Page 1

C7005A,B

Gas Pilot and Flame Rod Assemblies

PRODUCT DATA

FEATURES

• Used with Honeywell controls using the flame

rectification principle.

• C7005A is for continuous pilot applications. It includes

an insulated flame rod, properly positioned relative to

the flame retention type nozzle.

• C7005B is similar to C7005A, but includes an ignition

electrode suitable for automatic, electric-spark

ignition, gas pilot applications.

• Individually mounted flame rod and ignition electrode

in ceramic insulators allow the head assembly to fit

inside a 3-inch pipe.

• Stainless steel fins on the flame retention type pilot

head provide the correct ratio of flame rod area to

ground area for maximum flame signal, and are

beneficial in stabilizing the pilot flame.

GENERAL

The C7005A,B Gas Pilot Burner Assemblies include a flame

rod to prove the pilot flame. The assemblies are used with a

suitable flame safeguard control on industrial or commercial

gas burners or oil burners with gas pilots.

• Pilot flame retention nozzle and mixing tube are

threaded internally, 1/2-14 NPT and 3/8-18 NPT,

respectively, and can be assembled with standard pipe

fittings.

• Pilot can be installed in vertical, horizontal, or inclined

position.

• Rajah connectors facilitate electrical connections.

Contents

General ............................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Installation ........................................................................... 3

Adjustments and Checkout ................................................. 5

Operation ............................................................................ 8

Copyright © 1995 Honeywell Inc. • All Rights Reserved

60-2033-3

Page 2

C7005A,B GAS PILOT AND FLAME ROD ASSEMBLIES

SPECIFICA TIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed

specifications. Also, this product is tested and

calibrated under closely controlled conditions, and

some differences in performance can be expected if

those conditions are changed.

Models:

C7005A Gas Pilot and Flame Rod Assembly—for

continuous pilot applications; includes flame rod only.

C7005B Gas Pilot and Flame Rod Assembly—for

automatic pilot applications; includes flame rod and

ignition electrode.

Pilot Head:

Flame retention type with stainless steel bomb type fins.

Threaded onto 1/2 x 6 inch (152 mm) pipe nipple with

1/2-14 NPT external threads.

Type of Gas:

Models available for use with natural and propane gases.

