Page 1

Gas pressure switch C6097

Technical Information · GB

4 Edition 01.19

• Monitoring of gas and air pressures (positive, negative and

differential pressures)

• Switches with falling or rising pressure.

• FM and UL certified:

With lock-off and hand wheel with "WC/mbar scale

• EU certified pursuant to EN 1854: Hand wheel with mbar scale

Page 2

Contents

Gas pressure switch C6097..........................1

Contents ............................................2

1 Application ........................................3

1.1 Use .................................................4

1.1.1 CE approved pressure switches .......................4

1.1.2 FM approved and UL listed pressure switches........4

1.2 Application examples ..............................5

1.2.1 Low gas pressure monitoring .........................5

1.2.2 Differential pressure monitoring . . . . . . . . . . . . . . . . . . . . . .5

1.2.3 Systems leak tightness check .........................5

1.2.4 Air line with minimum pressure and flow monitoring .6

1.2.5 Low and high gas pressure protection device.........6

2 Certification .......................................7

2.1 EU cer tified ........................................ 7

2.2 FM approved ....................................... 7

2.3 UL listed ........................................... 7

2.4 Overview of product approvals .................... 7

3 Function ...........................................8

3.1 Vent limiter .........................................8

3.2 Positive pressure measurement ...................9

3.3 Negative pressure measurement ..................9

3.4 Differential pressure measurement ...............9

3.5 Connection diagram ..............................11

3.5.1 Blue pilot lamp for 230 V AC or 110/120 V AC .......11

3.5.2 Red/green pilot LED for 24 V DC/AC or 110 –

230 V AC ....................................................11

3.6 Wiring .............................................12

4 Project planning information . . . . . . . . . . . . . . . . . . . . .13

4.1 Installation ........................................13

4.2 Ports ..............................................14

4.2.1 CE cer tified pressure switches ......................14

4.2.2 UL , FM certified pressure switches .................15

4.3 Resetting pressure switches with manual reset ..16

5 Accessories.......................................17

5.1 Fastening set with screws, U-shape bracket .....17

5.2 Connecting set ...................................17

5.3 Restrictor orifice ..................................17

5.4 Standard socket set...............................18

5.5 Standard coupler plug ............................18

5.6 Pilot lamp set, red or blue .........................18

5.7 LED set, red/green................................19

5.8 Cover for auto reset ...............................19

5.9 Cover for manual reset............................19

5.10 Weather protection cover ...................... 20

6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.1 General............................................21

