Page 1

C7076A,D

Adjustable Sensitivity

Ultraviolet Flame Detectors

PRODUCT DATA

The C7076A and C7076D are identical except for their

housings. The C7076A is designed for standard installations

The explosion-proof housing used with the C7076D meets the

requirements for Division I, Class I, Groups C and D; and

Class II, Groups E, F, and G of the National Electrical Code

(NFPA70).

The C7076 features two sensitivity adjustments, each with a

400:1 dynamic range, and an integral flame signal meter jack

to facilitate precise sighting.

C7076A

C7076D

APPLICATION

The C7076 Adjustable Sensitivity Ultraviolet Flame Detector is

a solid-state, adjustable sensitivity, device for sensing the

ultraviolet radiation emanating from gas, oil and pulverized

coal flames. It is designed for burner management and flame

safety systems which require optimum sensitivity and/or flame

discrimination.

The flame detector is designed for use with Dynamic

Self-Check Ultraviolet Amplifiers R7476A and R7886 to

provide a closed-loop, self-checking circuit which insures the

integrity of both amplifier and flame detector. Improper

response to simulated flame loss results in a safety shutdown

and/or alarm.

FEATURES

• High level output permits long distance transmission

without special wiring.

• Solid state circuitry assures long life and stable

sensitivity over wide ranges of temperature and

voltage.

• Available in two versions:

— C7076A for use in standard installations.

— C7076D for use in installations requiring

explosion-proof packaging.

® U.S. Registered Trademark

Copyright © 2002 Honeywell • All Rights Reserved

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 7

Wiring ............................................................................... 8

Troubleshooting ................................................................ 16

Service ............................................................................. 18

95-8269-1

Page 2

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

SPECIFICATIONS

Models:

C7076A—Adjustable sensitivity flame detector packaged in

standard housing. Used with R7476A and R7886 Dynamic

Self-Check Ultraviolet Amplifiers.

Table 1. Electrical Ratings.

Line Voltage

(+10%, -15%) Frequency (Hz) Shutter Voltage

100 50/60 100 7 14

120 60 120 7 14

200 50/60 120 7 14

220/240 50/60 120 7 14

c

117

a

Supplied by the appropriate flame safeguard control operating at the designated line voltage.

b

Does not include shutter power, which is supplied by the flame safeguard control.

c

For applications in South Africa.

Temperature Ratings:

Maximum Aspirator Temperature (C7076A only): 225°F

(107°C).

Ambient Operating Temperatures:

C7076A: -40°F to +160°F (-40°C to +71°C).

NOTE: Derate ambient temperature 1°F for every 13°F of

aspirator temperature over 160°F.

C7076D: -40°F to +160°F (-40°C to +71°C).

Storage Temperature Range:

-60°F to +185°F (-51°C to +85°C).

Sensitivity Selection:

Remote Sensitivity Selection: External switch can be wired to

select the setting sensitivity control, either A or B.

External Selector Switch: Must rated for switching 20 mA at

48 Vdc.

Sensitivity Adjustment:

Range: 400 to 1.

Sensitivity Controls: Two, labeled A and B, on plug-in

electronics chassis. Each can be set independently and

locked to prevent drift due to vibration.

50 117 7 14

C7076D—Adjustable sensitivity flame detector packaged in

explosion-proof housing. Used with R7476A and R7886

Dynamic Self-Check Ultraviolet Amplifiers.

Electrical Ratings: See Table 1.

Maximum Power Consumption

a

Flame Signal Amplifiers:

R7476A or R7886 Dynamic Self-Check Ultraviolet Amplifier;

order separately.

Flame Signal:

Measured at flame current meter jack on C7076: 1.4 to 5.5

mA nominal.

Measured at flame current meter jack on R7476A amplifier:

2.5 to 5.5 mA nominal.

Measured at flame voltage meter jack on R7886 amplifier: 0.0

to 5.0 Vdc.

Shutter Frequency:

R7476A: 1.25 Hz nominal. Interrupts the line-of-sight of the

detector about 75 times per minute to provide

self-checking.

R7886: One test every 5 seconds to provide self-checking.

Pressure:

C7076A quartz viewing lens: 20 psig (138 kPa) maximum.

C7076D quartz viewing lens: 142 psig (981 kPa) maximum.

Watts VA

b

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Relations

Honeywell, 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

95-8269—1 2

Page 3

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

Interchangeability:

Models C7076A and C7076D are not interchangeable with

other flame detector models; they must be used with either

the R7476A or R7886 Dynamic Self-Check Ultraviolet

Amplifier.

Wiring Connections:

C7076A: Terminal block in front compartment of housing;

wire-clamp type, removable screws (terminal lugs can be

used).

Conduit fitting: 7/8 in. opening in housing to accommodate

1/2 inch flexible conduit; fitting must be water-tight to

meet NEMA 4 standards.

C7076D: Terminal block in front compartment of housing;

wire-clamp type, removable screws (terminal lugs can be

used).

Conduit fitting: 1/2 in. NPT tapped opening in bottom of

housing to accommodate conduit.

Plug-in Electronics Chassis:

Field-replaceable; plugs into octal socket in housing. Contains

ultraviolet sensing tube, shutter assembly, power supply,

solid state circuitry, sensitivity adjustment controls and

flame current meter jack. Keyed to housing to ensure

proper orientation.

Air Flow Requirements (C7076A only):

Purge Air: 0.7 SCFM (3.3 ml/sec) is required to maintain 4 in.

(102 mm) of differential pressure from the aspirator inlet to

the combustion chamber. An air flow of 3 SCFM

(14 ml/sec) is recommended.

Seal-off Air: 5 psig (34.5 kPa) maximum combustion chamber

pressure.

Housing:

C7076A: Meets NEMA 4 standards (water-tight and dust-tight,

indoor and and outdoor).

Construction: Aluminum and cadmium-plated steel.

Color: Light blue.

Front compartment contains terminal block; rear

compartment contains electronic chassis.

C7076D: Meets NEMA 7 requirements (explosion-proof).

Construction: Cast aluminum alloy.

Color: Light blue.

Front compartment contains terminal block; rear

compartment contains electronic chassis.

Mounting:

C7076A: Aspirator has 1-in. NPT tapping for mounting onto

sight pipe, and 3/8 in. NPT tapping for connecting to the air

supply.

Detector mounts on aspirator by means of a removable

piano-type hinge.

C7076D: Detector has 1-in. NPT tapping for mounting onto

sight pipe and two 5/16-18 UNC tapped holes for attaching

a bracket for additional security.

