Page 1

PRODUCT HANDBOOK

C7195A

WATER FLOW SENSOR

EN2R-- 9029 0101R2--NE

APPLICATION

The sensor is primarily designed to measure the Domestic

Hot Water (DHW) flow rate in domestic appliances as follows:

Combi boiler

Instanteneous Water Heater (IHW)

Other systems such as applications where the

instanteneous DHW is produced from district heat

input.

Contents

General Page

Description 2........................................

Typical applications 3................................

Technical

Specifications 4.....................................

Electrical specifications 5.............................

Performance 6......................................

General considerations 7.............................

Dimensional drawing 8...............................

Various

Standards and approvals 9............................

Ordering information 10..............................

Associated products 11...............................

Subject to change without notice. Printed in the Netherlands.

Page 2

EN2R-- 9029 0101R2--NE

2

DESCRIPTION

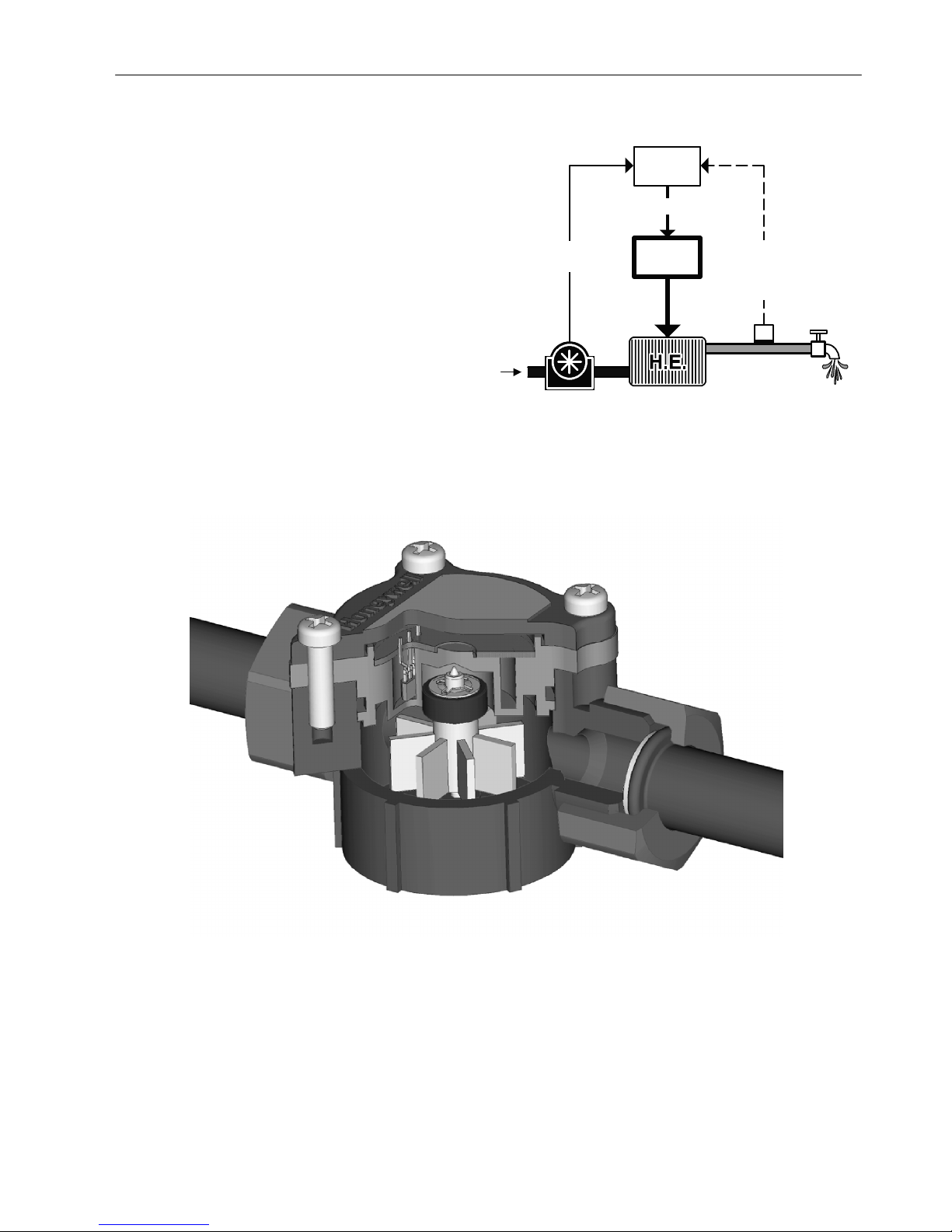

The C7195A is a mechanical water flow sensor (fig. 2.).

