Page 1

C437D,E,F,G,H,J,K and C637B Gas

GENERAL

The C437 and C637 Gas Pressure Switches are pressureactuated switching devices used in industrial gas system

applications for safety shutoff, pressure control, and

differential-pressure control.

Pressure Switches

PRODUCT DATA

FEATURES

• C437 models have direct- and reverse-acting (spst)

switching; C637B has single-pole, double-throw (spdt)

switching.

• Pressure ranges: 1/2 to 5-1/2 in. of water (10 to 140 mm

of water, or 0.1 to 1.4 kPa); 1 to 26 in. of water (50 to

700 mm of water, or 0.5 to 7 kPa); 1/2 to 5 psi (300 to

3500 mm of water, or 3 to 35 kPa); 1 to 10 psi (500 to

7000 mm of water, or 5 to 70 kPa).

• Models intended for lockout applications must be

manually reset before resuming operation.

• Trip-free mechanism on manual reset models ensures

that the limit function of the switch cannot be defeated

by jamming the reset lever.

• External manual reset button on side of lockout

models.

• Enclosed setting impedes tampering and provides

dust-resistant operation.

• Buna-N fiber-reinforced material for increased

strength of control diaphragm.

• Two Buna-N fiber-reinforced seal-off diaphragms for

added reliability.

• Clear glass cover allows observation of interior

mechanism to aid setting and checkout.

• Mercury switch provides visual indication of switch

position.

• Heavy die-cast case increases durability and

resistance to corrosion.

• Main control diaphragm completely enclosed a leakproof chamber can be vented to a safe area.

• Models with a pressure range of 1 to 26 in. of water

(50 to 700 mm of water, or 0.5 to 7 kPa) have a

restrictive orifice in the inlet pressure channel to

compensate for momentary surges in gas pressure.

• Field-addable orifices of various sizes are available.

• Models available with rainproof, dustproof, sleet- and

ice-resistant enclosure; meets NEMA 3R specification.

Copyright © 1995 Honeywell Inc. • All Rights Reserved

Contents

General ............................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Recycling Notice ................................................................. 4

Installation ........................................................................... 4

Setting and Checkout .......................................................... 6

