Page 1

User Manual

| Gas Detection

Honeywell BW™ Ultra

Portable Five-gas Detector

with Internal Pump

50122982265 ENB

Page 2

Limited Warranty and Limitation of Liability

BW Technologies by Honeywell LP (Honeywell) warrants

the product to be free from defects in material and

workmanship under normal use and service for a period

of three years, beginning on the date of shipment to the

buyer. This warranty extends only to the sale of new and

unused products to the original buyer. Honeywell’s warranty

obligation is limited, at Honeywell’s option, to refund of the

purchase price, repair, or replacement of a defective product

that is returned to a Honeywell authorized service center

within the warranty period. In no event shall Honeywell’s

liability here under exceed the purchase price actually paid

by the buyer for the product.

This warranty does not include:

• fuses, disposable batteries, or the routine replacement of parts due to the normal

wear and tear of the product arising from use;

• any damage or defects attributable to repair of the product by any person other

than an authorized dealer, or the installation of unapproved parts on the product

• any product which in Honeywell’s opinion has been misused, altered, neglected,

or damaged by accident or abnormal conditions of operation, handling, or use.

The obligations set forth in this warranty are conditional on:

• Proper storage, installation, calibration, use, maintenance, and compliance with

the product manual instructions and any other applicable recommendations of

Honeywell.

• The buyer promptly notifying Honeywell of any defect and, if required, promptly

making the product available for correction. No goods shall be returned to

Honeywell until receipt by the buyer of shipping instructions from Honeywell.

• The right of Honeywell to require that the buyer provides proof of purchase such

as the original invoice, bill of sale, or packing slip to establish that the product is

within the warranty period.

Warranty Registration

www.honeywellanalytics.com/support/productregistration

THE BUYER AGREES THAT THIS WARRANTY IS THE

BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. HONEYWELL SHALL NOT BE

LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING

LOSS OF DATA, WHETHER ARISING FROM BREACH OF

WARRANTY OR BASED ON CONTRACT, TORT, OR RELIANCE

OR ANY OTHER THEORY.

Since some countries and states do not allow limitation of

the term of an implied warranty, or exclusion or limitation

of incidental or consequential damages, the limitations

and exclusions of this warranty may not apply to every

buyer. If any provision of this warranty is held invalid or

unenforceable by a court of competent jurisdiction, such

holding will not affect the validity or enforceability of any

other provision.

Page 3

Table of Contents

Before You Begin ............................................................................................... 1

About this Publication ...............................................................................................................1

Trademarks .......................................................................................................................... 1

Introduction ................................................................................................................................... 1

What’s in the Box ......................................................................................................................... 1

Monitored Gases.......................................................................................................................... 1

Safety Information ...................................................................................................................... 2

Sensor Poisons and Contaminants ..................................................................................... 3

International Symbols ............................................................................................................... 3

Getting Started ................................................................................................... 4

Appearance .................................................................................................................................... 4

Main Screen. ...........................................................................................................................................................................................................................4

Screen Icons .................................................................................................................................. 4

Alarms ............................................................................................................................................... 5

Detector Operations ......................................................................................... 6

Activate the detector ..................................................................................................................6

Activate the backlight ................................................................................................................6

Deactivate the detector ............................................................................................................ 6

Navigate the menu ..................................................................................................................... 6

View detector’s general information ................................................................................... 6

Reset TWA or STEL readings .................................................................................................. 6

Reset Peak readings ................................................................................................................... 6

Reset TWA/STEL and Peak readings ..................................................................................7

Zero sensors ...................................................................................................................................7

Acknowledge alarms and messages ................................................................................... 7

Latching Alarms ........................................................................................................................... 7

Calibrate the detector ............................................................................................................... 7

Start a Bump Test ........................................................................................................................ 8

Perform a manual bump test ..................................................................................... 8

Set up IntelliFlash ....................................................................................................................... 8

Set up Reverse IntelliFlash ...................................................................................................... 8

Set up the Confidence and Compliance Beep interval .............................................. 8

Select an operation mode........................................................................................................ 9

Essentials mode ................................................................................................................ 9

Hole Watch mode ............................................................................................................. 9

Inert mode ............................................................................................................................ 9

Configure the Detector .............................................................................................................9

Connect With IntelliDoX ...........................................................................................................9

Connect With an IR Link........................................................................................................... 9

Bluetooth Pairing ..................................................................................................................... 10

Replace a Sensor ...................................................................................................................... 10

Review Logs ................................................................................................................................ 10

Maintenance .................................................................................................... 11

Maintenance .............................................................................................................................. 11

Gas Cylinder Guidelines ........................................................................................................ 11

Charge the Battery................................................................................................................... 11

Maintain the Battery ............................................................................................................... 11

Real Time Clock Display ........................................................................................................ 11

Languages ...................................................................................................................................11

Clean the Detector ................................................................................................................... 11

Upgrade the Firmware ........................................................................................................... 11

Service ............................................................................................................... 12

Replace the Printed Circuit Board (PCB) .......................................................................12

Replace the LCD ....................................................................................................................... 14

Replace the 1Series Sensors .............................................................................................16

Replace the 4R+ Sensors ...................................................................................................... 18

Replace the Pump ....................................................................................................................19

Replace the Battery .................................................................................................................20

Replace the Pump Inlet Filter ............................................................................................. 20

Appendices ....................................................................................................... 21

Auto detect gas ......................................................................................................................... 21

Gas Alarm Setpoints ................................................................................................................21

Sample Factory Alarm Setpoints .......................................................................................21

Specifications ............................................................................................................................21

Standards and Certifications .............................................................................................. 22

Label Information.....................................................................................................................24

BW Ultra Battery label ................................................................................................. 24

BW Ultra Instrument label ........................................................................................ 24

Part Number Format ............................................................................................................... 25

Troubleshooting .......................................................................................................................26

Glossary ........................................................................................................................................ 27

Contact Honeywell .................................................................................................................. 28

Page 4

Page 5

Before You Begin

About this Publication

While this information is presented in good faith and

believed to be accurate, Honeywell disclaims the implied

warranties of merchantability and fitness for a particular

purpose and makes no express warranties except as

may be stated in its written agreement with and for its

customers.

In no event is Honeywell liable to anyone for any indirect,

special, or consequential damages. The information and

specifications in this document are subject to change

without notice.

Trademarks

Brand or product names are trademarks of their respective

owners. The following brand or product names are

trademarks of Honeywell:

• Honeywell BW™ Ultra • IntelliDoX

• IntelliFlash • Reverse IntelliFlash

Introduction

The Honeywell BW™ Ultra gas detector warns of hazardous

gas at levels above user-defined alarm setpoints.

The detector is a personal safety device. It is your

responsibility to respond properly to the alarm.

This publication is intended for people who understand

how to configure, maintain and use personal gas detectors,

docking systems, and accessories.

Monitored Gases

The detector can monitor up to five gases at a time. Four

gases detected by default, and one optional gas selected

from the following list.

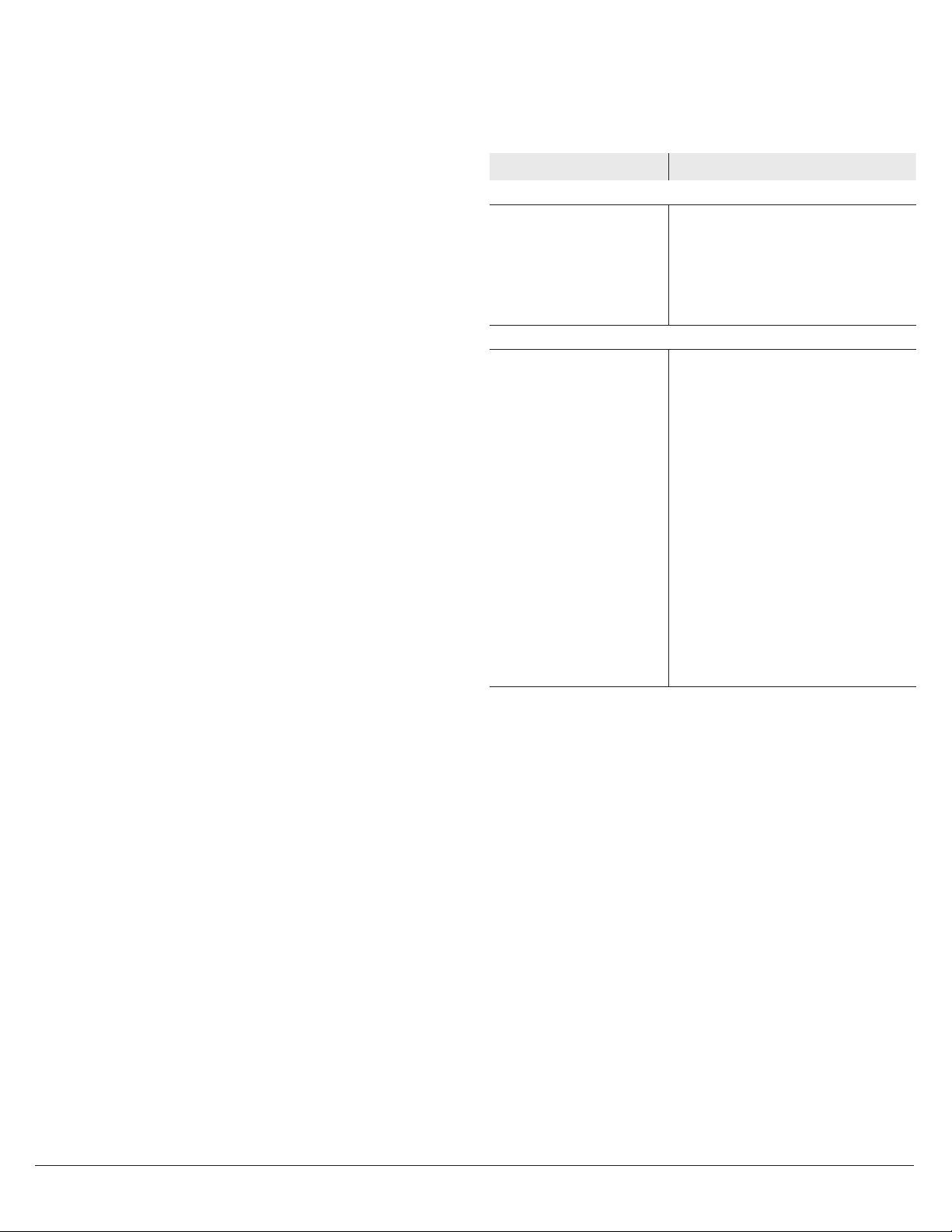

Monitored Gas Unit of Measure

Default detected gases

Hydrogen Sulfide (H2S) parts per million (ppm)