6.2 EU certified pressure switches ...................21

6.3 UL, FM certified pressure switches ..............22

6.4 Adjusting range, switching hysteresis ............22

6.4.1 CE certified pressure switches ......................22

6.4.2 UL, FM certified pressure switches .................23

6.5 Dimensions .......................................24

6.5.1 EU certified pressure switches...................... 24

6.5.2 UL, FM certified pressure switches .................25

6.6 Converting units ..................................26

7 Maintenance cycles...............................26

Feedback ...........................................27

For more information ...............................27

C60 97 · Edition 01.19 2

= To be continued

▼

Page 3

Application

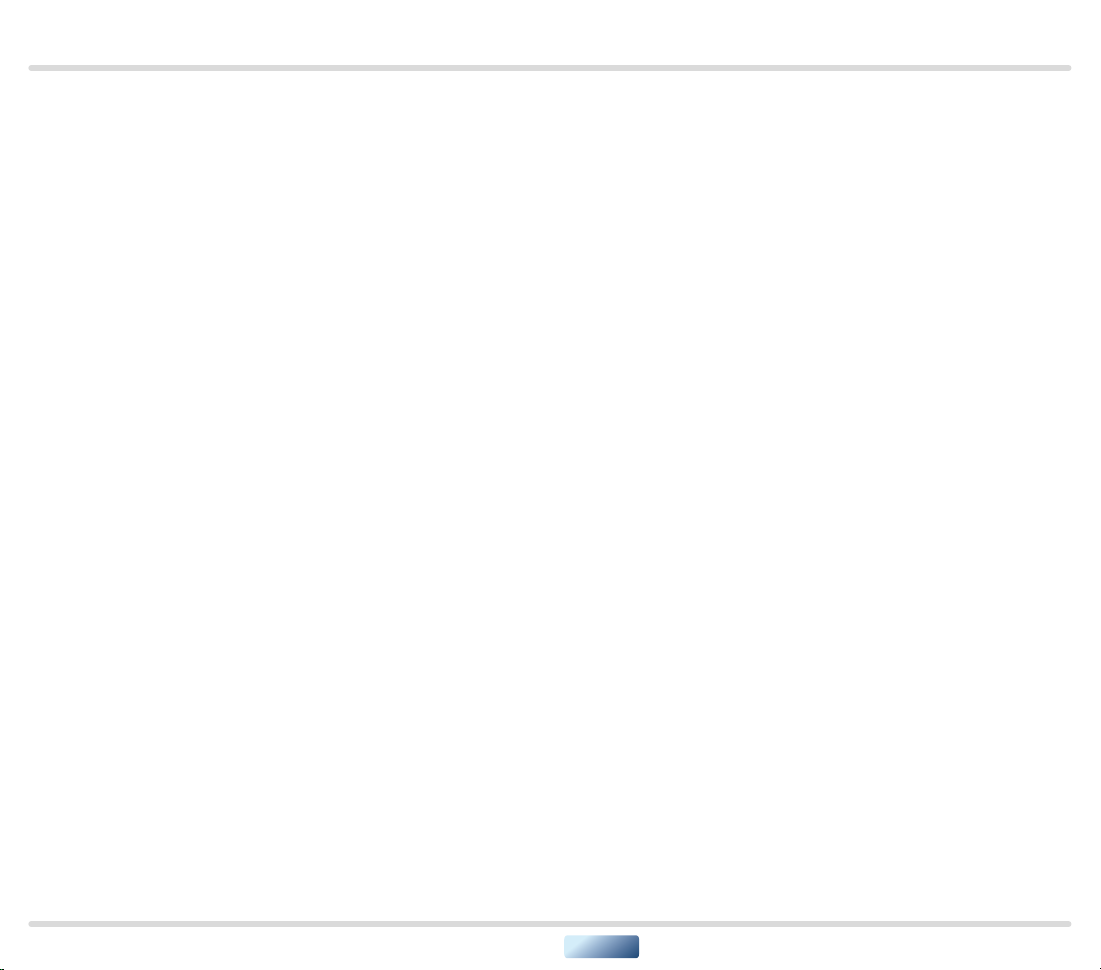

C6097 with CE approval.

Hand wheel with mbar scale.

M16 cable gland for electrical connection.

C6097 with UL listing and FM approval.

Hand wheel with "WC and mbar scale.

1/2" NPT conduit for electrical connection.

C6097 can be supplied with lock-off function.

1 Application

The pressure switch monitors extremely low pres-

sure differentials and triggers switch-on, switch-off

or switch-over operations if a set switching point is

reached.

The switching point can be adjusted using a hand

wheel.

The pressure switch monitors positive and negative gas

pressures on various industrial gas and air appliances,

such as boiler fan monitoring and differential pressure

monitoring in firing, ventilation and air-conditioning

systems.

C60 97 · Edition 01.19 3

Pressure switch C6097A switches in the event of decreasing pressure, C6097B switches in the event of

increasing pressure.

Pressure switches with manual reset lock off after

switching.

Pressure switches with an 0.2 mm (0.008") nozzle are

supplied with an integrated vent limiter, see page 8

(Vent limiter).

Page 4

Application

1.1 Use

1.1.1 CE approved pressure switches

Type Hand wheel setting/Switching properties Positive pressure Negative pressure Electrical connection

C6 097A 4110

C6 097A 4210

C6 097A 4310

C6 097A 441 0

1.1.2 FM approved and UL listed pressure switches

Type Hand wheel setting/Switching point Positive pressure Negative pressure Electrical connection

