Page 1

63-2590-05

Series 2000

C7021F

C7023F

C7031G

C7041F

C7021P

C7023P

C7041P

C7021R

C7023R

C7041R

C7021K

C7023K

C7041K

C7021D

C7023D

C7031D

C7041D

C7021J

C7023J

C7031J

C7041J

C7021B/C

C7023B/C

C7031B

C7041B/C

C7021N

C7023N

C7041N

Electronic Temperature Sensors

PRODUCT DATA

APPLICATION

The Series 2000 C7021, C7023, C7031 and C7041 Electronic

Temperature Sensors are designed for use with electronic

controllers in domestic or commercial heating and cooling

systems.

FEATURES

• C7021D, C7023D, C7031D, C7041D for immersion

mounting sense water temperature.

• C7021F, C7023F, C7031G, C7041F sense outdoor air

temperature and are weatherproof for outdoor use

(knockouts allow for 1/2 in. conduit connection).

• C7021J/R, C7023J/R, C7031J, C7041J/R sense average

duct air temperature.

• C7021B/C, C7023B/C, C7031B, C7041B/C sense duct

air temperature.

• C7021K, C7023K, C7041K with strap-on mounting

senses water temperature.

• C7021N, C7023N, C7041N probe senses water or air

temperature.

• C7021P, C7023P, C7041P senses air temperature.

• Solid state components not affected by dust or dirt.

Application......................................................................... 1

Features ............................................................................ 1

Specifications .................................................................... 2

Installation ......................................................................... 8

Wiring ................................................................................11

Operation and Checkout ...................................................11

Contents

Page 2

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

SPECIFICATIONS

See Table 1 for additional specifications.

Compatability:

Use Series 2000 C7031, C7041 Temperature Sensors with

Excel 10, 15, 80, 100, and 500 controllers.

Series 2000 C7031B,D,G,J sensors are compatible with

various Honeywell controllers. The C7031G2014 is

compatible with the T7350 Commercial Thermostat.

Series 2000 C7021 temperature sensors are compatible with

TB7600, TB7300 and TB7200 communicating thermostats.

Series 2000 C7023 temperature sensors are compatible with

WEBs-AX I/O modules.