Carbon Monoxide (CO) parts per million (ppm)

Oxygen (O2) % volume

Combustible gases (LEL)

Lower explosive limit

IR Flammable (IR LEL) % volume

Hydrogen (H2) parts per million (ppm)

Sulfur Dioxide (SO2) parts per million (ppm)

IRCarbon Dioxide (CO2) parts per million (ppm)

Ammonia (NH3) parts per million (ppm)

Volatile Organic Compounds

(VOC)

Chlorine (Cl2) parts per million (ppm)

Nitrogen Dioxide (NO2) parts per million (ppm)

Hydrogen Cyanide (HCN) parts per million (ppm)

Nitric Oxide (NO) parts per million (ppm)

CO sensor with a Hydrogen

filter (COH)

a) percent of lower explosive limit (%LEL)

b) percent by volume methane 05.0% v/v

Optional gases

parts per million (ppm)

parts per million (ppm)

What’s in the Box

• Honeywell BW™ Ultra gas

detector

• Battery (factory-installed) • Screwdriver telescope with double end

• Charging adapter • Quick Reference Guide

• 3m PVC tube • 1 Dust porous filter 7/16”

• 5 AssemblyHydrophobic filter • 2 Fitting male LuerLock to 1/8”

• 5 Pump filters • USB memory stick containing user

BW Ultra User Manual 1

• 1 Screen protector

manuals

Page 6

Safety Information

a CAUTION

READ THIS FIRST

Use the detector only as specified in this manual, otherwise

the protection provided by the detector may be impaired.

• Only the instrument capable of sounding the alarms and showing readings on a

display should be used for immediate safety critical use. Wireless communication

and infrastructure are only for informational monitoring.

• Use only Honeywell approved batteries (order number: HUBAT (P/N:

50122982130) with the Honeywell BW™ Ultra detector. Using any other

battery can cause an explosion or fire.

• The lithium battery in this product presents a risk of fire, explosion, and chemical

burn if misused. Do not open, crush, disassemble, incinerate, or heat above

212°F (100°C). Batteries exposed to heat at 266°F (130°C) for 10 minutes

can cause fire and explosion. Follow the manufacturer’s instruction. Batteries

must only be charged in a hazardous free area.

• Deactivating the detector by removing the battery pack may cause improper

operation and harm the detector.

• Use only Honeywell approved battery charger, that is certified for SELV/LVLC

(isolated) with an output Um of 6.3 V.

• If using the detector near its upper or lower operating temperature, Honeywell

recommends zeroing or activating the detector in that environment.

• Charge the detector before first-time use. Honeywell recommends the detector

also be charged after every workday.

• Calibrate the device on a regular schedule, depending on use and sensor

exposure to poisons and contaminants. Honeywell recommends calibrating at

least once every six months.

• For optimal performance, periodically zero the sensor in a normal atmosphere

(20.9% v/v O) that is free of hazardous gas.

• The combustible sensor is factory calibrated to 50% LEL methane. If monitoring

a different combustible gas in the % LEL range, calibrate the sensor using the

appropriate gas.

• Only the combustible gas detection portion of this detector has been assessed

for performance by CSA standard.

• Honeywell recommends that the combustible sensor is checked with a known

concentration of calibration gas after any exposure to contaminants/poisons

such as sulfur compounds, silicone vapors, halogenated compounds, etc.

• Honeywell recommends that the sensors be bump tested before each day’s

use to confirm their ability to respond to gas. Manually verify that the audible,

visual, and vibrator alarms are activated. Calibrate if the readings are not within

the specified limits.

• The detector is designed for use only in potentially explosive atmospheres

where oxygen concentrations do not exceed 20.9% (v/v). Oxygen deficient

atmospheres (<10% v/v) may suppress some sensor outputs.

• Extended exposure of the detector to certain concentrations of combustible

gases and air may stress the detector element and seriously affect its

performance. If an alarm occurs due to a high concentration of combustible

gases, a calibration should be performed. If necessary, contact Honeywell service

representative to replace the sensor.

• High concentrations of certain toxic gases, for example, H2S, may hurt the LEL

sensor. This effect, known as inhibition, is usually temporary but in extreme

circumstances can impair the sensitivity of the LEL sensor after any gas exposure

that causes alarm in the toxic gas sensors.

• The Honeywell BW™ Ultra is provided with an antistatic coating over the LCD

window to minimize the risk of ignition due to electrostatic discharge. Periodic

inspection of this coating is required to ensure no degradation, delamination,

abrasions or other deformities to this surface.

• Care must be taken to avoid exposure to excessive heat, harsh chemicals or

solvents, sharp edges and abrasive surfaces. Clean the exterior with a soft,

damp cloth.

• Portable safety gas detectors are life safety devices. The accuracy of ambient

gas reading(s) is dependent upon factors such as accuracy of the calibration

gas standard used for calibration and frequency of calibration.

• When Honeywell BW™ Ultra detector is equipped with Infrared (IR) sensor, do

NOT use BW Ultra at an atmospheric pressure exceeding 1.1 bar (110 kPa).

The IR sensor used in the detector is intended for use at atmospheric pressure

and shall not be used in pressures exceeding 1.1 bar (110 kPa).

• DO NOT rely on the Bluetooth BW Ultra output indication for security purposes.

a WARNINGS

• FOR SAFETY REASONS THIS EQUIPMENT MUST BE OPERATED AND

SERVICED BY QUALIFIED PERSONNEL ONLY. READ AND UNDERSTAND

INSTRUCTION MANUAL COMPLETELY BEFORE OPERATING OR SERVICING.

• Substitution of components may impair Intrinsic Safety.

• Protect the combustible sensor from exposure to lead compounds, silicones,

and chlorinated hydrocarbons. Although certain organic vapors (such as

leaded gasoline and halogenated hydrocarbons) can temporarily inhibit sensor

performance, in most cases the sensor will recover after calibration.

• The Canadian Standards Association (CSA) requires the LEL sensor to be bump

tested before each day’s use with calibration gas containing between 25%

and 50% LEL. The instrument must be calibrated if the displayed LEL value

during a bump test fails to fall between 100% and 120% of the expected

value for the gas.

• High off-scale LEL readings may indicate an explosive concentration.

• Any rapid up scaling reading followed by a declining or erratic reading may indicate

a gas concentration beyond the upper scale limit, which can be hazardous.

• Products may contain materials that are regulated for transportation under

domestic and international dangerous goods regulations. Return product in

compliance with appropriate dangerous goods regulations. Contact freight

carrier for further instructions.

• Dispose of used lithium cells immediately. Do not disassemble and do not

dispose of in fire. Do not mix batteries with the solid waste stream. Spent batteries

should be disposed of by a qualified recycler or hazardous materials handler.

Keep children away from the lithium cells.

• The pellistors used in the Catalytic flammable gas sensor can suffer from a

loss of sensitivity when in the presence of poisons or inhibitors, e.g. silicones,

sulphides, chlorine, lead or halogenated hydrocarbons.

• DO NOT rely on the Bluetooth BW Ultra output indication for security purposes.

• DO NOT use the screen protector in the hazardous location. The screen protector

must be removed in the explosive atmospheres.

• The accessories (e.g., fitting mini quick-connector to 1/8”, fitting male Luer-lock

to 1/8” etc.) are not the scope of intrinsic safe certification

• Do not install or remove any components when an explosive gas atmosphere

is present.

BW Ultra User Manual2

Page 7

a MISES EN GARDE

• POUR DES RAISONS DESECURITE, CET EQUIPEMENT DOlT ETRE UTILISE,

ENTRETENU ET REPARE UNIQUEMENT PAR UN PERSONNEL QUALIFIE.

ETUDIER LE MANUEL D’INSTRUCTIONS EN ENTIER AVANT D’UTILISER,

‘ENTRETENIR OU DE REPARER L’EQUIPEMENT.

• Avertissement : Le remplacement d’un composant de l’appareil peut altérer

sa sécurité intrinsèque.

• Pour éviter l’inflammation d’atmosphères inflammables ou combustibles,

couper l’alimentation électrique avant tout entretien.

• Avertissement: Pour réduire le risque d’ignition dans les atmosphères

inflammables, les piles doivent être chargées in a dans une zone sûre, exempte

de gaz dangereux.