60-2320-9

Page 2

C437D,E,F,G,H,J,K AND C637B GAS PRESSURE SWITCHES

SPECIFICATIONS

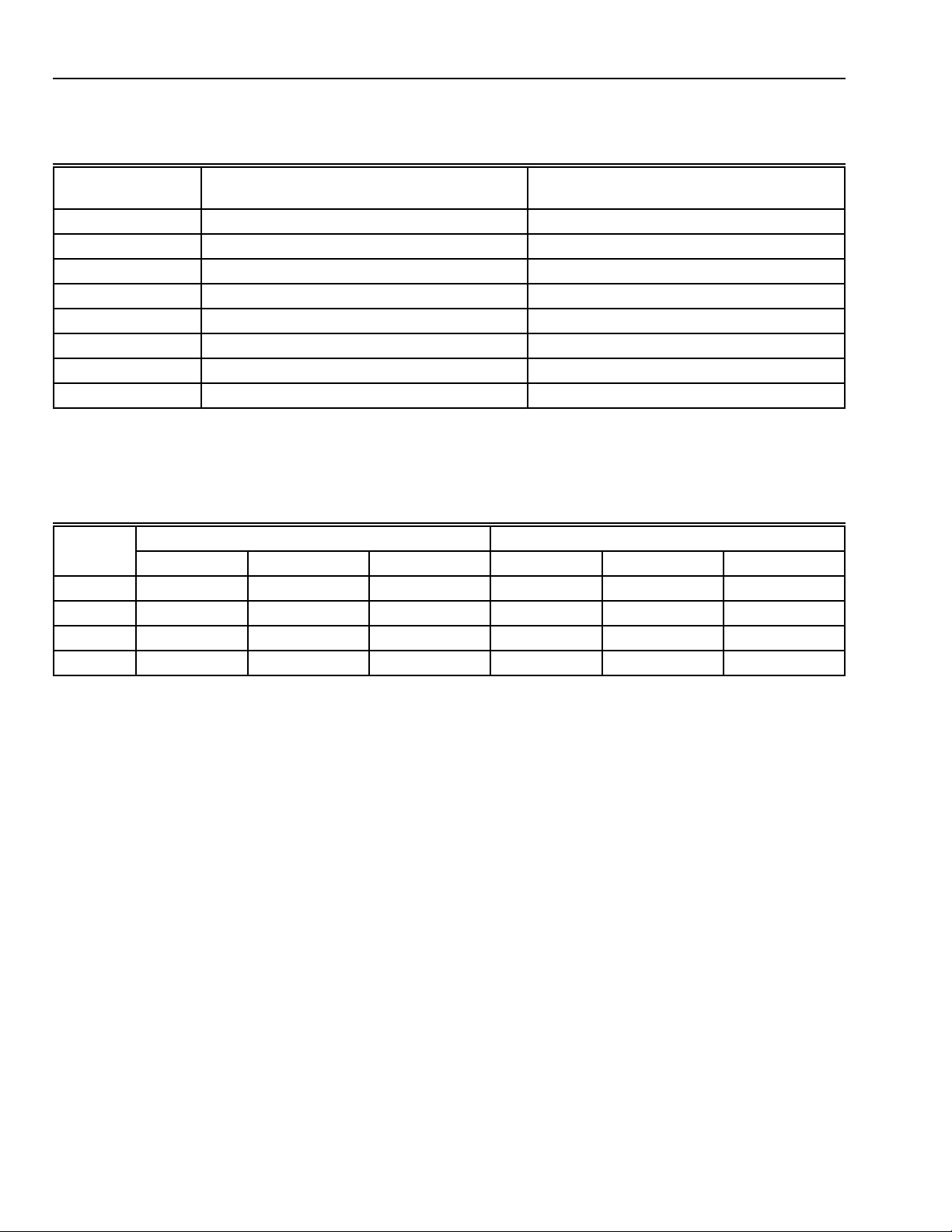

Models:

Model

Number

(Response at Setpoint to Pressure Change)

Switch Action

Manual Reset

(Locks Out on Switch Break)

C437D spst, breaks on rise yes

C437E spst, breaks on fall yes

b

C437F

C437G

C437H

a

a

2 spst circuitsc, breaks one, makes one no

spst, breaks on rise no

spst, breaks on fall no

C437J 2 spst circuitsc, breaks one, makes one yes (lockout on rise)

C437K 2 spst circuitsc, breaks one, makes one yes (lockout on fall)

C637B spst, breaks R-W and makes R-B on fall no

a

Designated Manual Reset 2; the trip-free reset mechanism does not permit the switch to function as an automatic-reset device

when the manual reset lever is held in the Reset position.

b

Weatherproof enclosure (NEMA 3R) available.

c

Two separate switches are contained in the same mercury bulb.

a

Switch Ratings (In Amperes):

C437E,G and H C437F,J,K

Voltage Full Load Locked Rotor Resistive Load Full Load Locked Rotor Resistive Load

120 Vac 8.0 48.0 10.0 8.0 48.0 10.0

240 Vac 5.1 30.6 5.0 5.1 30.6 5.0

120 Vdc 2.4 24.0 5.0 2.0 20.0 8.0

240 Vdc 1.2 12.0 2.0 1.0 10.0 3.0

C637B—62.5 VA at 120 and 240 Vac, pilot duty.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or your distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number, or specify—

1. Order number.

2. Pressure range.

3. Replacement parts, if desired.

4. Accessories, if desired.

If you have additional questions, need further information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Home and Building Control Division Sales Office (check white pages of phone directory).