C6097A3004

C6097A3053

C6097A3079

C6097A3137

C6097A3012

C6097A3038

C6097A3095

C6097A3111

C6097B3002

C6097B3028

C6097B3051

C6097B3085

C6097B3101

C6097B3119

Hand wheel set to decreasing pressure/

C6097 switche s with rising and falling pressure

Hand wheel set to decreasing pressure/

C6097 switche s with rising and falling pressure

Hand wheel set to decreasing pressure/

C6097 switche s with falling pressure and locks of f

Hand wheel set to increasing pressure/

C6097 switche s with rising pressure and locks off

Hand wheel set to increasing pressure/

C6097 switche s with rising and falling pressure

Gas, air, flue gas or

biogas

Gas, air, flue gas or

biogas

Gas, air, flue gas or

biogas

Gas, air, flue gas or

biogas

Gas, air, flue gas or

biogas

Air, flue gas

Air, flue gas

Air, flue gas

Air, flue gas

Air, flue gas

Screw terminals and

M16 cable gland

Screw terminals

½" NPT conduit

Screw terminals and

½" NPT conduit

Screw terminals

½" NPT conduit

Screw terminals

½" NPT conduit

C60 97 · Edition 01.19 4

Page 5

Application

1.2 Application examples

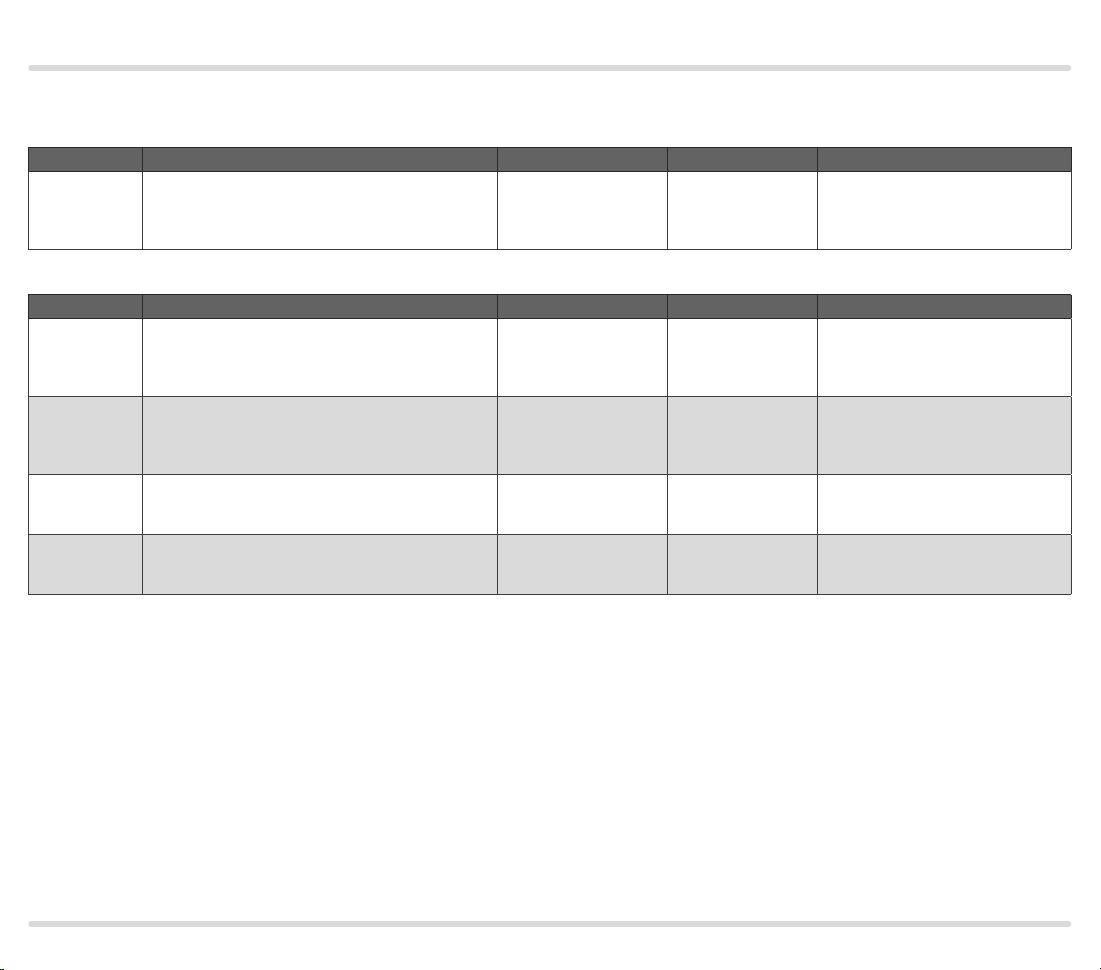

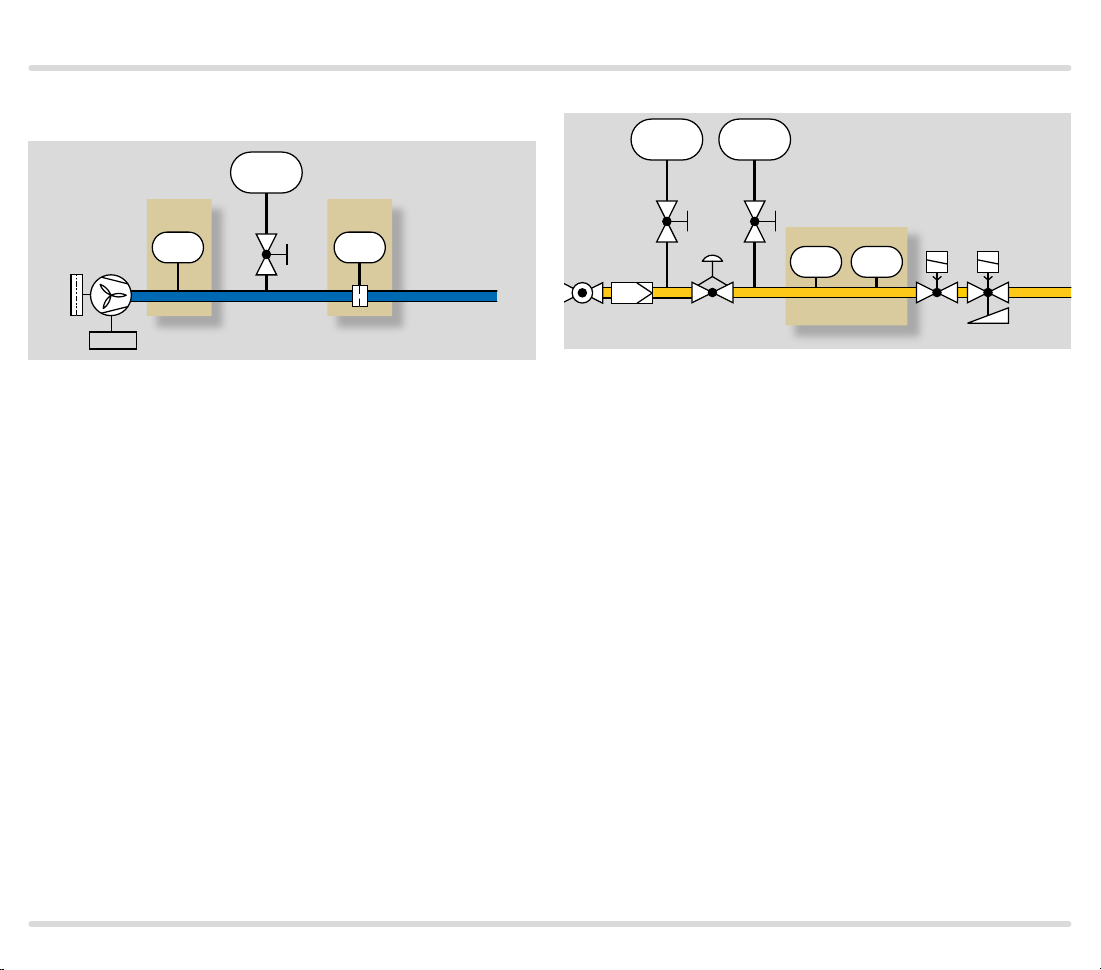

1.2.1 Low gas pressure monitoring

For monitoring the minimum gas inlet pressure

1.2.2 Differential pressure monitoring

1.2.3 Systems leak tightness check

Electronic safety shut-off valve SAV with leak tightness

check of downstream devices

Differential pressure switch for monitoring air filters

C60 97 · Edition 01.19 5

Page 6

Application

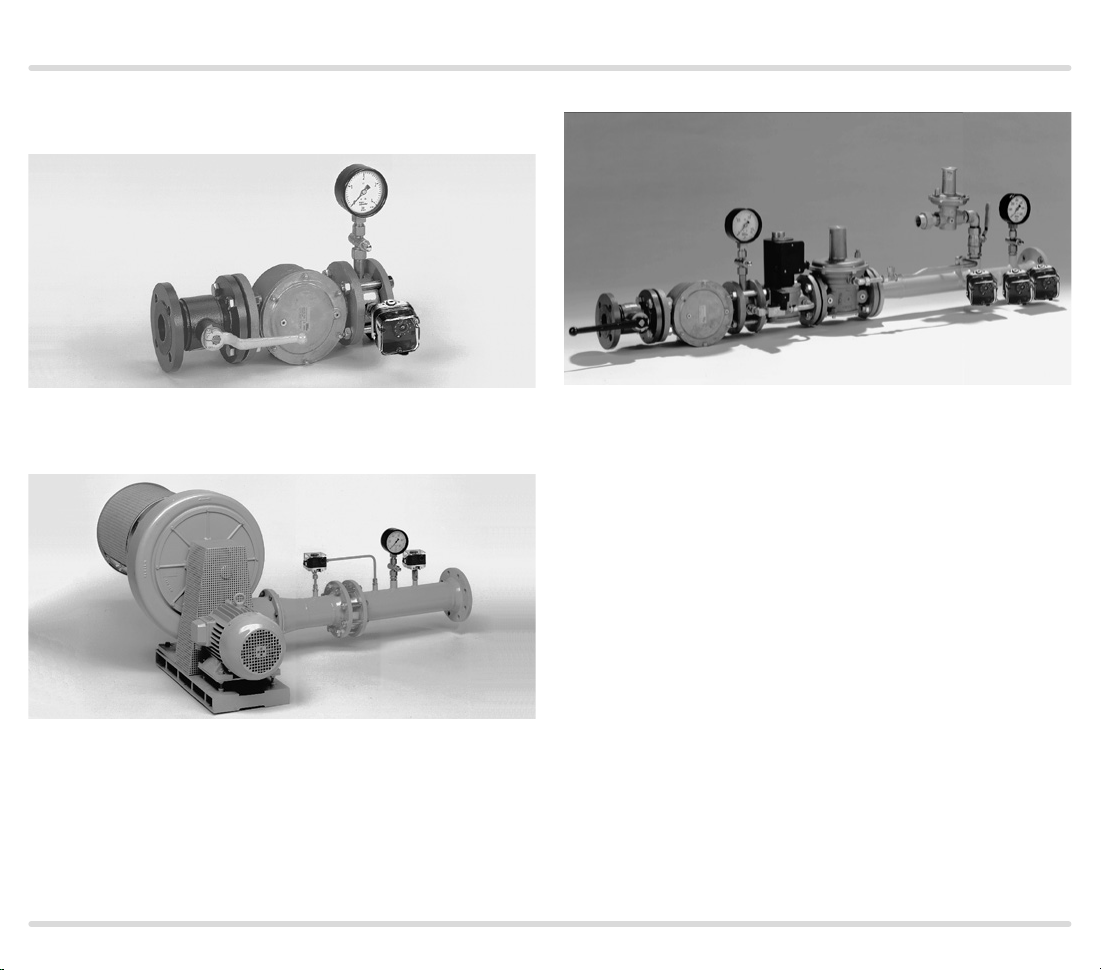

1.2.4 Air line with minimum pressure and flow

monitoring

PI

PZL PDS

C6097 C6097

1/min

KFM/RFM

The air flow generated by the fan may be monitored as

follows:

The static pressure is monitored by the pressure switch

(PZL) as long as it can be demonstrated that the display consequently shows an adequate and secured flow

of air, or the pressure switch (PDS) checks the flow of air

via the differential pressure on the orifice.

If there is no air pressure supplied or if there is no differential pressure on the orifice, the system will be blocked.

1.2.5 Low and high gas pressure protection device

AKT GFK

PI

KFM GDJ

PI

PZL PZH

KFM C6097

VAS..N VAS..L

Min./Max.

If the pressure is either too low or too high,

the min./max. pressure switch (PZL/PZH) switches in

order to avoid start-up or to initiate a safety shut-down.

C60 97 · Edition 01.19 6

Page 7

Certification

2 Certification

Certificates – see Docuthek.

2.1 EU certified

– 2014/35/EU (LVD) – Low Voltage Directive

– 2014/30/EU (EMC) – Electromagnetic Compatibility

Directive

– (EU) 2016/426 (GAR) – Gas Appliances Regulation

– EN 13611:2015+AC:2016

– EN 1854:2010

2.2 FM approved

Factory Mutual Research Class: 3510 Flow and pres-

sure safety switches. Designed for applications pursuant to NFPA 85 and NFPA 86. www.approvalguide.com

2.3 UL listed

USA and Canada

UL 353 Limit control.

Underwriters Laboratories – www.ul.com Tools (at the

bottom of the page) Online Certifications Directory

2.4 Overview of product approvals

Type EU certified FM approved UL listed

C6 097A 4110

C6 097A 4210

C6 097A 4310

C6 097A 441 0

C6097A3004

C6097A3012

C6097A3038

C6097A3053

C6097A3079

C6097A3095

C6097A3111

C6097A3137

C6097B3002

C6097B3028

C6097B3051

C6097B3085

C6097B3101

C6097B3119

–

– –

C60 97 · Edition 01.19 7

Page 8

Function

3 Function

Pressure switch C6097A switches with falling pressure,

C6097B switches with rising pressure.

