Page 1

69-1981-06

AQ255 and AQ257 Series

AQ25742B

AQ25582B

Expansion Zoning Panels

FEATURES

The AQ255/AQ257 Series Expansion Zoning Panels have the

following features:

• Availability of 4 Expansion Zoning Panels.

• Zone control of either pumps or zone valves, in

multiples of 4 zones

• 4-zone or 8-zone models for pump zoning; 4-zone

models for zone valves

• Ability to use both zone valve models and zone pump

models in the same installation

• Zone valve panels contain an AQ10X38 transformer

(power supply module), which connects to 120 Vac

power and supplies 24 Vac power to the Zoning

Module.

• Communications between components via the

AQUATROL® network, using communication bus

wiring.

• Any panel can be configured to activate a group pump

when zones are active

• Zone valve models can be used with Normally Open or

Normally closed valves

• Can be installed up to 500 ft. away from main AQ2000

Control Panel, for convenient operation of remote

zoning equipment

PRODUCT DATA

PRODUCT DESCRIPTION

The AQ255/AQ257 Series Expansion Zoning Panels provide

additional zoning capacity for an existing hydronic installation

controlled by an AQ2000 Series Boiler Control Panel such as

an AQ250 Relay Boiler Control, an AQ251 Reset Boiler

Control, or an AQ252 Universal Injection/Mixing Boiler Reset

Control.

IMPORTANT

To ensure correct installation and proper operation of

the zoning panel, perform the 7 installation steps in

the order numbered in the “Contents” below.

Contents

Specifications ................................................................... 2

1 Installation Preparation .................................................. 2

2 Mounting ........................................................................ 4

3 Wiring Procedure ........................................................... 5

4 Configure the Expansion Zoning Panel(s) DIP Switches 5

5 Test and Check Out the Installation ............................... 7

6 Purge Air from all System and Zone Piping .................. 8

7 Document and Keep a record of all System Settings .... 9

Troubleshooting ................................................................ 10

Appendix .......................................................................... 11

Wiring Diagrams ................................................... 11

Page 2

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

SPECIFICATIONS

The AQ2000 Series Expansion Zoning Panels are listed in

Table 1.

Table 1. AQ2000 Series Expansion Zoning Panels.

Expansion

Zoning Panel

AQ25542B AQ15540B 1 No

AQ25582B AQ15540B 2 No

AQ25742B AQ15540B 1 Yes

AQ25744B AQ15740B 1 Yes

Application: Controls zoning operations for hydronic zoning

systems.

Power and Electrical Ratings:

Power Supply: 120 Vac / 60Hz

B–B Communication Bus Terminals: Low voltage,

Class II, 2-wire polarity-insensitive, digital communicating link to other Control or Zoning modules

Zone Pump Output Rating: 120 Vac, 5A, 1/3 HP

Zone Valve Output Rating: 24 Vac, 0.5A, 12VA

Electrical Connections (Line Voltage): Wire-clamp

screw terminals; maximum 2 x 14 AWG each on line

voltage terminals

Environmental Ratings:

Temperature Rating: 32°F to 130°F (0°C to 55°C)

Operating Humidity Range (% RH): 5 to 90% RH,

non-condensing

Temperature Ratings:

Sensor Temperature Rating: -58°F to 230°F (-50°C

to 110°C)

Inputs/Outputs:

R–C Input: 24 Vac Class II

R–C Output (on transformer; AQ25742B and

AQ25744B only): 38 VA, 24 Vac Class II

Zoning

Module

# of Zoning

Modules

Transformer

included

Thermostat Compatibility: Digital non-communicating

thermostats and/or AQ1000 Series 2-wire communicating

thermostats

Dimensions (HxWxD): 8.0 x 9.4 x 3.3 in. (20.3 x 23.8 x

8.5 cm) approximate

Weight: 3.9 lb. (1.8 kg)

Approvals: Canadian Standards Association: Certified, File

No. LR76030

1 INSTALLATION

PREPARATION

NOTES: Throughout these instructions, the following

terminology conventions are used:

— AQ155 refers to the AQ15540B Zoning Module.

— AQ157 refers to the AQ15740B Zoning Module.

— AQ255 refers to all of the AQ25542B, AQ25582B and

AQ25742B Expansion Zoning Panels.

— AQ257 refers to the AQ25744B Expansion Zoning

Panel. Where there are specific instructions or details

relating to the -42B, -82B, or -44B Expansion Zoning

Panels, the full model number is used

(e.g., AQ25744B).

— AQ2000 Series Control Panel is used when the infor-

mation applies to any of the AQ2000 Series Boiler

Control Panels, including AQ25A, AQ250, AQ251,

AQ252, etc.

— Control Module refers to the component within the

AQ2000 Series Control Panel that performs the

master control operations.

— Control Panel refers to an assembled product, con-

sisting of a transformer, Control Module and (if applicable) a Zoning Module, all contained within an

AQ2000 panel enclosure.

— Expansion Zoning Panel refers to an assembled

product, consisting of a Zoning Module and (if applicable) a transformer, contained within an AQ2000 panel

enclosure.

— Zoning Module refers to the component within the

AQ2000 Series Control Panel that controls zoning

operations. Zoning Modules are available in either

4-zone or 8-zone configurations.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further information,

or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China, Czech

Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

69-1981—06 2

Page 3

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

WARNING

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

the application.

3. Installers must be trained, experienced, and licensed

service technicians.

4. Follow local codes for installation and application.

5. After installation is complete, check out the product

operation as printed in these instructions.

Risk of electrical shock.

Can cause severe injury, property damage or death.

Disconnect power supply before installation and before

servicing.

Check That You Have All the Necessary Equipment For a Successful Installation

• AQ2000 Series components

— AQ2000 Series Control Panel – already installed

— AQ Expansion Zoning Panel(s)

— Digital Thermostats (one for every space heating zone

being controlled)

• Low voltage thermostat wire

• Zoning equipment (zone valves or pumps)

Read All Instructions Carefully Before Proceeding

The AQ2000 Series Control Panels are a part of a totally new

family of hydronic controls. And although they, and other

AQ2000 system components, are very easy to install and

operate, they are different than other hydronic controls that you

have previously installed. Take a moment to read through this

document before

beginning the installation. Failure to follow

these instructions could damage the product or cause a

hazardous condition.