2. Home and Building Control Division Customer Logistics

Honeywell Inc., 1985 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9. International Sales

and Service offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France, Germany, Japan,

Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

60-2320—9

2

Page 3

C437D,E,F,G,H,J,K AND C637B GAS PRESSURE SWITCHES

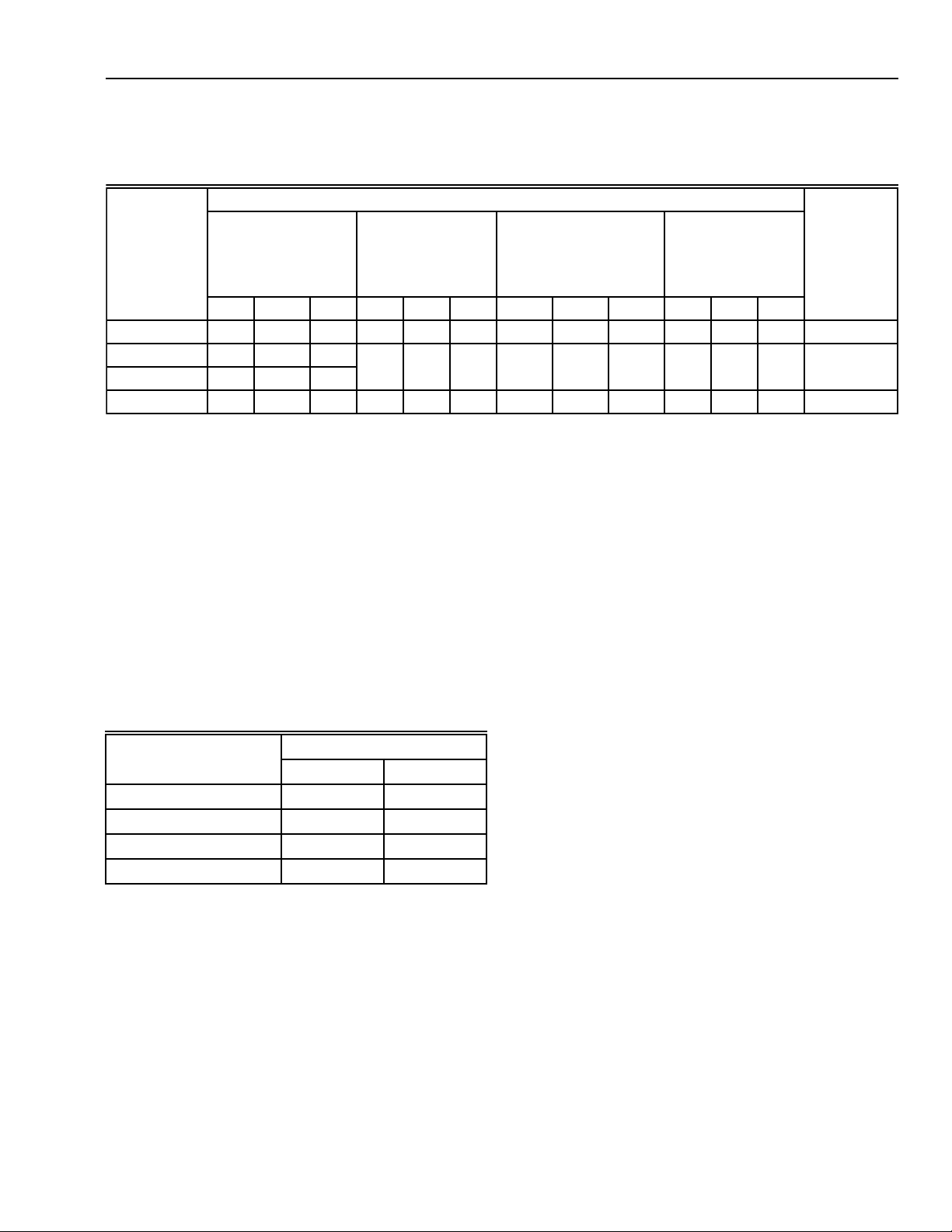

Switch:

Mercury switch (C437F,J and K have two spst switches in one mercury bulb).

Differentials:

Fixed, nominal; measured at pressure indicated:

Pressure Range

b

Model

Numbers

1/2 to 5-1/2 in.

(10-140 mm, or

0.1-1.4 kPa)

Differential Measured

at 1/2 in.

1 to 26 in.