• Protégez le capteur de gaz combustibles contre toute exposition aux composés

de plomb, aux silicones et aux hydrocarbures chlorés. Bien que certaines

vapeurs organiques (comme l’essence au plomb ou les hydrocarbures

halogénés) puissent neutraliser provisoirement les performances du capteur,

dans la plupart des cas, le capteur retrouvera son fonctionnement normal

après l’étalonnage.

• Attention : Des valeurs LIE hors échelle élevées peuvent indiquer la présence

d’une concentration explosive.

• Toute mesure en rapide augmentation suivie d’une diminution ou d’une

mesure fantaisiste peut indiquer une concentration de gaz au-delà de la limite

d’échelle supérieure, risquant donc d’être dangereuse.

• Les produits peuvent contenir des matériaux qui sont réglementés pour

le transport en vertu des règlements nationaux et internationaux de

marchandises

• dangereuses. Retourner le produit conformément à la réglementation sur

les marchandises dangereuses appropriées. Contactez transporteur pour

plus d’instructions.

• Avertissement: La batterie au lithium peut présenter un risque d’incendie ou

de brûlure chimique en cas de mauvaise utilisation. Elle ne doit jamais être

démontée, incinérée ni chauffée au-delà de 100 °C.

• Avertissement: Les piles au lithium polymère exposées à une température

supérieure à 130 °C pendant plus de 10 minutes peuvent provoquer un

incendie et/ou une explosion.

• Mettez immédiatement au rebut les batteries au lithium usagées. Ne pas

démonter et ne pas jeter au feu. Ne pas les mélanger aux autres déchets

solides. Les piles usagées doivent être éliminées par un centre de recyclage

agréé ou un centre de traitement des matières dangereuses. Éloignez les

enfants des piles au lithium.

• Ne comptez PAS sur l’indication de sortie Bluetooth BW Ultra à des fins de

sécurité.

• N’utilisez PAS le protecteur d’écran dans un endroit dangereux. Le protecteur

d’écran doit être retiré dans les atmosphères explosives

Sensor Poisons and

Contaminants

Many chemicals can contaminate and permanently

damage sensors. Follow these guidelines when using

cleaners, solvents, or lubricants near the detector:

• Use water-based (not alcohol-based) cleaners

• Clean the exterior only with a soft, damp, cloth

These products can damage the sensors. Do not use them

around the detector:

• Soaps • Tissues containing silicone

• Solvents • Aerosols

• Alcohol-based cleaners • Anionic detergents

• Brake cleaners • Citrus-based cleaners

• Dishsoaps • Hand sanitizers

• Insect repellents • Lubricants

• Methanol (fuel or antifreeze) • Mold release agents

• Polishes • Rust inhibitors

• Window and glass cleaners • Silicone-based adhesives,

sealants, or gels

• Silicone-based cleaners or

protectants

• Hand/body/medicinal creams

containing silicone

International Symbols

Symbol Meaning

Approved to both United States and Canada

standards by UL LLC.

International Electrotechnical Commission

IECEx

Scheme for Certification to Standards for

Electrical Equipment for Explosive Atmospheres

Natural Institute of Metrology, Quality, and

Technology. Conforms to Brazilian

INMETRO Certification.

ATEX

BW Ultra User Manual 3

Conforms to European ATEX Directives

Page 8

BW ULTRA

Getting Started

1

1

5

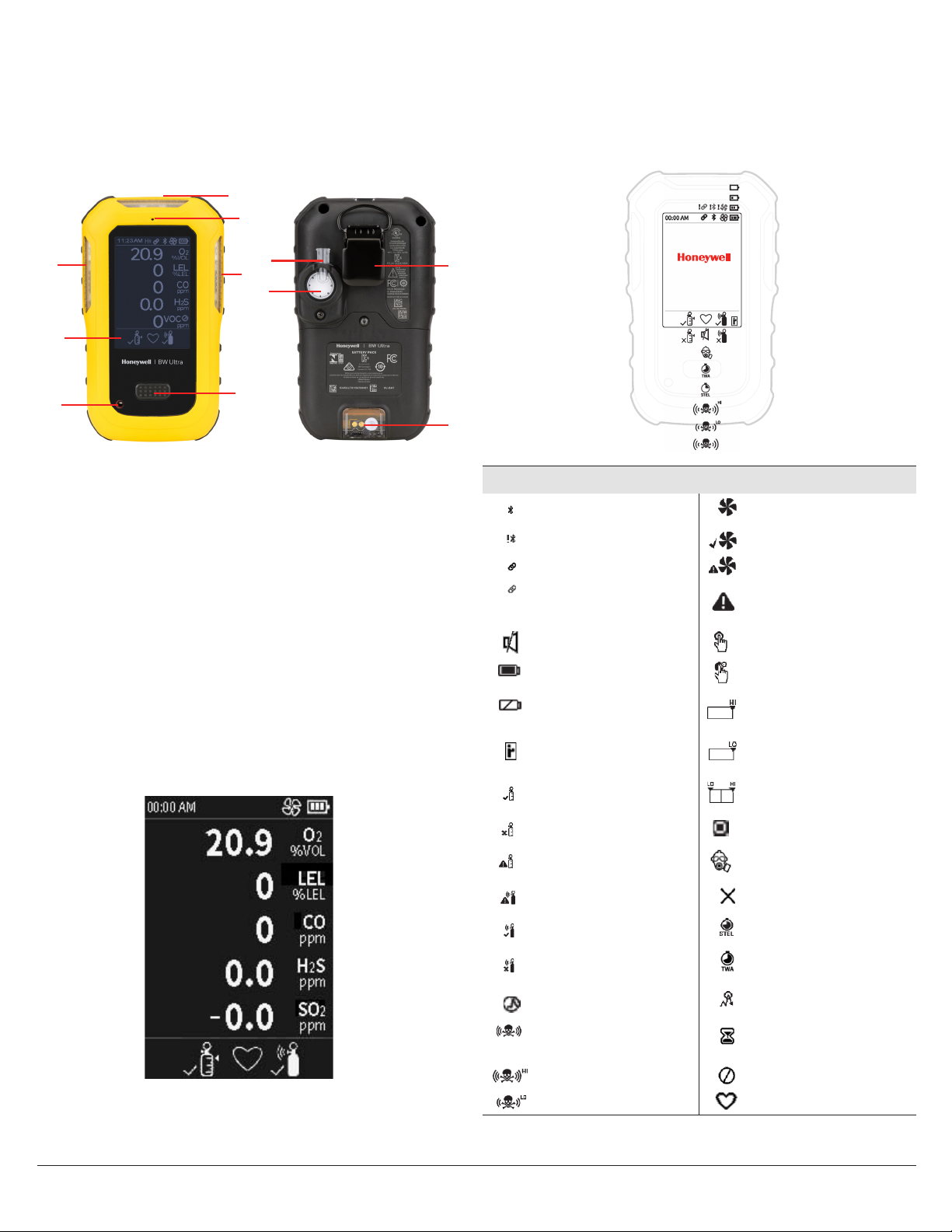

Appearance

2

Screen Icons

The detector’s screen, shown here with typical icons, will

display those shown in the following table as conditions

dictate.

6

1

8

3

4

1. Visual alarm indicator

2. Exhaust port

3. Screen

4. Button

5. Beeper Aperture

6. Pump inlet

7. Alligator clip

8. Pump assembly

9. Charging connector and IR Interface

Main Screen.

The start-up main screen is displayed as follows:

7

9

Screen Icons

BLE Pump/header

BLE Pairing Error Pump passed

Paired Pump critical fail

Pairing failed Warning/failure/

error/low battery

Stealth mode Press button

Battery -three levels Press & hold button

Low battery Hole watch mode

high

IR LINK connection Hole watch mode low

Calibration passed Hole watch Oxygen

bar

Calibration failed Target gas

Calibration cancelled Inert mode

Bump test cancelled Sensor failure

Bump test passed STEL alarm

Bump test failed TWA alarm

Correction factor Peak gas exposure

Over limit alarm Firmware update in

High alarm Sensor disabled

Low alarm Heartbeat

progress

BW Ultra User Manual4

Page 9

Alarms

When the detector goes into alarm, it flashes, vibrates,

and produces a loud siren noise. Depending on the type of

alarm, these flashes, vibrations, and noises will be different.

NOTE: In Stealth mode the Honeywell BW™ Ultra only

vibrates.

IMPORTANT: Regardless, when a detector goes into alarm,

always take appropriate action. Never ignore or dismiss an

alarm.

Refer to this information about the different alarm types

and their corresponding screens.