A turbine rotates with water flow. The turbine supports a

magnet which rotates in front of a Hall effect sensor.

This Hall effect sensor picks up the field of the magnet giving

a pulsed output.The output is directly proportional to the water

flow through the sensor.

This frequency output is easily processed by an electronic

controller which can then modulate the burner load (for

feed--forward loop) or simply open heat demand when the

flow reaches its defined minimum rate (electronic flow switch).

The sensor body is constructed from pressure and

temperature resistant plastic, with easy connections to

traditional pipes used in domestic appliances.

Feed forward control loop concept

See fig. 1.

Electronic

Controller

Flow rate input

for modulation

Cold water

Modulating control

Heat

supply

Temperature feed back

Option: Compensation

of tolerances and

hysteresis

_C

T7335

C7195A

Domestic

hot water

Fig. 1. Feed forward control loop concept

Fig. 2. Open view C7195

Page 3

EN2R-- 9029 0101R2--NE

3

TYPICAL APPLICATIONS

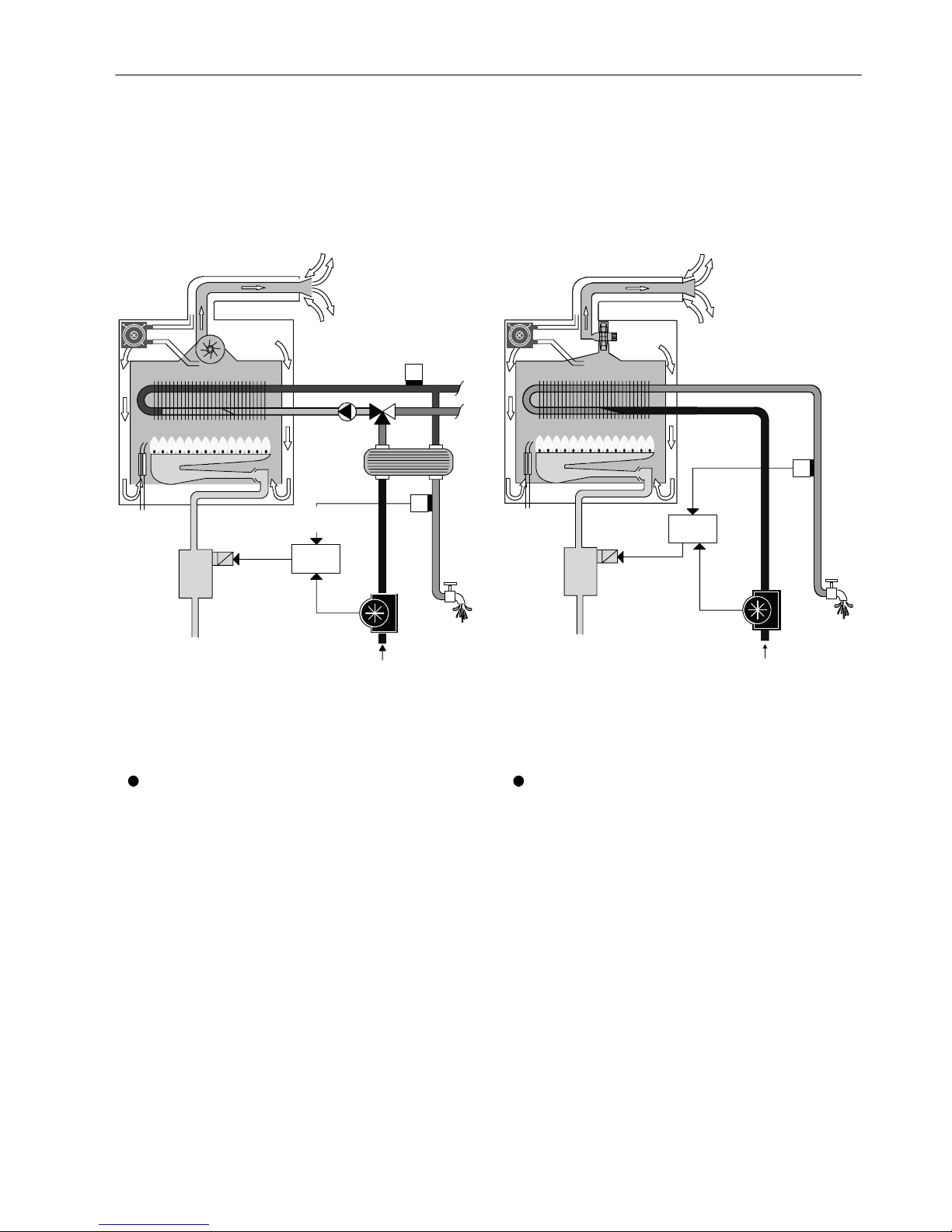

The C7195A sensor is designed to measure the Domestic Hot

Water (DHW) flow rate in appliances as follows:

Combi boiler (instanteneous or with small buffer)

Instanteneous Water Heater (IWH), gas or electric

powered.

Other systems where DHW is produced instantaneously

Modulation input

and/or electronic

flow switch

Modulating

control

Electronic

controller

Cold water

Temperature

feed back

Domestic hot

water