Familiarize Yourself With the AQ255 / AQ257 Expansion Zoning Panel

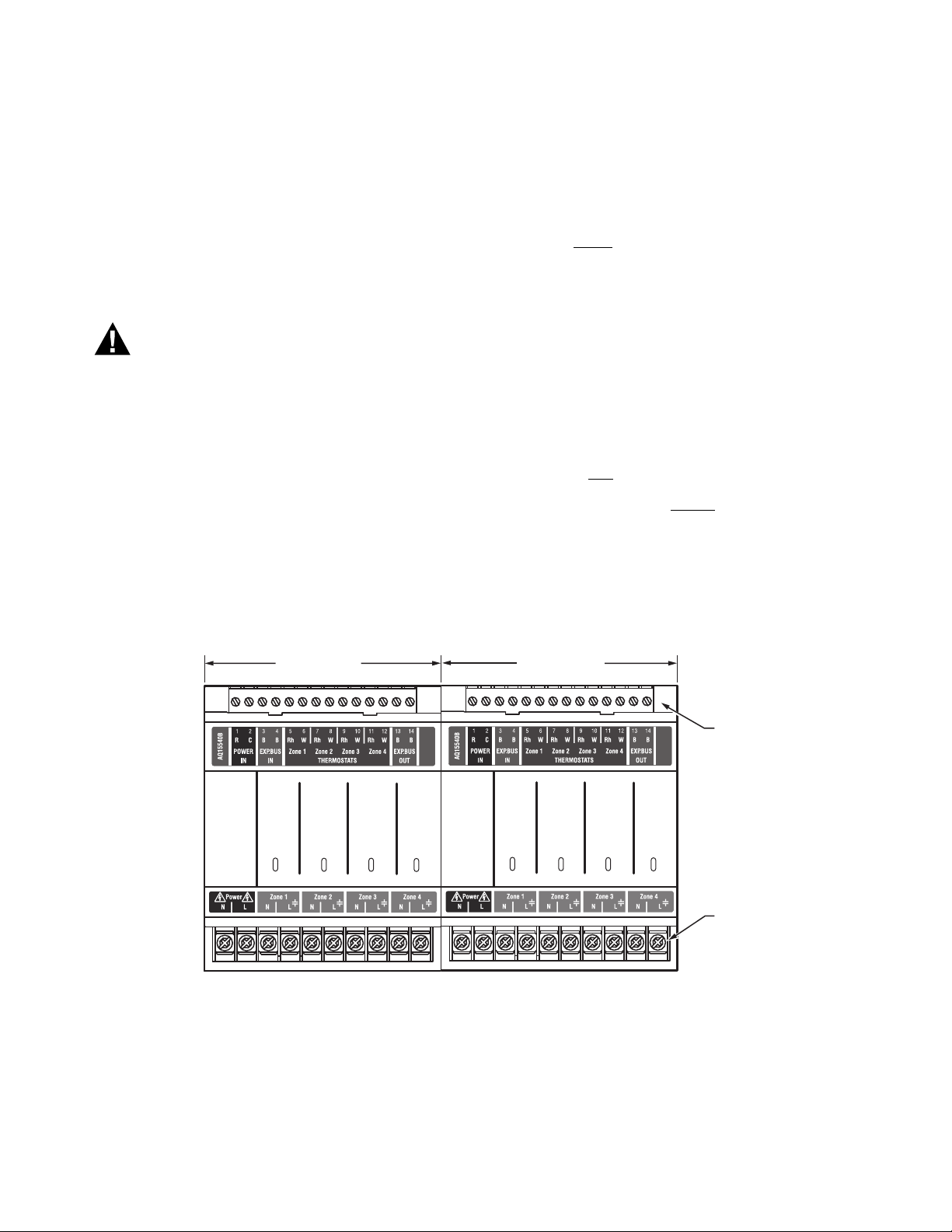

Refer to Fig. 1 on page 3. In general, the top terminals of all

AQ255 / AQ257 Expansion Zoning Panels carry low voltage

(24Vac) power and the bottom terminals carry either line

voltage (120 Vac) power for the AQ25542B and AQ25582B

models, or low voltage (24 Vac) power for the AQ25742B and

AQ25744B models. The two exceptions to this are:

1. AQ25744B Expansion Zoning Panel for use with zone

valves with

2. AQ25742B Expansion Zoning Panel when used with low

voltage zone valves without end switches.

For these the two exceptions, the bottom terminals of the

AQ10X38 Transformer carry line voltage (120 Vac), but the

bottom terminals of the Zoning Module will carry low voltage

(24 Vac) power.

end switches.

ZONING MODULE

Zone 1

Zone 2

Zone 3

Zone 4

ZONING MODULE

Zone 1

Zone 2

Zone 3

Zone 4

Fig. 1. AQ255 Expansion Zoning Panel Layout (AQ25582B shown).

LOW VOLTAGE

(24 V)

LINE VOLTAGE

(120 V)

M27831A

3 69-1981—06

Page 4

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

TRANSFORMER

LOW

VOLTAGE

(24 V)

LINE

VOLTAGE

(120 V)

Fig. 2. AQ257 Expansion Zoning Panel Layout (AQ25744B shown).