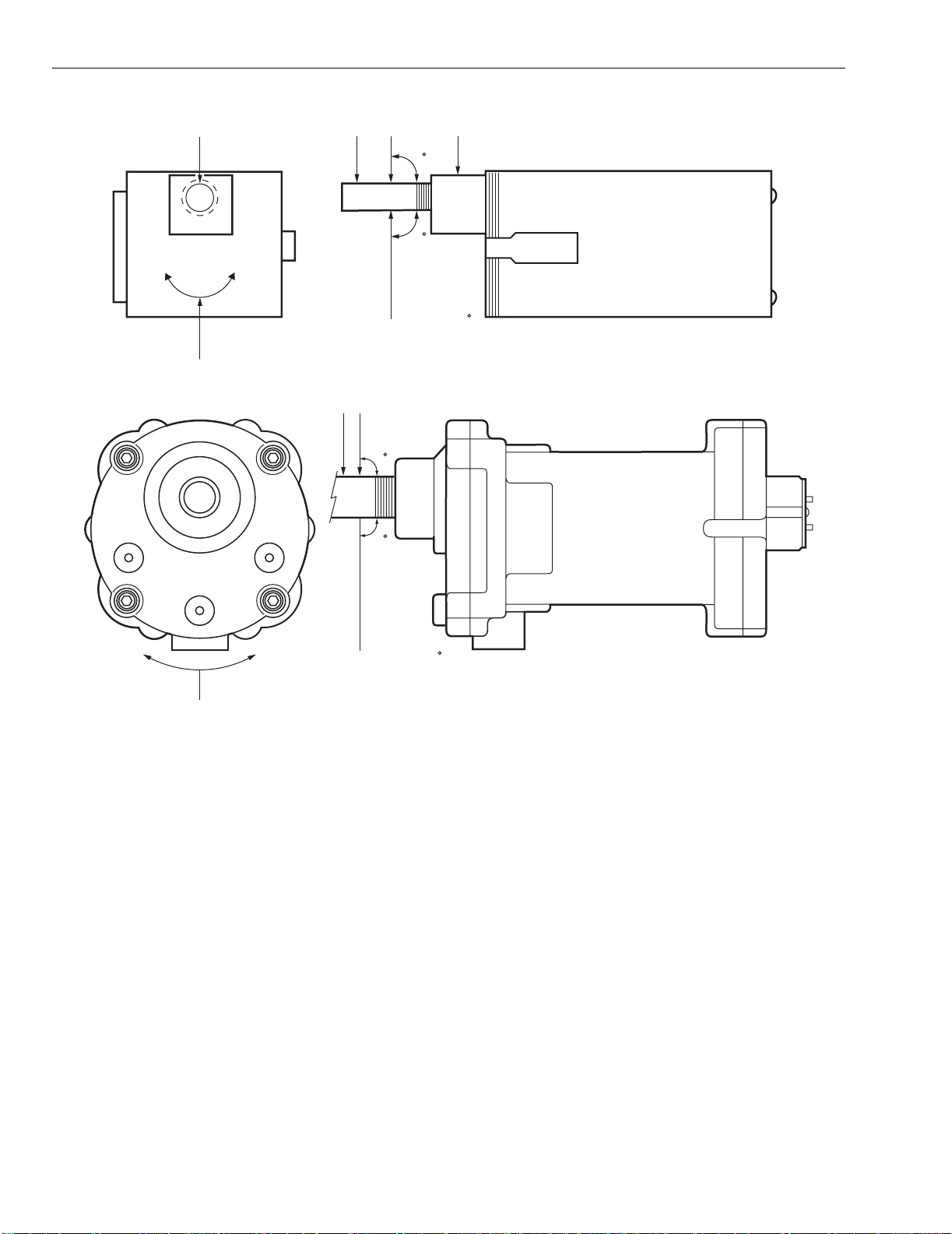

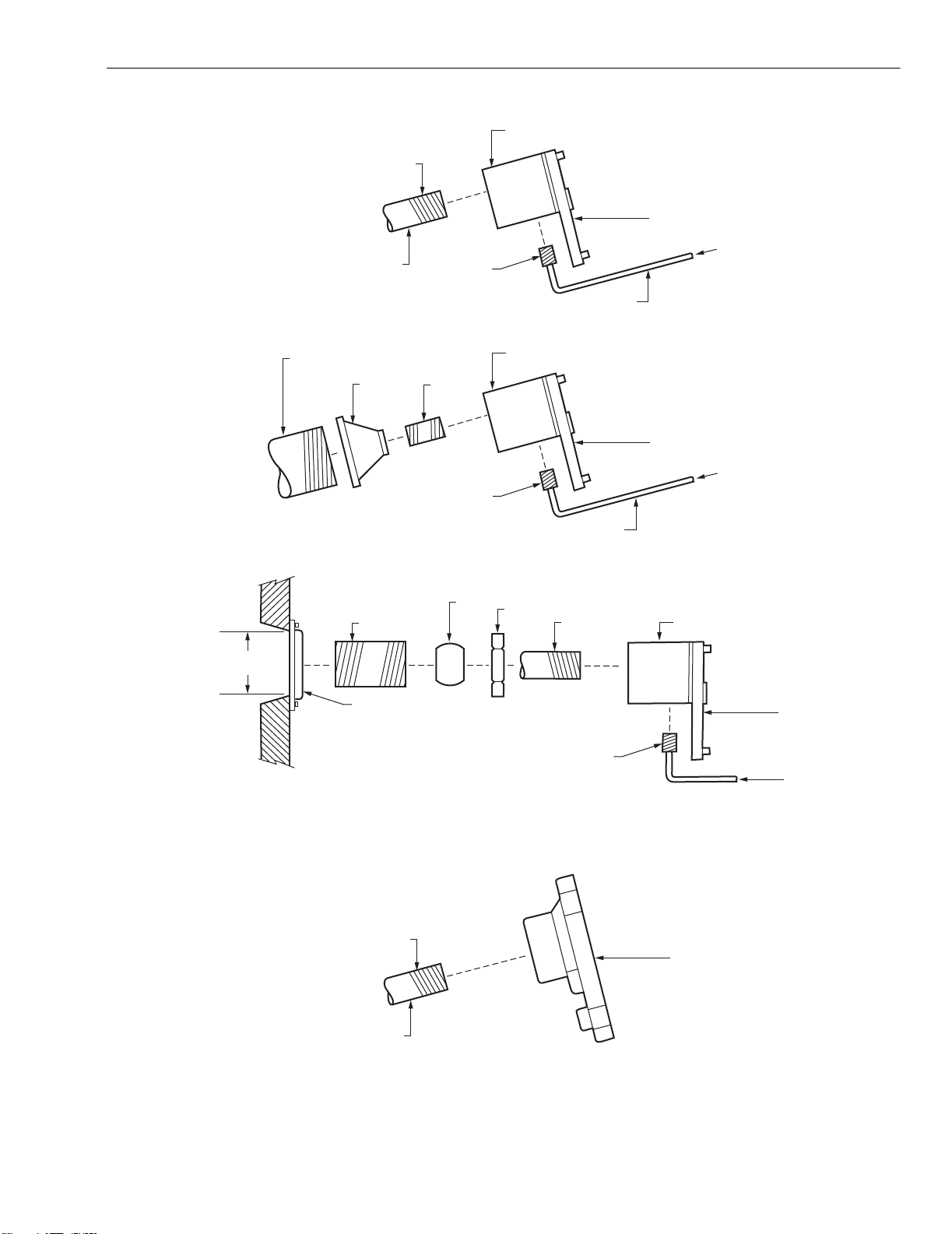

For allowable mounting positions, see Fig. 1.

Weight:

C7076A: 6.6 lb (3 kg).

C7076D: 17.6 lb (8 kg).

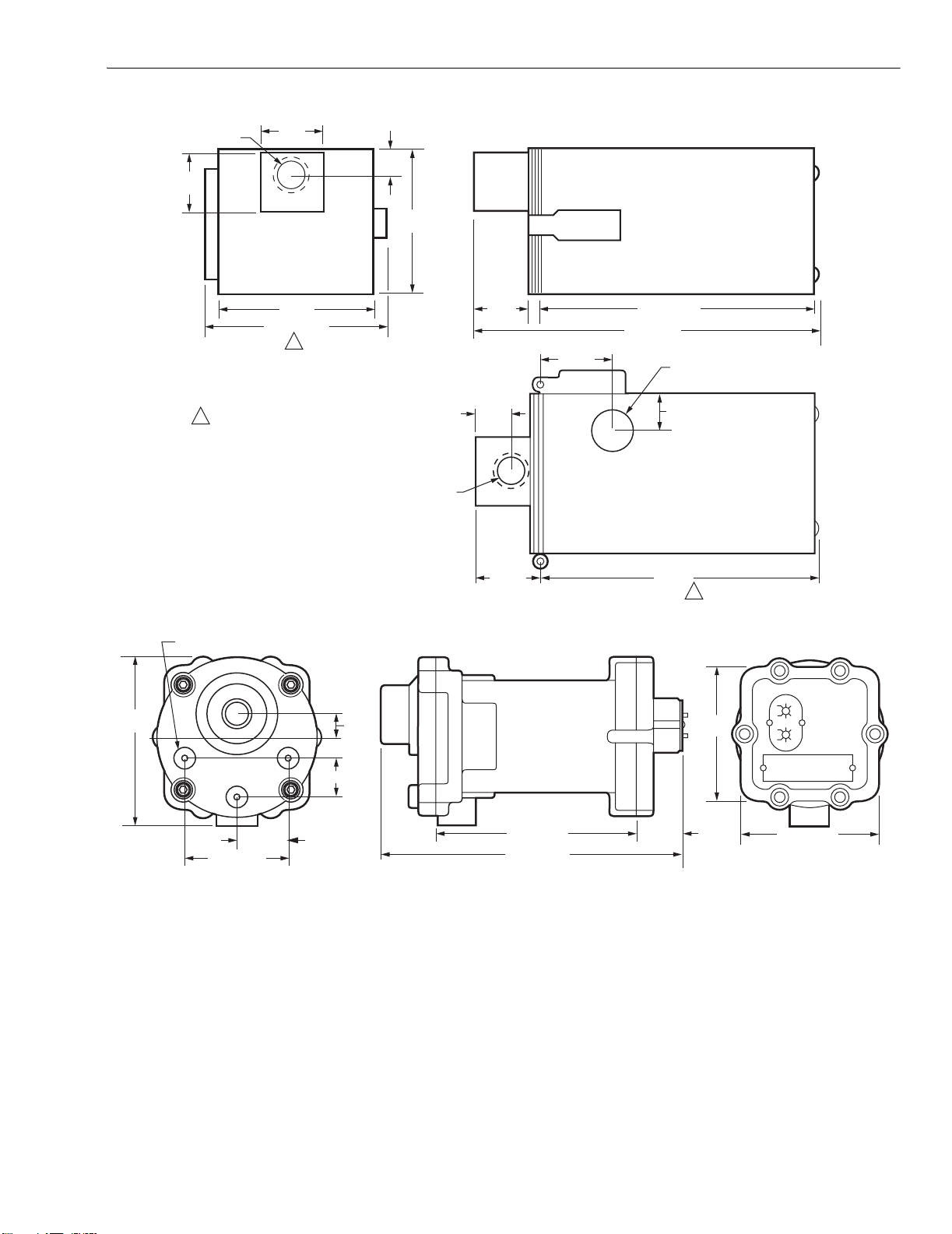

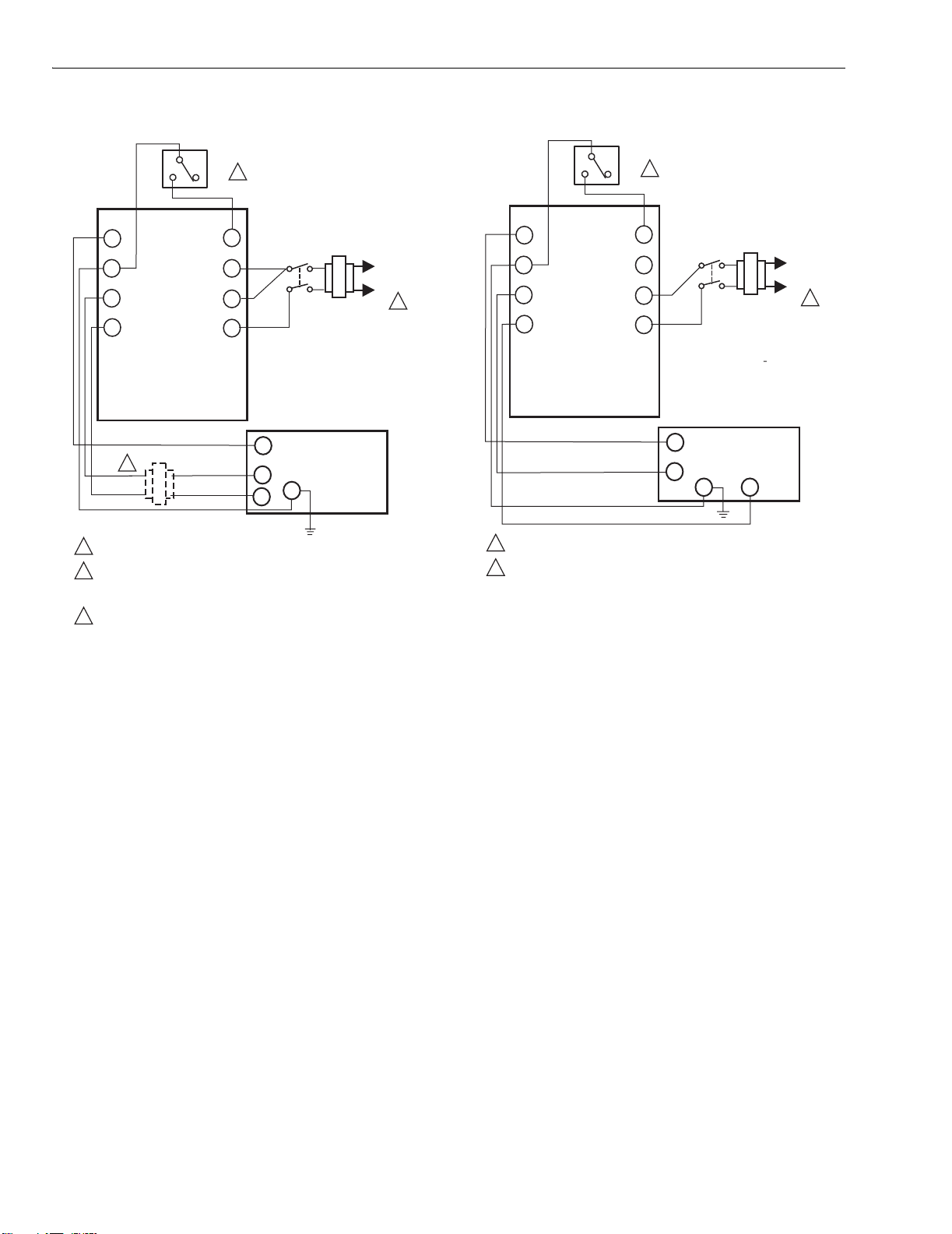

Dimensions: See Fig. 2.

Accessories:

118367A Swivel Mount.

W136A Test Meter (includes 117053 meter connector plug).

117053 Meter Connector Plug (for older W136A models).

Replacement Parts:

C7076A:

191002B Plug-in Electronics Chassis (without UV sensing

tube).

190971E Coil and Shutter Assembly (for all models except

100V model).

190971F Coil and Shutter Assembly (for 100V model).

190998A Aspirator Assembly.

191205 Pin and Chain.

191055A Cover Assembly for 120 Vac models.

191055B Cover Assembly for 220/240 models.

191203-767 Hinge.

191053 Ultraviolet Sensing Tube.

191050 Viewing Lens.

190999 grommet, silicone rubber for viewing lens.

191054 Gasket, silicone-rubber seal for front and rear

cover plates.

C7076D:

191002R Plug-in Electronics Chassis (without UV sensing

tube).

190971E Coil and Shutter Assembly (for all models except

100V model).

190971F Coil and Shutter Assembly (for 100V model).

191053 Ultraviolet Sensing Tube.

191050 Viewing Lens.

24400152-001 Lens Kit (consists of quartz window gasket

and gasket seal).

Approvals:

C7076A:

Underwriters Laboratories Inc. Listed (120V models only):

File No. MP268, Guide No. MCCZ.

Canadian Standards Association (CSA) Certified (120V

models only): File No. LR1620.

Factory Mutual Approved: Report No. FM26980.

C7076D:

Underwriters Laboratories Inc. Listed: File No. E34649,

Guide No. ZTSZ.

Industrial Risk Insurers Approvable.

3 95-8269—1

Page 4

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

SIGHT PIPE

ASPIRATOR

DETECTOR CANNOT BE

ROTATED IN THIS PLANE.

THE ASPIRATOR MUST BE ON TOP.

SIGHT PIPE

90

90

DETECTOR MAY

BE ROTATED 90 IN

EITHER DIRECTION

FROM HORIZONTAL

C7076A

90

90

ASPIRATOR

DETECTOR CANNOT BE

ROTATED IN THIS PLANE.

