Page 1

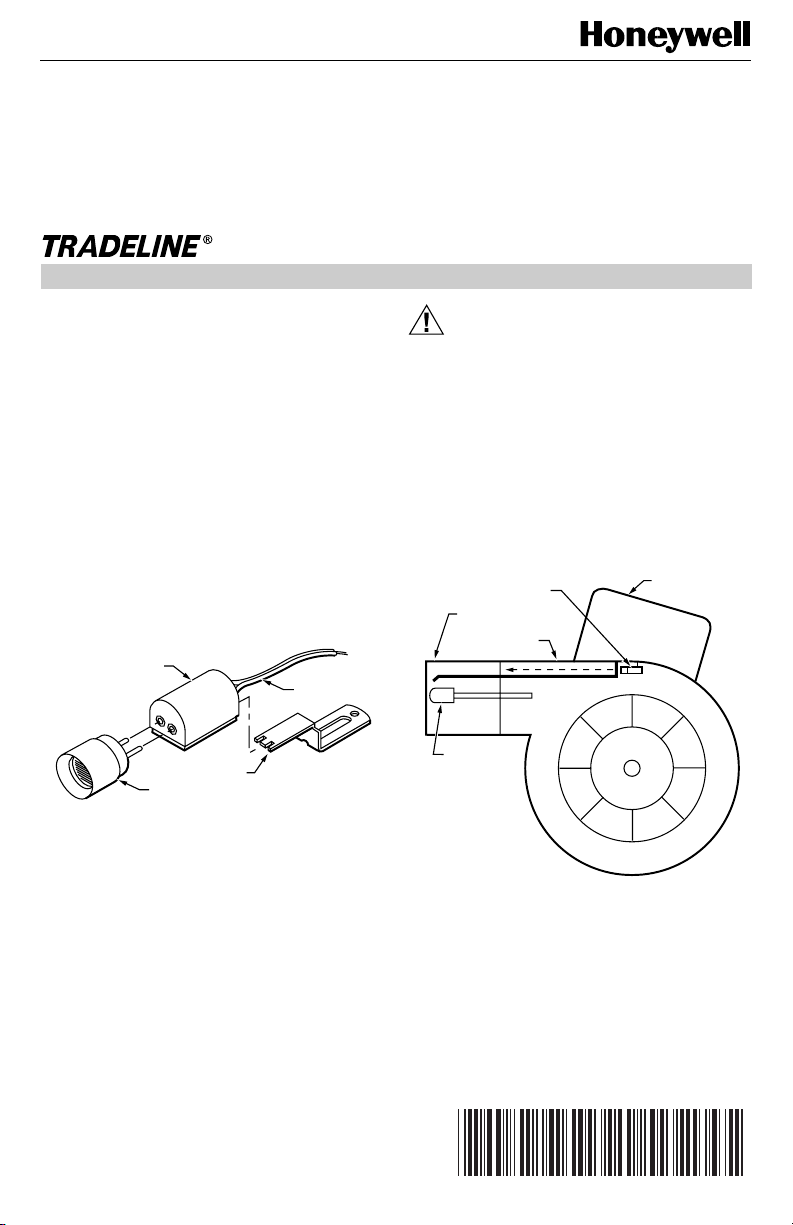

C554A

Cadmium Sulfide Flame Detector

INSTALLATION INSTRUCTIONS

APPLICATION

The C554A Cadmium Sulfide Flame Detector (cad cell) is

a photo conductive flame detector (see Fig. 1) used with

oil primary controls such as R4166, R4184, R8182,

R8184, R8185, R8404 and R8991. It consists of a plug-in,

light sensitive cell and a socket with Type E mounting

bracket, factory-installed leadwire and an oil line adapter

bracket. Leadwire length is 60 in. (1520 mm). The detector

is installed inside the air tube of the burner where the cell

can view the flame and is wired to the F-F terminals of the

oil primary control.

The photocell is a ceramic disk coated with cadmium

sulfide and overlaid with a conductive grid. Electrodes

attached to the ceramic disk transmit an electrical signal to

the primary control. In darkness, cadmium sulfide has a

very high resistance to the passage of electrical current. In

visible light, its resistance is very low and current is

allowed to pass. The entire cell is hermetically sealed

(glass to metal) to prevent cell deterioration.