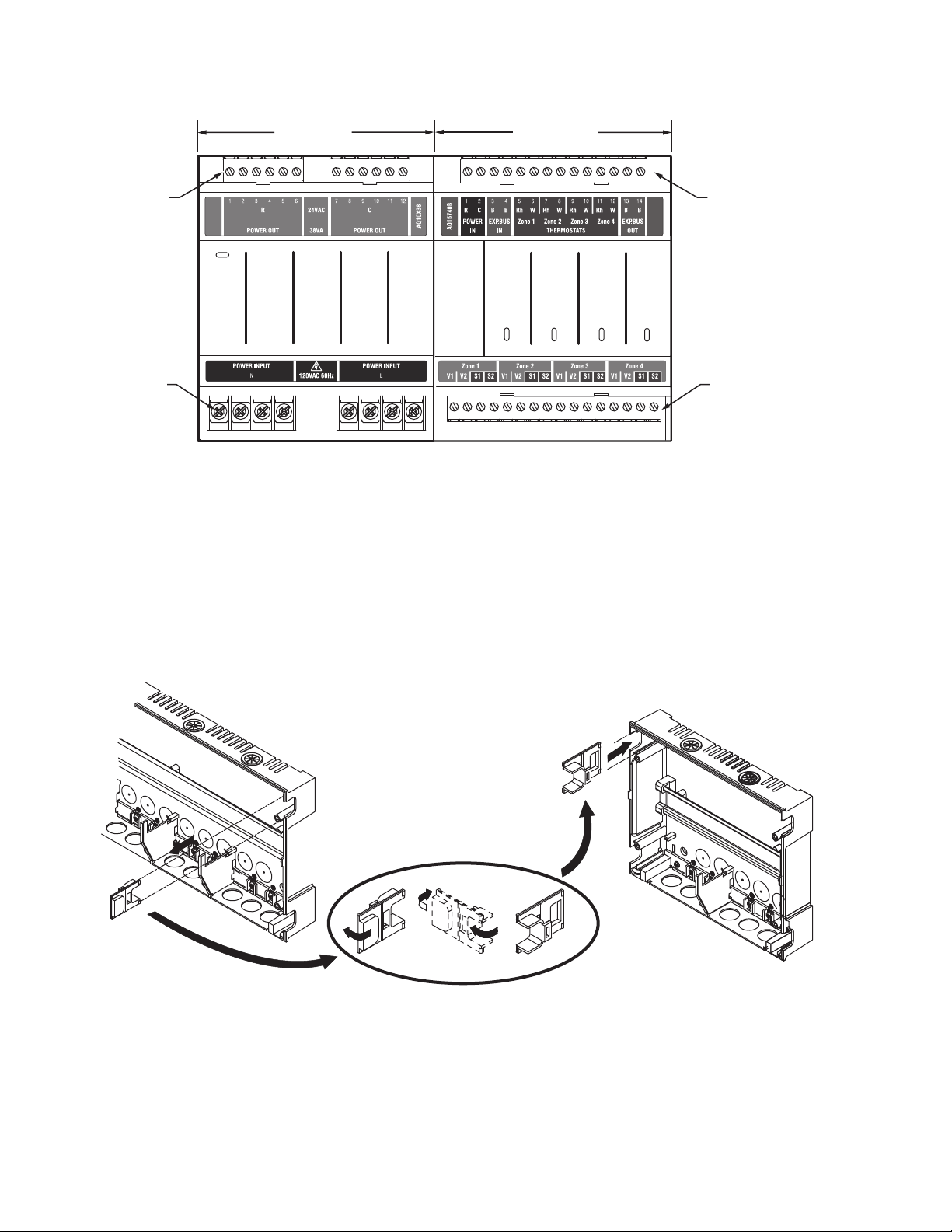

2 MOUNTING

This section describes how to mount the Expansion Zoning

Panels and thermostats.

Mount Expansion Zoning Panel(s)

1. Remove wire channel plugs from the Control Panel and

any Expansion Panels (see Fig. 3).

2. Mount Expansion Zoning Panel on the right-hand end of

the Main Control Panel.

ZONING MODULE

LOW VOLTAGE

(24 V)

Zone 1

Zone 2

Zone 3

Zone 4

LOW VOLTAGE

(24 V)

M27832A

3. Reverse wire channel plugs and re-insert them into their

slot to from a wiring channel between the Main Control

Panel and the Expansion Zoning Panel (see Fig. 3) and

to connect the two panels together.

4. Install two top screws of the Expansion Zoning Panel,

ensuring it is level with the adjoining Main Control Panel,

and install two lower screws.

5. Repeat steps 1–4 for any additional Expansion Zoning

Panels.

Fig. 3. Orientation of wire channel plugs for creating pass-through wire channel and

for joining Main Control Panel to Expansion Zoning Panels.

69-1981—06 4

M13757

Page 5

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

Mount and Wire Thermostats in the Zones

Install the thermostats on the walls in the zones that are to be

controlled by the AQ2000 Control Panels and Expansion

Zoning Panels.

When using AQ1000 thermostats, refer to the included

installation instructions included with that model.

If not done already, run low voltage thermostat wire (24 gauge

or heavier) from the thermostats back to the Expansion Zoning

Panel for use in section 3, “Wiring Procedure” .

NOTE: If not otherwise specified, low voltage wiring

should be run with 18 gauge thermostat wire and

line voltage wiring should be run with 14 gauge

wire. AQUATROL line voltage screw terminals are

approved for use with 22 to 12 gauge copper

conductors.

Several wiring diagrams are included in this

document. For additional information, refer to

http://customer.honeywell.com or your local

distributor.

3 WIRING PROCEDURE

The AQ255 / AQ257 Expansion Zoning Panels are pre-wired at

the factory, making for faster installation.

• For the AQ25742B and AQ25744B models, the low voltage

output terminals located at the top of the transformer are

wired to the R and C input terminals at the top of the Zoning

Module. In addition, for the AQ25742B model, the low

voltage output terminals located at the top of the

transformer are wired to the R and C input terminals at the

bottom of the Zoning Module.

• For the AQ25582B model, which contains two AQ15540B

Zoning Modules, the B-B “Exp.Bus OUT” terminals of the

Zoning Module on the left side are wired to the B-B

“Exp.Bus IN” terminals of the Zoning Module on the right

side.

NOTE: For examples of wiring Expansion Zoning Panels

to AQ2000 Series Control Panels and wiring

additional low voltage VA capacity, refer to the

“Wiring Diagrams” section in the “Appendix”

beginning on page 11.

sitive, so it does not matter which of the BB “Exp.Bus

OUT” terminals is connected to which of the B-B

“Exp.Bus IN” terminals.

4. Wire the zoning equipment to the output terminals (bottom edge) of the Expansion Zoning Panel – line voltage

circulators or valves for the AQ25542B and AQ25582B

and low voltage zone valves for the AQ25742B and

AQ25744B.