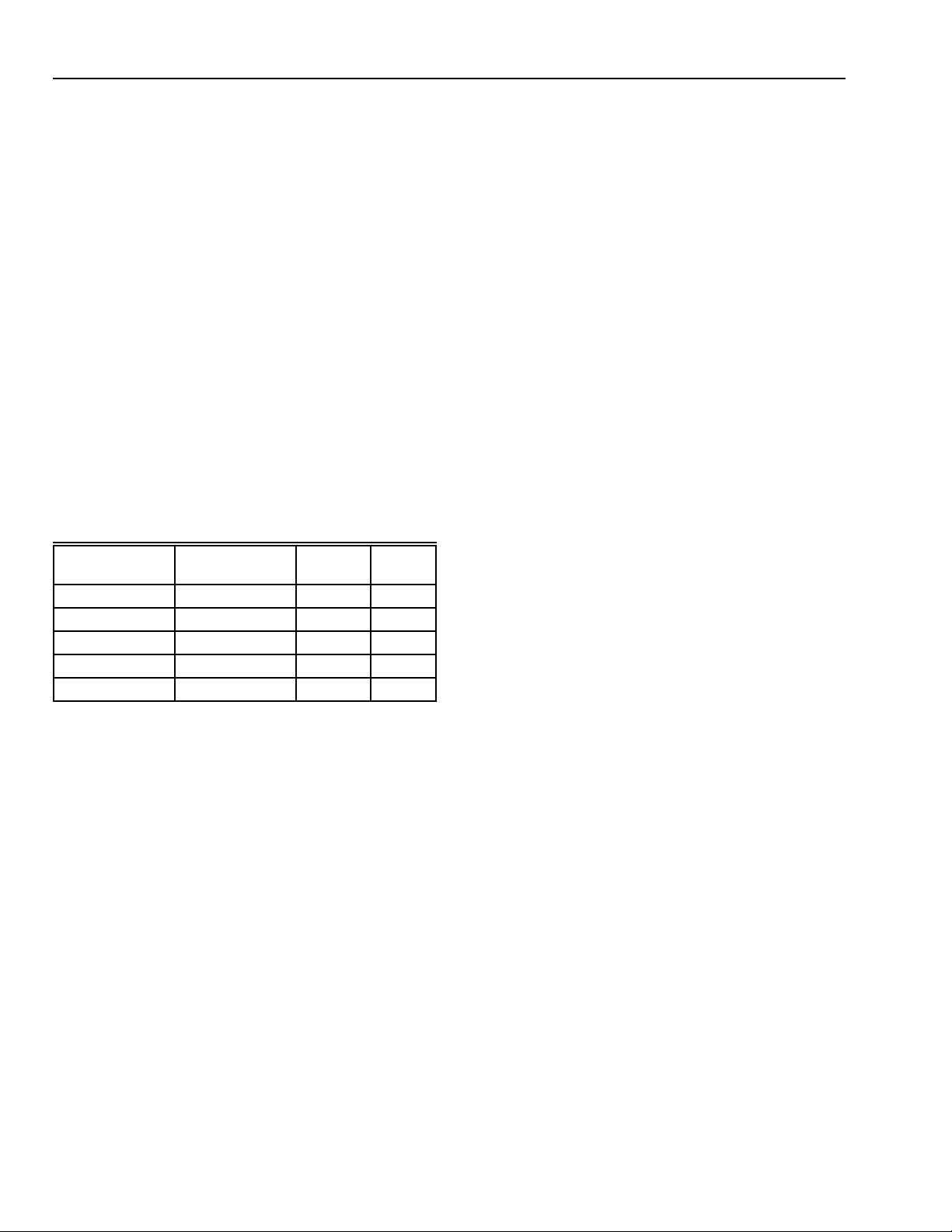

Gas Capacity (Varies with Gas Pressure):

Gas Pressure

in. wc

3 0.75 12.0 0.34

4 0.99 13.7 0.39

5 1.24 15.3 0.43

6 1.49 16.8 0.48

7 1.74 18.2 0.52

Flame Rod/Ignition Electrode Insulators:

Ceramic.

Maximum Temperature at Flame Rod Insulator:

500°F (260°C).

Capacity

kPa ft

3

/hr m3/hr

Flame Rod/Ignition Electrode Material:

Kanthal A-1 (2462°F [1350°C] maximum operating

temperature rating).

Optional: Stainless steel (2000°F [1093°C] maximum

operating temperature rating).

Electrical Connectors:

Rajah, male; companion connectors included.

Insulator Brackets:

Adjustable to change location of flame rod or ignition

electrode; lock securely using setscrew.

Mixing T ube:

Inspirating (Venturi type) with primary air adjustment.

Approximately 4-9/16 inches (116 mm) long, 1-3/4 inches

(44.5 mm) diameter. Inlet tapping 1/4-18 NPT; outlet tapping

3/8-18 NPT.

Mounting:

Vertical, horizontal, or inclined.

Dimensions:

Overall—Height 13-1/2 inches (343 mm); width can be

adjusted to pass through a 3-inch pipe.

Pilot Head—Length 4-7/16 inches (113 mm), diameter

1-5/8 inches (41.3 mm).

Spark Gap (C7005B only—1/8 to 3/16 inch (3.2 to

4.8 mm).

Approvals:

Underwriters Laboratories Inc. Listed: File No. MP268.

Canadian Standards Association Certified: C7005 only—

Master file LR-95329—1.

Industrial Risk Insurers acceptable.

Accessories;

• High Temperature Cable (for operation above 125°F

[52°C])—specify length:

— R1298020 Flame Rod Leadwire, rated up to 400°F

(204°C) for continuous duty.

— R1061012 Ignition Leadwire, rated at 350°F (176°C) for

continuous duty.

— R1239001 High Tension Ignition Leadwire, for

installations in a contaminating environment, rated at

200°F (93°C) for continuous duty.