_C

_C

Fig. 3. Instanteneous combi boiler with feed forward or

feed back control loop

Temperature

feed back

Modulating

control

Modulation input

and/or electronic

flow switch

Electronic

controller

Cold water

Domestic

hot water

_C

Fig. 4. Instanteneous water heater with feed forward or

feed back control loop

For the above mentioned appliances, the sensor can be used in two specific ways:

1

Feed forward control loop

This is an advanced electronic control concept which

improves the DHW temperature control thanks to fast

reaction to flow rate changes. Indeed, before the

temperature sensor sees a change in hot side, the

electronic board can react promptly following the flow

measurement. A temperature sensor can be used

anyway as an option to compensate the tolerances and

hysteresis of the complete system.

2

Feedback control loop

This is the traditional electronic control, reacting to the

DHW temperature sensor output. A flow detector is

needed to detect when the DHW is tapped.

The C7195 water flow sensor can be used as an

electronic flow switch with the following advantages

over ON/OFF switches:

Flexibility:

Electronically (auto)adjustable ON--point, for

instance depending on DHW temperature setting

point (to avoid ON/OFF recycling)

Safety:

Can not be blocked in ON position (the turbine can

only turn with flow).

Page 4

EN2R-- 9029 0101R2--NE

4

SPECIFICATIONS

Model

C7195A water flow sensor

Ambient temperature

--20 ... + 85 _C

Dimensions

See fig. 11.