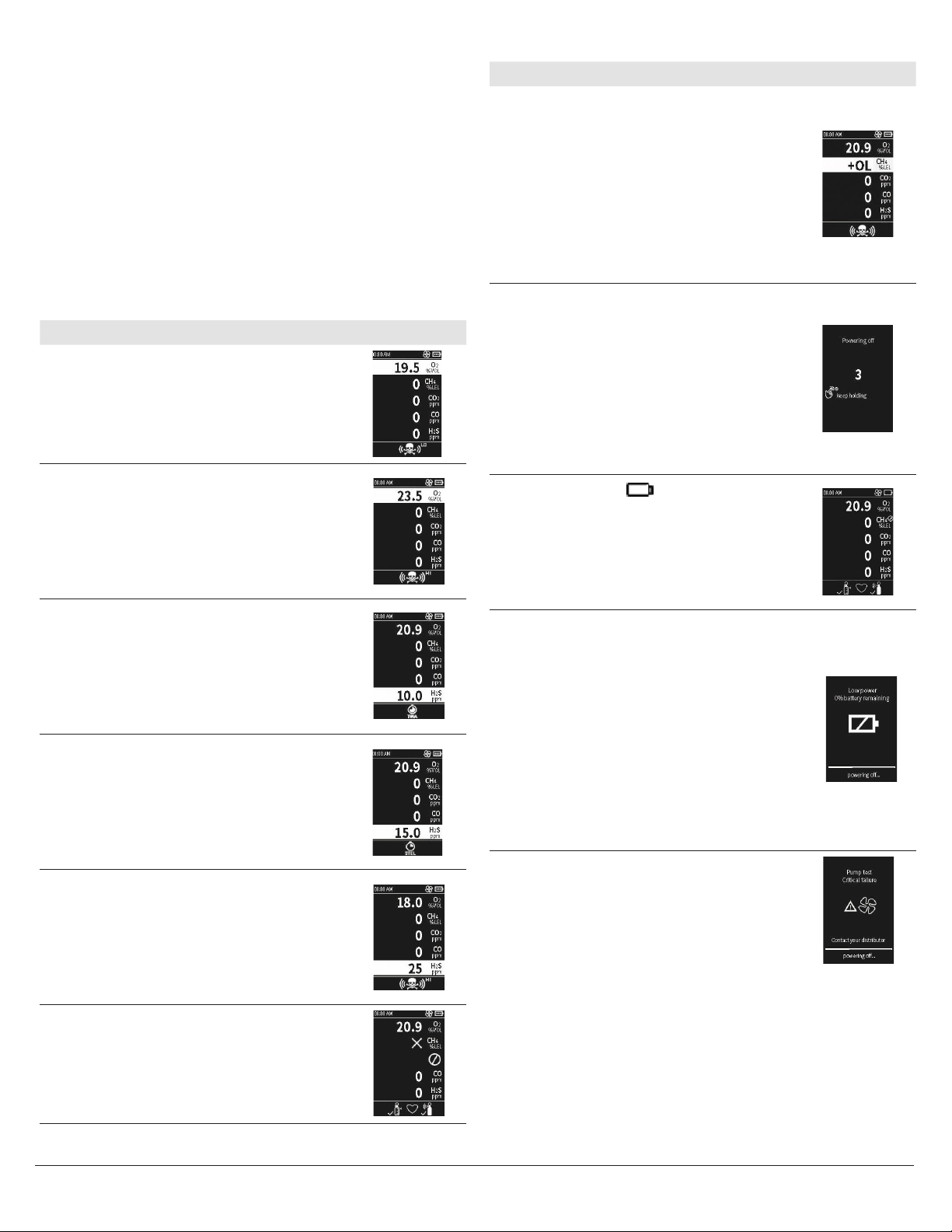

Alarm Type Description Screen

Slow siren (upward tone)

Slow flash

Low Alarm

High Alarm

Time

Weighted

Average

(TWA) Alarm

Short Term

Exposure

Limit (STEL)

Alarm

Multi Alarm

Black box around gas

flashes

Vibrator alarm activates

Fast siren (downward

tone)

Fast flash

Black box around gas

flashes

Vibrator alarm flashes

Fast siren (downward

tone)

Fast flash

Black box around gas

flashes

Vibrator alarm activates

Fast siren (downward

tone)

Fast flash

Black box around gas

flashes

Vibrator alarm activates

Alternating low and high

alarm

Black box around gas

flashes

Type of alarm alternates

Vibrator alarm alternates

Alarm Type Description Screen

Fast siren (downward

tone)

Fast flash

Over Limit

(OL) Alarm

Normal

Deactivation

Low Battery

Alarm

Critical

Battery

Alarm

Pump Alarm

Black box around gas

flashes

Vibrator alarm activates

Sequence of alternating

beeps and alternating

flashes

Vibrator alarm activates

Countdown initiates

“OFF” is displayed

Sequence of 10 rapid

sirens and alternating

flashes followed by

7 seconds of silence

(continues for 15

minutes)

Vibrator alarm pulses

After 15 minutes of

the low battery alarm

sequence, the detector

will enter critical alarm

Fifteen minutes after low

battery alarm activates,

sequence of 10 rapid

sirens and alternating

flashes with 1 second

of silence in between

(sequence reactivates

seven times)

Vibrator alarm pulses

“Low Battery Powering

Off” is displayed and the

detector deactivates

Detector is in pump alarm

when gas is turned off

during calibration.

flashes

Sensor

Failure

Alarm

BW Ultra User Manual 5

is displayed

Î

Page 10

Detector Operations

Activate the detector

Turn-on the detector in a safe area with an atmosphere of

20.9% oxygen and free of hazardous gas.

1. For first time use, charge the battery for up to 8 hours

or until LED light turns green using the charging

adapter provided. Refer to Charge the battery for more

information.

2. Press and hold the button for three seconds.

3. For first time use, a Warming sensors message is

displayed and a 30 minutes countdown is displayed.

In most cases, this countdown only lasts a couple of

minutes.

4. When the detector displays Pump test Block inlet,

block the pump inlet with a finger, and then after a

couple of seconds unblock the pump inlet.

The detector performs a quick pump test. A Pump Test

passed message is displayed.

If you do not block the pump inlet, the detector will turn

off after two minutes.

The detector will then perform a self-test, including

testing the sensors. This process could take several

minutes.

If necessary, you will be instructed by screen prompts to

calibrate newly-installed sensors.

5. When the self-test is complete, press and hold the

button to zero sensors. After the autozero is complete,

the detector then checks the sensors for calibration and

bump test.

If the detector identifies sensors requiring calibration or

bump testing, press the button and follow the on-screen

instructions.

Navigate the menu

There are four main menu items.

• See Information

• Start Bump Test

• Zero Sensors

• Start Calibration

1. Double pressing the button displays all four options on

the screen. See Information is selected and highlighted

by default.

2. Press the button to transition the selection to the next

choice.

3. Press and hold for three seconds to enter the selected

option.

4. Follow on-screen instructions for your selected

operation. Most of the detector’s procedures are

described in this guide.

View detector’s general information

1. Double-press the button to enter the main menu.

2. Select See information and press the button to scroll

through the following information:

Peak readings

STEL readings

TWA readings

Bump test intervals

Calibration

BLE information (BLE should be enabled)

LEL Correction Factor

Low Alam setpoint

Hi Alam setpoints

STEL setpoints

TWA setpoints

Activate the backlight

To activate the backlight on the screen, press the button.

Deactivate the detector

1. Press and hold the button during the powering-off

countdown.

2. Release the button when OFF is displayed.

Reset TWA or STEL readings

Before you begin.

You need to enable TWA/STEL Reset in Fleet Manager II to

reset readings in the detector.

1. Go to the main menu and select > See Information >

TWA readings or STEL readings.

2. Press and hold for 3 seconds to reset readings.

A reset message is displayed.

Reset Peak readings

Before you begin.

You need to enable Peak Reset in Fleet Manager II to reset

readings in the detector.

1. Go to the main menu and select > See Information >

Peak readings.

2. Select Hold to reset peak readings. Press and hold for 3

seconds to reset readings.

BW Ultra User Manual6

Page 11

Reset TWA/STEL and

Latching Alarms

Peak readings

Before you begin.

You need to enable TWA/STEL Reset and Peak Reset in

Fleet Manager II to reset readings in the detector.

1. Go to the main menu and select > See Information >

Peak readings.

2. Select Hold to reset all readings. Press and hold for 3

seconds to reset readings.

Zero sensors

Before you begin.

Connect the Nitrogen if this is a CO2 unit.

1. Go to the main menu and select Zero Sensors.

2. Press and hold for 3 seconds.

A Zeroing process starts automatically.

The screen displays all current gas measurements,

highlighting entries above zero.

Ambient air is applied to zero all sensors that are not

CO2.

The screen displays all current gas measurements,

highlighting entries being reset to zero.

3. If you are not zeroing O2, Click NO in the prompted

message: Is this a CO2 unit?.

Zero results are displayed.

Press the button or wait for six seconds to end the

Zeroing process.

4. Click Yes if this is a CO2 unit and you want to apply

Nitrogen to zero CO2.

A two minutes gas measure process starts

automatically.

All current gas measurements and entries reset to zero

are displayed.

5. Turn off the gas following on-screen instructions.

Zero results are displayed.

6. Press the button or wait for six seconds to end the

Zeroing process.

Zero results are displayed as follows:

• A check mark for sensors that passed Zero

• A cross mark for sensors that failed Zero

• An exclamation mark for sensors that skipped Zero

Acknowledge alarms and messages

Press and release the button to perform any of the

following:

• To acknowledge a latching alarm

• To acknowledge a low alarm

• To acknowledge due today message (for example, calibration and bump test

reminders). Note that the force calibration and force bump test features cannot

be bypassed.

If enabled, during an alarm condition the Latching Alarms

option causes the low and high gas alarms (audible, visual,

and vibrator) to persist until the alarm is acknowledged and

the gas concentration is below the low alarm setpoint. The

LCD displays the peak concentration until the alarm no

longer exists. Local regulations in your region may require

the Latching Alarms option be enabled.

The detector is shipped with the Latching Alarms option

disabled.

Calibrate the detector

Perform a calibration to adjust the sensitivity levels of

sensors and ensure accurate responses to gases.

The detector can be calibrated in two ways:

• Apply gas from a cylinder to the sensors manually through the pump inlet.

• Use an IntelliDoX module.

Before you begin. Move to a normal atmosphere (20.9%

v/v O2) that is free of hazardous gas.

1. Go to the main menu and select > Start Calibration.

2. Press and hold the button for three seconds to display

the Powering Off countdown and continue to hold for

the Starting Calibration countdown.

The detector will enter the zero function. The Zeroing

process starts automatically and lasts for five minutes.