ORDERING INFORMATION

When purchasing replacement and modernization products from your Authorized Flame Safeguard Distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

1. Order number.

2. High temperature cable, if required (specify length).

3. Ignition transformer, if required (C7005B only).

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitee, 740 Ellesmere Road, Scarborough, Ontario M1P 2V9 International Sales

and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2033—3

2

Page 3

C7005A,B GAS PILOT AND FLAME ROD ASSEMBLIES

• Ignition Transformer, 6000 volts secondary (C7005B only):

— Part no. 22042; 120V, 60 Hz primary.

— Part no. 101079; 240V, 60 Hz primary.

Replacement Parts:

100204B Mixing Tube (Venturi type used with natural gas).

101867B Mixing Tube (Venturi type used with LP gas).

100205B Grounding Assembly

101738A Ignition Assembly—includes electrode, Rajah

connector and bracket (C7005B).

101738B Flame Rod Assembly.

101739 Ignition Electrode, 4 inch (102 mm), stainless

steel (C7005B).

101740 Flame Rod, 8 inch (203 mm) stainless steel.

103534 Flame Rod, 8 inch (203 mm) Kanthal.

101741 Connector—Rajah, plug end, 7/8 inch long.

101742 Clamp—for flame rod or ignition electrode mounting.

101743 Bracket—mounting.

14182 Washer—brass (plain), between Rajah connector

and flame rod or ignition electrode mounting.

37356 Connector—Rajah, socket end straight.

7617CV Insulator Assembly—includes electrode insulator

and mounting hardware.

INSTALLATION

CAUTION

1. Installer must be a trained, experienced, flame

safeguard control service technician.

2. Turn off the gas supply before beginning

installation.

3. Disconnect power supply to the flame safeguard

control before beginning installation to prevent

electrical shock and equipment damage. There

may be more than one disconnect involved.

4. All wiring must comply with applicable local

electrical codes, ordinances, and regulations.

5. All wiring must be NEC Class 1 (line voltage).

6. Perform all required checkout tests after

installation is complete.

Mounting

If special provisions for mounting the pilot were made by the

burner manufacturer, carefully follow those instructions. If the

manufacturer did not supply instructions, use the

recommendations below.