Fluid

Water for sanitary use

Permissible fluid temperatur

0 ... 80 _C

Minimum operating flow rate

1.5 liter/minute or lower

Maximum operating flow rate

30 liter/minute

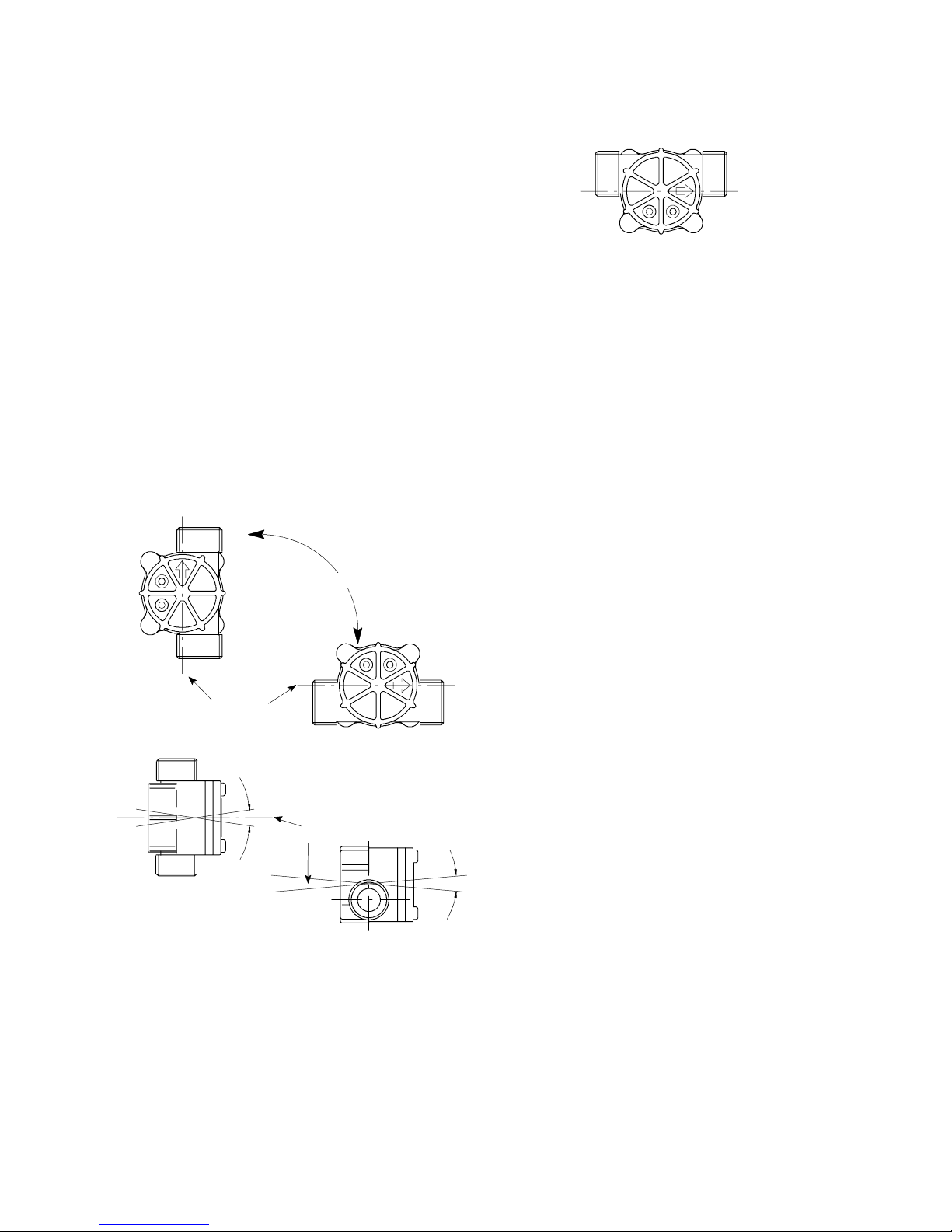

Mounting position

The shaft of the rotor shall be horizontal ¦ 5_. See fig. 5.

Provided the shaft of the rotor is horizontal, most

positions are acceptable, but the position as indicated in

fig. 6. is not recommended because water will remain in

the sensor when the installation is drained (frost risk).

All positions

Shaft axis

Shaft axis

5_

5_

5_

5_

Fig. 5. Mounting positions

Fig. 6. Not recommended mounting position

Measuring range

2.1 ... 30 liter/min

Nominal output frequency

f = Q x 7.0 (Q = flow rate in l/min; f = pulse signal in Hz) with

> 60 mm straight pipe on both sides.

Accuracy

¦ 10% of measurement over the measuring range.

Withstand pressure

When a water pressure of 17.5 bar is applied, no external

leakage shall be measured and no body damage shall occur.

Water connections

PF

1

/2” minimum 8 mm (4.4 threads)

Recommended tightening torque of inlet/outlet connections

2.5 ... 3.5 Nm

Pressure drop

0.15 bar or less at 10 l/min flow rate.

(Outlet pressure is at atmospheric pressure)

Endurance

Indicated value will shift < 5% under following conditions:

10000 hr at 10 l/min and 20 _C

7000 hr at 4 l/min and 45 _C

or

100,000 cycles ON/OFF at 10 l/min and 45 _C

Page 5

EN2R-- 9029 0101R2--NE

5

ELECTRICAL SPECIFICATIONS

Nominal voltage (Vcc): 12 V (absolute maximum: 18 V)

Current (I

sink

): 10 mA (absolute maximum: 15 mA)

Output saturation voltage (V

sat

):< 0.4 V

with output “ON” and at I

sink

=10mA

Supply current (I

cc

): 8 mA with output “OFF”

Electrical connection

C7195A 1003: see fig 7.