5. Bring power to the Expansion Zoning Panel as follows:

a. AQ25542B: run 14 AWG jumper wires from the N

and L terminals on the bottom of the AQ2000 Series

Control Panel’s AQ10X38 transformer to the N and L

terminals on the bottom of the AQ15540B module.

b. AQ25582B: run 14 AWG jumper wires from the N

and L terminals on the bottom of the AQ2000 Series

Control Panel’s AQ10X38 transformer to the N and L

terminals on the bottom of EACH AQ15540B Zoning

Module.

c. AQ25742B: run 14 AWG jumper wires from the N

and L terminals on the bottom of the AQ2000 Series

Control Panel’s AQ10X38 transformer to the N and L

terminals on the bottom of the AQ25742B’s

transformer module (AQ10X38).

d. AQ25744B: run 14 AWG jumper wires from the N

and L terminals on the bottom of the AQ2000 Series

Control Panel’s AQ10X38 transformer to the N and L

terminals on the bottom of the AQ25744B’s

transformer module (AQ10X38).

The AQ255 / AQ257 Expansion Zoning Panels can control up

to 4 space heating zones (or 8, for the AQ25582B Expansion

Zoning Panel). The heart of each Expansion Zoning Panel is its

Zoning Module. The corresponding Panels and Modules are

shown in Table 1 on page 2.

For the -42B and -82B Panels, line voltage pumps are used for

the zoning equipment so low voltage (24 Vac) power is not

required. That’s why there isn't a transformer included with

these Panels. A small amount of low voltage power is required

to power the electronic components inside the Zoning

Modules, and this is supplied by jumper wires connecting the R

and C terminals of the AQ2000 Series Control Panel’s

AQ10X38 transformer with the R and C terminals on the

AQ15540B Zoning Module.

For the -42B and -44B Valve Panels, an AQ10X38 transformer

is included to provide sufficient low voltage power to drive the

zone valves.

Wiring the AQ255 / AQ257 Expansion Zoning Panel to an AQ2000 Series Control Panel

To wire the Expansion Zoning Panel to an AQ2000 Series

Control Panel or another AQ255 / AQ257 Expansion Zoning

Panel:

1. Ensure the power to the AQ2000 Series Main Control

Panel is disconnected before proceeding.

2. For each zone to be added to the existing AQ2000 system, connect one zone thermostat to its corresponding

TH input terminals on the top of the Expansion Zoning

Panel being installed.

3. The B-B “Exp.Bus IN” terminals of the Expansion Zoning

Panel being installed connect to the B-B “Exp.Bus OUT”

terminals on the Control Module or previously installed

Zoning Module on the furthest right side of the AQ2000

Series installation. These connections are polarity insen-

4 CONFIGURE THE EXPANSION

ZONING PANEL(S) DIP

SWITCHES

Setting up the AQ255 / AQ257 Expansion Zoning Panels is

quick, simple and straightforward. All that's needed is to check

and if necessary adjust, the DIP switch settings.

For all Expansion Zoning Panels, DIP switches are located

behind the blank cover in the left most section of the Zoning

Module (beside the section labeled Zone 1). Refer to Fig. 4.

The DIP switches come pre-set from the factory with default

settings that are the most commonly-used by hydronics

contractors across North America. That means that most of the

settings only need to be checked by the installing contractor to

make sure they’re suitable for the job, rather than having to

adjust the DIP switch settings from scratch, which is a great

time savings.

5 69-1981—06

Page 6

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

M23731

Although for many installations, these factory default DIP

switch settings will be suitable, Honeywell recommends that

they be reviewed and changed, as necessary, to get optimal

performance of the hydronic system controlled by the AQ2000

Series products.

Expansion Zoning Module DIP Switch

Location

The AQ15540B (pump Zoning Module) and AQ15740B (valves

with end switches Zoning Module) both have DIP switches in 8switch banks and are concealed behind snap-on covers, as

shown in Fig. 4. A chart of the different settings for each DIP

switch is affixed to the inside of the DIP switch covers.

More detailed explanations for these DIP switch settings,

including the pre-set factory defaults for each, are shown in

Table 2 on page 7.

Fig. 4. Location of concealed DIP switches for AQ155 /

AQ157 Expansion Zoning Modules.

Expansion Zoning Module DIP Switch

Settings

Refer to Table 2 on page 7 and check all DIP switch settings. If

necessary, change the switch settings to suit the desired

operation of the hydronic installation.

1. DIP switches #1-4 define the identity (or address) of

each zone on the AQ network. This is how the Control

Module knows that, for example, the zone labeled

Zone 1 on the first Zoning Module is different than the

zone labeled Zone 1 on another Zoning Module.

NOTE: If more than one Zoning Module is connected to

an AQ2000 Series Control Panel, DIP switches #14 must

be set to uniquely identify each Module

and its zones. If any of these four DIP switches is

set to the right hand (ON) position for two or more

zoning modules - for example, if two zoning modules both have their DIP switch #1 in the ON position - the AQ2000 Series control will operate

unpredictably.

a. For the first Zoning Module connected to an AQ2000

Series Control Module (this first Zoning Module is

often included as a component of the main AQ2000

Series Control panel), make sure that DIP switch #1

is set to the right hand position (ON) and DIP

switches #2- 4 are set to the left (OFF).

b. For the second Zoning Module connected to an

AQ2000 Series Control Module, make sure that DIP

switch #2 is set to the right hand position (ON) and

DIP switches #1, 3, and 4 are set to the left.

c. For the third Zoning Module connected to an AQ2000

Series Control Module, make sure that DIP switch #3

is set to the right hand position (ON) and DIP

switches #1, 2, and 4 are set to the left.

d. For the fourth Zoning Module connected to an

AQ2000 Series Control Module, make sure that DIP

switch #4 is set to the right hand position (ON) and

DIP switches #1, 2, and 3 are set to the left.

2. Review the settings for DIP switches 5 through 8 of each

Zoning Module connected to an AQ2000 Series Control

Panel to ensure they are correct before system start-up.

a. DIP Switch 5 enables or disables Zone Synchroniza-

tion:

• The factory setting disables Zone Synchronization,

which is an energy saving feature of the AQ2000

panels. Zone Synchronization coordinates zone

demands to start at the same time when the boiler

cycle begins. The AQ2000 functions as activating

valves. The valve logic induces a delay before

activating the boiler pump even when zone pumps

are used. When Zone Synchronization is not

selected, the zone demands are served whenever

they call for heat.

