Page 1

AQS51/61

CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

FOR WALL MOUNTING

INSTALLATION INSTRUCTIONS

GENERAL INFORMATION

The AQS51 and AQS61 CO2 / Temperature Sensors are

used to measure the concentration and temperature of

carbon dioxide in indoor air. The units can be configured as

controllers with programmable outputs for both ON/OFF relay

control and the linear control of e.g. mixed air dampers and

fans. The wall mounting housing has been designed with

snap-in features to minimize installation time.

The units can be directly connected to common VAV

(Variable Air Volume) controllers, Direct Digital Control (DDC)

devices, or standalone control systems. The linear output

functions are pre-programmed as CO

transmitters. In addition, the AQS51 and AQS61 have a relay

output pre-programmed as a CO

modified from a PC (Windows 95, 98, NT) using the AQSUSPxx (version 4.0 or higher) software together with the

AQS3/4-CABLE communication cable.

and temperature

2

limiter. All functions can be

2

® U.S. Registered Trademark EN1B-0189GE51 R0102

Copyright © 2002 Honeywell Inc. • All rights reserved

Page 2

AQS 51/61 CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

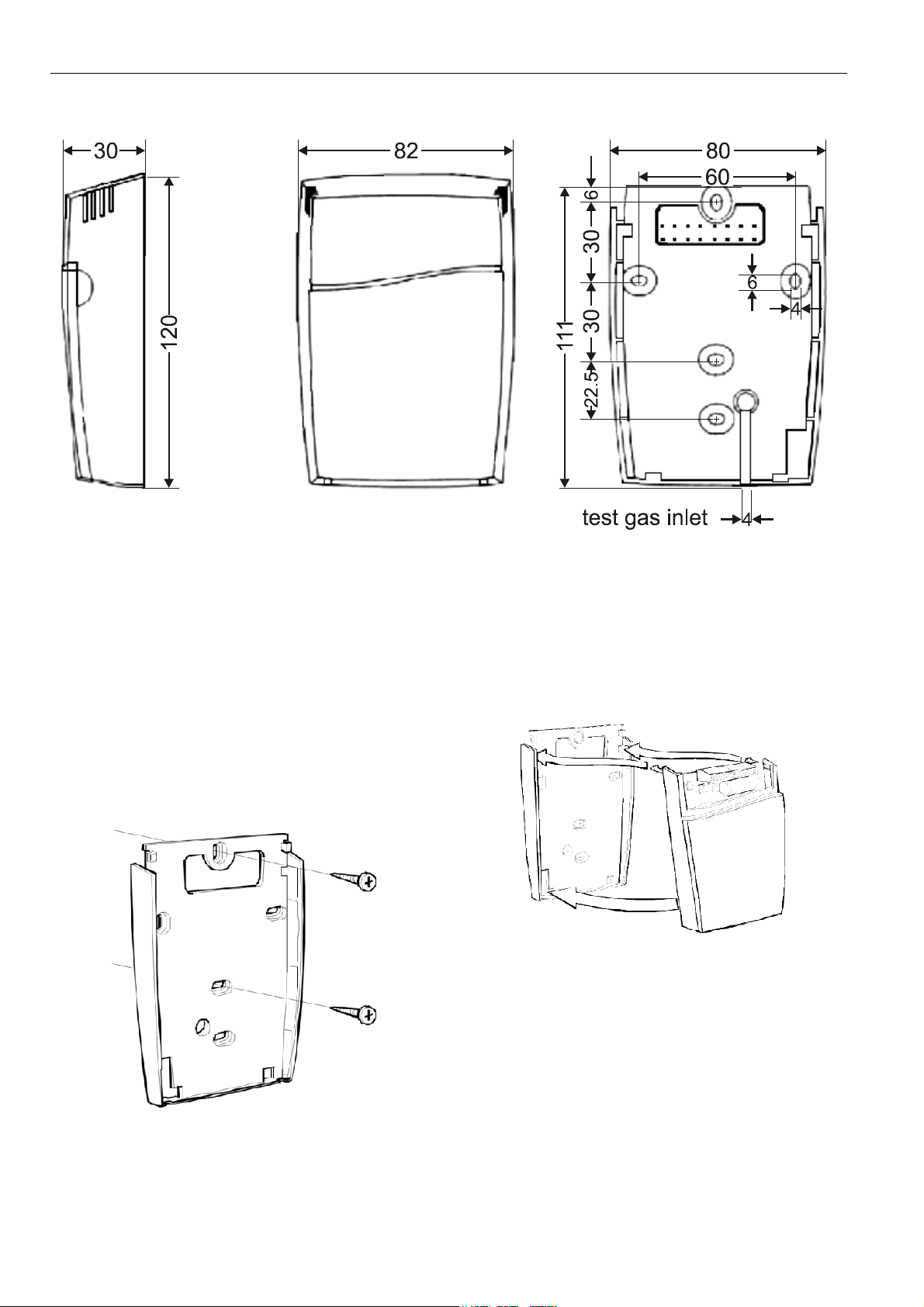

DIMENSIONS

Fig. 1. Dimensions (in mm) of AQS 51/61 (all oval holes have the same size)

WALL MOUNTING

Mounting the Wall Plate

The wall plate mounts vertically on the wall or on the wall

wiring outlet box.

1. Position and level the wall plate on the wall and use a

pencil to mark the mounting holes.

2. Remove the wall plate from the wall, drill two holes for

M4 screws in the wall as marked, and insert dowel into

the holes.

3. Position the wall plate over the holes and pull the wires

through the wiring opening.

4. Loosely insert the mounting screws into the holes and

tighten them (see Fig. 2).

Mounting System Unit onto Wall Plate

1. Bend the wires to the top to allow wiring connections to

the terminals.

2. Engage first the top tabs of the sensor/controller protection case into the top holes of the wall plate and then

press the lower edge of the case onto the wall plate to

latch (see Fig. 3). Be careful not to damage the temperature sensor.