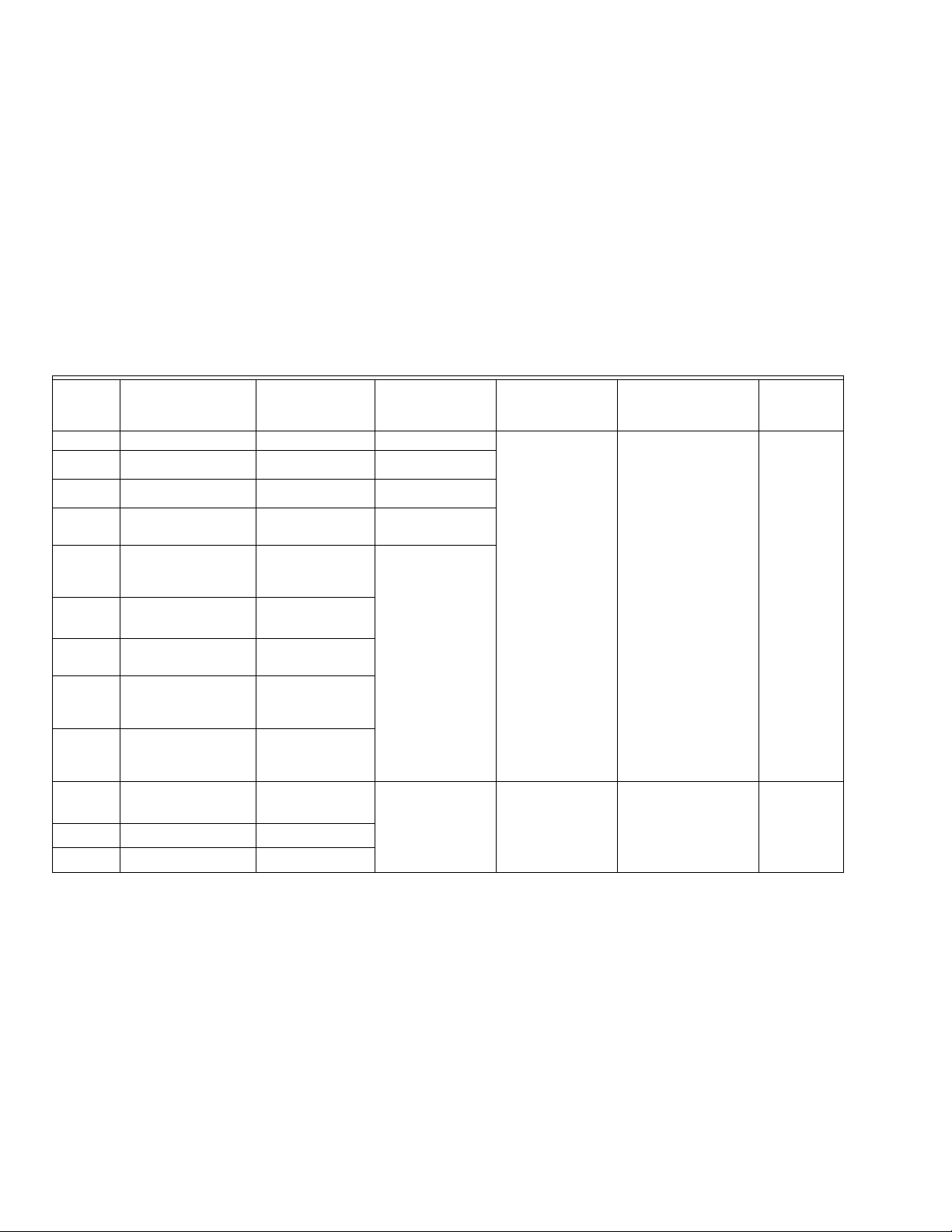

Table 1. Sensor Selection and Application Guide

Element

Model Control Application

C7021B Duct discharge air 6 in. (152) or 12

C7021C Duct discharge air 18 in. (457 mm)

C7021D

C7021F Outdoor air — -40° to 158°F

C7021J Duct discharge air

C7021K Hot water (strap-on

C7021N Water / Air (bullet

C7021P Space air

C7021R Duct discharge air

C7023B Duct discharge air 6 in. (152) or 12

C7023C Duct discharge air 18 in. (457 mm)

C7023D

Hot or chilled water

(averaging sensor

with 4 elements)

mounting)

probe)

temperature (button

probe)

(rigid copper

averaging sensor)

Hot or chilled water

f

Insertion Length

b

5 in. (127 mm)

12 ft (3.7m)

12 ft (3.7m) or 24

ft (7.3m)

in. (305 mm)

b

5 in. (127 mm)

Element

Operating Range

(-40° to 70°C)

-40° to 250°F

(-40° to 121°C)

-40° to 250°F

(-40° to 121°C)