(50-700 mm, or

0.5-7 kPa)

differential

measured at 15 in.

in. mm kPa in. mm kPa psi mm kPa psi mm kPa Type

C437D,J — — — 1-3/4 44.5 0.44 1/2 352 3.45 1c703c6.89cSubtractive

C437E,F,H,K 0.25e6.4e0.06e1-1/4 31.8 0.31 1/4 176 1.72 1/2e352e3.45eAdditive

C637B 0.15 3.8 0.04

C437G — — — 1-1/4 31.8 0.31 1/4 176 1.72 1/2 352 3.45 Subtractive

a

in. = inches of water; mm = millimeters of water.

b

Restrictive orifice in inlet pressure channel to compensate for momentary surges in gas pressure.

c

Not available for C437J.

d

Subtractive models: switching action occurs on pressure rise to the setpoint.

e

Not available for C437K.

f

Additive models: switching action occurs on pressure fall to the setpoint.

a

1/2 to 5 psi

(300-3500 mm, or

3-35 kPa) differential

measurement at

midscale

1 to 10 psi

(500-7000 mm,

or 5-70 kPa)

differential

measurement

a

d

f

Pressure Ranges (Scale Range):

Specify one:

1/2 to 5-1/2 inches of water (10 to 140 mm of water, or

0.1 to 1.4 kPa).

1 to 26 inches of water (50 to 700 mm of water, or 0.5 to

7 kPa).

1/2 to 5 lb per sq in. (300 to 3500 mm of water, or 3 to

35 kPa).

1 to 10 lb per sq in. (500 to 7000 mm of water, or 5 to

70 kPa).

Maximum Sustained Operating Pressure:

Maximum Pressure

Pressure Range psi kPa

1/2 to 5-1/2 in. of water 3.0 20.7

1 to 26 in. of water 5.0 34.5

1/2 to 5 psi 15.0 103.4

1 to 10 psi 30.0 206.8

Pipe Connections:

Main or High Pressure: 1/2 in. NPT, female.

Vent or Low Pressure: 1/8 in. NPT, female.

Electrical Wiring: Hole tapped for 1/2 in. conduit.

Maximum Ambient Temperature:

125°F (52°C).

Minimum Temperature:

32°F (0°C).

Approvals:

Underwriters Laboratories Inc. Listed: File No. MP2168,

Guide No. MFHX.

Canadian Standards Association Certified: File No. 1620,

Guide No. 380-W-1.16.

Factory Mutual Approved: Report No. 13031-S5 and

19291.

Replacement Parts:

106729 Cover Glass, 6 in. (152.4 mm) diameter.

139870A Cover Glass, for rainproof enclosures.

106747 Cover Retaining Ring, for models manufactured

before 1973.

118733-21 Retaining Clip, for models manufactured since

1975.

Accessories:

4074BWK Bag Assembly: Contains two 137755 Mounting

Brackets and four self-tapping screws: for surface

mounting (standard on C437G and H). Mounting

brackets are shown by dashed lines in Fig. 1.

Field-addable Orifices:

124674: 0.011 in. (0.28 mm) diameter.

122160: 0.018 in. (0.46 mm) diameter.

3

60-2320—9

Page 4

C437D,E,F,G,H,J,K AND C637B GAS PRESSURE SWITCHES

5/16 (7.9) (4)

5/8

(15.9)

(4)

7-11/16

DIA.

(195.3)

2

45°

1/8–27 NPT

1

137755 MOUNTING BRACKET (2), IN 4074BWK BAG ASSEMBLY – STANDARD

ON C437G AND H; OPTIONAL ON OTHER MODELS.

2

VENT TAPPING. REMOVE DUST-SEAL LABEL BEFORE MOUNTING.

6-1/4 (158.8)

7-3/8 (187.3)

1/2–14 NPT

1

45°

TAPPED FOR 1/2 IN.

CONDUIT

7-3/4

(196.9)

6-1/2

(165.1)

3-7/16 (87.3)

2 (50.8)

1-5/16

(33.3)

1/8

(3.2)

1

(25.4)

M7192

Fig. 1. Installation dimensions of the C437 and C637 gas pressure switches, in in. (mm).

