Page 1

GENERAL

AQS51/61

COMBINED CO2-/TEMPERATURE

ROOM SENSOR/CONTROLLER

SERVICE & CHECKOUT INSTRUCTION

IMPORTANT The use of the service mode using the push

Display Mode (AQS61)

In this mode, the push button MENU is used to select the

actual value indicated on the display - CO

alternating, error code, CO

OUT1, OUT2 and OUT4, all in percent.

After restart, the display indication will always return to the

default display mode (CO

Functional Test

A simple and visual functional test can be easily performed.

Take a breath and blow onto the sensor from a distance of a

few centimeters. The sensor will detect a rapid increase in

the carbon dioxide concentration. As a result, the red LED

will light up if the CO2 level exceeds 1000 ppm (sensor

default setting).

buttons or PC is restricted to competent

trained service personnel only.

A good knowledge of the sensor/controller

functionality and the service mode is required

to perform this checkout or calibration.

and temperature

, temperature, output signal

2

and temperature alternating).

2

2

The AQS51and AQS61 temperature sensor / controller

feature two push buttons (MENU and ESC), accessible

behind the flip-down lid on the front of the sensor / controller,

providing a display selection mode and a maintenance mode

for testing and calibration purposes. In the case of the ductmounted version (AQS61-KAM), activation of the push

buttons is simulated by short-circuiting the two halves of the

zig-zag trace using a screwdriver.

The YELLOW LED will acknowledge each successful push

by a short flash. More information is shown on the LCDdisplay.

All functions available with the push buttons are also

accessible via the UART serial communication port by using

a PC together with the User Interface Program Software

AQS-USP22. This tool also provides more complex configurations, calibrations, and performance checkouts of these

sensors/controllers.

If the sensor is connected to a controller, the flow of the

ventilation system will eventually increase by changing the

fan speed or opening a damper actuator (depending on the

installation/application).

In the case of the AQS61, the present output values of the

outputs OUT1, OUT2 and OUT4 can be viewed on the LCD

by pressing MENU four to six times. The displayed values are

in %FS (percent full scale) and can be compared with the

actual output value measured using a multimeter.

® U.S. Registered Trademark EN2B-0224GE51 R0903

Copyright © 2003 Honeywell Inc. • All rights reserved

Page 2

AQS51/61 COMBINED CO2-/TEMPERATURE ROOM SENSOR/CONTROLLER

MAINTENANCE

General

The AQS51/61 is basically maintenance-free. An internal

self-adjusting calibration function takes care of normal longterm drift associated with the CO

highest accuracy, a time interval of max. five years is

recommended between CO

special situations have occurred.

A zero-point calibration can be performed using the push

button functions (for AQS61), or (in the case of a complete

overview) using a PC together with the AQS-USP22 software

version 4.0 (or higher). This software and a special RS232cable are included in the service kit AQS-F0005. The cable is

to be connected to the UART port slide connector. To change

control parameters and for recalibration (CO

perature), this PC tool must be used. The check can be done

on site without interfering with the ventilation system.