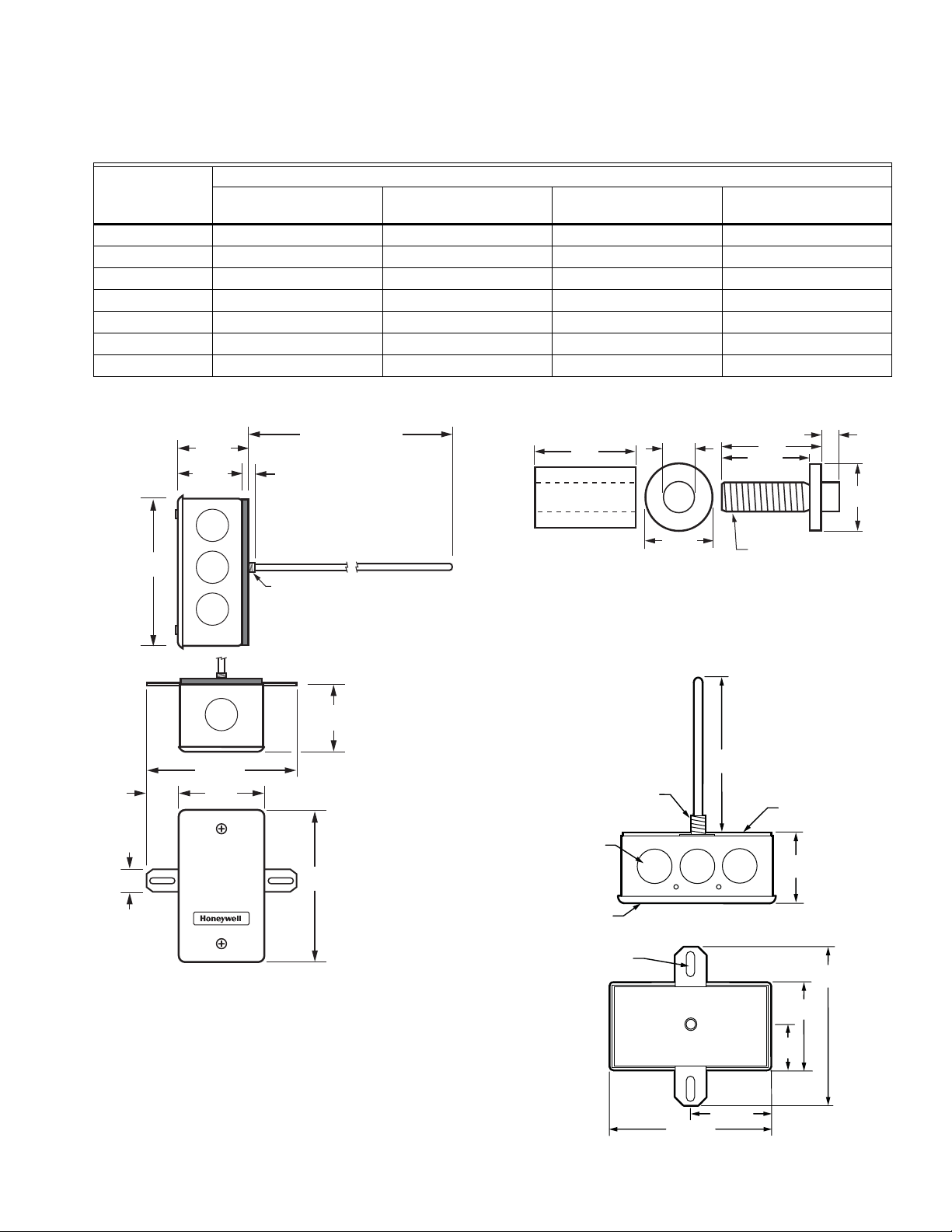

Dimensions:

See Fig. 1 through Fig. 11.

Sensor Accuracy:

±0.36°F at 77°F (±0.2°C at 25°C) for 20K ohm NTC sensors

and 10K ohm NTC Type II and Type III sensors.

Accessories:

32006523-001 20K Probe: to allow replacement of old style

C7031D1062-1 with non-threaded well.

50001774-001 Stainless Steel 304 Well Assembly: 1/2 in.

external and internal NPT threading. Use with C7021D/

C7023D/C7031D/C7041D.

50001775-001 Well Adapter: Used with C7021D/C70231D/

C7031D/C7041D to allow threading sensor into previouslyinstalled Series 1000 32005960-001 Well.

Element Max

Ambient

Tempe rature

250°F (121°C) 10K Ohms NTC @

250°F (121°C)

Sensor Resistance

in Ohms Sensitivity

77° F Type II

10K Ohms NTC @

77° F Type III

—

—

a

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

63-2590—05 2

Page 3

Table 1. Sensor Selection and Application Guide

Model Control Application

C7023F Outdoor air

C7023J Duct discharge air

(averaging sensor

with 4 elements)

Element

Insertion Length

12 ft (3.7m)

Element

Operating Range

-40° to 158°F

(-40° to 70°C)

-40° to 250°F

(-40° to 121°C)

C7023K Hot water (strap-on

mounting)

f

C7023N Water / Air (bullet

probe)

C7023P Space air

temperature (button

probe)

C7023R Duct discharge air

(rigid copper

averaging sensor)

12 ft (3.7m) or 24

ft (7.3m)

-40° to 250°F

(-40° to 121°C)

C7031B Duct discharge air 6 in. (152 mm) -40° to 250°F

(-40° to 121°C)

C7031D Hot or chilled water 5 in. (127 mm) 40° to 350°F

(4° to 115°C)

C7031G

-2006

C7031G

-2014

C7031J Duct discharge air

Outdoor air — -40° to 120°F

(-40° to 49°C)

Outdoor air —

d

-40° to 120°F

(-40° to 49°C)

12 ft (3.7m) 40° to 180°F

(averaging sensor

(4° to 82°C)

with 4 elements)

C7041B Duct discharge air 6 in. (152 mm) or

12 in. (305 mm)

-40° to 250°F

(-40° to 121°C)

C7041C Duct discharge air 18 in. (457 mm)

b

C7041D

Hot or chilled water

5 in. (127 mm)

C7041F Outdoor air — -40° to 158°F

(-40° to 70°C)

C7041J Duct discharge air

12 ft (3.7m)

(averaging sensor

with 4 elements)

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

Element Max

Ambient

Tempe rature

250°F (121°C)

250°F (121°C)

370°F (187°C)

120°F (49°C)

120°F (49°C)

250°F (121°C)

250°F (121°C)

Sensor Resistance

in Ohms Sensitivity

10K Ohms NTC @

77° F Type III

1097 at 77° (25°C)

1097 at 77° (25°C)

c

c

1715 at 90°F (32°C)

3484 at 77°F (25°C)

1097 at 77° (25°C)

c

20K Ohms NTC at

77°F (25°C)

e

2.1 (3.9)

2.1 (3.9)

c

2.2 (3.4)

c

2.1 (3.9)

2.1 (3.9)

—

a

—

C7041K Hot water (strap-on

f

C7041N

mounting)

Water / Air (bullet

probe)

C7041P Space air

temperature (button

probe)

C7041R Duct discharge air

(rigid copper

averaging sensor)

-40° to 250°F

(-40° to 121°C)

—

—

12 ft (3.7m) or

24 ft (7.3m)

3 63-2590—05

Page 4

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

a

Control sensitivity in ohms per degree F (per degree C) for element operating range.

b

Order immersion well separately (50001774-001)

c

Resistance increases as temperature increases.

d

Use with T7350 Commercial Thermostat.

e

Nonlinear resistance decreases as temperature increases.

f

Not equipped with well; temperature sensed at surface of pipe.