Current gas measurements are displayed, and entries

above zero are highlighted.

3. Connect the calibration hose to the pump inlet. Make

sure to use a demand flow regulator.

4. Confirm that you want to apply Nitrogen to zero CO2.

5. When Apply calibration gas now is displayed,

apply the gas and wait for a maximum of five minutes.

The detector first tests for a specific type of gas. When

it detects enough of that gas for sensor calibration, a

check box will be displayed next to that gas. Calibration

then begins. Gas values will adjust on the screen during

the calibration.

6. When Turn gas o is displayed, disconnect the device

from gas. Check marks will be displayed next to the

calibrated sensors. These sensors reset to the number

of days until the next calibration is due (for example,

180 days).

The calibration cycle will take about two minutes after

which the user will be prompted to Press button to

continue.

7. If the calibration was successful, Calibration

Passed will be displayed. Press the button to exit

calibration.

If the calibration failed for some or all of the gases,

either a Cal Error All gases applied mixed

results message (if the detector was not successfully

BW Ultra User Manual 7

Page 12

calibrated for all gases) or a Fail all gases message

will be displayed. After the button is pressed, a Cal

overdue message will be displayed.

Start a Bump Test

Perform a bump test regularly to test sensors and alarms.

To bump test, expose the sensors to a gas concentration

that exceeds alarm setpoints and confirm that the sensors

and alarms work correctly.

The detector can be bump tested in two ways:

• Apply gas from a cylinder to the sensors manually through the pump inlet.

• Use an IntelliDoX module.

Perform a manual bump test

Before you begin.

Connect the calibration hose to a demand flow regulator on

the gas cylinder.

1. Double-press the button and select > Start Bump test.

2. Press and Hold the button for three seconds.

The detector displays Starting Bump test.

Bump test started is displayed, and then the

detector makes noise, flash, and vibrate.

3. The detector will prompt you Did you see and hear

the alarms?, select Pass, and Press and hold for

three seconds to confirm that the visual, audible, and

vibrator alarms work correctly.

An Audio-Visual test passed message is

displayed.

Skip to Step 5.

4. If the visual, audible, and vibrator alarms failed, select

Fail, and press and hold the button. An Audio-Visual

test failed message is displayed.

Then you can:

a) Apply gas, Skip to Step 5

b) Press the button to skip gas application and follow

on-screen instructions to end the Bump Test.

Bump test results are displayed, and the test ends.

5. If you want to apply gas, follow on-screen instructions.

Wait for about 30 seconds; gas measurements are

displayed for each pertinent gas sensor.

A Bump Test pass confirmation is displayed.

6. After the Turn gas o message is displayed, remove

the hose from the pump inlet. The detector will remain

in alarm until the gas clears from the sensors.

Bump test results are displayed showing check marks

next to the tested sensors. These sensors reset to the

number of days until the next Bump Test is due.

7. Press the button to finish the procedure.

Set up IntelliFlash

The IntelliFlash® feature causes the detector, if it is in

compliance (for example, bump tested and calibrated),

to flash a green light every second (the factory setting

default) from the top visual alarm indicator. In Fleet

Manager II, use the IntelliFlash Interval option to change

how often the detector flashes.

Set up Reverse IntelliFlash

IntelliFlash flashes a green light when the detector is in

compliance, but Reverse IntelliFlash® flashes an amber

light when the detector is not in compliance (a bump test

or calibration is overdue, or a sensor is not working and has

been overridden).

Use Fleet Manager II to change how often the detector

flashes for Reverse IntelliFlash.

IntelliFlash and Reverse IntelliFlash can be configured in

one of four scenarios:

Scenario 1

When both IntelliFlash and Reverse IntelliFlash are

enabled, the detector’s green LED will flash until it goes out

of compliance, then its amber LED will flash instead.

Scenario 2

If IntelliFlash is enabled and Reverse IntelliFlash is

disabled, the detector’s green LED flashes until it goes out

of compliance, then it stops flashing.

Scenario 3

If IntelliFlash is disabled and Reverse IntelliFlash is

enabled, neither LED will flash while the detector is in

compliance. The amber LED will flash if it goes out of

compliance.

Scenario 4

When both IntelliFlash and Reverse IntelliFlash are

disabled, neither LED will flash under any circumstances.

Set up the Confidence and

Compliance Beep interval

The Confidence Compliance Beep is a sound that tells

the user the detector is in compliance (for example,

bump tested and calibrated). In Fleet Manager II use the

Confidence/Compliance Beep option to change how often

the detector beeps for Confidence Compliance Beep.

a CAUTION

Honeywell recommends to bump test the sensors before each day’s

use to confirm their ability to respond to gas by exposing the sensors

to a gas concentration that exceeds the alarm setpoints.

BW Ultra User Manual8

Page 13

Select an operation mode

The detector can be used in one of three modes: Essentials

mode, Hole Watch mode, and Inert mode.

Note: Honeywell BW™ Ultra always monitors gas levels, regardless of

the operating mode. If the detector detects a sudden gas exposure,

it will flash, vibrate, and produce a loud siren noise. A gas level alarm

takes precedence over all of the detector’s other functions.

Configure the Detector

You can configure the Honeywell BW™ Ultra detector’s

device and sensor using Fleet Manager II.

Necessary to configure detector settings:

• Honeywell BW™ Ultra detector

• IR Link adapter or IntelliDoX docking station

• Computer with Fleet Manager II software installed.

Essentials mode

The detector only shows the gas readings.

Hole Watch mode

The Hole Watch mode is the default operating mode. It is

used for confined space monitoring. Use Hole Watch mode

to monitor all gas levels in the same screen view. Hole

Watch mode uses bar graphs that fill when the detector

detects rising gas concentrations.

• When the detector detects normal gas levels, Hole Watch mode displays

empty bar graphs.

• When the detector detects non-critical gas levels, Hole Watch mode displays

filling bar graphs.

• When the detector activates a single gas alarm, Hole Watch mode highlights

the detected gas level for that gas in a solid bar.

• When the detector activates a multiple gas alarm, Hole Watch mode continues

to display the first detected gas level, as well as highlight other detected gas

levels in a solid bar.

• For oxygen, Hole Watch mode displays low and high levels in a bar graph. As

the detector detects a low oxygen level, the bar graph fills toward LO.

• As the detector detects a high oxygen level, the bar graph fills toward HI.

Inert mode

You can configure Inert Mode in Fleet Manager II. The

threshold for operation is 10%. If oxygen readings fall

below 10%, the detector prompts the user to enter the Inert

mode. The detector does not start automatically in Inert

Mode.

When the detector goes into Inert Mode, the alarms

setpoint get activated. If the detector does not enter in Inert

mode, The O2 readings are considered normal.

For device settings, a startup message can be added;

Confidence Compliance Beep can be activated, bump tests

can be forced, stealth mode can be enabled, etc.

For sensor settings, the calibration gas type and frequency

can be changed, the bump test interval and alarm setpoints

can be set, STEL and TWA can be selected, etc.

You can perform some other calibrations with Fleet

Manager II.

Note: When the operator configures the Honeywell BW™ Ultra using

FleetManager II, Honeywell strongly recommends reviewing the

detector’s settings before the operation to ensure that settings were

applied successfully and comply with performance requirements.

Custom configuration created in Fleet Manager II can be

used to configure detector settings.

Example: Five detectors must have the same bump test

reminders and alarm setpoints. Each detector could be

configured separately or Fleet Manager II can be utilized to

create a custom settings configuration. This configuration

can then be loaded on each detector. This saves time and

allows settings to be managed from one location.

Connect With IntelliDoX

If a detector’s calibration is overdue and the forced

calibration feature is enabled, the calibration can be

performed with an IntelliDoX docking station or through

the calibration option from the detector’s main menu.

Connect With an IR Link

The detector can be paired with an IR link, aka dongle.

There is an IR connection at the bottom of the detector

that allows FleetManager II configurations to be efficiently

transferred to multiple detectors. The IR link will also allow

new firmware to be transferred to detectors or data/event

logs to be transferred to FleetManager II.

Note: You should have the IR Connectivity Kit (sold separately) to

transfer the data from a computer to the detector.

BW Ultra User Manual 9

Page 14

Bluetooth Pairing

The user can pair the Honeywell BW™ Ultra to a mobile

device via built in Bluetooth Low Energy (BLE). The

Honeywell Safety Communicator app, installed on the

mobile phone, can then show gas readings and alarms

from the Honeywell BW™ Ultra unit that is connected.

Readings and alarms can then be sent to Honeywell’s

remote monitoring software.

1. On the mobile device, turn on the Bluetooth connection

and look for available detectors.

On the Honeywell BW™ Ultra, the Bluetooth connection

is on by default.

2. On the mobile device, select the detector and then enter

100000.

Note: Pairing is not allowed at start up, during calibration, or bump

test.

Warning: Wireless communication and infrastructure

should be used as informational monitoring only.

Replace a Sensor

Use only sensors designed by Honeywell for the

Honeywell BW™ Ultra detectors. Replace the sensors in a

non-hazardous location.

The Honeywell BW™ Ultra detector can be configured for a

maximum of 5 gases and may contain dummy sensors.

Review Logs

Many of the detector events are logged and can be

reviewed via IntelliDoX or BLE. Typical logged events would

be:

• bump test failed • self-test failed

• last calibration failed • calibration overdue

• calibration forced • calibration canceled

• calibration error • calibration passed

• sensors in alarm • system reset

• sensors zeroed • event logs vs. data logs

• “Turn cal gas off...” message is displayed

BW Ultra User Manual10

Page 15

Maintenance

Maintenance

Perform the following tasks to maintain the detector in

good operating condition:

• Calibrate, bump test, and inspect the detector on a regular schedule.