Once the set switching point is reached, a micro switch

is activated in the pressure switch which is designed as

a change-over contact.

The switching pressure is adjusted using a hand wheel.

CE approved pressure switches

Hand wheel

M16 x 1.5

Screw plug,

Rp 1/4"

2

Nozzle

0.8 mm

NO

NC

COM

4

3

1

Measurement point

Micro switch

FM approved and UL listed pressure switches

Hand wheel

1/2" NPT

Conduit

NO

NC

COM

4

Micro switch

1

Filter pad/nozzle

Pressure switches which lock off after switching can

only be unlocked with a manual reset, see page 16

(Resetting pressure switches with manual reset).

Measurement point

3.1 Vent limiter

The flow on FM approved and UL listed pressure

switches is limited by the nozzle. In the event of a

diaphragm tear, the escape of gas is limited to less

than 1.0 CFH of natural gas, see max. inlet pressure,

page 23 (UL, FM certified pressure switches), Adjusting range, switching hysteresis.

C60 97 · Edition 01.19 8

Page 9

Function

▼

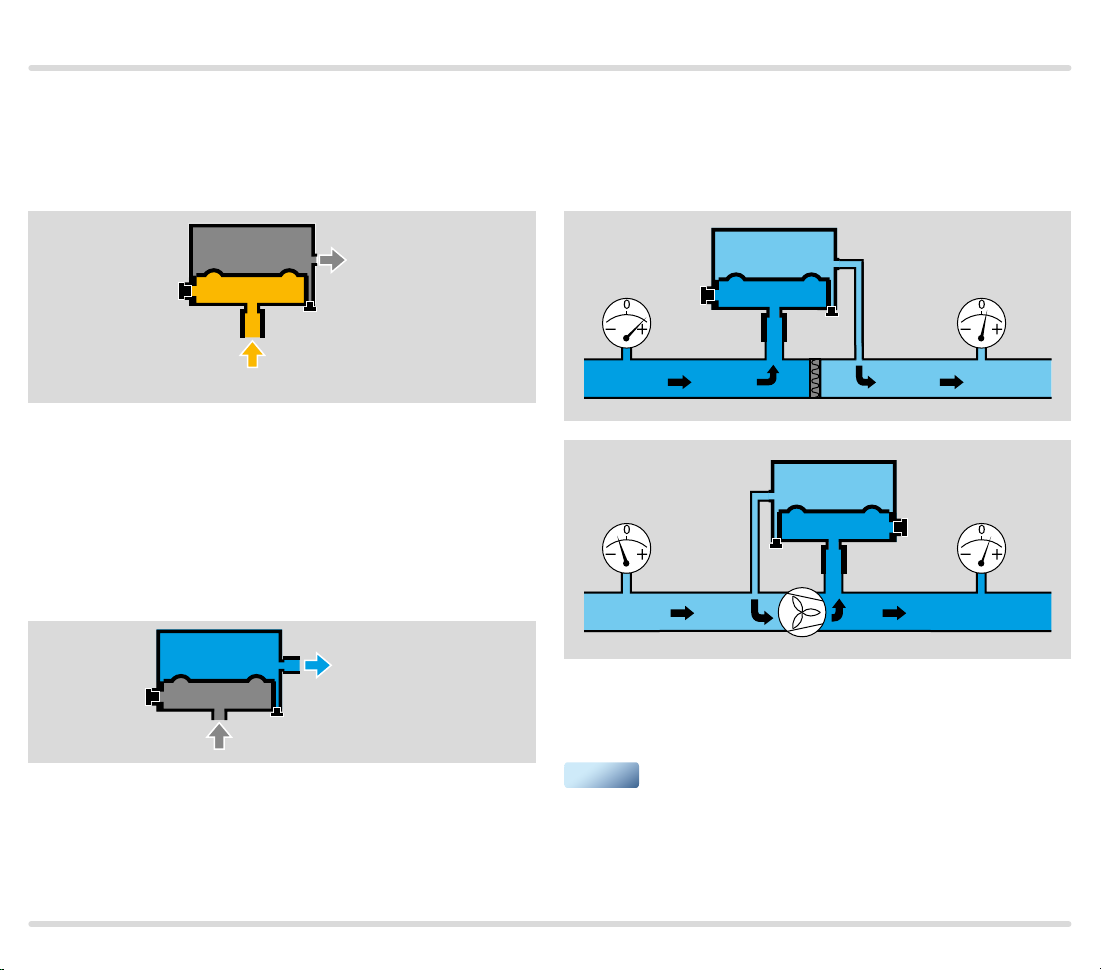

3.2 Positive pressure measurement

Positive pressure measurement is designed, for ex-

ample, for checking the fan function or measuring the

min./max. gas pressure.

4

2

1

3

Gas, air, flue gas, biogas

The positive pressure is measured in the lower dia-

phragm chamber, port 1 (or 2). The upper diaphragm

chamber is ventilated via port 4 (or 3).

3.3 Negative pressure measurement

Negative pressure measurement is designed, for exam-

ple, for monitoring a suction pressure blower.

4

2

1

Air, flue gas

3

3.4 Differential pressure measurement

Differential pressure measurement is designed for

safeguarding an air flow rate or for monitoring filters

and fans, for example.

4

2

1

4

The higher absolute pressure is connected to port 1 (or

2), and the lower absolute pressure to port 4 (or 3). The

remaining ports must be tightly plugged.

3

2

3

1

The negative pressure is measured in the upper dia-

phragm chamber, port 4 (or 3). The lower diaphragm

chamber is ventilated via port 1 (or 2).