63-2590—05 4

Page 5

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

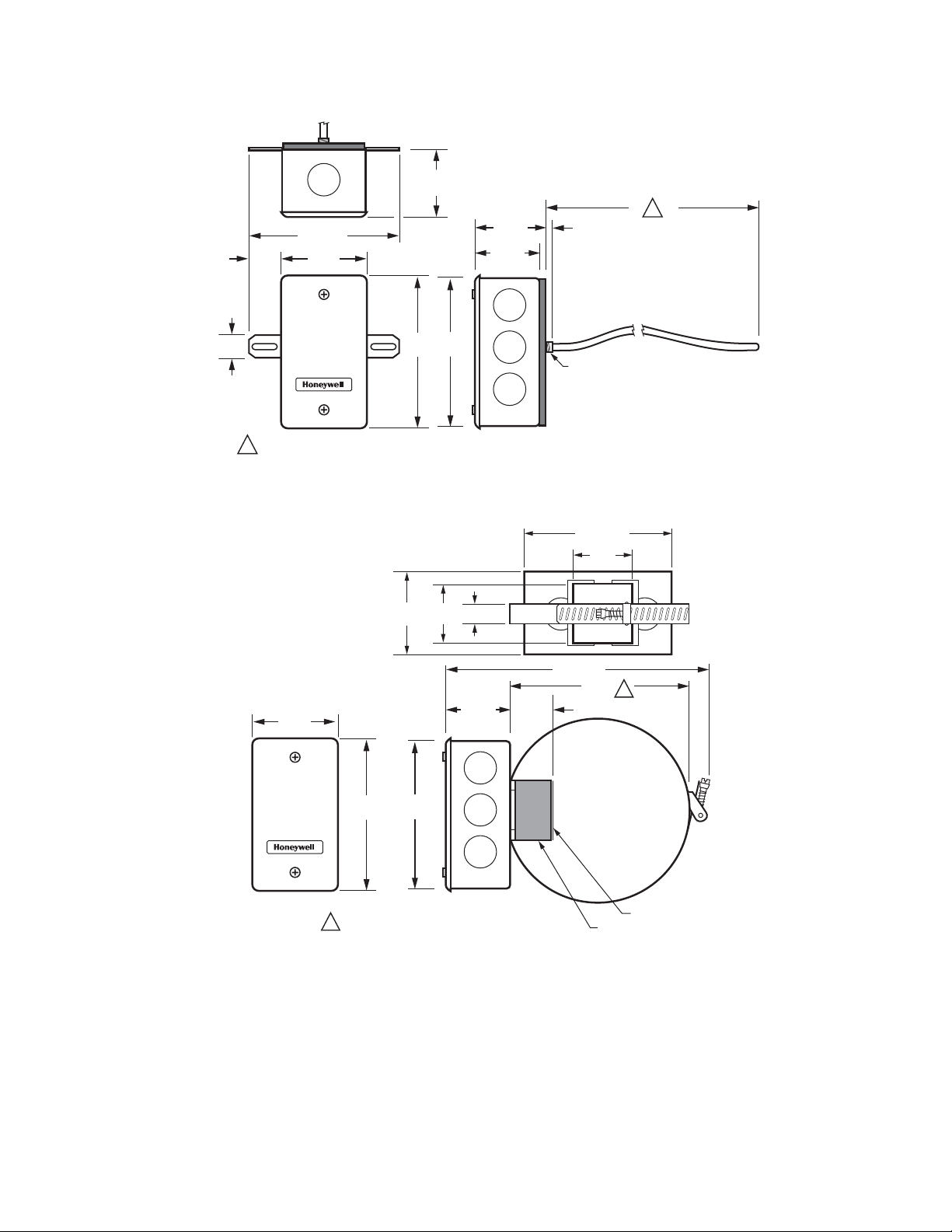

2-5/16

(59)

15/16

(23)

1-11/16

(43)

4-3/16

(107)

3/4

(19)

4

(102)

1-11/16

(43)

C7031B: 5-11/16 (145)

C7021B, C7023B, C7041B: 11-5/8 (295)

C7021B, C7023B, C7041C: 17-5/8 (448)

M27010A

1-13/16

(46)

7/16 (12)

1/8 NPSM (3)

3-7/8 (99)

1 (26)

11/16

(18)

5/8 (16)

M22821

5/16

(8)

SPACER SENSOR

1 (26)

7/8 (22)

3/16 (4)

3/8 IN.-16 THREAD

Sensor Resistance

Table 2. Typical Resistance of Sensor Models.

