

Improper use can create dangerous situations.

Use in application for sensing carbon dioxide only.

For life-safety applications, this device can function

only as a secondary or lesser device.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

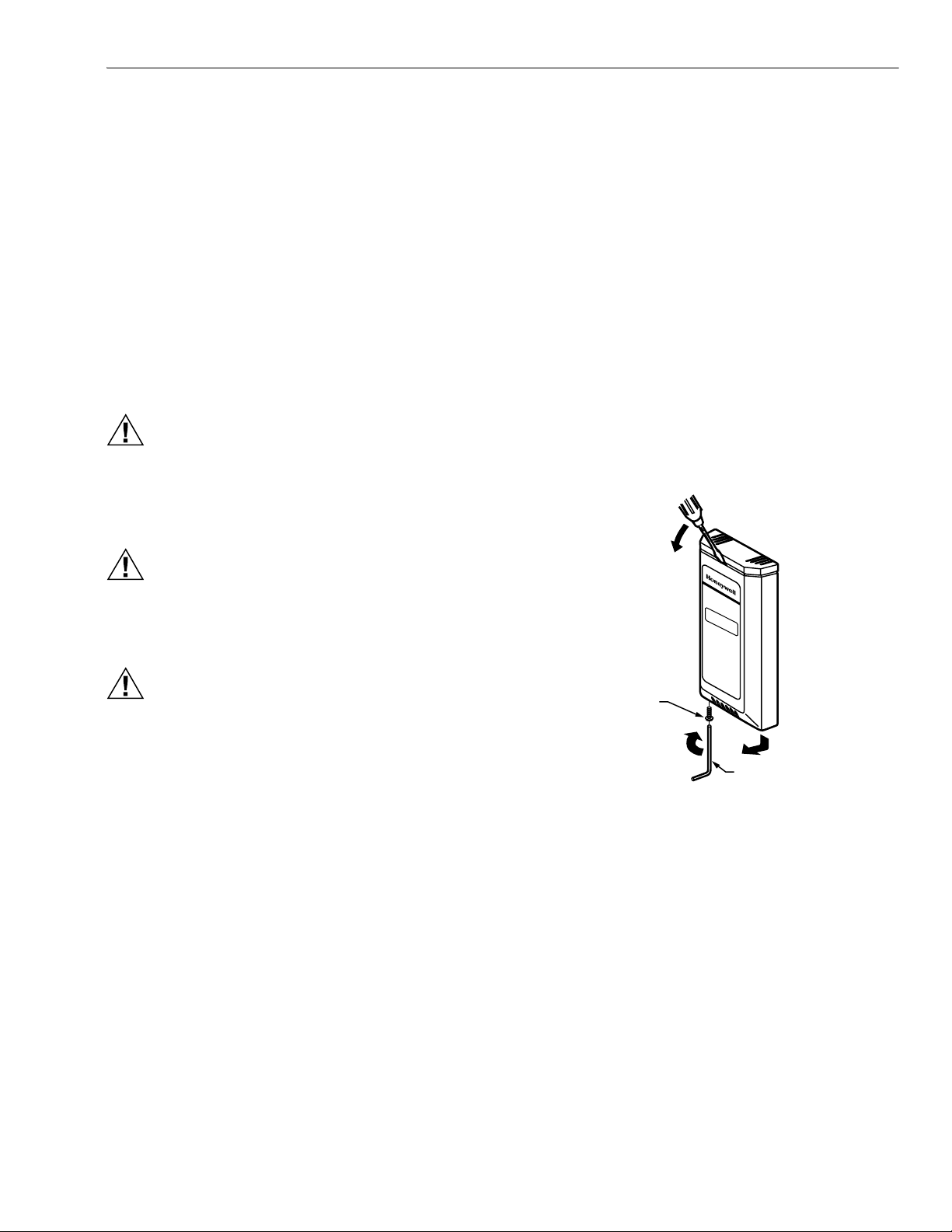

C7232A Cover Removal/Replacement

C7232A Cover Removal (see Fig. 3)

1. Remove button head socket cap screw and set it aside.

2. Insert the head of a small screwdriver into the slot at the

center and near the top of the cover.

3. Gently pull the handle down toward the bottom of the

device until a small gap between the subbase and the

cover appears.

4. Remove the screwdriver and pull the cover straight

down until it meets a stop.

5. Pull the cover straight off the subbase.

C7232A Cover Replacement

1. Feed the wires through the opening in the subbase.

2. Place the cover, with a small gap at the top, flat on top

of the subbase.