DETECTOR MAY

BE ROTATED 90 IN

EITHER DIRECTION

FROM HORIZONTAL

C7076D

Fig. 1. C7076 allowable mounting positions.

INSTALLATION

Planning the Installation

Proper flame detector application is the basis of a safe and

reliable flame safeguard installation. Refer to the burner

manufacturer instructions as well as to those included here.

Follow all instructions carefully.

Determine the Location

Before beginning the actual installation, estimate the best

location for mounting the detector based upon the following

factors:

Temperature

Install the flame detector where the surrounding temperature

will remain within the specified ambient operating temperature

ratings.

M20748

For the C7076A, to keep the detector temperature within

specifications, the aspirator temperature must not exceed

225°F (107°C). If the aspirator temperature will exceed

temperature ratings, the introduction of cooling-purging air will

be required.

Vibration

Do not install the detector where it could be subjected to

excessive vibration; it shortens the life of the electronic

components. Vibrations with a magnitude greater than 1g will

require an antivibration mount to cushion the detector.

Clearance

Make sure there will be enough room to swing out the detector

for servicing. Refer to Fig. 2 as applicable.

Radiation Sources Other Than Flame

Examples of radiation sources, other than flame, which could

actuate the detector system include:

95-8269—1 4

Page 5

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

6

1 INCH NPT

2-1/4

(57)

1

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

5/16-18 UNC (3 PLCS)

X 0.47 (12) DEEP

2-1/4

(57)

4 (102)

4-25/32 (122)

1

1-1/16

(27)

(102)

3/8 INCH NPT

4

2-9/32

1-5/8

(19)

(58)

2-21/32

(68)

3/4 (19)

7-13/32 (188)

10-1/4 (261)

29/32 (22) OPENING FOR

1/2-INCH CONDUIT

1 (25)

7-19/32

(194)

1

C7076A

-23/32

(171)

1-31/32 (50)

3-15/16 (100)

15/16

(24)

25/32 (20)

1-9/16 (40)

C7076D

7-13/16 (198)

11-13/16 (300)

1-27/32

(47)

5-25/32

(147)

5-25/32 (147)

M20749A

Fig. 2. C7076 dimensions in in. (mm).

1. Ultraviolet sources:

a. Radiant surfaces above 2200°F (1200°C).

b. Sparks from ignition transformers and welding arcs.

c. Gas lasers.

d. Sun lamps.

e. High voltage condensers.

f. Radioisotopes.

Except under very unusual circumstances, none of these

sources, except a radiant surface or ignition spark, would be

present in or near the combustion chamber.

e. Germicidal lamps.

f. Incandescent lamps held close to the sensing tube

2. Gamma ray and X-Ray sources:

(filament above 2200°F [1200°C]).

The detector may respond to a radiant surface at a

temperature above 2200°F (1200°C) if both of these

conditions are present:

a. Diffraction analyzers.

b. Electron microscopes.

c. Radiographic x-ray machines.

• The detector sensitivity control is set at (or near) maximum,

and

d. High voltage vacuum switches.

5 95-8269—1

Page 6

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

• the surface represents a significant percentage of the

detector field of view.

If the temperature or a radiant surface causes the flame relay

(in the flame safeguard control) to pull in, re-aim the sight pipe

so the detector views a cooler area, or decreases the

sensitivity of the detector.

Ignition spark is a rich source of ultraviolet radiation. When

installing the detector, make sure it does not respond to

ignition spark.

Single Burner Requirements

The detector must have an unobstructed view of the flame it is

supervising under all firing conditions. This implies a proper

sighting angle and the minimization of screening effects.

Sighting Angle

The first 30 percent of a flame (the root) radiates the most

intense ultraviolet energy. Low angle sighting permits the

detector to view a greater depth of the flame root, thus

reducing the effects of irregularities in the flame pattern. The

best sighting angle is nearly parallel to the axis of the flame,

as shown in Fig. 3.

DETECTOR IN GOOD

SIGHTING POSITION

(LOW ANGLE SIGHTING)

BURNER

NOZZLE

DETECTOR IN POOR

SIGHTING POSITION

Fig. 3. Detector sighting angle.

NOTE: When possible, it is desirable to tilt the detector and

sight pipe downward to prevent the buildup of soot in

the pipe or on the viewing lens.

FLAME DEPTH–

ANGLE VIEW

UNBURNED FUEL

FLAME DEPTH–

PERPENDICULAR VIEW

M1956

reaching the detector and may cause flame signal

deterioration resulting in a shutdown. The adverse affects of

screening may be minimized by proper burner adjustment,

increasing the detector viewing area (shorten sight pipe

and/or increase its diameter), and optimizing detector

sensitivity.

Multiburner-Multifuel Requirements

In addition to meeting the requirements for a single burner, a

multiburner installation also requires flame discrimination.

Flame discrimination may be defined as the location of all

flame detectors such that each detector responds only to the

flame(s) produced by the burner it is supervising.

MULTIBURNER REQUIREMENTS

In multiple burner systems, not every detector can be

positioned so that its line of sight does not intercept flames

from other burners. This situation occurs in front-fired boiler

furnaces having more than one row of burners, or in multilevel

opposed-fired furnaces where the burners face each other.

When planning such an installation, locate each flame

detector so that it has the best possible view of the first 30

percent closest to the burner nozzle (the flame root) it is

supervising, and the worst possible view of all other flames.

Fig. 4 illustrates a critical detector application problem that

requires flame discrimination. Flame discrimination is

accomplished for Detector A by repositioning it until the flame

relay (in the flame safeguard control) does not respond to

Flame B. Note that Detector A is aimed at the first 30 percent

of Flame A where the ultraviolet radiation is most intense. It

sights the tip of Flame B, but it is not aimed at the first 30

percent of Flame B where ultraviolet radiation is intense.

Detector A is repositioned to assure maximum response to

Flame A while rejecting Flame B. Similarly, Detector B is

positioned to assure maximum response to Flame B while

rejecting Flame A.

If the sensitivity control on a detector is set at its minimum

position and flame discrimination cannot be achieved, insert

an orifice plate in the sight pipe. An orifice of the proper

diameter will reduce the ultraviolet radiation reaching the

detector so that the sensitivity can be adjusted to effect flame

discrimination.

In most installations, the detector will need to respond to the

pilot flame alone, then to the pilot flame and main burner

flame together, and finally to the main burner flame alone. The

detector must meet all sighting requirements which apply.

1. Pilot flame alone—the smallest pilot flame that can be

detected must be capable of reliably lighting the main

burner.

2. Pilot and main burner flame together—the detector

must sight the junction of both flames.

3. Main burner flame alone—the detector must sight the

most stable part of the flame for all firing rates.

Screening Effects

Smoke, fuel mist, dirt and dust are masking agents that

absorb ultraviolet radiation from the flame. They create a

screen that reduces the amount of ultraviolet radiation

95-8269—1 6

DETECTOR A

FLAME A

FLAME B

DETECTOR B

M1957

Fig. 4. Example of flame discrimination problem

(opposed-fired burners).

Page 7

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

MULTIFUEL REQUIREMENTS

Detectors supervising burners that alternately fire more than

one fuel may require a different sensitivity level for each fuel.

For example, a higher sensitivity is required to reliably sense

pulverized coal or No. 6 fuel oil in contrast to natural gas or to

No. 2 fuel oil. Reliable flame sensing and flame discrimination

may not be maintained simultaneously (without changing the

sensitivity setting) when alternating between two fuels.

The C7076 has two integral sensitivity adjustments that can

be remotely and automatically selected. The two sensitivity

adjustments can be chosen by means of the fuel selector

switch (refer to Remote Sensitivity Selection in the Installation

section). The sensitivity adjustments should be made for both

fuels as described in the section on multiburner requirements,

using one adjustment pot for each fuel.

Parallel Flame Detectors

Two C7076 detectors can be connected in parallel to the

same flame signal amplifier and still provide independent

sensitivity adjustment. This capability is particularly useful for

multiburner, multifuel applications.

Shifting flame patterns, commonly encountered on burners

with wide turndown ratios, may require parallel detectors to

prove the flame at the highest and lowest firing rates. In this

case, one detector supervises the pilot (interrupted) and both

detectors supervise supervise the main burner flame. During

the main burner run period, either detector is capable of

maintaining system operation.

In addition to assuring more reliable flame detection, parallel

detectors facilitate maintenance during burner operation.

Each detector can be removed in turn without shutting down

the supervised burner. However, a flame simulating failure

occurring in the flame signal amplifier or in either detector will

cause a shutdown.

Redundant Flame Detection System

Two C7076 detectors connected to two flame signal amplifiers

wired in parallel comprise a redundant flame detection

system. In addition to the features of parallel flame detectors,

a redundant system increases reliability and is therefore

recommended for critical burner applications. A flame failure,

flame signal loss, or flame simulating failure occurring in either

detector subsystem will cause an alarm (not a shutdown)

allowing corrective action to avert a shutdown.

When Installing this Product…

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced flame

safeguard service technician.

4. All wiring must comply with applicable local electrical

codes, ordinances and regulations.

5. All wiring must be NEC Class 1 (line voltage).

6. Voltage and frequency of the power supply connected to

this detector must agree with the values marked on the

detector.

7. If an air supply is connected to the aspirator on the

C7076A, its pressure must equal or exceed that

required to seal off the detector from the combustion

chamber.

8. On multiburner installations, each detector must

respond only to the flame(s) produced by the burner it is

supervising.

9. Do not connect more than two detectors in parallel to a

single R7476A or R7886 Dynamic Self-Check

Ultraviolet Amplifier.

10. Perform all required adjustments and checkout tests

after installation is complete.

Selecting and Installing Sight Pipe

After you have determined the approximate location and

sighting angle, select the sight pipe. A black iron pipe is

recommended to provide reliable flame sensing. Stainless

steel and galvanized pipes have bright surfaces that initially

transmit ultraviolet radiation very well. However, their ability to

transmit ultraviolet radiation will decay when the bright

surfaces become dull with age or contamination, and flame

detection will become less reliable with time.

The aspirator on the faceplate of the C7076A, and the

faceplate on the C7076D, are tapped for a 1-inch NPT

threaded pipe. A larger pipe may be necessary to obtain

proper performance; an diameter other than 1 inch will require

a reducer coupling. The geometry of the sight pipe affects the

performance of the detector. If the flame signal is too small,

reduce the length or increase the diameter of the pipe to

increase the field of view of the detector. If a sight pipe longer

than 1 foot is required, use a 2-inch diameter pipe with the

reducer as close to the detector as possible.

INSTALLATION

WARNING

Electrical Shock Hazard.

Can cause serious injury, death or equipment

damage.

Disconnect power supply before beginning installation.

More than one disconnect may be necessary.

NOTE: Sight pipe couplings cannot be used with C7076D

due to the need to safeguard the integrity of the

explosion-proof quality of this model. The size of the

sight pipe for the C7076D, therefore, is restricted to

1-inch diameter.

Cut a hole of the proper diameter for the sight pipe in the

burner front or windbox at the selected location. The hole

should be at least 2 inches in diameter to allow adjustment of

the sighting angle. If register vanes interfere with the desired

line of sight, trim the interfering vane(s) to assure an

unobstructed view of the flame.

Cut the pipe to the desired length. Thread one end of the pipe

to fit the desired mating component; i.e., reducer coupling,

aspirator on the faceplate of the C7076A aspirator; or

7 95-8269—1

Page 8

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

faceplate on the C7076D Detector. Insert the other end of the

pipe into the mounting hole, align it to the desired sighting

angle, and tack weld it in position.

NOTE: When initially mounting the pipe, tack weld it in place

to allow further sighting adjustments. Make sure the

tack weld will support the weight of the detector

when it is installed.