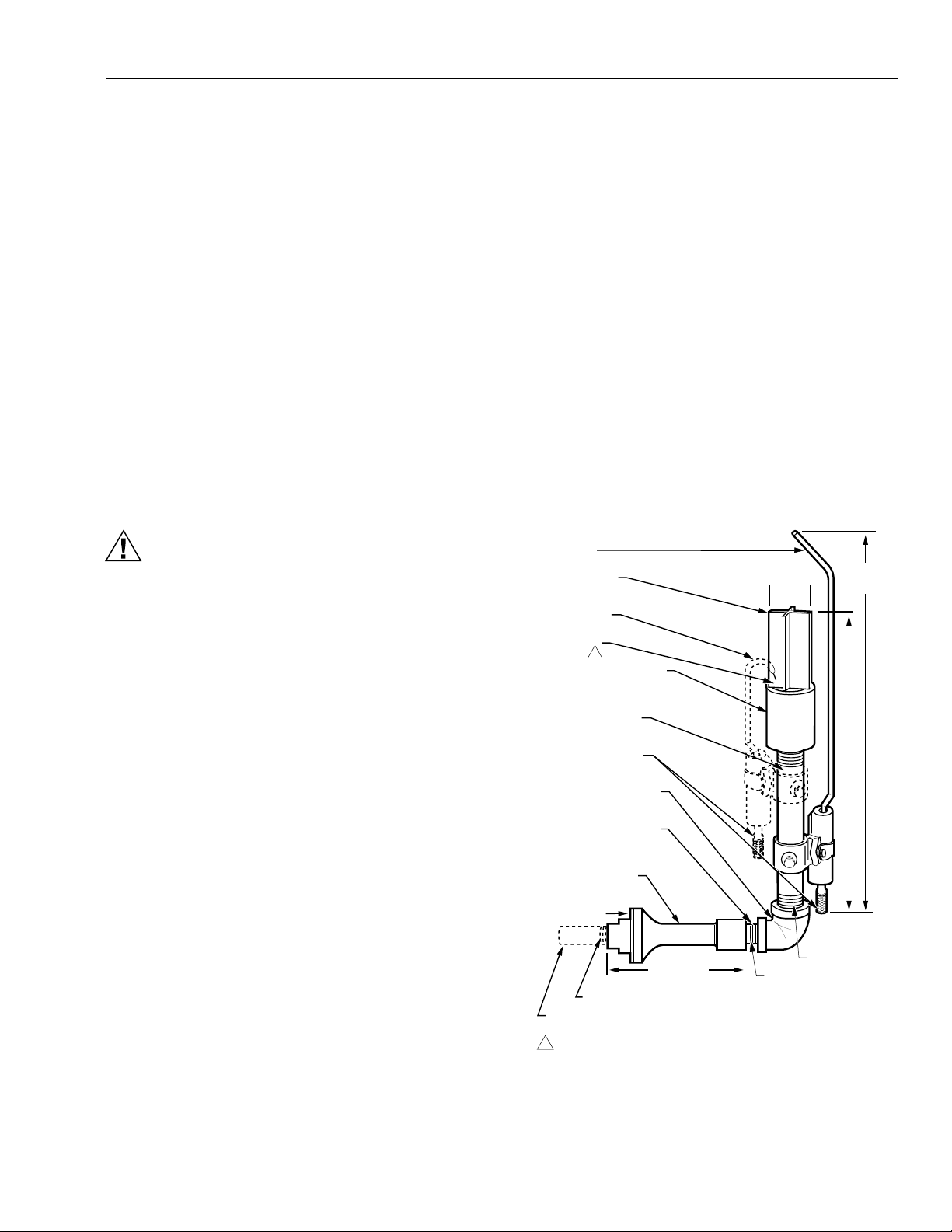

Fig. 1 illustrates the use of a 90 degree reducing elbow (not

furnished) to provide a right-angle connection. Use a straight

reducing coupling or a 45 degree reducing elbow (not

furnished) for piping and mounting if more convenient.

Position the flame rod so that a weak pilot flame contacts the

flame rod only at the junction of the main burner flame and

pilot flame.

weak pilot flame that is incapable of igniting the main burner

(Fig. 2).

IMPORTANT

Do not position the flame rod so it can detect a

To assure an adequate pilot flame to ignite the main

burner, you MUST perform the pilot turndown test,

as described in the instructions for the flame

safeguard control.

Install the pilot so the pilot flame has full contact with the gas

stream from the main burner heads, jets or nozzles (Fig. 3,

4, 5). If it is necessary to prove both pilot and main flames,

mount the pilot so the flame travels in the same direction as

the air movement at the mounting point, rather than where

the air movement is at right angles to the flame travel. The

pilot should be mounted far enough forward so that the flame

rod just enters the envelope of the main burner flame. The

pilot can be mounted either beside or below the burner head.

Keep the pilot burner below or behind the main burner so that

the burner frame and refractory help protect the pilot from

radiant heat. Locating the pilot in the secondary airstream

also provides considerable cooling. The primary air

adjustment must be accessible and outside the high

temperature area.

On radiant type burners, the pilot is often mounted outside

the burner box. Fig. 3 shows the pilot assembly in a diagonal

channel cut through the brickwork and a straight-through

connection used to support the pilot. The flame rod is at the

junction of the main burner flame and pilot flame. The pilot

assembly can be mounted below or alongside the burner box

and an angle connection used so the pilot flame travels into

the main flame. The air mixer is normally mounted outside the

boiler.