•The Zone Synchronization feature replaces the pump/

valve selection of previous AQ2000 versions.

b. Dip Switch 8 functionality:

•The factory setting enables 1-stage per zoned

thermostat. The zoning module operates as four

1-stage zones.

•When using a 2-stage thermostat, set DIP switch 8 to

2-Stg. The 2-stage selection uses TH1 and TH2

inputs for 2-stage thermostat control. For the

selected zone, TH1 is the first stage input from the

thermostat and TH2 is the second stage input.

Inputs TH3 and TH4 operate in same manner. The

2-stage selection reduces the zoning module to a 2

zone module from a 4 zone module.

•When using digital 2-stage thermostats (non-AQ1000

thermostats), the system set-up process changes

slightly. During system set-up, create an artificial

demand on the zoning module by increasing the set

point on the thermostat. The artificial demand is

required during the PRI/SEC setup menu to select

the primary and secondary loop for each zone and

stage.

3. Replace the DIP switch cover of each Expansion Zoning

Panel.

•If DIP switches were set for a zoning module included

in the main AQ2000 Control Panel, be sure to

replace the DIP switch cover on the Zoning Module

before replacing the main Control Panel’s front

cover.

4. The Expansion Zoning Panel is now ready for Test and

Checkout. Continue with 5, “Test and Check Out the

Installation” on page 7.

69-1981—06 6

Page 7

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

CAUTION

A

DIP

Switch Switch Description Label and Factory Settings

Zone Address: The positions of these 4 DIP switches define the unique address for

1

each zone on the AQUATROL network. For each group of 4 zones, there can be only

2

one DIP switch in the right hand (ON) position.

3

4

The correct DIP switch settings for each zone module are:

• First Zone (1-4) Module: 1 = ON position; 2, 3, and 4 = OFF position

• Second Zone (5-8) Module: 2 = ON position; 1, 3, and 4 = OFF position

• Third Zone (9-12) Module: 3 = ON position; 1, 2, and 4 = OFF position

• Fourth Zone (13-16) Module: 4 = ON position; 1, 2, and 3 = OFF position

• If set to SYNC, zone synchronization is enabled.

5

• If set to NOT, zone synchronization is disabled.

• If zone valves are normally closed (N.C.), set the NC/NO DIP switch to the OFF

position.

• If zone valves are normally open (N.O.), set the NC/NO DIP switch to the ON

6

7

8

a

If used with an AQ250 RelayPlus Control Panel, the AQ15000B Boiler Control Module’s DIP switch #5 must be set to “GROUP”

position and DIP switch #6 must be set to “MAIN” position.

If used with an AQ25A, AQ251 or AQ252 Control Panel, the EQUIPMENT SETUP > AUXILIARY I/O > AUX PUMP menu option

on the Control Panel must be set to “GROUP.”

position.

• If set to Group (ON position), the AUX Pump contacts on the Control Module are

switched when any of the zones on this Zoning Module are active.

• If set to - (OFF position), the AUX Pump contacts are not affected by activity on

these zones.

• If set to 2-stage (ON position), then 2-stage operation is activated on thermostat

inputs. The zoning module operates as two 2-stage zones.

• If set to 1-stage (OFF position), then operates as four 1-stage zones.

Table 2. AQ15540B Zoning Module (Pump Zoning Module) DIP Switch Arrangement.

AQ15540B

a

M23720

Diagnostic

Test

Test

12345678

M34972

ON

5 TEST AND CHECK OUT THE

INSTALLATION

If this AQ255 / AQ257 Expansion Zoning Panel is part of a

completely new AQ2000 installation, refer to the Test and

Check Out Procedure (for a complete AQ2000 system) in the

Product Data document for the main AQ2000 Series Control

Panel. The form numbers (and models) are: 69-1974 (AQ251),

69-1986 (AQ252), or 69-2119 (AQ25A).

If this Expansion Zoning Panel is being added (as a retrofit

project) to an AQ2000 system already in operation, then only

the zones of this Panel need to be tested and checked out.

Startup

Apply power to the AQ2000 Series Control Panel only after all

of the AQ2000 components (Control Panel, thermostats,

sensors, Zoning Modules/Panels) have been wired to the other

components in the hydronic heating system (boiler, zone

valves or pumps, DHW Aquastat®, etc.).

Once powered, the AQ2000 Series Control Panel begins its

start-up routine, establishing communication with all other

AQ2000 components on the AQUATROL network.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

When line voltage is applied to an AQ255 / AQ257

Expansion Zoning Panel and the front cover of the

Panel is removed, there is a risk of electrocution. Be

careful to avoid contact with the line voltage (N and L)

terminals, either with your fingers or with metal tools

(such as a screwdriver) when power is applied to the

Control Panel.

Test and Checkout Routines

For Expansion Zoning Panels connected to AQ250 Control

Panels, continue with the “Test Expansion Zoning Panels used

with AQ250 Control Panels” section.

For Expansion Zoning Panels connected to AQ25A, AQ251, or

AQ252 Control Panels, go to “Test Expansion Zoning Panels

used with AQ25A, AQ251, and AQ252 Control Panels” on

page 8.

Test Expansion Zoning Panels used with AQ250 Control Panels

Auto Test - AQ155 / AQ157 Zoning Modules

Auto Test operation for Zoning Modules enables the installer to

test all zones wired to the Zoning Module by sequentially

activating the zoning equipment connected to each zone

output. Each step of the Auto Test routine may be paused or

skipped by pressing the Test button.

7 69-1981—06

Page 8

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

STATUS LEDS

Every status LED light (Zone 1, Zone 2, Zone 3, Zone 4) will be

turned on for 15 seconds when its corresponding output is

activated during Auto Test.

DIAGNOSTIC LED

This light is used by the AQ155 / AQ157 to communicate

diagnostic data to the user:

• Constantly ON indicates that the unit is working properly.

• Constant, fast blinking indicates that the unit is in the Auto

Test mode. Constant, slow blinking indicates that Auto Test

mode has been paused.

• Coded blinking is used to communicate an error code to the

user. Refer to the Troubleshooting section of these

instructions for an explanation of these codes.

NOTE: NOTE: The DIAGNOSTIC LED is OFF when the

AQ155 / AQ157 Zoning Module is not powered.