NOTE: When installing a C7076A Detector, a Honeywell

118367A Swivel Mount is recommended to facilitate

sighting the flame properly. For installation

instructions for the Swivel Mount, see form 60-0361.

Installing the C7076A Detector

Mounting the Aspirator

The aspirator on the faceplate of the C7076A Detector screws

directly onto the 1-inch NPT threaded pipe. Remove the

aspirator from the C7076A Detector by removing the hinge

pin. Use an adjustable wrench to tighten the aspirator onto the

pipe. For alternate mounting methods and further information

refer to Fig. 5.

Mounting the Detector

Mount the detector on the faceplate by placing the detector on

its hinge and re-inserting the hinge pin. Install 1/2 inch flexible

conduit to the detector as follows:

Loosen the four captive screws in the front coverplate (with

the viewing lens) and remove the plate.

Seal off of the sight pipe prevents hot gases from escaping

from a positive pressure combustion chamber when the

detector is swung open on its hinge for maintenance. Refer to

Fig. 9 for the minimum inlet pressure or air flow required to

seal off a sight pipe against a positive combustion chamber

pressure.

Fig. 10 shows a method of supplying a constant airflow to

purge the sight pipe, while also providing enough pressure to

seal off the sight pipe when needed.

Mounting the Faceplate

The faceplate of the C7076D Detector screws directly onto the

1-inch NPT threaded pipe (see Fig. 5). Screw the faceplate

onto the pipe; hand-tighten in place, making certain that the

four mounting holes in the faceplate are properly aligned to

allow the detector to be in the desired position when secured

to the faceplate.

Mounting the Detector

Mount the detector on the faceplate and fasten in place using

the four mounting screws supplied for this purpose. Do not

tighten the screws at this time, because the detector must still

be wired.

Obtain a piece of conduit that is not longer than 18 inches in

length and has 1/2-inch NPT threads at both ends. Screw this

piece of conduit into the threaded opening in the bottom of the

detector housing (see fig. 11). Install an approved seal box on

the other end of the piece of conduit and then complete the

conduit installation as required.

Install a flexible conduit fitting in the opening in the bottom of

the detector (Fig. 7). To meet NEMA 4 standards, use

watertight conduit and a watertight fitting (such as an Appleton

ST50 Liquid-Tight® Connector with an STG-50 Neoprene

O-ring and Steel Gasket Assembly). See Table 2 for other

applicable connectors.

Table 2. Applicable Watertight Connectors.

Manufacturer Coupling No. O-Ring No.

T&B 5232 5262

Efcor 11-50 LTG-1

Raco 3402 2452

Steel City LT-101 LR-531

Crouse Hines LT-50 SG-1

Connecting Air Supply (Optional)

Use a flexible air supply line which will allow repositioning of

the sight pipe until the permanent detector position has been

verified.

The aspirator air inlet can be plugged, left open, or connected

to a clean (oil/moisture-free) air supply. Use a 3/8 in. NPT

connector if aspirator air is used (see Fig. 5). The aspirator

allows air to flow through the sight pipe into the combustion

chamber to cool, clean and seal off the sight pipe. The airflow

eliminates the need for frequent lens cleaning. See Fig. 8 for

purge air requirements.

WIRING

WARNING

Electrical Shock Hazard.

Can cause serious injury, death or property

damage.

Disconnect all power before beginning wiring. More

than one disconnect may be involved.

1. All wiring must comply with applicable local electrical

codes, ordinances and regulations. Use NEC Class 1

wiring.

NOTE: The detector has color-coded and labeled,

plastic-insulated no. 18 leadwires, 8 ft (2.4 m) long,

rated for 221°F (105°C).

2. Keep the flame signal leadwires as short as possible

from the flame detector to the terminal strip or wiring

subbase. Capacitance increases with wire length,

reducing the signal strength. the maximum permissible

leadwire length depends on the type of leadwire and the

conduit type and diameter. The ultimate limiting factor in

flame signal leadwire length is the signal current or

voltage at the flame safeguard device. See Table 1.

95-8269—1 8

Page 9

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

0

F

1

E

S

ASPIRATOR

FACEPLATE

AIR SUPPLY

1 INCH (25)

SIGHT PIPE

DIRECT MOUNTING

1 INCH (25)

NPT

THREADS

3/8 INCH (9)

NPT THREADS

URNACE

WALL

2-3/8

(60)

SIGHT PIPE

LARGER

THAN

1 INCH (25)

DIAMETER

USING A REDUCER OR LARGER PIPES

USING A SWIVEL MOUNT (PART NO. 118367A)

REDUCER

2 INCH (50)

NIPPLE

MOUNTING

FLANGE

1 INCH (25)

CLOSE

NIPPLE

3/8 INCH (9)

NPT THREADS

SWIVEL

BALL

ASPIRATOR

NUT

FACEPLATE

AIR SUPPLY

1 INCH (25)

CLOSE

NIPPLE

3/8 INCH (9)

NPT THREADS

ASPIRATOR

FACEPLATE

AIR

SUPPLY

M2075

Fig. 5. Installing the sight pipe for the C7076A Detector.

1 INCH (25)

NPT

THREADS

1 INCH (25)

IGHT PIPE

FACEPLAT

M2075

Fig. 6. Installing the sight pipe for the C7076D Detector.

9 95-8269—1

Page 10

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

2

3

AIR FLOW (SCFM)

8

E

4

MINIMUM ASPIRATOR INLET PRESSURE REQUIRED FOR SEAL OFF – PSIG

R

60

TERMINAL

BLOCK

FLAME

DETECTOR

WIRES

LUCK NUT

FLEXIBLE

WATER TIGHT

CONDUIT

FITTING

CONDUIT

M2075

Fig. 7. Connecting the watertight flexible conduit.

6

4

Pchamber

2

10" OF ASPIRATOR PIP

(1" PIPE)

50

40

30

OR

20

10

MINIMUM ASPIRATOR AIR FLOW REQUIRED FOR SEAL OFF – SCFM

0

AIR FLOW (SCFM)

123 4 5

POSITIVE CONBUSTION CHAMBER PRESSURE – PSIG

INLET PRESSURE (PSIG)

Fig. 9. Minimum inlet pressure or airflow.

2

MANUAL SHUTOFF

VALVE (BALL VALVE)

M2075

Pinlet

012

DIFFERENTIAL PRESSURE ( P = Pinlet – Pchamber)(PSI)

M2075

AIR SUPPLY

PRESSURE

Fig. 8. C7076A purge air requirements.

1

2

3

Fig. 10. Supplying a constant airflow for purge.

1

TO ASPIRATO

NEEDLE

3

VALVE

EQUALS OR EXCEEDS THE PRESSURE REQUIRED TO

SEAL OFF THE SIGHT PIPE FROM A POSITIVE

PRESSURE COMBUSTION CHAMBER.

OPEN ONLY WHEN SERVICING THE DETECTOR.

ADJUST TO PROVIDE ENOUGH AIR TO COOL THE

ASPIRATOR AND MAINTAIN A CLEAR SIGHT PIPE.

REMOVE HANDLE AFTER ADJUSTING.

M20755

95-8269—1 10

Page 11

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

6

R

1

C

T

E

FSP5075

C7076

A

E

FLAME SAFEGUARD

C

C7076

A

g. Floating grounds—ground at some voltage above

earth ground.

h. No G wire—burner used as ground.

i. Detector output less than maximum attainable for

the installation (inadequate sighting).

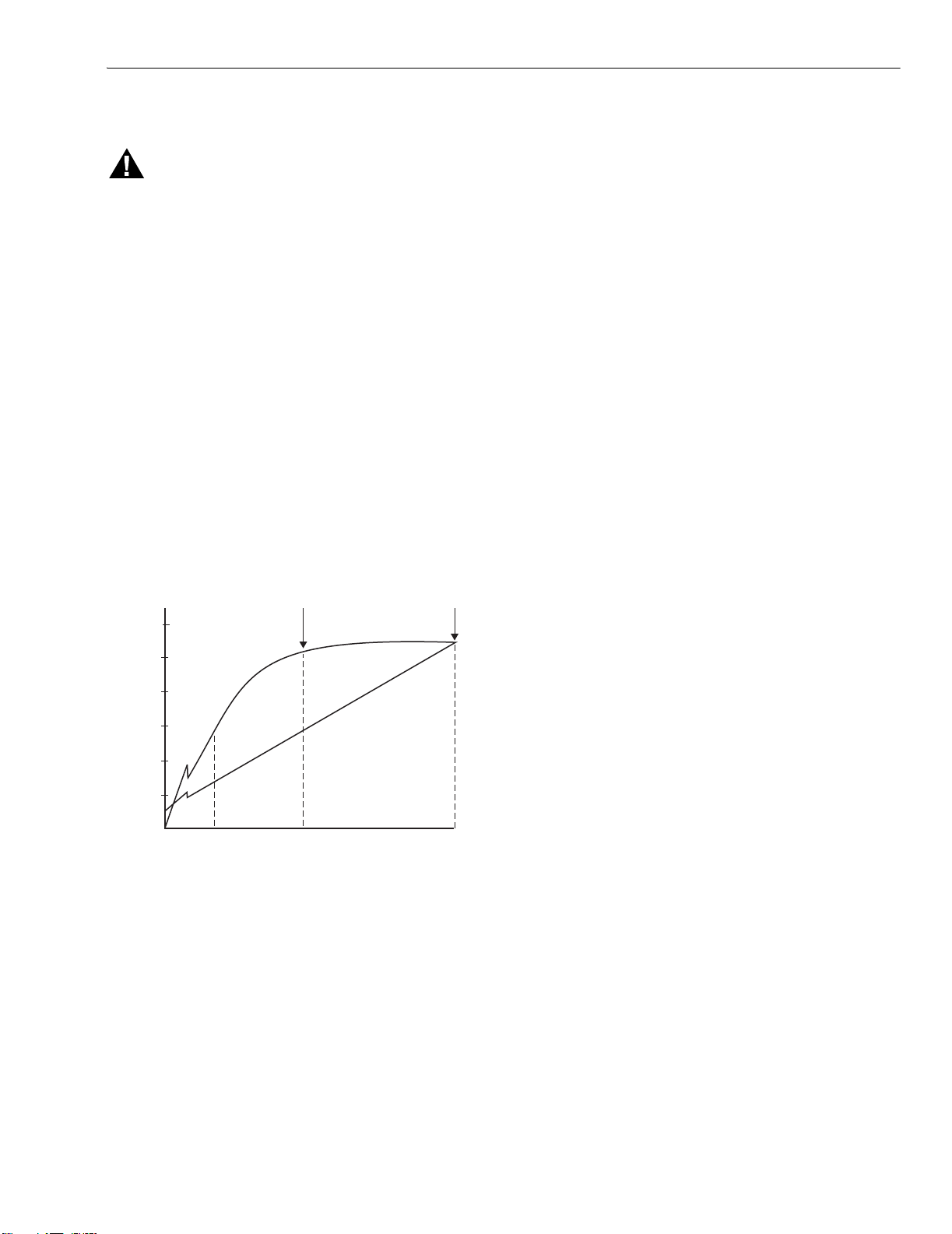

Wiring Diagrams

Follow approved system wiring diagrams. Refer to Fig. 12, 13,

TERMINAL

BLOCK

14, or 15 for approved system wiring diagrams.

1

/2 INCH NPT

ONDUIT SECTION

O SEAL BOX

1

NOT MORE THAN 18 INCHES IN LENGTH.

FLAME

DETECTO

WIRES

M2075

Fig. 11. Mounting the C7076D Detector.

3. Detector leadwires can be spliced for longer leadwire

runs observing the following considerations:

a. Make required splices in a junction box.

b. Use moisture-resistant no. 14 wire suitable for at

least 167°F (75°C).

c. For High Temperature Installations, use Honeywell

specification no. 32004766-003 or equivalent for the

F leadwire. This wire is rated up to 480°F (250°C)

for continuous duty. It is tested for operation up to

20,000 volts and for breakdown up to 35,000 volts.