C7195A 1011: see fig 7.

C7195A 1029: see fig 8.

C7195A 1037: see fig 9.

Lead wire length

C7195A 1003: 500 mm

C7195A 1011: 1000 mm with 550 mm insulation tube

C7195A 1029: 160 mm

C7195A 1037: 250 mm

Electrical code

Red: V

cc

White: V

out

Black: ground

Duty cycle of electrical output signal

30 ... 70%

Housing: 5239-- 042

Terminal: 5167T

4--V

cc

:red

3--V

out

:white

2 -- Blank

1 -- Ground: black

AWG24 UL1430

Fig. 7. Electrical connection C7195A 1003/1011

Housing: JST EPL--03V

Terminal: JST SLF--01Y--Pt.3E

1 -- Ground: black

2--V

out

:white

3--V

cc

:red

AWG24 UL1430

Fig. 8. Electrical connection C7195A 1029

A

WG24 UL1430

Lumberg serie 3150 03K07 S01

Red

Black

White

Fig. 9. Electrical connection C7195A 1037

10 kτ

+

V

cc

+V

out

Gnd

5 ... 12

V

V

cc

< 0.4 V

Hall IC

Fig. 10. Suggested interface schematic

Page 6

EN2R-- 9029 0101R2--NE

6

PERFORMANCE

Design life

10,000 hour continious operation at 10 l/minute at 20 _C

7,000 hour continious operation at 10 l/minute at 45 _C

or:

100,000 cycles operation (ON = 5 s/OFF = 5 s) at 10 l/minute

at 45 _C.

After life test accuracy must be within ±5% of measured

value at first stage.

Page 7

EN2R-- 9029 0101R2--NE

7

GENERAL CONSIDERATIONS

When magnetic materials like iron or materials which

generates magnetism are close to the flow sensor, operation

characteristics may change.

In order to avoid the invasion of small particles like sand, iron

and rust into the water flow sensor, it is advisable to install a

mesh filter.

The waterflow to the inlet of the flow sensor should be

undisturbed to meet the accuracy specifications.

If a device causes significant flow disturbance at the inlet of

the device, contact your Honeywell representative.

Page 8

EN2R-- 9029 0101R2--NE

8

DIMENSIONAL DRAWING

Made in Japan

7.5

11

8

9635

MODEL C7195A 1003

Max.Pr ess.:1 .72 MPa

Max.Temp: 80 _C

>PPS<

40

30

30.5

30.5

11

11

PF1/2“

PF1/2“

15

2.5

12.5

11

7.5

7.5

61

WATER FLOW SENSOR

* Cable connection A 1029

*

Fig. 11. Dimensional drawing C7195

Page 9

EN2R-- 9029 0101R2--NE

9

STANDARDS AND APPROVALS

Approvals

The C7195 water flow sensor has been appproved according

the United Kingdom Byelaws and Regulations

Certificate N0. 9711081, and can therefore be used in potable

water applications.

Other countries in general accept this certification.

For more details please c ontact Standards and Appprovals

department, Honeywell Combustion Control Center NL05.

Page 10

EN2R-- 9029 0101R2--NE

10

ORDERING INFORMATION

C

Water flow sensor

719

A 9999

Specification number

Ordering Specification number

5

Mechanical type (turbine)

Fig. 12. Model number chart C7195A water flow sensor

Page 11

EN2R-- 9029 0101R2--NE

11

ASSOCIATED PRODUCTS

Electronic controller

W4115C series for IWH application

W4115B series for Combi boiler application

W7073C series for Combi boiler application

Temperature senso rs

T7335 series(NTC thermistor probes), many options

available.

Home and Building Control

Combustion Controls Center Europe

Honeywell BV

Phileas Foggstraat 7

7821 AJ Emmen

The Netherlands

Tel: +31 (--)591 695911

Fax: +31 (--)591 695200

http://europe.hbc.honeywell.com

Loading...

Loading...