SOCKET

LEADWIRE

MOUNTING

BRACKET

PLUG-IN-CELL

Fig. 1. C554A Cadmium Sulfide Flame

Detector (cad cell).

M7854

INSTALLATION

CAUTION

Disconnect power supply before beginning

installation to prevent electrical shock or equipment

damage.

Location

The burner manufacturer determines the cad cell location

(see Fig. 2). If an alternate location must be used, make

sure that:

쐃 The cell has a clear view of the flame.

쐇 Ambient light does not reach the cell.

쐋 Ambient temperature at the cell location is below

140°F (60°C).

쐏 Movement, shielding, or radiation of metal surfaces

near the cell do not affect cell function.

CAD CELL

IGNITION

ELECTRODE

AIR TUBE

NOZZLE

Fig. 2. Cad cell location.

IGNITION

TRANSFORMER

M7857

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

®U.S. Registered Trademark

Copyright © 1996 Honeywell Inc. • All Rights Reserved

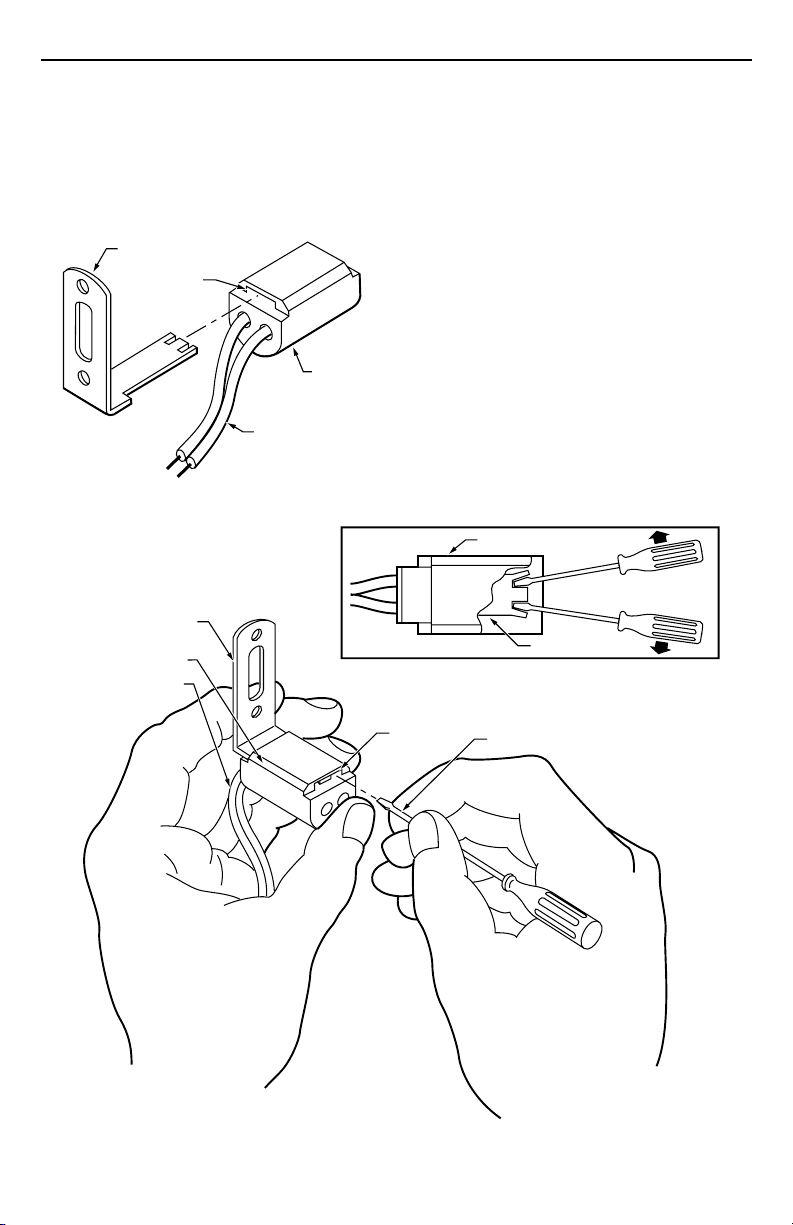

Mounting

Direct Replacement

쐃 Remove the cell from the socket.