For the other leadwires, use moisture-resistant no.

14 wire selected for a temperature rating above the

maximum operating temperature.

d. F and G wires (blue and yellow) must be run in their

own conduit, independent of other power-carrying

leadwires. More than one scanner F and G wires

can be run in the same conduit.

e. A shielded twisted-pair wire may be substituted for

using conduit for routing the F leadwire (blue). Be

advised of the capacitance per foot of shielded wire

effectively reduces the flame signal at the flame

safeguard device. Be sure to ground the shield to

the G terminal at the flame safeguard wiring

subbase.

f. The detector power and shutter wires need to be run

in their own conduit, as well, avoiding other

electrical noise-carrying wiring.

g. The scanner wires should remain separated 2 in.

(51 mm) minimum from other line voltage wires in

the main control panel to the flame safeguard

device.

4. Installation considerations to be avoided that can

influence detector operation and maximum leadwire

length:

a. Moisture.

b. Ignition interference.

c. High resistance connections and poor grounds.

d. Leadwire capacitance.

e. Voltage fluctuations.

f. Induced line transients.

TERMINALS

L1

L2

2

13

G

F

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. POWER SUPPLY MUST MATCH VOLTAG

AND FREQUENCY RATING OF FLAME DETECTOR.

2

OPTIONAL SPST SWITCH FOR REMOTE SENSITIVITY SELECTION.

TERMINALS

1

L2

SHUTTER

3

SHUTTER

4

5

7

6

SENSITIVITY

SELECTOR

SWITCH

A

L1

(HOT)

L2

1

2

B

M20757

Fig. 12. Wiring C7076A,D to FSP5075.

ONTROL TERMINALS

X

X

G

F

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED. POWER SUPPLY MUST MATCH VOLTAG

AND FREQUENCY RATING OF FLAME DETECTOR.

2

OPTIONAL SPST SWITCH FOR REMOTE SENSITIVITY SELECTION.

TERMINALS

1

L2

SHUTTER

3

SHUTTER

4

5

7

6

SENSITIVITY

SELECTOR

SWITCH

A

L1

(HOT)

L2

1

2

B

M20758

Fig. 13. Wiring C7076A,D to flame safeguard control.

11 95-8269—1

Page 12

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

)

EXTERNAL

A

.

T)

EXTERNAL

0

SELECTOR

SWITCH

3

B

F

6

G

5

4

SHUTTER

SHUTTER

C7076A1031 OR

C7076D1043,

220/240 VAC, 50/60 HZ

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

CA UTION: PREVENT POSSIBLE DAMAGE TO SHUTTER MECHANISM

2

ON EC7800 SERIES RELAY MODULE APPLICATIONS ONLY.

INSTALL A 200/220/240 VAC TO 120 VAC, 10VA MINIMUM STEP-DOWN

TRANSFORMER (NOT PROVIDED) TO DRIVE THE SHUTTER.

3

OPTIONAL SPST SWITCH FOR REMOTE SENSITIVITY SELECTION.

A

7

8

L1

1

2

L2

MASTER

SWITCH

F

WIRING SUBBASE

22

G

L2

Q7800

L1

(HOT

L2

M20759

SELECTOR

SWITCH

2

B

F

6

G

5

4

1

SHUTTER

SHUTTER

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

1

PROTECTION AS REQUIRED.

2

OPTIONAL SPST SWITCH FOR REMOTE SENSITIVITY SELECTION.

A

7

8

L1

1

2

L2

MASTER

SWITCH

F

WIRING SUBBASE

22

G

Q7800

L1

(HO

L2

1

L2

M2076

Fig. 15. Wiring 120 Vac C7076A,D to RM78XX wiring

subbase.

Fig. 14. Wiring C7076A,D to EC78XX Wiring

Subbase at 220/240 Vac, 50/60 Hz.

Remote System Sensitivity

For systems firing more than one fuel, each with a different

level of UV emission, or whose flame patterns change with

firing rate, two sensitivity adjustments are provided. An

external selector switch (spst) is required to choose between

the two sensitivity settings. (Refer to Sensitivity Adjustments

in the Adjustments and Checkout section.) With the external

selector switch open, the A sensitivity control setting will

determine the sensitivity of the detector; with the switch

closed, the B setting will determine the sensitivity. For

automatic sensitivity selection, the switch may be

incorporated into the fuel selector switch or the firing rate

switch.

Connecting Detectors in Parallel

Two C7076A or two C7076D Flame Detectors with the same

voltage rating can be connected in parallel to the same

terminals. To avoid exceeding the rating of the shutter control

circuit, do not connect more than two detectors in parallel.

Making the Connection

1. Provide access to the terminal block in the detector as

follows:

a. For the C7076A, swing open the detector from the

faceplate. Loosen the four captive screws that

secure the cover plate (with the viewing lens) to the

detector, and remove the plate to provide access to

the terminal block.

b. For the C7076D, remove the four screws that

secure the faceplate (attached to the sight pipe) to

the detector. Force the faceplate from the housing

far enough to allow the detector to be sufficiently

reoriented on the conduit to provide access to the

terminal block.

2. Run the wires from the flame safeguard control through

the conduit to the C7076A or C7076D detector.

3. Connect each wire to the proper terminal on the

terminal block in the detector.

4. Reassemble the detector by performing step 1a or 1b

above, as applicable, in the reverse order.

95-8269—1 12

Page 13

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

Adjustments and Checkout

WARNING

Fire or Explosion Hazard.

Can cause serious injury, death or equipment

damage.

Consult the burner/boiler manufacturer instructions

and sequence of operation for the burner

management system before initial burner lightoff.

Flame Signal Readings

The final sighting position of the C7076A or C7076D Detector

may be most readily determined by using a Honeywell W136

Test Meter connected to the Flame Current meter jack on the

plug-in electronics chassis. This output is the unprocessed

flame signal from the detector and is intended as a diagnostic

aid. Readings taken at the detector will facilitate installing the

detector in the best sighting position by pinpointing the region

of greatest UV intensity for a given flame.

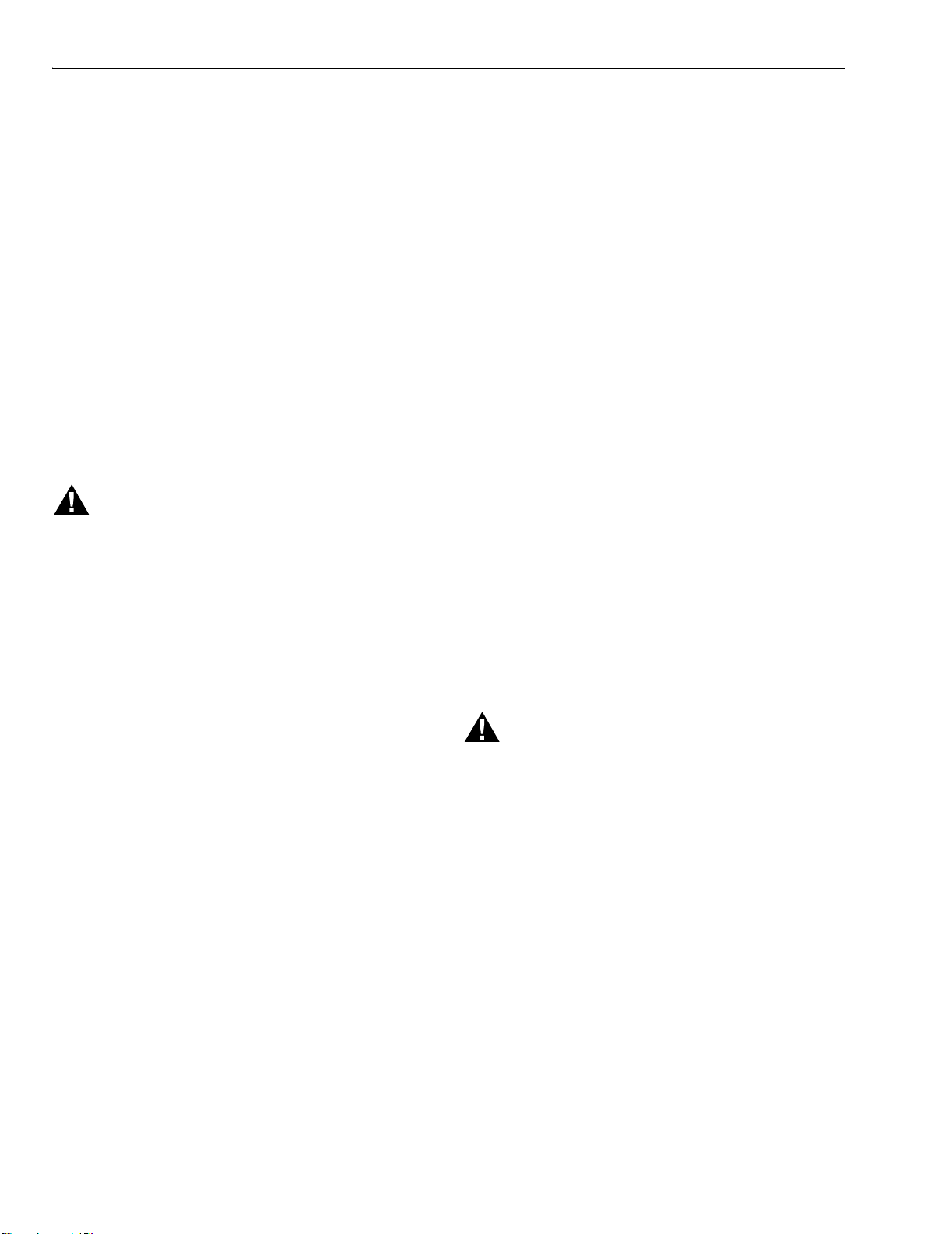

Fig. 16 illustrates the relationship between the detector and

amplifier readings. Detector saturation (the point at which an

increase in UV intensity does not product a noticeable

increase in flame signal strength) occurs at point A. Point B

represents the point at which the amplifier is saturated while

the minimum UV sensitivity required for system operation is at

point C.

AMPLIFIER

6

5

4

3

2

1

NORMAL FLAME SIGNAL - MICROAMPS

6

C7076A

OR

R7476A AMPLIFIER

C7076D DETECTOR (UNPROCESSED)

CB

ULTRAVIOLET INTENSITY

SATURATION

Fig. 16. Comparison of UV intensity, amplifier saturation

and detector saturation.

The linearity of the detector output curve shows that a unit

increase in UV intensity is accompanied by a corresponding

increase in flame signal strength. This condition facilitates

pinpointing the location of the most intense UV radiating from

a flame. Thus, by locating the optimum flame signal with the

detector, the peak UV signal, and therefore the most reliable

reading, is obtained.

The minimum acceptable stable flame signal readings are:

a. C7076A and C7076D Flame Detectors: 1.4

microamperes.

b. R7476A Flame Signal Amplifier: 2.5 microamperes.

c. R7886 Flame Signal Amplifier: 1.2 Vdc.

DETECTOR

SATURATION

M20761

A

Sensitivity Adjustments

General Considerations

1. If a single detector is required to supervise both the pilot

and main burner flame, verify the flame signal for each

flame individually.

2. Make sure the minimum acceptable stable flame signal

(1.4 microamperes at the detector, or 2.5 microamperes

at the R7476 Amplifier, or 1.2 Vdc at the R7886 Amplifier) is obtained throughout the entire turndown range of

the burner.

3. Parallel detectors may be required if a single sighting

angle will not provide a proper flame signal for both the

pilot and main burner flames throughout the entire

turndown range of the burner.

Single Burner System Using the C7076A Detector

1. Loosen the four captive screws in the rear cover plate of

the C7076A and remove the plate.