Typical Resistance (in ohms)

C7021 Sensors

(10K Ohm NTC Type II)

At 41°F (5°C) 25,392 23,467 1,020 54,200

At 50°F (10°C) 19,901 18,789 1,039 41,758

At 59°F (15°C) 15,712 15,137 1,059 32,427

At 68°F (20°C) 12,493 12,268 1,078 25,370

At 77°F (25°C) 10,000 10,000 1,097 20,000

At 86°F (30°C) 8,057 8,196 1,117 15,856

At 95°F (35°C) 6,531 6,754 1,136 12,654

C7023 Sensors

(10K Ohm NTC Type III)

C7031 Sensors

(1097 Ohms PTC)

C7041 Sensors

(20K ohm NTC)

Fig. 1. C7021B/C, C7023B/C, C7041B/C dimensions in in.

(mm).

Fig. 2. Dimensions of the C7021P, C7023P, C7041P in in.

(mm)

5.75 ± 0.25

(146)

1/8 INCH NPSM

STRAIGHT

THREADS

[8] 1/2 INCH

CONDUIT

KNOCKOUTS

SINGLE GANG

RACO COVER

[2] 1/64 (5) X 5/8 (16)

MOUNTING HOLES

2-3/32 (53)

4-3/16 (106)

FOAM PAD

1-59/64

(49)

2-19/64

(58)

1-5/32

(29)

3-57/64

(99)

M27006

Fig. 3. C7031B dimensions in in. (mm)

5 63-2590—05

Page 6

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

2-1/4 (57)

3/4

(19)

1 (25)

5

(127)

7/8

(22)

8-5/16

(211)

M22132

3-5/8 (91)

2-5/16

(59)

1-11/16

(43)

4-3/16

(107)

1/4

(6)

4

(70)

1-11/16

(43)

6-11/16 (170)

M22596

5 (127)

1/2 NPSM (13)

Fig. 4. C7031G, C7021F, C7023F, C7041F dimensions in in.

(mm).

Fig. 5. C7021D, C7023D, C7031D, C7041D dimensions in in. (mm)

NOTE: The C7021D, C7023D, C7041D uses the 50001774-

001 Well Assembly. See Fig. 4 for dimensions.

FITS 1/2 NPT TAPPED HOLE

(26)

3/4

1

(19)

(mm)

1/2 NPSM

INTERNALLY

THREADED

Fig. 6. 50001774-001 Immersion Well dimensions in in.

4 (102)

3/8 (10)

M27052

63-2590—05 6

Page 7

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

2-5/16

(59)

15/16

(23)

1-11/16

(43)

4-3/16

(107)

3/4

(19)

4

(70)

1-11/16

(43)

M22818

1-13/16

(46)

7/16 (12)

1/8 NPSM (3)

3-7/8 (99)

DEPENDING ON THE MODEL, THE ELEMENT LENGTH IS EITHER 12 FT (366 CM) OR 24 FT (732 CM).

1

1

2-5/16

(59)

4-3/16

(107)

4

(70)

1-11/16

(43)

7-1/8 (182)

9/16 (14)

1-1/2

(38)

1-1/2

(38)

2-5/16

(59)

M22134

1-1/4

(32)

5 (127)

MAXIMUM PIPE DIAMETER SHOWN.

MINIMUM PIPE DIAMETER: 1-5/8 (41)

1

1

4-3/16 (107)

COPPER PLATE

FOAM PAD

Fig. 7. C7021R, C7023R, C7041R dimensions in in. (mm).

Fig. 8. C7021K, C7023K, C7041K dimensions in in. (mm).

7 63-2590—05

Page 8

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

CAUTION

2-5/16

(59)

1(25)

1-11/16

(43)

4-3/16

(107)

4 THERMISTORS PLACED

ON A 12 FOOT (3.7M) WIRE.

4

(70)

1-11/16

(43)

M22133

PROBE

1 X Ø 1/32 (1)

CONDUCTOR CABLE

POTTING MATERIAL LEVEL

0.063 MAX. FROM TOP OF PROBE

6 FT ± 6 IN (1829 ±152)

Fig. 9. C7021N, C7023N, C7041N dimensions in in. (mm).

Fig. 10. C7021J, C7023J, C7031J, C7041J dimensions in in.

(mm).

INSTALLATION

STRIP LENGTH

2X 1/4 (6)

2 ± 1/2 (51 ± 13)

M33019

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Mounting

The method of mounting depends on the particular application

of the temperature sensor. The following procedures include

outdoor, duct, immersion well and strap-on applications. Also

refer to the instructions for the electronic control.