Fig. 3. Mounting the sensor/controller onto the wall plate

Fig. 2. Mounting of the wall plate

EN1B-0189GE51 R0102 2

Page 3

AQS 51/61 CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

ll

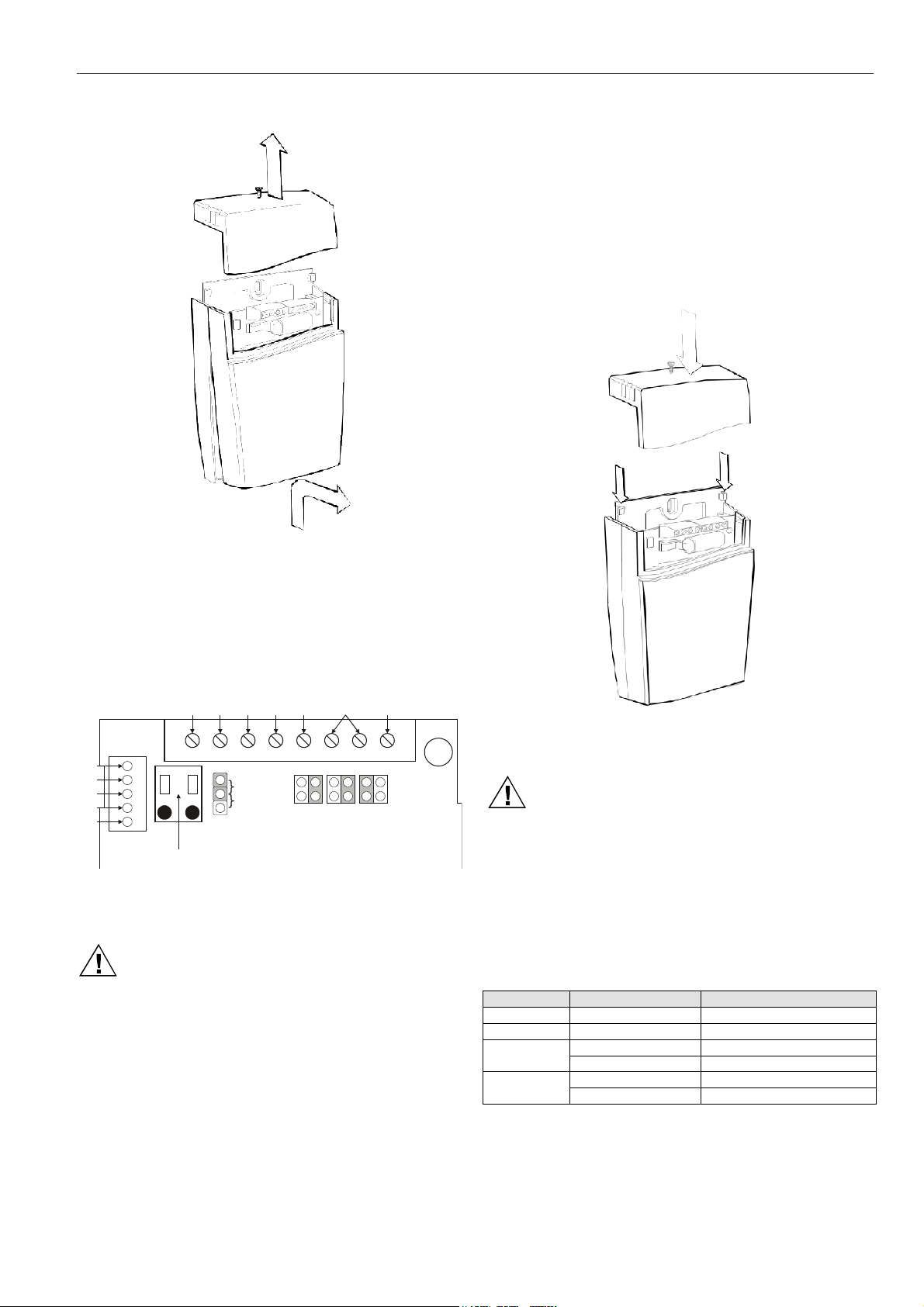

Removing System Unit from Wall Plate

Fig. 4. Removing the wiring terminal cover and the

sensor/controller

1. Loosen the screw on top of the wiring terminal cover and

remove the wiring terminal cover from the wall plate (see

Fig. 4).

2. Pull out first the bottom of the sensor/controller, then

disengage the top tabs and remove the top.

separate floating transformers for sensor and controller /

DDC system.

1. Connect the correct wires to the terminals and securely

tighten each terminal screw. Follow the actual job wiring

diagrams if available or refer to Table 2 for terminal

designations. A sticker is located on the inside of the

terminal cover that identifies the terminals (see Fig. 5).

All wiring must comply with local electrical codes,

ordinances and regulations.

2. Place the wiring terminal cover by fitting the notches of

the cover into the hooks of the wall plate. Tighten the

locking screw (see Fig. 6).

Wiring

y-open

norma

relay

current

voltage

OUT1 OUT2 OUT4

open

current

voltage

collector

voltage

R/T

GND

+5 V

RXD

TXD

G+ G0

digital input

startpoint

selection

jumper

OUT1

0%

20%

OUT2 OUT4M

Fig. 5. Connections and jumpers on AQS51/61. The

shaded positions represent the default settings

CAUTION

Check that all wiring is correctly completed before