3. When the cover rests flat on the subbase, slide it

straight up until it latches in place.

B

UTTON HEAD

CAUTION

Equipment Damage Hazard.

Electrostatic discharge can short equipment

circuitry.

Ensure that you are properly grounded before

handling the unit.

OCKET CAP

CREW

A

M17541

Fig. 3. C7232A cover removal.

C

ALLEN TOO

3 63-2571—4

Page 4

C7232A,B SENSOR AND CONTROLLER

2

B

S

S

1

Location and Mounting

C7232 Sensors mount directly on the wall, sheet metal duct,

or a panel. When planning the installation, allow enough

clearance for maintenance and service. Mount the sensor in a

well-ventilated area.

FLOW

NOTES: Do not install the sensor where it can be affected by:

— drafts or dead spots behind doors and in corners.

— air from ducts.

Wall Mounting

The C7232 Wall Mount models can be mounted using two or

four screws:

1. Remove C7232 cover.

2. Mount the subbase to the wall using washers and two or

four screws (not supplied) appropriate for the wall

material.

NOTE: When mounting on a junction box, see Fig. 4.

3. Replace the cover.

Duct Mounting (see Fig. 5)

1. Place gasket on aspiration tube.

IMPORTANT

Ensure largest tab at tube control end is at the top.

2. Insert tube into duct; attach using screws and washers.

IMPORTANT

Leakage into the duct or the C7232 box cover from

the room will skew the sensor readings. Ensure the

box cover and duct seal completely.

3. Place o-ring on tube end; mount the control to the tube.

M1759

Fig. 5. Duct mounting (C7232B).

WIRING

The factory ships the device with the output default settings

shown in Tables 2 and 3. Set the jumpers and wire the device

(see Table 1 and Fig. 6).

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

STANDARD UTILITY CONDUIT BOX

NO. 6 SCREW

FRONT

COVER

UTTON HEAD

OCKET CAP

CREW

NO. 6 SCREW

Fig. 4. Junction box mounting (C7232A).

SUBBASE

M1754

CAUTION

Equipment Damage Hazard.

Electrostatic Discharge Can Short Equipment

Circuitry.

Ensure that you are properly grounded before

handling the unit.

IMPORTANT

1. All low voltage connections to this device must be

24 Vac Class 2.

2. All wiring must comply with applicable local codes,

ordinances and regulations.

Table 1. C7232 Wiring Connections (see Fig. 6).

Wire Color Designation Function

Red G+ 24 Vac Hot

Black G0 24 Vac Common

Yellow OUT1 Analog Output Signal

Brown M Analog Output Common

Orange NO Relay Output Normally Open

Green COM Relay Output Common

63-2571—4 4

Page 5

C7232

ANALOG

24V

OUT

+

–

RED

BLACK

YELLOW

BROWN

ORANGE

GREEN

L1

(HOT)

L2

1

1 POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND

OVERLOAD PROTECTION

AS REQUIRED.

M17543

Fig. 6. Wiring the C7232.

Input Signal

The C7232 Sensors have an adjustable range. These ranges

are determined by the SW1 and SW2 jumper settings (see

Table 2).

Table 2. CO

SW1 SW2 AN (ppm) Relay

Range Jumper Settings

2

a

(ppm)

On On 0 to 1000 1000

On Off 0 to 2000 1200

Off

b

On

b

500 to 1500 800

Off Off 500 to 2000 1200

a

When the level reaches this value, the contacts close; when

the level drops 100 ppm below this value, the contacts open.

b

Setting when shipped from the factory.

Output Signal

The output signal can be adjusted for 0/2-10Vdc or 0/4-20mA

(see Table 3).

C7232A,B SENSOR AND CONTROLLER

Table 3. Output Signal Jumper Settings

OUT

AN

0-100% 20-100%

Voltage 0-10Vdc 2-10Vdc

Current 0-20 mA 4-20 mA

NOTES:

— On duct models, remove the screw holding the

board in place to view jumper settings on reverse.

(See Fig. 7.)

— The CO

are independent of each other. 0-100% and

settings and the output signal settings

2

20-100% are simply markings for the OUT jumper

settings on the sensor (to differentiate between

the two voltage and the two current ranges) and

do not refer to or alter the ppm range chosen.

SW2SW1 OUT

ON

OFF

ON

OFF

AN

20 – 100%

0 – 100%

Current

Voltage

Fig. 7. C7232 default jumper settings.