FLAME ROD

FLAME GROUND

IGNITION ELECTRODE

(C7005B ONLY)

SPARK GAP

FLAME RETENTION NOZZLE

1/2 X 6 INCH (152.4 mm)

PIPE NIPPLE (1/2 -14 NPT

EXTERNAL THREADS)

RAJAH CONNECTORS

1/2-14 NPT X 3/8-18 NPT

ELBOW (NOT FURNISHED)

3/8-18 NPT PIPE

NIPPLE (NOT FURNISHED)

MIXING TUBE

(3/8-18 NPT X 1/4-18 NPT

INTERNAL THREADS)

PRIMARY AIR

ADJUSTMENT

1

1

4-9/16 (115)

1/4-18 NPT

PIPE (NOT FURNISHED

SPARK GAP BETWEEN IGNITION ELECTRODE AND GROUND MUST BE

1/8 TO 3/16 INCH (3.2 TO 4.8 mm).

)

1-1/2

(31)

3/8-18 NPT

13-1/2

(342)

9-3/4

(247)

1/2-14 NPT

M3035A

Fig. 1. C7005 gas pilot and flame rod

assembly in in. (mm).

3

60-2033—3

Page 4

C7005A,B GAS PILOT AND FLAME ROD ASSEMBLIES

THE FLAME ROD SHOULD BE LOCATED

NOTE:

ON EITHER SIDE OR BELOW THE PILOT.

WRONG

Fig. 2. Improper position of flame rod.

M3038

M3036

Fig. 4. T ypical mounting of gas pilot and flame rod

assembly on multiple head gas burner.

MAIN BURNER

M3037

Fig. 3. T ypical mounting of gas pilot and flame rod

assembly on radiant inshot type burner.

On multiple head installations (Fig. 4), the pilot is usually

centrally located. The pilot can usually be mounted vertically

between burner heads with the pilot flame traveling upward

across the junction of the gas stream from the burner heads.

If the pilot is mounted horizontally on a level with the burner

heads or the flat arch, the pilot flame should travel across the

junction of the gas streams coming from at least two heads.

If a group of inspirating (Venturi type) burners are mounted

within a burner box, sufficient spacing is usually available so

the pilot can be mounted as illustrated in Fig. 5 to

simultaneously light as many burners as possible. If available

space does not allow central mounting within the burner box,

see Fig. 3.

60-2033—3

C7005 GAS PILOT AND

FLAME ROD ASSEMBLY

PRIMARY

IGNITION

TRANSFORMER

FURNACE

Fig. 5. T ypical mounting of gas pilot and flame rod

assembly on inspirating (Venture type) gas burner.

Wiring

CAUTION

1. Turn off gas supply before starting installation.

2. Disconnect power supply before beginning

installation to prevent electrical shock and

equipment damage. There may be more than one

disconnect involved.

4

M3039

Page 5

All wiring must comply with applicable electrical codes,

FLAME

ROD

IGNITION

ELECTRODE

(C7005B ONLY)

PILOT

HEAD

BURNER

GROUND

CASE

GROUND

6000 VOLT

IGNITION

TRANSFORMER

SECONDARY

PRIMARY

F

L2

HIGH TENSION

TERMINAL

FLAME

SAFEGUARD

CONTROL

M3034

ordinances, and regulations. Use NEC Class 1 (Line

Voltage) wiring.

For normal installations:

For the ignition electrode,

•

use high tension wire

electrically equivalent to type GTO-10, and rated

for the temperature and humidity encountered in

the application.

For the flame rod,

•

use moisture-resistant no. 14

AWG wire suitable for at least 167°F (75°C) if

used with a flame safeguard primary control, or

suitable for at least 194°F (90°C) if used with a

flame safeguard programming control.

For high temperature installations:

For the ignition electrode,

•

use Honeywell

specification no. R1061012 Ignition Cable or

equivalent. (This wire is rated at 350°F (176°C)

for continuous duty, and up to 500°F (260°C) for

intermittent use. It has been breakdown tested to

15,000 volts.)

For the flame rod,

•

use Honeywell specification

no. R1298020 or equivalent. This wire is rated up

to 400°F (204°C)for continuous duty. It is tested

for operation up to 600 volts and breakdown up to

7500 volts.