turning the power on! Do not connect wires when the

unit is powered. Do not detach the sensor/controller

from the wall plate when the power is on!

The AQS51/61 signal ground (M) is not galvanically

separated from the power supply G0 terminal. If the analog

output signals are connected to controllers or DDC systems,

these units must have the same ground. If necessary, use

Fig. 6. Installing the wiring terminal cover

Electrical Connections

CAUTION

The power supply must be connected to G+ and G0.

G0 is considered as system ground. If the analog

output is connected to a controller, the same ground

reference must be used for the AQS51/61 unit and for

the control system! Unless different transformers are

used, special precautions must be taken!

NOTE: The signal ground of the AQS 51/61 is not

Terminal Default output Default output range

OUT1 0...10 Vdc 0...2000 ppm CO

OUT2 0...10 Vdc 0...50 °C

Relay

OUT4

galvanically separated from its power supply!

Table 1. Default output configurations for AQS51/61

2

closed > 1000 ppm CO

open < 900 ppm CO

closed > 2000 ppm CO

open < 1900 ppm CO

2

2

2

2

EN1B-0189GE51 R01023

Page 4

AQS 51/61 CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

Table 2. Electrical terminal connections for AQS51/61

Connection

terminal

G+ power (+) 24 Vac/dc+ (±20%), 3 W 2 W without output load

G0 power ground (-) 24 Vac/dc-

OUT1 analog output 1 (+)

OUT2 analog output 2 (+) same as output 1

M signal ground (-) connected to G0 via PTC fuse See note 1!