Auto Test Sequence of Operation

1. When the Auto Test button is pressed, Zone 1 of the

Zoning Module energizes and the DIAGNOSTIC LED on

the AQ155 / AQ157 begins to blink quickly. Zone 1

remains energized for 15 seconds, then shuts off

2. Following that, each of the remaining zones energizes

sequentially (starting with Zone 2) for 15 seconds, and

then shuts off.

3. After Zone 4 de-energizes, the AQ155 / AQ157 exits the

Auto Test routine and the DIAGNOSTIC LED on the

Module returns to steady illumination (no blinking).

NOTE: This Auto Test routine works for Zoning Modules

when connected to any AQ2000 Series Control

Panel.

If zones are tested simultaneously (TEST: ALL ZONES), zone

pumps energize immediately (with a delay of 1/10th of a

second delay between each pump to minimize the effect of

inrush currents from the pumps' motors) along with the main

boiler pump.

When zone valves are tested simultaneously, the valves are

energized immediately but the boiler pump is energized only

after either:

a. the valves end switches close, or

b. the TIME TO OPEN value (in the EQUIPMENT

SETUP > ZONING menu) has elapsed, to allow

enough time for the zone valves to fully open.

A zero (0) displayed after a zone's ID address (e.g., Zone A1 0,

A2 0, … A16 0) indicates that the Control Module has received

confirmation that the zone's pump relay is not energized or its

zone valve is fully closed.

Similarly, a one (1) displayed after a zone's ID address (e.g.,

Zone A1 1, A2 1, … A16 1) indicates that the Control Module

has received confirmation that the zone's pump relay is

energized or its zone valve is fully open.

To test zones individually, position the indicator arrow (¬)

beside a selected zone and press the “+” button to energize it,

and then press the “–” button to de-energize it. As each zone is

tested, the Status LED on the Zoning Module associated with

that zone illuminates. To test additional zones, position the

indicator arrow (¬) beside the zone to be tested, press the “+”

button to energize the zone's pump or valve, and then press

the “–” button to de-energize it. When finished testing the

zones, press the MENU button to return to the SETUP >TEST

AND PURGE menu.

If no errors were detected in the Auto Test routine, the AQ255 /

AQ257 is now ready for operation. If errors were detected, refer

to “Troubleshooting” on page 10 for details.

Test Expansion Zoning Panels used with AQ25A, AQ251, and AQ252 Control Panels

If this AQ255 / AQ257 Expansion Zoning Panel is connected to

an AQ25A, AQ251 or AQ252 Control Panel, the Test and

Check Out procedure can be done either manually (by

following the preceding method outlined in the “Auto Test AQ155 / AQ157 Zoning Modules” on page 7 of this document),

or through the Control Panel’s Test and Purge tools. The TEST

feature enables the installer to checkout the system's zone

equipment as part of system commissioning (Checkout).

NOTE: If checking out the operation of more than the

newly-added Expansion Zoning Module, refer to

the Product Data document for the main AQ2000

Series Control Panel: AQ25A (form 69-2119),

AQ251 (form 69-1974) or AQ252 (form 69-1986).

Test Zones

When TEST ZONES is selected, the Installer can test zones

connected to the AQ25A, AQ251 or AQ252 (space heating and

DHW) simultaneously or individually.

6 PURGE AIR FROM ALL

SYSTEM AND ZONE PIPING

For Expansion Zoning Panels connected to AQ250 Control

Panels, continue with the “AQ250 Models” section.

For Expansion Zoning Panels connected to AQ25A, AQ251, or

AQ252 Control Panels, go to “AQ25A, AQ251 and AQ252

models” on page 9.

AQ250 Models

Purging air from all zones in the hydronic system can be easily

accomplished with the AQ250 by using a modification to the

AUTO TEST feature as follows:

1. To purge all zones on the AQ250 network at the same

time, press the TEST button on the AQ15000B Control

Module. All zone equipment relays energize simultaneously and remain energized for the duration of the Auto

Test routine.

2. The AQ250 then begins its Auto Test routine, starting

with energizing the Boiler pump.

3. When the Boiler pump LED lights up, quickly press the

TEST button to pause the Auto Test routine. The DIAGNOSTIC LED blinks slowly while in paused mode.

4. The Boiler pump and all zones continue to be energized

(and therefore are purging their loops of air) until the

TEST button is pressed again.

5. When the boiler loop has been purged sufficiently, press

the TEST button again to energize the AUX relay. If there

is a pump connected to the AUX output, press the TEST

button again as soon as the AUX LED is illuminated, to

perform the purge routine on the AUX loop. If the AUX

69-1981—06 8

Page 9

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

CAUTION

loop does not need to be purged, or there is not a pump

connected to the AUX relay, press the TEST button again

to advance to the next step in the test sequence.

6. When the DHW device energizes, its LED lights up.

Quickly press the TEST button to pause the Auto Test

routine and purge the DHW loop for as long as necessary The DIAGNOSTIC LED blinks slowly while the Auto

Test is paused.

7. When the DHW loop has been purged sufficiently, press

the TEST button again to advance to the next step in the

test sequence (shorting the Boiler T-T dry contacts).

Press the TEST button again to skip this step and finish

the Purge procedure.

8. The Auto Test routine is complete when the DIAGNOSTIC LED steadily illuminates (no blinking).

If additional purging is required for any zone, the Auto Test

procedure can be activated for any Zoning Module by pressing

the TEST button located above that Zoning Module’s DIP

switches. Refer to the “Auto Test Sequence of Operation” on

page 8.

AQ25A, AQ251 and AQ252 models

The PURGE operation on the AQ25A, AQ251, and AQ252

Control Panels allow the installer to purge all zones (loops)

sequentially, or each zone individually, for a period of time

PURGE TIME selected in the EQUIPMENT SETUP >TEST

AND PURGE > PURGE menu. PURGE TIME can be adjusted

in multiples of one (1) minute, up to a maximum of 30 minutes

per loop to be purged.

Once you have selected which loops to purge (ALL loops, or an

individual loop) and for how long (using the Control Panel’s

menus), position the indicator arrow (¬) beside the START

PURGE option and press the OK button. The START PURGE

display changes to STOP PURGE and the Control Panel’s

display begins counting down the time remaining for the purge

cycle. When the purge time has elapsed for the first loop, the

control proceeds to subsequent loops and performs the

PURGE operation on each of them. After all selected loops are

purged, the display changes to PURGE COMPLETED.