2. Adjust Sensitivity Control A for maximum sensitivity.

a. If the remote sensitivity selection feature is used,

make sure the external selector switch is open for

Control A adjustment.

b. Loosen the setpoint locking nut on Sensitivity

Control A.

c. Turn the control clockwise to MAX position.

d. Tighten the setpoint locking nut 1/4 turn past hand

tight. Do not over-tighten.

3. Read the flame signal in microamperes at the Flame

Current jack.

a. Use a Honeywell W136A test meter with the

selector switch at the SPL position. (If a W136 is not

available, a microammeter with a 0 to 25

microampere dc range, shunted with a 50

microFarad capacitor, may be used.)

b. A 117053 Meter Connector Plug is needed (supplied

with the W136A, or it may be ordered separately).

Connect the red spade tip to the red (+) meter lead

and the black spade tip to the black (-) meter lead.

See Fig. 17.

c. Insert the plug into the Flame Current meter jack

and allow a few seconds for the meter reading to

stabilize.

d. Read the average stable current, disregarding the

peaks due to shutter operation.

4. Optimize the flame signal.

a. Observe the flame signal while varying the line of

sight of the detector.

(1) Swivel the detector if it is mounted on a

Honeywell 118367A Swivel Mount, or

(2) Adjust the angle and/or position the sight pipe

(which was only tack welded as previously

instructed).

b. Try several sighting angles until you obtain the

highest and most stable meter reading possible. (If it

is less than 1.4 microamperes, refer to the

Troubleshooting section.)

c. Repeat step b for both the pilot and the main burner

flame. Do not sacrifice the main flame signal to

obtain an unnecessarily high pilot flame signal.

5. Repeat steps 2 and 3 for Sensitivity Control B, if used.

Make sure the external selector switch is closed while

adjusting Control B.

13 95-8269—1

Page 14

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

SELECTOR

SPADE TIP

6. Secure the swivel mount (if used), or tack weld the sight

pipe. Do not weld the sight pipe permanently into place

until you have accomplished the spark hold-in and pilot

turndown tests.

7. Remove the plug from the Flame Current meter jack.

8. Replace the rear cover plate and tighten the four screws

securely.

Multiburner System Using C7076A Detector (Flame

Discrimination)

1. Complete steps 1 through 8 under Single Burner

System above for each burner.

2. With all A sensitivity controls set to MAX position and all

burners firing at full load, select one burner and proceed

as follows:

a. Shut down the chosen burner, then note the flame

signal reading.

b. Loosen the locking nut on Sensitivity Control A.

c. Gradually reduce the sensitivity by turning Control A

counterclockwise until the flame relay (in the flame

safeguard control) drops out.

W136A TEST METER

SWITCH

(SET AT SPL)

d. Relight the burner and note the flame signal

reading. The difference between the new reading

and the initial reading in step a represents the

degree of flame discrimination.

e. Repeat the run-shutdown-dropout procedures

(steps 2a-d) until the optimum setting has been

achieved.

f. Hand tighten the locking nut on Sensitivity Control

A, then tighten another 1/4 turn, but do not

overtighten.

NOTE: If the sensitivity control on a detector is reduced to

MIN position and flame discrimination cannot be

achieved, insert an orifice plate in the sight pipe. An

orifice of the proper diameter will reduce the

ultraviolet radiation reaching the detector so that the

sensitivity can be adjusted to effect flame

discrimination.

3. Repeat step 2 for Sensitivity Control A on each burner.

4. Repeat step 2 for Sensitivity Control B (if used) on each

burner. Verify that Sensitivity Controls A and B on each

detector are properly indexed by the system fuel

selector, firing rate switch, etc.

RED (+)

METER LEAD

BLACK (–)

METER LEAD

Fig. 17. Set up for Sensitivity Controls A and B adjustments, C7076A Detector.

Multifuel System

For multifuel systems, use one sensitivity control for each fuel.

Follow steps 2 and 3 above for each fuel.

BLACK

SENSITIVITY

ADJUSTMENT

LOCKING NUT

PLUG

117053

METER

CONNECTOR

PLUG

RED

SPADE TIP

SENSITIVITY

CONTROL

C7076A

FLAME

DETECTOR

PLUG-IN

ELECTRONICS

CHASSIS

(REAR VIEW)

M20762

95-8269—1 14

Page 15

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

Single Burner System Using the C7076D Detector

WARNING

Fire or Explosion Hazard.

Can cause serious injury, death or property

damage.

Make sure that the environment surrounding the

C7076D is free of all explosive or hazardous

conditions before exposing the interior of the detector

to the atmosphere during the performance of the

following adjustment procedures.

1. Loosen the six screws in the rear cover plate of the

C7076D Detector and remove the plate.

2. Adjust Sensitivity Control A for maximum sensitivity.

a. If the remote sensitivity selection feature is used,

make sure the external selector switch is open for

Control A adjustment.

b. Turn Sensitivity Control A to MAX position.

3. Read the flame signal in microamperes at the Flame

Current jack.

a. Use a Honeywell W136A Test Meter with the

selector switch set at the SPL position. (If a W136A

is not available, a microammeter with a 0 to 25

microampere dc range, shunted with a 50

microFarad capacitor, may be used.

b. A 117053 Meter Connector Plug is needed (supplied

with the W136A or it may be ordered separately).

Connect the red spade tip to the red (+) meter lead

and the black spade tip to the black (-) meter lead.

See Fig. 17.

c. Insert the plug into the Flame Current meter jack

and allow a few seconds for the meter reading to

stabilize.

d. Read the average stable current, disregarding the

peaks due to shutter operation.

4. Optimize the flame signal.

a. Observe the flame signal while varying the line of

sight of the detector.

b. Adjust the angle and/or position of the sight pipe

(which was only tack welded as previously

instructed).

c. Try several sighting angles until you can obtain the

highest and most stable meter reading possible. (If it

is less than 1.4 microamperes, refer to the

Troubleshooting section).

d. Repeat step c for both the pilot and main burner

flame. Do not sacrifice the main flame signal to

obtain an unnecessarily high pilot flame signal.

5. Repeat steps 2 and 3 for Sensitivity Control B, if used.

Make sure the external selector switch is closed while

adjusting Control B.

6. Secure the swivel mount (if used) or tack weld the sight

pipe. Do not weld the sight pipe permanently into place

until you have completed the spark hold-in and pilot

turndown tests.

7. Remove the plug from the Flame Current meter jack.

8. Replace the rear cover plate on the detector. Ensure

that the tips of the sensitivity control extensions on the

rear cover are positioned properly to engage the slots of

the respective sensitivity controls on the rear of the

electronic chassis without altering their adjustments.

Reinstall the six screws in the cover plate and tighten

them securely.

Multiburner System Using the C7076D Detector

(Flame Discrimination)

1. Complete steps 1 through 8 under Single Burner

System above for each burner.

2. With all A sensitivity controls set to MAX position and all

burners firing at full load, select one burner and proceed

as follows:

a. Shut down the chosen burner, then note the flame

signal reading.

b. Gradually reduce the sensitivity by turning Control A

counterclockwise until the flame relay (in the flame

safeguard control) drops out.

c. Relight the burner and note the flame signal

reading. The difference between the new reading

and the initial reading in step a represents the

degree of flame discrimination.

d. Repeat the run-shutdown-dropout procedures

(steps 2a-c) until the optimum setting has been

achieved.

NOTE: If the sensitivity control on a detector is reduced to

MIN position and flame discrimination cannot be

achieved, insert an orifice plate in the sight pipe. An

orifice of the proper diameter will reduce the

ultraviolet radiation reaching the detector so that the

sensitivity can be adjusted to effect flame

discrimination.

3. Repeat step 2 for Sensitivity Control A on each burner.

4. Repeat step 2 for Sensitivity Control B (if used) on each

burner. Verify that Sensitivity Controls A and B on each

detector are properly indexed by the system fuel selector, firing rate switch, etc.

Multifuel System

For multifuel systems use one sensitivity control for each fuel.

Follow steps 2 and 3 above for each fuel.

Ignition Spark Response Test

An ignition spark response test must be done for all detectors

to ensure that ignition spark will not actuate the flame relay in

the flame safeguard control The test is done by manually

closing all fuel valves, starting the system, and observing the

flame relay when the ignition comes on. If the flame relay pulls

in, the detector must be repositioned to eliminate the

response to ignition spark.

Pilot (Ignitor) Turndown Test

A pilot (ignitor) turndown test must be done for all applications

in which the detector must prove the pilot before the main fuel

valve can open. This test proves that the smallest pilot flame

which can hold in the flame relay (in the flame safeguard

control) is also capable of safely igniting the main burner. The

test consists of closing the main fuel valve, reducing the pilot

flame until it is just able to hold in the flame relay, and then

opening the main fuel valve to verify a safe main burner

lightoff.

Secure the Sight Pipe or Swivel Mount

1. When the flame signal is acceptable and all adjustments

have been made, remove the detector.

2. Secure the sight pipe (or swivel mount):

15 95-8269—1

Page 16

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

a. Weld the sight pipe in its final position, or

b. Tack weld the swivel ball in place in its socket if

using a Honeywell 118367A Swivel Mount.

3. Reinstall the detector.

Aspirator Adjustment (C7076A Detector Only)

Make the final connections and adjustments of the optional air

supply (if used). Refer to the paragraph entitled Connecting

Air Supply.

Final Checkout

Before putting the burner(s) into service, check out the

installation using procedures in the Checkout section of the

instruction sheet for the appropriate flame safeguard control.

After completing the checkout, run the burner(s) through at

least five complete cycles to verify proper operation.

TROUBLESHOOTING

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Open the master switch before removing or installing

the plug-in electronics chassis or the detector. Line

voltage is present on some of the terminals when

power is on.

Preliminary Procedures for C7076A Flame Detector

IMPORTANT

If the combustion chamber has a positive pressure,

make sure the aspirator inlet pressure equals or

exceeds that required for sight pipe seal off, as given

on Fig. 9, before unlatching the detector.

1. If you are using remote sensitivity selection, make sure

that the external selector switch is open if adjusting

Sensitivity Control A or closed if adjusting Sensitivity

Control B.

2. Unlatch the detector and swing it away from the

faceplate.

3. Loosen the four captive screws in the front cover plate

(with the viewing lens) and remove the plate to expose

the terminal block. The wiring diagram is on the inside

of the front cover plate.

4. After each step in the following procedures, relatch the

detector to the faceplate and check for a meter reading

at the Flame Current jack on the detector (Fig. 17).

a. If you get a reading above 1.4 microamperes and

the flame relay (in the flame safeguard control) pulls

in, return to Sensitivity Adjustments.

b. If you do not get a reading, unlatch the detector and

proceed with Troubleshooting Procedure A,

following.

c. If you get a reading but the flame relay (in the flame

safeguard control) does not pull in, unlatch the

detector and proceed with Troubleshooting

Procedure B, following.

General

If you cannot obtain a satisfactory flame signal while adjusting

the sensitivity, refer to the preliminary and troubleshooting

procedures that follow. If you encounter other problems in the

system, refer to the Troubleshooting section in the instruction

sheet for the appropriate flame safeguard control.

Upon completion of the troubleshooting, be sure to perform

the adjustment and checkout procedures previously specified

for the detector.

NOTE: Instructions for replacing the viewing lens, sensing

tube, coil and shutter assembly and plug-in

electronic chassis are given in the Service section.

Before making a replacement, make sure you have the

correct part (check its part number and voltage rating).

Equipment Required

1. Voltmeter (Honeywell W136A or equivalent) with 0 to

300 volt ac scale.

2. Microammeter (Honeywell W136A or equivalent) with 0

to 25 microampere range, SPL damping.

3. Meter connector plug (Honeywell part no. 117053 or

equivalent)—required for some meters.