C60 97 · Edition 01.19 9

Page 10

Function

-6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6

Increasing

negative pressure

Decreasing

negative pressure

Do not connect port 4 (or 3) to pipes carrying gas! For

further information, see page 14 (Ports).

Increasing pressure

Decreasing pressure

C60 97 · Edition 01.19 10

Page 11

Function

NC

1

COM

3

NO

NO

2

N

NO

2

NC

1

COM

3

L1

N

3.5 Connection diagram

L1

3

COM

0

NO

2

NC

1

Contacts 3 and 2 close when subject to increasing

pressure.

Contacts 1 and 3 close when subject to falling pressure.

On pressure switches that switch with rising pressure:

The contact switches from NC 1 to NO 2.

On pressure switches that switch with falling pressure:

The contact switches from NO 2 to NC 1.

NO

1

2

NC

3

COM

3.5.1 Blue pilot lamp for 230 V AC or 110/120 V AC

N

3

COM

2

NO

2

NO

L1

L1

3

COM

NC

1

NC

1

N

NO

NC

NO

NO

1

2

NC

1

2

NC

3

COM

N

3

COM

N

3.5.2 Red/green pilot LED for 24 V DC/AC or 110 –

230 V AC

NO

+

2

3 COM

1 NC

–

NO

1

2

NC

3

COM

N

C60 97 · Edition 01.19 11

Page 12

Function

3.6 Wiring

When using silicone tubes, only use silicone tubes which

have been sufficiently cured. Vapours containing silicone can adversely affect the functioning of electrical

contacts. In the case of low switching capacities, such

as 24 V, 8 mA, for example, we recommend using an

RC module (22 Ω, 1 μF) in air containing silicone or oil.

C = 1 µF R = 22 Ω

NO

2

NC

1

In the case of high humidity or aggressive gas components (H2S), we recommend using a pressure switch

with gold contact due to its higher resistance to corrosion. Closed-circuit current monitoring is recommended under difficult operating conditions.

COM

3

C60 97 · Edition 01.19 12

Page 13

Project planning information

4 Project planning information

4.1 Installation

Installation in the vertical or horizontal position, or

sometimes upside down, preferably with vertical diaphragm.

If installed in a vertical position, the switching point p

will correspond to the scale value SK set on the hand

wheel. If installed in another position, the switching point pS will change and no longer correspond to

the scale value SK set on the hand wheel. Switching

point pS must be checked.

ps =

SK

ps = SK + 0.18 mbar ps = SK - 0.18 mbar

The housing must not be in contact with masonry. Mini-

mum clearance 25 mm (1").

Continuous operation at high temperatures (e.g. maxi-

mum ambient temperature) accelerates the ageing

of elastomer materials and reduces the service life

(please contact manufacturer). Ozone concentrations

exceeding 200 µg /m

3

or gases containing more than

0.1 %-by-vol. H2S accelerate the ageing of elastomer

materials and reduce the service life.

S

Vapours containing silicone can adversely affect the

functioning of electrical contacts. When using silicone

tubes, only use silicone tubes which have been sufficiently cured.

Condensation must not be allowed to get into the

housing (if possible, install pipework with an ascending

gradient). Otherwise, there is a risk of icing of condensation at subzero temperatures, the switching point

shifting or corrosion in the device which can lead to

malfunctions.

When installing outdoors, place the pressure switch

in a roofed area and protect from direct sunlight (even

IP 65 version).

In case of highly fluctuating pressures, install a restrictor orifice, see page 17 (Restrictor orifice).

C60 97 · Edition 01.19 13

Page 14

Project planning information

4.2 Ports

4.2.1 CE certified pressure switches

2

Rp ¼"

Rp ¼"

1

1

"

8

/

Rp

3

Positive ressure Connect Seal Free*

C6097

1 2 3 or 4

2 1 3 or 4

Negative ressure Connect Seal Free*

C6097

*

It is recommended that the port which is best protected from water

and dirt be left open.

4 3 1 or 2

3 4 1 or 2

Connect

Differential

pressure

for the higher

absolute

pressure

C6097 1 or 2 3 or 4

4

1

Rp

/

8

"

for the lower

absolute

pressure

Seal

Seal por ts that

are not in use

Ports 3 and 4 are connected to the micro switch chamber.

Pipes carrying gas must not be connected to port 3

or 4!

The port that is best protected against soiling (dust/hu-

midity) is to be left open for ventilation (positive pressure measurement) to the atmosphere.

C60 97 · Edition 01.19 14

Page 15

Project planning information

4.2.2 UL, FM certified pressure switches

¼"

NPT

1

4

1

/

8

" NPT

Positive pressure Connect Free

C6097 1 4

Negative pressure Connect Free

C6097 4 1

Connect

Differential pressure

C6097 1 4

Port 4 is connected to the micro switch chamber.

For this reason, pipes carrying gas must not be con-

nected to port 4!

If necessary, port 4 (1/8" NPT) can be used to connect

the venting line.

A filter pad at port 4 protects the electrical contacts in

the pressure switch from dirt particles in the surrounding air or in the medium.

for the higher

absolute pressure

for the lower absolute

pressure

4

IP 65

If port 4 is at the top, IP 65 will not be satisfied.

C60 97 · Edition 01.19 15

Page 16

Project planning information

4.3 Resetting pressure switches with

manual reset

Manual reset

C6097A3012, C6097A3038, C6097A3095,

C6097A3111 lock off if the pressure drops to the set

switching point.

For resetting, the pressure must have risen to at least

the set switching point plus the pressure differential

between the switching pressure and possible reset.

C6097B3002, C6097B3028, C6097B3051 lock off if

the pressure rises to the set switching point.