7 DOCUMENT AND KEEP A

RECORD OF ALL SYSTEM

SETTINGS

Once the hydronic installation with the AQ2000 Series Control

Panel has been set up, and the entire installation is operating

properly, it is important to document all the system settings for

future reference.

SAVE Feature (AQ25A, AQ251, and AQ252 Control Panels)

In addition to the hardcopy Installation Job Records, the

AQ25A, AQ251, and AQ251 Control Panels have a convenient

SAVE feature that allows the installing contractor to save the

specific equipment setting for this installation in the Control

Panel’s memory for future recall, in case the system’s settings

are inadvertently changed. This feature is found in the

EQUIPMENT SETUP > SAVE/RESTORE sub-menu of the

Control Panel.

There are three levels of settings in the AQ25A’s memory –

CURRENT, FACTORY and SETUP.

• CURRENT settings are the settings that are currently

displayed in any of the menus and are the settings that the

Control Panel uses to operate. Any time a value is changed

in any of the menus, the CURRENT settings are changed

and these new settings are instantly used by the Control

Panel.

• FACTO RY settings are the default values loaded at the

factory and are the starting point for programming the

AQ25A, AQ251 or AQ252 Control Panel. These values are

permanently stored in memory and cannot be over-written

or erased. The Control Panel can be restored to factory

settings through the RESTORE FACTORY option in the

SAVE / RESTORE sub-menu. A warning prompt,

RESTORE FACTORY—ARE YOU SURE?, displays and

YES or NO must be chosen before proceeding. If YES is

selected, the FACTORY settings are be copied to the

Control Panel’s CURRENT settings and the Control Panel

begins to operate with these values immediately.

• SETUP settings are the specific settings for this installation

which an installer has saved after the Control Panel is set

up and operating well. These are saved for future recall, in

case the system’s settings are inadvertently changed.

— To save this installation's settings for the first time, go to

the Control Panel’s EQUIPMENT SETUP > SAVE/

RESTORE sub-menu. Position the indicator arrow (¬)

beside SAVE SETUP and press OK. This saves the

current system settings to the SETUP values.

— To retrieve the SETUP values at any time in the future,

go to the EQUIPMENT SETUP > SAVE/RESTORE

sub-menu and select RESTORE SETUP to load those

values into the AQ25A as the CURRENT settings. The

system will now operate according to these retrieved

settings.

— If the current settings are modified after a RESTORE

SETUP operation is performed, simply select SAVE

SETUP again to overwrite these new settings into the

SAVE settings memory.

Job Records

All AQ2000 Series Expansion Zoning Panels are shipped with

Installation Job Records for documenting these settings. These

should be filled out completely and saved in the Installing

Contractor’s files.

If you change any system settings after a RESTORE

SETUP operation, you change the current settings

that the Control Panel (AQ25A, AQ251, or AQ252)

uses as its basis of operation.

9 69-1981—06

Page 10

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

TROUBLESHOOTING

The following information helps the installer correctly identify

system problems, making troubleshooting much faster. Table 3

describes the possible error codes that can be communicated

on the AQ155 / AQ157 Zoning Modules' DIAGNOSTIC LEDs.

Troubleshooting When Using Expansion Zoning Panels with an AQ2000 Series Control Panel

Communications Loss

Because all AQ2000 Series components communicate with

each other via the dedicated AQUATROL network when

controlling a hydronic system, one possible failure mode of an

AQ25A, AQ251, or AQ252 Control Panel would be loss of

communication between the Control Module and any

connected Zoning Modules, or between a Zoning Module and

any zone thermostats connected to the AQUATROL network.

In general, the Control Module:

• Periodically tries to re-establish communication with any lost

components on the network.

• Initializes any component that re-establishes its

communication.

• Displays an error code on the Control Panel’s System

Status page, until the error is corrected and/or

communication is re-established.

Control Module Reaction

When the AQ25A, AQ251, or AQ252 control loses

communication with any number of zones for more than one

minute (as long as there’s still at least one zone communicating

on the AQUATROL network), its Control Panel continues to

deliver heat to the other non-communicating zones and the

address of each lost zone (e.g., A-7, B-4) displays on the

Control Panel’s System Status page.

When communication is lost with all

AQ251, or AQ252 enters BOILER FREEZE PROTECTION

mode, in which it fires the boiler and then activates the Boiler

(supply) pump and zone equipment for a period of 10 minutes

every hour. This should provide sufficient heat to the system to

prevent a building from freezing up until communication is reestablished between the AQ2000 Series components.

zones, the AQ25A,

Zoning Module Reaction

When a Zoning Module loses communication with the Control

Module (as long as there is at least one other Zoning Module

communicating with the Control Module), the Zoning Module

operates its pumps or valves in a conventional, nonsynchronized zoning fashion. That is, it operates according to

the demands from the thermostats, without zone

synchronization or waiting for permission from the Control

Module to operate. This allows the zones to extract any heat

provided by the boiler.

When communication is lost between a Zoning Module and

any of its thermostats, that zone is invisible to the Control

Module. The Zoning Module stops serving that zone and the

zone’s pump or valve de-energizes. Under this condition, the

AQ2000 Series control operates in the same way as

non-networked heating systems.

• The AQ250 provides Control Module diagnostic information

via the DIAGNOSTIC LEDs located above the DIP switches

on the AQ1500 Control Module.

• The AQ25A, AQ251 or AQ252 presents Control Module

diagnostic information on the Home Page display of its LCD.

All AQ2000 Series Control Panels provide Zoning Module

diagnostic information via the DIAGNOSTIC LEDs located

above the DIP switches on their Zoning Module(s).

Troubleshooting When Using Expansion Zoning Panels with AQ25A, AQ251, or AQ252 models

If a zone loses communication with the Control Module or is

malfunctioning, this can be seen in the AQ25A/AQ251/AQ252

Control Panel’s System Status Page. The System Status Page

display indicates which zone has lost communication with the

Control Panel (for diagnostics and troubleshooting).