RECYCLING NOTICE

This control contains mercury in a sealed tube. Do

place control in the trash at the end of its useful life.

If this control is replacing a control that contains

not

mercury in a sealed tube, do

place your old

control in the trash.

Contact your local waste management authority for

instructions regarding recycling and the proper

disposal of this control, or of an old control containing

mercury in a sealed tube.

not

INSTALLATION

When Installing this Product…

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

Installer must be a trained, experienced, flame

safeguard control technician.

After installation is complete, check out product

operation as provided in these instructions.

60-2320—9

4

Page 5

C437D,E,F,G,H,J,K AND C637B GAS PRESSURE SWITCHES

CAUTION

Disconnect all power to the pressure switch before

beginning installation to prevent electrical shock and

equipment damage.

IMPORTANT

1. Remove the dust-seal label from the vent tapping

before mounting.

2. Accurately level the pressure switch for proper

operation.

3. The C637B pressure switch is a low differential

device. Mount it in a vibration-free location to prevent

chattering.

4. Do not hand tighten the pressure switch by holding

the case.

Follow local codes or ordinances

from these recommendations.

Fig. 1 shows the mounting dimensions for the C437 and C637

models, and for the accessory mounting bracket (standard on

C437G and H). See Fig. 2 for the individual components.

in all cases

when different

Use nipple and T for pipe mounting or the mounting

bracket for surface mounting. If a mounting bracket is

used, install the bracket before making piping

connections (standard on C437G and H). Mount the

bracket horizontally with the four 10-24 flathead tapping

screws provided.

Level the device carefully.

a. Level the device so that the point of leveling

pendulum is aligned with the mark on the inside

of the case.

b. When pipe mounting, install the device at right

angles to the pipe so that it can be leveled by

additional tightening of the pipe fittings.

c. The surface mounting bracket has elongated

holes that allow limited leveling after the mounting

screws are started.

d. Accurate leveling is most essential at very low

pressure settings.

e. If necessary, make arrangements to hold pipe-

mounted units steady and level with bracing.

Location

Mount the gas pressure switch downstream from the pressure

regulator. Mount low gas pressure switches upstream of any

shutoff valve. Mount high gas pressure switches just

upstream from the burner. When pipe mounting, locate the

device on the portion of the pipe that is most level because

the mercury switch requires level orientation. See step 4 in

the Mounting section.

PRESSURE SETTING

INDICATOR

SCALEPLATE

TERMINAL

STRIP

VENT

TAPPING

(ON SIDE

NOT SHOWN)

MAIN PRESSURE TAPPING

1

1

REMOVE DUST-SEAL LABEL BEFORE MOUNTING

MERCURY SWITCH

CONDUIT

TAPPING

LENS GASKET

(G,H ONLY)

SETTING

SCREW

UNDER

RETAINER

MANUAL

RESET

BUTTON

(CC437D,

E,J,K)

RETAINER

LEVELING

PENDULUM

M7630

Fig. 2. Principal parts of the gas pressure switch.

Mounting

Remove the dust-seal label from the vent tapping.

Remove the screws and retainers, and the cover glass.

Mount the device on the pipe or nearby vertical surface.

PENDULUM

LEVEL

LINE

M7196A

Fig. 3. Properly leveled C437/637.

IMPORTANT

To avoid leaks and case damage, use a parallel jaw

wrench on the hexagonal part of the case close to

the pipe. Carefully make all connections and test for

leakage. Do not tighten the pressure switch by

holding the case.

Complete the main piping.

Connect the piping to the pressure switch. Select the

application from the following, and proceed as

instructed.

a. Hazardous-gas applications: Install a 1/8 in. NPT

pipe at the vent tapping on all hazardous-gas

applications.

WARNING

The vent must be installed so that any gas leakage is

vented into a safe place in event of a diaphragm

failure.

b. Differential-pressure applications:

5

60-2320—9

Page 6

C437D,E,F,G,H,J,K AND C637B GAS PRESSURE SWITCHES

(1) Connect the high-pressure side of the

system to the 1/2 in. NPT main pressure

tapping on the gas pressure switch.