For resetting, the pressure must have dropped to

at least the set switching point minus the pressure

differential between the switching pressure and

possible reset.

For details of the pressure differential between the

switching pressure and possible reset, see page 22

(Adjusting range, switching hysteresis).

C60 97 · Edition 01.19 16

Page 17

Accessories

47,5 (1.87"

5 Accessories

5.1 Fastening set with screws, U-shape

bracket

50 (1.97")

30 (1.18")

20

(0.79")

45 (1.77")

25 (0.98")

5,2

6 (0.24")

16

24 (0.94")

43

(1.69")

-0,3

64 (2.52")

(0.63")

+0,1

4,20

Order No.: 32003042003/U

20

(0.79")

10

(0.4")

(0.2")

(0.17")

75 (2.95")

M4 x 12

M4 x 10

39 (1.53")

)

5.2 Connecting set

For monitoring a minimum and maximum inlet pressure with two pressure switches attached to one another.

Order No.: 32003043003/U

40 (1.57")

2

1

21 3 4

2

2 x

1 x

5.3 Restrictor orifice

For CE certified pressure switches

Rp

¼

¼

R

In the case of high pressure fluctuations, we recommend using a restrictor orifice (contains non-ferrous

metals):

Hole diameter Ø 0.2 mm, Order No.: 32003051003/U,

Hole diameter Ø 0.3 mm, Order No.: 32003052003/U.

C60 97 · Edition 01.19 17

Page 18

Accessories

5.4 Standard socket set

For CE certified pressure switches

Order No.: 32003053003/U.

For FM, UL certified pressure switches

Order No.: 32003054003/U.

5.5 Standard coupler plug

For CE certified pressure switches

Order No.: 32003055003/U.

For FM, UL certified pressure switches

Order No.: 32003056003/U.

5.6 Pilot lamp set, red or blue

Pilot lamp, red:

110/120 V AC, I = 1.2 mA, Order No.: 32003044003/U.

230 V AC, I = 0.6 mA, Order No.: 32003046003/U.

Pilot lamp, blue:

110/120 V AC, I = 1.2 mA, Order No.: 32003045003/U.

230 V AC, I = 0.6 mA, Order No.: 32003047003/U.

21 3 4

C60 97 · Edition 01.19 18

Page 19

Accessories

5.7 LED set, red/green

24 V DC, I = 16 mA; 24 V AC, I = 8 mA, Order No.:

32003048003/U

110 – 230 V AC, Order No.: 32003049003/U.

.

21 3 4

5.8 Cover for auto reset

Order No.: 32003040003/U

5.9 Cover for manual reset

Order No.: 32003041003/U

C60 97 · Edition 01.19 19

Page 20

Accessories

5.10 Weather protection cover

When the DG is installed outdoors, the weather protection cover provides permanent protection against condensation and weathering of housing parts.

The weather protection cover is made of 1 mm (0,04")-

thick stainless steel.

Installation position: vertical with the cable gland pointing downwards.

E

A

D

C

B

F

2 M4 x 16 screws with 2 cap nuts.

The enclosed filter pad is designed to protect the open

" port from the ingress of dirt or insects.

Scope of delivery:

A 2 x covers, 100 x 100 x 100 mm

B 2 x M4 x 16 screws

C 4 x nuts

D 2 x washers

E 2 x cap nuts

F 1 x filter pad (" port)

Order No.: 32003050003/U.

C60 97 · Edition 01.19 20

Page 21

Technical data

▼

6 Technical data

6.1 General

Gas type: natural gas, town gas, LPG (gaseous), flue

gas, biogas (max. 0.1 %-by-vol. H2S) and air.

Max. inlet pressure p

page 22 (Adjusting range, switching hysteresis).

Electrical connection type: screw terminals.

Diaphragm pressure switch, silicone-free.

Diaphragm: NBR.

Housing: glass fibre reinforced PBT plastic with low gas

release.

Lower housing section: AlSi 12.

Enclosure: IP 65, safety class: 1.

Max. medium and ambient temperatures, see

page 21 (EU certified pressure switches) and

page 22 (UL, FM certified pressure switches).

Storage and transport temperature:

20 to +40°C (4 to +104°F).

Long-term use in the upper ambient temperature range

accelerates the ageing of the elastomer materials and

reduces the service life (please contact manufacturer).

The set switching point may palpably change in media

and ambient temperatures below 22°F (30 °C).

= withstand pressure, see

max.

Recommended tightening torque:

Component Tightening torque [Ncm]

Cover screws 65

M16 x 1.5 cable gland 50

½" NPT conduit 170 (15 lb")

Rp pipe connection, aluminium 250

Rp ¼ (¼" NPT) gas connection 1300

Rp air connection, switch housing 250

Clamping terminal screws 80

T15 test point screw 150

Weight:

270 to 320 g (9.5 to 11.3 oz) depending on equipment.

6.2 EU certified pressure switches

Max. test pressure for testing the entire system:

temporarily < 15 minutes 2 bar (29 psig).

Switching capacity:

U = 24–250 V AC,

I = 0.05–5 A at cos ϕ = 1,

I = 0.05–1 A at cos ϕ = 0.6.

Maximum medium and ambient temperatures:

20 to +80°C (4 to +176°F),

Line entrance:

M16 x 1.5 cable gland,

clamping range: diameters of 4 to 10 mm.

Cable diameter: AWG 24 to AWG 13,

0.5 to 1.8 mm (0.02 to 0.07").