Relay normally open

OUT4

DI1 digital input 1

Function Electrical data Remarks

0...10 Vdc or 0...20 mA

2...10 Vdc or 4...20 mA

According to positions of OUT1 and start

point of jumpers

According to positions of OUT2 and start

point of jumpers

analog output 4 (+)

or open collector

contact-free relay; min. load: 1 mA / 5 V;

rated load: 0.5 A / 125 Vac, 1 A / 24 Vdc

0...10 Vdc; max. 0.5 A, 60 Vdc / 40 Vac

(half-wave rectifier protection)

closed contact current: 1 mA, open

voltage contact: max. 5 V

Triggered by register OUT3

According to positions of OUT4. See also

notes 2 and 3!

Do not apply any voltage to this input!

2

2

1

NOTE 1:

The ground terminal is used as negative power supply DC input or AC phase ground G0 (half-wave rectifier). The

signal ground M, protected by a PTC resistor, is the same as power ground G0 (permitting a ”3-wire” configuration). A

single transformer may be used for the entire system.

NOTE 2:

AQS51/61 can deliver both a voltage or a current loop for OUT1/OUT2. For OUT4 a voltage output or an open

collector output is selected with jumper OUT4. To change between voltage and current output mode the hardware

jumpers are used. There is one jumper for OUT1 and one for OUT2, so that one output can be a voltage output and

the other a current output. Both voltage output and current output can have start points 0 % (0-10 VDC or 0-20mA) or

20% (2-10 VDC or 4-20mA). The same start point is used for both outputs. See Table 1.

NOTE 3:

The open collector's current is internally returned to the G0 terminal.

Output Configurations

The sensors/controllers are supplied from the factory (unless

otherwise ordered) with 0...10 Vdc linear outputs for OUT1

and OUT2 and for OUT4 when it is used as an open collector

output (see Table 1). If different outputs are needed for the

application, these have to be configured before the unit is

Table 3. Configuration jumpers for AQS51/61

Jumper Position Function

start point

of the

selection

jumper

OUT1

OUT2

OUT4

0%

20%

current Connection in the "current" position provides a 0/4...20 mA output range for OUT1.

voltage Connection in the "voltage" position provides a 0/2...10 Vdc output range for OUT1.

current Connection in the "current" position provides a 0/4...20 mA output range for OUT2.

voltage Connection in the "voltage" position provides a 0/2...10 Vdc output range for OUT2.

current

voltage Connection in the "voltage" position provides a 0...10 Vdc output range for OUT4.

Jumper top position provides a 0 Vdc or 0 mA start point for OUT1 and OUT2 (0...20 mA or 0...10 V).

OUT4 has a 0 V output start point when jumper OUT4 is in the “voltage” position (0...10 V).

Jumper bottom position provides a 2 Vdc or 4 mA start point for OUT1 and OUT2 (4...20 mA or

2...10 V). OUT4 has a 0 V output start point when jumper OUT4 is in the “voltage” position (0...10 V).

Connection in the "open collector" position provides an open collector output. Max. 0.5 A, 60 Vdc /

40 Vac (half-wave rectifier).

powered up. To select alternative output ranges, position the

four jumpers as required for the application. Each jumper

selection is independent from the others, except in the case

of the “Start point selection” jumper, which affects both linear

outputs (i.e. OUT1 and OUT2).

Push Button Operation for AQS61

This sensor has two push buttons, MENU and ESC, located

on the front panel behind the flip-down lid. The YELLOW

LED will acknowledge a successful push by a short flash.

The push button MENU is available for selection of display

value or maintenance commands, whereas ESC is available

to escape back from a selected level.

Display Modes

In the DISPLAY MODE, the push button MENU is used to

select the value to be indicated on the display: CO

EN1B-0189GE51 R0102 4

con-

2

centration and temperature (alternating), error code, CO

,

2

temperature, output 1, output 2, or output 4. After the device

is powered up, the display will always return to the default

display mode

Page 5

AQS 51/61 CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

Maintenance Level

A number of execution options are available from the

MAINTENANCE MENU (see Table 4). This level is accessed

only from the display mode in the OUT1 % selection. Simultaneously pressing two push buttons restricts access,

intended for competent trained service personnel only (see

Fig. 7). The ENTER command is issued by simultaneously

pressing MENU and ESC.