Outdoor Mounting (C7031G, C7021F,

C7023F, C7041F)

The C7031G, C7021F, C7023F and C7041F sense outdoor air

temperature. Mount this control where it can sense average

outdoor air temperature. Normally, the north side of a building

provides a suitable location.

NOTE: These sensors are weatherproof for outdoor use.

Knockouts allow for 1/2 in. conduit connection.

1. Remove and set aside the wiring box cover.

2. Mount the sensor to standard 1/2 in. conduit.

NOTE: Mount sensor so that the element points down.

3. Make wiring connections using two wire nuts.

4. Reattach the wiring box cover.

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

63-2590—05 8

Duct Mounting

The C7031B, C7031J, C7021B/C/J, C7023B/C/J, C7041B/C/J

can be mounted in a duct to sense air temperature.

IMPORTANT

Select a spot for the sensor where it will be exposed

to average duct air temperature. Avoid locations

where stratification can cause sensing errors.

C7021B,C/C7023B/C, C7041B/C MOUNTING

1. Cut a hole in the duct just large enough to accept the

sensing element.

2. Use the sensor case to mark the locations of the pilot

holes for the mounting screws.

3. Drill the pilot holes and fasten the sensor to the duct.

Page 9

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

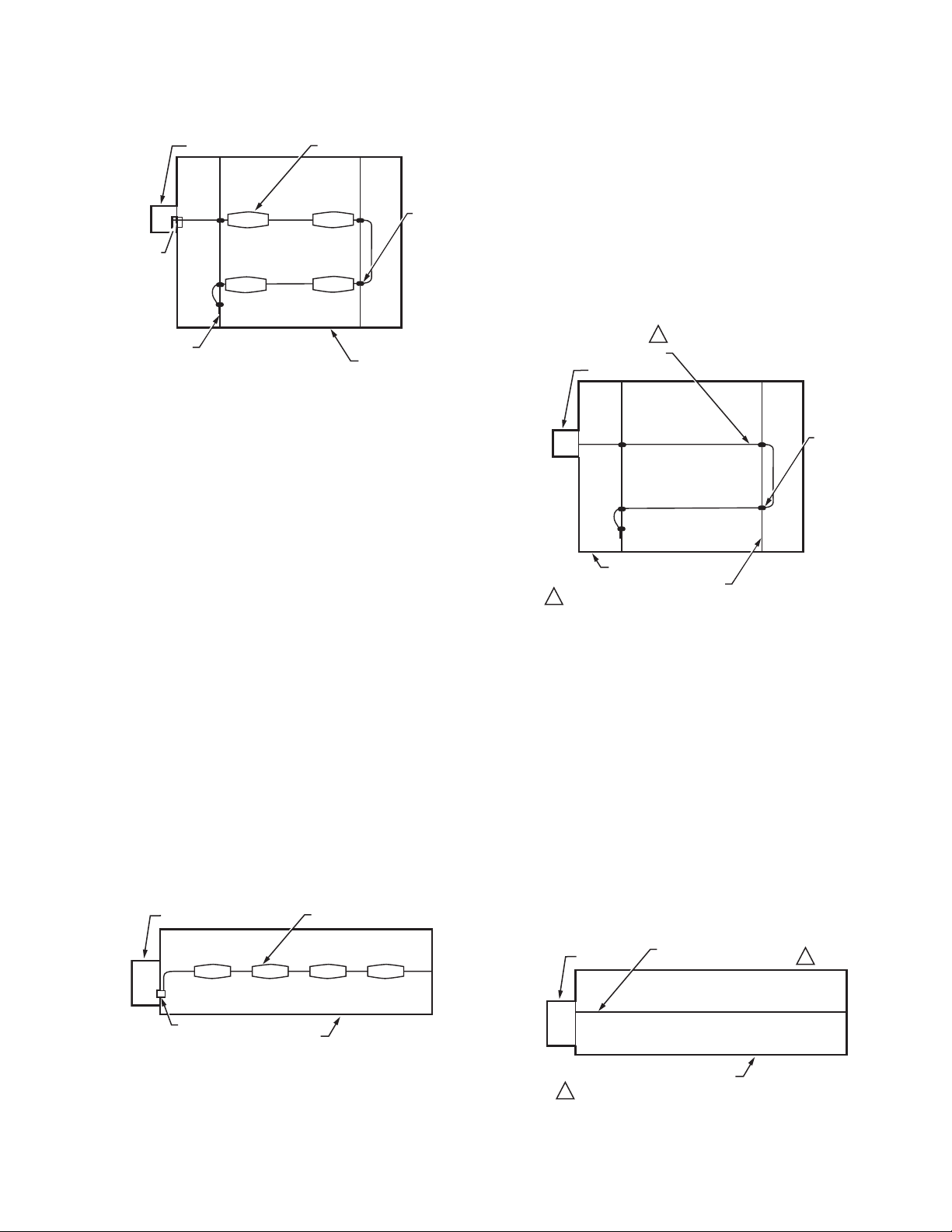

M8929A

SENSING ELEMENTS (4)