• Maintain an operations log of all maintenance, bump tests, calibrations, and

alarm events.

• Keep the exterior of the detector clean.

Gas Cylinder Guidelines

• Use a premium-grade calibration gas that is approved by the National Institute

of Standards and Technology.

• Verify the expiration date on the cylinder before use.

• Do not use an expired gas cylinder.

• Contact Honeywell if a certified calibration of the detector is required.

Languages

Honeywell BW™ Ultra supports eight languages: English,

French, German, Portuguese, Spanish, Simplified Chinese,

Russian, Italian, Dutch, Slovak, Czech, Polish, Norwegian,

Danish, Swedish, Finnish, Turkish, and Arabic.

These are configurable through FleetManager II.

Custom startup text can be entered in all languages except

Simplified Chinese through FleetManager II.

Clean the Detector

Clean the exterior of the detector with a soft, damp cloth.

Use only water-based (non-alcohol) cleaners. Do not use

soaps, solvents, or polishes.

Upgrade the Firmware

Upgrade the Firmware via IR Link using the Fleet Manager

II Software.

Charge the Battery

You can charge the battery using the provided charging

adapter, that is certified for SELV/LVLC (isolated) with an

output Um of 6.3 V.

It can take up to 8 hours to get the battery fully charged in a

temperature range from 5 °C to 35 °C.

Note: If you charge with the power on, charging may not be completed

within 8 hours.

Maintain the Battery

Lithium-ion batteries do not respond well to cycles of full

discharge followed by a full charging cycle. Recharge the

battery before it is exhausted.

Do not charge the battery at low or elevated temperatures.

30°C (86ºF) is considered an elevated temperature and

should be avoided whenever possible.

A rechargeable battery’s runtime decreases approximately

20% over a two-year period of typical use.

Real Time Clock Display

The real time clock is displayed in the upper left corner

of the detector’s screen. It is configurable through

FleetManager II in 12 or 24-hour formats.

The date display can also be configured in several formats

through FleetManager II.

The time/date information is retained even when the

detector’s battery is being changed.

Before you begin.

• You should have the IR Connectivity Kit (sold separately) to transfer the data

from a computer to the detector.

• Download and save the firmware update file to a PC or network drive.

Do not rename the file.

• Download the BWFleetManager2.exe file and install Fleet Manager II.

• For more information refer to the Fleet Manager II User Manual.

1. Turn on the detector.

2. Start Fleet Manager II application.

a) Expand Administration from the left pane.

b) Click Login/Logout.

c) Type in the default password: Admin.

d) Click OK to continue.

3. In the left pane select Devices > Configure device via IR

link.

In the Device Selection window:

a) Select Honeywell BW™ Ultra.

b) Click OK.

4. In the Honeywell BW™ Ultra configuration window, click

Bootloader to select the binary file.

In the Honeywell BW™ Ultra Bootloader window, click

Choose File.

5. In the Choose Firmware File to Upload window, select

the downloaded file, and then click Open.

6. Connect the Honeywell BW™ Ultra detector to the

computer using the IR Link connector.

7. Click Send to initiate the file transfer to the gas detector.

After the file transfer is complete, the Bootload process

will start. During Bootload, the display will go blank and

the detector will beep several times.

8. The Programming Succeeded message is displayed.

Press the button to finish the procedure, and then

disconnect the detector from the computer.

BW Ultra User Manual 11

Page 16

Service

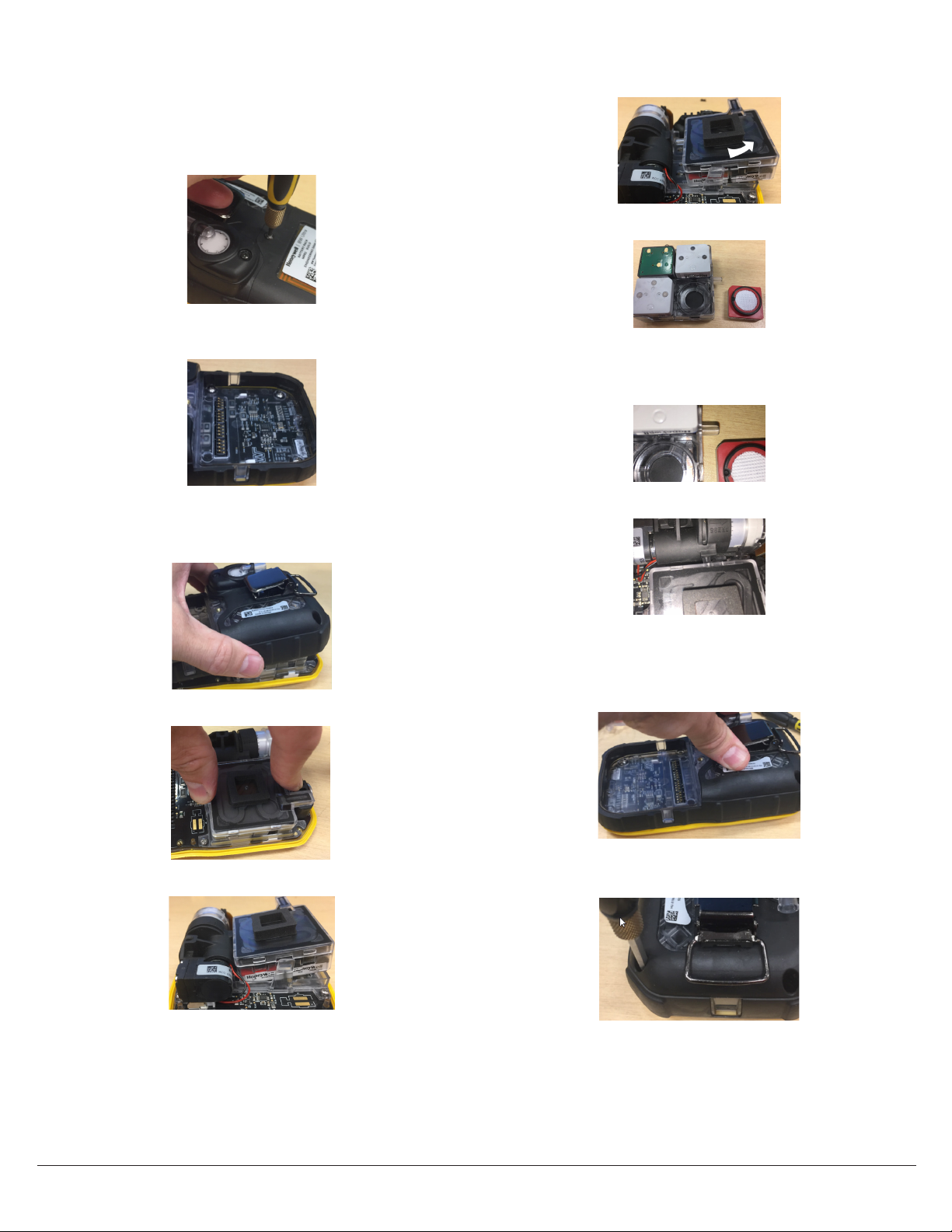

Replace the Printed Circuit Board

(PCB)

3. Remove the LCD:

a) Disengage the two snaps on the upper sides of the

LCD carrier.

1. Turn the instrument off.

2. Remove the front shell:

a) Turn the instrument face down and unscrew on the

battery pack.

b) Remove the battery pack and the four screws in the

battery compartment.

c) Remove the two screws at the top of the instrument

and pull the back shell apart from the front shell.

b) Swing LCD forward watching for the ZIF connector.

c) Lift the latch on the ZIF connector, and then pull the

LCD cable forward and remove LCD assembly.

4. Disengage the two snaps holding the manifold carrier

in place and carefully pull up the manifold carrier off the

PCB.

d) Remove the two screws holding the PCBA in place.

e) Remove the PCB assembly from the front shell.

5. Lift the latch on the 4R+ ZIF connector and pull out the

4R+ cable assembly to disconnect the pump connector

from the PCB.

6. Retrieve the new PCB.

7. Connect the pump to the PCB.

8. Align the snaps on the manifold carrier and push down

to engage the snaps to the PCB.

BW Ultra User Manual12

Page 17

9. Insert the 4R+ ribbon cable into the ZIF connector and

press down on the 4R+ ZIF latch to engage the cable.

10. Re-connect the 4R+ sensor cable.

b) Place the PCB into the front shell and insert the two

screws (torque 34 in-lbs) to fasten both pieces.

c) Replace the back shell and install the four screws

back into the battery compartment (torque 45 in-lbs).

11. Attach the LCD:

a) Insert the LCD ribbon cable into the ZIF connector

and press down on the ZIF connector latch to engage

the cable.

b) Lever the LCD assembly back toward the PCB, then

press down until the side snaps are engaged.

12. Attach the shells:

a) On the front shell, ensure the LCD gasket is aligned

with the pins. The frame should be facing up.

d) Reinstall the two screws at the top of the instrument

(torque 45 in-lbs).

13. Place the battery pack:

a) Engage hooks on the bottom of the battery pack.

b) Push the battery pack into place.

c) Tighten the battery retention screw (torque 45 inlbs).

14. Turn on the instrument and allow for the sensors to

stabilize.

Calibrate sensors.

BW Ultra User Manual 13

Page 18

Replace the LCD

1. Turn the instrument off.

2. Remove the battery:

a) Turn the instrument face down and unscrew on the

battery pack.

b) Remove the battery pack and the four screws in the

battery compartment.