M19424

Example

For a CO2 setting of 0-2000 ppm and a voltage output of 0-10 Vdc, the output would be as shown in Table 4 (arbitrary points

along the analog curve).

Table 4. 0-10 Vdc Output Example.

CO2 Level (ppm)

Voltage Output (Vdc)012345678910

For a CO

along the analog curve).

setting of 0-2000 ppm and a voltage output of 2-10 Vdc, the output would be as shown in Table 5 (arbitrary points

2

CO

Level (ppm)

2

Voltage Output (Vdc) 2 3 4 5 6 7 8 9 10

0 200 400 600 800 1000 1200 1400 1600 1800 2000

Table 5. 2-10 Vdc Output Example.

0 250 500 750 1000 1250 1500 1750 2000

5 63-2571—4

Page 6

C7232A,B SENSOR AND CONTROLLER

CALIBRATION

Typically, calibration is unnecessary. No calibration kits are

available. However, if CO

chamber using a general gas purge device, the sensor can be

rezeroed:

IMPORTANT

Any CO

zero level resulting in incorrect CO

1. Once the sensor stabilizes, use a screwdriver to

connect the two MENU soldering pads.

2. The display should indicate CAL.

3. Execute the zero calibration by connecting the two

ENTER soldering pads.

4. The display should return to providing the measured

CO

2

present during calibration skews the sensor

2

level.

gas can be purged from the sensor

2

level reports.

2

CHECKOUT

Perform a quick test of the unit with the unit powered:

1. Stand close to the unit and breathe air into the sensor.

2. Check the CO

ensure a strong rise.

3. When connected to a damper in a ventilation system,

the controller typically signals an increase in air flow.

level registered by the controller to

2

63-2571—4 6

Page 7

APPENDIX

4

IMPORTANT

This page is only for models with date code prior to 0309.

Pre 0309 Date Code Jumper Settings

C7232A,B SENSOR AND CONTROLLER

Input Signal

The C7232 Sensors have an adjustable range. These ranges

are determined by the SW2 and OUT1 jumper settings (see

Table 6).

NOTE: When choosing analog output, be sure to set the

SW1 jumper to the On position.

Table 6. CO

Range Jumper Settings for models

2

with date code prior to 0309.

Jumper SW1 Jumper SW2

Jumper Setting

b

OUT1

AN1 X

AN2

Relay Switching

b

a

a

On

X

Off On

c

—

c

—

X

X

a

Setting when shipped from the factory.

b

OUT1 jumper setting does not affect the Relay Switching.

c

The analog output will not work properly when SW1 is Off.

d

When the level reaches this value, the contacts close; when the

level drops 100 ppm below this value, the contacts open.

a

Off

0 to 1000 0 to 2000

500 to 1500 500 to 2000

800

1000

d

d

1200

d

Output Signal

The output signal can be adjusted for 0/2-10Vdc or 0/4-20mA

(see Table 7).

Table 7. Output Signal Jumper Settings for models

with date code prior to 0309.

AN1 and AN2 (set

both the same)

0-100% 20-100%

OUT

Voltage 0-10Vdc 2-10Vdc

Current 0-20 mA 4-20 mA

NOTES:

— On duct models with date code prior to 0309, remove

the screw holding the board in place to view jumper

settings on reverse. (See Fig. 8.)

—The CO

independent of each other. 0-100% and 20-100% are

simply markings for the OUT jumper settings on the

sensor (to differentiate between the two voltage and the

two current ranges) and do not refer to or alter the ppm

range chosen.

SW2SW1 OUT

ON

OFF

settings and the output signal settings are

2

OFF

ON

0 – 100%

AN2 AN1

20 – 100%

Current

Voltage

Current

Voltage

OUT1

Select

AN1

AN2

M2049

Fig. 8. C7232 default jumper settings for models

with date code prior to 0309.

7 63-2571—4

Page 8

Automation and Control Solutions Honeywell International Honeywell Europe S.A. Honeywell Latin American

Honeywell International Inc. Honeywell Limited-Honeywell Limitée Control Products 3 Avenue du Bourget

1985 Douglas Drive North 35 Dynamic Drive Honeywell Building 1140 Brussels 480 Sawgrass Corporate Parkway

Golden Valley, MN 55422 Scarborough, Ontario 17 Changi Business Park Central 1 Belgium Suite 200

M1V 4Z9 Singapore 486073 Sunrise FL 33325

Region

63-2571—4 B.B. Rev. 3-03 www.honeywell.com

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...