For ignition installations in a contaminating environment,

Honeywell specification no. R1239001 High Tension Ignition

Cable or equivalent. This wire is very resistant to severe

conditions of oil, heat, and corona, and is tested to withstand

high voltages up to 25,000 Vrms in a salt bath for one minute

without breakdown. It is rated at 200°F (93°C) for continuous

duty, and up to 350°F (176°C)for intermittent use.

Make connections to the flame rod and ignition electrode

(C7005B) using Rajah connectors. See Fig. 6 for typical field

wiring connections.

Connect the flame rod (see callout 1, Fig. 1) to the F terminal

of the flame safeguard control. Keep this leadwire as short as

possible; capacitance increases with leadwire length,

reducing the flame signal strength.

is the flame signal

(see Table 1).

The ultimate limiting factor

For a C7005B:

• Use a 6000 volt ignition transformer with the

same electrical ratings as the power supply of the

flame safeguard control. Select the appropriate

Honeywell transformer, or its equivalent.

— For 120V, 60 Hz, use part no. 22042.

— For 240V, 60 Hz, use part no. 101079.

• Connect the primary leadwires of the ignition

transformer between the ignition and the L2

terminals of the flame safeguard control.

• Connect the ignition electrode of the C7005B

(callout 3, Fig. 1) to the secondary high tension

terminal of the ignition transformer.

use

C7005A,B GAS PILOT AND FLAME ROD ASSEMBLIES

Fig. 6. T ypical field wiring diagram for C7005

gas pilot and flame rod assembly .

IMPORT ANT

Do not run high voltage ignition transformer wires in

the same conduit with the flame rod wiring.

No ground leadwires are required. The flame ground and

flame retention nozzle (callouts 2 and 4, Fig. 1) act as the

ground electrode for the flame rod and the ignition electrode.

The case of the ignition transformer will act as the ground

connection when it is securely fastened to the burner.

ADJUSTMENTS AND CHECKOUT

Adjust the Air-Gas Mixture

IMPORT ANT

For initial burner lightoff, consult the burner

manufacturer’s instructions or the instructions for the

flame safeguard control.

With the gas pilot installed and the pilot burner running, adjust

the primary air adjustment (callout 10, Fig. 1) for an air-gas

mixture that provides the type of flame required for the

particular installation. Be sure you have the proper mixing

tube for the type of gas (natural or LP) being used. A

medium-hard flame generates the greatest response from the

flame detector circuit.

If air movement conditions are severe or change with

modulation, it may be desirable to operate the premixed pilot

on moderate to high gas pressure (normally not more than

one psi). This is particularly true when the main burner fires

with high pressure gas. Increasing the pilot pressure tends to

harden and lengthen the pilot flame, increasing its stability

under adverse draft conditions.

5

60-2033—3

Page 6

C7005A,B GAS PILOT AND FLAME ROD ASSEMBLIES

Adjust Flame Rod Position

The pilot flame must make good contact with the flame rod

and furnish reliable ignition for the main burner. Check to be

sure that the flame rod is located at the junction of the main

burner flame and the pilot flame. Ensure that the main valve

opens or unlocks only when the pilot flame is strong enough

to ignite the main burner.

Secondary air velocity over the pilot nozzle must not cause

unstable flame contact with the flame rod, because this

produces chattering of the flame detector relay.

Measure the Flame Signal

With the pilot and main burner(s) operating, adjust the position

of the flame rod for optimum flame signal (current or voltage).

Most existing Honeywell flame safeguard controls incorporate

a flame signal jack located on the control amplifier or on the

control itself. These controls require a Honeywell W136A Test

Meter (see Fig. 7) or its equivalent for measuring the flame

signal in microamperes. The flame signal (current) is

measured by the following procedure:

A Use a Honeywell W136A Test Meter. (If a W136A is not

available, a microammeter with a 0 to 25 microamp dc

range can be used.)

W136A TEST

METER

SELECTOR

SWITCH

196146 METER

CONNECTOR

PLUG

D Insert the plug into the flame signal meter jack and

allow a few seconds for the meter reading to stabilize.

E When using a RA890H,J self-checking flame safeguard

control, press the test button on the control to stabilize

the current reading while making the measurement.