(2) Connect the low pressure side to the 1/8 in.

NPT vent tapping.

WARNING

No venting is possible in this case. Do not use this

device for differential pressure control with the

hazardous gases.

c. Negative-pressure applications: Connect the low

pressure side to the 1/8 in. NPT vent tapping.

WARNING

This application is for use only with nonhazardous

gases. Do not use this device for negative-pressure

applications with hazardous gases.

Install other controls in the system. Connect wiring, and

complete setting and checkout before replacing the

cover glass and retainers. See Setting and Checkout

section.

Wiring

CAUTION

1. Disconnect all power to the pressure switch

before connecting wiring to prevent electrical

shock and equipment damage.

2. When using a C437F,J, or K, both ends of the

switch (W-R and B-R) must be used at the same

voltage in the same branch circuit.

All wiring must comply with local electrical codes, ordinances,

and regulations. Do not exceed the switch ratings given in the

Specifications section.

Wiring diagrams for the different models are shown in Fig. 4,

5 and 6. The switches make or break as indicated in the

diagrams. Connect the wiring to the screw terminals on the

terminal strip after removing the cover glass. Route the wires

through the conduit tapping.

C437D,G: BREAKS ON PRESSURE RISE

C437E,H: BREAKS ON PRESSURE FALL

TERMINAL

STRIP

M7195

Fig. 4. Wiring diagram for C437D,E,G,H.

MAKES ON

PRESSURE

FALL

1

BOTH ENDS OF THE SWITCH (W-R AND B-R) MUST BE USED

AT THE SAME VOLTAGE IN THE SAME BRANCH CIRCUIT.

RISE

W

1

R

R

B

1

MAKES ON

PRESSURE

RISE

TERMINAL

STRIP

C437F,J,K

M7193

Fig. 5. Wiring diagram for C437F,J,K.

MAKES R TO B

ON PRESSURE

FALL

RISE

W

R

B

MAKES R TO W

ON PRESSURE

RISE

TERMINAL

STRIP

C637B

M7194

Fig. 6. Wiring diagram for C637B.

SETTING AND CHECKOUT

Setting

In the C437D,G and J models, the differential is

upper

The

the

operating point is determined by the

lower

operating point is determined by the setpoint

the differential. In the C437E,F,H,K and C637B models, the

differential is

by the

additive

setpoint

by the setpoint

. The

lower

operating point is determined

, while the

plus

upper

operating point is determined

the differential. Operating points are

shown in Fig. 7.

Remove the retainer and adjust the

setpoint

operating pressure (cutout pressure on a C437D,E,G, or H

spst model) by turning the setting screw (Fig. 2) clockwise

to increase the setpoint and counterclockwise to

decrease it.

Trip-Free Manual Reset Feature

(C437D,E,J and K only)

The C437D breaks and the C437J breaks R-B and makes

R-W when the pressure rises to the setpoint. The C437E

breaks, and the C437K breaks R-W and makes R-B when the

pressure falls to the setpoint. None of these pressure

switches will automatically return to their former positions.

subtractive

setpoint

, while

minus

for the desired

.

60-2320—9

6

Page 7

C437D,E,F,G,H,J,K AND C637B GAS PRESSURE SWITCHES

To reset one of these pressure switches, wait until the

pressure

J), or

falls

rises

to the setpoint minus the differential (C437D or

to the setpoint plus the differential (C437E or K).

Then depress the manual reset button (Fig. 2) and release it.

The pressure switch will not be reset until you release the

manual reset button

an automatic-reset device if the reset button is stuck, held in,

or tied down.

. This prevents the switch from becoming

Checkout

Adjust the setpoint for normal operation and check to see that

the gas pressure switch performs as intended. Use a

manometer or accurate pressure gauge connected upstream

from the switch to measure the actual pressure.

The most likely cause of inaccurate operation is off-level

mounting. Refer to step 4 in the Mounting section and correct

any installation that does not check out satisfactorily.

C437D,G or J (Subtractive Differential)

Put the system into normal operation, and set the

pressure switch at the normal setpoint (above the

normal operating pressure).

