Page 1

C7057

1

8

Cadmium Sulfide Photocell

INSTALLATION INSTRUCTIONS

APPLICATION

The C7057 Cadmium Sulfide Photocell is used to sense

ambient light levels. It is used as the sensing element for

the CR7075A Lighting Controller which can provide

on/off control of two separate lighting banks based on

user determined ambient light intensity levels. Typical

applications include outdoor cosmetic and parking lot

lighting in fast food restaurants retail establishments,

supermarkets, banks and lighted billboards.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Dimensions (Fig. 1)

3/4 (19)

3/16

(21)

1-9/16

(40)

Location

Locate the photocell sensor so that the lens is exposed

to full daylight. (See Fig. 2.)

NOTES:

— Select an area which will not become shaded.

— Mount only with light entrance facing

horizontally.

— Avoid overexposure to direct east/west

sunlight.

Mounting

IMPORTANT

Mount the photocell sensor to the top of a

watertight, outdoor FS junction box.

1. Use the gasket provided to prevent moisture entry.

2. Screw stem into 1/2-14 threaded knockout.

NOTE: The photocell sensor can be mounted in a

7/8 in. hole (or knockout).

Wiring

CAUTION

Electrical Shock or Equipment Damage

Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

2-1/8 (54)

3 (76)

Fig. 1. C7057 approximate dimensions in in. (mm).

Before Installation

IMPORTANT

The photocells develop a hysteresis (or “light memory”)

when packed for shipping. Until the photocell has been

exposed to bright light for at least 16 hours, light level

setpoints will shift.

® U.S. Registered Trademark

Copyright © 2001 Honeywell • All Rights Reserved

Expose the photocell to light for 16 hours.

1-9/16 (40)

M2007

IMPORTANT

• All wiring must agree with applicable codes,

ordinances and regulations.

• When wiring the input power, apply only one

source of power to the CR7505A.

• With line-voltage loads, the power and load

voltage must be the same.

Refer to chart on the inside of the controller cover or

Fig. 3 for locating the power inputs, photocell sensor

inputs, TOD and load relay terminals.

