Page 1

AT150F, AT175F

Universal Circuit Breaker T ransformers

INSTALLATION INSTRUCTIONS

APPLICA TION

These transformers provide power to 24 Vac circuits in heating/cooling control systems. Although the transformers are

typically used in heating/cooling control systems, they can be used in any application that does not exceed the load

ratings. They include a button for manually resetting the circuit breaker. They meet National Electrical Code Class 2 “not

wet” and Class 3 “wet” requirements and are Underwriters Laboratories (UL) Inc. listed under UL 1585. Transformers can

be foot-mounted or conduit/panel mounted. See Table 1 for additional specifications.

Table 1. Model Specifications.

Primary Secondary

Voltage

Model

Number

AT150F 120/208/240 9 in. leadwires 27.0 24.0 9 in. leadwires 50 VA

AT175F 120/208/240 9 in. leadwires 27.0 24.0 9 in. leadwires 75 VA

Input Voltage

(60 Hz)

208/277/480

208/277/480

Wiring

Connections

Open

Circuit

At Rated Power

Output

Wiring

Connections

INST ALLATION

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Disconnect power supply before beginning

installation to prevent electrical shock or equipment

damage.

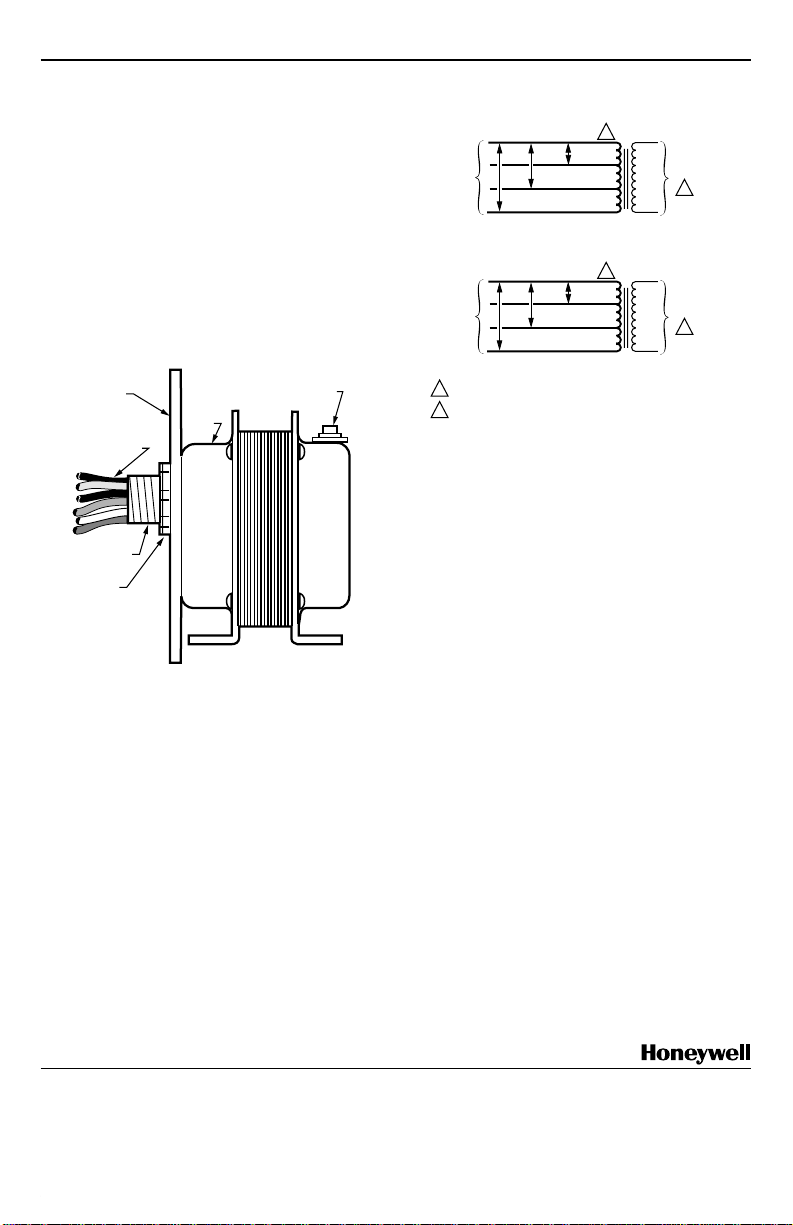

The transformer can be foot-mounted or conduit/panel

mounted.