Table 4. Maintenance functions available on the AQS61

Function

line

Display Time limit

1

For checking/adjusting connected auxiliary equipment.

Provides access to a sub-menu in which output selection XX = 1...4 is done by pressing

MENU. The selected output FOXX (= OUT1-4) is fixed via ENTER

provides 2 V /4 mA regardless of the position of the start point selection jumper, but

1FOUtno

voltage or current according to the position of the jumper. OFF/ON is true for the relay and

open collector outputs.

FO 1,2 LO: selected output is fixed to 2V / 4 mA

FO 3 LO: relay contact is open

FO 4 LO: OUT4 is 0V/open state

FOXX HI: selected output is fixed to 10V/20mA/closed state

CO

-sensor calibration with fresh air. An easy way to correct a zero-point error of a sensor.

2bCALyes

2

The sensor needs fresh air (380...420 ppm CO

pushing ENTER

3CALyes

1

The phrase "time limit" refers to an internal time-out which returns the LCD and the maintenance function back to normal.

2

ENTER is achieved by simultaneously pressing MENU and ESC.

Zero-point calibration of the CO

instruction of zero-point calibration. The calibration must be confirmed by pushing ENTER.

Always use the ESC button to return to the MENU selection

block in the left-hand portion of Fig. 7. Several pushes of the

ESC button may be needed to return to the DEFAULT mode.

The ENTER command (press MENU and ESC simultaneously) may result in the execution of functions with temporary or

permanent changes to parameters affecting sensor/controller

outputs and system operation.

Functional description

2

. For XX=1,2 LO always

). The calibration must be confirmed by

2

sensor. The sensor needs zero gas. See the calibration

2

Fig. 7. Push-button menu flow-chart for the AQS61

EN1B-0189GE51 R01025

Page 6

AQS 51/61 CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

FUNCTIONAL TEST OF THE AQS51/61 CO2 AND TEMPERATURE SENSOR

Functional Test

The unit has two LED’s - yellow and red - on the front panel

(found under the front lid). These LED’s indicate the

controller's status.

Yellow LED - ”Call for maintenance” is lit if an error flag has

been set or the measurement is out of range. In the case of

the AQS61, this information is also shown on the display by

the wrench icon. Any push button press, or executed maintenance function, is acknowledged by this LED lighting up.

Red LED - ”Relay active” is lit when the relay has been

activated (contact closed).

A simple and visual functional test can easily be performed.

Take a breath and blow the air from a distance of a few

centimeters onto the sensor. The sensor will detect a rapid

increase in the carbon dioxide concentration. As a result, the

red LED will light up as the CO

(sensor default setting). If the sensor is connected to a

controller, the flow of the ventilation system will eventually

increase by change of the fan speed or opening of a damper

actuator (depending on the installation/application).

In the case of the AQS61, the present output values of the

outputs OUT1, OUT2 and OUT4 can be viewed on the LCD

by pressing MENU four to six times. The displayed values are

in %FS (percent full scale) and can be compared with the

actual output value measured with a multimeter.

level exceeds 1000 ppm

2

Test Gas Verification

Insert 4 mm plastic tubing in the test gas inlet at the bottom

of the wall plate. The plastic tubing should be inserted as far

as possible into the inlet. Flow test gas at a rate of about 0.5

liter/minute. Check the display (or OUT1 with a multimeter) to

read the CO

NOTE: The sensor accuracy is defined at continuous

-value when it has stabilized.

2

operation (at least 3 weeks after installation).

Self Diagnostics

The system contains complete self diagnostic procedures. A

full system test is executed automatically every time the

power is turned on. In addition, the sensor probes are constantly checked against failure during operation by checking

the valid dynamic measurement ranges. All EEPROM

updates (initiated by the sensor itself or by external connections) are checked by subsequent memory read back and

data comparisons. These different system checks return

error bytes to the system RAM. If any error is detected, the

yellow LED will light up until the error has vanished and the

error flag is reset. “Warm up” and “Out of Range” are the only

bits that are reset automatically after return to normal state.

All other error bits have to be reset manually after return to

normal state – either by pushing the MENU and ESC buttons

simultaneously for ENTER (AQS61 only) or by power off and

restart.

The error code number Exxx can be made to appear on the

LCD (AQS61) by pressing the ”MENU” push button.

Descriptions of the different codes are listed below.