The green flame indicating lamp should be on

continuously while reading the flame signal.

stable

F Read the average

current. For an R7247B

self-check rectification amplifier (AMPLI-CHECK™),

disregard the peaks due to self-checking operation. The

red flame-indicating lamp on an R7247B should blink

about 2-1/2 to 4 times a second (from bright to dim). If

the lamp is on or off continuously while reading the

flame signal, replace the amplifier.

POSITIVE (+)

NEGATIVE (-)

METER LEAD

METER LEAD

ONE

MEGOHM/VOLT

METER

PLUG

FLAME SIGNAL

METER JACK

PLUG-IN FLAME

RED (+)

METER

LEAD

SIGNAL AMPLIFIER

RED CONNECTOR

BLACK CONNECTORBLACK (–) METER LEAD

M6532

Fig. 7. Measuring microamp flame signal.

B Set the selector switch on the test meter to 25 uA for all

standard amplifiers and flame safeguard controls, or to

SPL for an R7247B AMPLI-CHECK™ self-check

rectification amplifier. (If the test meter is not a W136A,

shunt the 0 to 25 microamp dc range with a 50

microfarad capacitor.)

C Use a 196146 Meter Connector Plug (ordered

separately). Connect the red spade tip to the red (+)

meter lead and the black spade tip to the black (–)

meter lead.

M7382

Fig. 8. Measuring flame signal voltage

of 7800 SERIES control.

G The meter reading must be as specified in Table 1 after

all tests are completed and all adjustments are made.

With the Honeywell 7800 Series controls, the flame signal is

measured in Vdc. The voltage flame signal measurement

requires a volt-ohmmeter with a minimum sensitivity of one

megohm/volt and a 0 to 5 or10 Vdc scale. To make the flame

signal measurement on 7800 SERIES controls, use the

following procedure:

A Set the meter to the appropriate scale.

B Insert the positive (red) meter probe into the positive (+)

jack of the 7800 SERIES control amplifier and the

negative (black) probe into the negative (-Com) jack of

the amplifier (see Fig. 8).

C Allow a few seconds for the meter reading to stabilize.

D When using an AMPLI-CHECK™ amplifier, read the

average stable voltage and disregard the peaks due to

the self-check operation.

E The flame signal voltage must be at least the minimum

acceptable voltage as indicated in Table 1.

F If the 7800 SERIES control has the optional Keyboard

Display Module, the flame signal will be displayed on

the module.

60-2033—3

6

Page 7

C7005A,B GAS PILOT AND FLAME ROD ASSEMBLIES

Table 1. Flame Signal For C7005A,B.

Minimum

Flame

Signal

Amplifier

R7247A BC7000L; R4140G,L,M; R4138C,D; 2.0 5.0

R4075C,D,E

R7247B

AMPLI-

CHECK™

R7257A R4150 2.0 5.0

R7289A R4795 2.0 5.0

R7847A RM7800E,G,L,M; RM7838A,B;

R7847B

AMPLI-

CHECK™

a

Set W136A selector switch to SPL (damped) position to read current.

b

Press test button while reading current.

Measure the flame signal for the pilot alone, the main burner

flame alone, and both together (unless monitoring only the

pilot flame when using an intermittent pilot, or only the main

burner flame when using direct spark ignition). Also measure

the flame signal at high and low firing rates and while

modulating in between (as applicable). With the detector in its

final position, all required flame signals must be steady (or

stable) and as specified in Table 1.

a

BC7000L; R4140G,L,M; R4138C,D;

R4075C,D,E

RM7840E,G,L,M; RM7885A;

RM7890A,B; RM7895A,B,C,D

RM7800E,G,L,M; RM7838A,B;

RM7840E,G,L,M; RM7885A;

RM7890A,B; RM7895A,B,C,D

None RA890F, R7795B,D,F,H; R7023B,

R485

None R4181

Flame Safeguard

Control

b

Acceptable

Steady Current

(uA)

1.25 2.50

2.0 5.0

8.0 15.0

Pilot Turndown Test

If the flame rod is used to prove a pilot flame before the main

fuel valve can be opened, perform a Pilot Turndown Test.