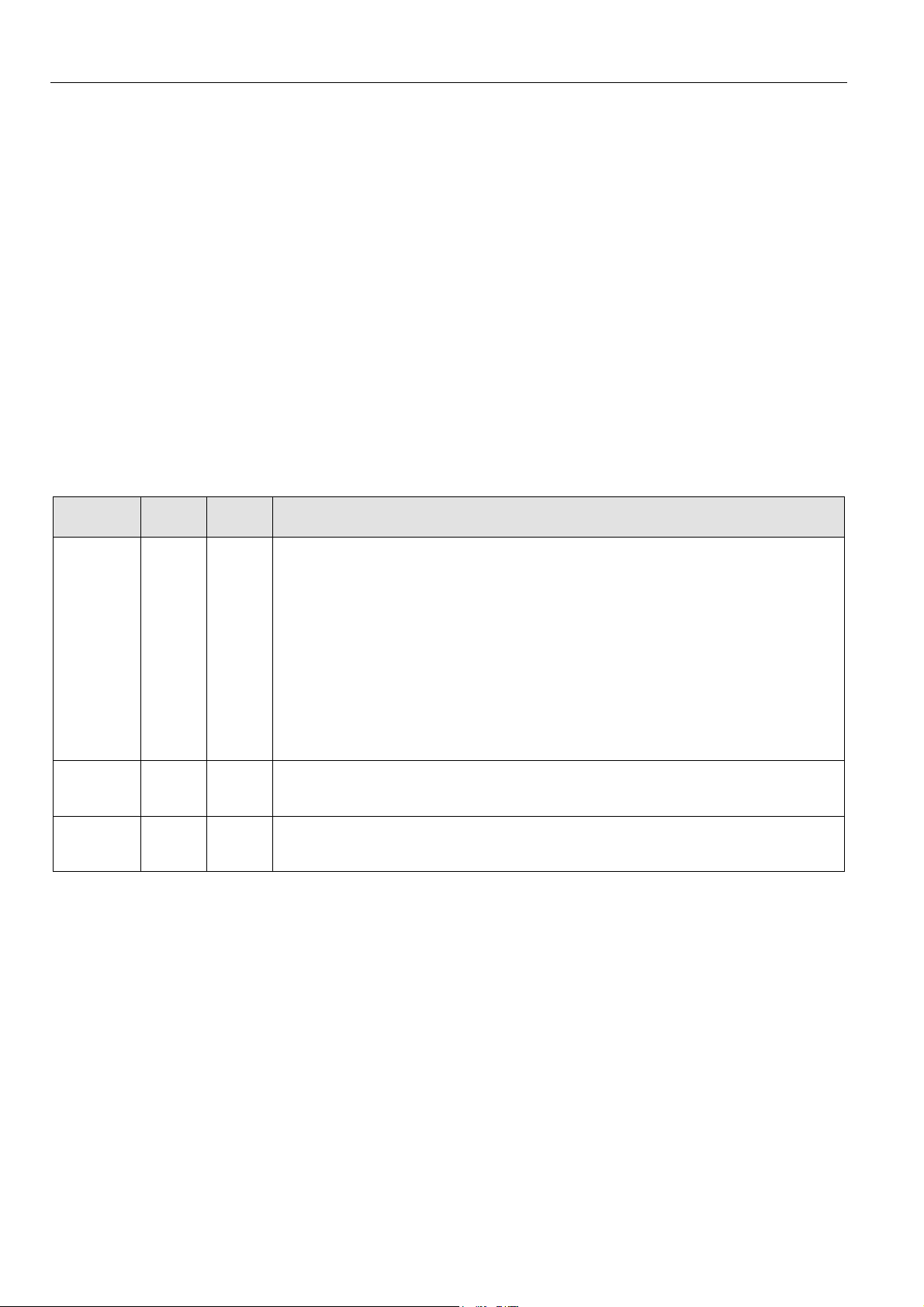

Table 1. Maintenance functions available on AQS61. Time limit refers to an internal time-out that returns the LCD and

maintenance function back to normal. ENTER is a simultaneous pressing of MENU and ESC.

Function

line

Display

sensor. To ensure the

2

calibrations, unless some

2

and tem-

2

Time-

limit

For checking/adjusting connected auxiliary equipment.

Maintenance Mode AQS61

A number of execution options as listed in Table 1 for test

functions and calibrations are available from the MAINTENANCE MENU. Access to this maintenance level is provided only from the selected display mode OUT1. By pushing

the MENU and the ESC button simultaneously as ENTER

command, the sensor/controller leaves the standard display

mode OUT1 and enters the maintenance selection mode.

With the MENU button, the required maintenance function

can be selected (see Table 1). The selected mode is shown

on the display.

Always use the ESC button to return to the previous MENU

selection mode, especially if any uncertainty exists regarding

the operation needed to return back to the DISPLAY MODE.

The ENTER command (push MENU and ESC simultaneously) may result in the execution of functions with temporary or

permanent changes to parameters affecting sensor/controller

outputs and system operation. Prior to such an execution, a

“SurE” message is shown on the display.