4. Replacement parts—see Specifications section.

Preliminary Procedures for C7076D Flame Detector

WARNING

Fire or Explosion Hazard.

Can cause serious injury or death.

Make sure that the environment surrounding the

C7076D Flame Detector is free of all explosive or

hazardous conditions before exposing the interior of

the detector to the atmosphere during the

performance of the following troubleshooting

procedures.

1. If you are using remote sensitivity selection, make sure

that the external selector switch is open if adjusting

Sensitivity Control A, or closed if adjusting Sensitivity

Control B.

2. Remove the six screws that secure the cover plate to

the rear of the detector to provide access to the Flame

Current jack on the electronics chassis.

3. Remove the four screws that secure the faceplate

(attached to the sight pipe) to the detector housing.

Force the faceplate from the housing far enough to

allow the detector to be sufficiently reoriented on the

conduit to provide access to wiring at the terminal block

in detector.

95-8269—1 16

Page 17

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

4. After each step in the following procedures, realign the

detector with the faceplate and check for a meter

reading at the Flame Current jack on the detector (Fig.

18).

a. If you get a reading above 1.4 microamperes and

the flame relay (in the flame safeguard control) pulls

in, return to Sensitivity Adjustments.

b. If you do not get a reading, orient the detector away

from the faceplate sufficiently far enough to provide

access to the wiring at the terminal block and

proceed with troubleshooting Procedure A.

c. If you get a reading but the flame relay (in the flame

safeguard control) does not pull in, orient the

detector away from the faceplate sufficiently far

enough to provide access to the wiring at the

terminal block and proceed with troubleshooting

Procedure B.

Troubleshooting Procedures for C7076A and C7076D Flame Detectors.

NOTE: If the detector develops a signal at the Flame Current

Procedure A: Zero Flame Signal Reading at

Detector; Flame Relay Does not Pull In.

NOTE: The nominal voltage rating is printed on the trans-

Nominal Voltage

100 85 110

117 99.5 128.7

120 102 132

200 170 220

220 187 242

240 204 264

jack, skip troubleshooting Procedure A.

1. Complete the Preliminary Procedures listed above.

2. Refer to the wiring diagram on the inside of the front

cover plate or to Fig 14 or 15 for terminal locations.

3. Check for proper line voltage. Connect an ac voltmeter

across terminals 2 and 1 (or 8, if detector is nonEuropean 240 volt, 50/60 Hz model) on the terminal

block. Make sure the ac voltage measured is within the

voltage range listed in Table 3, below, for the particular

detector model used.

former cover next to the sensitivity controls on the

rear of the plug-in electronics chassis.

a. If there is no voltage, make sure line voltage power

is connected to the master switch, the master switch

is closed and overload protection (circuit breaker,

fuse, or similar device) has not opened the power

circuit.

b. If the measured voltage is not within the proper

voltage range, make sure the main power supply is

of the correct voltage and frequency. Then trace the

wiring between the detector and the main power

supply to determine the problem.

Table 3. Line Voltage Ratings for the Detector.

Acceptable Line Voltage

Rating

Minimum Maximum

4. Determine if the self-checking shutter is open by looking

into the front of the detector through the pipe in the

wiring compartment.

a. If the shutter is not open, connect an ac voltmeter

across terminals 3 and 4 on the terminal block.

Make sure the ac voltage measured is within the

voltage range listed in Table 4.

NOTE: The nominal voltage rating is printed on the

transformer cover next to the sensitivity controls on

the rear of the plug-in electronics chassis.

Table 4. Shutter Voltage Range.

Nominal Detector

Voltage Range

100 85 110

117, 120, 200, 220,

240 or 220/240

(1) If the proper voltage is present, replace the coil

and shutter assembly or the entire plug-in

electronics chassis (see Service section).

(2) If the measured voltage is not within the proper

voltage range, connect a dc voltmeter (capable

of measuring 50 volts) across terminals 6 (F)

and 5 (G) on the terminal block (F is+, G is -)

(a)If the voltage is 2 volts or more, replace the

plug-in electronics chassis )(See Service

section).

(b)If the voltage is less than 2 volts, trace the

shutter wiring between the detector and the

flame safeguard control (refer to Fig 14 or 15).

If the wiring is correct but the proper voltage is

still not present, replace the plug-in R7476A or

R7886 Dynamic Self-Check Ultraviolet

Amplifier.

b. If the shutter is open, make sure the sensitivity

control on the plug-in electronics chassis is not set

too low for the flame conditions encountered. (Refer

to Adjustments and Checkout section.)

5. Make sure the viewing path is clear.

a. Clean the sight pipe. Make sure there are no

obstructions in it.

b. Make sure the proper viewing lens is used.

NOTE: Window glass does not transmit ultraviolet radiation.

You can check for an improper lens by testing the

detector with the lens removed.

c. Clean the viewing lens with a soft, clean cloth.

6. If the previous actions have not corrected the problem,

replace the 191053 Ultraviolet Sensing Tube (See

Service section).

7. If you still do not get a meter reading, replace the plug-in

electronics chassis.

Acceptable Shutter Voltage

Minimum Maximum

99.5 132

Procedure B: Flame Signal Reading Present at

Detector; Flame Relay Does Not Pull In)

1. Complete the Preliminary Procedures listed above.

2. Determine if the self-checking shutter is closed by look-

ing into the front of the detector through the pipe in the

wiring compartment.

17 95-8269—1

Page 18

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

3. If the shutter is closed and the signal at the Flame

Current jack on the detector is 1 microampere or more,

remove the ultraviolet sensing tube (see Service

section) and operate the detector.

a. If the shutter opens, replace the 191053 Ultraviolet

Sensing Tube.

b. If the shutter stays closed, replace the plug-in

electronics chassis (see Service section).

4. If the flame signal measured at the Flame Current jack

on the detector is weak (less than 1.4 microamperes),

proceed as follows:

a. Clean the sight pipe. Make sure there are no

obstructions in it.

b. Clean the viewing lens with a soft, clean cloth.

c. Make sure the sensitivity control on the plug-in

electronics chassis is not set too low for the flame

conditions encountered. (Refer to Adjustments and

Checkout section.)

d. Resight the detector. See Planning the Installation

and Installation sections.

5. If the flame signal measured at the Flame Current jack

on the detector is strong (greater than 1.4

microamperes), but the flame relay does not pull in,

connect a dc voltmeter (capable of measuring 50 volts)

across terminals 6 (F) and 5 (G) on the terminal block (F

is +; G is -).

a. If the voltage is less than 5 volts and the shutter is

not oscillating, disconnect the F leadwire from

terminal 6 for a moment.

(1) If the voltage (5 to 6) rises, trace the wiring

between the detector and the flame safeguard

control (refer to Fig. 14 or 15). If the wiring is

correct (no short circuits), replace the plug-in

R7476A or R7886 Dynamic Self-Check

Ultraviolet Amplifier.

(2) If the voltage (F to G) does not rise, replace the

plug-in electronics chassis (see Service section).

b. If the voltage is 5 volts or more, check the F and G

leadwires between the detector and the flame

safeguard control. If they are wired properly (no

open circuits), replace the plug-in R7476A or R7886

Dynamic Self-Check Ultraviolet Amplifier.

6. If the previous actions have not corrected the problem,

replace the plug-in electronics chassis.

SERVICE

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Open the master switch before removing or installing

the plug-in electronics chassis or the detector.

IMPORTANT

If the combustion chamber (C7076A Flame Detector)

has a positive pressure, make sure the aspirator inlet

pressure equals or exceeds that required for sight

pipe seal off, as given on Fig. 9, before unlatching

the detector.

IMPORTANT

Only qualified flame safeguard technicians should

attempt to service or repair flame safeguard controls

and burner management systems.

Periodic Maintenance

1. Scheduled replacement of the detector components is

not necessary.

2. Keep the flame detection system adjusted for safe and

reliable operation

3. Clean the viewing lens regularly. Use a soft, clean cloth.

If the lens is damaged, or if it is coated with a substance

which cannot be cleaned off, replace it (see

Maintenance Procedures, following).

4. C7076A Detector only: Replace the silicone-rubber

gaskets which seal the front and rear cover plates if they

are damaged or deteriorated (see Maintenance

Procedures, following).

Maintenance Procedures

CAUTION

Equipment Damage Hazard.

Improper part replacement can damage the

equipment.

Before making a replacement, make sure you have

the correct part (check its part number and voltage

rating).

Replacing the Plug-In Electronics Chassis

REPLACING THE PLUG-IN ELECTRONICS CHASSIS IN THE C7076A

FLAME DETECTOR

1. Open the master switch to interrupt all power to the

detector.

2. Loosen the four captive screws in the rear cover plate

and remove the plate.

3. Remove the four standoffs that hold the plug-in electronics chassis and pull the chassis out of the housing.

4. Align the slot in the top of the new chassis with the key

in the housing.

IMPORTANT

Make sure the part number and the voltage rating of

the new chassis are correct.

WARNING

Fire or Explosion Hazard.

Can cause serious injury or death.

Make sure that the environment surrounding the

C7076D Flame Detector is free of all explosive or

hazardous conditions before exposing the interior of

the detector to the atmosphere during the

performance of the following troubleshooting

procedures.

95-8269—1 18

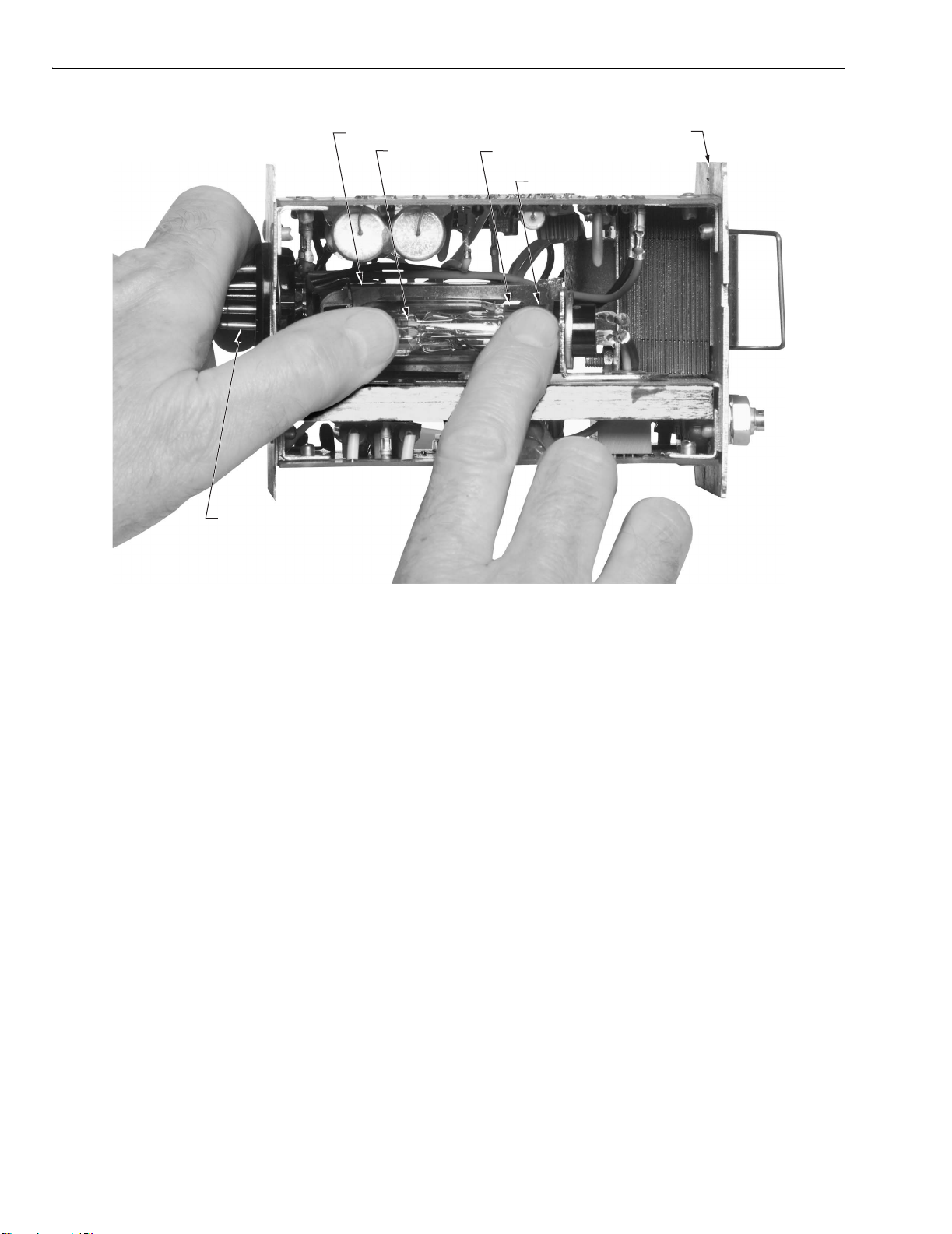

5. Insert the new chassis in the housing and firmly push it

all the way in (see Fig. 18). Make sure the octal plug on

the chassis is securely seated in the socket in the

housing.

