Page 1

GENERAL

The C7110A Room Air Quality Sensor is suitable for

measuring air quality in rooms, offices, and production bays.

This mixed gas sensor can be used to control ventilation

plants. It detects unpleasant odors, tobacco smoke, and

vapors emitted by such materials as furniture, carpets, paint,

glue, etc. As proven in practice, this device detects those

substances typically present in air having a poor quality,

some of which may otherwise go undetected by room

occupants, themselves. This sensor has proven itself in

numerous applications over many years.

NOTE: The mixed gas sensor does not measure or indicate

the concentration of individual gases, and thus

cannot be used for the monitoring or control of

specific substances.

Models

Order Number Description Output

C7110A1005 Room Air Quality Sensor 0...10Vdc

C7110A

ROOM AIR QUALITY SENSOR

SPECIFICATION DATA & INSTALLATION INSTRUCTIONS

FEATURES

• Measurement of a variety of air quality factors

• Output signal: 0...10 Vdc (adjusted using potentio-

meter)

• Adjustable output offset

• Easy installation and wiring connection

SPECIFICATION

Supply voltage 15...30 Vdc / 24 Vac (+/-10%)

Power consumption < 1 W

Output signal 0...10 Vdc (increases as air

quality worsens); adjustable

Max. load at output 5 kOhm

Weight /Dimensions approx. 125 g / see page 3

Electrical connection Screw terminal block for

Air Quality Sensor

Sensitivity/Linearity see Fig. 1 on page 2

Dynamic behavior see Fig. 6 on page 4

Ambient Limits

Transport/storage temp. -30...+60 °C (-22...+140 °F

Operating temperature 0...+50 °C (+32...+122 °F)

Humidity 5...95%rh, non-condensing

Safety

Protection class II as per EN60730-1

Protection standard IP30 as per EN60529

Flame retardant V0 as per UL94 Plastic ABS

using potentiometer

conductors up to 1.5 mm²

)

® U.S. Registered Trademark EN0B-0295GE51 R0409

Copyright © 2009 Honeywell Inc. • All rights reserved

Page 2

C7110A ROOM AIR QUALITY SENSOR

R

R

FUNCTION

The electrical conductivity of a heated tin-dioxide semiconductor sensor varies in proportion to the number of

molecules of the reducing agents. This leads to a voltage at

the measuring element which is amplified to an output

voltage of 0 to 10 Vdc.

The following particles and gases can be detected:

cigarette smoke, hydrogen, carbon monoxide, ethanol,

ammonia, etc.

In contrast to CO

2 sensors, which selectively measure the

concentration of only one type of gas, a mixed gas sensor

is a broadband detector, i.e. the sensor signal does not

indicate the type of gas or its concentration in ppm (parts

per million). The complex and constantly changing composition of room air makes it necessary to perform

broadband air quality measurement.