3. Remove the front shell:

a) Remove the two screws at the top of the instrument

and pull the back shell apart from the front shell.

4. Remove the LCD:

a) Disengage the two snaps on the upper sides of the

LCD carrier.

b) Swing LCD forward watching for the ZIF connector.

c) Lift the latch on the ZIF connector, pull the LCD cable

forward and remove LCD assembly to remove the LCD

assembly.

b) Remove the two screws holding the PCB in place.

c) Remove the PCB assembly from the front shell.

d) Pull the LCD cable forward and remove the LCD

assembly.

5. Retrieve the new LCD.

6. Attach the LCD:

a) Insert the LCD ribbon cable into the ZIF connector

and press down on the ZIF connector latch to engage

the cable.

b) Lever the LCD assembly back towards the PCB, then

press down until the side snaps are engaged.

BW Ultra User Manual14

Page 19

c) On the front shell, ensure the LCD gasket is aligned

with the pins. The frame should be facing up.

7. Attach the front shell:

a) Place the PCB into the front shell and insert the two

screws (torque 34 in-lbs) to fasten both pieces.

b) Replace the back shell and install the four screws

back into the battery compartment (torque 45 in-lbs).

b) Push the battery pack into place and tighten the

battery retention screw (torque 45 in-lbs).

c) Turn on the instrument and allow for the sensors to

stabilize.

c) Reinstall the 2 screws at the top of the instrument

(torque 45 in-lbs).

8. Attach the battery:

a) To place the battery pack correctly, first engage

hooks on the bottom of the battery pack.

BW Ultra User Manual 15

Page 20

Replace the 1-Series Sensors

1. Turn the instrument off.

2. Remove the battery:

a) Turn the instrument face down and unscrew on the

battery pack.

b) Remove the battery pack and the four screws in the

battery compartment.

3. Remove the sensor:

a) Remove the two screws at the top of the instrument

and pull the back shell apart from the front shell.

d) Pull the sensor manifold out from the pump

manifold.

e) Remove the desired sensor.

4. Install the new sensor:

a) Mind the orientation key, and then push the sensor

down into manifold.

b) Insert manifold inlet into pump manifold.

b) Pull back the two retaining clips on the manifold.

c) Lift the manifold sideways, farthest from the pump.

c) Push manifold down and as the two latches engage,

listen for two snapping sounds.

5. Replace the back shell and install the four screws back

into the battery compartment (torque 45 in-lbs).

6. Reinstall the 2 screws at the top of the instrument

(torque 45 in-lbs).

BW Ultra User Manual16

Page 21

7. Attach the battery:

a) To place the battery pack correctly, first engage

hooks on the bottom of the battery pack.

b) Push the battery pack into place and tighten the

battery retention screw (torque 45 in-lbs).

8. Turn on the instrument and allow for the sensors to

stabilize.

BW Ultra User Manual 17

Page 22

Replace the 4R+ Sensors

1. Turn the instrument off.

2. Remove the battery:

a) Turn the instrument face down and unscrew on the

battery pack.

b) Remove the battery pack and the 4 screws in the

battery compartment.

3. Remove the sensor:

a) Remove the two screws at the top of the instrument

and pull the back shell apart from the front shell.

4. Install the new sensor:

a) Retrieve the new sensor and insert it into the

manifold aligning the sensor guides to the instrument’s

slots.

b) Push sensor forward until it stops moving.

c) Re-connect the 4R+ sensor cable.

5. Replace the back shell and install the four screws back

into the battery compartment (torque 45 in-lbs).

b) Disconnect the 4R+ cable from the sensor.

c) Push at the PRESS marking in the manifold toward

the top of the instrument.

d) Use the tabs on the sensor to pull it out of the

manifold.

Reinstall the two screws at the top of the instrument

(torque 45 in-lbs).

6. To place the battery pack correctly, first engage hooks

on the bottom of the battery pack.

7. Push the battery pack into place and tighten the battery

retention screw (torque 45 in-lbs).

8. Turn on the instrument and allow for the sensors to

stabilize.

9. Calibrate new sensor.

BW Ultra User Manual18

Page 23

Replace the Pump

1. Turn the instrument off.

2. Remove the battery:

a) Turn the instrument face down and unscrew on the

battery pack.

b) Remove the battery pack and the four screws in the

battery compartment.

3. Remove the two screws at the top of the instrument and

pull the back shell apart from the front shell.

b) Fold the pump wires across the bottom of the pump

motor.

c) Insert the pump into the manifold assembly.

6. Replace the back shell and install the 4 screws back into

the battery compartment (torque 45 in-lbs).

7. Reinstall the two screws at the top of the instrument

(torque 45 in-lbs).

4. Remove the pump:

a) Pull the pump out of the manifold assembly.

b) Release the pump connector retainer clip and pull the

pump connector out.

5. Install the new pump:

a) Retrieve the new pump and insert the pump

connector.

8. To place the battery pack correctly, first engage hooks

on the bottom of the battery pack.

9. Push the battery pack into place and tighten the battery

retention screw (torque 45 in-lbs).

BW Ultra User Manual 19

Page 24

Replace the Battery

Replace the Pump Inlet Filter

1. Turn the instrument off.

2. Turn the instrument face down and unscrew on the

battery pack.

3. Remove the battery pack.

4. To place the new battery pack correctly, first engage

hooks on the bottom of the battery pack.

5. Push the battery pack into place and tighten the battery

retention screw (torque 45 in-lbs).

1. Turn the instrument off.

2. Unthread the screw on the pump inlet cover.

3. Rotate the cover counter-clockwise.

4. Remove the cover.

5. Remove both the particulate and hydrophonic filter.

Note: Use only the HU-BAT Honeywell battery pack.

6. First, Install both the hydrophonic and then the

particulate filters.

7. Place the filter cover and rotate the filter cover clockwise

until stop.

8. Tighten the screw (torque to 34 in-lbs).

BW Ultra User Manual20

Page 25

Appendices

Auto detect gas

While the gas is applied during calibration, the detector will

wait for up to 300 seconds to allow the gas to stabilize. If

the gas has not stabilized by then, the detector will display

a Gas unstable message. If the gas stabilizes within

300 seconds, it will be automatically detected and will not

have to be selected from a menu. The name of the gas and

a Span calibration in progress message will be

displayed. If a quad gas mixture was used, the detector will

display the names of all four gases.

Gas Alarm Setpoints

Gas alarms are activated when detected gas concentrations

are above or below the user-defined setpoints. The gas

alarms are described as follows.

Alarm Condition

Low Toxics and combustibles: Ambient gas level

above low alarm setpoint.

Oxygen: Ambient gas level may be set above or

below 20.9% (or 20.8%).

High Toxics and combustibles: Ambient gas level

above high alarm setpoint.

Oxygen: Ambient gas level may be set above or

below 20.9% (or 20.8%).

TWA Toxics only: Accumulated value above the TWA

alarm setpoint.

STEL Toxics only: Accumulated value above the STEL

alarm setpoint.

Multi-gas Two or more gas alarm conditions

simultaneously.

Over Limit (OL) OL or OL displays when readings are above or

below the sensor detection range, respectively.

Specifications

Detector dimensions: 8.1 x 14.6 x 5.1cm

Weight: 444.2 g

Operating temperatures: 4°F to +122°F (20°C to +50°C)

Battery operating times: 10 hours.

Rechargeable battery: 8 hours in a temperature range

from 5 °C to 35 °C.

Storage temperature: 40°F to +122°F (40°C to +50°C)

Operating humidity: 0% to 95% relative humidity

(non-condensing)

Detection range:

H2S: 0 – 100 ppm (1 / 0.1 ppm increments)

CO: 0 – 500 ppm (1 ppm increments)

O2: 0 – 30.0% vol. (0.1% vol. increments)

Combustible (LEL): 0% to 100% LEL (1% LEL

increments) or 0.0% to 5.0% v/v methane

Sensor type:

Alarm conditions: STEALTH, TWA alarm, STEL alarm, low

alarm, high alarm, multi-gas alarm, low battery alarm,

confidence beep, automatic deactivation alarm

Audible alarm: 95 dB at 30 cm (1 ft.) (100 dB typical)

variable pulsed beeper

Visual alarm: Red light-emitting diodes (LED)

Display: Alphanumeric liquid crystal display (LCD)

Screen resolution: 160X240 pixels.

Backlight: Activates when the pushbutton is pressed and

deactivates after 5 seconds; also activates during an alarm

condition

Self-test: Initiated upon activation.

Calibration: Automatic zero and automatic span.

Sample Factory Alarm Setpoints

Following table lists alarm setpoints as defined by the US

Occupational Safety and Health Association (OSHA).

Gas TWA STEL Low High

H2S 10 ppm 15 ppm 10 ppm 15 ppm

CO 35 ppm 50 ppm 35 ppm 200 ppm

O2 N/A N/A 19.5% vol. 23.5% vol.

LEL N/A N /A 10% LEL 20% LEL

Note: To disable an alarm, set the alarm setpoint to 0 (zero) in Fleet

Manager II.

BW Ultra User Manual 21

Page 26

Standards and Certifications

The Honeywell BW™ Ultra gas detector is in conformity with

the following standards and certifications:

IECEx: UL 18.0061X

IEC 600790:2017

IEC 6007911:2011

IEC 600791:2014

Approvals:

Approved by UL to both U.S. and Canadian Standards

UL 913, 8th Edition

UL 600790, 6th Edition

UL 600791, 7th Edition.