DUCT

GROMMET

(NOT

INCLUDE)

SENSOR

SUPPORTS (2)

PLASTIC

TIES (5)

A

M22820

COPPER TUBING

WITH SENSING

ELEMENTS (4 OR 9)

DUCT

SENSOR

SUPPORTS (2)

PLASTIC

TIES (5)

NUMBER OF ELEMENTS DEPENDS

ON LENGTH OF COPPER TUBING.

1

1

M22819

DUCT

SENSOR

COPPER TUBING WITH

SENSING ELEMENTS (4 OR 9)

NUMBER OF ELEMENTS DEPENDS

ON LENGTH OF COPPER TUBING.

1

1

C7021J, C7023J, C7031J, C7041J MOUNTING

Fig. 11. Duct cross section showing method of installing

C7021J, C7023J, C7031J, C7041J Averaging Electronic

Sensor.

1. Install two supports inside the duct to hold the averaging

element.

2. Cut a 7/8 in. (22 mm) hole in the side of the duct to insert

the averaging element.

3. Fasten the terminal box to the outside of the duct and

thread the element through the hole and into the duct.

4. Use plastic wire ties to fasten the element to supports.

Seal the hole around the element with a rubber

grommet.

5. Secure the end of the element to the duct on the

support to prevent continuous flexing or abrasion.

C7021R, C7023R, C7041R MOUNTING

1. Install two supports inside the duct to hold the

averaging element.

2. Cut a 7/8 in. (22 mm) hole in the side of the duct.

3. Insert the averaging element into the duct through the

hole.

4. Fasten the terminal box to the outside of the duct and

thread the element through the hole and into the duct.

5. Use plastic wire ties to fasten the element to the

supports. Seal the hole around the element with a rubber

grommet.

6. Secure the end of the element to the duct on the

support to prevent continuous flexing or abrasion.

IMPORTANT

NOTE: When the sensor is used as a deck sensor in a

Install one C7021J, C7023J, C7031J, C7041J just upstream

from the cold deck zone dampers and the other C7021J,

C7023J, C7031J, C7041J upstream from the hot deck zone

dampers. Position the thermistors to sense the average deck

temperature.

Fig. 12. Duct cross section showing method of installing

C7021J, C7023J, C7031J, C7041J in a multizone system.

To assure that the C7021J, C7023J, C7031J, C7041J

senses average duct temperature, position the

temperature elements approximately as shown in Fig.

11. Do not allow the elements to touch or be close to

the duct sides.

multizone system, be sure to space the elements

equally in the duct midstream as shown in Fig. 12.

SENSOR

GROMMET

(NOT FURNISHED)

SENSING ELEMENTS (4)

DUCT

Fig. 13. Duct cross section showing method of installing

C7021R, C7023R, C7041R Averaging Electronic Sensor.

IMPORTANT

To ensure that the C7021R, C7023R, C7041R senses

average duct temperature, position the temperature

elements approximately as shown in Fig. 13. Do not

allow the elements to touch or be close to the duct

sides.

NOTE: When the sensor is used as a deck sensor in a

multizone system, be sure to space the elements

equally in the duct midstream as shown in Fig. 14.

Install one C7021R, C7023R, C7041R just upstream from the

cold deck zone dampers and the other C7021R, C7023R,

C7041R upstream from the hot deck zone dampers. Position

the thermistors to sense the average deck temperature.

M8928

Fig. 14. Duct cross section showing method of installing

C7021R, C7023R, C7041R in a multizone system.

9 63-2590—05

Page 10

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

1/2 NPT (13)

M22135

SENSING ELEMENT

(SEALED IN STAINLESS STEEL

TUBE INSIDE OF INSERTION WELL)

M22136

SENSOR

PIPE

COPPER PLATE MUST

MAKE GOOD CONTACT

WITH METAL PIPE

WORM GEAR

Immersion Well Mounting (C7021D,

C7023D, C7031D, C7041D)

The C7031D Sensor includes an immersion well. The C7021D,

C7023D, and C7041D sensors do not include a well. For the

C7021D, C7023D, and C7041D, order the well as an

accessory (part no.: 50001774-001).

When used on a boiler, follow the manufacturer instructions for

location. If a tapped hole is not provided for the immersion well,

provide one as follows:

1. Drain boiler and drill a 23/32 in. (18 mm) hole at the

selected location.

2. Cut threads in the hole with a 1/2 in. (13 mm) by 14 NPT

tap.