1

methane

/

gas air

0.1

0.01

1

ammonia

acetic acid

CO

ethanol

hydrogen

ppm

100010010

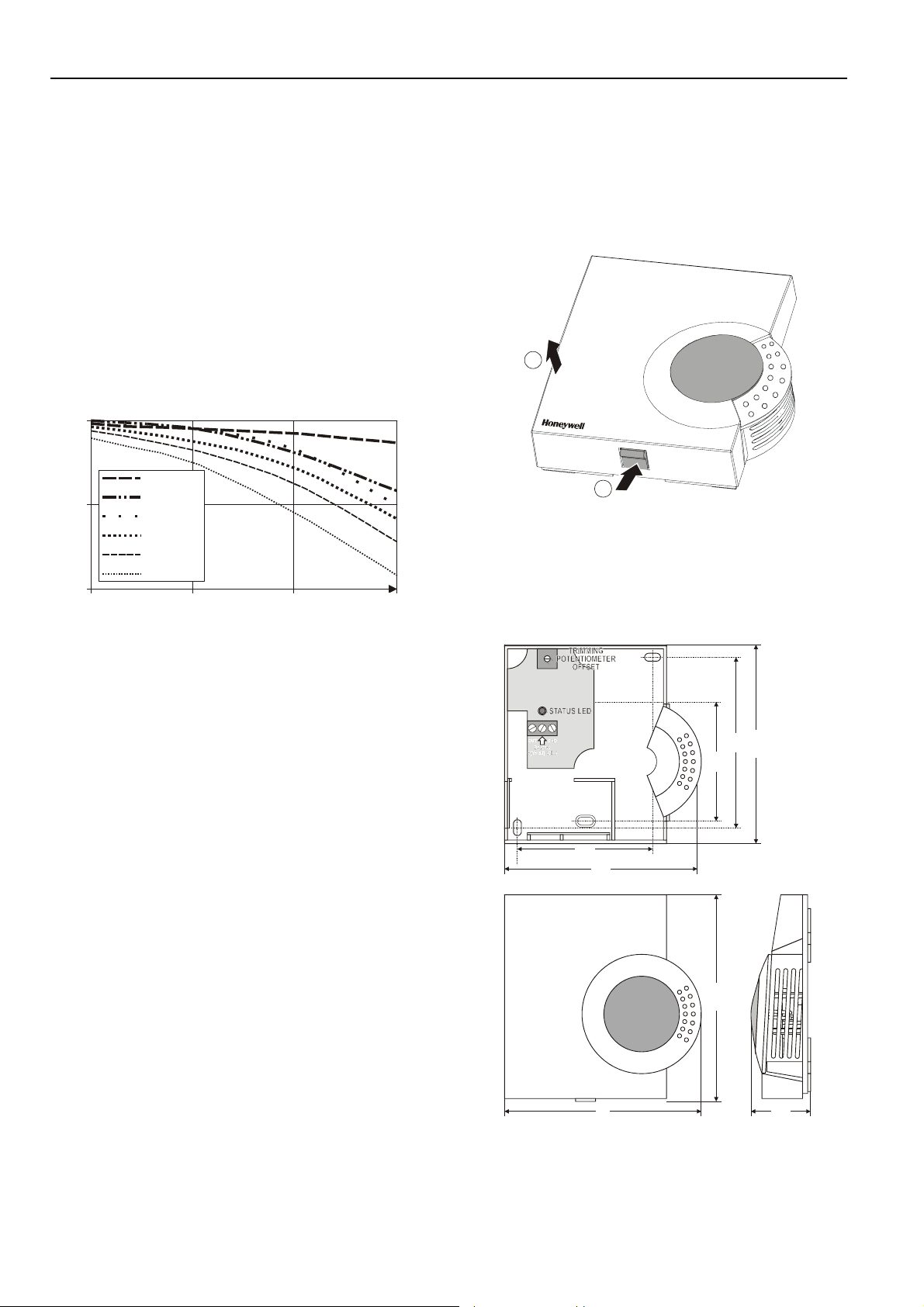

Fig. 1 Sensor sensitivity with different gases

INSTALLATION

Wiring

All wiring must comply with local electrical codes and

ordinances or as specified on installation wiring diagrams.

Wall module wiring can be sized from 16 to 22 AWG (1.5 to

0.34 mm

length of wire from a device to a wall module is 1000 ft (305

m). Twisted pair wire is recommended for wire runs longer

than 100 ft (30.5 m).

Keep wiring at least one ft (305 mm) away from large

inductive loads such as motors, line starters, lighting

ballast, and large power distribution panels.

Run wall module wiring separately from 50 Vac or greater

power wiring.

Positioning

To avoid falsifying the measuring results, the device should

be installed at sites at which typical air quality prevails.

Direct exposure to sunlight and drafts should be avoided.

If the device is mounted on a standard flush box, the end of

the installation tube in the flush box must be sealed so to

avoid any draft in the tube falsifying the measuring result.

2

), depending on the application. The maximum

Maintain a mounting clearance of approx. 4 in. (10 cm) to

the right-hand side of the module in order to allow free

airflow to the air quality sensor.

Mounting

1. The cover of the air quality sensor is fixed by a tab

on the underside of the unit; to disassemble the

cover and the sub-base, see Fig. 2.