Functional description

Provides access to a sub-menu where output selection XX = 1...4 is done by pressing

MENU. The selected output FOXX (= OUT1...OUT4) is fixed by pressing ENTER. For XX

= 1 & 2 LO always gives 2 V / 4 mA independent of the position of the start point selection

jumper, but voltage or current according to the position of the jumper. OFF/ON is true for

1FOUtno

2bCALyes

3CALyes

the relay and open collector outputs.

FO1 & 2 LO -selected output is fixed to 2 V / 4 mA

FO3 LO -relay contact is open

FO4 LO -OUT4 is 0 V/open state

FOXX HI -selected output is fixed to 10 V / 20 mA/closed state

-sensor calibration with fresh air. An easy way to correct a zero-point error of a

CO

2

sensor. The sensor needs fresh air (380...420 ppm CO

confirmed by pushing ENTER.

Zero-point calibration of the CO

calibration instruction of zero-point calibration. The calibration must be confirmed by

pushing ENTER.

FUNCTIONS

FOUt- Fixing of Analog and Digital Outputs

This is a functional test for final control elements connected

to the outputs. When entering this operation mode, the

output is set automatically to 20%, 0% or 100% of full scale

as listed in Table 1 and Fig. 1.

Pushing the MENU and ESC button simultaneously for

ENTER, provides access to the output selection mode.

Select with the MENU button the output (F01 to F04) to be

fixed. Push MENU and ESC (ENTER) and select with the

MENU button LO or HI to fix the output to a low or high value

as requested.

). The calibration must be

2

sensor. The sensor needs zero gas. See the

2

Push MENU and ESC (ENTER) to fix the output.

To release (unfix) the temporary manual output override,

push the MENU button in fixed state.

NOTE: In the event of a power failure or power-off stage, no

automatic reset of the selected fixed state is performed. To unfix the output(s) in the power-on mode,

enter the maintenance mode FOUt and release the

fixed output(s) as described above.

EN2B-0224GE51 R0903 2

Page 3

AQS51/61 COMBINED CO2-/TEMPERATURE ROOM SENSOR/CONTROLLER

bCAL- CO2 - Sensor Baseline Calibration

with “Fresh Air”

This mode provides calibration of the CO2 sensor to background level without the need of test gas. This “fresh air”

calibration is an alternative to the more-precise “zero gas

level” calibration. The accuracy depends on how much the

actual sample gas deviates from the specified background

level of 400 ppm CO

NOTE: Take care to avoid contaminating the “fresh air” in

the sensor sample cell during and before this

calibration.

Push MENU and ESC simultaneously for the ENTER

command as long as SurE is shown on the display.

Confirm the access of the calibration mode by pushing

MENU and ESC (ENTER) again. The sensor/controller will

automatically return to the display mode.

concentration.

2

CAL- Zero-Point CO2 - Calibration

This mode is suitable for zero-level calibration of the CO

sensor. For calibration, a test gas with 0 ppm CO2 concentration is required. It is recommended to use for this purpose

the service bag AQS-F0005 which produces a CO

calibration gas by means of chemical absorption.

1. Insert the 4 mm ∅ plastic tube as far as possible into the

test gas inlet at the bottom of the wall plate.

2. Provide zero flow test gas at a rate of about 0.5 l/min for

approx. 1 min to the sensor.

3. Push MENU and ESC simultaneously for ENTER as long

as SurE is shown on the display.

4. Confirm the access of zero-point CO

pushing MENU and ESC (ENTER) again.

5. The sensor/controller will automatically return to the

display mode.

calibration by

2

-free

2

2

Test Gas Verification

Insert the plastic tube into the test gas inlet and provide a

flow test gas as described above in zero-point calibration.

Check the display reading of OUT1 (AQS61) or measure the

output value with a multimeter on OUT1 (AQS61) when it has

stabilized. The display reading or output value measured

should be equal to the used test gas.

3 EN2B-0224GE51 R0903

Page 4

AQS51/61 COMBINED CO2-/TEMPERATURE ROOM SENSOR/CONTROLLER

Fig. 1. Flow chart

Automation and Control Solutions

Honeywell GmbH

Böblinger Straβe 17

D-71101 Schönaich

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://europe.hbc.honeywell.com

Subject to change without notice. Printed in Germany Manufacturing location certified to

EN2B-0224GE51 R0903

Loading...

Loading...