C60 97 · Edition 01.19 21

Page 22

Technical data

▼

6.3 UL, FM certified pressure switches

Switching capacity:

U = 24–240 V AC,

I = max. 5 A at cos ϕ = 1,

I = max. 0.5 A at cos ϕ = 0.6.

Maximum medium and ambient temperatures:

40 to +60°C (40 to +140°F).

Line entrance:

½" NPT conduit.

Cable diameter: AWG 24 to AWG 13,

0.02 to 0.07" (0.5 to 1.8 mm).

6.4 Adjusting range, switching hysteresis

6.4.1 CE certified pressure switches

Type

C6 097A 4110 1–10 0.25–0.4 500 – ± 15% ± 15%

C6 097A 4210 2.5–50 0.8–1.5 500 – ± 15% ± 15%

C6 097A 4310 30–150 3–5 600 – ± 15% ± 15%

C6 097A 441 0

* Adjusting tolerance = ± 15% of the scale value.

Adjusting

range*

mbar

100–500 8–17 600 – ± 15% ± 15%

Mean switching

differential at min. and

max. setting

mbar

Max. inlet pressure

p

= withstand

max.

pressure

mbar

Difference between

switching pressure and

possible reset

mbar

Deviation from the switching point during

testing pursuant to EN 1854

Gas pressure switch Air pressure switch

Switching properties, see page 4 (Use).

C60 97 · Edition 01.19 22

Page 23

Technical data

6.4.2 UL, FM certified pressure switches

pressure and

Lock-off

possible reset

Difference

between

switching

"WC (mbar)

0.16 – 0.4

(0.4–1)

Medium

Air/ga s 1 /4"

Max. inlet pressure

Type

Adjusting range

"WC (mbar)

Mean switching

*

differential at min.

and max. setting

"WC (mbar)

with without

venting line

psi (mbar) psi (mbar)

C6097A3004

C6097A3012

C6 097A 303 8

C6 097A 305 3

0.4 – 4 (1–10) 0.1 – 0.16 (0.25–0.4) 8.5 (600) 7 (480) No – Air/ga s 1 /4"

1 – 20 (2.5–50) – 8.5 (600) 7 (4 80) Yes 0.4 – 0.8 (1–2) Air/ga s 1/4"

12 – 60 (30–150) – 8.5 (600) 7 (480) Ye s 0.8 – 4.8 (2–12) Air/g as 1 /4"

1 – 20 (2.5–50) 0.3 – 0.6 (0.75–1.5) 8.5 (600) 7 (480) No – Air/ga s 1 /4"

C6097A3079 12 – 60 (30–150) 1.2 – 2 (3–5) 8.5 (600) 7 (480) No – Air/ga s 1 /4"

C6097A3095

C6097A3111

0.4 – 4 (1–10) – 8.5 (600) 7 (480) Ye s

40 – 200 (100–500) – 8.5 (600) 7 (480) Yes 2 – 7.2 (5–18) Air/gas 1 /4"

C6097A3137 40 – 200 (100–500) 3.2 – 6.8 (8–17) 8.5 (600) 7 (480) No – Air/g as 1 /4"

C6097B3002

C6097B3028

C6097B3051

C6097B3085

C6097B3101

C6097B31 19

* Adjusting tolerance = ± 15% of the scale value.

12 – 60 (30–150) – 8.5 (600) 7 (480) Ye s 0.8 – 4.8 (2–12) Air/g as 1 /4"

1 – 20 (2.5–50) – 8.5 (600) Yes 0.4 – 0.8 (1–2) Air/ga s 1/4"

40 – 200 (100–500) – 8.5 (600) Yes 2 – 7.2 (5–18) Air/g as 1 /4"

12 – 60 (30–150) 1.2 – 2 (3–5) No – A ir/gas 1/4"

40 – 200 (100–500) 3.2 – 6.8 (8–17) No – A ir/gas 1/4"

1 – 20 (2.5–50) 0.3 – 0.6 (0.75–1.5) No – A ir/gas 1/4"

For further information, see page 4 (Use).

properties at

NPT

setpoint value

connection

NO-toCOM

connection is

interrupted if the

pressure drops

NC-toCOM

connection is

interrupted if the

pressure rises

Switching

C60 97 · Edition 01.19 23

Page 24

Technical data

6.5 Dimensions

6.5.1 EU certified pressure switches

13,1

(0.52")

ø 4,2

(ø 0.17")

76 (3")

10,5 (0.41")

36 (1.42")

1

Rp

/

8

1)

Holes 10 mm (0.4") deep, for self-tapping screws.

(2.76")

50 (2")

70

Rp ¼

4 x ø 3,6

(ø 0.14")

17 (0.7")

Rp 1/

8

M16 x 1,5

1)

30,5 (1.2")

43 (1.7")

30 (1.2")

28,5

13 (0.51")

2,5 (0.1")

64 (2.52")

(1.12")

C60 97 · Edition 01.19 24

Page 25

Technical data

6.5.2 UL, FM certified pressure switches

13,1

(0.52")

ø 4,2

(ø 0.17")

76 (3")

10,5 (0.41")

36 (1.42")

1

/

8" NPT

50 (2")

1)

Holes 10 mm (0.4") deep, for self-tapping screws.

70

(2.76")

11

(0.43")

¼" NPT

½" NPT

Conduit

43 (1.7")

30 (1.2")

13 (0.51")

4 x ø 3,6

(ø 0.14")

64 (2.52")

18

1)

(0.7")

C60 97 · Edition 01.19 25

Page 26

7 Maintenance cycles

At least once per annum, at least twice per annum for

biogas.

C60 97 · Edition 01.19 26

Page 27

03251584

Loading...

Loading...