If a zone has been permanently, and intentionally,

disconnected from the network, turn off the Control Panel at

the distribution panel and wait 10 seconds. Power the control

back up and, as part of it’s boot up routine, the AQ25A/AQ251/

AQ252 will detect all equipment connected to the network. In

doing this, the control no longer recognizes the disconnected

zone and the LOST ZONE message disappears from the

System Status page.

Table 3. AQ155 / AQ157 Zoning Module LED Display and System Condition.

DIAGNOSTIC LED Status System Condition Action Required

Steady (no blinking) No system problem detected None

Fast blinking (4 blinks per second) Auto Test is in operation None. Allow the control to finish its Auto Test

routine.

Slow blinking (2 blinks every 3 seconds) Auto Test has been paused. Press the Test button to resume the Auto Test

routine.

Coded blinking = ERROR 2 blinks,

then pause

3 blinks,

then pause

69-1981—06 10

Freeze protection activated

across the entire AQUATROL

network

Communication lost with all

thermostats on the Zoning

Module

All zones have lost communication with the

Control Module. Check B–B wiring between the

Control Module and each Zoning Module.

Check thermostat wiring to each Zoning

Module.

Page 11

APPENDIX

This appendix provides examples for wiring Expansion Zoning

Panels to AQ2000 Series Control Panels and wiring additional

low voltage VA capacity.

Wiring Diagrams

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

Fig. 5. Wiring of AQ25542B Expansion Zoning Panel to AQ2000 Series Control Panel.

11 69-1981—06

Page 12

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

OK

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

{

{

TH

SENSOR

TO B-B

“EXP.BUS IN”

CONNECTION

ON AQ15540B (#2)

FROM “R”

ON AQ10X38

TRANSFORMER

FROM B-B

“EXP.BUS OUT”

CONNECTION

ON AQ1554P2 (#1)

FROM “C”

ON AQ10X38

TRANSFORMER

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

{

{

TH

SENSOR

{

{

TH

SENSOR

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

ZONE 1 ZONE 2 ZONE 3 ZONE 4

M27833C

ZONE 1 ZONE 2 ZONE 3 ZONE 4

ZONE 1 ZONE 2 ZONE 3 ZONE 4

AQ15540B (#1)

AQ15540B (#2)

AQ15540B (#3)

TO N ON

AQ10X38

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

1

TO L ON

AQ10X38

120 VAC

1

120 VAC

1

N

L

N

L

AQ25582B

ZONING MODULE OF AN EXISTING

AQ2000 SERIES CONTROL PANEL

AQ15100B

Fig. 6. Wiring of AQ25582B Expansion Zoning Panel to AQ2000 Series Control Panel.

69-1981—06 12

Page 13

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

CAUTION

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

M31171

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

Zone 1

Zone 2

Zone 3

Zone 4

USING AN AQ15740B

VALVE ZONING MODULE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

Zone 1

Zone 2

Zone 3

Zone 4

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

24 VAC

100 VA

TRANSFORMER

115 VAC

115 VAC

24 VAC

100 VA

TRANSFORMER

1

1

USING AN AQ15540B

PUMP ZONING MODULE

AQ15540B

NOTE: When wiring zone valves with end switches, note

the transformer's VA:

If low voltage zone valves with end switches are

used for zone control, make sure the selected

zone valves do not draw more power (VA) than the

38 VA capacity of the AQ10X38 transformer supplied with the AQ2000 Series Control Panel. This

integral transformer has enough power to operate

4 motorized zone valves (such as Honeywell

V8043E valves or 4 valves using low-amperage

draw, heat motor actuators, such as Honeywell

MV100 actuators), plus power the electronics of

the AQ2000 Series Control Module and up to 16

AQ1000 thermostats. If zone valves with highamperage draw, heat motor actuators are used

(such as Taco 500 series zone valves), additional

24 Vac transformer capacity will need to be wired

to the Zoning Module to power the valves. See

Fig. 7 on page 13 for recommended wiring of

additional low voltage VA capacity to AQ2000

Series Zoning Modules.

Equipment Damage Hazard.

Can damage internal circuitry of Zoning Module.

The ES1 and ES2 terminals of the AQ15740B Zoning

Module are powered terminals and must only

be

connected to a set of dry contacts, such as a zone

valve motor's end switch. If power is applied to these

contacts (for example, by running line voltage through

the zone valves’ end switches to bring on a circulator

feeding those valves), the internal circuitry of the

Zoning Module will be damaged, in which case the

warranty for this product will be voided.

Fig. 7. Wiring of additional low voltage VA capacity.

13 69-1981—06

Page 14

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

{

{

TH

SENSOR

TO B-B

“EXP.BUS IN”

CONNECTION

ON AQ15540B (#2)

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

M27835C

M M

M

M

M M M M

FROM B-B

“EXP.BUS OUT”

CONNECTION

ON AQ15540B (#1)

AQ15540B (#1)

AQ15540B (#2)

AQ10X38

120 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

N

L

AQ25742B

ZONING MODULE OF AN EXISTING

AQ2000 SERIES CONTROL PANEL

OK

AQ15100B

THERMOST A TS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

{

{

TH

SENSOR

M27836C

M M M M

Zone 1

Zone 2

Zone 3

Zone 4

FROM B B

“EXP. BUS OUT”

CONNECTION

ON AQ15740B (#1)

TO B-B

“EXP.BUS IN”

CONNECTION

ON AQ15740B (#2)

THERMOST A TS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

{

{

TH

SENSOR

M M M M

Zone 1

Zone 2

Zone 3

Zone 4

AQ15740B (#2)

AQ10X38

AQ15740B (#1)

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

1

120 V AC

1

N

L

AQ25744B

ZONING MODULE OF AN EXISTING

AQ2000 SERIES CONTROL P ANEL

OK

AQ15100B

Fig. 8. Wiring of AQ25742B Expansion Zoning Panel to AQ2000 Series Control Panel.

Fig. 9. Wiring of AQ25744B Expansion Zoning Panel to AQ2000 Series Control Panel.

AQUATROL® is a registered trademark of Honeywell International Inc.

Aquastat® is a registered trademark of Honeywell International Inc.

69-1981—06 14

Page 15

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

15 69-1981—06

Page 16

AQ255 AND AQ257 SERIES EXPANSION ZONING PANELS

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2013 Honeywell International Inc.

69-1981—06 M.S. Rev. 08-13

Printed in United States

Loading...

Loading...