In other installations, mount the immersion well in an elbow

with a heel outlet as shown in Fig. 15.

1. Drain the system, if you have not already done it, and

open the tapped hole.

2. Put pipe joint compound on the threads of the

immersion well and screw it into the tapped hole or

elbow, tightening it securely.

3. Refill the system and check for leaks.

Mount the C7021D, C7023D, C7031D and C7041D into the

well:

NOTE: Mounting using previously installed Honeywell

wells (part no.: 32005960-001) requires an

adapter (part no.: 50001775-001).

makes contact before mounting (remove insulation from the

pipe at the point of installation if necessary). Thermal

compound is recommended with the strap-on C7021K,

C7023K, C7041K Sensor. Locate the sensor on the discharge

pipe within 3 feet (0.9m) of the boiler. See Fig. 16.

Fig. 16. Strap-on mounting of C7021K, C7023K, C7041K

Sensor.

NOTE: Insulation around the contact area increases sensor

accuracy.

1. When an adapter is required, first thread it into the well

no more than one or two turns.

2. Slide the sensor into the well.

3. Rotate the sensor to thread it tightly into the adapter and

the adapter tightly into the well.

Fig. 15. Method of mounting C7021D, C7023D, C7031D,

Strap-On Mounting (C7021K, C7023K,

C7041K)

Strap-on mounting is well-suited for retrofit applications where

installation costs can be reduced by not draining the system.

The C7021K, C7023K, C7041K Sensor mounts on metal pipes

from 1-5/8 inch to five inches in diameter using the straps

supplied. Clean the surface of the pipe where the sensor

C7041D Sensor.

Button Probe Mounting

The C7021P, C7023P, C7041P Button Probe Sensor design

simplifies mounting into a variety of standard structural

materials.

The locking nut can be used to secure the probe. See Fig. 18.

The plastic spacer helps insulate the probe from drywall, wood,

or other material in which the probe is mounted. The spacer is

sized to fit snugly into 1/2 in. metal conduit. See Fig. 17.

NOTES:

— The plastic spacer is threaded for easy installation.

— Use of both the locking nut and spacer requires

cutting spacer to shorter length.

C7041P MOUNTING RECOMMENDATIONS

Determine the proper location based upon the following:

— Mount the probe to an inside wall approximately 54 in.

(1372 mm) from the floor (or in the specified location) to

allow exposure to the average zone temperature.

— Do not mount the probe to an outside wall, a wall containing

waterpipes, or near air ducts.

— Avoid locations exposed to register discharge air, or

radiation from lights, appliances, or the sun.

M22797

Fig. 17. Mounting sensor in conduit.

63-2590—05 10

Page 11

Fig. 18. Mounting sensor in wall with nut only.

CAUTION

CAUTION

M22799

WALL

Bullet Probe Sensor Mounting (C7021N,

C7023N, C7041N)

The bullet probe sensor is a water-resistant sensor that

provides a cost-effective solution for surface contact

temperature measurement of conditioned water pipes, low

pressure steam or refrigerant lines. These sensors are ideal for

applications where immersion wells are not practical to install.

These sensors can also be use to sense air temperature.

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

IMPORTANT

1. All wiring must agree with applicable codes,

ordinances and regulations.

2. Do not mount sensor in incorrect environment.

3. Wire according to the applicable controller

instructions.

OPERATION AND CHECKOUT

Operation

The C7041 Temperature Sensors are designed for use with

XL500, XL100, XL50, XL15, XL10, and Honeywell LCBS

Controllers or any controller requiring 20K ohm NTC

non-linear input. As the temperature at the C7041 Sensor

increases, the resistance of the sensor decreases, causing the

controller to operate and offset the temperature change.

The C7021 Temperature Sensors are designed for use with the

TB7600, TB7300, and TB7200 Series Communicating

Thermostats or any controller requiring a 10K ohm NTC Type II

input.

The C7023 Temperature Sensors are designed for use with

WEBs-AX I/O Modules or any controller requiring a 10K ohm

NTC Type III input.

WIRING

Erratic System Operation Hazard.

Failure to follow proper wiring practices can

introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive

loads such as motors line starters, lighting ballasts,

and large power distribution panels.

Shielded cable is required in installations where these

guidelines cannot be met.

Ground shield only to grounded controller case.

Checkout

Refer to the applicable controller instructions when checking

out the complete heating and cooling systems.

To check out the sensors, move the thermostat or remote

setpoint potentiometer below the temperature of the cooling or

heating medium. Watch the motor, valve or damper for the

correct movement.

11 63-2590—05

Page 12

SERIES 2000 ELECTRONIC TEMPERATURE SENSORS

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2011 Honeywell International Inc.

63-2590—05 M.S. Rev. 08-11

Printed in United States

Loading...

Loading...