6. Insert the four standoffs that hold the chassis and

tighten them securely.

7. Close the master switch and perform the Adjustments

and Checkout.

8. Put the rear cover plate back on and tighten the four

screws securely.

Page 19

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

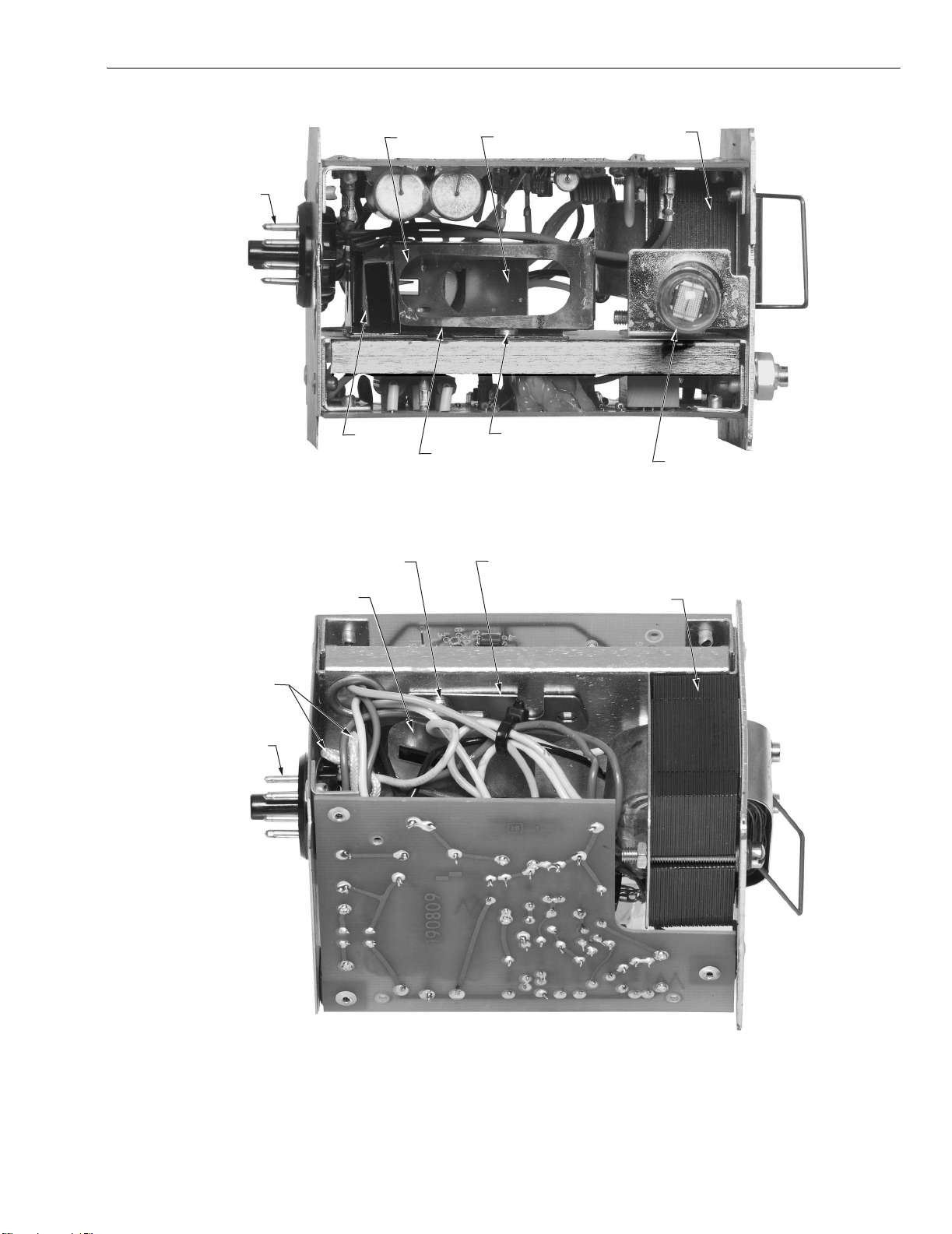

ASPIRATOR HOUSING

KEY

SLOT

1

STANDOFF (4)

REAR COVER

1

C7076D HAS SCREWS, NOT STANDOFFS.

PLUG-IN ELECTRONICS CHASSIS

(CHECK VOLTAGE RATING)

Fig. 18. Replacing the plug-in electronics chassis in the C7076 Flame Detector.

M20763A

REPLACING THE PLUG-IN ELECTRONICS CHASSIS IN THE C7076D

FLAME DETECTOR.

NOTE: Removing and replacing the plug-in electronics

chassis in the C7076D is identical to the procedure

for the C7076A, above, with the exception of steps 2,

8 and 9, below.

1. Open the master switch to interrupt all power to the

detector.

2. Remove the six screws securing the cover plate to the

rear of the housing and remove the cover plate.

3. Remove the four screws securing the plug-in electronics

chassis and pull the chassis out from the housing.

4. Align the slot in the top of the new chassis with the key

in the housing.

IMPORTANT

Make sure the part number and the voltage rating of

the new chassis are correct.

5. Insert the new chassis in the housing and firmly push it

all the way in Make sure the octal plug on the chassis is

securely seated in the socket in the housing.

6. Reinstall the four screws that hold the chassis in the

housing and tighten them securely.

7. Close the master switch and perform the Adjustment

and Checkout procedures previously specified.

8. Replace the rear cover plate on the detector. Make sure

that the tips of the sensitivity control extensions on the

rear cover are positioned properly to engage the slots of

the respective sensitivity controls on the rear of the

electronics chassis without altering their adjustments.

9. Reinstall the six screws in the cover plate and tighten

them securely.

REPLACING THE ULTRAVIOLET SENSING TUBE

1. Open the master switch and remove the plug-in

electronics chassis as specified in Replacing the Plug-in

Electronics Chassis, above.

2. Locate the sensing tube near the top of the chassis.

(See Fig. 19.)

3. Gently push the alignment guide away from the tube

until the tip of the tube is free.

4. While holding the alignment guide away from the tube

tip, grasp the tab on the tube bracket and swing the tube

out from the chassis.

5. Pull the tube out of its socket.

6. Align the three pins on the new tube with the holes in

the socket.

7. Push the new tube firmly into the socket. Make sure it is

seated securely.

8. Swing the tube back into place in the chassis. The

alignment guide will snap into place around the tip of the

tube.

9. Reinstall the plug-in electronics chassis as specified in

Replacing the Plug-in Electronics Chassis, above.

10. Close the master switch and perform the adjustments

and checkout.

IMPORTANT

Be very careful not to kink or otherwise damage the

shutter (Fig. 19).

19 95-8269—1

Page 20

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

PLUG-IN ELECTRONICS

OCTAL PLUG

ALIGNMENT GUIDE

191053

ULTRAVIOLET

SENSING TUBE

TAB ON

TUBE BRACKET

TUBE SOCKET

CHASSIS

M20764

Fig. 19. Replacing the ultraviolet sensing tube.

REPLACING THE COIL AND SHUTTER ASSEMBLY

1. Open the master switch and remove the plug-in

electronics chassis as specified in Replacing the Plug-in

Electronics Chassis, above.

2. Locate the coil near the bottom of the chassis (Fig. 22).

3. Cut the two white coil wires as close to the coil as

possible.

4. Remove the mounting screw from the base of the coil

and shutter assembly.

5. Turn the chassis over and locate the sensing tube.

6. Gently push the alignment guide away from the tube

(just enough to free the tip of the sensing tube) and

swing the tube out from the chassis as far as it will go

(Fig. 21).

7. Remove the other mounting screw from the base of the

coil and shutter assembly (Fig. 22).

8. Carefully slide the coil and shutter assembly out of the

chassis.

NOTE: It may be necessary to move some of the

transformer leadwires out of the way in order to slide

the coil and shutter assembly past them.

9. Slide the new coil and shutter assembly into place.

Make sure its part number and voltage rating are

correct.

10. Remove about 1/4 in. (6 mm) of insulation from each of

the two short, white leadwires still connected to the octal

plug.

11. Using wire nuts, connect one of the coil wires to one of

the short, white leadwires on the plug and connect the

other coil wire to the other short, white leadwire.

12. Insert the two mounting screws in the base of the coil

and shutter assembly and tighten them securely.

13. Swing the sensing tube back into place in the chassis.

The alignment guide will snap into place around the tip

of the tube.

14. Reinstall the plug-in electronics chassis as specified in

Replacing the Plug-in Electronics Chassis, above.

15. Close the master switch.

IMPORTANT

Be very careful not to kink or otherwise damage the

shutter.

95-8269—1 20

Page 21

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

TRANSFORMER

O

C

BASE OF 120625B, C, OR D

CTAL PLUG

COIL

MOUNTING SCREW

SHUTTER

ALIGNMENT

GUIDE

BASE OF 120625B, C, OR D COIL AND

SHUTTER ASSMBLY (CHECK VOLTAGE

RATING–100 OR 120)

Fig. 20. Location of the coil and shutter assembly.

MOUNTING

COIL

SCREWS

COIL AND SHUTTER ASSEMBLY

(CHECK VOLTAGE RATING)

TRANSFORMER

SENSING TUBE

M20765

CUT WHITE

OIL WIRES (2)

OCTAL PLUG

M20766

Fig. 21. Replacing the coil and shutter assembly.

REPLACING THE VIEWING LENS

detector.

2. If the combustion chamber has a positive pressure,

Replacing the Lens in the C7076A Flame Detector

1. Open the master switch to interrupt all power to the

make sure the airflow through the aspirator equals or

exceeds the value required for seal-off (Fig. 10).

21 95-8269—1

Page 22

C7076A,D ADJUSTABLE SENSITIVITY ULTRAVIOLET FLAME DETECTORS

7

CAPTIVE

3. Unlatch the detector and swing it away from the

faceplate-aspirator.

4. Loosen the four captive screws in the front cover plate

and remove the plate.

5. Press on the back of the silicone-rubber grommet until it

pops out of the cover plate.

6. Push on the back of the lens until it pops out of the

grommet.

7. Insert the new lens, flat side toward the grommet small

flange and curved side toward the flame, into the recess

in the grommet. Make sure the recess completely

encloses the lens.

8. Push the small flange of the grommet through the hole

in the cover plate until it pops into place. Make sure the

flange is completely through the the hole and the

grommet is properly seated.

9. Clean both sides of the viewing lens with a soft, clean

cloth.

10. Put the front cover plate back on and tighten the four

screws securely.

11. Latch the detector against the faceplate-aspirator and

close the master switch.

Replacing the Lens in the C7076D Flame Detector