Turn the setting screw (Fig. 2) slowly toward a lower

pressure setting (counterclockwise ) to simulate a

pressure increase.

When the setpoint is approximately equal to the

pressure indicated on the pressure gauge, the C437D

or G should break contact and turn off the controlled

equipment; the C437J should break R to B and make R

to W.

The C437D or J should lock out.

SET POINT

(SWITCH BREAKS,

C437D,G

PRESSURE

RISE

C437J

C437E,H

C437F,K

C637B

PRESSURE

RISE

PRESSURE

FALL

PRESSURE

FALL

C437D AND J ARE MANUAL RESET MODELS; THEY CAN BE

1

MANUALLY RESET WHEN THE PRESSURE FALLS TO THE SET

POINT MINUS THE DIFFERENTIAL.

2

C437E AND K ARE MANUAL RESET MODELS; THEY CAN BE

MANUALLY RESET WHEN THE PRESSURE RISES TO THE SET

POINT PLUS THE DIFFERENTIAL.

C437D LOCKS OUT)

SUBTRACTIVE

DIFFERENTIAL

SET POINT MINUS

DIFFERENTIAL (SWITCH MAKES)

SET POINT

(BREAKS R-B MAKES R-W

AND LOCKS OUT)

SUBTRACTIVE

DIFFERENTIAL

SET POINT MINUS

DIFFERENTIAL (BREAKS R-W,

MAKES R-B)

SET POINT PLUS

DIFFERENTIAL (SWITCH MAKES)

ADDITIVE

DIFFERENTIAL

SET POINT

(SWITCH BREAKS,

C437E LOCKS OUT)

SET POINT PLUS

DIFFERENTIAL (BREAKS R-B

MAKES R-W)

ADDITIVE

DIFFERENTIAL

SET POINT

(BREAKS R-W, MAKES R-B,

C437K LOCKS OUT)

1

1

2

2

M7197

Turn the setting screw toward a high pressure setting

(clockwise ) to simulate a pressure decrease

greater than the differential

. The C437G should make

contact and turn on the controlled equipment.

Push the manual reset button (Fig. 2) on the C437D or

J; the C437D should make, and the C437J should

break R to W and make R to B.

C437E,F,H,K or C637B

(Additive Differential)

Put the system into normal operation and gradually

close the upstream gas shutoff valve to cause a

pressure decrease.

When the pressure gauge indicates that the pressure is

approximately equal to the setpoint, the C437E or H

should break contact and turn off the controlled

equipment; the C437F,K or C637B should break R to W

and make R to B.

The C437E or K should lock out.

Open the gas shutoff valve to increase the pressure

again. When the pressure rises to the setpoint

differential

, the C437H should make contact and turn on

plus the

the controlled equipment; the C437F or C637B should

break R to B and make R to W.

Push the manual reset button (Fig. 2) on the C437E or

K; the C437E should make, and the C437K should

break R to B and make R to W.

Completing the Installation

Remove the pressure gauge or manometer used for

testing. Visually recheck the piping, wiring, and setting.

Replace the cover glass and retainers.

Return the system pressure to normal.

Push the manual reset button (C437D,E,J or K only).

Installing a Pressure Orifice (Fig. 8)

To compensate for momentary surges in gas pressure, install

a restrictive orifice in the inlet pressure channel of the

pressure switch. (Refer to Accessories in the Specification

section for the orifice sizes available.)

Align pressure orifice into reset located inside of the main

pressure tapping at the bottom. Press orifice into place using

1/8 in. dowel rod.

MAIN PRESSURE

TAPPING

PRESSURE

ORIFICE

(SELECTED)

1/8 IN. DOWEL ROD

Fig. 8. Installing a pressure orifice to compensate for

pressure surges.

M7191A

Fig. 7. C437 and C637 operating points.

7

60-2320—9

Page 8

C437D,E,F,G,H,J,K AND C637B GAS PRESSURE SWITCHES

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

60-2320—9 L.Z. Rev. 9-95

60-2320—9

8

customer.honeywell.com

Loading...

Loading...