EN1B-0189GE51 R0102 6

Page 7

AQS 51/61 CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

Bit # Error code Error description Suggested action

0 N/A Fatal error: The yellow LED flashes con-

tinuously. The push buttons do not function.

12 Reserved

2 4 Âlgorithm error: An incorrect EEPROM

configuration is indicated.

3 8 Output error: Detected errors during output

signal calculation and generation.

4 16 Self diagnosis error: May indicate the need of

zero-point calibration or sensor replacement.

6 64 Memory error: Non-fatal error during memory

operations.

7 128 Warm-up state: Is always set after power-up or

power failure. Resets after restart sequence.

Try to restart the sensor by turning the power off and

on again. Contact local distributor.

Try to restart the sensor by turning the power off and

on again. Check detailed settings and configuration

with AQS-USP software version 4.0 and higher.

Contact local distributor.

Check connections and output loads. Check detailed

status of outputs with AQS-USP software version 4.0

and higher.

Check detailed self-diagnostic status with AQS-USP

software version 4.0 and higher. Contact local

distributor.

Check detailed settings and configuration with AQSUSP software version 4.0 and higher.

If it doesn't disappear within 30 seconds, check power

stability.

NOTE: One of the probes is out of range. Occurs, for instance, during over-exposure of the CO2 sensor, in which case the

error code will automatically reset when the measurement values return to normal. Could also indicate the need of

zero-point calibration. A background calibration using push button function ”bCAL” will remedy this error (a more exact

zero-point calibration using ”CAL” may be performed later, if required). If the CO

code remains, the temperature sensor might be broken.

readings are normal but the error

2

REMARK:

If several errors are detected at the same time, the different error code numbers will be added together into one single

error code.

Maintenance

Basically speaking, the AQS51/61 is maintenance-free. An

internal self-adjusting calibration function takes care of

normal long-term drift associated with the CO

sensor. To

2

Limited Warranty

This product has been accurately tested and examined for

proper operation. Please operate this product only in

accordance with the instructions.

ensure the highest accuracy, a time interval of max. five

years is recommended between CO

calibrations unless

2

some special situations have occurred. A zero-point

calibration can be performed using the push button functions

(for AQS61), or for a complete overview, by using a PC

together with the AQS-USPxx software version 4.0 (or

higher). This software and a special RS232-cable are

The warranty period of the product against defects in work-

manship and material is one year from date of purchase by

the original owner. If the product should become defective

within this warranty period, the customer owns the right for

repair or exchange the product free of charge. Please contact

your retailer for further information.

included in the AQS-F0005 service kit. The cable is to be

connected to the UART port slide connector (see Fig.9). For

changing control parameters and re-calibration (CO

and

2

temperature), this PC tool must to be used. The check can

be done on site without interfering with the ventilation system.

If, for some reason, the printed circuit board (PCB) needs to

be removed, special precautions must be taken in order to

avoid damaging the temperature probe. When putting the

PCB back into the protective housing, the temperature probe

must be gently positioned in the small probe compartment

(see Fig. 8)!

The retailer is not responsible for any consequential loss or

damages, which may occur by reason of purchase and use

of this product. The warranty is, in any event, strictly limited

to the replacement/repair of the product.

This product is in accordance with the EMC Directive

89/336/EEC and the Low-Voltage Directive 73/23/EEC,

including amendments by the CE-marking Directive

93/68/EEC.

This product fulfills the following requirements:

• EN50081-1

• EN55011(B)

• EN50082-2

• EN61000-4-2.-3.-4.-5. Level 3

EN1B-0189GE51 R01027

Page 8

AQS 51/61 CO2 / TEMPERATURE SENSOR WITH BUILT-IN CONTROLLER

Fig. 8. Positioning the temperature sensor (the black dot), enlargement at right

Home and Building Control Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited-Honeywell Limitee Honeywell AG

Honeywell Plaza 155 Gordon Baker Road Böblinger Straβe 17 manufacturing

P.O. Box 524 North York, Ontario D-71101 Schönaich location certified to

Minneapolis, MN 55408-0524 M2H 3N7 Germany

USA Canada

http://www.honeywell.com http://www.honeywell.ca http://europe.hbc.honeywell.com

EN1B-0189GE51 R0102 printed in Germany Subject to change without notice

Loading...

Loading...