62- 0074- 1

Page 2

C7057 CADMIUM SULFIDE PHOTOCELL

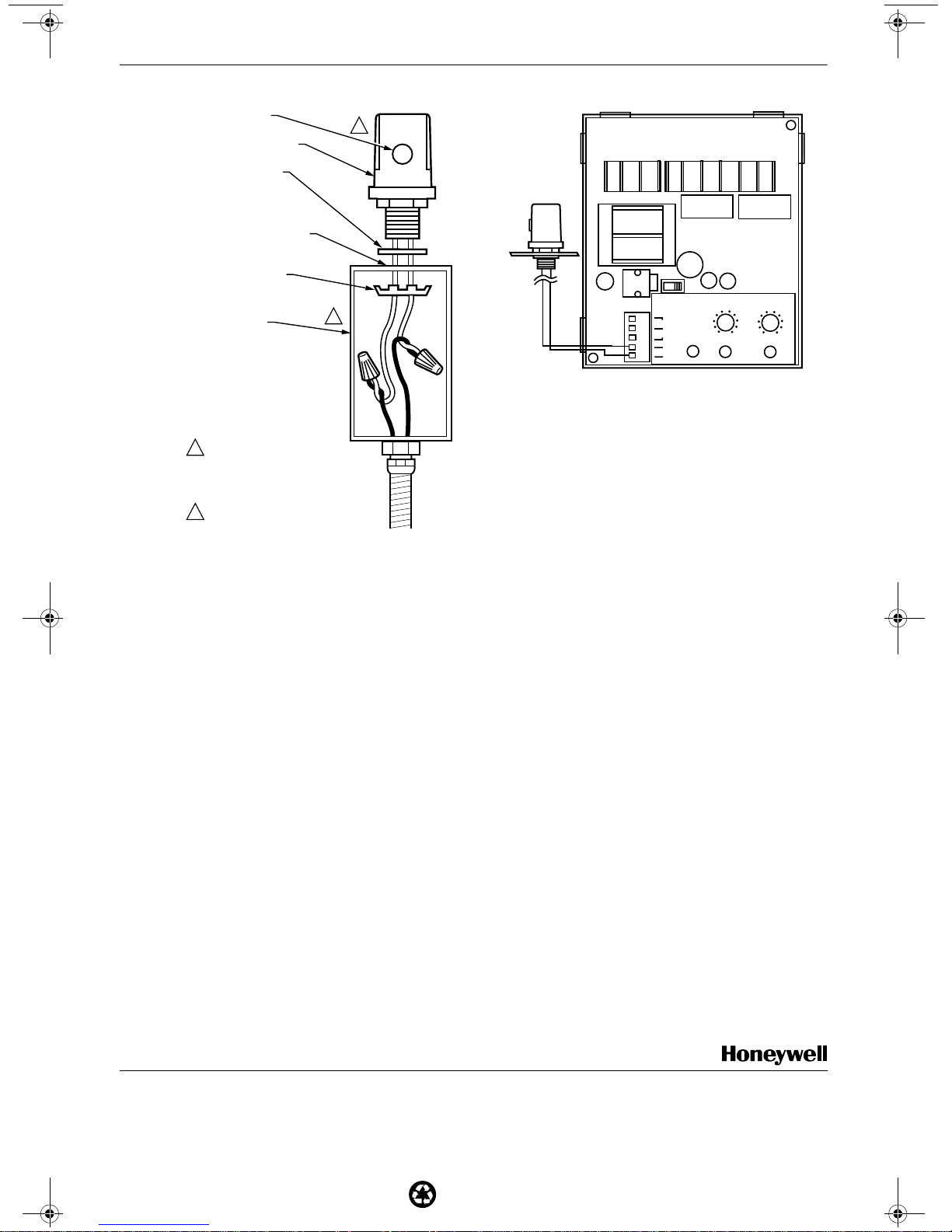

M

LENS

PHOTOCELL

GASKET

1/2-14 THREADED

KNOCKOUT OR

7/8 INCH HOLE

HEX NUT

JUNCTION

BOX

1

FOR BEST RESULTS, EXPOSE LENS

TO LIGHT FROM THE NORTHERN SKY

(IN THE NORTHERN HEMISPHERE)

OR THE SOUTHERN SKY (IN THE

SOUTHERN HEMISPHERE).

2

USE WATERTIGHT JUNCTION BOX

WITH PROPER GASKETS AND SEALS.

20060

1

2

Fig. 2. Vertical mounting configuration.

NOTES:

— The photocell sensor has no polarity.

— Wire to terminal strip T2, terminals 4 and 5.

— Access to terminals can be gained through

standard conduit knockouts (A-E) located

around the perimeter of the enclosure.

— Use knockout A only for the photocell sensor

and TOD wiring.

— Photocell wires should be at least 18 AWG

two conductor. If not run in watertight conduit,

use suitable outdoor wiring insulation.

— Shielded wiring is not required.

OPERATION AND CHECKOUT

CAUTION

ONE POWER SOURCE ONLY

M2032A

LINE POWER

240

120

COM

VAC

VAC

1

2

3

4

5

OUTPUT 1

N0 COMNCN0 COM NC

SET

T.O .D. 1

T.O .D. 2

T2

POWER

SENSOR

RUN

7

8

9

10

STAGE 1

OUTPUT 2

LIGHT LEVEL

56

4

7

3

8

2

9

1

10

STAGE 2

56

4

3

2

1

Fig. 3. Wiring for 120 Vac input; 24 Vac load.

Calibration

After the controller and photocell sensor are installed

(with wiring and settings verified), and the photocell has

been exposed to light for 16 hours, apply power. The light

intensity threshold levels can be calibrated when the

desired outdoor light level has occurred.

NOTES:

— Calibration achieves best results when

making adjustments at or near the light

conditions required for equipment switching.

— Calibrating at extreme light conditions can

cause switching to be unachievable.

1. At the desired outdoor light level place SET-RUN

switch to the SET position.

2. Slowly rotate stage 1 light level potentiometer

counterclockwise until the stage 1 LED lights.

3. Stage 1 is now calibrated to the light level existing

at the sensor and the stage 1 load is energized.

4. Return the SET-RUN switch to the RUN position.

NOTE: To calibrate stage 2, repeat this process

except adjust the stage 2 light level

potentiometer.

In the following procedures, refer to the diagram inside

the CR7075A cover or Fig. 3. These show locations of

all operating controls, LED lights, and wiring connection

points.

Initial Adjustments

1. Adjust both light level potentiometers to the fully

clockwise position (#1 index level).

2. Place the SET-RUN switch to the RUN position.

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to, the

literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages, including

attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Home and Building Control Home and Building Control

Honeywell Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario

62-0074—1 B.B. Rev. 9-01 www.honeywell.com

M1V 4Z9

IMPORTANT

After initial setup is complete, make certain the

switch is in the RUN position to avoid short

cycling the loads.

NOTE: The SET-RUN switch removes the integrating

time delay (short-cycle protection) circuitry in

the SET position. In the RUN position (normal

operation) the calibrated light level must be

present for 30 seconds before the load

switches.

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...