LIFT

2

1

PRESS

Fig. 2 Cover disassembly

2. a) Mount the sensor onto the wall outlet box,

or

b) bore wall holes as specified in Fig. 3 and mount

the wall module with appropriate screws.

60

68

97

104

99 30

Fig. 3 Dimensions and mounting holes (mm)

86

100

EN0B-0295GE51 R0409 2

Page 3

IMPORTANT

Screw-type terminal blocks are designed to accept

no more than one 16 AWG (1.5 mm

3. Connect the wires to the terminal block as follows:

a) Strip 3/16 in. (5 mm) of insulation from the

conductor.

b) Insert the wire in the required terminal location

(see Fig. 5) and tighten the screw to complete

the termination.

4. Remount the cover as shown in Fig. 4 and make

sure that the tab on the underside engages.

5. Adjust the trimming potentiometer offset (see

section “Adjusting the Trimming Potentiometer

Offset”).

6. The sensor is now operational. When the air quality

deteriorates, the voltage of the output signal will

rise.

2

) conductor.

1

2

Fig. 4 Cover assembly

Adjusting the Trimming Potentiometer

Offset

After mounting the device, the output signal should be

adjusted in accordance with expected ambient conditions

and individual preferences.

The output signal is adjusted using the trimming potentiometer located on the sensor board (see Fig. 5). The offset

of the output signal is increased or lowered by means of

this potentiometer.

C7110A ROOM AIR QUALITY SENSOR

OUT GND

24V/AC

+(15-30) V/DC

Fig. 5 Wiring Connection and Trimming Potentiometer

• Turning the potentiometer counterclockwise decreases

the output signal.

• Turning the potentiometer clockwise increases the

output signal.

The sensor cannot distinguish pleasant from unpleasant

smells. The final adjustment whether air quality is

satisfactory or not must be made by the persons living or

working in the room. Moreover, various air compositions

are occurring in different rooms.

Thus, the default (factory) setting of the setpoint is

provisional, only. The setpoint must be optimized to

correspond to the subjective feelings of the room

occupants.

Adjustment Procedure:

1. Connect sensor and switch operating voltage on.

2. Ensure good air conditions close to the sensor (by

means of ventilation, etc.).

3. After approx. 30 minutes of operation, one must

verify the output signal. The voltage level should lie

in the range 1…3 V. Please correct an excessively

high or excessively low voltage level using the

trimming potentiometer: The potentiometer should

be turned to counterclockwise until the red status

LED is almost extinguished. The output signal will

then amount to approx. 0.7 V.

NOTE: The red status LED is located on the sensor

board, visible when the cover has been removed

(see Fig. 5) which indicates the device's operating

status. The brightness of the red status LED is

proportional to 0..10 V output for reference.

3 EN0B-0295GE51 R0409

Page 4

C7110A ROOM AIR QUALITY SENSOR

v

oltag

mV)

EXAMPLE OF DYNAMIC BEHAVIOR

Fig. 6 shows the dynamic characteristics of the air quality

sensor, monitored during test measurements in a sample

room. This voltage diagram as a function of different

occupancy conditions is only an example and must be

proven for other ambient conditions.

10000

9000

8000

7000

10000

6000

e (

5000

4000

3000

2000

1000

0

0 50 100

time (minutes)

ROOM UNOCCUPIED,

IDLING.

AIR QUALITY SENSOR

ROOM OCCUPIED

ROOM OCCUPIED

BY TWO PERSONS.

ROOM OCCUPIED

(INCL. 1 SMOKING).

BY THREE PERSONS.

BY THREE PERSONS.

ROOM OCCUPIED BY 3

WINDOW FAN

SWITCHED ON.

ALL THREE PERSONS

HAVE VACATED ROOM.

ROOM UNOCCUPIED,

Fig. 6 Dynamic behavior of Room Air Quality Sensor

IDLING.

AIR QUALITY SENSOR

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich, Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0295GE51 R0409

Loading...

Loading...