쐇 Insert the mounting bracket into the socket slot

(Fig. 3) as far as it will go.

NOTE: Bend the mounting bracket to fit, if

necessary.

X-XX UL

60-0164-1

Page 2

C554A CADMIUM SULFIDE FLAME DETECTOR

쐋 While holding the mounting bracket in the slot,

insert the screwdriver in the other end of the slot

(Fig. 4). Bend the screwdriver first to the left, then

to the right, to crimp the end of the mounting

bracket and hold it in position.

쐏 Remove the screwdriver and replace the cell.

쐄 Mount the new cell and bracket assembly in the

location of the old assembly.

BRACKET

SLOT

SOCKET

LEADWIRE

M7853

Fig. 3. Insert mounting bracket into socket slot.

SOCKET

BRACKET

LEADWIRE

Oil Line Mounting

If desired, mount the C554A on the oil line using the oil line

adapter bracket and the mounting bracket supplied.

쐃 Remove the cell from the socket.

쐇 Insert the mounting bracket into the slot on the

socket (Fig. 3) as far as it will go.

NOTE: Bend the mounting bracket to fit, if

necessary.

쐋 While holding the mounting bracket in the slot, insert

the screwdriver in the other end of the slot (Fig. 4).

Bend the screwdriver first to the left, then to the

right, to crimp the end of the mounting bracket and

hold it in position.

쐏 Remove the screwdriver and replace the cell.

쐄 Slide the mounting bracket into the sleeve on the oil

line adapter bracket. Push firmly to lock the cell and

the bracket assembly in position.

쐂 Mount the oil line adapter bracket on the oil line

using the screw and nut provided (Fig. 5).

SOCKET

SCREWDRIVER

BRACKET

INSERT SCREWDRIVER AND MOVE IN DIRECTION SHOWN BY

ARROWS TO SECURE BRACKET IN SOCKET

60-0164—1

SLOT

SCREWDRIVER

Fig. 4. Insert screwdriver to secure bracket in socket.

2

M7855

Page 3

C554A CADMIUM SULFIDE FLAME DETECTOR

SCREW

OIL LINE

MOUNTING

BRACKET

LEADWIRE

Fig. 5. Use oil line adapter bracket to mount

Wiring

Disconnect power supply before beginning wiring to

prevent electrical shock or equipment damage.

All wiring must comply with local electrical codes and

ordinances. See Fig. 6 for a typical C554A hookup to the

oil burner primary control.

THERMOSTAT

(24 VOLT)

C554A

CAD CELL

SOCKET

C554A on oil line.

OIL BURNER RELAY

OIL LINE ADAPTER

BRACKET

PLUG-IN

CELL

T

T

F

F

TO

NOZZLE

M7856

CHECKOUT

To check cad cell operation, use the following procedure:

쐃 Disconnect cad cell leadwires; then start burner.

Shortly after burner starts, place a temporary jumper

between terminals F-F. Connect an ohmmeter

across cad cell leadwires; resistance should be less

than 1600 ohms.

쐇 Stop burner and remove temporary jumper.

쐋 With burner off, check dark cell resistance across

cad cell leadwires. Resistance should be greater

than 20,000 ohms.

NOTE: If cell resistances are different than

specified, recheck wiring and location of

cell. If necessary, replace plug-in portion of

cell, Honeywell part no. 130367 Replacement Cad Cell.

쐏 Reconnect cad cell leadwires. Check the

Protectorelay (burner sequencing relay) control

according to the instructions packed with the control.

SERVICE AND REPLACEMENT

Under normal operating conditions, the C554A does not

require cleaning. If a badly adjusted burner causes heavy

accumulation of dirt and soot on the cell surface, carefully

wipe the cell surface to restore full view of the oil flame.

If the C554A is damaged, replace the plug-in portion of the

cell. Order Honeywell part no. 130367 Replacement Cad

Cell.

Fig. 6. Typical hookup for C554A to oil

burner primary control.

M7858

3

60-0164—1

Page 4

C554A CADMIUM SULFIDE FLAME DETECTOR

Automation and Control Solutions

Honeywell Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

60-0164—1

60-0164—1 J.S. Rev. 2-96

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Scarborough, Ontario

M1V 4Z9

4

Loading...

Loading...