UL 6007911, 6th Edition

ANSI/ISA 60079291 (12.13.01) - 2013

CSA C22.2 No.152M1984 (R2016)

CSA C22.2 No. 600790:15

CSA C22.2 No. 6007911:14

CSA C22.2 No. 600791:16

UL: E480011

Class I, Division I, Group A, B, C and D, Temperature code

T4, 40 ≤ Tamb ≤ +50°C

Class I, Zone 0, AEx ia IIC T4 Ga, 40 ≤ Tamb ≤ +50°C

(without LEL and IR sensor installed)

Class I, Zone 0, AEx da ia IIC T4 Ga, 40 ≤ Tamb ≤ +50°C

(with LEL sensor installed and without IR sensor installed)

Class I, Zone 0, AEx ia IIC T4 Ga, 20°C ≤ Tamb ≤ +50°C

(with IR sensor installed and without LEL sensor installed)

Class I, Zone 0, AEx da ia IIC T4 Ga, 20°C ≤ Tamb ≤ +50°C

(with LEL and IR sensor installed)

CSA: E480011

Class I, Division I, Group A, B, C and D, Temperature code

T4, 40 ≤ Tamb ≤ +50°C

Ex ia IIC T4 Ga, 40 ≤ Tamb ≤ +50°C

(without LEL and IR sensor installed)

Ex da ia IIC T4 Ga, 40 ≤ Tamb ≤ +50°C

(with LEL sensor installed and without IR sensor installed)

Ex ia IIC T4 Ga, 20°C ≤ Tamb ≤ +50°C (with IR sensor

installed and without LEL sensor installed)

Ex da ia IIC T4 Ga, 20°C ≤ Tamb ≤ +50°C (with LEL and IR

sensor installed)

ATEX: DEMKO 18 ATEX 1833X

EN IEC 600790:2018

EN 6007911:2012

EN 600791:2014

I M1 Ex ia I Ma, II 1 G Ex ia IIC T4 Ga, 40°C ≤ Tamb ≤ +50°C

(without LEL and IR sensor installed)

I M1 Ex da ia I Ma, II 1 G Ex da ia IIC T4 Ga, 40°C ≤ Tamb ≤ +50°C

(with LEL sensor installed and without IR sensor installed)

I M1 Ex db ia I Ma, II 2 G Ex db ia IIC T4 Gb, 20°C ≤ Tamb ≤ +50°C

(with IR sensor installed)

Ex ia I Ma, Ex ia IIC T4 Ga, 40°C ≤ Tamb ≤ +50°C

(without LEL and IR sensor installed)

Ex da ia I Ma, Ex da ia IIC T4 Ga, 40°C ≤ Tamb ≤ +50°C

(with LEL sensor installed and without IR sensor installed)

Ex db ia I Ma, Ex db ia IIC T4 Gb, 20°C ≤ Tamb ≤ +50°C

(with IR sensor installed)

The following additional previous editions of Standards

noted under the “Standards” section of this Certificate

were applied to integral Components as itemized below.

There are no significant safety related changes between

these previous editions and the editions noted under the

“Standards” section.

Product Certificate Num Standards

Dynament Ltd.

Gas Sensors Type

MSH2ia***

City Technology

Limited, Miniature

Combustible Gas

Sensor - 1 LEL 75

FCC Compliance

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

This transmitter must not be co-located or operated in

conjunction with any other antenna or transmitter. This

equipment complies with FCC radiation exposure limits

set forth for an uncontrolled environment. End users must

follow the specific operating instructions for satisfying RF

exposure compliance.

NOTE: This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference

when the equipment is operated in a commercial

environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required

to correct the interference at his own expense.

IECEx FTZU

15.0002U

IECEx ULD

16.0016U

IEC 600790

Edition 2011

IEC 600790

Edition 2011

BW Ultra User Manual22

Page 27

CAUTION

Changes or modifications not expressly approved by the

manufacturer responsible for compliance could void the

user’s authority to operate the equipment.

This device complies with FCC radiation exposure limits

set forth for an uncontrolled environment and meets the

FCC radio frequency (RF) Exposure Guidelines. This device

has very low levels of RF energy that it is deemed to comply

without maximum permissive exposure evaluation (MPE).

RED Compliance

Honeywell Analytics Asia Pacific Co., Ltd. hereby declares

that this gas detector, Honeywell BW™ Ultra, is in

compliance with the essential requirements and other

relevant provisions of Directive 2014/53/EU.

Canada, Industry Canada (IC) Notices

This device complies with Industry Canada license-exempt

RSS. Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including

interference that may cause undesired operation of the

device.

This device complies with FCC/ISED radiation exposure

limits set forth for an uncontrolled environment and meets

the FCC/ISED radio frequency (RF) Exposure Guidelines.

This device has very low levels of RF energy that it is

deemed to comply without maximum permissive exposure

evaluation (MPE).

For the compliance of CSA C22.2 No.152 and ISA 60079

291, the adjustable alarm point shall not exceed 60 %

LEL and the highest alarm shall be configured as latching

alarm.

In ISA 60079291, Honeywell BW™ Ultra was tested only

for IP54. Other IP ratings are not the scope of ISA 60079

291. Honeywell BW™ Ultra was pressure tested for 80, 100

and 120 kPa in ISA 60079291. Outside of 80 - 120 kPa is

NOT the scope of ISA 60079291.

Canada, avis d’Industrie Canada (IC)

Cet appareil est conforme aux normes RSS exemptes de

licence d’Industrie Canada. Son utilisation est soumise aux

deux conditions suivantes :

(1) cet appareil n’engendre pas d’interférences, et

(2) cet appareil doit tolérer tout type d’interférences,

notamment les interférences pouvant provoquer une

utilisation non désirée de l’appareil.

Cet équipement est conforme aux limites établies par FCC/

Industrie Canada en matière d’exposition aux radiations

dans un environnement non contrôlé. Cet équipement ne

doivent pas être colocalisés ou fonctionner en conjonction

avec tout autre antenne ou émetteur.

In terms of North America flammable gas performance

approval:

Honeywell BW™ Ultra is approved for ISA 60079291 and

CSA C22.2 No.152.

Only Honeywell BW™ Ultra catalytic bead flammable sensor

was evaluated for CSA C22.2 No.152 and ISA 60079291.

The evaluation is valid only with the pumping flow rate 300

ml/min, 3 m length tube and CH4 (Methane) gas.

The other options are not the scope of CSA C22.2 No.152

and ISA 60079291.

BW Ultra User Manual 23

Page 28

Label Information

1

2

5

6

7

3 4

BW Ultra Battery label

cULus ATEX IECEx

4321

BW Ultra Instrument label

1

2

3

7

8

9

4

10

cULus

5

1. BW Ultra battery serial number and2D

barcode

2. Manufacturer information

3. CEC battery charging system approval

marking

4. WEEE marking

5. Chinese EPUP marking

5

1. cULus certificate marking

2. Class Division protection marking

3. Class Zone protection markingwhen BW Ultra is

configured without LEL and IR sensor

6

4. Class Zone protection markingwhen BW Ultra is

configured with LEL and without IR sensor

5. Class Zone protection marking when BW Ultra is

configured with IR sensor and without LEL sensor

6. Class Zone protection marking when BW Ultra is

configured with IR sensor and with LEL sensor

7. North America flammable performance approval

8. FCC and IC certificate number

9. BW Ultra part number and 2D barcode

10. BW Ultra serial number and 2D barcode

ATEX

1. ATEX QAN notified body number

2. ATEX protection markingwhen BW Ultra is

configured without LEL and IR sensor

3. ATEX protection markingwhen BW Ultra is

configured with LEL and without IR sensor

4. ATEX protection markingwhen BW Ultra is

configured with IR sensor

5. ATEX certificate number

6. BW Ultra part number and 2D barcode

24

7. BW Ultra serial number and 2D barcode

BW Ultra User Manual

Page 29

IECEx

1

Ex ia I Ma,

Ex ia IIC T4 Ga

-40°C ≤ Tamb ≤ +50°C

Ex ia I Ma,

Ex ia IIC T4 Ga

2 3

-40°C ≤ Tamb ≤ +50°C

Ex ia I Ma,

Ex ia IIC T4 Ga

-40°C ≤ Tamb ≤ +50°C

1. IECEx protection markingwhen BW Ultra is

configured without LEL and IR sensor

2. IECEx protection markingwhen BW Ultra is

configured with LEL and without IR sensor

4

3. IECEx protection markingwhen BW Ultra is

configured with IR sensor

4. IECEx certificate number

5. BW Ultra part number and 2D barcode

5

6

6. BW Ultra serial number and 2D barcode

Part Number Format

BW Ultra’s explosion-proof protection type varies per the sensor configuration.

The user can notice the sensor configuration with the part number format.

HU

W1: 1 LEL 75 sensor

W2: 1 LEL 75C sensor

W3: 1 LEL 75M sensor

00: Dummy sensor

X1: Oxygen sensor

00: Dummy sensor

M1: CO sensor

00: Dummy sensor

H1: H2S sensor

00: Dummy sensor

1 digit of alphabet: country code

Y: Yellow enclosure

B: Black enclosure

Q1: PID sensor

W4: LEL IR sensor

B1: CO2 IR sensor

S1: SO2 sensor

A1: NH3 sensor

R1: H2 sensor

C1: Cl2 sensor

D1: NO2 sensor

Z1: HCN sensor

N1: NO sensor

M2: COH sensor

00: Dummy sensor

BW Ultra User Manual

25

Page 30

Troubleshooting

Problem Probable Cause Solution

Detector does not display normal gas reading