USE SCREWS OR

BOLTS THROUGH

SLOTS (4) IN

MOUNTING FEET

LEADWIRES

FOR PRIMARY

AND SECONDARY

CONNECTIONS

Output Rating

at 100 Percent

Power Factor

RESET

BUTTON

Mounting

Foot Mounting

Mount the transformer using screws (not included) through

the four 3/16 in. x 3/8 in. holes in the mounting feet. See

Fig. 1. Make line voltage primary connections within an

approved enclosure.

® U.S. Registered Trademark

Copyright © 1996 Honeywell Inc. • All Rights Reserved

X-XX UL

MOUNTING

FOOT (2)

Fig. 1. Foot mounting.

M6905

69-1014-1

Page 2

AT150F, AT175F UNVIVERSAL CIRCUIT BREAKER TRANSFORMERS

Conduit/Panel Mounting

Mount the transformer on a plate or panel (not included)

with a 7/8 in. knockout. The transformer has a 1/2-14

NPSM conduit connector and lock nut.

1. With the conduit connector side of the transformer

facing the plate, thread the leadwires through the

plate knockout.

2. Insert the connector in the knockout.

3. While holding the plate in place, assemble and

tighten the lock nut to fasten the transformer

securely. See Fig. 2. Avoid damaging the leadwires

with the screwdriver.

4. Make line voltage primary connections within an

approved enclosure.

MOUNTING

PLATE (NOT

INCLUDED)

LEADWIRES

FOR PRIMARY

AND SECONDARY

CONNECTIONS

CONDUIT

CONNECTOR

LOCK NUT

END

BELL

RESET

BUTTON

M6906

Fig. 2. Conduit/panel mounting (plate not included).

Wiring

1. All wiring must comply with local codes and ordinances. Disconnect power before making wiring

connections to prevent electrical shock or equipment

damage.

2. Make the primary connections to the line voltage

power supply. Be sure to use the correct leadwires

for the available power supply. See Fig. 3.

3. Insulate the ends of the unused leadwires using wire

nuts or capping with a solderless connector.

4. Make the secondary connections to the 24 Vac

control circuit.

120/208/240 VAC MODELS

COMMON

PRIMARY

PRIMARY

1 SECONDARY LEADWIRES ARE BLUE AND YELLOW LEADWIRES.

BLACK IS COMMON WITH RESPECT TO THE TRANSFORMER

2

WINDING ONLY AND NOT THE EXTERNAL CIRCUIT.

120V

208V

240V

208/277/480 VAC MODELS

COMMON

208V

277V

480V

BLACK

WHITE

RED

ORANGE

BLACK

RED

BROWN

BLACK/RED

2

SECONDARY

1

2

SECONDARY

1

M6907

Fig. 3. Transformer schematics.

CHECKOUT

V oltage Check

After the installation is complete, turn on the power supply

and perform a voltage check.

1. Place the controlled equipment in operation and

observe through one complete cycle.

2. Using a voltmeter, verify the proper primary and

secondary voltages.

3. If the voltage readings are incorrect, make sure the

primary voltage connections are made properly.

4. Measure the voltage again.

a. If the proper primary voltage is measured and

the secondary voltage is significantly less than

the voltage shown in Table 1, the transformer

winding is damaged. Replace the transformer

and repeat the checkout procedures.

b. If the primary voltage is 0V, make sure the

power supply is connected properly or repair if

necessary. Repeat the checkout procedures.

5. Do not put the system into operation unless the

correct primary and secondary voltages are

measured.

Circuit Breaker

Overloading the transformer results in tripping the circuit

breaker. If the secondary side of the transformer is short

circuited, the circuit breaker trips in less than one minute.

Reset the circuit breaker by pressing the reset button on

the side of the transformer. It can take up to one hour for

the transformer to cool, allowing it to reset. If the circuit

breaker continues to trip, thoroughly check the system for

short circuits and the current draw.

Home and Building Control

Honeywell Inc.

Honeywell Plaza

P.O. Box 524

Minneapolis, MN 55408-0524

69-1014—1 C.H. Rev. 9-96 Printed in China

69-1014

Home and Building Control

Honeywell Limited-Honeywell Limitée

155 Gordon Baker Road

North York, Ontario

M2H 2C9

Helping You Control Your World®

2

Loading...

Loading...