Follow the Instruction procedures for the appropriate flame

safeguard control, and the burner manufacturer’s instructions.

Ignition Interference Test

Maximum

Expected

Current

(uA)

Minimum

Acceptable

Steady voltage

(Vdc)

1.25 5.0

1.25 5.0

Maximum

Expected

Steady voltage

(Vdc)

If the signal is unstable or less than the minimum acceptable

current, check the flame rod installation and circuitry:

• Check the supply voltage at terminals L1-L2 on the wiring

subbase or terminal strip for the flame safeguard control.

• Check the wiring for defects including:

— wrong type or size of wire.

— deteriorated wire.

— open circuits.

— short circuits.

— leakage paths caused by moisture, soot, or

accumulated dirt.

• Make sure:

— there is enough ground area.

— the flame rod is properly located in the flame.

— temperature at the flame rod insulator is no greater

than 500°F (260°C).

— ignition interference is not present (see Ignition

Interference Test below).

• Make sure that the flame adjustment is not too lean.

• If necessary, reposition the flame rod.

If you cannot obtain proper operation, replace the plug-in

amplifier if applicable. If you still cannot obtain proper

operation, replace the flame rod.

C7005B

Test to make certain that a false signal from the spark ignition

system is not superimposed on the flame signal.

Ignition interference can subtract from (decrease) or add to

(increase) the flame signal. If it decreases the flame signal

enough, it causes safety shutdown. (The flame relay will not

pull in and the flame safeguard control will act as though the

pilot or main burner, if using direct spark ignition, has not

been ignited.) If it increases the flame signal, it could cause

the flame relay to pull in when the true flame signal is below

the minimum acceptable value.

Test

Start the burner and measure the flame signal with both

ignition and pilot or main burner on, and then with only the

pilot or main burner on. Any significant difference greater than

0.5 microamp, or 0.25 Vdc with 7800 SERIES controls,

indicates ignition interference.

To Eliminate Ignition Interference

A Make sure there is enough ground area.

B Be sure the ignition electrode and the flame rod are on

opposite sides of the ground area (Fig. 1).

7

60-2033—3

Page 8

C7005A,B GAS PILOT AND FLAME ROD ASSEMBLIES

C Check for correct spacing between the ignition

electrode and ground for 6000 volt systems—1/8 to

3/16 inch (3.2 to 4.8 mm).

D Make sure the leadwires from the flame rod and ignition

electrode are not too close together.

E Replace any deteriorated leadwires.

F If the problem cannot be eliminated, consider changing

to an ultraviolet flame detection system with a

Q624A1014 solid-state spark generator.

Final Checkout

Before putting the burner into service, check out the

installation by following the Checkout procedures in the

Instructions for the appropriate flame safeguard control. After

completing the checkout, run the burner through at least one

complete cycle to verify operation.

OPERATION

The C7005B Gas Pilot and Flame Rod Assembly includes an

ignition electrode and a flame rod. The operation of these two

electrodes in a simple electrically-operated, gas pilot

installation is as follows.

At the beginning of the starting cycle, a high voltage from the

secondary winding of the ignition transformer is applied to the

ignition electrode. A spark jumps across the outlet of the pilot

burner. The pilot gas valve is either automatically or manually

opened, and the spark ignites the gas.

When the ignition transformer is energized, ac voltage is

applied to the flame rod through a flame safeguard control.

When the pilot flame appears, this ac voltage is changed to

dc voltage through a rectifying action. This dc voltage then

operates a relay, opening the valve to the main burner (or

permitting it to be manually opened). In the event of flame

failure, flame rectification stops, the gas valves are deenergized, the valves close, and the system shuts down.

Home and Building Control

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

60-2033—3

60-2033—3 Rev. 11-95 J.A. Printed in U.S.A.

Home and Building Control

Honeywell Limited-Honeywell Limitée

740 Ellesmere Road

Scarborough, Ontario

M1P 2V9

Helping You Control Your World

QUALITY IS KEY

8

Loading...

Loading...